Electricity Production by the Application of a Low Voltage DC-DC Boost Converter to a Continuously Operating Flat-Plate Microbial Fuel Cell

Abstract

:1. Introduction

2. Results

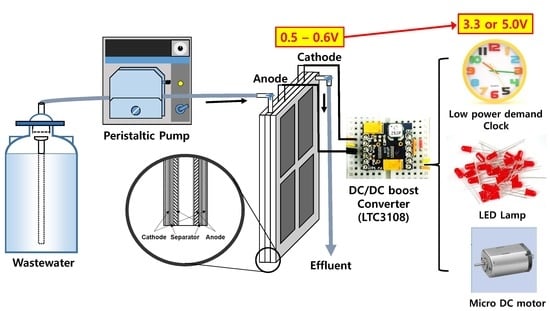

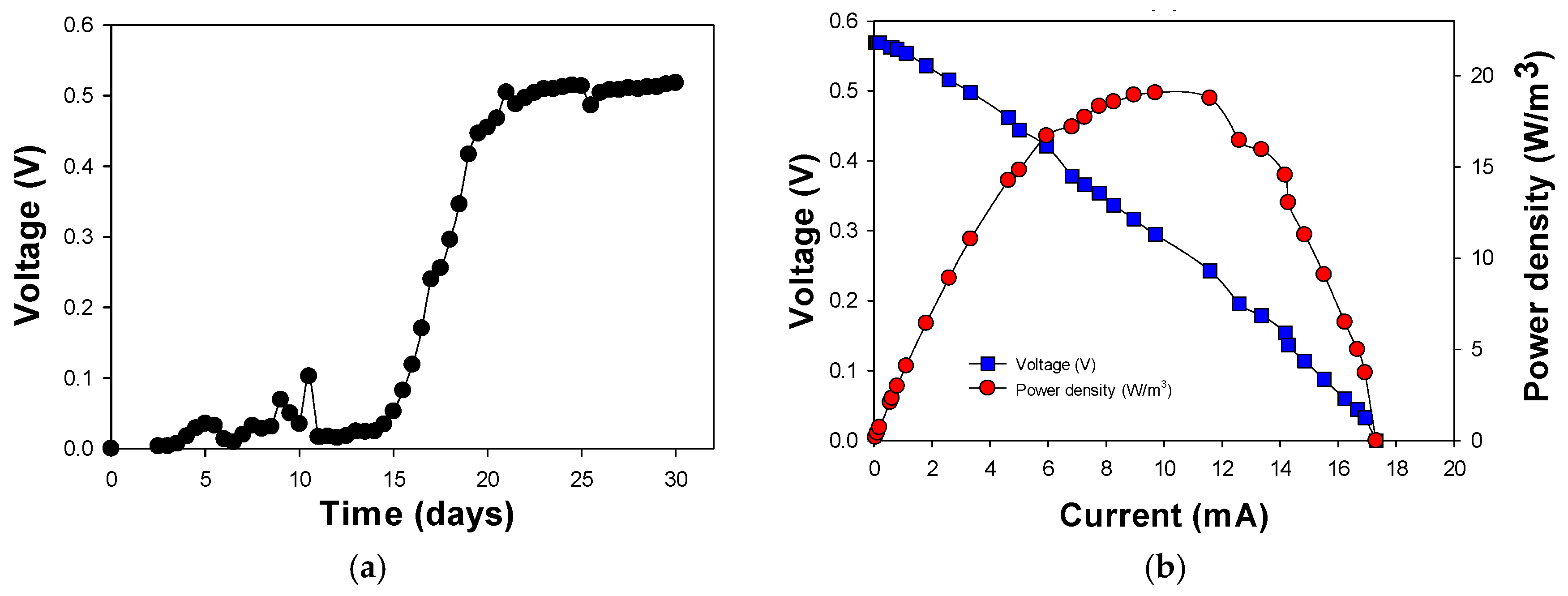

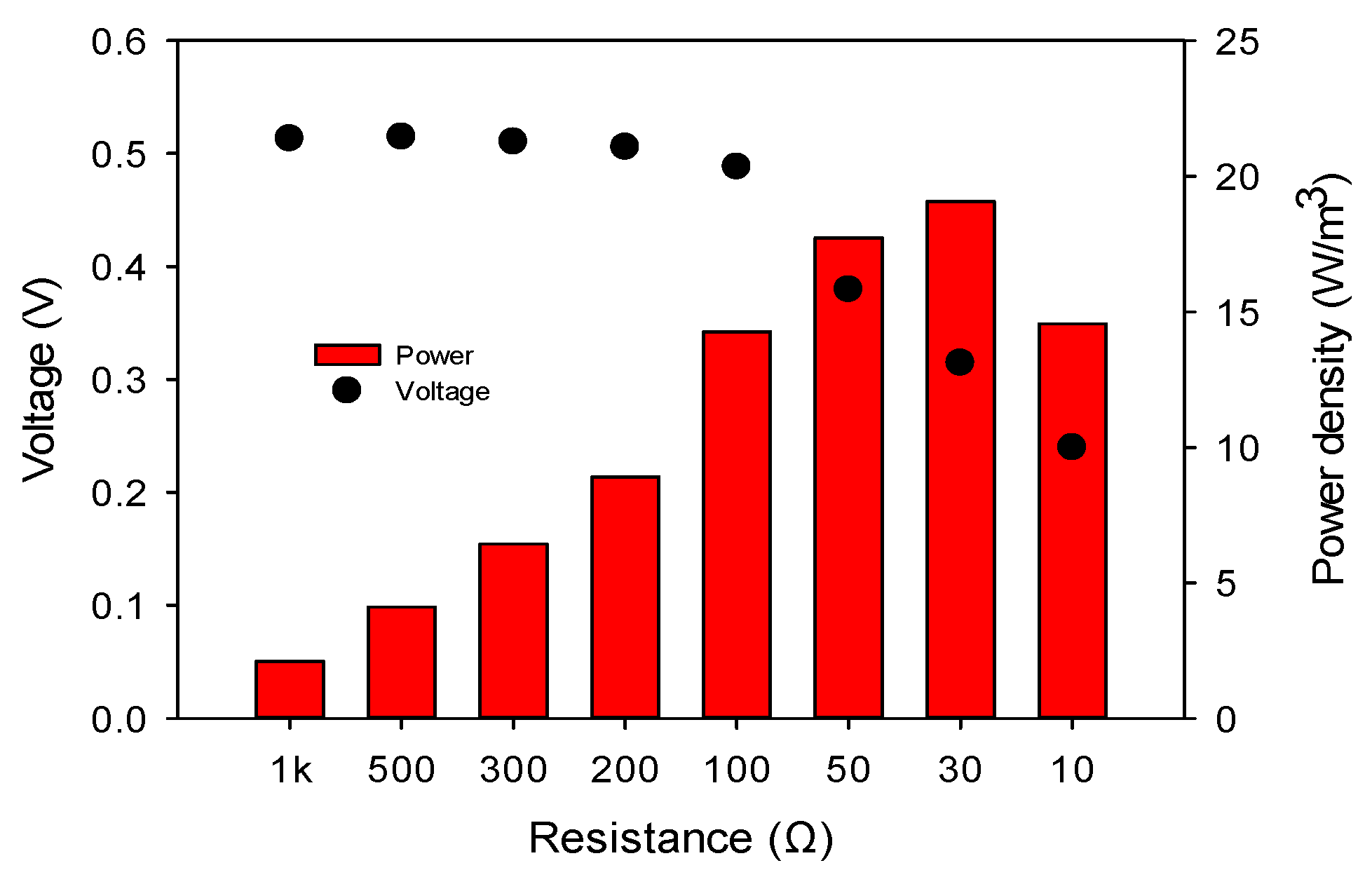

2.1. Enrichment and Polarization Curves for Flat-Plate Microbial Fuel Cell (FPM)

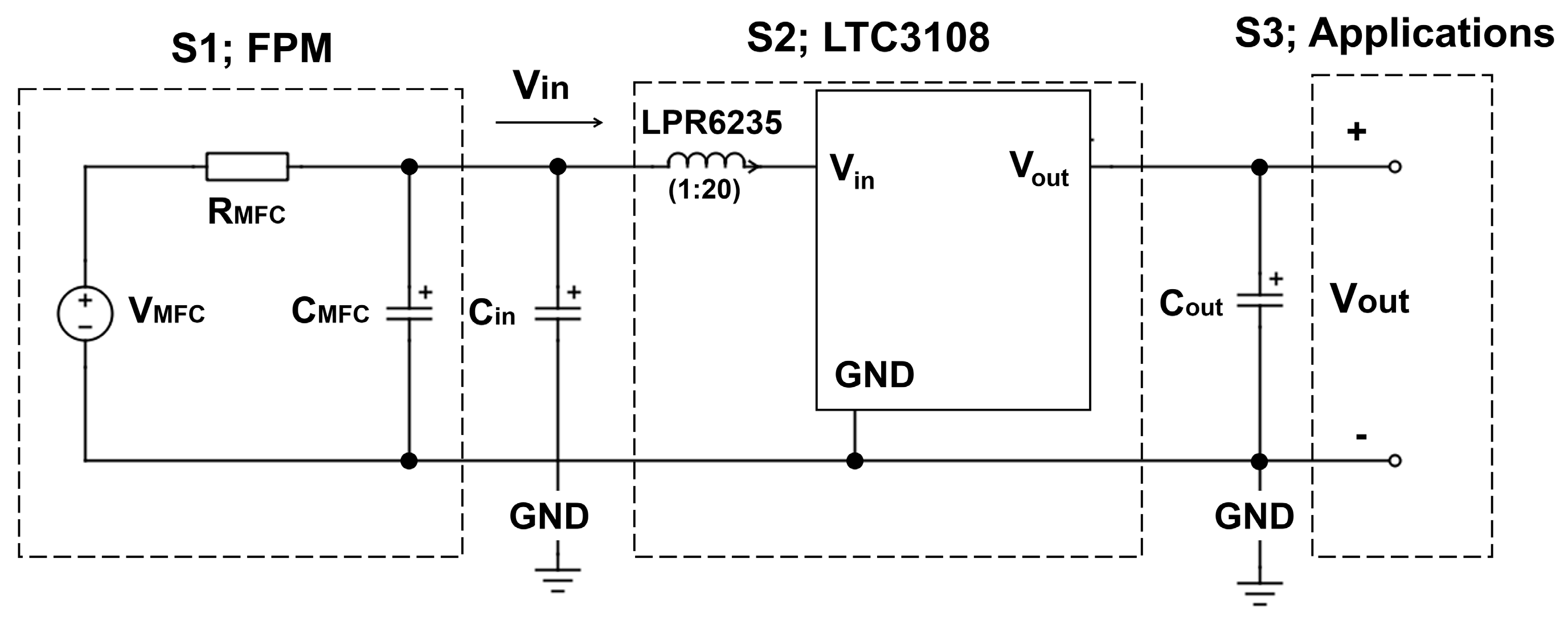

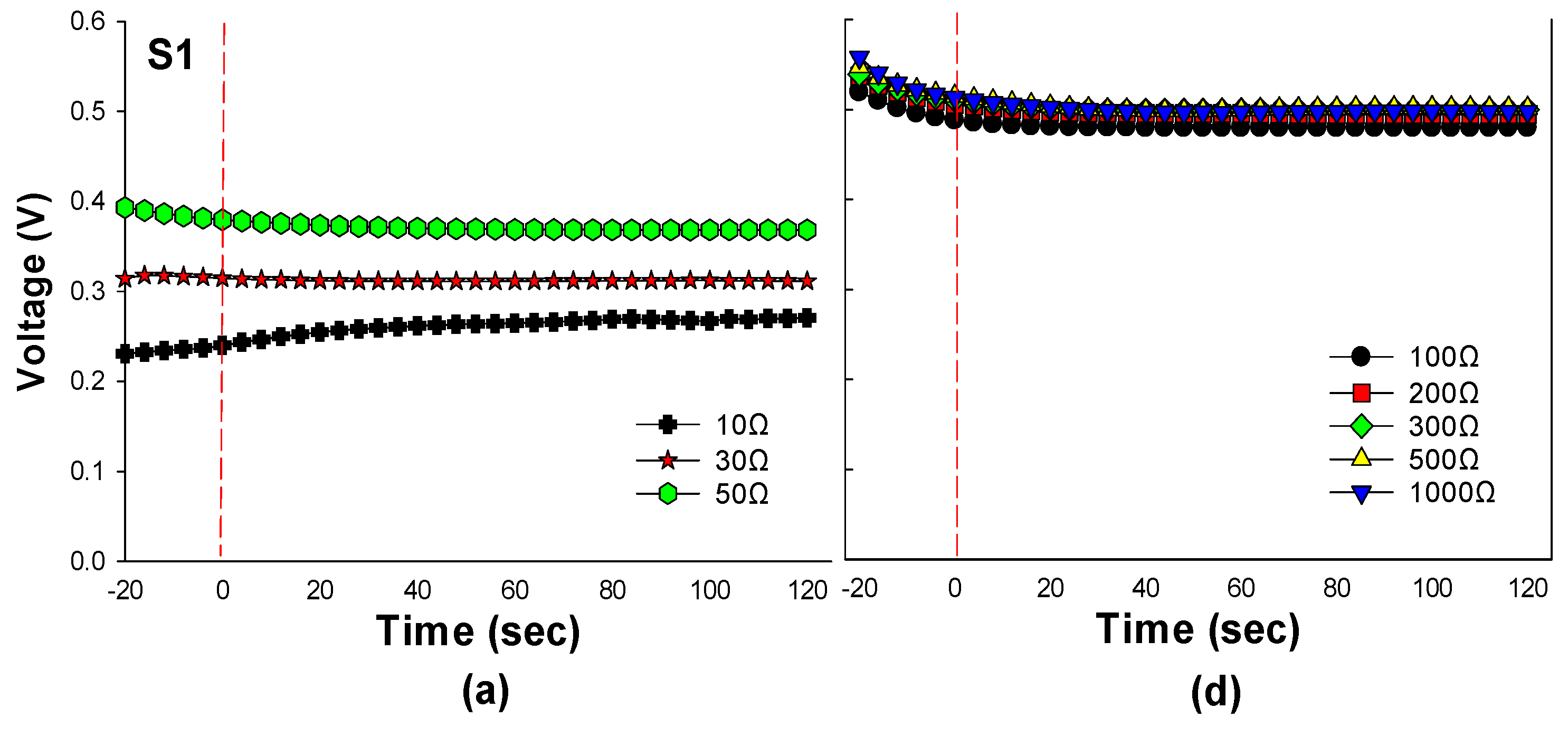

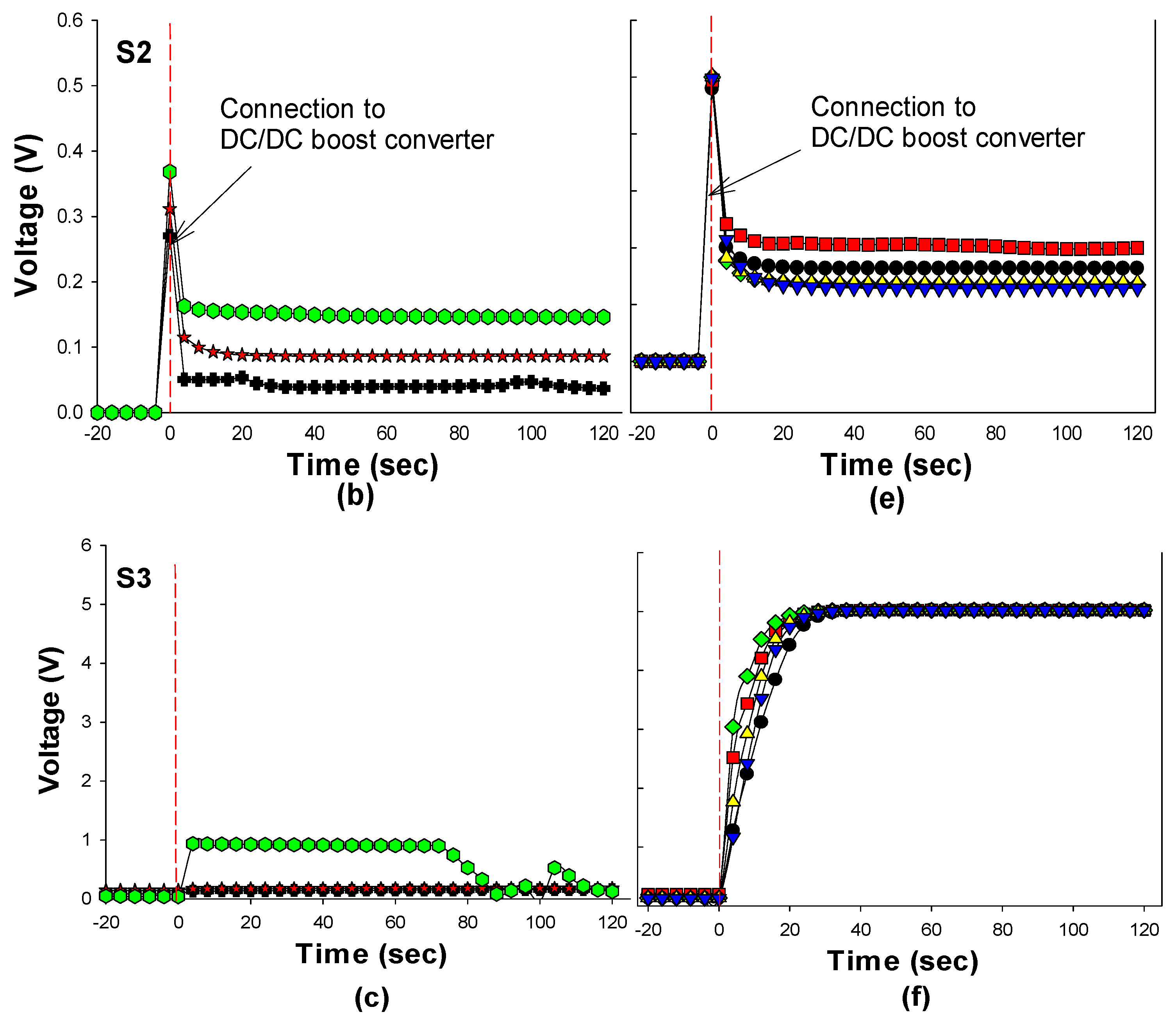

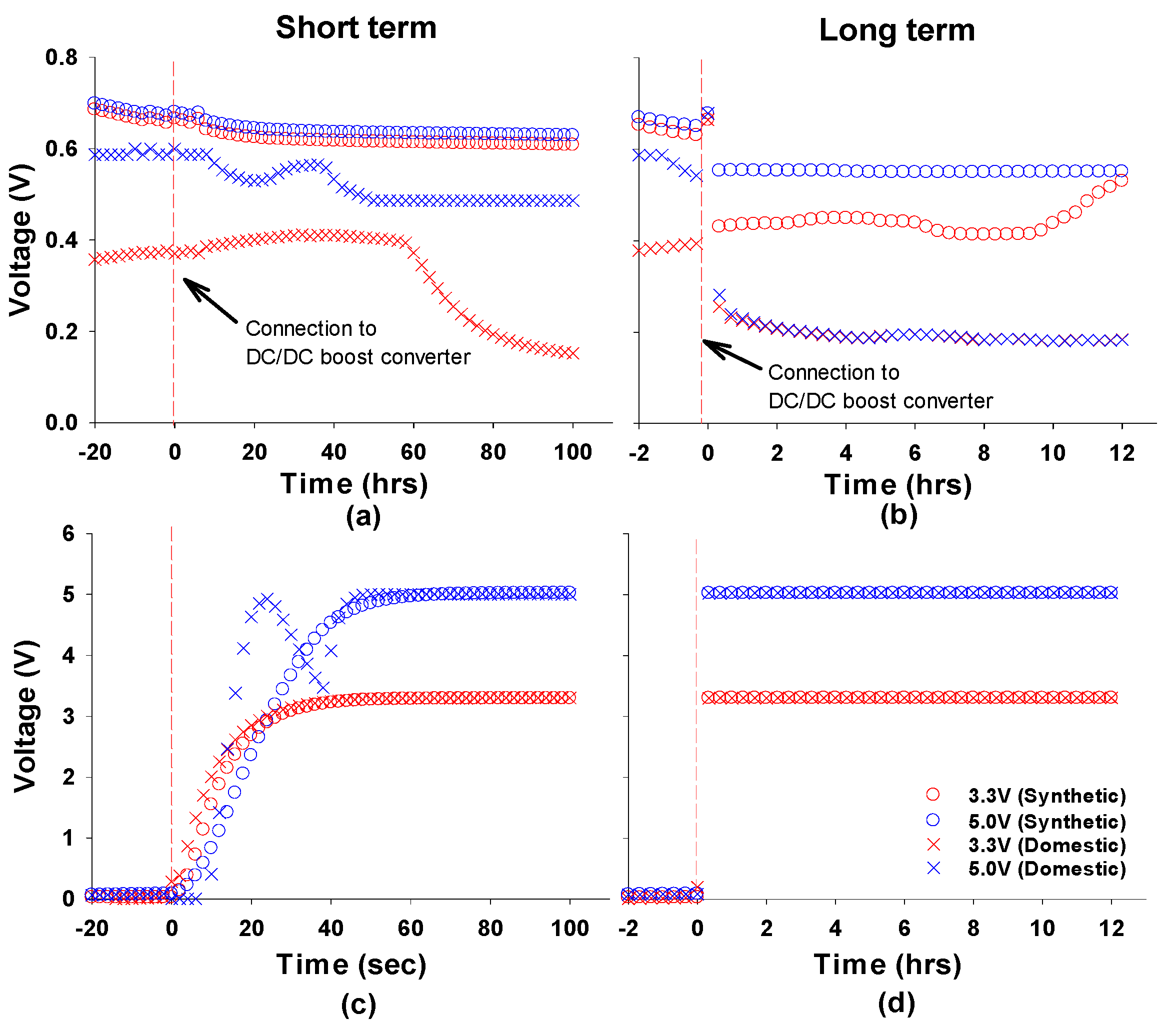

2.2. Performance of DC-DC Booster with FPM

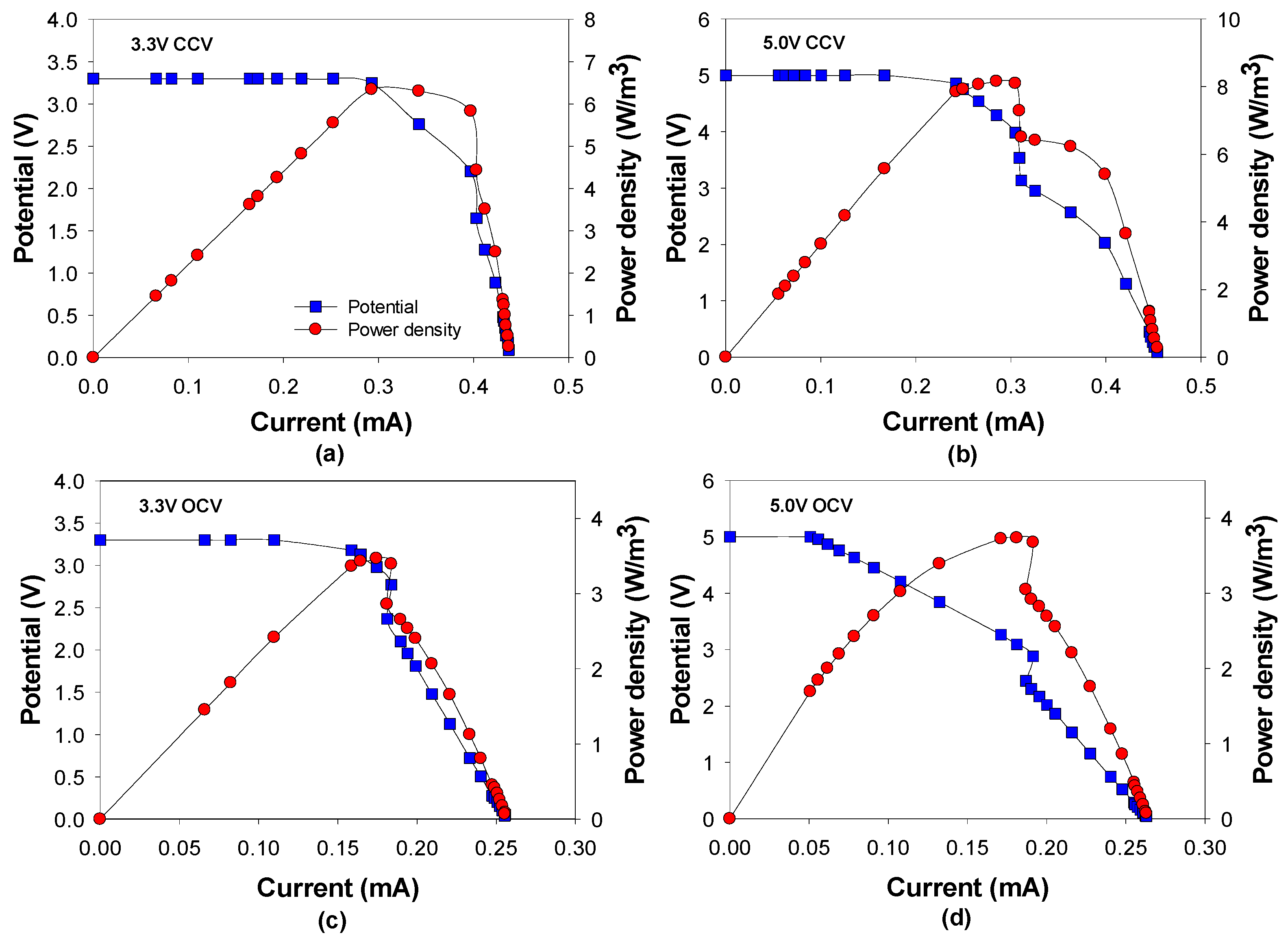

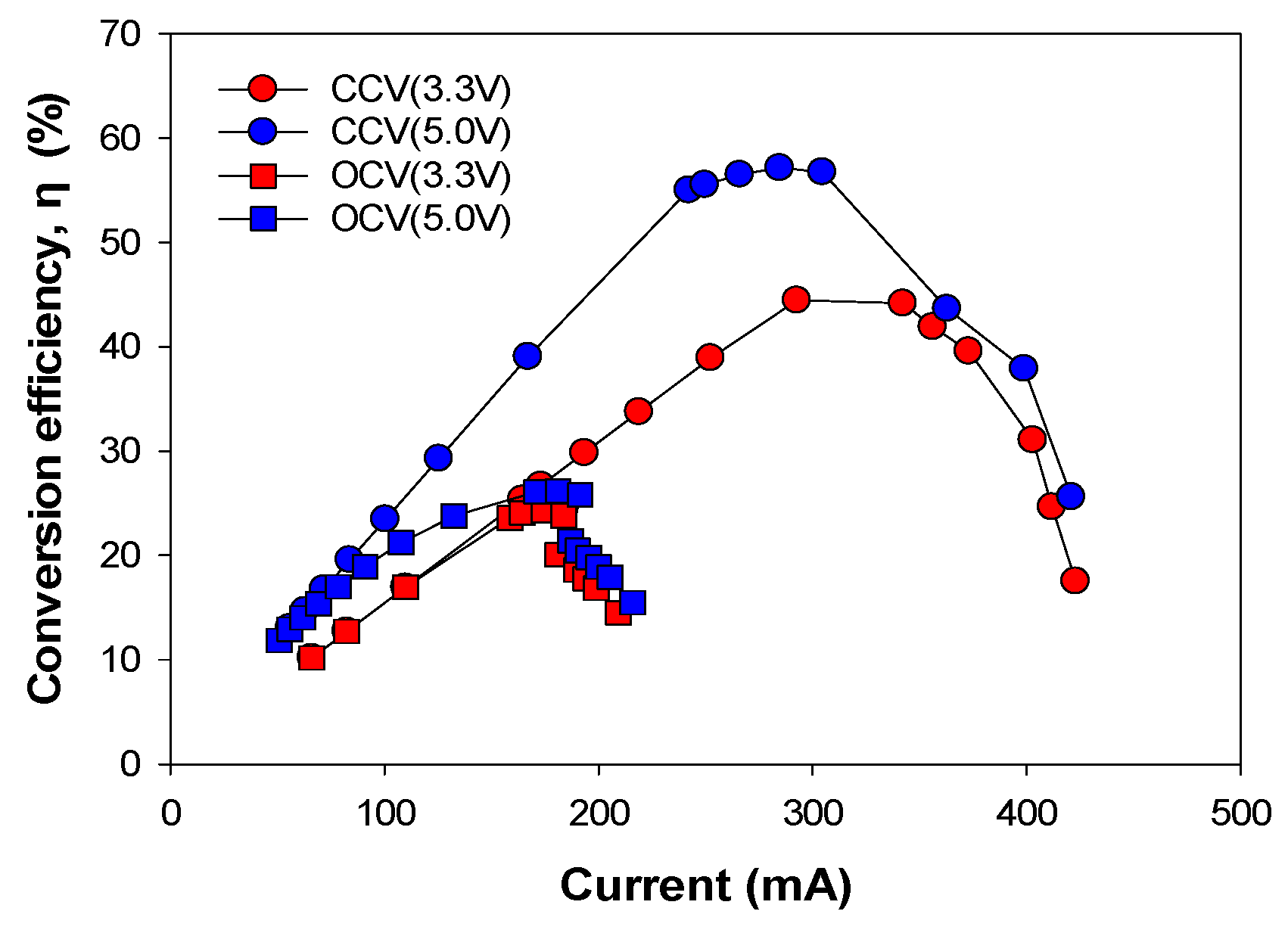

2.3. Comparison of the Closed and Open Circuit with the DC-DC Booster

2.4. Effect of Different Wastewaters on Boosting the Power from Flat-Plate MFC

2.5. Operating Low Power Electronic Devices through the DC-DC Booster

3. Discussion

3.1. DC-DC Boosting Strategy for MFCs

3.2. Interrelation between the MFC and DC-DC Booster

3.3. Application of the Developed Booster to Low Power Demand Electronics

3.4. Prospect of Energy Recovery of MFC System Combined with a DC-DC Booster from Wastewater Treatment

4. Materials and Methods

4.1. Flat-Plate MFC Configuration and Start-up

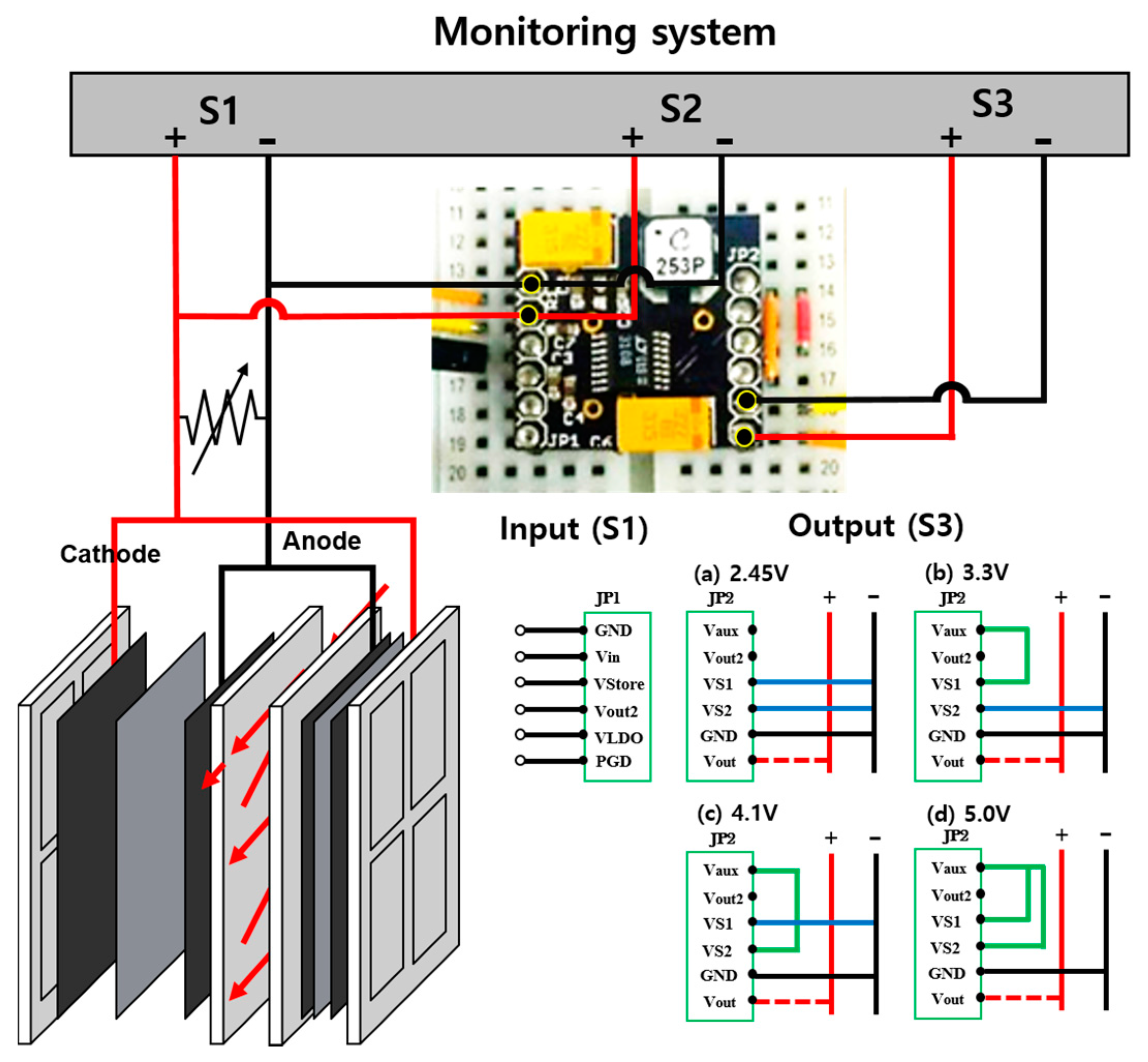

4.2. Specification of DC-DC Boost Converter Circuit

4.3. DC-DC Boost Converter Operation with FPM

4.4. Analyses

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cheng, S.; Liu, H.; Logan, B.E. Increased performance of single-chamber microbial fuel cells using an improved cathode structure. Electrochem. Commun. 2006, 8, 489–494. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Wang, B.-S.; Pan, B.; Chen, Q.-Y.; Yan, W. Electricity production from a bio-electrochemical cell for silver recovery in alkaline media. Appl. Energy 2013, 112, 1337–1341. [Google Scholar] [CrossRef]

- Rabaey, K.; Verstraete, W. Microbial fuel cells: Novel biotechnology for energy generation. Trends Biotechnol. 2005, 23, 291–298. [Google Scholar] [CrossRef] [PubMed]

- Premier, G.C.; Kim, J.R.; Michie, I.; Dinsdale, R.M.; Guwy, A.J. Automatic control of load increases power and efficiency in a microbial fuel cell. J. Power Sources 2011, 196, 2013–2019. [Google Scholar] [CrossRef]

- Shin, S.H.; Choi, Y.J.; Na, S.H.; Jung, S.H.; Kim, S. Development of bipolar plate stack type microbial fuel cells. Bull. Korean Chem. Soc. 2006, 27, 281–285. [Google Scholar]

- Aelterman, P.; Rabaey, K.; Pham, H.T.; Boon, N.; Verstraete, W. Continuous electricity generation at high voltages and currents using stacked microbial fuel cells. Environ. Sci. Technol. 2006, 40, 3388–3394. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.E.; Logan, B.E. Voltage reversal during microbial fuel cell stack operation. J. Power Sources 2007, 167, 11–17. [Google Scholar] [CrossRef]

- Ieropoulos, I.; Melhuish, C.; Greenman, J.; Horsfield, I. EcoBot-II: An artificial agent with a natural metabolism. J. Adv. Rob. Syst. 2005, 2, 295–300. [Google Scholar] [CrossRef]

- Papaharalabos, G.; Greenman, J.; Stinchcombe, A.; Horsfield, I.; Melhuish, C.; Ieropoulos, I. Dynamic electrical reconfiguration for improved capacitor charging in microbial fuel cell stacks. J. Power Sources 2014, 272, 34–38. [Google Scholar] [CrossRef]

- Donovan, C.; Dewan, A.; Peng, H.; Heo, D.; Beyenal, H. Power management system for a 2.5 W remote sensor powered by a sediment microbial fuel cell. J. Power Sources 2011, 196, 1171–1177. [Google Scholar] [CrossRef]

- Meehan, A.; Gao, H.; Lewandowski, Z. Energy harvesting with microbial fuel cell and power management system. IEEE Trans. Power Electron. 2011, 26, 176–181. [Google Scholar] [CrossRef]

- Erickson, R.W. DC-DC Power Converters. In Wiley Encyclopedia of Electrical and Electronics Engineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2001. [Google Scholar]

- Wu, P.K.; Biffinger, J.C.; Fitzgerald, L.A.; Ringeisen, B.R. A low power DC/DC booster circuit designed for microbial fuel cells. Process Biochem. 2012, 47, 1620–1626. [Google Scholar] [CrossRef]

- Park, J.-D.; Ren, Z. High efficiency energy harvesting from microbial fuel cells using a synchronous boost converter. J. Power Sources 2012, 208, 322–327. [Google Scholar] [CrossRef]

- Adami, S.E.; Degrenne, N.; Vollaire, C.; Allard, B.; Buret, F.; Costa, F. Autonomous Ultra-Low Power DC/DC Converter for Microbial Fuel Cells. In Proceedings of the 2011 18th IEEE International Conference on Electronics, Circuits and Systems (ICECS 2011), Beirut, Lebanon, 11–14 December 2011; pp. 398–401. [Google Scholar]

- Wang, H.; Park, J.-D.; Ren, Z.J. Practical energy harvesting for microbial fuel cells: A review. Environ. Sci. Technol. 2015, 49, 3267–3277. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhang, D.; Shimotori, T.; Wang, K.-C.; Huang, Y. Study of transformer-based power management system and its performance optimization for microbial fuel cells. J. Power Sources 2012, 205, 86–92. [Google Scholar] [CrossRef]

- Pathirana, W.; Muhtaroglu, A. Low Voltage DC-DC Conversion without Magnetic Components for Energy Harvesting. In Proceedings of the 2012 International Conference on Energy Aware Computing, Guzelyurt, Cyprus, 3–5 December 2012; pp. 1–6. [Google Scholar]

- Zhang, D.; Yang, F.; Shimotori, T.; Wang, K.-C.; Huang, Y. Performance evaluation of power management systems in microbial fuel cell-based energy harvesting applications for driving small electronic devices. J. Power Sources 2012, 217, 65–71. [Google Scholar] [CrossRef]

- Boghani, H.C.; Kim, J.R.; Dinsdale, R.M.; Guwy, A.J.; Premier, G.C. Control of power sourced from a microbial fuel cell reduces its start-up time and increases bioelectrochemical activity. Bioresour. Technol. 2013, 140, 277–285. [Google Scholar] [CrossRef] [PubMed]

- Donovan, C.; Dewan, A.; Heo, D.; Beyenal, H. Batteryless, wireless sensor powered by a sediment microbial fuel cell. Environ. Sci. Technol. 2008, 42, 8591–8596. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Hatzell, M.C.; Hutchinson, A.J.; Logan, B.E. Capturing power at higher voltages from arrays of microbial fuel cells without voltage reversal. Energy Environ. Sci. 2011, 4, 4662–4667. [Google Scholar] [CrossRef]

- Park, J.-D.; Ren, Z. Efficient Energy Harvester for Microbial Fuel Cells using DC/DC Converters. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition (ECCE 2011), Phoenix, AZ, USA, 17–22 September 2011; pp. 3852–3858. [Google Scholar]

- Degrenne, N.; Buret, F.; Morel, F.; Adami, S.E.; Labrousse, D.; Allard, B.; Zaoui, A. Self-Starting DC:DC Boost Converter for Low-Power and Low-Voltage Microbial Electric Generators. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition (ECCE 2011), Phoenix, AZ, USA, 17–22 September 2011; pp. 889–896. [Google Scholar]

- Gao, H.; Meehan, A.; Lewandowski, Z. New Microbial Fuel Cell Power System for Efficiency Improvement. In Proceedings of the 2011 International Conference on Electrical Machines and Systems (ICEMS 2011), Beijing, China, 20–23 August 2011; pp. 1–5. [Google Scholar]

- Donovan, C.; Dewan, A.; Heo, D.; Lewandowski, Z.; Beyenal, H. Sediment microbial fuel cell powering a submersible ultrasonic receiver: New approach to remote monitoring. J. Power Sources 2013, 233, 79–85. [Google Scholar] [CrossRef]

- Thomas, Y.R.; Picot, M.; Carer, A.; Berder, O.; Sentieys, O.; Barrière, F. A single sediment—Microbial fuel cell powering a wireless telecommunication system. J. Power Sources 2013, 241, 703–708. [Google Scholar] [CrossRef]

- Karra, U.; Muto, E.; Umaz, R.; Kölln, M.; Santoro, C.; Wang, L.; Li, B. Performance evaluation of activated carbon-based electrodes with novel power management system for long-term benthic microbial fuel cells. Int. J. Hydrogen Energy 2014, 39, 21847–21856. [Google Scholar] [CrossRef]

- Ewing, T.; Ha, P.T.; Babauta, J.T.; Tang, N.T.; Heo, D.; Beyenal, H. Scale-up of sediment microbial fuel cells. J. Power Sources 2014, 272, 311–319. [Google Scholar] [CrossRef]

- Alaraj, M.; Ren, Z.J.; Park, J.-D. Microbial fuel cell energy harvesting using synchronous flyback converter. J. Power Sources 2014, 247, 636–642. [Google Scholar] [CrossRef]

- Xu, Z.; Hao, R.; Soonjae, P.; Jae-Ik, L.; Jongbaeg, K.; Junseok, C. A high-efficiency DC-DC boost converter for a miniaturized microbial fuel cell. IEEE Trans. Power Electron. 2015, 30, 2041–2049. [Google Scholar]

- Carreon-Bautista, S.; Erbay, C.; Han, A.; Sanchez-Sinencio, E. Power management system with integrated maximum power extraction algorithm for microbial fuel cells. IEEE Trans. Energy Convers. 2015, 30, 262–272. [Google Scholar] [CrossRef]

- Fradler, K.R.; Kim, J.R.; Boghani, H.C.; Dinsdale, R.M.; Guwy, A.J.; Premier, G.C. The effect of internal capacitance on power quality and energy efficiency in a tubular microbial fuel cell. Process Biochem. 2014, 49, 973–980. [Google Scholar] [CrossRef]

- Sevda, S.; Dominguez-Benetton, X.; Vanbroekhoven, K.; De Wever, H.; Sreekrishnan, T.; Pant, D. High strength wastewater treatment accompanied by power generation using air cathode microbial fuel cell. Appl. Energy 2013, 105, 194–206. [Google Scholar] [CrossRef]

- Yu, J.; Park, Y.; Lee, T. Effect of separator and inoculum type on electricity generation and microbial community in single-chamber microbial fuel cells. Bioprocess Biosyst. Eng. 2014, 37, 667–675. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Liu, H.; Logan, B.E. Increased power generation in a continuous flow MFC with advective flow through the porous anode and reduced electrode spacing. Environ. Sci. Technol. 2006, 40, 2426–2432. [Google Scholar] [CrossRef] [PubMed]

| Operation | Flat-Plate MFC (w/o Boosting) | CCV a | OCV b | ||

|---|---|---|---|---|---|

| Voltage output (V) | 0.6 | 3.3 | 5.0 | 3.3 | 5.0 |

| Power (mW) | 2.86 | 0.95 | 1.22 | 0.52 | 0.56 |

| Power density (W/m3) | 14.27 | 6.34 | 8.16 | 3.47 | 3.74 |

| Efficiency (η, %) | – | 44.43 | 57.14 | 27.82 | 26.21 |

| Case 1: Synthetic Wastewater | |||||||

| Clock Movement (1.9 mW) | LED Lamp (80 mW) | Micro DC Motor (80 mW) | |||||

| Short Term * | Long Term * | Short Term * | Long Term * | Short Term * | Long Term * | ||

| FPM | Single (0.6 V) | − | − | − | − | − | − |

| Dual (1.1 V) | − | − | − | − | + | + | |

| Boosted FPM ** | Boosted to 3.3 V | + | + | − | − | + | − |

| Boosted to 5.0 V | + | + | + | + | + | − | |

| Case 2: Domestic Wastewater | |||||||

| Clock Movement (1.9 mW) | LED Lamp (80 mW) | Micro DC Motor (80 mW) | |||||

| Short Term * | Long Term * | Short Term * | Long Term * | Short Term * | Long Term * | ||

| FPM | Single (0.6 V) | − | − | − | − | − | − |

| Dual (1.1 V) | − | − | − | − | + | − | |

| Boosted FPM ** | Boosted to 3.3 V | + | + | − | − | + | − |

| Boosted to 5.0 V | + | + | + | − | + | − | |

| MFC Type | Volume | Operational Mode | Substrate | Anode | Cathode | Input | Output | Converting Efficiency | Maximum Power | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Sediment | N/A | N/A | River water (MnO2) | Graphite plate | Stainless steel wire (1.2 m2) | 0.4 V | 3.3 V | 73% at 0.88 V | 0.12 mW | [21] |

| Cubic inner cylindrical chamber | 27 mL | Fed-Batch | Acetate | Carbon brushes | Carbon paper (pt) | 0.7 V | 2.5 V | 92.3% at 0.85 V (with 4 cell) | 0.78 mW | [22] |

| Lab scale Two-chamber | 48 mL | Batch | Acetate | Carbon paper | Carbon cloth | 0.328 V | 3.3 V | N/A | 1.2 mW | [23] |

| Single chamber | 1 L | Batch | Domestic wastewater | Graphite fiber brush | Carbon paper | 0.3 V | 2.7 V | 74% at 0.3 V | 540 μW | [24] |

| Sediment | N/A | N/A | River water | Graphite Plate | Graphite | 0.395 V | 5 V | 80.6% at 4.07 V (Vin = 0.395 V) | 24.32 mW | [10] |

| Sediment | 1.01 L | N/A | Lactate | Graphite plate | Carbon bend | 0.7 V | 3.3 V | 79% at 1.8 V (Vin = 0.7 V) | > 21 mW | [25] |

| Sediment (open water system) | 1.01 L | N/A | Lactate | Graphite plate | Carbon bend | 0.7 V | 3.3 V | 87% at 1.8 V (Vin = 0.7 V) | 1 mW | [11] |

| Single chamber | 0.9 L | Batch | Acetate | Carbon fiber brush | Carbon paper | 0.475 V | 2–7.5 V | 60.2% at 0.475 V | 113 μW | [15] |

| Two-chamber (cubic) | 140 mL | Batch | Acetate | Heated graphite brushes | Carbon paper | 0.315 V | 2.5 V | 73% at 0.315 V | 378 μW | [14] |

| Sediment | N/A | N/A | River water | Graphite plate | Graphite plate | 0.52 V | 3.6 V | 75.3% at 0.52 V | 10.7 mW | [26] |

| Sediment | 0.8 L | Batch | Acetate | Graphite granules | Carbon felt disc | 0.193 V | 3.3 V | 53% at 0.193 V | 2.5 mW | [27] |

| Underwater benthic | 500 mL | Batch | Acetate | Carbon fiber brush | Carbon paper | 0.6 V | 3.3 V | 22.45% at 0.6 V | 0.56 W/m2 | [28] |

| Sediment | 240 L | Batch | River water | Graphite felt | Graphite felt | ~0.8 V | 2.7 V | 59.5% at 0.8 V (output current: 2 mA) | 0.68 mW | [29] |

| Two-chamber (cubic) | 150 mL | Batch | Acetate | Graphite brushes | Carbon cloth | 0.3 V | 2.13 V | 50.3% after 25 min | 3.21 mW | [30] |

| Miniaturized MFC | 50 μL | Batch | Acetate | Vertically aligned carbon nanotube | Cr/Au | >0.6 V | 0.9–1.2 V | 85% at 0.9 V | 10 μW | [31] |

| Two-chamber | 240 mL | Batch | Acetate | Carbon felt | Carbon cloth | 0.72 V | 2.5 V | 58% at 0.72 V | 320 μW | [32] |

| Flat-plat MFC | 150 mL | Continuous | Acetate and domestic wastewater | Carbon felt | Carbon cloth | ~0.7 V | 5.0 V | 57.17% at 0.46 V | 2.86 mW | This study |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.E.; Boghani, H.C.; Kim, H.S.; Kim, B.G.; Lee, T.; Jeon, B.-H.; Premier, G.C.; Kim, J.R. Electricity Production by the Application of a Low Voltage DC-DC Boost Converter to a Continuously Operating Flat-Plate Microbial Fuel Cell. Energies 2017, 10, 596. https://doi.org/10.3390/en10050596

Song YE, Boghani HC, Kim HS, Kim BG, Lee T, Jeon B-H, Premier GC, Kim JR. Electricity Production by the Application of a Low Voltage DC-DC Boost Converter to a Continuously Operating Flat-Plate Microbial Fuel Cell. Energies. 2017; 10(5):596. https://doi.org/10.3390/en10050596

Chicago/Turabian StyleSong, Young Eun, Hitesh C. Boghani, Hong Suck Kim, Byung Goon Kim, Taeho Lee, Byong-Hun Jeon, Giuliano C. Premier, and Jung Rae Kim. 2017. "Electricity Production by the Application of a Low Voltage DC-DC Boost Converter to a Continuously Operating Flat-Plate Microbial Fuel Cell" Energies 10, no. 5: 596. https://doi.org/10.3390/en10050596

APA StyleSong, Y. E., Boghani, H. C., Kim, H. S., Kim, B. G., Lee, T., Jeon, B.-H., Premier, G. C., & Kim, J. R. (2017). Electricity Production by the Application of a Low Voltage DC-DC Boost Converter to a Continuously Operating Flat-Plate Microbial Fuel Cell. Energies, 10(5), 596. https://doi.org/10.3390/en10050596