Dielectric Properties of Biomass/Biochar Mixtures at Microwave Frequencies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biochar Preparation

2.2. Biomass Sample Preparation

2.3. Measurement Procedure

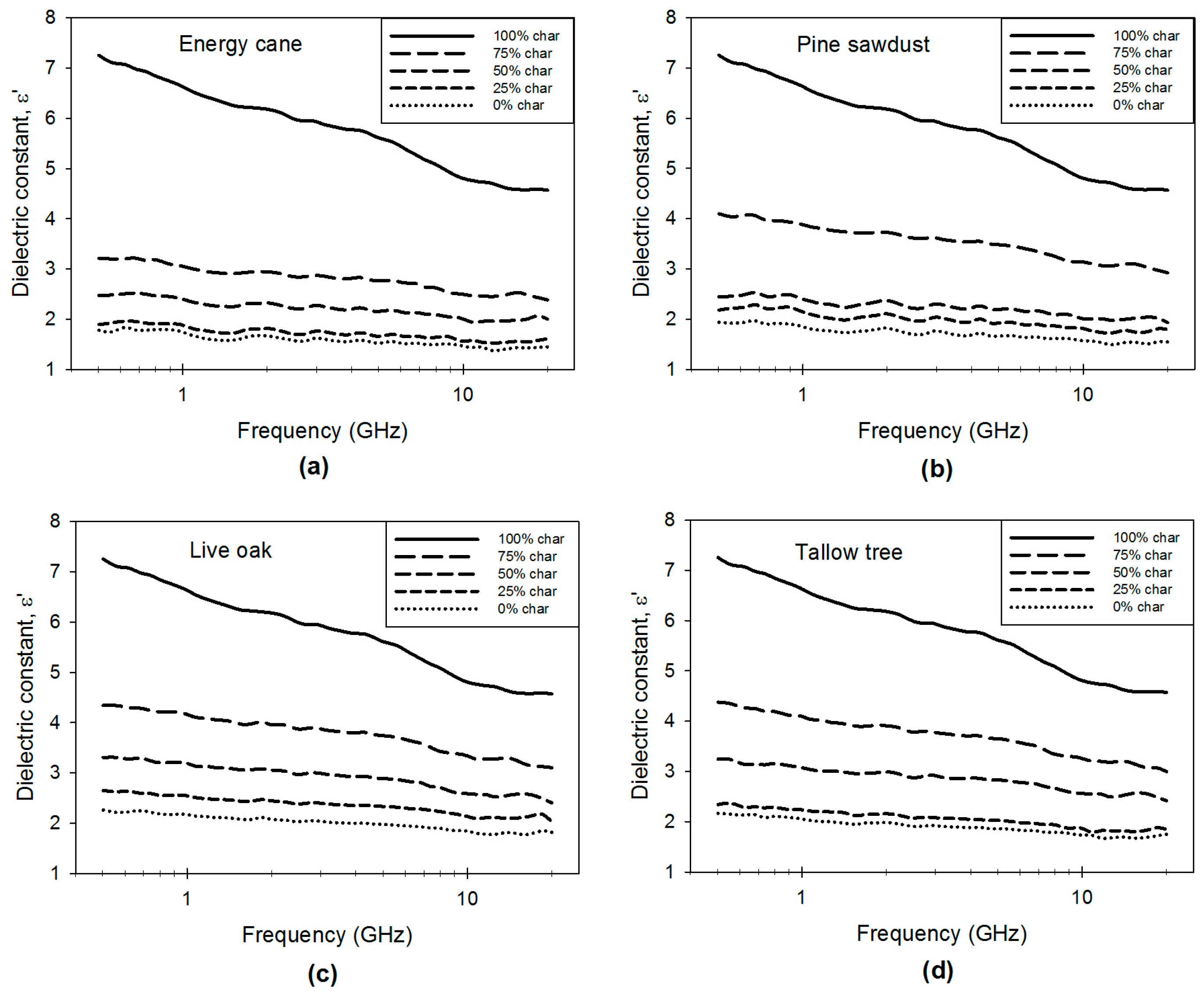

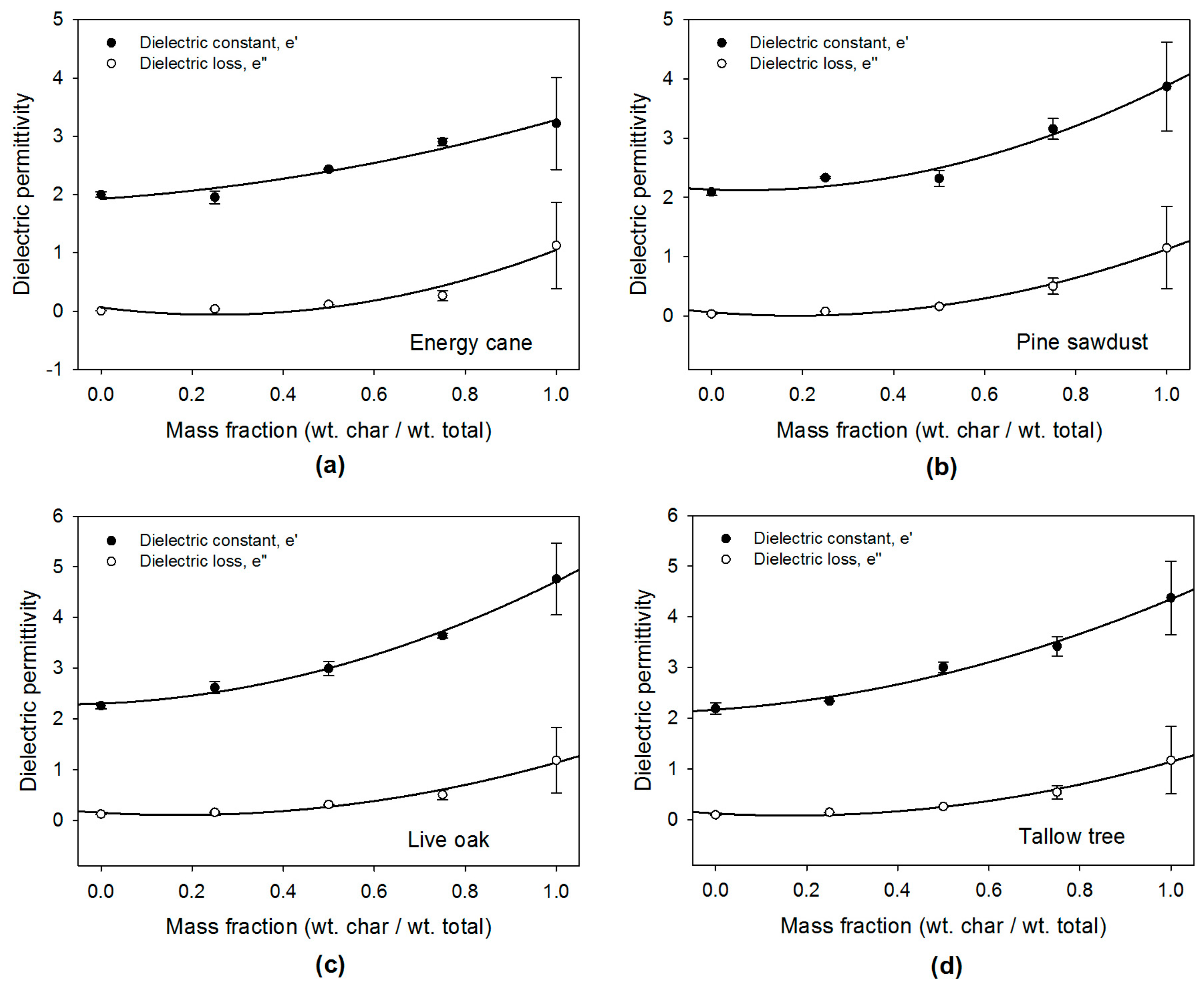

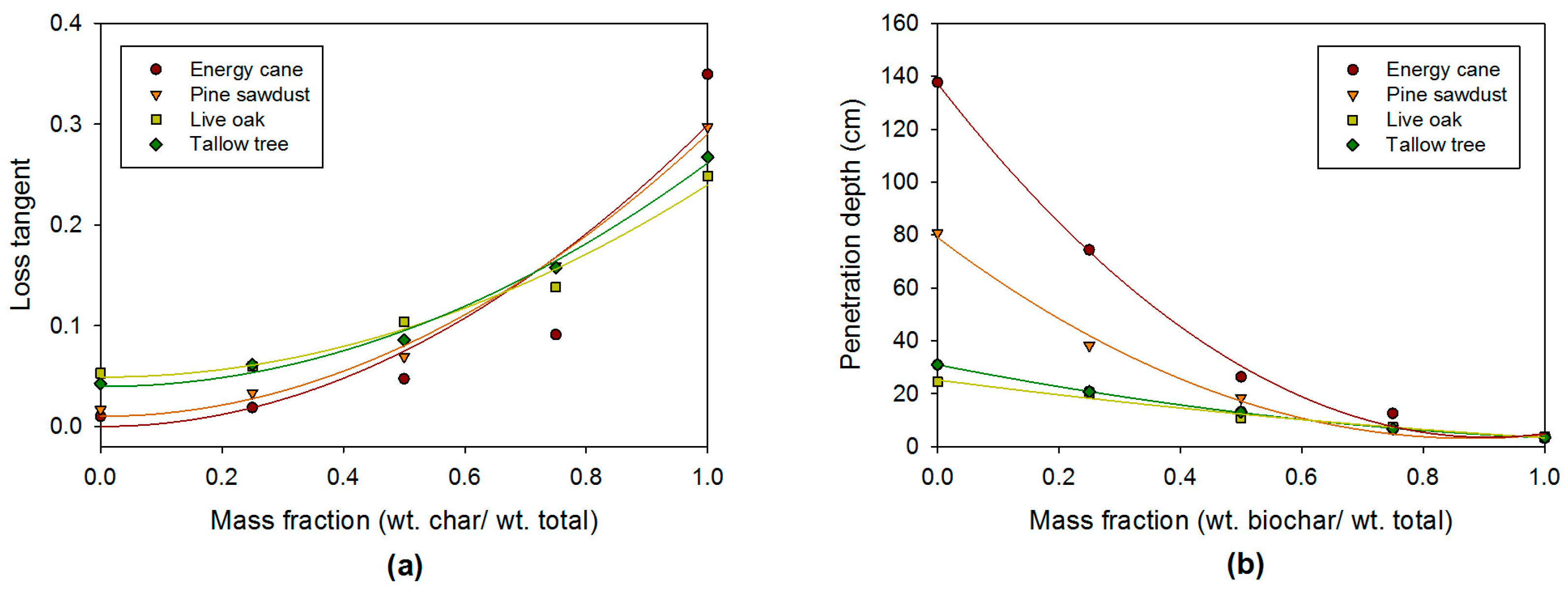

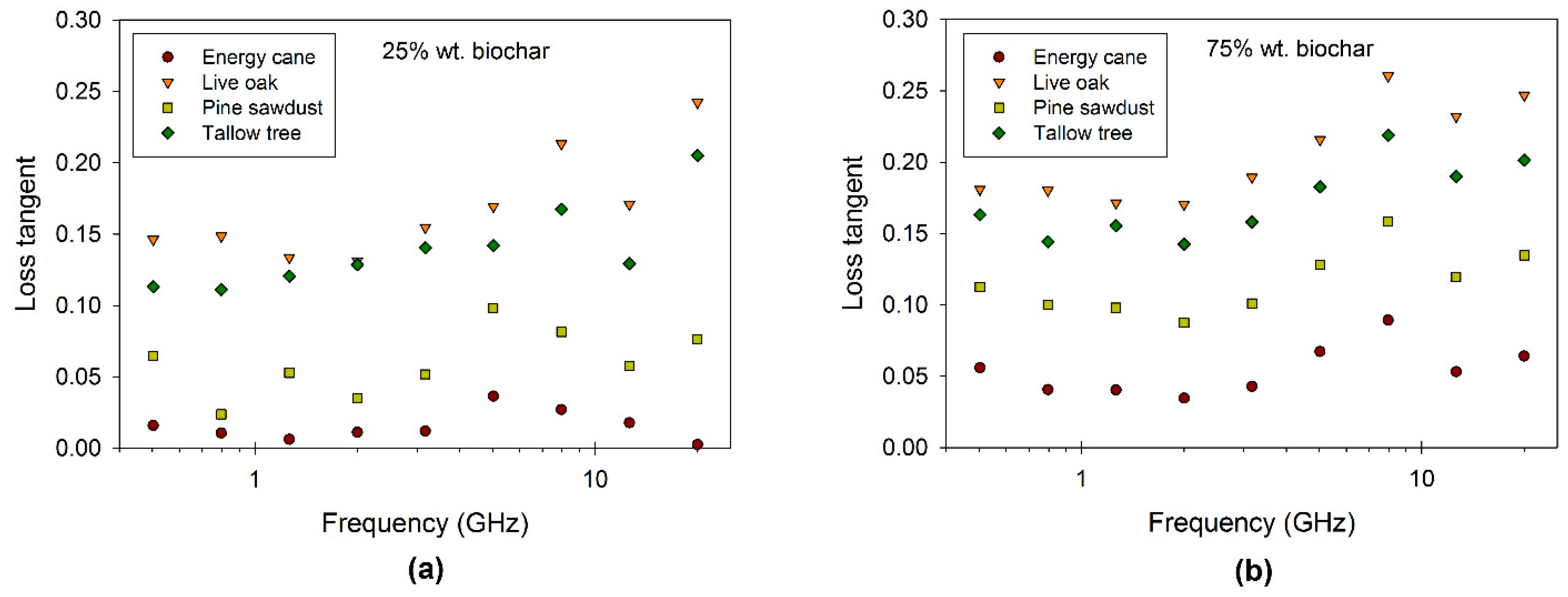

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- U.S. Department of Energy. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy; Langholtz, M.H., Stokes, B.J., Eaton, L.M., Eds.; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016; p. 448.

- Henkel, C.; Muley, P.D.; Abdollahi, K.K.; Marculescu, C.; Boldor, D. Pyrolysis of energy cane bagasse and invasive Chinese tallow tree (Triadica sebifera L.) biomass in an inductively heated reactor. Energy Convers. Manag. 2016, 109, 175–183. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Principles and practice of biomass fast pyrolysis processes for liquids. J. Anal. Appl. Pyrolysis 1999, 51, 3–22. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Salema, A.A.; Ani, F.N. Microwave induced pyrolysis of oil palm biomass. Bioresour. Technol. 2011, 102, 3388–3395. [Google Scholar] [CrossRef]

- Undri, A.; Abou-Zaid, M.; Briens, C.; Berruti, F.; Rosi, L.; Bartoli, M.; Frediani, M.; Frediani, P. Bio-oil from pyrolysis of wood pellets using a microwave multimode oven and different microwave absorbers. Fuel 2015, 153, 464–482. [Google Scholar] [CrossRef]

- Liu, G.; Wright, M.; Zhao, Q.; Brown, R.C. Catalytic fast pyrolysis of duckweed: Effects of pyrolysis parameters and optimization of aromatic production. J. Anal. Appl. Pyrolysis 2015, 112, 29–36. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Microwave processing: Fundamentals and applications. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

- Meredith, R.J. Engineers' Handbook of Industrial Microwave Heating; Institution of Electrical Engineers: London, UK, 1998. [Google Scholar]

- Nelson, S.O. Correlating dielectric properties of solids and particulate samples through mixture relationships. Trans. ASAE 1992, 35, 625–629. [Google Scholar] [CrossRef]

- Torgovnikov, G.I. Dielectric Properties of Wood and Wood-Based Materials; Springer: Berlin, Germany, 1993. [Google Scholar]

- Olmi, R.; Bini, M.; Ignesti, A.; Riminesi, C. Dielectric Properties of Wood from 2 to 3 GHz. J. Microw. Power Electromagn. Energy 2000, 35, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Ramasamy, S.; Moghtaderi, B. Dielectric Properties of Typical Australian Wood-Based Biomass Materials at Microwave Frequency. Energy Fuels 2010, 24, 4534–4548. [Google Scholar] [CrossRef]

- Paz, A.M.; Trabelsi, S.; Nelson, S.O.; Thorin, E. Measurement of the Dielectric Properties of Sawdust Between 0.5 and 15 GHz. IEEE Trans. Instrum. Meas. 2011, 60, 3384–3390. [Google Scholar] [CrossRef]

- McKeown, M.S.; Trabelsi, S.; Tollner, E.W. Effects of temperature and material on sensing moisture content of pelleted biomass through dielectric properties. Biosyst. Eng. 2016, 149, 1–10. [Google Scholar] [CrossRef]

- Motasemi, F.; Afzal, M.T.; Salema, A.A. Microwave dielectric characterization of hay during pyrolysis. Ind. Crops Prod. 2014, 61, 492–498. [Google Scholar] [CrossRef]

- Motasemi, F.; Afzal, M.T.; Salema, A.A.; Hutcheon, R.M. Microwave dielectric characterization of switchgrass for bioenergy and biofuel. Fuel 2014, 124, 151–157. [Google Scholar] [CrossRef]

- Fennell, L.P.; Boldor, D. Dielectric and Thermal Properties of Sweet Sorghum Biomass. J. Microw. Power Electromagn Energy 2014, 48, 244–260. [Google Scholar] [CrossRef]

- Salema, A.A.; Yeow, Y.K.; Ishaque, K.; Ani, F.N.; Afzal, M.T.; Hassan, A. Dielectric properties and microwave heating of oil palm biomass and biochar. Ind. Crops Prod. 2013, 50, 366–374. [Google Scholar] [CrossRef]

- Motasemi, F.; Salema, A.A.; Afzal, M.T. Dielectric characterization of corn stover for microwave processing technology. Fuel Process. Technol. 2015, 131, 370–375. [Google Scholar] [CrossRef]

- Namazi, A.B.; Allen, D.G.; Jia, C.Q. Probing microwave heating of lignocellulosic biomasses. J. Anal. Appl. Pyrolysis 2015, 112, 121–128. [Google Scholar] [CrossRef]

- Zuo, W.; Tian, Y.; Ren, N. The important role of microwave receptors in bio-fuel production by microwave-induced pyrolysis of sewage sludge. Waste Manag. 2011, 31, 1321–1326. [Google Scholar] [CrossRef] [PubMed]

- Motasemi, F.; Afzal, M.T. A review on the microwave-assisted pyrolysis technique. Renew. Sustain. Energy Rev. 2013, 28, 317–330. [Google Scholar] [CrossRef]

- Shang, H.; Lu, R.R.; Shang, L.; Zhang, W.H. Effect of additives on the microwave-assisted pyrolysis of sawdust. Fuel Process. Technol. 2015, 131, 167–174. [Google Scholar] [CrossRef]

- Zhang, S.; Dong, Q.; Zhang, L.; Xiong, Y. High quality syngas production from microwave pyrolysis of rice husk with char-supported metallic catalysts. Bioresour. Technol. 2015, 191, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Qin, F.; Brosseau, C. A review and analysis of microwave absorption in polymer composites filled with carbonaceous particles. J. Appl. Phys. 2012, 111, 061301. [Google Scholar] [CrossRef]

- Menéndez, J.A.; Arenillas, A.; Fidalgo, B.; Bermúdez, J.M. Review: Microwave heating processes involving carbon materials. Fuel Process. Technol. 2010, 91, 1–8. [Google Scholar] [CrossRef]

- Tripathi, M.; Sahu, J.N.; Ganesan, P.; Monash, P.; Dey, T.K. Effect of microwave frequency on dielectric properties of oil palm shell (OPS) and OPS char synthesized by microwave pyrolysis of OPS. J. Anal. Appl. Pyrolysis 2015, 112, 306–312. [Google Scholar] [CrossRef]

- McKeown, M.S.; Trabelsi, S.; Tollner, E.; Nelson, S.O. Dielectric spectroscopy measurements for moisture prediction in Vidalia onions. J. Food Eng. 2012, 111, 505–510. [Google Scholar] [CrossRef]

- Moreau, J.M.; Aziz, R. Dielectric study of granular media according to the type of measurment device: Coaxial cell or open-ended probe. Meas. Sci. Technol. 1993, 4, 124–129. [Google Scholar] [CrossRef]

- Agilent Technologies. Agilent 85070E Dielectric Probe Kit Technical Overview; Agilent Technologies, Inc.: Santa Clara, CA, USA, 2008. [Google Scholar]

- Nelson, S.O.; Bartley, P.G. Open-ended coaxial-line permittivity measurements on pulverized materials. IEEE Trans. Instrum. Meas. 1998, 47, 133–137. [Google Scholar] [CrossRef]

- Blackham, D.V.; Pollard, R.D. An improved technique for permittivity measurements using a coaxial probe. IEEE Trans. Instrum. Meas. 1997, 46, 1093–1099. [Google Scholar] [CrossRef]

- Nelson, S.O. Density-Permittivity Relationships for Powdered and Granular Materials. IEEE Trans. Instrum. Meas. 2005, 54, 2033–2040. [Google Scholar] [CrossRef]

- Zhou, F.; Cheng, J.; Liu, J.; Wang, Z.; Zhou, J. Activated carbon and graphite facilitate the upgrading of Indonesian lignite with microwave irradiation for slurryability improvement. Fuel 2016, 170, 39–48. [Google Scholar] [CrossRef]

- Atwater, J.E.; Wheeler, R.R. Complex permittivities and dielectric relaxation of granular activated carbons at microwave frequencies between 0.2 and 26 GHz. Carbon 2003, 41, 1801–1807. [Google Scholar] [CrossRef]

| Biochar (% wt) | Energy Cane | Sawdust | Live Oak | Chinese Tallow Tree | ||||

|---|---|---|---|---|---|---|---|---|

| MC (% wet basis) | Density (g/cm3) | MC (% wet basis) | Density (g/cm3) | MC (% wet basis) | Density (g/cm3) | MC (% wet basis) | Density (g/cm3) | |

| 0 | 10.70 ± 0.13 | 0.21 | 11.09 ± 0.12 | 0.27 | 11.50 ± 0.00 | 0.40 | 11.33 ± 0.10 | 0.35 |

| 25 | 9.32 ± 0.20 | 0.25 | 9.68 ± 0.06 | 0.30 | 10.87 ± 1.00 | 0.41 | 9.00 ± 0.17 | 0.37 |

| 50 | 7.93 ± 0.00 | 0.29 | 8.05 ± 0.02 | 0.37 | 8.57 ± 0.30 | 0.46 | 7.30 ± 0.22 | 0.41 |

| 75 | 6.50 ± 0.01 | 0.32 | 6.57 ± 0.12 | 0.45 | 6.84 ± 0.05 | 0.49 | 6.63 ± 0.08 | 0.48 |

| 100 | 5.00 ± 0.01 | 0.56 | 5.00 ± 0.01 | 0.56 | 5.00 ± 0.01 | 0.56 | 5.00 ± 0.01 | 0.56 |

| Biochar | Energy Cane | Pine Sawdust | Live Oak | Chinese Tallow Tree |

|---|---|---|---|---|

| 0 | 8.83 | 8.98 | 21.48 | 11.61 |

| 25 | 5.06 | 2.35 | 27.04 | 24.37 |

| 50 | 11.86 | 7.64 | 30.81 | 28.09 |

| 75 | 25.49 | 28.91 | 34.98 | 35.02 |

| 100 | 44.41 | 44.41 | 44.41 | 44.41 |

| Sample | ε′ | ε″ | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | R2 | A | B | C | R2 | |

| Energy cane | 0.8187 | 0.5373 | 1.9260 | 0.9604 | 1.9732 | −0.9848 | 0.0615 | 0.9429 |

| Pine sawdust | 2.0488 | −0.2974 | 2.1348 | 0.9711 | 1.6801 | −0.6170 | 0.0639 | 0.9914 |

| Live oak | 2.0412 | 0.3712 | 2.3027 | 0.9947 | 1.5136 | −0.5243 | 0.1488 | 0.9767 |

| Tallow tree | 1.5599 | 0.6214 | 2.1689 | 0.9891 | 1.5184 | −0.4990 | 0.1205 | 0.9896 |

| Sample | Loss Tan | Penetration Depth | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | R2 | A | B | C | R2 | |

| Energy cane | 0.2992 | 2.06 × 10−12 | 2.06 × 10−12 | 0.8827 | 162.4 | −294.7 | 137.3 | 0.9963 |

| Pine sawdust | 0.2802 | 2.52 × 10−12 | 0.0101 | 0.9941 | 98.5 | −172.9 | 79.1 | 0.9938 |

| Live oak | 0.1909 | 5.96 × 10−12 | 0.0490 | 0.9814 | 7.8 | −29.7 | 25.2 | 0.9789 |

| Tallow tree | 0.2219 | 1.72 × 10−12 | 0.0397 | 0.9929 | 17.3 | −44.8 | 31.0 | 0.9996 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ellison, C.; McKeown, M.S.; Trabelsi, S.; Boldor, D. Dielectric Properties of Biomass/Biochar Mixtures at Microwave Frequencies. Energies 2017, 10, 502. https://doi.org/10.3390/en10040502

Ellison C, McKeown MS, Trabelsi S, Boldor D. Dielectric Properties of Biomass/Biochar Mixtures at Microwave Frequencies. Energies. 2017; 10(4):502. https://doi.org/10.3390/en10040502

Chicago/Turabian StyleEllison, Candice, Murat Sean McKeown, Samir Trabelsi, and Dorin Boldor. 2017. "Dielectric Properties of Biomass/Biochar Mixtures at Microwave Frequencies" Energies 10, no. 4: 502. https://doi.org/10.3390/en10040502

APA StyleEllison, C., McKeown, M. S., Trabelsi, S., & Boldor, D. (2017). Dielectric Properties of Biomass/Biochar Mixtures at Microwave Frequencies. Energies, 10(4), 502. https://doi.org/10.3390/en10040502