1. Introduction

Owing to the advantages of a high energy density, low self-discharge ratio and lack of memory effect, lithium-ion batteries are more and more commonly used in portable electronics, spacecrafts and electric vehicles [

1]. As a critical component in many systems, lithium-ion batteries’ performance plays an important role to ensure the security and reliability of the whole system. An effective battery management system will help to run the battery more efficiently while increasing its lifetime. In the battery management system, a very crucial aspect is to efficiently monitor the battery’s health status.

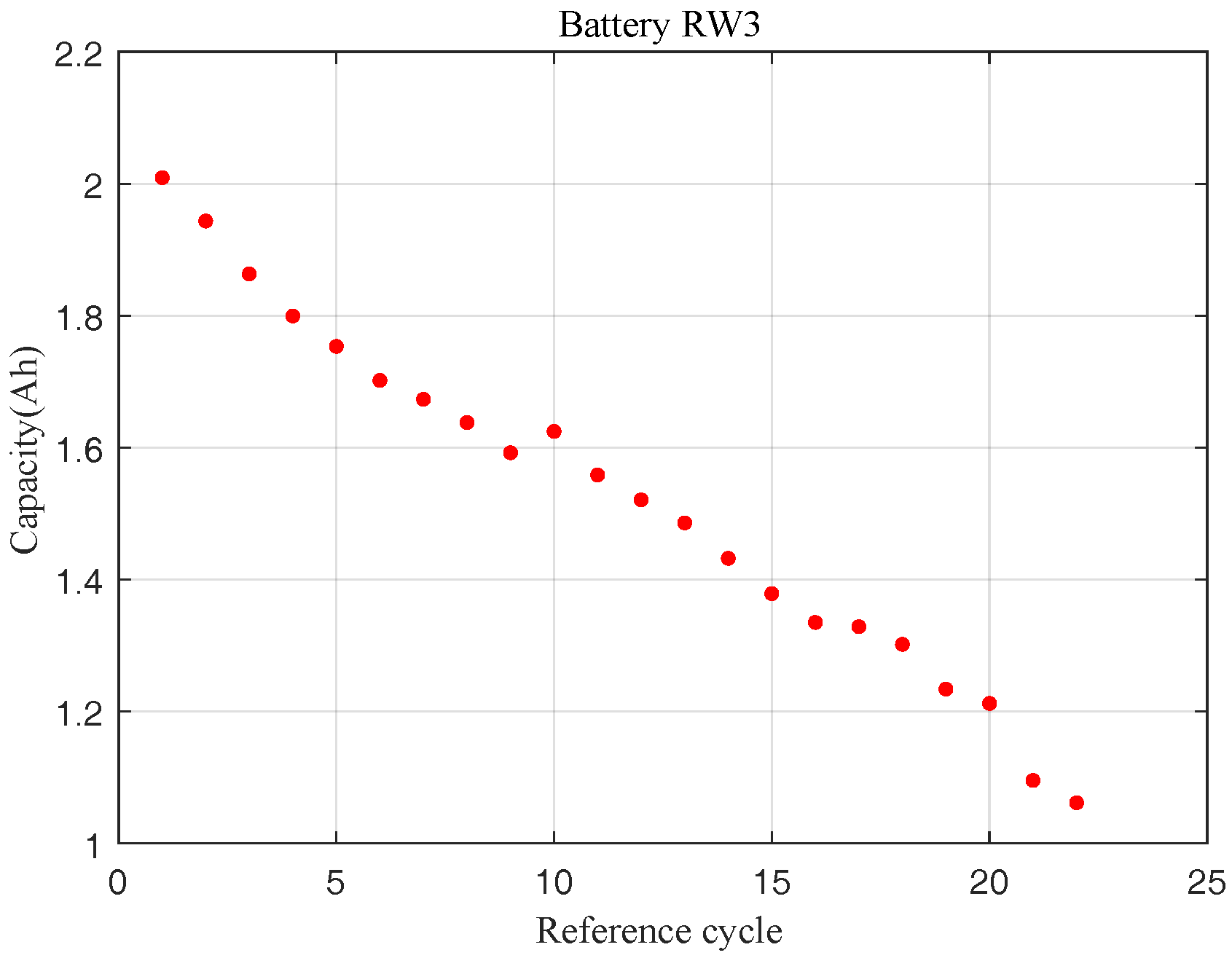

The health status of a lithium-ion battery is often defined as the state-of-health (SOH). The most typical definition of the SOH is based on the battery’s capacity. The capacity decreases gradually with the degradation of the battery [

2]. When the capacity reaches a given threshold, the lithium-ion battery is considered to be failed. Thus, if we can accurately estimate the capacity, the health status of the lithium-ion battery can be known in advance to assist timely maintenance and prevent serious disaster.

In recent years, lots of approaches have been proposed to estimate the SOH of lithium-ion batteries. These approaches can be classified as model-based approaches, data-driven approaches and hybrid approaches, which combine the model-based approach and the data-driven approach. See

Table 1 for a brief summary of SOH estimation approaches for lithium-ion batteries. The model-based approach [

3,

4,

5,

6,

7,

8,

9,

10] relies on the degradation model that describes the physical nature of the battery’s degradation. In the model, the battery’s SOH is linked to the battery’s electrochemical parameters. For example, Samadi et al. [

5] developed an electrochemical-based aging model to estimate (State-of-charge) SOC and SOH of the battery. These model-based approaches can achieve high estimation accuracy, but they also require heavy work in the model development. For the data-driven approach [

11,

12,

13,

14], it is not necessary to understand the degradation principle of the battery; it only uses degradation data to build the degradation model. For example, Rezvani et al. [

12] used an adaptive neural network (ANN) and linear prediction error method for the SOH quantification of a lithium-ion battery. Different features from three different regimes (charge, discharge, and impedance) are extracted as the input of the ANN. However, these approaches require a lot of data to achieve good estimation accuracy. To combine advantages of both model-based and data-driven approaches, some researchers have utilized both, such as in [

15,

16,

17]. In these hybrid approaches, the degradation behavior of lithium-ion batteries is described by a physical model, and then the monitoring data is used to refine the model parameters.

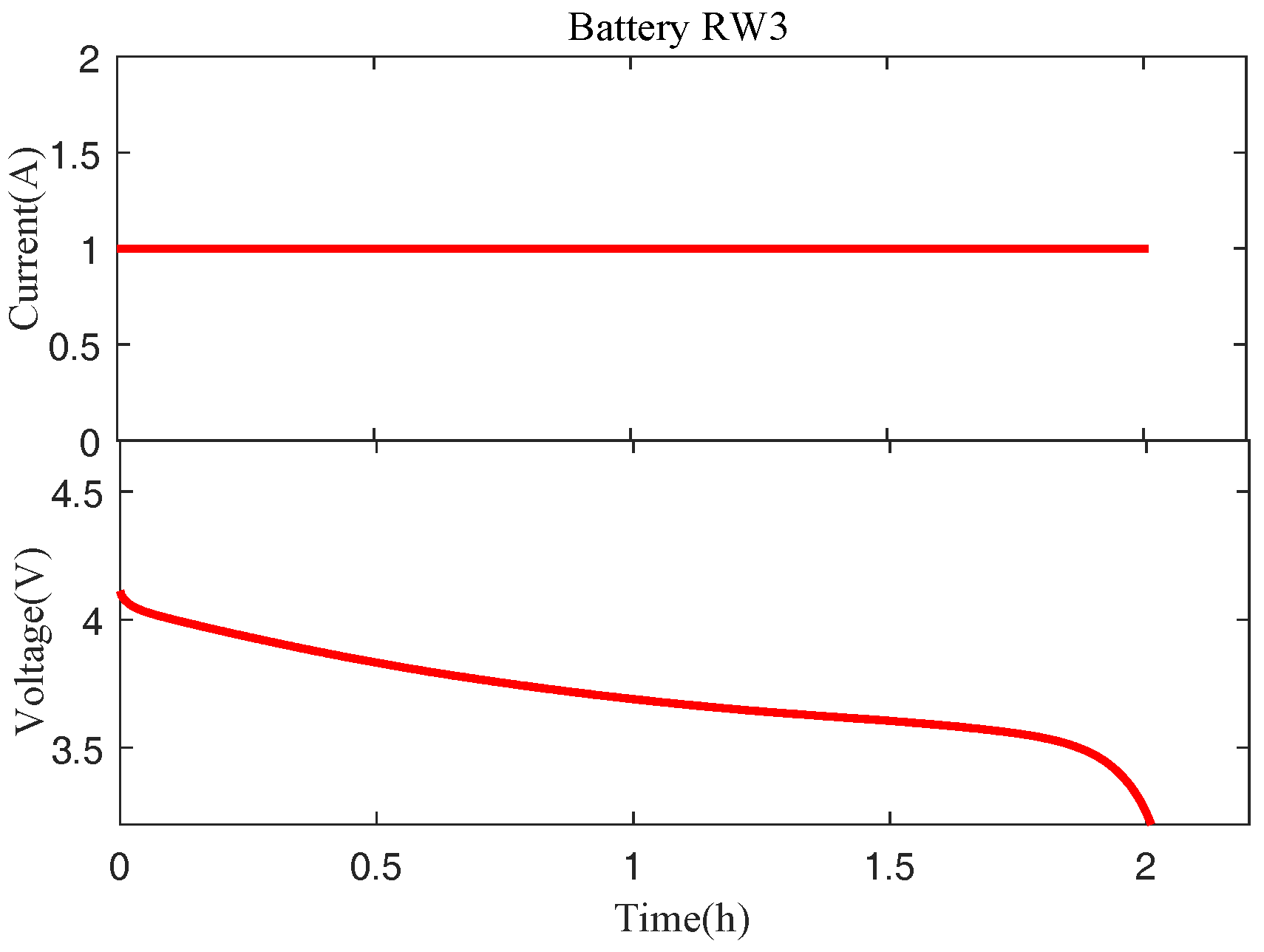

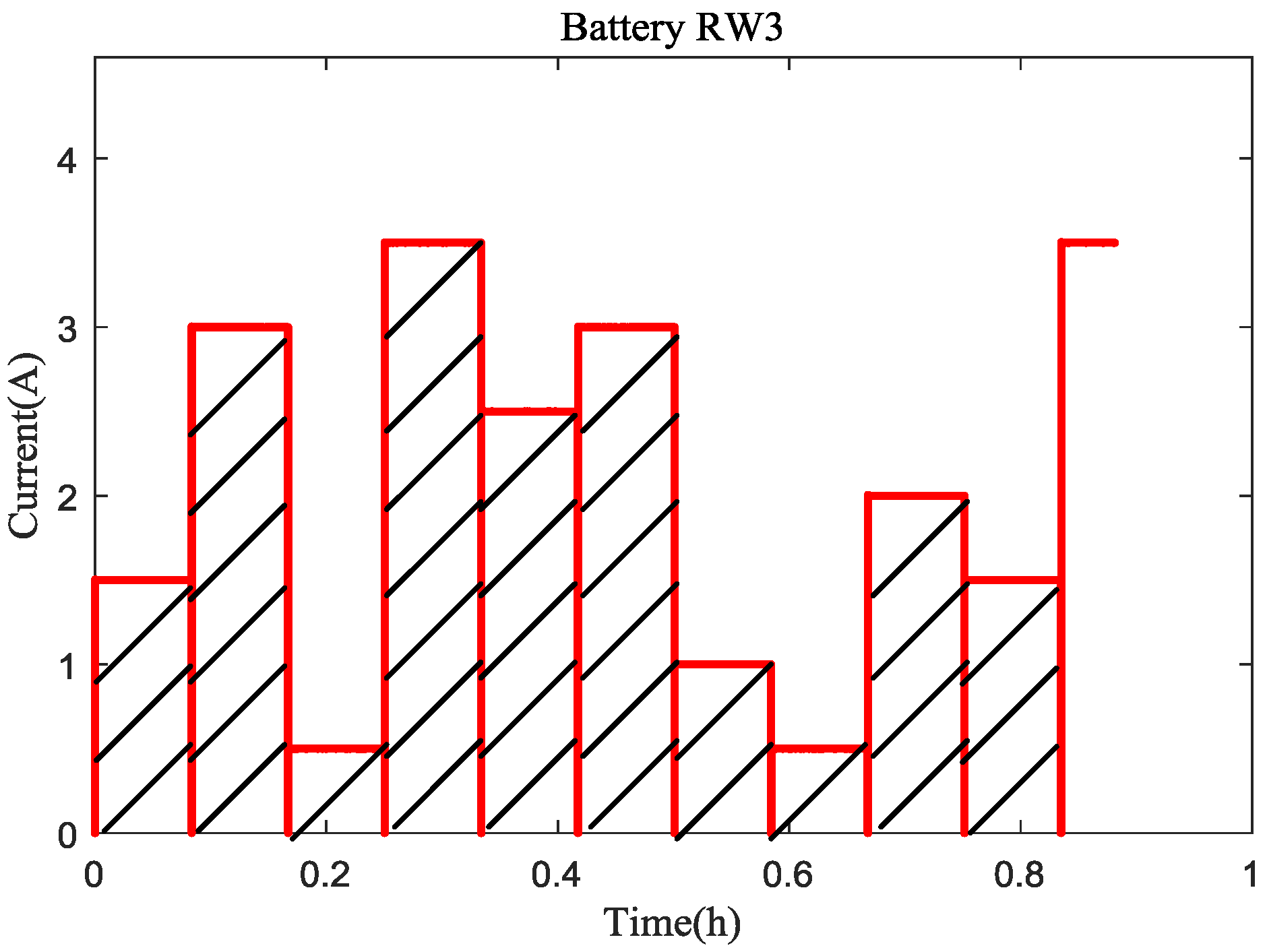

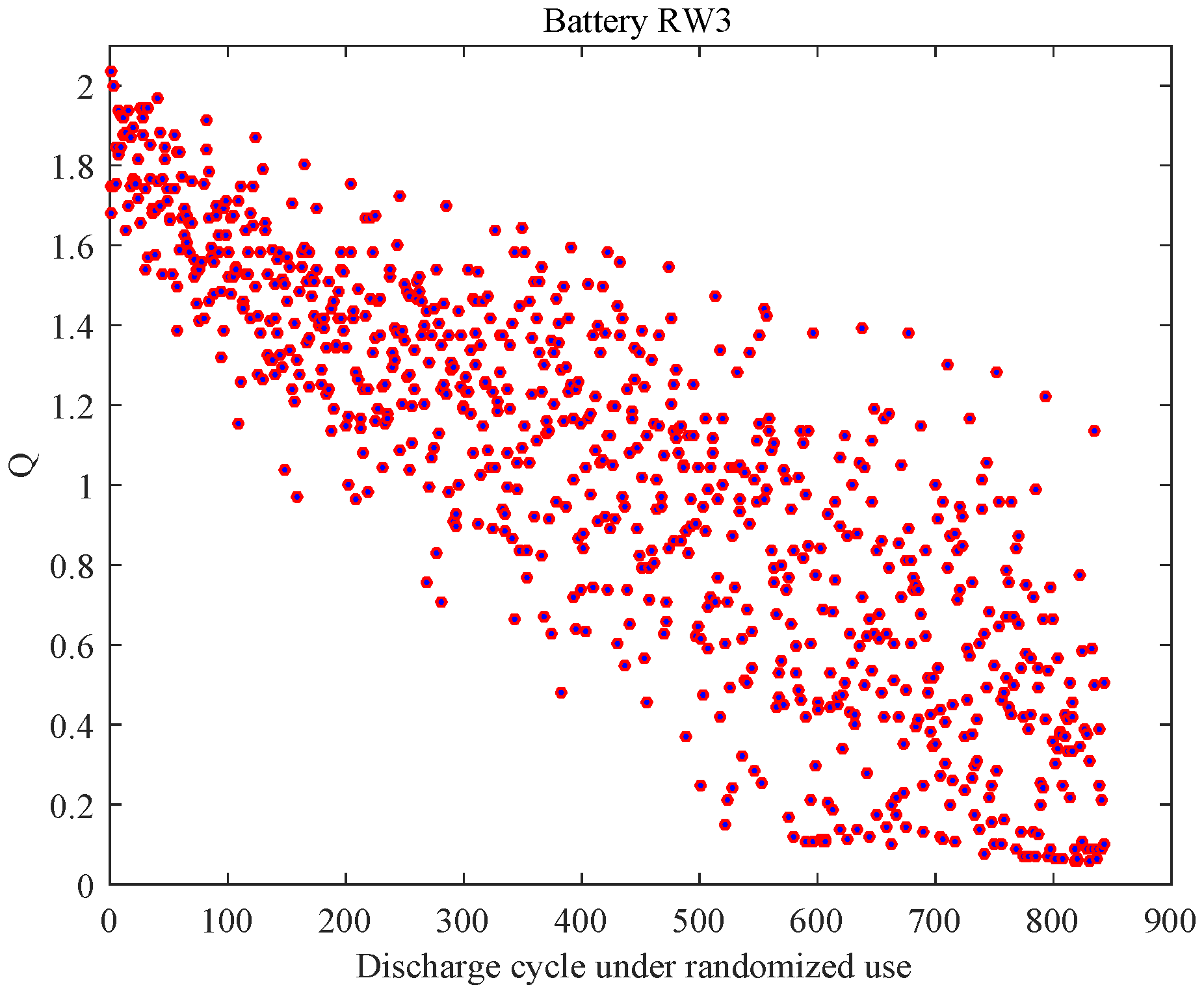

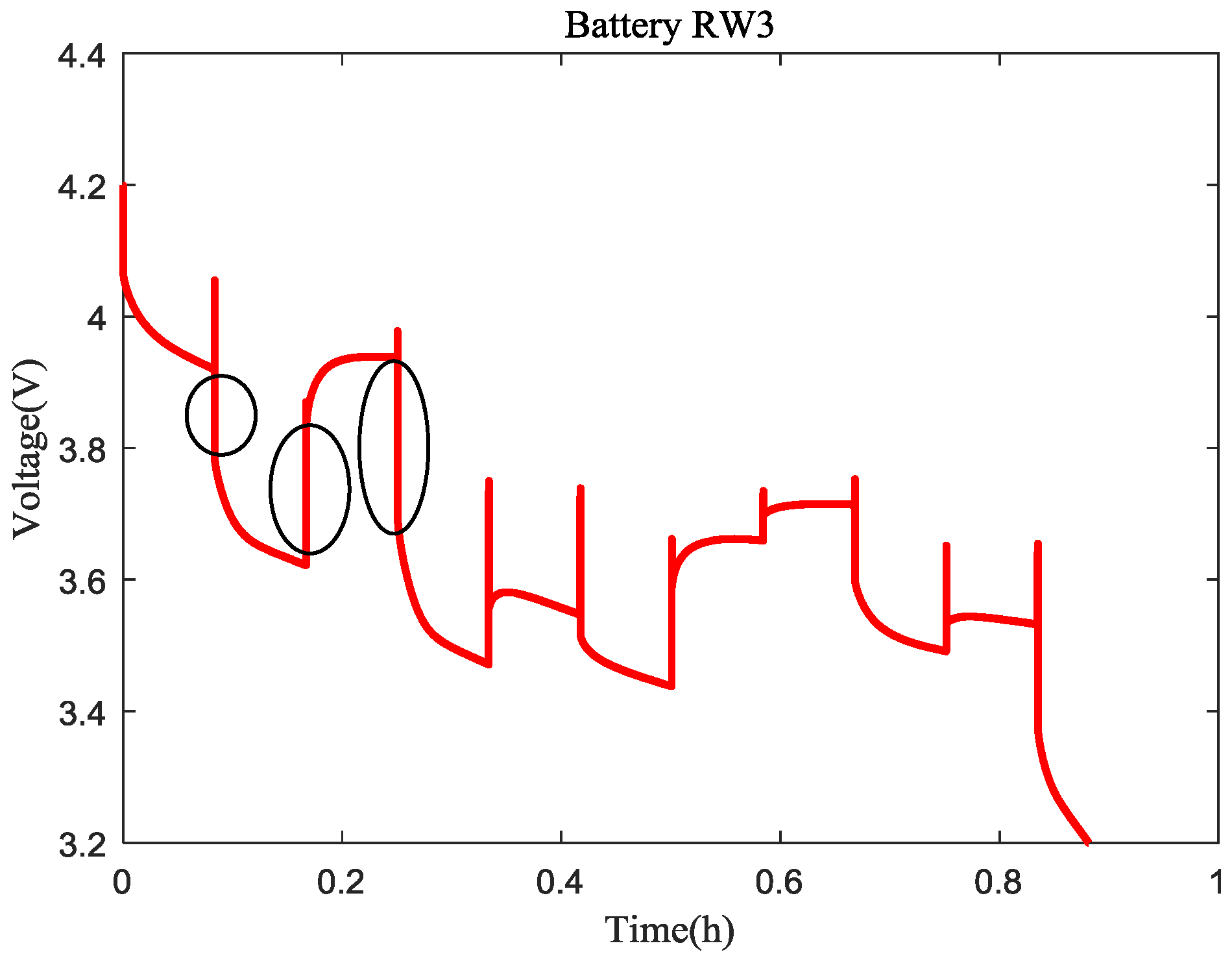

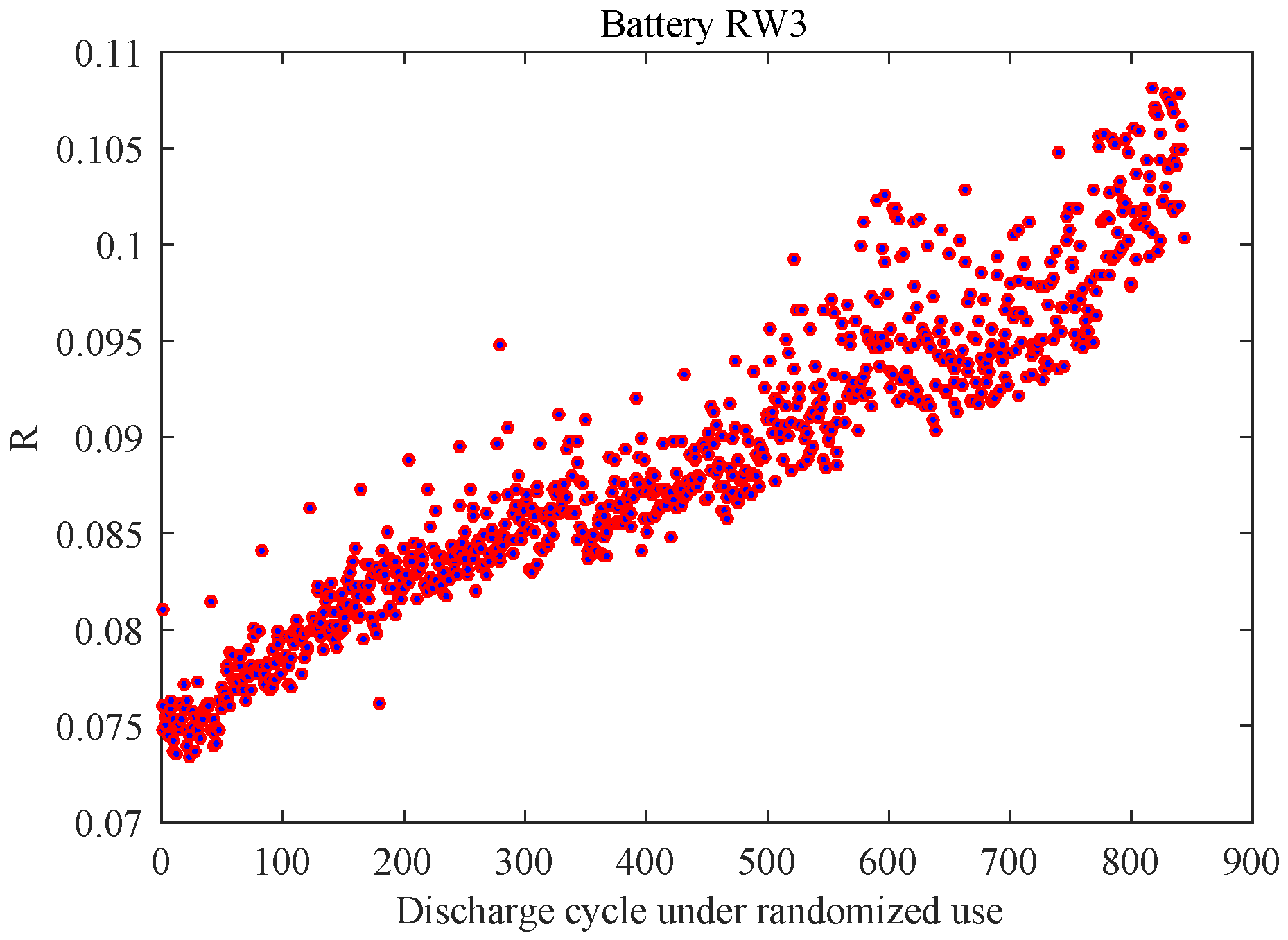

It can be noted that most of the existing literature mainly focuses on improving SOH estimation algorithms by using direct SOH indicators such as the battery’s capacity and internal resistance, while only a little attention has been paid to finding indirect health indicators (HIs) for SOH estimation, such as voltage and current, which can be easily measured during the usage of the battery. In fact, when lithium-ion batteries are used in electronic equipment, the battery’s capacity and internal resistance are very difficult to measure via existing sensors. Moreover, these quantities can only be used under constant loading conditions, which occur much less frequently in real practice. Therefore, it is necessary to find indirect HIs under randomized use of the battery for the online estimation of the SOH.

Among these limited works that have extracted indirect HIs for SOH estimation of lithium-ion batteries, two different approaches are used. One is analyzing HIs under a constant discharge process, and the other is achieved under a constant charge process. For example, Saha et al. [

19] used the battery’s impedance as the HI for the SOH of battery, and Tong et al. [

20] considered the open-circuit voltage, both under the circumstances of constant discharge. Moreover, Liu et al. [

21] discovered that the time interval of equal discharging voltage difference in each discharge cycle can be used as a HI to represent the capacity degradation; Li et al. [

22] used the temperature-change rate as the battery’s HI. For the HIs extracted under a constant charge process, some contributions are worthy of attention. For example, Wu et al. [

23] selected the velocity and the arclength curvature of the charge curve as the HI, and then the group method of data handling was employed to estimate the SOH of the battery.

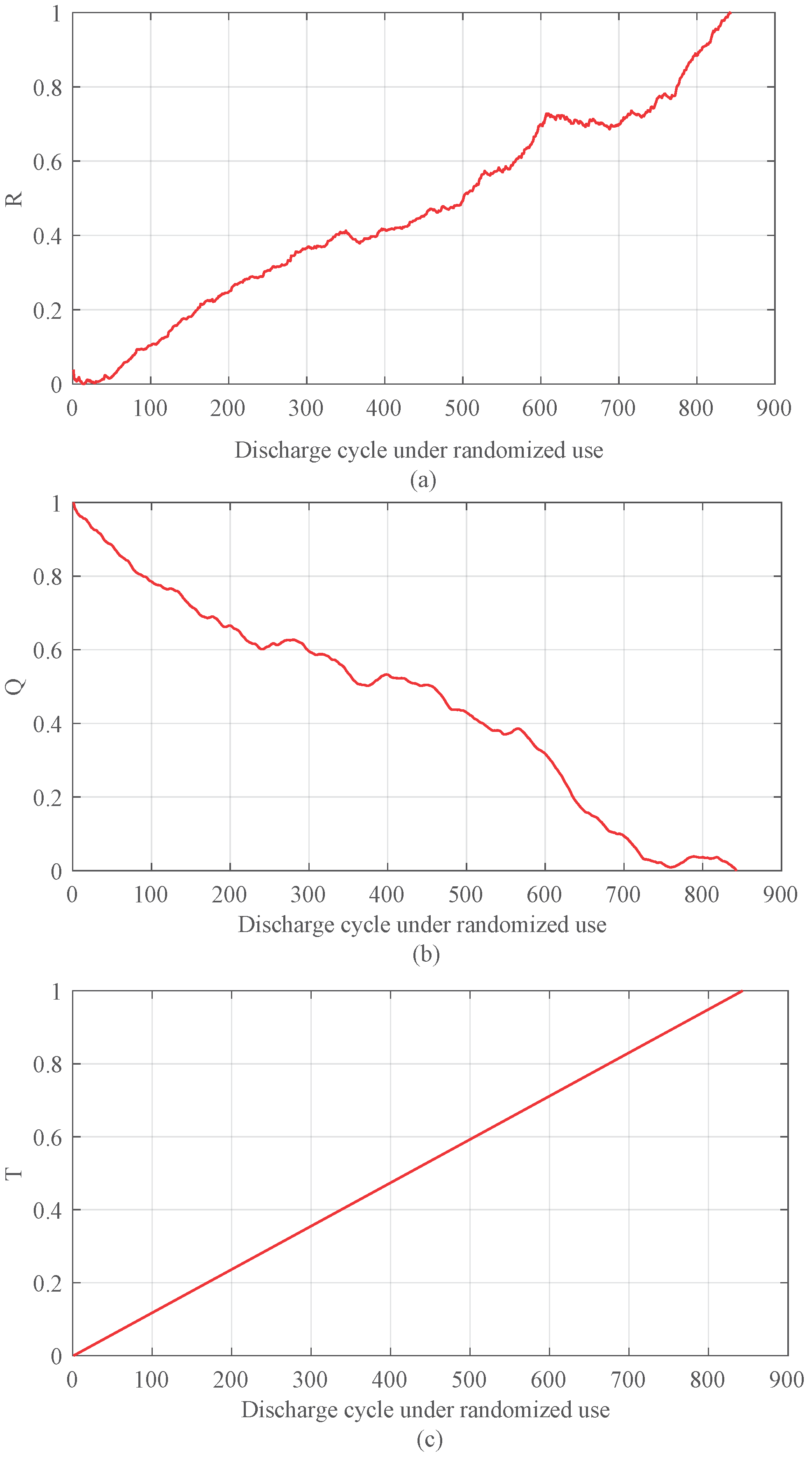

All the above HIs are extracted under a constant discharge cycle or constant charge cycle [

24]. No contribution has been made to find indirect HIs for a battery’s SOH estimation under randomized loading conditions. However, in real engineering practice, a randomized loading condition is indeed the general situation. Therefore, in this paper, we dedicate efforts to extracting some indirect HIs for batteries’ SOH estimation under randomized loading conditions. For this purpose, we first explore HIs that can be easily obtained from the online condition-monitoring of the battery’s voltage and current, and we then develop a model based on an elastic net to build the linkage between these HIs and the battery’s SOH, considering the usually existing redundancies between the HIs. To our knowledge, we are the first to successfully build up indirect HIs to represent the battery’s health status under randomized use. In order to improve the online accuracy of the SOH estimation, we apply a particle filter (PF) to automatically update the model with possible available measurements of the true SOH.

The rest of this paper is organized as follows:

Section 2 details the HI extraction. In

Section 3, the relation between the HIs and capacity is constructed using the elastic net method. In

Section 4, the PF is used to update the model with the new data, and the capacity of the batteries is predicted with the updated model. Finally, conclusions of the results as well as further work are given in

Section 5.

3. State-of-Health Modeling Using Indirect Health Indicators

After the extraction of indirect HIs, a quantitative model that describes the relationship between these HIs and the battery’s SOH should be developed. We consider that the SOH and these HIs follow a linear regression model, that is, as follows:

where

is the estimated battery’s SOH for the

kth cycle,

is the model coefficient vector we have to estimate,

, and

is the error term. We assume the errors are identically and independent distributed with a zero mean and finite variance

, which means

.

Considering possible multi-collinearity among the HIs, we apply the elastic net method to estimate the model coefficients. Proposed by Zou and Zhang [

31], the elastic net is a regularized regression method that linearly combines the L1 and L2 penalties of the lasso and ridge methods. Compared to the Lasso, which tends to select one variable from a group of highly correlated variables, the elastic net tends to distribute different weights to different variables. Therefore, the elastic net removes the limitation on the number of selected variables and stabilizes the L1 regularization path.

To demonstrate the necessity of using the elastic net to construct our model, we need to prove the existence of multi-collinearity among the HIs. Firstly, we use Pearson’s correlation coefficient [

32] between two different HIs to find whether these HIs are linearly correlated. The results are shown in

Table 3.

Table 3 indicates that there is a remarkable linear correlation between these HIs. Then, we use the variance inflation factor (VIF) [

33] to quantify the severity of multi-collinearity. This indicates high multi-collinearity when its value is greater than 10. The result of VIF was 100, which is an indicator of high multi-collinearity. The existence of multi-collinearity forces us to use methods that can alleviate the influence of multi-collinearity. This is why we chose the elastic net method.

The elastic net loss function defined as

where

is the battery’s true SOH at the

kth cycle,

and

are user-defined parameters, and

We define

; then our target is to solve the following optimization problem:

where the function

is called the elastic net penalty, which is a convex combination of the lasso and ridge penalty. When

, the elastic net becomes simple ridge regression, and when

, the elastic net becomes simple lasso regression. In this paper, we consider

to combine advantages of both regression methods.

The estimates of model coefficients are obtained by

After obtaining the estimate of model coefficient

by the elastic net method, the battery’s SOH can be estimated using the values of

,

and

. We used the dataset described in

Section 2.1 to estimate the model coefficient

for each battery and to demonstrate the effectiveness of the model. The estimation results are shown in

Table 4. Using these estimates, we were able to estimate the SOH of each battery at each cycle time.

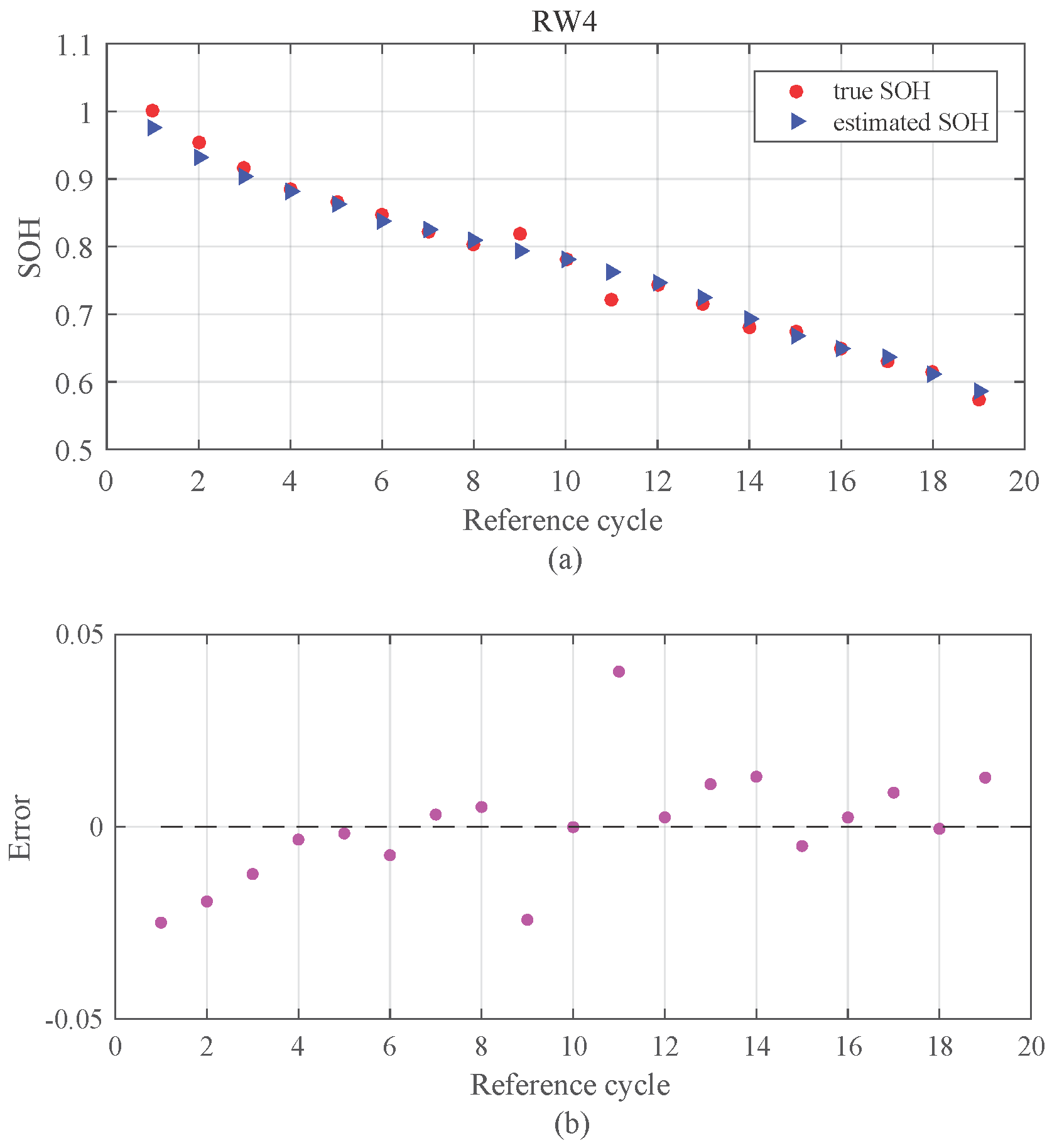

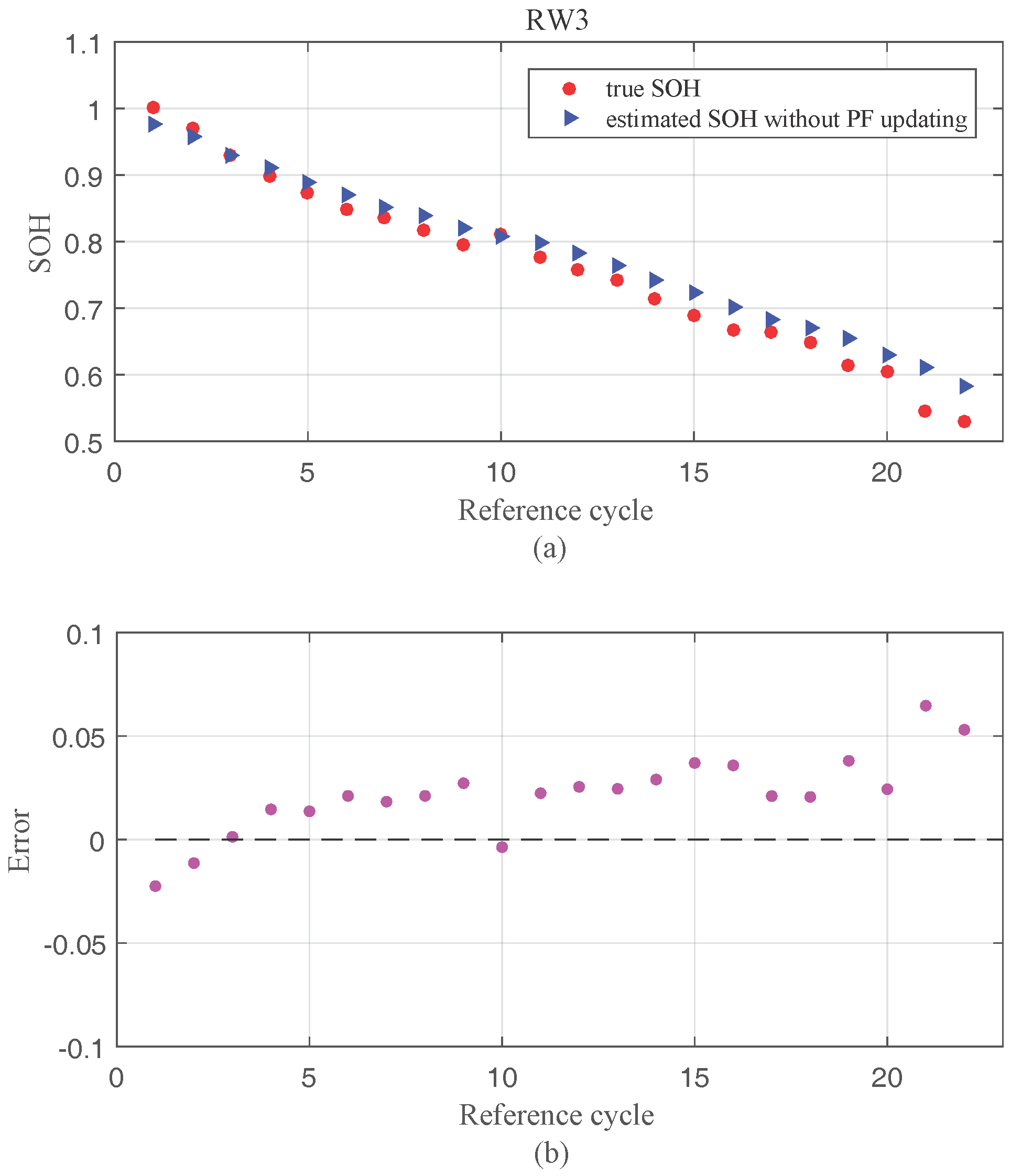

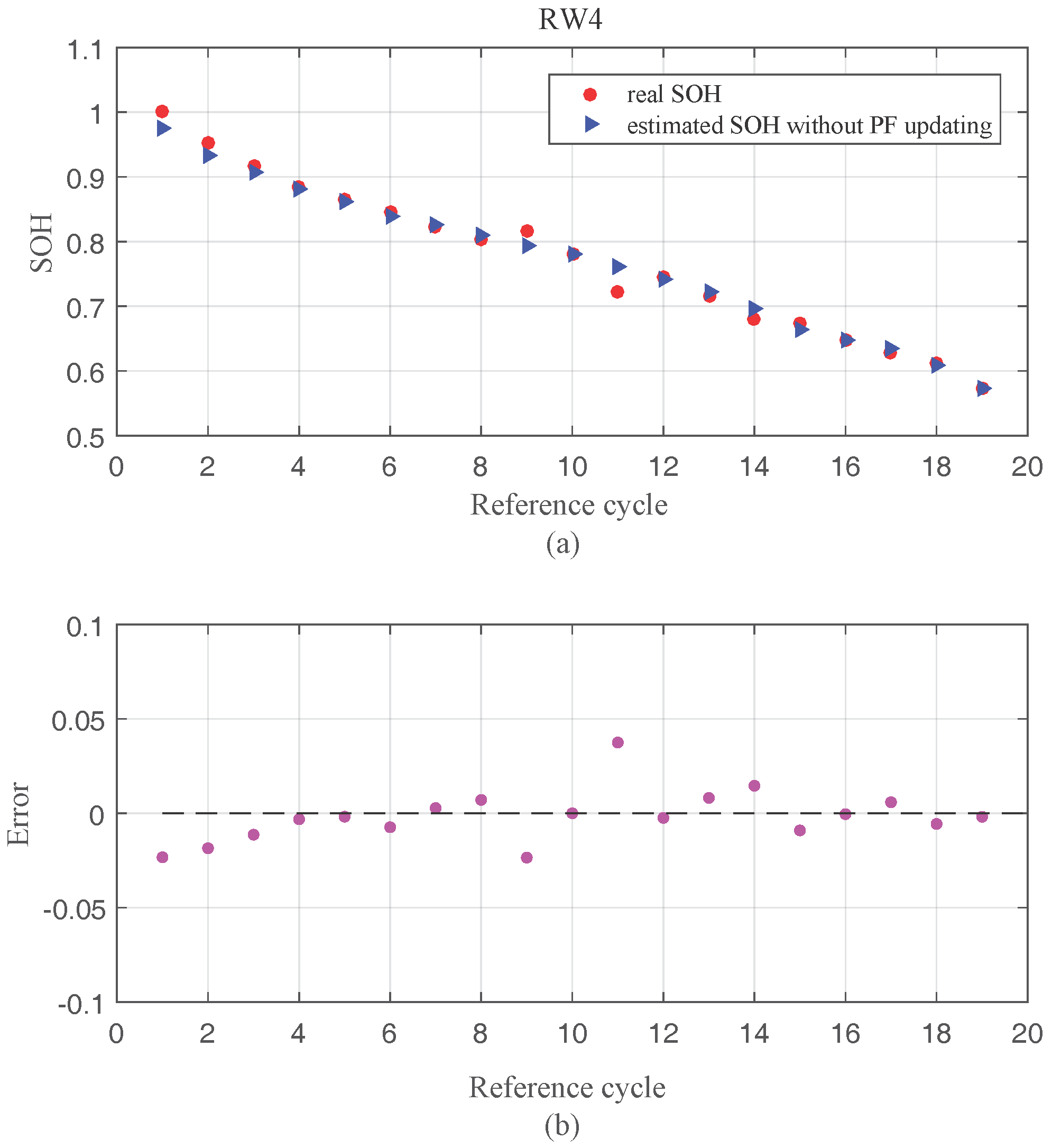

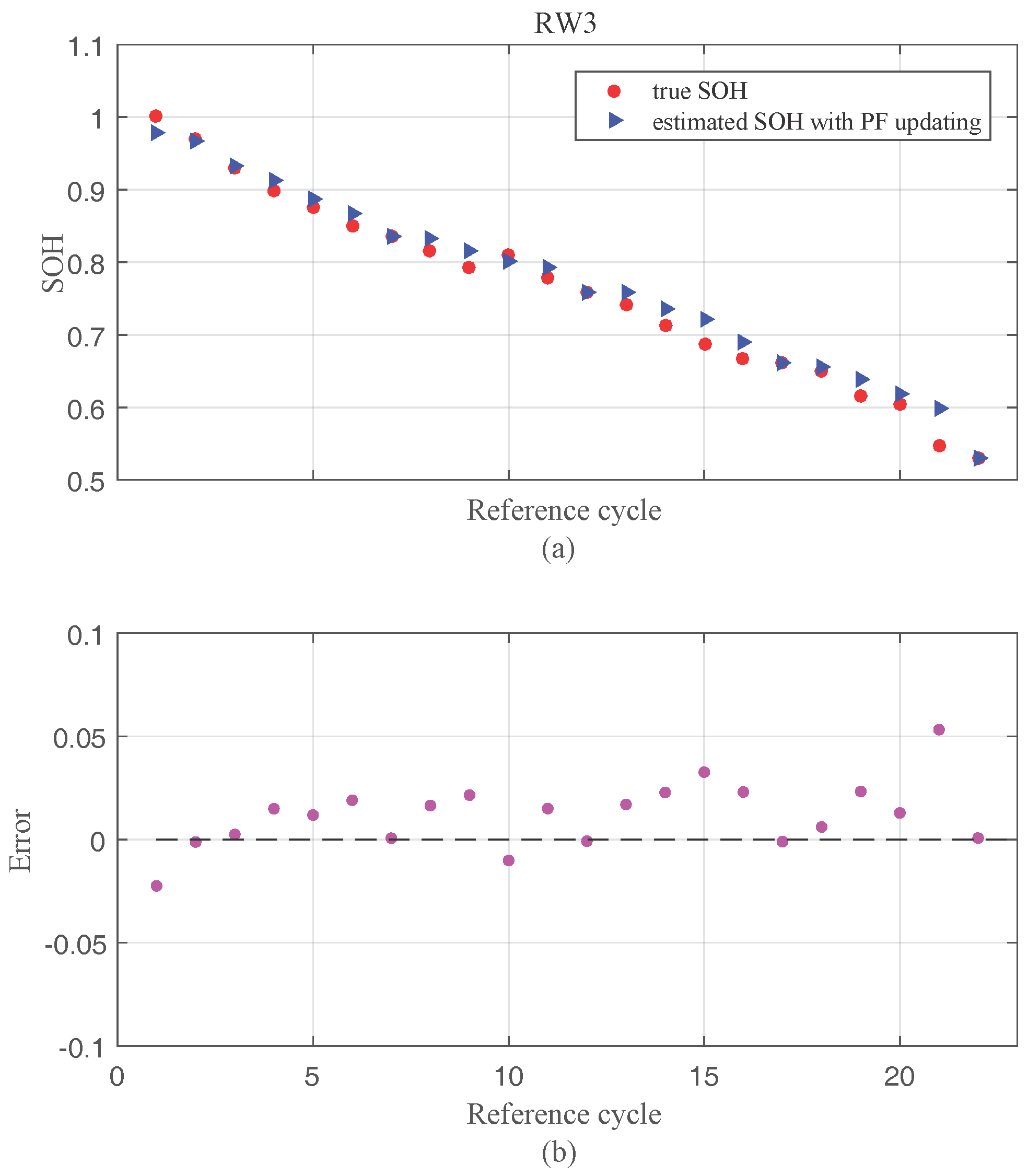

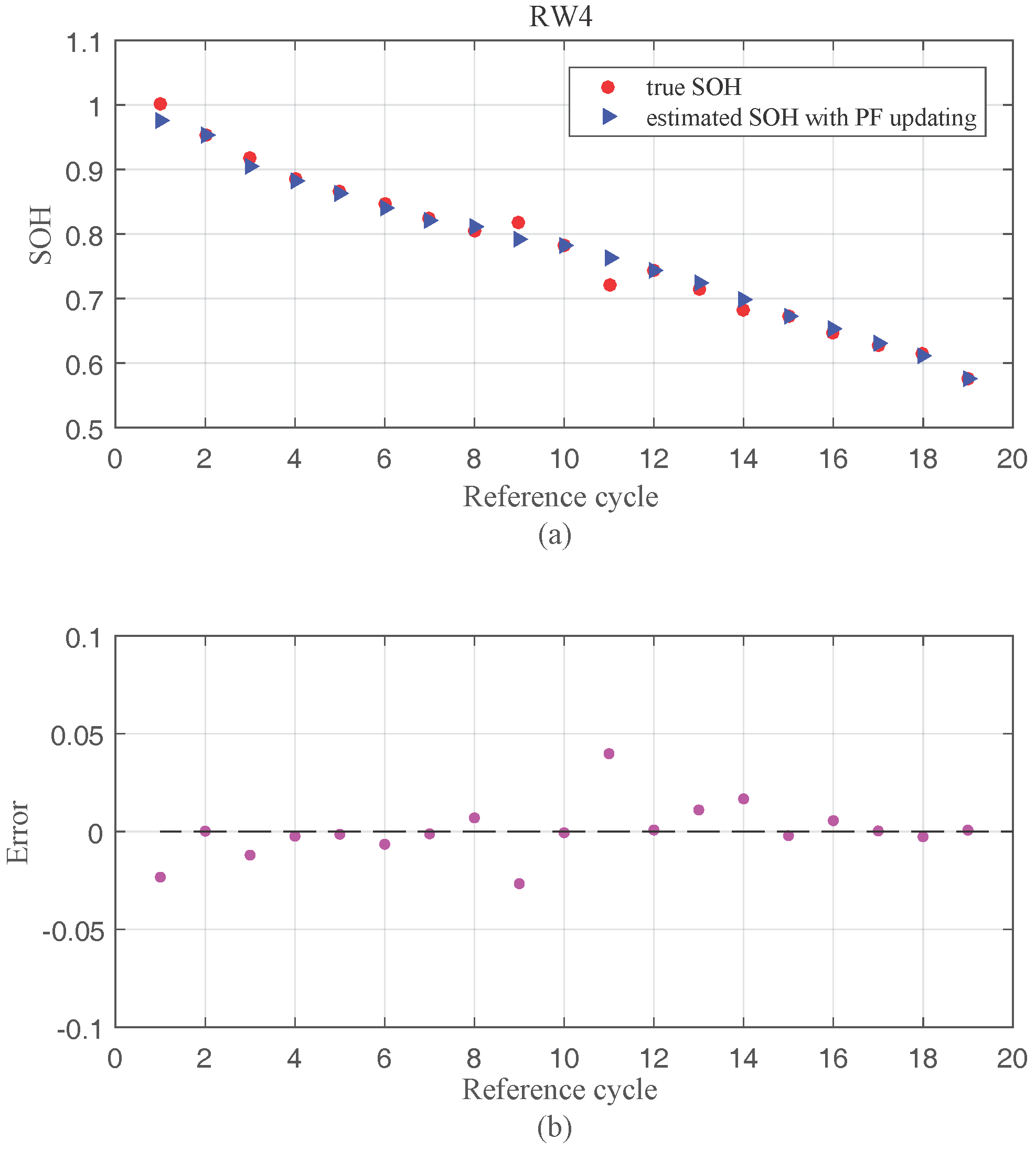

Figure 10,

Figure 11 and

Figure 12 show the SOH estimation results for each battery, accompanied with the true SOH measured in the reference cycle. The results support that the model is effective to describe the relationship between HIs and the battery’s SOH.

5. Conclusions

Timely estimating lithium-ion batteries’ SOH is very important for preventing disasters caused by battery failure. A general idea to estimate the SOH is through the measurement of the battery’s capacity. However, direct and simultaneous measurement of the battery’s capacity is not that easy in practice. Moreover, the battery is always running under randomized loading conditions, which makes the estimation even more difficult. Motivated by the above difficulties, this paper proposes an indirect SOH estimation method that relies on three indirect HIs that can be measured easily during the battery’s operation. The three indicators are extracted from the battery’s voltage, the current and the number of cycles the battery has been through, which are far easier to measure than the battery’s capacity. In order to build a quantitative relationship between the SOH and these indirect HIs, we propose a method based on an elastic net to develop an empirical model between them, considering the possible multi-collinearity between these HIs. Finally, to further improve the accuracy of SOH online estimation, we adopt the PF to automatically update the model when new capacity data are available. The experiment shows that our extracted indirect HIs are quite effective and our proposed SOH estimation method based on these HIs is accurate enough to support SOH estimation under randomized use in real practice.

In this paper, we have successfully applied our method to estimate the SOH of batteries under randomized use. However, there are some limitations, on which we will conduct research in the future. The data we used was obtained from a constant-temperature environment. Therefore, performing a validation with temperature consideration is necessary. In this paper, the PF was used to update the parameters in the model. Comparing the PF with other estimation schemes is necessary.