Reliable Biomass Supply Chain Design under Feedstock Seasonality and Probabilistic Facility Disruptions

Abstract

1. Introduction

- We propose a three-stage multi-period model for the design of biomass supply chain under feedstock seasonality and probabilistic facility disruptions. The output of our model provides biomass shipment quantity, inventories, locations, and allocations of collection facilities.

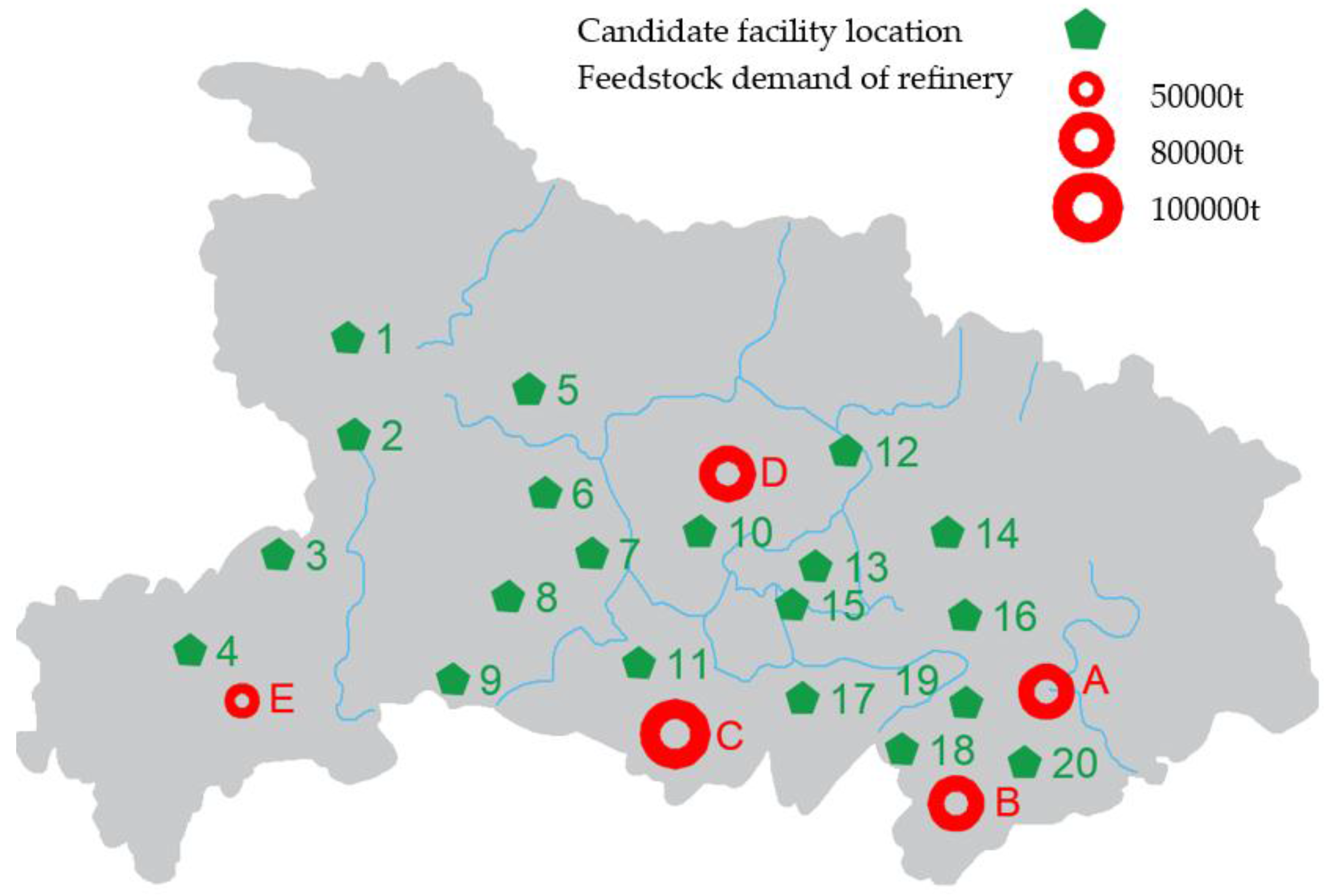

- Through case studies, we explore the relationship between biomass supply chain decisions (e.g., collection facility locations and inventories) and uncertainties (e.g., disruption risks and feedstock seasonality). The results provide valuable guidance and managerial insights for the Hubei NE Biofuel Company, the biggest biofuel company in Hubei Province, China.

2. Literature Review

2.1. Biomass Supply Chain Design

2.2. Disruption Risks in Supply Chain

3. Materials and Methods

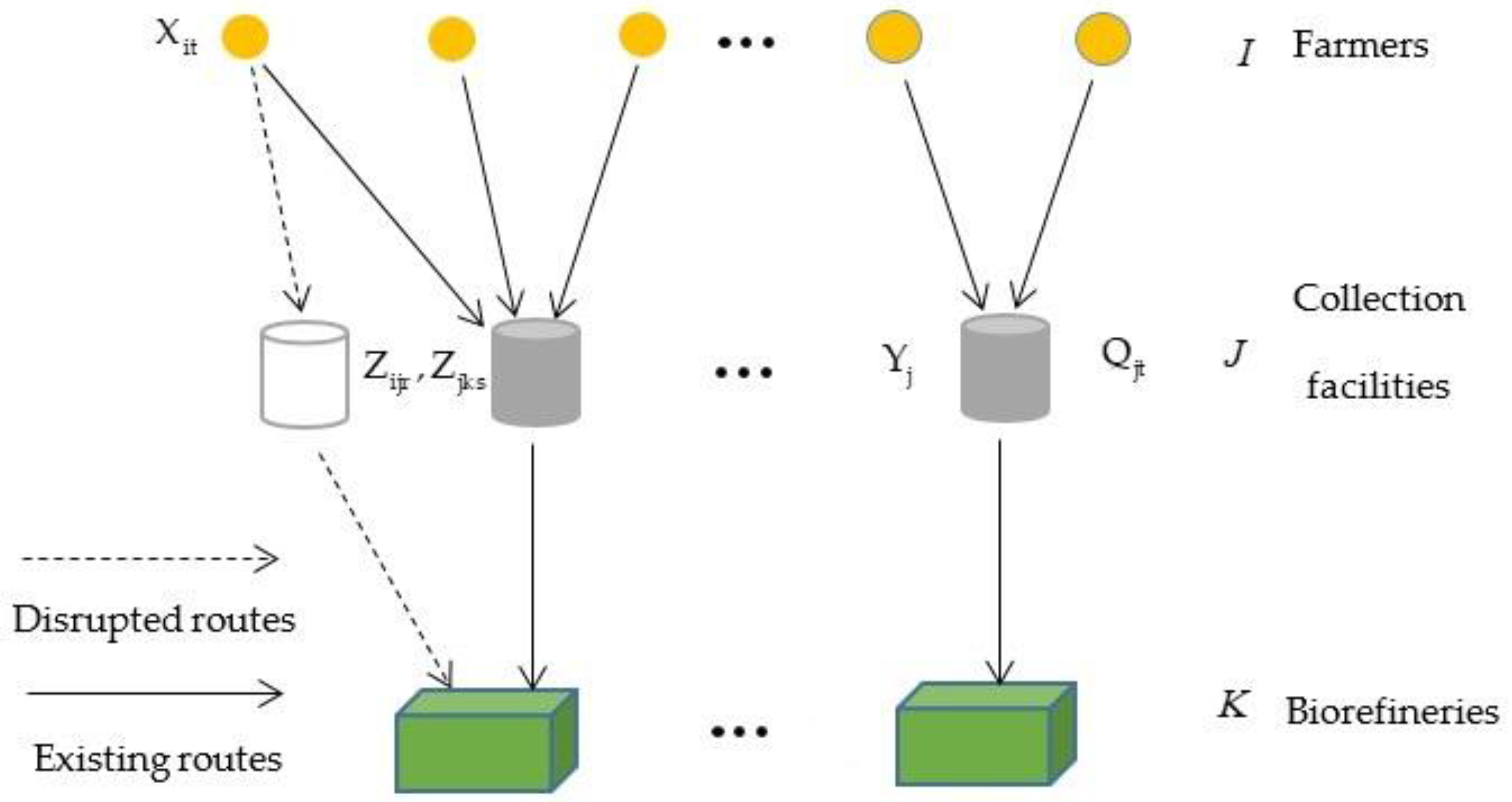

3.1. Problem Definition

- There is no ordering cost and lead time for the collection facilities to collect biomass from farmers. The biofuel company always signs contracts with given farmers at the beginning of the year to maintain cooperative relationships, thus the company can collect feedstock from farmers at any time.

- Considering fragmented farmland in China, we assume that the feedstock cannot be stored at the farmers’ place, so the collection facility cannot collect biomass produced in the previous seasons.

- The failure probabilities of collection facilities over time are known a priori (e.g., estimated based on historical data).

- Collection facility, once it fails, will remain disrupted in the rest of the planning horizon. Building and repairing the collection facility will cost a lot of money and time. In this model, we make decisions for a year, and hence it is unrealistic to repair the disrupted facility during that time period.

- Once a facility fails, it cannot ship the biomass, but its inventory can still be kept. In the system, disruptions “pause” the flow of feedstock into the collection facilities, but outflow can still be maintained based on inventory at the collection facilities.

- We assume that the inventory storage capacity of a collection facility is unlimited, because most facilities are built in rural areas.

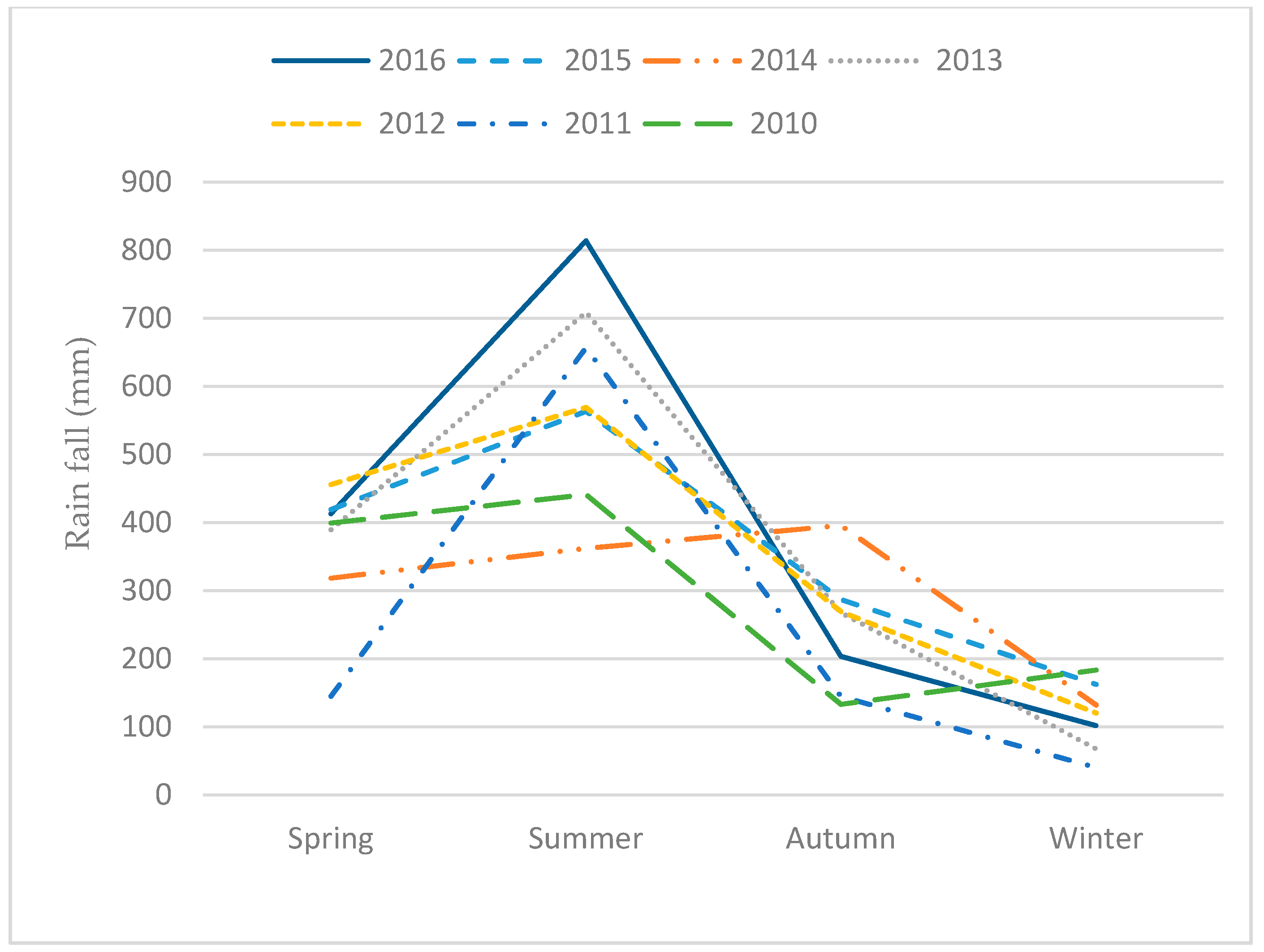

- The first time period of our planning horizon is the autumn in which the production of feedstock is far more than the demand. Then we assume that the total amount of available feedstock supply across all seasons is more than the total demand at the biorefineries; i.e., there is not an overall shortage at any time.

3.2. Mathematical Formulation

3.3. Data Sources

4. Results

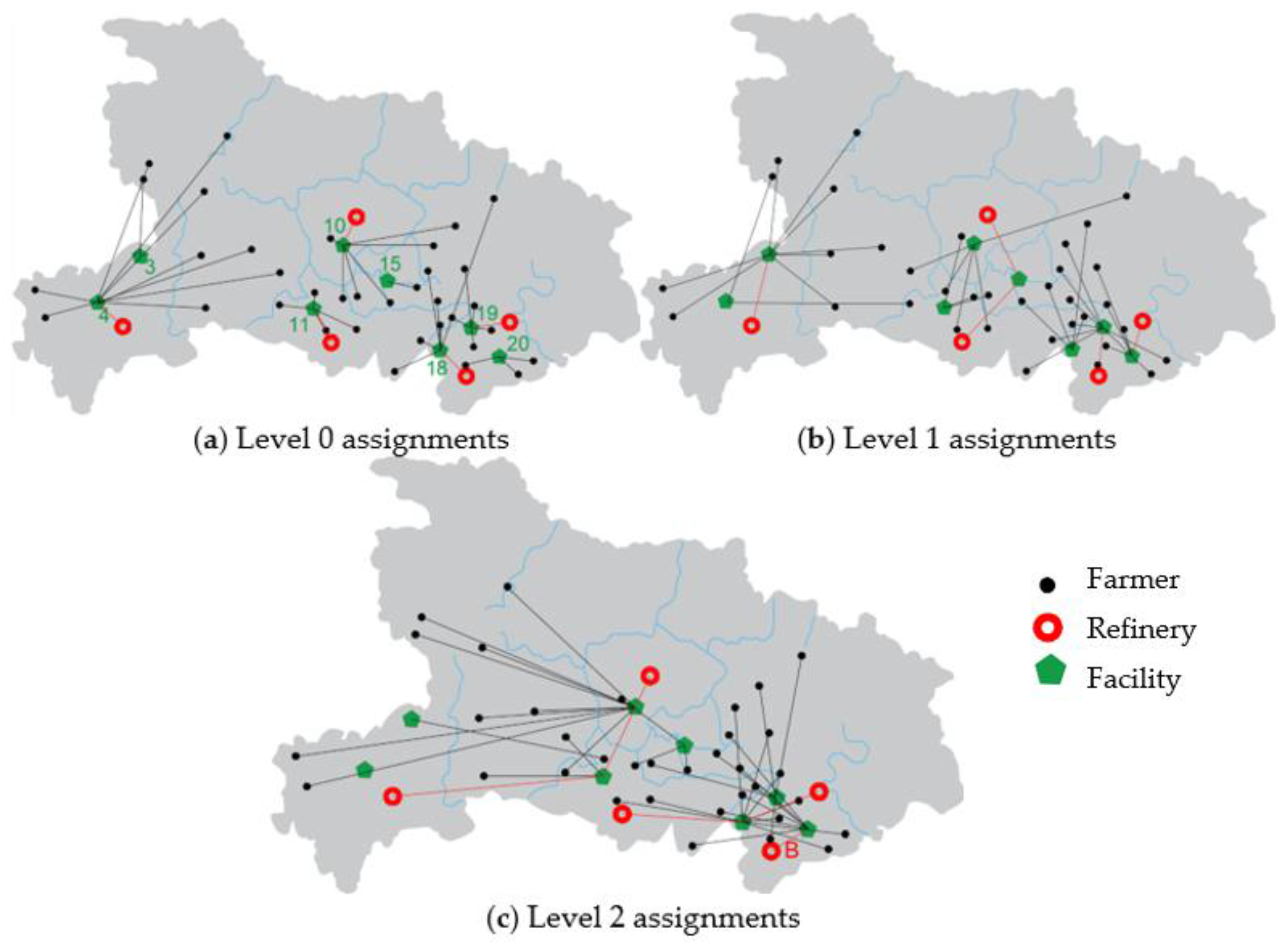

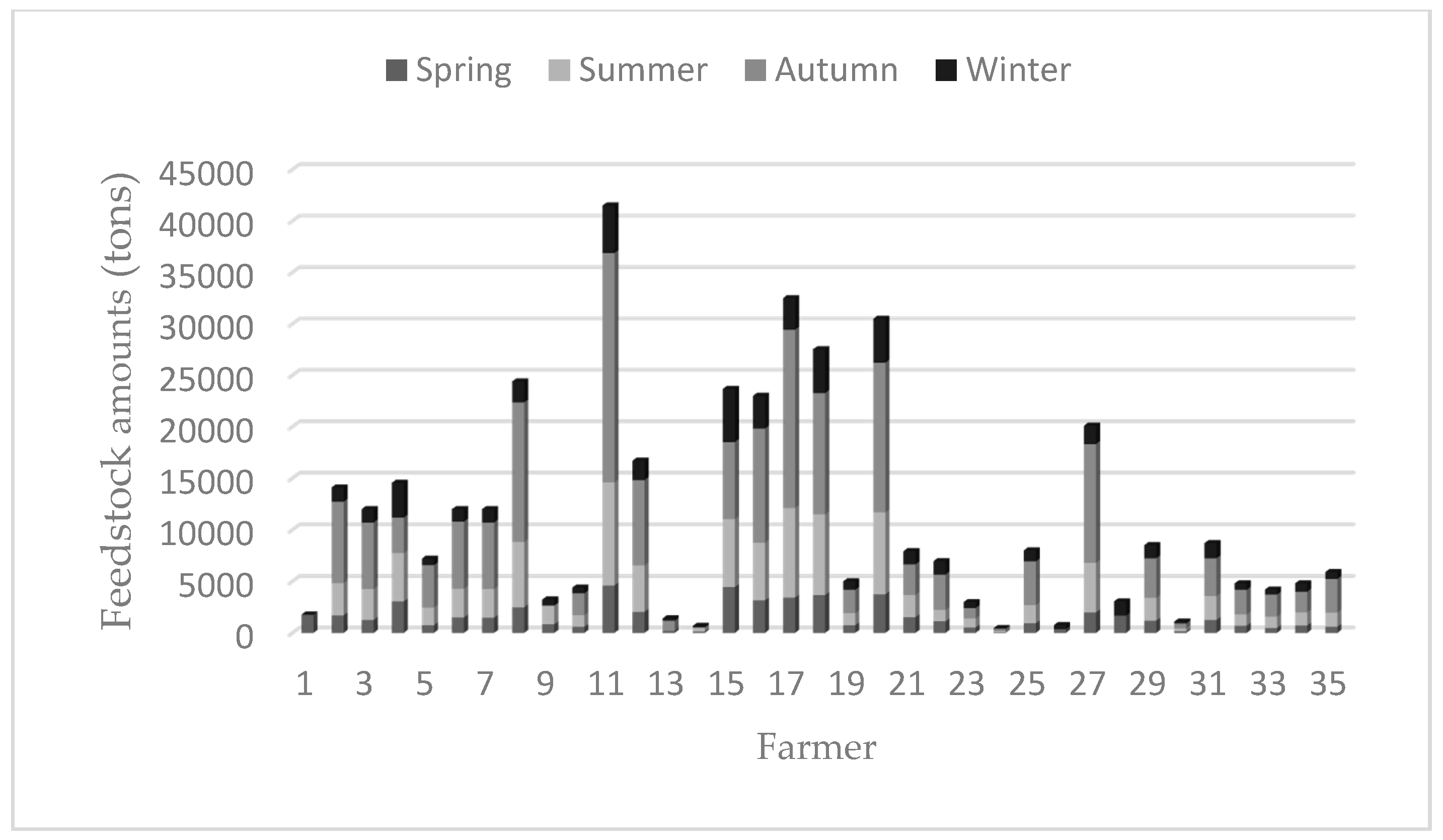

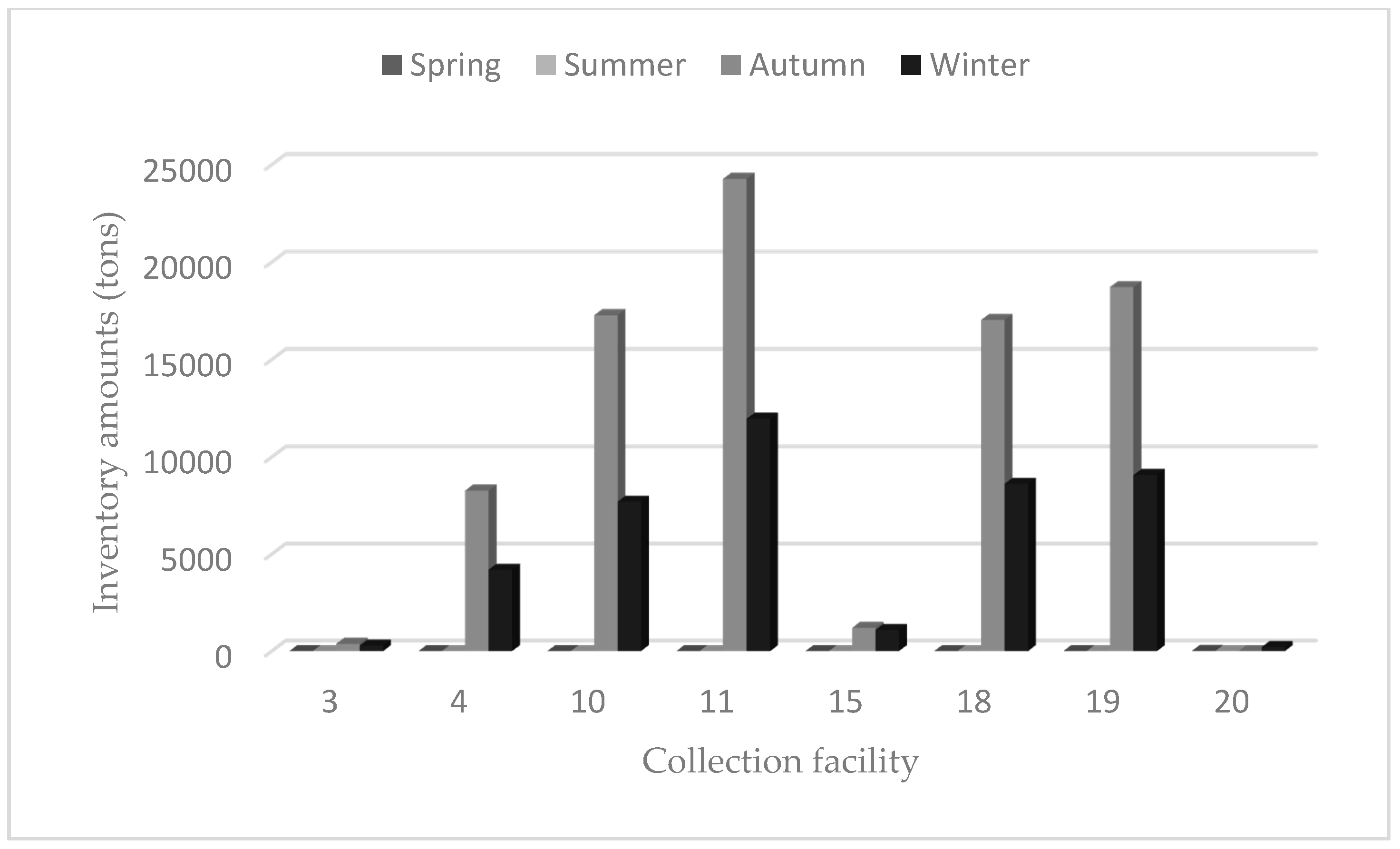

4.1. Model Outputs

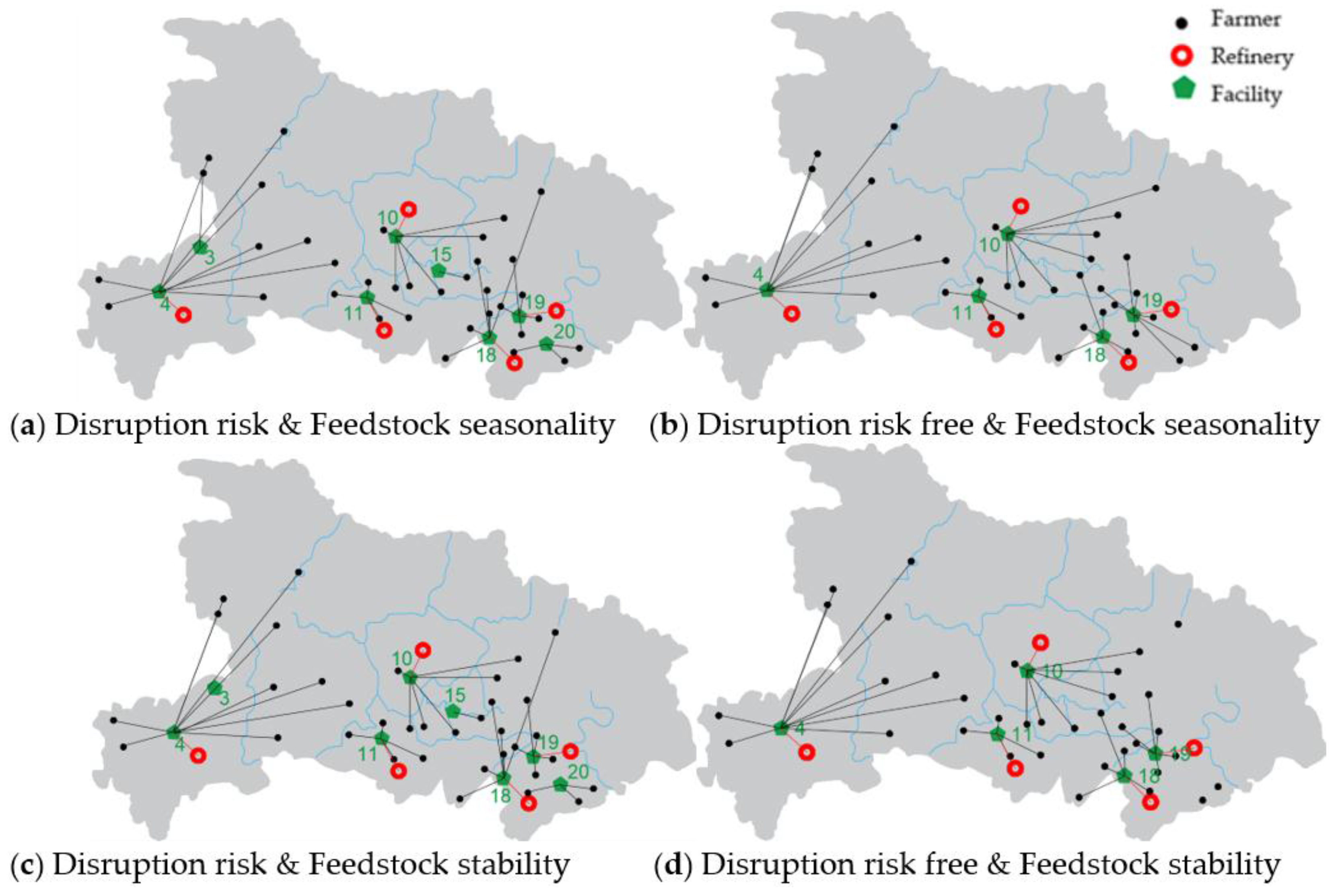

4.2. Impact of Seasonality and Disruption Risk

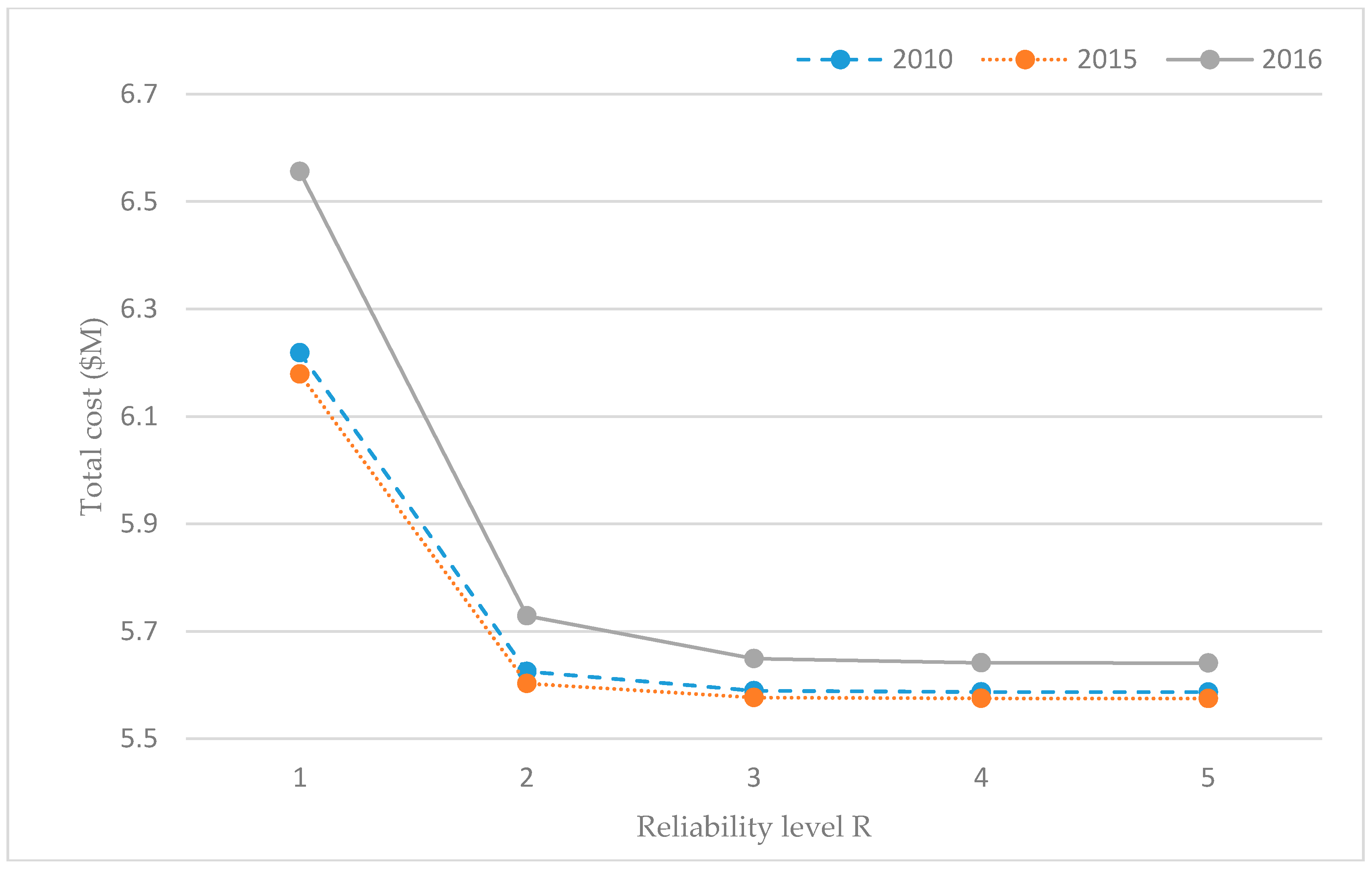

4.3. Impact of Failure Probability and Reliability Level

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Perlack, R.D.; Wright, L.L.; Turhollow, A.F.; Graham, R.L.; Stokes, B.J.; Erbach, D.C. Biomass as Feedstock for a Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billion-Ton Annual Supply; Oak Ridge National Labboratory: Oak Ridge, TN, USA, 2005.

- Ebadian, M. Design and Scheduling of Agricultural Biomass Supply Chain for a Cellulosic Ethanol Plant. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2013. [Google Scholar]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wu, H.; Ding, S.; Zhu, C. Analysis of seasonality and sustainability of straw resources. Resour. Sci. 2011, 33, 1537–1545. [Google Scholar]

- Li, X.P.; Ouyang, Y.F. A continuum approximation approach to reliable facility location design under correlated probabilistic disruptions. Transp. Res. Part B Methodol. 2010, 44, 535–548. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Tolis, A.J.; Tatsiopoulos, I.P. Logistics issues of biomass: The storage problem and the multi-biomass supply chain. Renew. Sustain. Energy Rev. 2009, 13, 887–894. [Google Scholar] [CrossRef]

- Ekşioğlu, S.D.; Acharya, A.; Leightley, L.E.; Arora, S. Analyzing the design and management of biomass-to-biorefinery supply chain. Comput. Ind. Eng. 2009, 57, 1342–1352. [Google Scholar] [CrossRef]

- Chen, C.W.; Fan, Y.Y. Bioethanol supply chain system planning under supply and demand uncertainties. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 150–164. [Google Scholar] [CrossRef]

- Xie, F.; Huang, Y.X.; Eksioglu, S. Integrating multimodal transport into cellulosic biofuel supply chain design under feedstock seasonality with a case study based on California. Bioresour. Technol. 2014, 152, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.X.; Fan, Y.Y.; Chen, C.W. An integrated biofuel supply chain to cope with feedstock seasonality and uncertainty. Transp. Sci. 2014, 48, 540–554. [Google Scholar] [CrossRef]

- Pettersson, K.; Wetterlund, E.; Athanassiadis, D.; Lundmark, R.; Ehn, C.; Lundgren, J.; Berglin, N. Integration of next-generation biofuel production in the Swedish forest industry—A geographically explicit approach. Appl. Energy 2015, 154, 317–332. [Google Scholar] [CrossRef]

- Ouraich, I.; Lundmark, R. A geographically explicit approach for price determination of forest feedstock under different next-generation biofuel production scenarios-the case of Sweden. In Proceedings of the Swedish Association for Energy Economics Conference on Meeting Sweden’s Current and Future Energy Challenges, Luleå, Sweden, 23–24 August 2016. [Google Scholar]

- Nasiri, F.; Mafakheri, F.; Adebanjo, D.; Haghighat, F. Modeling and analysis of renewable heat integration into non-domestic buildings—The case of biomass boilers: A whole life asset-supply chain management approach. Biomass Bioenergy 2016, 95, 244–256. [Google Scholar] [CrossRef]

- Huang, Y.X.; Chen, C.W.; Fan, Y.Y. Multistage optimization of the supply chains of biofuels. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 820–830. [Google Scholar] [CrossRef]

- Dal-Mas, M.; Giarola, S.; Zamboni, A.; Bezzo, F. Strategic design and investment capacity planning of the ethanol supply chain under price uncertainty. Biomass Bioenergy 2011, 35, 2059–2071. [Google Scholar] [CrossRef]

- You, F.; Wang, B. Life cycle optimization of biomass-to-liquid supply chains with distributed–centralized processing networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- Walther, G.; Schatka, A.; Spengler, T.S. Design of regional production networks for second generation synthetic bio-fuel—A case study in Northern Germany. Eur. J. Oper. Res. 2012, 218, 280–292. [Google Scholar] [CrossRef]

- Akgul, O.; Shah, N.; Papageorgiou, L.G. An optimisation framework for a hybrid first/second generation bioethanol supply chain. Comput. Chem. Eng. 2012, 42, 101–114. [Google Scholar] [CrossRef]

- Gautam, S.; LeBel, L.; Carle, M.A. Supply chain model to assess the feasibility of incorporating a terminal between forests and biorefineries. Appl. Energy 2017, 198, 377–384. [Google Scholar] [CrossRef]

- Marufuzzaman, M.; Ekşioğlu, S.D. Managing congestion in supply chains via dynamic freight routing: An application in the biomass supply chain. Transp. Res. Part E Logist. Transp. Rev. 2017, 99, 54–76. [Google Scholar] [CrossRef]

- Tang, C.S. Perspectives in supply chain risk management. Int. J. Prod. Econ. 2006, 103, 451–488. [Google Scholar] [CrossRef]

- Ivanov, D.; Pavlov, A.; Dolgui, A.; Pavlov, D.; Sokolov, B. Disruption-driven supply chain (re)-planning and performance impact assessment with consideration of pro-active and recovery policies. Transp. Res. Part E Logist. Transp. Rev. 2016, 90, 7–24. [Google Scholar] [CrossRef]

- Peng, M.; Peng, Y.; Chen, H. Post-seismic supply chain risk management: A system dynamics disruption analysis approach for inventory and logistics planning. Comput. Oper. Res. 2014, 42, 14–24. [Google Scholar] [CrossRef]

- Marufuzzaman, M.; Eksioglu, S.D.; Li, X.; Wang, J. Analyzing the impact of intermodal-related risk to the design and management of biofuel supply chain. Transp. Res. Part E Logist. Transp. Rev. 2014, 69, 122–145. [Google Scholar] [CrossRef]

- Gedik, R.; Medal, H.; Rainwater, C.; Pohl, E.A.; Mason, S.J. Vulnerability assessment and re-routing of freight trains under disruptions: A coal supply chain network application. Transp. Res. Part E Logist. Transp. Rev. 2014, 71, 45–57. [Google Scholar] [CrossRef]

- Snyder, L.V.; Daskin, M.S. Reliability models for facility location: The expected failure cost case. Transp. Sci. 2005, 39, 400–416. [Google Scholar] [CrossRef]

- Berman, O.; Krass, D.; Menezes, M.B. Facility reliability issues in network p-median problems: Strategic centralization and co-location effects. Oper. Res. 2007, 55, 332–350. [Google Scholar] [CrossRef]

- Cui, T.T.; Ouyang, Y.F.; Shen, Z.J.M. Reliable facility location design under the risk of disruptions. Oper. Res. 2010, 58, 998–1011. [Google Scholar] [CrossRef]

- Lim, M.; Daskin, M.S.; Bassamboo, A.; Chopra, S. A facility reliability problem: Formulation, properties, and algorithm. Nav. Res. Logist. 2010, 57, 58–70. [Google Scholar] [CrossRef]

- Shen, Z.-J.M.; Zhan, R.L.; Zhang, J. The reliable facility location problem: Formulations, heuristics, and approximation algorithms. INFORMS J. Comput. 2011, 23, 470–482. [Google Scholar] [CrossRef]

- Chen, Q.; Li, X.P.; Ouyang, Y.F. Joint inventory-location problem under the risk of probabilistic facility disruptions. Transp. Res. Part B Methodol. 2011, 45, 991–1003. [Google Scholar] [CrossRef]

- Lim, M.K.; Bassamboo, A.; Chopra, S.; Daskin, M.S. Facility location decisions with random disruptions and imperfect estimation. Manuf. Serv. Oper. Manag. 2013, 15, 239–249. [Google Scholar] [CrossRef]

- Xie, W.J.; Ouyang, Y.F.; Wong, S.C. Reliable location-routing design under probabilistic facility disruptions. Transp. Sci. 2016, 50, 1128–1138. [Google Scholar] [CrossRef]

- Hasani, A.; Khosrojerdi, A. Robust global supply chain network design under disruption and uncertainty considering resilience strategies: A parallel memetic algorithm for a real-life case study. Transp. Res. Part E Logist. Transp. Rev. 2016, 87, 20–52. [Google Scholar] [CrossRef]

- Khosrojerdi, A.; Zegordi, S.H.; Allen, J.K.; Mistree, F. A method for designing power supply chain networks accounting for failure scenarios and preventive maintenance. Eng. Optim. 2016, 48, 154–172. [Google Scholar] [CrossRef]

- Zhao, M.; Cui, J.; Li, X.; Parsafard, M.; An, S. A Reliable Model for Integrated Supply Chain Design under Disruption Risk. In Proceedings of the 95th Annual Meeting on Transportation Research Board, Washington, DC, USA, 10–14 January 2016. [Google Scholar]

- Bai, Y.; Li, X.P.; Peng, F.; Wang, X.; Ouyang, Y.F. Effects of disruption risks on biorefinery location design. Energies 2015, 8, 1468–1486. [Google Scholar] [CrossRef]

- Sherali, H.D.; Alameddine, A. A new reformulation-linearization technique for bilinear programming problems. J. Glob. Optim. 1992, 2, 379–410. [Google Scholar] [CrossRef]

- Bureau of Stastics of the Hubei Province. Hubei Stastical Yearbook 2016; China Statistics Press: Beijing, China, 2016; pp. 120–121.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2015; China Statistics Press: Beijing, China, 2015; pp. 184–185.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2016; China Statistics Press: Beijing, China, 2016; pp. 186–187.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2014; China Statistics Press: Beijing, China, 2014; pp. 175–176.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2013; China Statistics Press: Beijing, China, 2013; pp. 182–183.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2012; China Statistics Press: Beijing, China, 2012; pp. 183–184.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2011; China Statistics Press: Beijing, China, 2011; pp. 178–179.

- National Bureau of Stastics of the People’s Republic of China. China Stastical Yearbook 2010; China Statistics Press: Beijing, China, 2010; pp. 173–174.

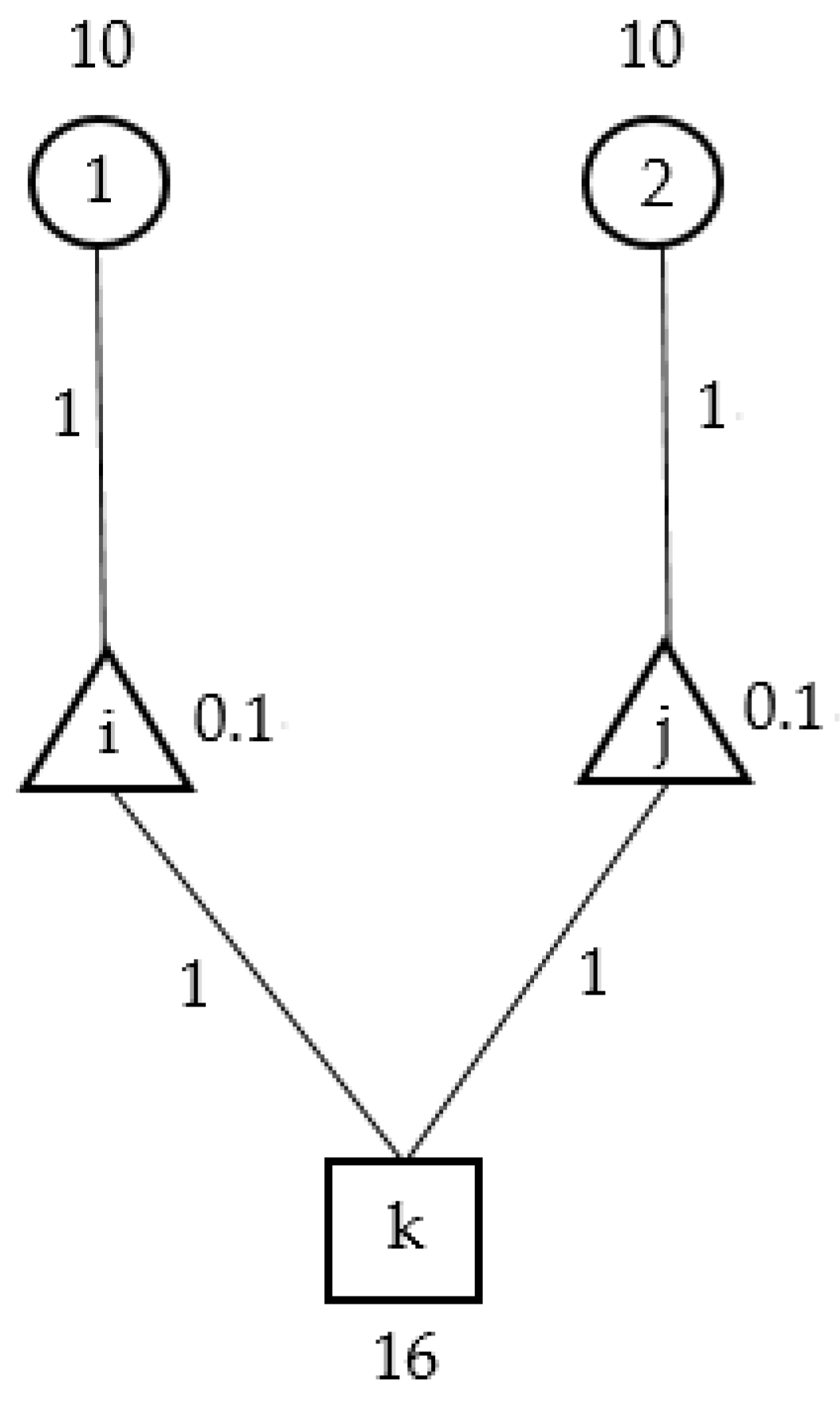

| Sets | Description |

| The set of farmers, . | |

| The set of facilities, | |

| The set of biorefineries, | |

| The set of time periods, | |

| Parameters | Description |

| Reliability level for farmer, | |

| Reliability level for biorefinery, | |

| Transportation cost per unit biomass from to | |

| Amount of biomass at farmer i at time t | |

| Amount of biomass demanded at biorefinery k at time t | |

| Holding cost of one unit of biomass for one unit of time at facilities j | |

| Fixed cost of opening and operating a facility at j | |

| φ | Penalty cost for per unit of missed collection biomass |

| Failure probability for facility at time t | |

| Probability that a facility is functioning at time t | |

| Probability that a farmer incurs a penalty at time t | |

| Probability that a facility incurs a penalty at time t | |

| Probability that facility j serves farmer i at level r at time t | |

| Probability that facility j serves biorefinery k at level s at time t | |

| Decisions | Description |

| Amount of biomass shipped from farmer i at time t | |

| Amount of biomass shipped from farmer i to facility j at time t | |

| Amount of biomass kept in inventory at facility j at time t | |

| 1 if facility at j is open | |

| 1 if facility j is assigned to farmer at level r | |

| 1 if facility j is assigned to biorefinery k at level s | |

| Amount of biomass shipped to facility j at time t | |

| Amount of biomass shipped from facility j at time t | |

| , |

| Year | Total Area (km2) | Damage Area (km2) | Damage Rate |

|---|---|---|---|

| 2016 | 185,900 | 27,470 | 14.78% |

| 2015 | 15,243 | 8.21% | |

| 2014 | 2936 | 1.58% | |

| 2013 | 4557 | 2.45% | |

| 2012 | 6672 | 3.59% | |

| 2011 | 8911 | 4.79% | |

| 2010 | 19,989 | 10.75% |

| Case | Facility Location | Objective ($M) | Evaluated Cost under Disruption ($M) | Cost Difference (%) | Inventory Cost ($M) | |

|---|---|---|---|---|---|---|

| Disruption | Seasonality | |||||

| Yes | Yes | 3, 4, 10, 11, 15, 18, 19, 20 | 5.65 | 5.65 | 0 | 1 |

| No | Yes | 4, 10, 11, 18, 19 | 5.41 | 6.56 | 17.5 | 0.99 |

| Yes | No | 3, 4, 10, 11, 15, 18, 19, 20 | 4.64 | 4.64 | 0 | 0.003 |

| No | No | 4, 10, 11, 18, 19 | 4.38 | 5.68 | 22.8 | 0 |

| Reliability Level | Facility Locations | Fixed Cost ($M) | Transportation Cost ($M) | Inventory Cost ($M) | Total Cost ($M) |

|---|---|---|---|---|---|

| 1 | 4, 10, 11, 18, 19 | 0.23 | 5.38 | 0.94 | 6.55 |

| 2 | 3, 4, 10, 11, 15, 18, 19, 20 | 0.37 | 4.36 | 0.99 | 5.72 |

| 3 | 3, 4, 10, 11, 15, 18, 19, 20 | 0.37 | 4.28 | 1 | 5.65 |

| 4 | 3, 4, 10, 11, 15, 18, 19, 20 | 0.37 | 4.27 | 1 | 5.64 |

| 5 | 3, 4, 10, 11, 15, 18, 19, 20 | 0.37 | 4.26 | 1 | 5.63 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wang, S.; Ouyang, Y. Reliable Biomass Supply Chain Design under Feedstock Seasonality and Probabilistic Facility Disruptions. Energies 2017, 10, 1895. https://doi.org/10.3390/en10111895

Liu Z, Wang S, Ouyang Y. Reliable Biomass Supply Chain Design under Feedstock Seasonality and Probabilistic Facility Disruptions. Energies. 2017; 10(11):1895. https://doi.org/10.3390/en10111895

Chicago/Turabian StyleLiu, Zhixue, Shukun Wang, and Yanfeng Ouyang. 2017. "Reliable Biomass Supply Chain Design under Feedstock Seasonality and Probabilistic Facility Disruptions" Energies 10, no. 11: 1895. https://doi.org/10.3390/en10111895

APA StyleLiu, Z., Wang, S., & Ouyang, Y. (2017). Reliable Biomass Supply Chain Design under Feedstock Seasonality and Probabilistic Facility Disruptions. Energies, 10(11), 1895. https://doi.org/10.3390/en10111895