Characteristics of Pore Structure and Fractal Dimension of Isometamorphic Anthracite

Abstract

:1. Introduction

2. Samples and Methods

2.1. Samples

2.2. Experimental Methods

3. Results and Discussion

3.1. Pore Properties

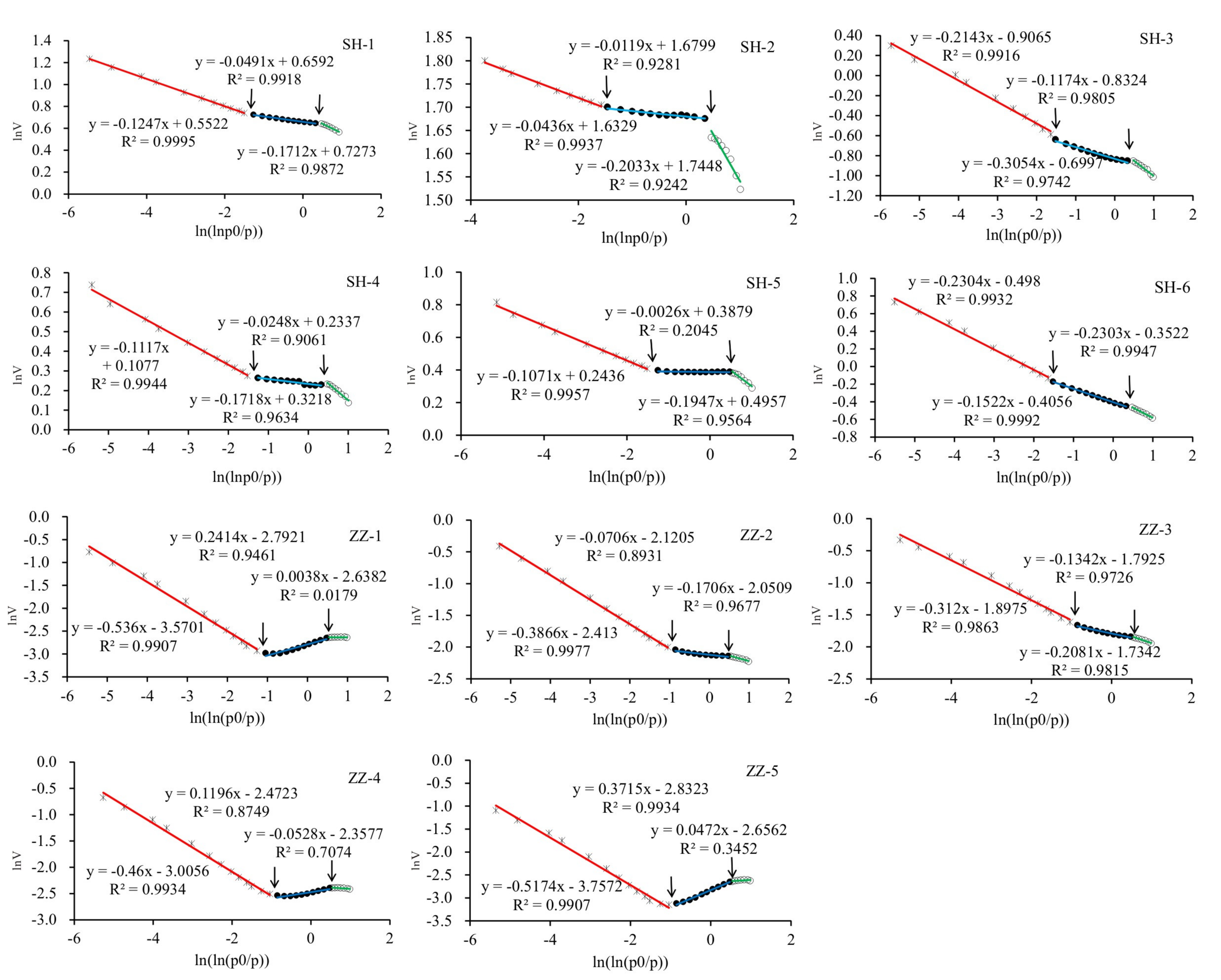

3.2. Fractal Characteristics of Coal Pores

- (1)

- The lnV values of coal samples from Sihe Colliery were mostly greater than 0, whereas the lnV values of coal samples from Zhaozhuang Colliery were mostly less than 0. This suggests that the specific surface area of Sihe coal samples is generally larger than that of Zhaozhuang coal samples.

- (2)

- The curve simulation showed three curve sections, indicating that the fractal features of the pores differ among these three sections. Therefore, we performed separate linear fitting. The fractal boundary points of samples from Sihe Colliery were at ln(ln(P0/P)) = −1.52 and ln(ln(P0/P)) = 0.54, respectively. The Kelvin equation describes the change in vapor pressure due to a curved liquid–vapor interface. The vapor pressure at a convex curved surface is higher than that at a flat surface. It can be used for determination of pore size distribution of a porous medium using adsorption porosimetry. According to the Kelvin equation, the two boundary points correspond to pore diameters of approximately 1 nm and 9 nm, respectively. For samples from Zhaozhuang Colliery, the boundary points were located at pore diameters of 7 nm and 1 nm, respectively. Moreover, when ln(ln(P0/P)) > 1, i.e., the pore diameter is less than 0.7 nm, the pores did not exhibit fractal features.

- (3)

- When D was calculated by using equations and , the D values calculated from formula were small. Many of these values were less than 2, which is not realistic. Therefore, in this study, the D value was calculated by using formula ; the results are listed in Table 2. Pores with diameters greater than 9 nm and 7 nm for samples from Sihe and Zhaozhuang Collieries, respectively, exhibited obvious fractal features and a correlation coefficient is approximately equal to 1; pores of less than 1 nm showed no obvious fractal features. Second, the fractal dimensions for samples from Sihe and Zhaozhuang Collieries are between 2.5 and 3.4. The fractal dimensions of pores with diameters of 1–9 nm (7 nm) were significantly larger than those of pores larger than 9 nm (less than 1 nm) in diameter for Sihe (Zhaozhuang) Colliery. This indicates that micro pores contribute more to the specific surface area. Furthermore, the overall fractal dimension of samples from Sihe Colliery was greater than that of samples from Zhaozhuang Colliery, suggesting that the roughness of coal pores in Sihe Colliery is greater than that in Zhaozhuang Colliery. This also indirectly explains why the coal in Sihe Colliery has a larger specific surface area.

3.3. Pore Characteristics and CBM Recoverability

4. Conclusions

- (1)

- The majority of pores in Sihe and Zhaozhuang Collieries are adsorption type. The pore size of samples from Sihe (Zhaozhuang) Colliery was predominantly less than 5 nm (6.5–50 nm). The micro pores of samples from Sihe Colliery were significantly more developed than those from Zhaozhuang Colliery, and the specific surface area in Sihe Colliery was significantly larger than that in Zhaozhuang Colliery, which further confirmed that adsorption pores contributed the most to the specific surface area, at more than 88%. However, for different experimental methods, pores of different sizes showed different contributions to pore volume. Low-temperature nitrogen adsorption analysis revealed that small pores accounted for 49.4–72.1% of the pore volume, whereas mercury porosimetry revealed that large pores accounted for 35.7–62.2% of the pore volume.

- (2)

- On the basis of FHH fractal theory, the lnV versus ln(ln(P0/P)) scatter plot revealed that pore features had two clear boundaries corresponding to 1 nm and either 9 nm Sihe Colliery samples or 7 nm for Zhaozhuang Colliery samples. The dimension calculation formula, A = D − 3, was shown to be more suitable for the analysis. The calculation results showed that the fractal dimensions in Sihe and Zhaozhuang Collieries were between 2.5 and 3.4. The fractal dimensions of pores with sizes between 1 nm and 9 nm (or 7 nm) were significantly larger than those of pores with sizes greater than 9 nm or less than 1 nm. The overall fractal dimension was larger in Sihe Colliery than that in the Zhaozhuang Colliery.

- (3)

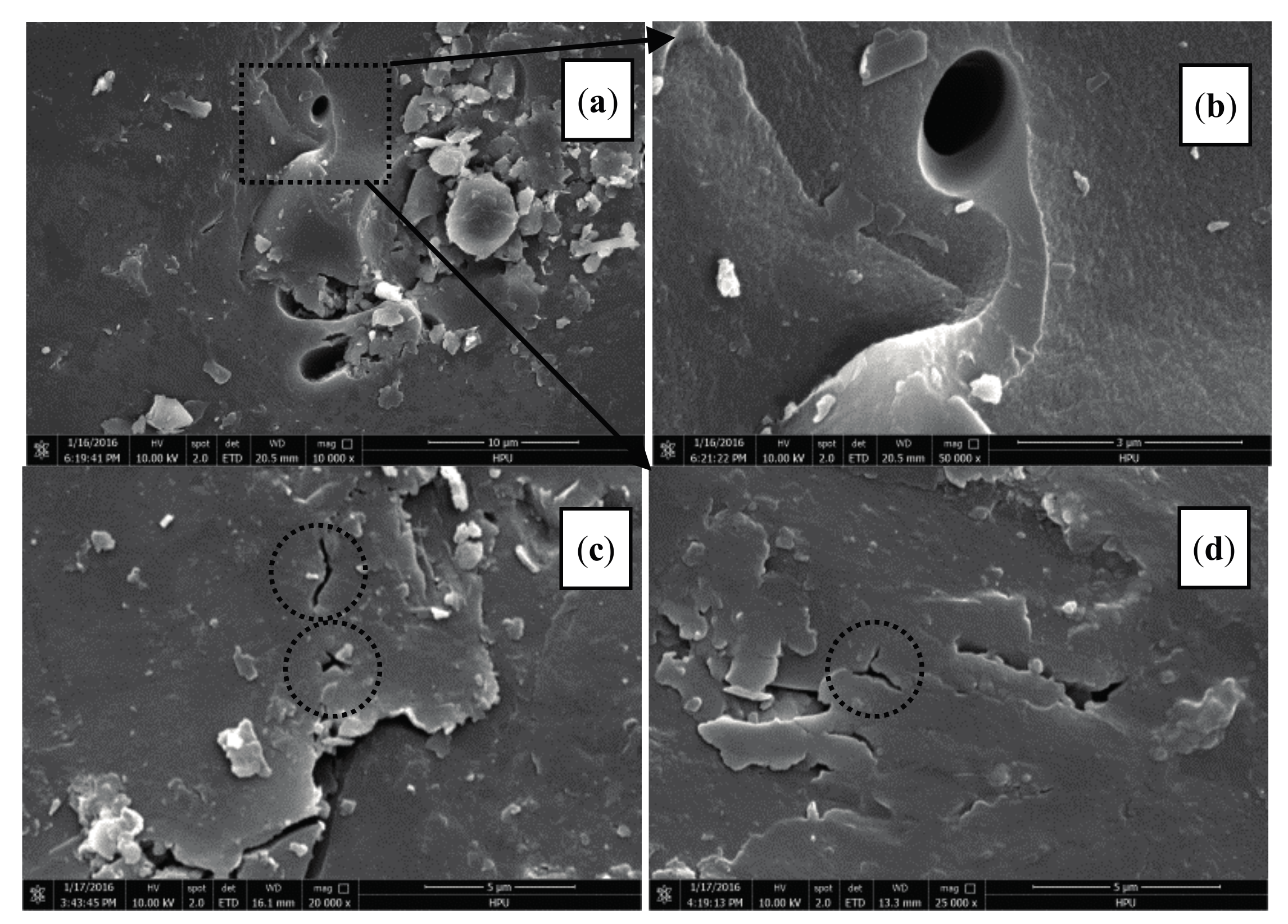

- The pores of samples from Sihe Colliery were mainly open with spherical or ellipsoidal shapes and were highly connected, making them conducive to the migration and accumulation of CBM. For samples from Zhaozhuang Colliery, the pores were mainly Y-shaped, V-shaped, neck shaped, and ink bottle shaped with poor connectivity.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hotot, B.B. Coal and Gas Outburst; China Coal Industry Publishing House: Beijing, China, 1961; pp. 23–35. [Google Scholar]

- Clarkson, C.R.; Rahmanian, M.; Kantzas, A.; Morad, K. Relative permeability of CBM reservoirs: Controls on curve shape. Int. J. Coal Geol. 2011, 88, 204–217. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Zhai, C.; Qin, L.; Liu, S.M.; Xu, J.Z.; Tang, Z.Q.; Wu, S.L. Pore structure in coal: Pore evolution after cryogenic freezing with cyclic liquid nitrogen injection and its implication on coalbed methane extraction. Energy Fuels 2016, 30, 6009–6020. [Google Scholar] [CrossRef]

- Pan, J.N.; Zhu, H.T.; Hou, Q.L.; Wang, H.C.; Wang, S. Macromolecular and pore structures of Chinese tectonically deformed coal studied by atomic force microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Wang, H.P.; Yang, Y.S.; Yang, J.L.; Nie, Y.H.; Jia, J.; Wang, Y.D. Evaluation of Multiple-Scale 3D Characterization for Coal Physical Structure with DCM Method and Synchrotron X-ray CT. Sci. World J. 2015, 2015, 414262. [Google Scholar] [CrossRef] [PubMed]

- Amooie, M.A.; Soltanian, M.R.; Xiong, F.; Dai, Z.; Moortgat, J. Mixing and spreading of multiphase fluids in heterogeneous bimodal porous media. Geomechan. Geophys. Geo-Energy Geo-Resour. 2017, 3, 225–244. [Google Scholar] [CrossRef]

- Ranathunga, A.S.; Perera, M.S.A.; Ranjith, P.G.; Silva, G.P.D.D. A macro-scale view of the influence of effective stress on carbon dioxide flow behaviour in coal: An experimental study. Geomechan. Geophys. Geo-Energy Geo-Resour. 2017, 3, 13–28. [Google Scholar] [CrossRef]

- Xue, Y.; Ranjith, P.G.; Gao, F.; Zhang, D.; Cheng, H.; Chong, Z.; Hou, P. Mechanical behaviour and permeability evolution of gas-containing coal from unloading confining pressure tests. J. Nat. Gas Sci. Eng. 2017, 40, 336–346. [Google Scholar] [CrossRef]

- Wei, C.T.; Zou, M.J.; Sun, Y.M.; Cai, Z.X.; Qi, Y. Experimental and applied analyses of particle migration in fractures of coalbed methane reservoirs. J. Nat. Gas Sci. Eng. 2015, 23, 399–406. [Google Scholar] [CrossRef]

- Lai, F.P.; Li, Z.P.; Meng, Y.; Yang, Z.H.; Guo, Z.Z.; Li, H. Dynamic prediction of coalbed methane well considering pseudo-steady state diffusion. Int. J. Oil Gas Coal Technol. 2016, 11, 264. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Tang, D.Z.; Tang, S.H.; Huang, W.H. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tang, S.H.; Tang, D.Z.; Huang, W.H.; Pan, Z.J. Determining fractal dimensions of coal pores by FHH model: Problems and effects. J. Nat. Gas Sci. Eng. 2014, 21, 929–939. [Google Scholar] [CrossRef]

- Sun, W.J.; Feng, Y.Y.; Jiang, C.F.; Chu, W. Fractal characterization and methane adsorption features of coal particles taken from shallow and deep coalmine layers. Fuel 2015, 155, 7–13. [Google Scholar] [CrossRef]

- Pan, J.N.; Wang, K.; Hou, Q.L.; Niu, Q.H.; Wang, H.C.; Ji, Z.M. Micro-pores and fractures of coals analysed by field emission scanning electron microscopy and fractal theory. Fuel 2016, 164, 277–285. [Google Scholar] [CrossRef]

- Fu, H.J.; Tang, D.Z.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.Y.; Chen, B.L.; Zhang, C.; Wang, L.L. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of lower Jurassic Xishanyao coal in the southern Junggar basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Vinod, A.M.; Mollika, B.; Atul, K.V.; Alka, D.K.; Subhashree, M.; Bhagwan, D.S. Fractal and pore dispositions of coal seams with significance to coalbed methane plays of east bokaro, Jharkhand, India. J. Nat. Gas Sci. Eng. 2017, 38, 412–433. [Google Scholar] [CrossRef]

- Crosdale, P.J.; Beamish, B.B.; Valix, M. Coalbed methane sorption related to coal composition. Int. J. Coal Geol. 1998, 35, 147–158. [Google Scholar] [CrossRef]

- Fan, J.J.; Ju, Y.W.; Hou, Q.L.; Tan, J.Q.; Wei, M.M. Pore structure characteristics of different metamorphic-deformed coal reservoirs and its restriction on recovery of coalbed methane. Earth Sci. Front. 2010, 17, 325–335. [Google Scholar]

- Su, X.B.; Lin, X.Y.; Liu, S.B.; Zhao, M.J.; Song, Y. Geology of coalbed methane reservoirs in the Southeast Qinshui Basin of China. Int. J. Coal Geol. 2005, 62, 197–210. [Google Scholar] [CrossRef]

- Cai, Y.D.; Liu, D.M.; Yao, Y.B.; Li, J.Q.; Qiu, Y.K. Geological controls on prediction of coalbed methane of No. 3 coal seam in Southern Qinshui Basin, North China. Int. J. Coal Geol. 2011, 88, 101–112. [Google Scholar] [CrossRef]

- Fu, H.J.; Tang, D.Z.; Xu, H.; Xu, T.; Chen, B.L.; Hu, P.; Zheng, Y.Y.; Wu, P.; He, G.J. Geological characteristics and CBM exploration potential evaluation: A case study in the middle of the southern Junggar basin, NW China. J. Nat. Gas Sci. Eng. 2016, 30, 557–570. [Google Scholar] [CrossRef]

- Bao, Y.; Wei, C.T.; Neupane, B. Generation and accumulation characteristics of mixed coalbed methane controlled by tectonic evolution in Liulin CBM field, eastern Ordos basin, China. J. Nat. Gas Sci. Eng. 2015, 28, 262–270. [Google Scholar] [CrossRef]

- International Organization for Standardization. Methods for the Petrographic Analysis of Bituminous Coal and Anthracite-Part 5: Method of Determining Microscopically the Reflectance of Vitrinite; ISO 7404.5-1994; ISO: Geneva, Switzerland, 1994. [Google Scholar]

- International Organization for Standardization. Methods for the Petrographic Analysis of Coals—Part 3: Method of Determining Maceral Group Composition; ISO 7404.3:2009; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- International Organization for Standardization. Coal—Proximate Analysis; ISO 17246:2010; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Gigabyte. Experimental Method of High-Pressure Isothermal Adsorption to Coal; GB/T 19560-2008; China National Standards: Beijing, China, 2008. [Google Scholar]

- International Organization for Standardization. Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 2: Analysis of Mesopores and Macropores by Gas Adsorption; ISO 15901.2-2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. Evaluation of Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 1: Mercury Porosimetry; ISO 15901-1-2005; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- SY. Analytical Method of Rock Sample by Scanning Electron Microscope; SY/T 5162-1997; China Petrolem & Natural Gas Standards: Beijing, China, 1997. [Google Scholar]

- Friesen, W.I.; Mikule, R.J. Fractal dimensions of coal particles. J. Colloid Interface Sci. 1987, 120, 263–271. [Google Scholar] [CrossRef]

- Fu, X.H.; Qin, Y.; Zhang, W.H.; Wei, C.T.; Zhou, R.F. Research of coal pore fractal classification and natural classification based on the coalbed methane migration. China Sci. Bull. 2005, 50, 51–55. [Google Scholar] [CrossRef]

- Wang, C.Y.; Hao, S.X.; Sun, W.J.; Chu, W. Fractal dimension of coal particles and their CH4 adsorption. Int. J. Min. Sci. Technol. 2012, 22, 855–858. [Google Scholar] [CrossRef]

- Bu, H.L.; Ju, Y.W.; Tan, J.Q.; Wang, G.C.; Li, X.S. Fractal characteristics of pores in non-marine shales from the Huainan coalfield, Eastern China. J. Nat. Gas Sci. Eng. 2015, 24, 166–177. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in noninteger dimensions between two and three (I): Fractal theory of heterogeneous surfaces. J. Chem. Phys. 1984, 80, 3558–3565. [Google Scholar] [CrossRef]

- Bae, J.S.; Bhatia, S.K.; Rudolph, V.; Massarotto, P. Pore accessibility of methane and carbon dioxide in coals. Energy Fuels 2009, 23, 3319–3327. [Google Scholar] [CrossRef]

- Melnichenko, Y.B.; He, L.L.; Sakurovs, R.; Kholodenko, A.L.; Blach, T.; Mastalerz, M.; Radlinski, A.P.; Cheng, G.; Mildner, D.F.R. Accessibility of pores in coal to methane and carbon dioxide. Fuel 2012, 91, 200–208. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M. Effects of igneous intrusions on coal petrology, pore-fracture and coalbed methane characteristics in Hongyang, Handan and Huaibei coalfields, North China. Int. J. Coal Geol. 2012, s96–s97, 72–81. [Google Scholar] [CrossRef]

| Sample ID | Ro, max (%) | Ad (%) | Clay Minerals (%) | Carbonates (%) | BET Surface Area (m2/g, LTNA) | Pore Volume (10−6 m3/g, LTNA) | Total Pore Area (m2/g, MP) | Total Intrusion Volume (10−6 m3/g, MP) | Langmuir Volume VL/(10−6m3/g) | Langmuirpressure PL/MPa |

|---|---|---|---|---|---|---|---|---|---|---|

| SH-1 | 2.76 | 10.99 | 7.860 | 0 | 6.33 | 0.0053 | 6.446 | 0.0356 | 36.23 | 3.12 |

| SH-2 | 2.68 | 10.51 | 2.646 | 0 | 16.95 | 0.0095 | 5.703 | 0.0387 | 34.48 | 2.99 |

| SH-3 | 3.07 | 9.54 | 2.524 | 1.262 | 1.45 | 0.0021 | 6.116 | 0.0354 | 36.50 | 2.68 |

| SH-4 | 2.96 | 47.4 | 51.150 | 0.660 | 4.20 | 0.0032 | 5.873 | 0.0351 | 28.57 | 2.90 |

| SH-5 | 2.73 | 8.51 | 3.240 | 0 | 4.89 | 0.0035 | 6.522 | 0.0492 | 35.84 | 2.97 |

| SH-6 | 2.53 | 12.83 | 5.560 | 0 | 2.13 | 0.0032 | 6.916 | 0.0380 | 35.71 | 2.77 |

| ZZ-1 | 2.42 | 9.62 | 2.940 | 0.320 | 0.22 | 0.00071 | 6.150 | 0.0276 | 31.06 | 2.68 |

| ZZ-2 | 2.65 | 8.40 | 4.6510 | 0.332 | 0.39 | 0.0010 | 7.468 | 0.0362 | 30.67 | 2.06 |

| ZZ-3 | 2.72 | 11.08 | 5.938 | 0 | 0.53 | 0.0011 | 7.555 | 0.0352 | 28.17 | 2.01 |

| ZZ-4 | 2.45 | 9.17 | 1.829 | 0.305 | 0.29 | 0.00079 | 7.850 | 0.0373 | 32.89 | 2.45 |

| ZZ-5 | 2.44 | 13.49 | 7.164 | 0.300 | 0.22 | 0.00052 | 5.836 | 0.0277 | 26.39 | 2.17 |

| Sample ID | 0.54 ≤ ln(ln(P0/P)) | −1.52(−1.04) < ln(ln(P0/P)) < 0.54 | ln(ln(P0/P)) ≤ −1.52(−1.04) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | D | R2 | A | D | R2 | A | D | R2 | |

| SH-1 | −0.1712 | 2.8288 | 0.99 | −0.0491 | 2.9509 | 0.99 | −0.1274 | 2.8726 | 1.0 |

| SH-2 | −0.2033 | 2.7967 | 0.92 | −0.0119 | 2.9881 | 0.93 | −0.0436 | 2.9564 | 0.99 |

| SH-3 | −0.3054 | 2.6946 | 0.97 | −0.1174 | 2.8826 | 0.98 | −0.2143 | 2.7857 | 0.99 |

| SH-4 | −0.1718 | 2.8282 | 0.96 | −0.0248 | 2.9752 | 0.91 | −0.1117 | 2.8883 | 0.99 |

| SH-5 | −0.1947 | 2.8053 | 0.96 | −0.0026 | 2.9974 | 0.20 | −0.1071 | 2.8929 | 1.0 |

| SH-6 | −0.2303 | 2.7697 | 0.99 | −0.1522 | 2.8478 | 1.0 | −0.2304 | 2.7696 | 0.99 |

| ZZ-1 | 0.0038 | 3.0038 | 0.02 | 0.2414 | 3.2414 | 0.95 | −0.5360 | 2.4640 | 0.99 |

| ZZ-2 | −0.1706 | 2.8294 | 0.97 | −0.0706 | 2.9294 | 0.89 | −0.3866 | 2.6134 | 1.0 |

| ZZ-3 | −0.2081 | 2.7919 | 0.98 | −0.1342 | 2.8658 | 0.97 | −0.3120 | 2.6880 | 0.99 |

| ZZ-4 | −0.0528 | 2.9472 | 0.71 | 0.1196 | 3.1196 | 0.87 | −0.4600 | 2.5400 | 0.99 |

| ZZ-5 | 0.0472 | 3.0472 | 0.34 | 0.3715 | 3.3715 | 0.99 | −0.5174 | 2.4826 | 0.99 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, D.; Li, M.; Wang, B.; Hu, B.; Liu, J. Characteristics of Pore Structure and Fractal Dimension of Isometamorphic Anthracite. Energies 2017, 10, 1881. https://doi.org/10.3390/en10111881

Gao D, Li M, Wang B, Hu B, Liu J. Characteristics of Pore Structure and Fractal Dimension of Isometamorphic Anthracite. Energies. 2017; 10(11):1881. https://doi.org/10.3390/en10111881

Chicago/Turabian StyleGao, Di, Meng Li, Baoyu Wang, Bin Hu, and Jianguo Liu. 2017. "Characteristics of Pore Structure and Fractal Dimension of Isometamorphic Anthracite" Energies 10, no. 11: 1881. https://doi.org/10.3390/en10111881

APA StyleGao, D., Li, M., Wang, B., Hu, B., & Liu, J. (2017). Characteristics of Pore Structure and Fractal Dimension of Isometamorphic Anthracite. Energies, 10(11), 1881. https://doi.org/10.3390/en10111881