1. Introduction

Since the economic and energy structures have been continuously improved, and the energy consumption structures have kept changing in various countries, abundant studies have been done on the centralized power generation taking natural gas as the fuel [

1] and the distributed energy sources system. Distributed energy sources are valued by many countries for their unique advantages [

2]. Scholars from different countries have done a great deal of research based on the economic and energy environment of their own countries. A Combined Cooling, Heating and Power (CCHP) energy system possesses excellent adaptability, since it does not impose high requirements on heat source varieties and can be operated with biofuels [

3,

4], as well as wind power and photovoltaic power [

5,

6]. Abundant studies can be found in CCHP energy systems using gas turbines as their driving force [

7,

8,

9].

A Combined Cooling, Heating and Power (CCHP) system is a new type of energy system built at the user location or nearby. It is based on the concept of energy cascade utilization, which integrates refrigeration, heating and power generation [

10]. Compared with other distributed energy forms, CCHP systems are mature and widely used internationally, and they are the main direction of China’s distributed energy development.

CCHP systems achieves the cascade utilization of the heat after the combustion of natural gas. High-grade heat moves the gas turbine to generate electricity, and then uses the exhaust heat in the gas turbine to provide refrigeration and heating. The cold and heat energy are directly supplied to the nearest demand, producing the economic benefits. The CCHP system can be operated independently or in multiple units to cope with user demand under different power loads. CCHP systems can have energy efficiencies of up to 80% [

11] due to the lack of long-distance transmission losses and the full utilization of thermal energy. Moreover, CCHP systems play an important role in energy conservation and emission reduction with the function of load shifting on power grids and natural gas pipeline networks. They can not only enhance the safety of the energy supply, but also save social public costs [

12].

As early as in 2000, the former State Development Planning Commission together with other four ministries issued the notice on the Development of Combined Heat and Power (CHP), and encouraged the CHP development in relatively decentralized public buildings [

13]. In the following years, the National Development and Reform Commission (NDRC), the Ministry of Finance (MOF), Housing and Urban-Rural Development (MOHURD), the National Energy Administration (NEA), the State Grid Corporation of China (SGCC) and other relevant units have jointly or independently introduced the policies to promote CCHP energy systems. In August 2010, the MOHURD issued a technical regulation for the development and construction of CCHP systems [

14]. NDRC, NEA and MOHURD jointly issued the “The Implementation Rules of Natural Gas Distributed Energy Demonstration Project” to provide relevant incentives and preferential policies for demonstration projects. Although there is strong policy support, CCHP systems are currently not widely applied in China [

15].

Theoretical studies of exergy analysis and thermoeconomics in China started very early and have been applied to a certain degree. The thermoeconomics model and the exergy cost model for the plant based on the Fuel-Product concept have been defined to quantify the productive interaction between different devices [

16]. By using a simulator, Structural Theory is a powerful and effective tool, and it can make up the insufficiencies of the conventional thermodynamic methods and can be used for the cost-effective operation analysis and optimization in thermal power plants and other complex energy systems [

17]. Based on the exergy balance equations, a general matrix equation for regenerative systems of fossil fired power sets has been deduced. These equations may also serve as the basis for constructing relevant general exergy analysis models of exergy distribution not only of regenerative systems, but also of whole power sets [

18]. A cost analysis method based on thermoeconomics was applied to a 300-MW pulverized coal fired power plant. The results show that the specific irreversibility cost is more suitable than the unit exergy cost of product in quantifying and representing the production performance of a component [

19]. Thermo-economic structural theory was used to analyze two modes of a solar-aided power generation system. The power output is 57.2 MW higher in power-boosting mode and the thermo-economic cost of solar energy was found to be very high because of this large investment [

20].

For the technical-economic feasibility of various heating and/or cooling systems, a comparative analysis of various heating systems for residential buildings in a Mediterranean climate by using the equipment’s efficiency and the lifecycle cost as criteria has shown in [

21]. The Energy Hub methodology is presented and used as tool for evaluating energy consumption. The results obtained are useful to identify benefits that might be obtained by the CHP system, depending on its regulation and on the economic variables [

22]. For the limited existing projects and industry experience of CCHP distributed energy systema, it needs to establish the economic evaluation model based on the second law of thermodynamics [

23]. For CCHP systema based on micro-gas turbines, the economic optimization model with an objective function of minimizing the cost was developed. A variety of contributing factors such as load ratio differences, and fuel costs are incorporated to show their influences on systems economics [

24]. The building of CCHP systems has no economic benefit under the existing price system and the economic benefits are getting worse with the rising price of gas [

25]. A combination of exergy analysis and life cycle assessment (LCA) was presented to show the comparative exergoenvironmental analysis and assessment of various residential heating systems [

26]. From the above analysis, most scholars have evaluated the economy of heating and/or cooling systems for specific cases. Since the energy system has different operating environments and loads in different regions, this kind of discussion has certain limitations. According to the definition of exergy [

27], in this paper, the steam generated after high temperature flue gas from gas turbine enters the heat recovery boiler directly goes through the heating and meanwhile, each part was calculated based on energy balance rather than heat exchange calculation. Then two methods (energy equivalent and economic value equivalent) based on the Levelized Cost of Energy (LCOE) are employed in the paper to evaluate the economical efficiency of a CCHP system.

The remainder of the paper will be organized as follows:

Section 2 provides an analysis framework.

Section 3 presents two evaluation methods for CCHP system and their comparison.

Section 4 presents the sensitivity analysis and

Section 5 concludes the paper and provides the policy suggestions.

2. Analysis Framework

In order to evaluate the economical efficiency of the CCHP system, this paper takes exergy into consideration and calculates the energy that can be sold according to the enthalpy change when the working fluids go through each part of the energy system. Moreover, the economical evaluation of the supposed system is also examined based on the LCOE, a widely applied method to determine the economical efficiency of energy [

28,

29,

30].

In this paper, a 16.6 MW gas turbine was taken as an example to introduce the method of economical efficiency evaluation, because gas turbine manufacturers are protective of the performance parameters of their systems, but in this case the data are mostly available. The selection of a 16.6 MW turbine is only a demonstration example of the proposed methodology. If necessary and with available data, the economy of other capacity systems can also be calculated by this method.

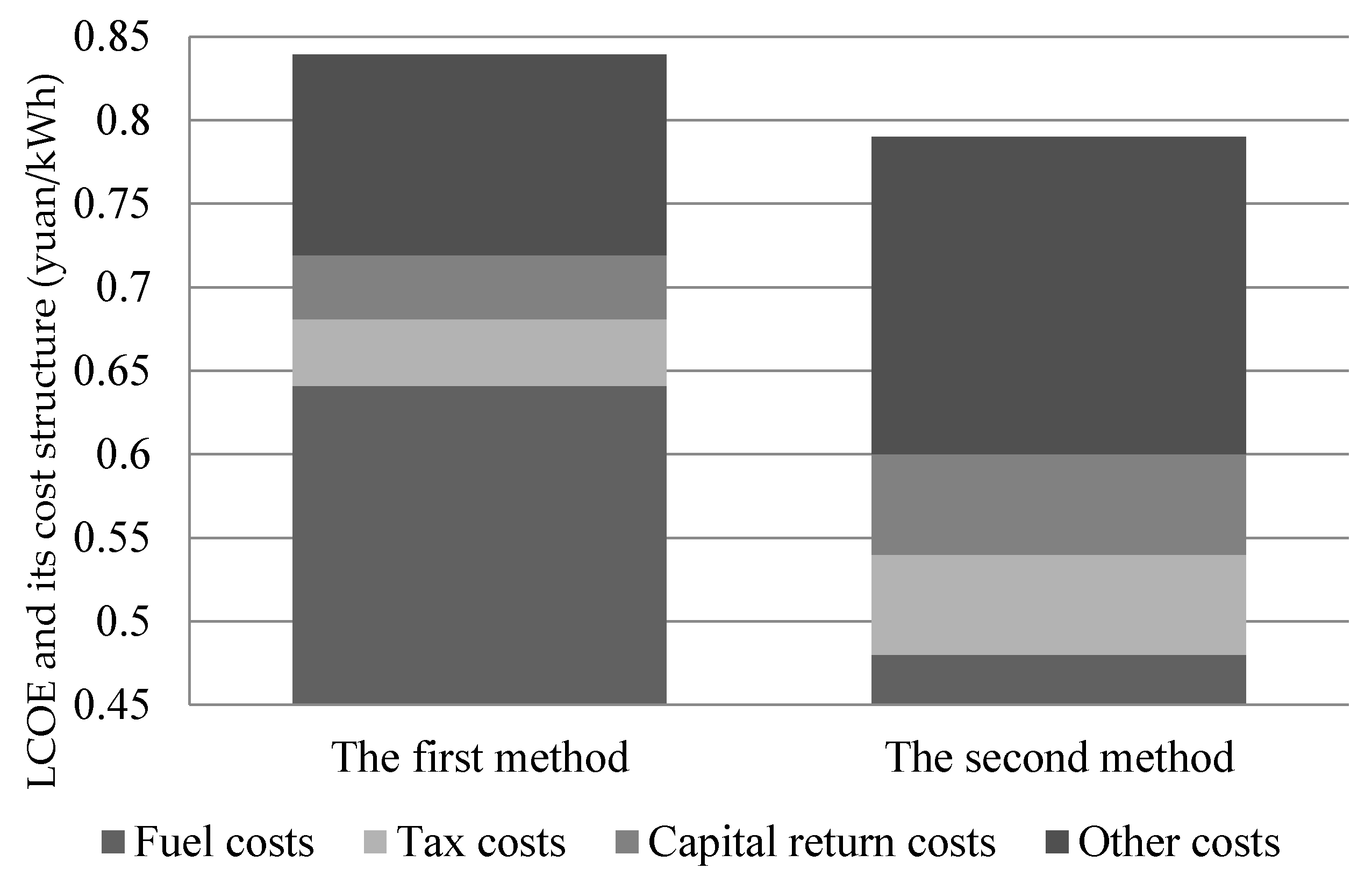

Due to the external environment constraints in commercial operation, the case of second entry of steam into the gas turbine was not taken into consideration. In order to analyze the economical efficiency of the CCHP energy system, two processes were adopted for mutual verification. In the first process, heating and cooling output of CCHP energy system is converted to electric energy based on kilowatts of energy, then the kilowatt cost is calculated based on the LCOE. In the second process, according to market price, the heating and cooling energy is converted to income to compensate for some costs; then the LCOE of electricity produced by the CCHP energy system is calculated.

2.1. Flowing Path of Working Fluids in the CCHP Energy System

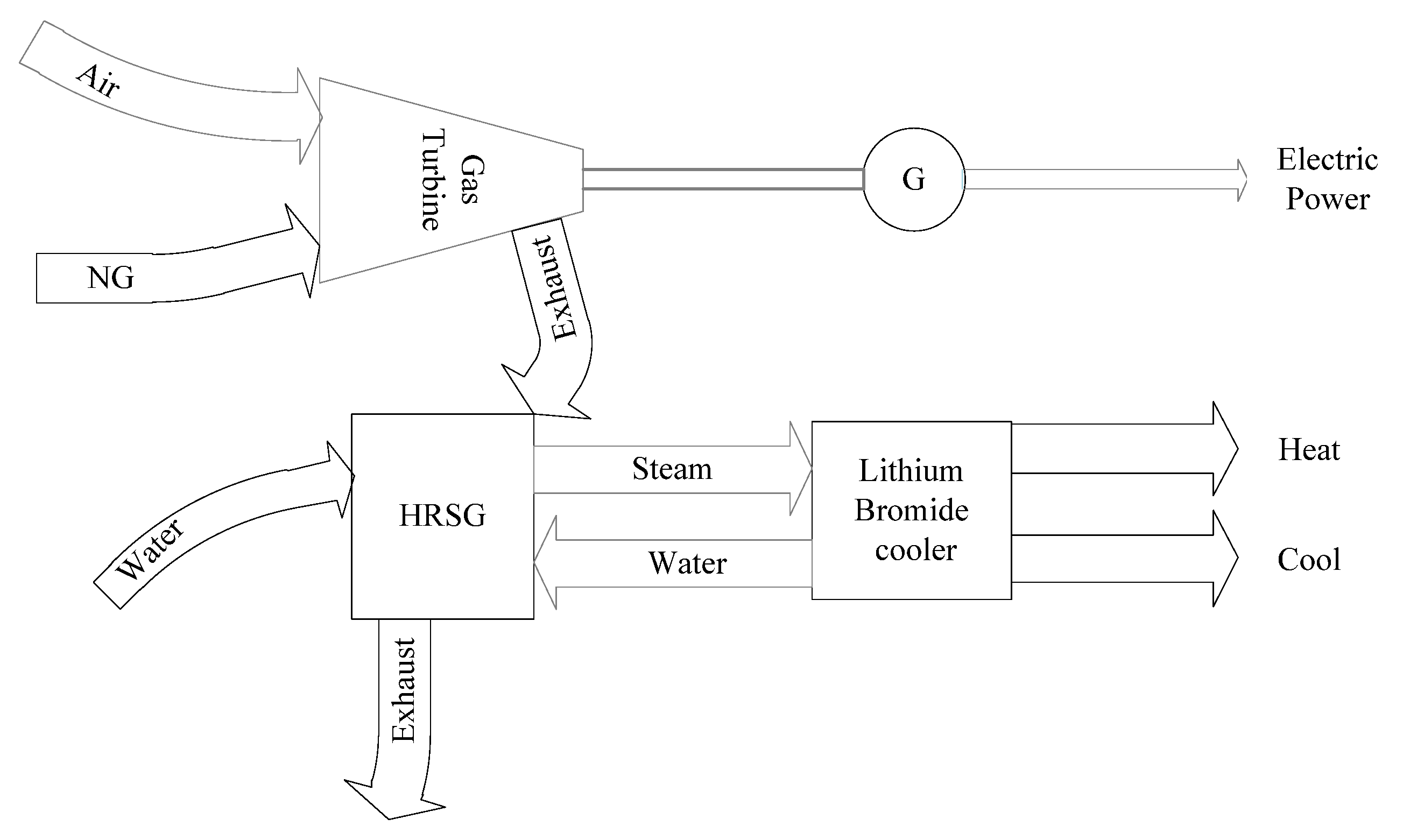

There are multiple kinds of CCHP combinations. In this study, the mode of prime mover + heat recovery boiler + absorption-type water chiller-heater unit was adopted. The flow of the working fluids is shown in

Figure 1.

The enthalpy calculation starts from the exhaust of the gas turbine. Since the enthalpy declines and the working fluid changes as it flow through different apparatus, the energy loss is calculated by the stages. The exergy for the use of consumers is then calculated and converted to equivalent electricity in relation to the cooling and heating COP parameters of the electric compressor. Based on such calculations, the economical efficiency is therefore evaluated.

2.2. Enthalpy Calculation

2.2.1. Calculation of Exhaust Enthalpy in Gas Turbine

The gas turbine and its running parameters are listed in

Table 1.

Based on related literature [

32] and the price fitting equation of a gas turbine (1), its price can be estimated; heat emission from the gas turbine per second can be calculated by Equations (2) and (3) is used for calculating gas consumption per hour:

2.2.2. Enthalpy Calculation of the Heat Recovery Boiler

Considering the position of the CCHP system, the non-complementary type of heat recovery boiler was adopted in this study. If there are cases of insufficient power in heat and cold supply within the range of CCHP energy system, the heat and cold will be compensated on the user side.

In the process of exhaust emission of the gas turbine through the exhaust port of the heat recovery boiler, the heat in the backwater and the efficiency of heat recovery boiler under different steam supply environments are taken into consideration. Then the energy output is calculated based on the energy balance The symbols and corresponding meanings are shown in

Table 2.

The enthalpy exchange equations of the process are:

Without taking the backwater loss into consideration, the following can be obtained based on conservation of mass:

Considering the differences in temperature environment in the heating and cooling period, in supplying heat, the efficiency of the heat recovery boiler is set as 85% and efficiency of the boiler in the cooling period is set as 80%. The heat exchange parameters of the heat recovery boiler are shown in

Table 3.

2.2.3. Calculation of Lithium-Bromide Heat-Cooler

The double-effect steam-type lithium bromide refrigerator was adopted in this paper. The symbols and parameters in the equations are shown in

Table 4 and

Table 5.

Heat balance of lithium bromide unit in heating period:

Heat balance of lithium bromide unit in cooling period:

The power transmitted to user side can be calculated by the COP value of the lithium-bromide heat-cooler as follows:

Electricity-driven refrigeration and heating power can be obtained as follows after conversion:

Fitting formula of the lithium bromide refrigerator:

According to the research results by health departments at home and abroad, when the human body has suitable clothing, warm and quiet, it feels comfortable when the indoor temperature is maintained at 20 °C, and it does not feel cold at 18 °C, but it feels obviously cold at 15 °C. According to the requirements of the current Indoor Air Quality Standard (GB/T 18883), the indoor temperature range of main rooms of civil buildings should be maintained at 16–24 °C. In Beijing, for example, the heating period is definite, and cooling is supplied when the monthly average temperature is higher than 24 °C. The cold energy is then supplied and consumed. Based on the requirements above, the total required time for cold and heat energy is 214 days, namely 5136 h.

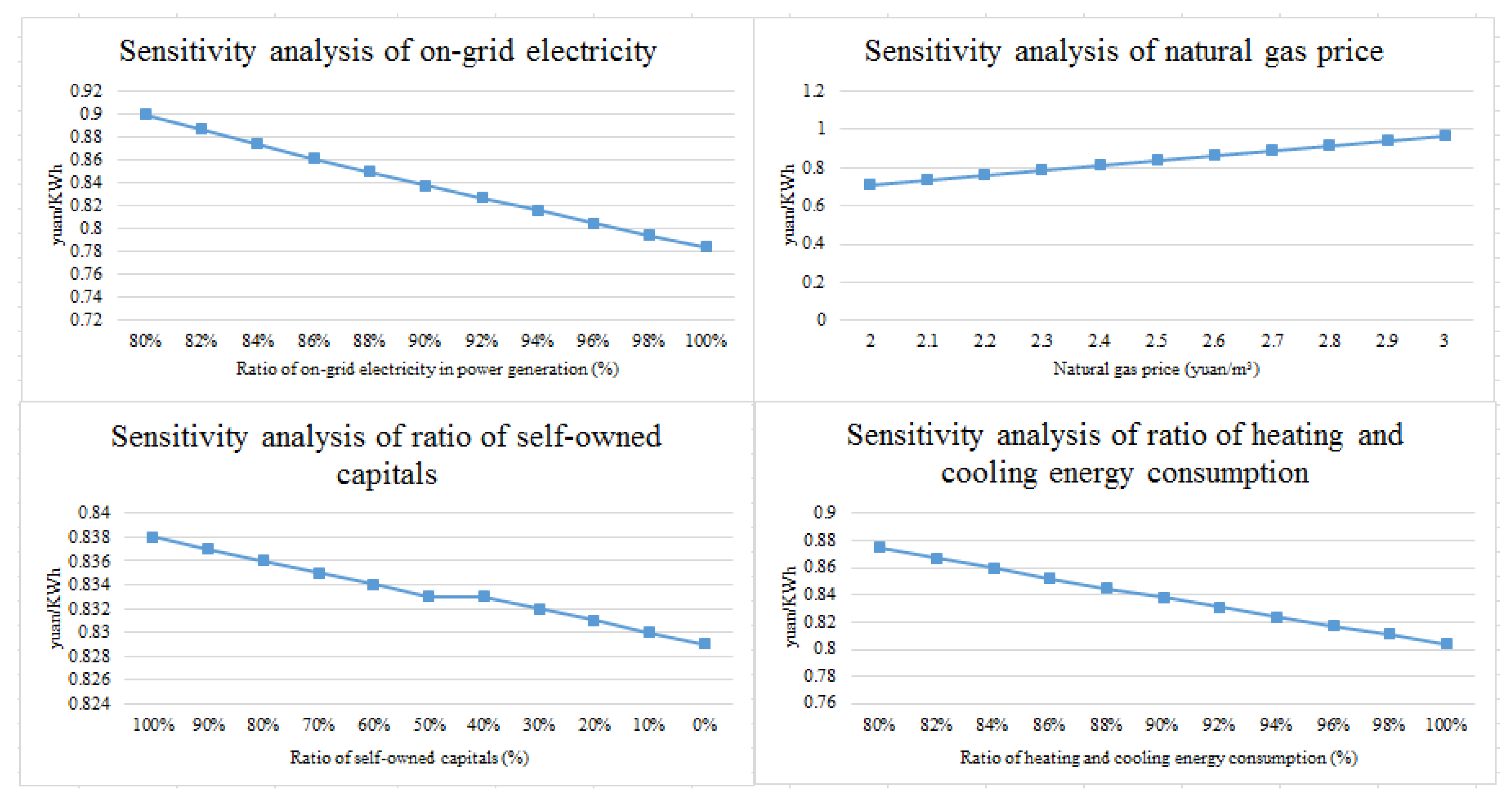

4. Sensitivity Analysis

The sensitivity analysis results show that, the more the usable exergy produced by the CCHP system is, the lower the natural gas price and the ratio of self-owned capital will be, and the higher competitiveness of the LCOE price will be. First, the change in fuel price has great impact on the LCOE of the system, because the fuel cost accounts for about 75% of the total cost. With the rise in natural gas price, the LCOE cost will also increase along with the rise of natural gas price (

Figure 4). When the fuel price is equal to the natural gas price of gas stations (2 yuan/m

3), the LCOE is about 0.65 yuan/kWh. In this case, the economical efficiency of the system is relatively high.

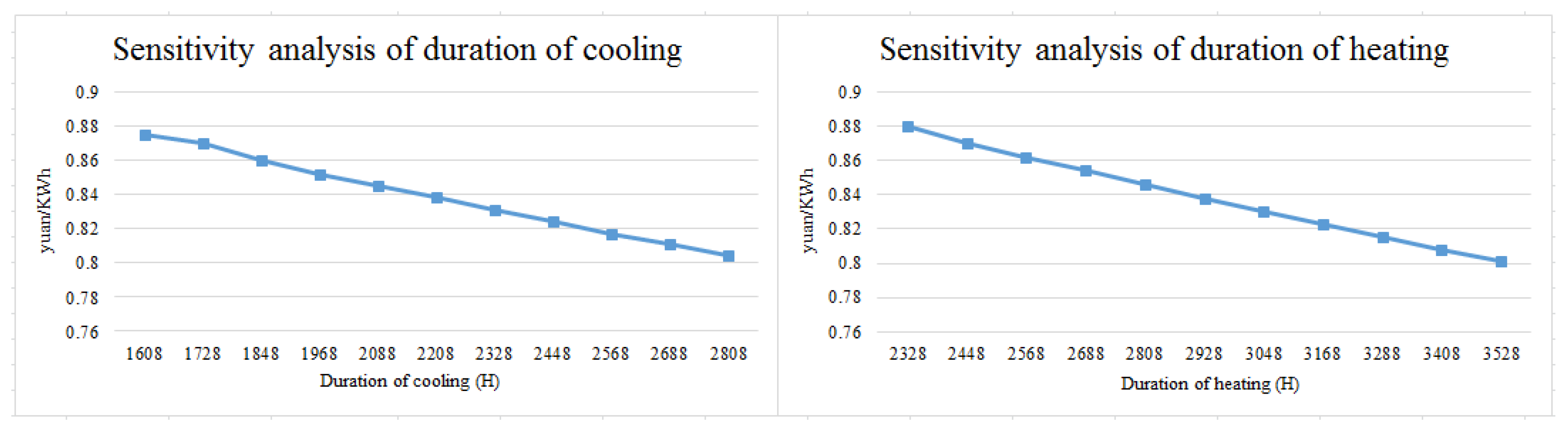

Second, the influence of demand intensity in heating and cooling energy on the LCOE is only second to the natural gas price, and the power output and consumption in the energy system also affects the LCOE. In the energy system structure studied in this paper, when the heating and cooling consumption intensity determined by the climate and the ratio of heating and cooling consumption expands in terms of time and percentage, the LCOE of the energy system has a descending trend (

Figure 4 and

Figure 5). When the consumption of heating and cooling energy increases, the unit cost decreases by 0.1 yuan/kWh. The reason for the significant decline lies in that, with the increase of the utilization rate of heating and cooling energy in the CCHP system, the output of exergy increases. Therefore, when the cost is fixed, the price of per unit exergy also decreases. It shows that the CCHP energy system has good economical efficiency in regions that have higher demands on heating and cooling energy. When on-grid power ratio decreases by 20%, the kilowatt cost may increase by 0.1 yuan (

Figure 5). Therefore, in planning the CCHP energy system, local climate and the rigid demand on heating and cooling energy should be taken into account. Meanwhile, local economic status should also be considered. Whether the heating and cooling energy output can be consumed is another key factor for the LCOE of the system. Besides, favorable policies for on-grid power also influence the competitiveness of the system.

Lastly, another factor in the LCOE of the CCHP energy system is the ratio of bank loans. The change in bank loan ratio has impact on the LCOE, and the sensitivity of bank loan ratio (or self-owned capital) is very low (

Figure 5).

The sensitivity analysis of the above factors shows that, the factors in the economical efficiency of the CCHP energy system mainly include the natural gas price and the final exergy consumption. Based on the quantitative analysis of these factors, the authors propose the main factors that influence the large-scale advancement of the CCHP energy system and the corresponding policy suggestions.

5. Conclusions and Policy Suggestions

5.1. Conclusions

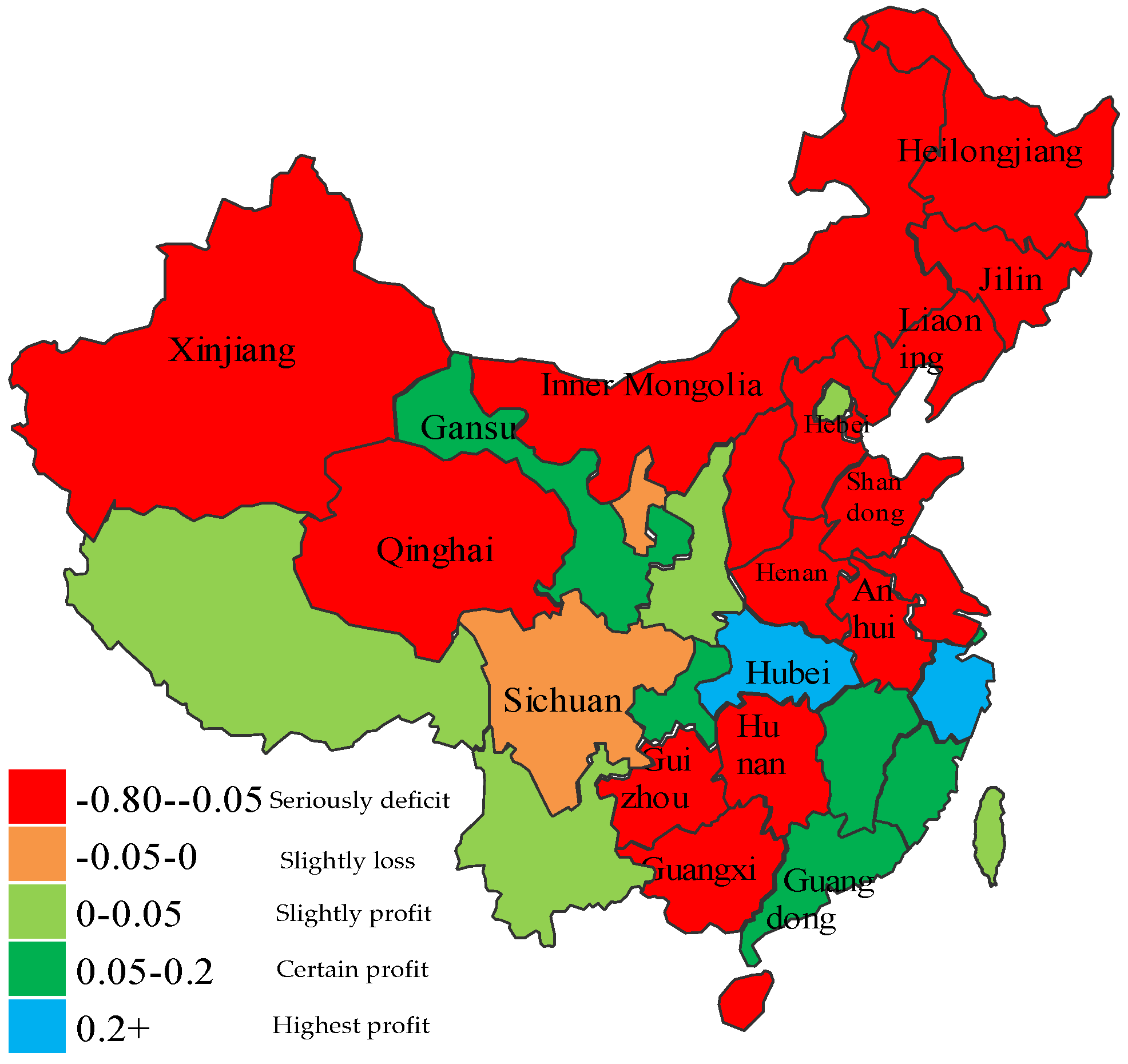

Two methods are employed in this paper to calculate the LCOE for evaluating the economical efficiency of CCHP energy systems. According to the first method based upon energy equivalent, fuel costs account for about 75% of the total cost. In the second method based upon economic value equivalent, the profits from heating and cooling are converted to fuel costs, resulting in a significant decline of fuel costs (60% of the total cost). Then the heating and cooling parameters of gas turbine exhaust, heat recovery boiler, lithium-bromide heat-cooler and commercial tariff of provincial capitals were set as benchmarks based on geographic division among provinces, and the economical efficiency of combined cooling heating and power system in each province was evaluated. From the national profitability map and economic analysis, it shows that the CCHP energy system has economical efficiency only under good operation environment conditions, and it possesses great potential in the central and eastern part of China where market demand and commercial electricity tariffs are higher. In the condition of the internal rate of return of 8%, Guangdong, Chongqing, Hubei, Zhejiang and other provinces still have a high competitive edge. Further reforms in the natural gas market and electricity retailing have laid a foundation for the improvement of the economic efficiency of CCHP energy systems, and their positioning in the entire energy system will be gradually clarified. The economical efficiency of CCHP systems is greatly influenced by the quantity of exergy consumption, and it has poor economical efficiency in areas with temperate climates.

A sensitivity analysis was conducted on key influencing factors, including fuel cost, demand intensity in heating and cooling energy, and bank loans ratio. It shows that the fuel cost has a decisive influence on the economical efficiency of the CCHP energy system. The main reason is that the fuel costs account for about 75% of the total cost. With the rise in natural gas prices, the unit’s costs must rise. Then, the influence of demand intensity in heating and cooling energy on LCOE is only second to fuel cost. When the consumption of heating and cooling energy increases, the unit cost decreases by 0.1 yuan/kWh, and when on-grid power ratio decreases by 20%, the cost may increase by 0.1 yuan/kWh. The paper also provides the policy suggestions of setting a reasonable natural gas price, distributed energy output and energy consumption policy to promote the CCHP system.

5.2. Policy Suggestions

5.2.1. Improve the Development Mechanism for the CCHP Energy System

The positioning of the CCHP energy system in the energy structure should be determined as soon as possible, and the energy structure should be optimized for the development of non-coal energy systems. CCHP energy systems are very sensitive to the operating environment, thus it is necessary to determine its status in relation to the regional resource environment, and formulate promotion policies according to environmental differences.

5.2.2. Enhance Energy Supply and Consumption Market Reform

- (1)

Electricity market. It is necessary to improve the pricing mechanism of the electricity market, and give full play to the characteristics of gas turbine generator sets, in order to achieve electricity output at peak time, and reduce the total cost of the system. Moreover, technological support should be provided for the on-grid electricity in CCHP systems and technology technological standards for grid-connection should be established as soon as possible.

- (2)

Natural gas market. Based on the analysis of the two different cost compositions, natural gas prices have a crucial impact on the economical efficiency of CCHP energy systems. However, the pricing of natural gas should not only consider the costs and profits, but also the social, energy-saving and environmental benefits for gas users. Thus different ways of calculation for gas transmission and distribution prices can reduce the fuel costs of CCHP energy systems, and promote the development of CCHP energy systems.

- (3)

Heating and cooling supply market. The consumption quantity of heating and cooling energy demonstrates the ability of changing anergy into exergy. The thermal efficiency of the system lies in the output and consumption of heating and cooling energy. According to the different climates of different regions and the results of the second method, the form of subsidies can be diversified to fully improve the competitiveness of the CCHP energy systems in each region.