Using an Integrated Script Control Unit (ISCU) to Assist the Power Electronics Education

Abstract

:1. Introduction

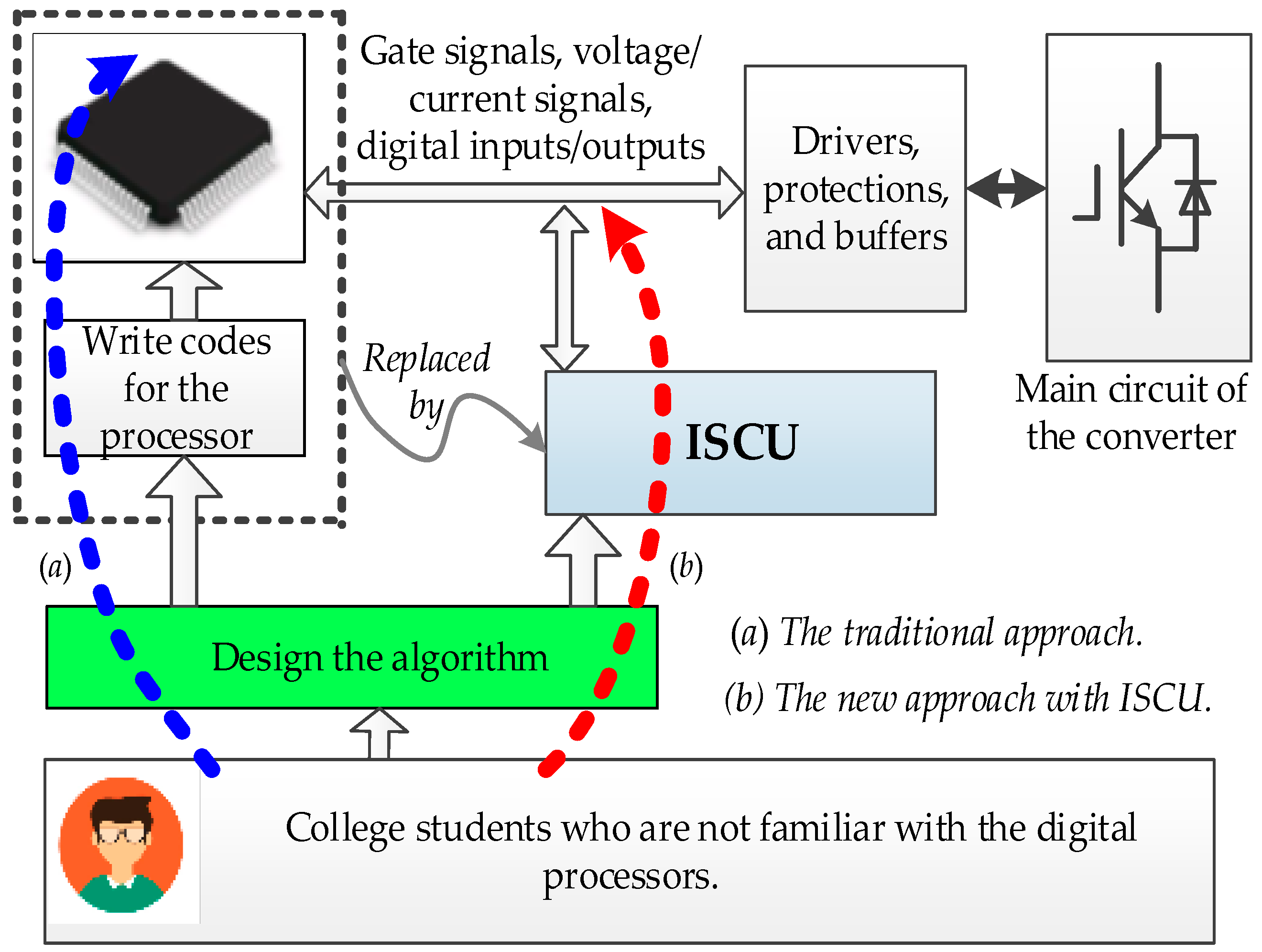

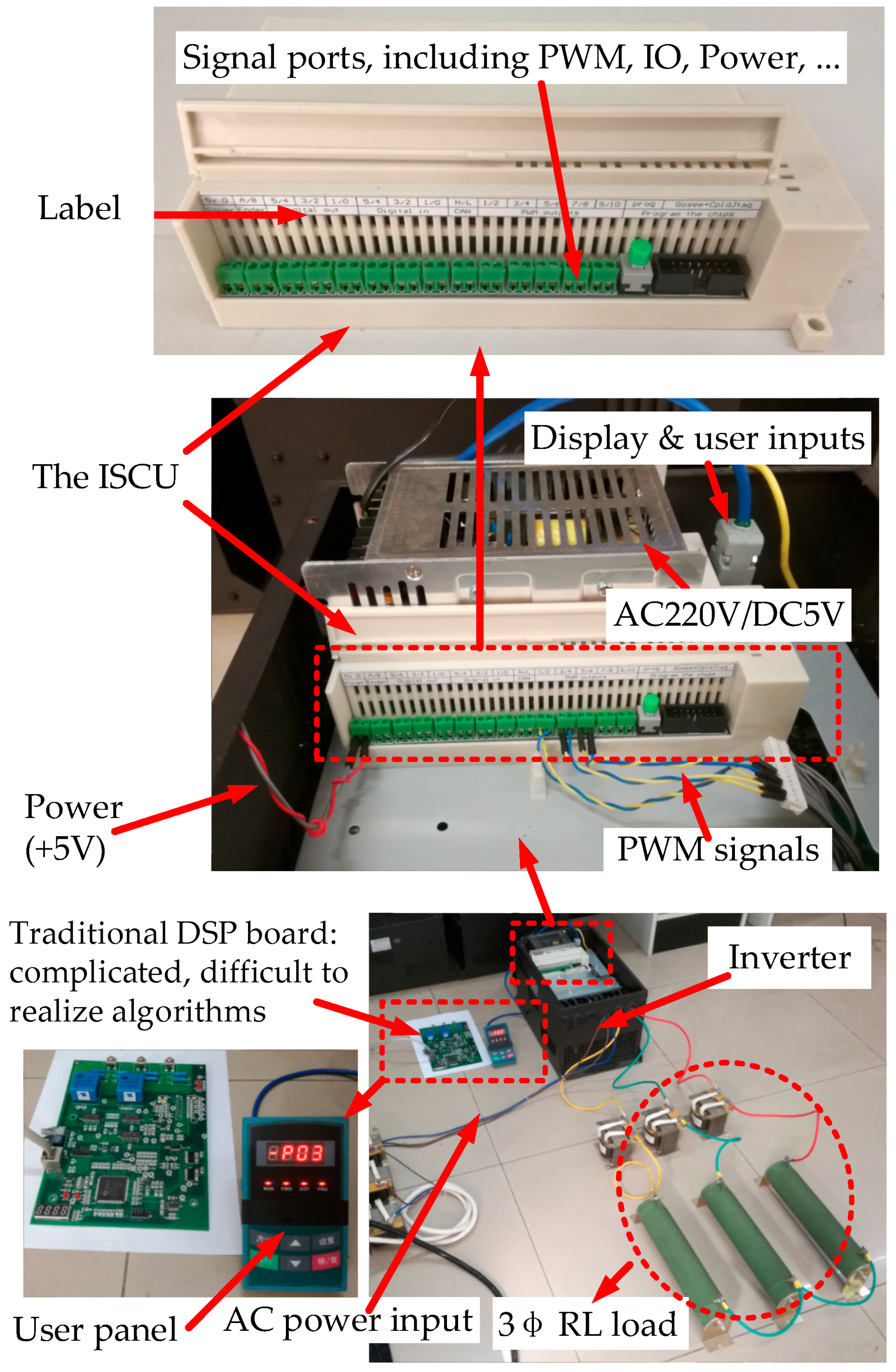

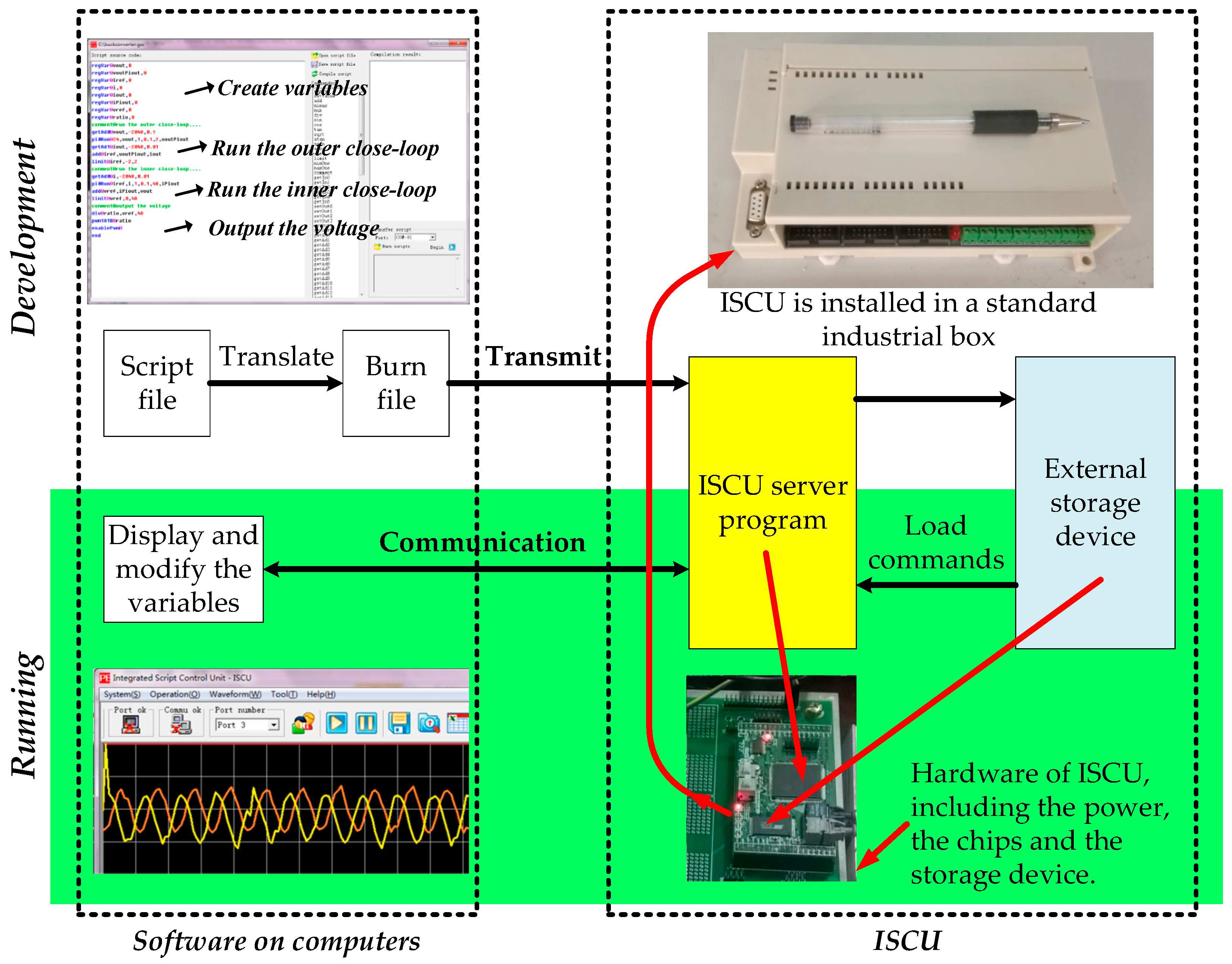

2. The Topology of ISCU

2.1. Subparts of the ISCU

- (1)

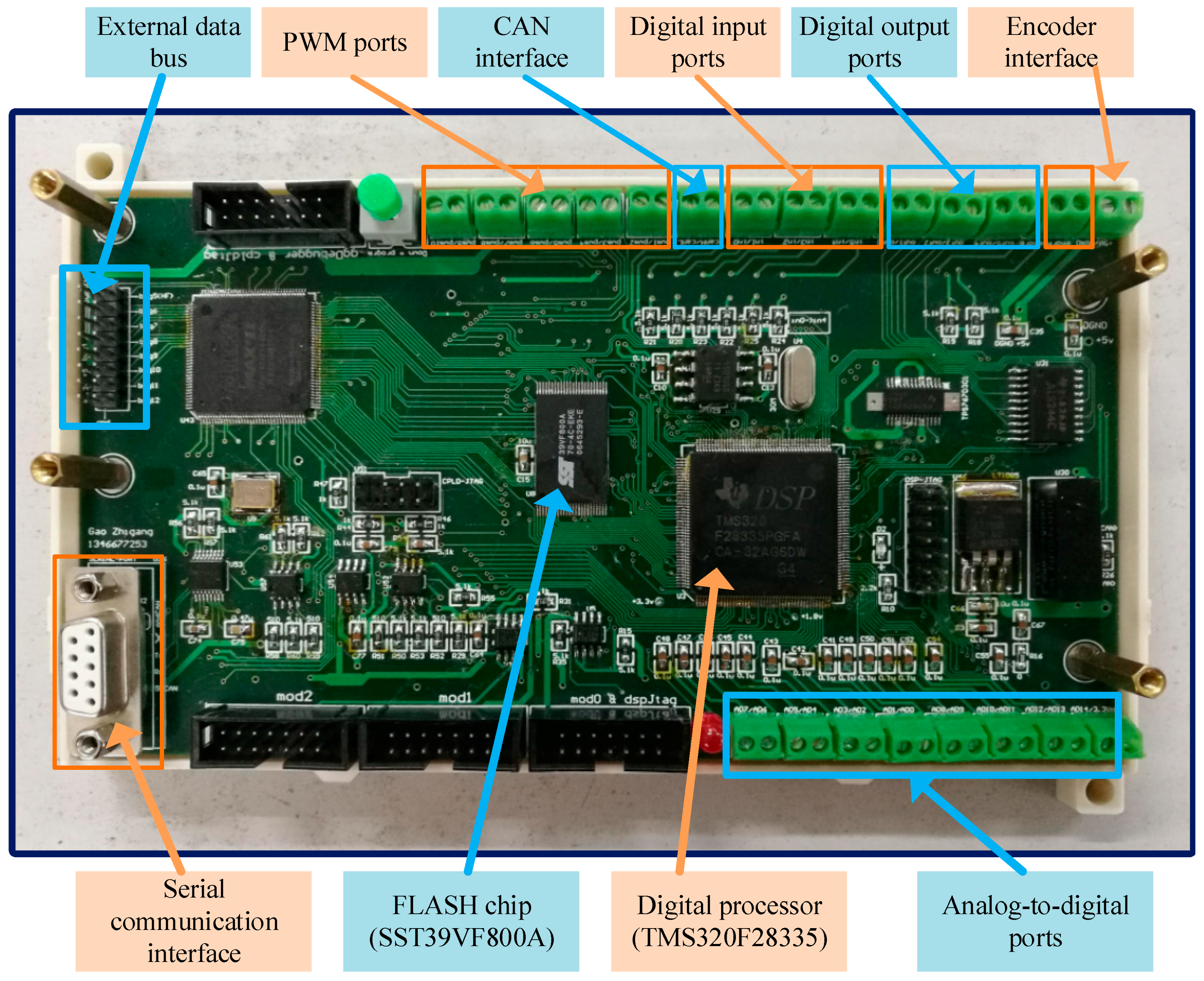

- The control board is based on a digital processor. It has the necessary interfaces to control the converter, for example, analog-to-digital ports, digital input/output ports and PWM ports. On the control board, there is an external storage chip, in which the scripts are stored. The digital processor will load the scripts in the storage chip and execute them when power up.

- (2)

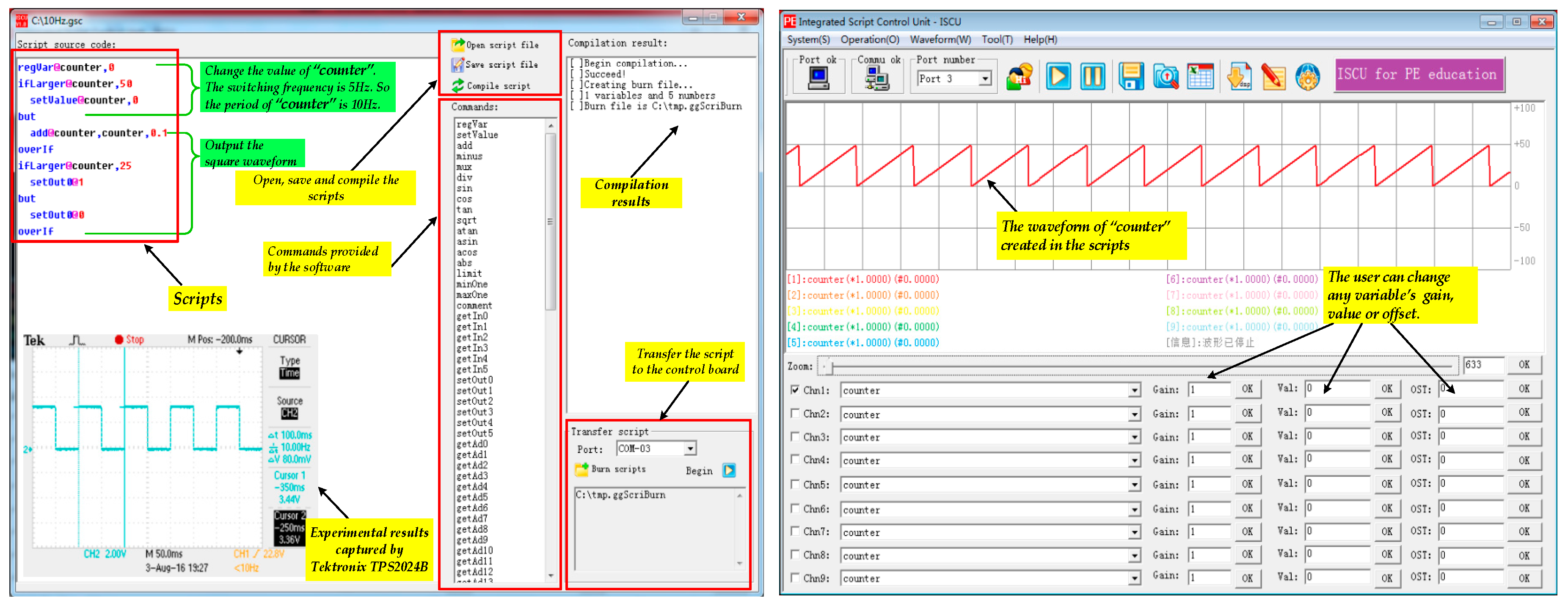

- The computer software provides environment for the users to write scripts and save them into the storage chip on the control board. Also, it can show that the waveforms of the variables defined in the scripts by the user. Figure 2 shows the structure of ISCU.

2.2. The Hardware Platform

2.2.1. Resources and Supporting Functions

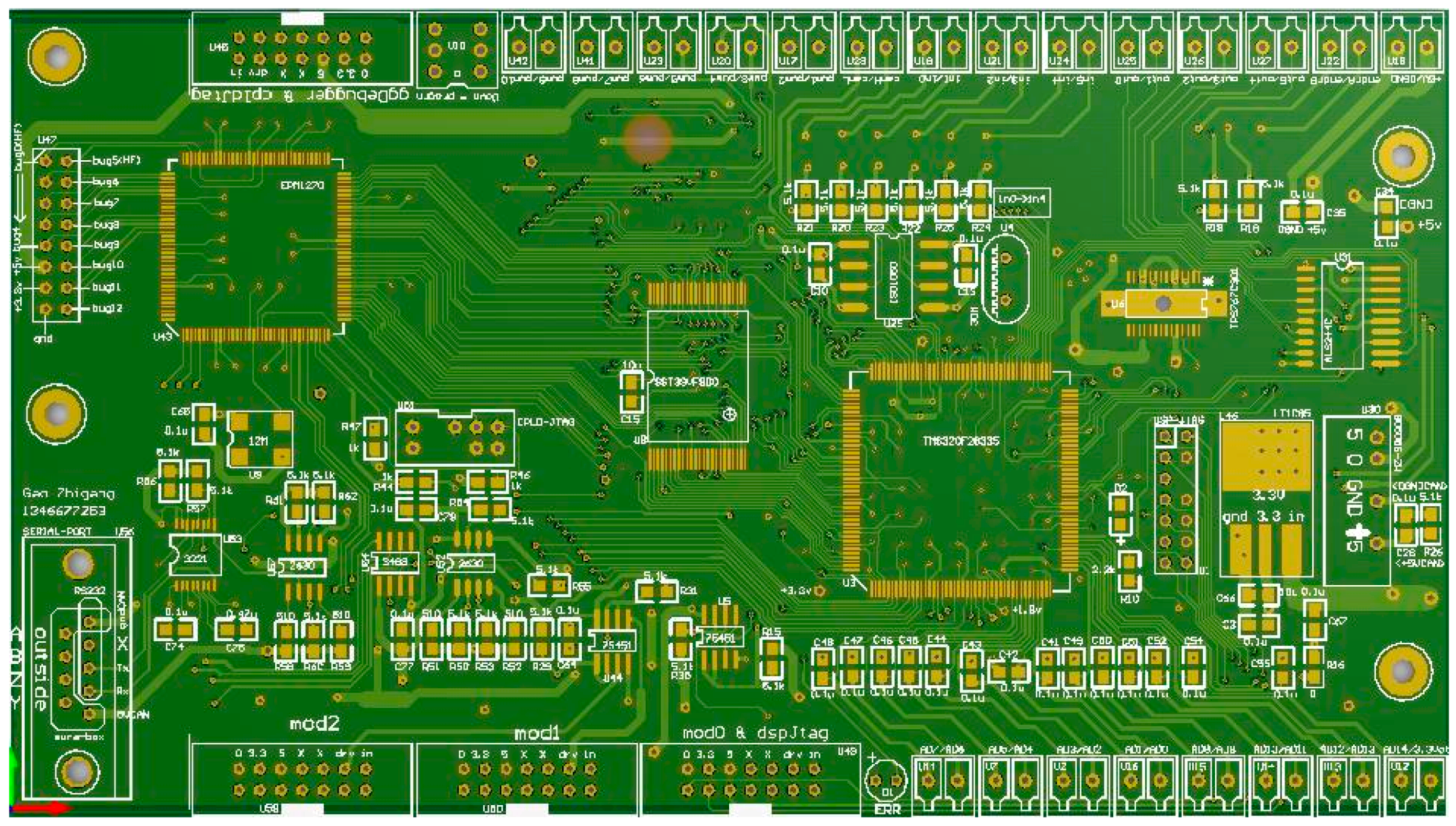

2.2.2. Schematic and Layout Diagrams

2.2.3. “Why Selected” Discussion

- TMS320F28335 DSP chips, one kind of Texas Instruments C2000 microcontrollers, are widely used in many industrial fields with the advantages of high precision, low cost, small power consumption, and high peripheral integration. In order to validate algorithms for converters in power electronic education, the digital processor of ISCU need to have powerful abilities of controlling and signal processing. Given the considerations mentioned above, a DSP-F28335 chip is used as the digital processor.

- SST39V800A devices are 512 K × 16 CMOS Multi-Purpose Flash with high performance CMOS Super flash technology. They are suited for applications that require convenient and economical updating of program, configuration, or data memory. Using such a device as an external FLASH chip on the control board makes it possible to store all the data transmitted from the burn file before being loaded and executed.

- All of the terminals are designed to form relevant signal transmission paths between the control board and the computer or the converters. They are all economical and widely used in industrial applications. It is proved that they all can ensure high precision of transmitting signals.

2.3. The Computer Software

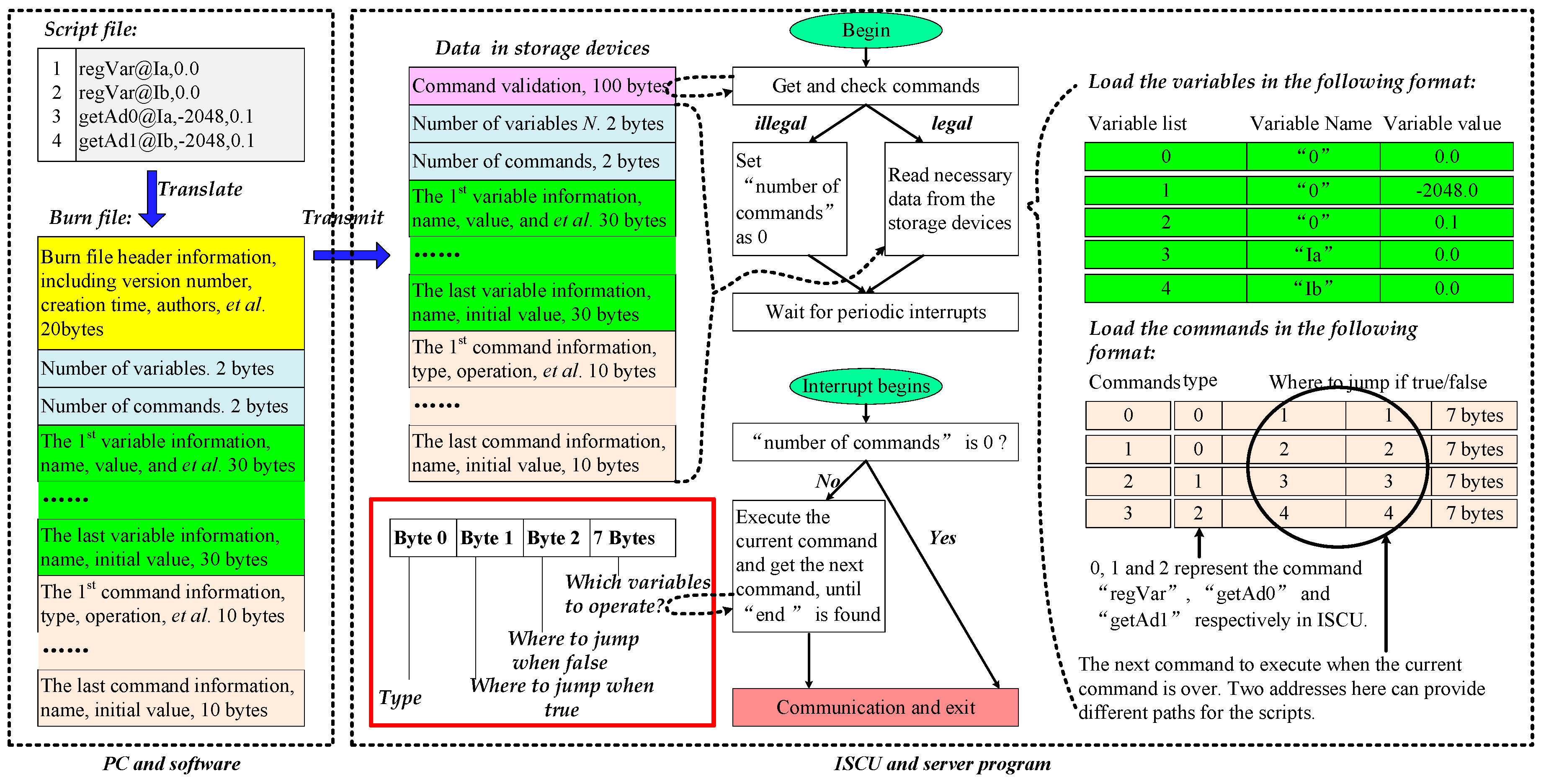

3. Script Systems in ISCU

3.1. Commands and the Classification

3.2. The Compilation and Storage for the Scripts

- Divided the scripts into a number of pieces.

- The compiler tries to find the commands and the parameters for each piece. If the format is not correct or the parameters are not available, the compilation will fail.

- Record the variables created by the user. Every variable is stored in 30 bytes, 26 of which are about the variable name. The last 4 bytes are about the initial value of the variable.

- Record each piece into 10 bytes, which are used to store the command type, the parameters and the logic information.

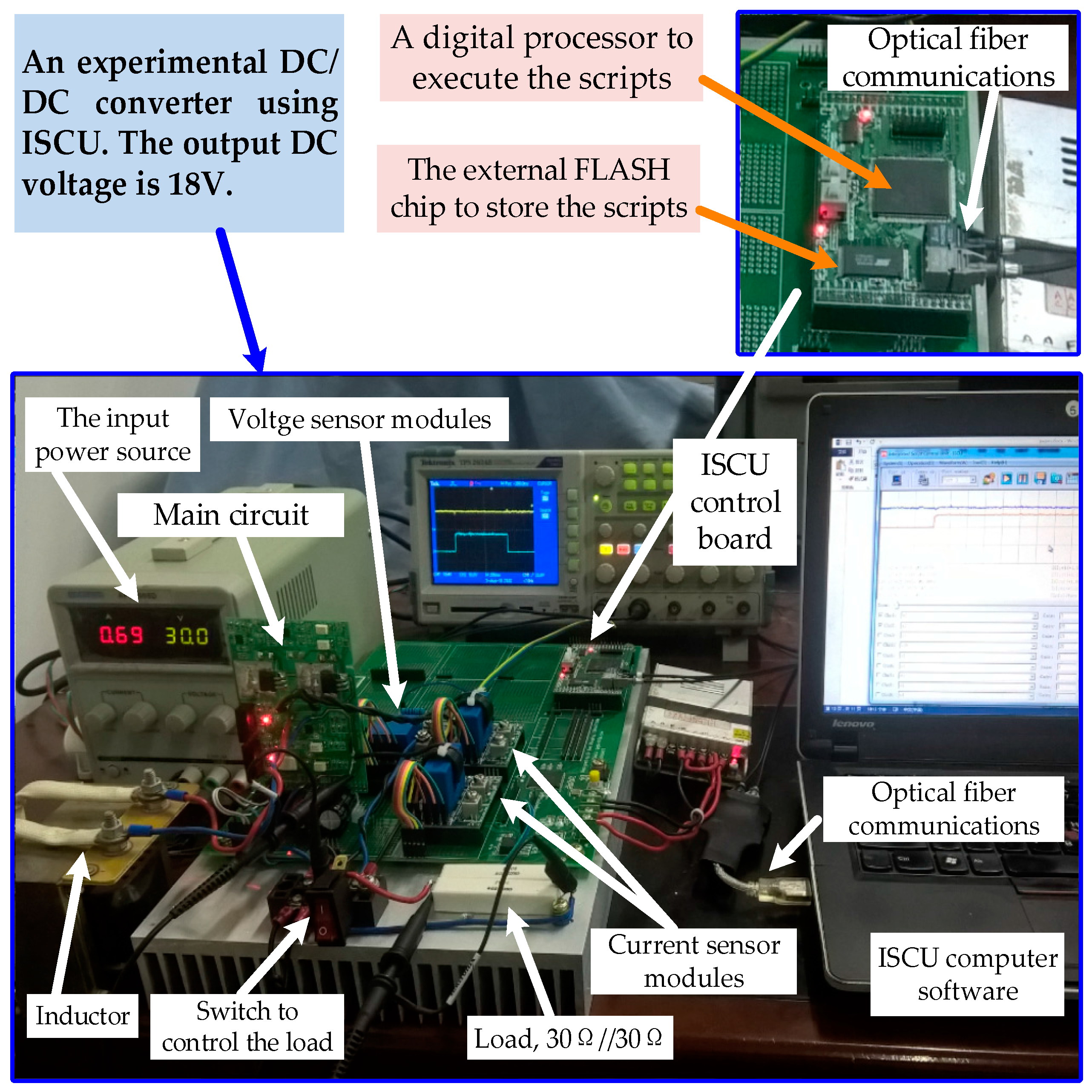

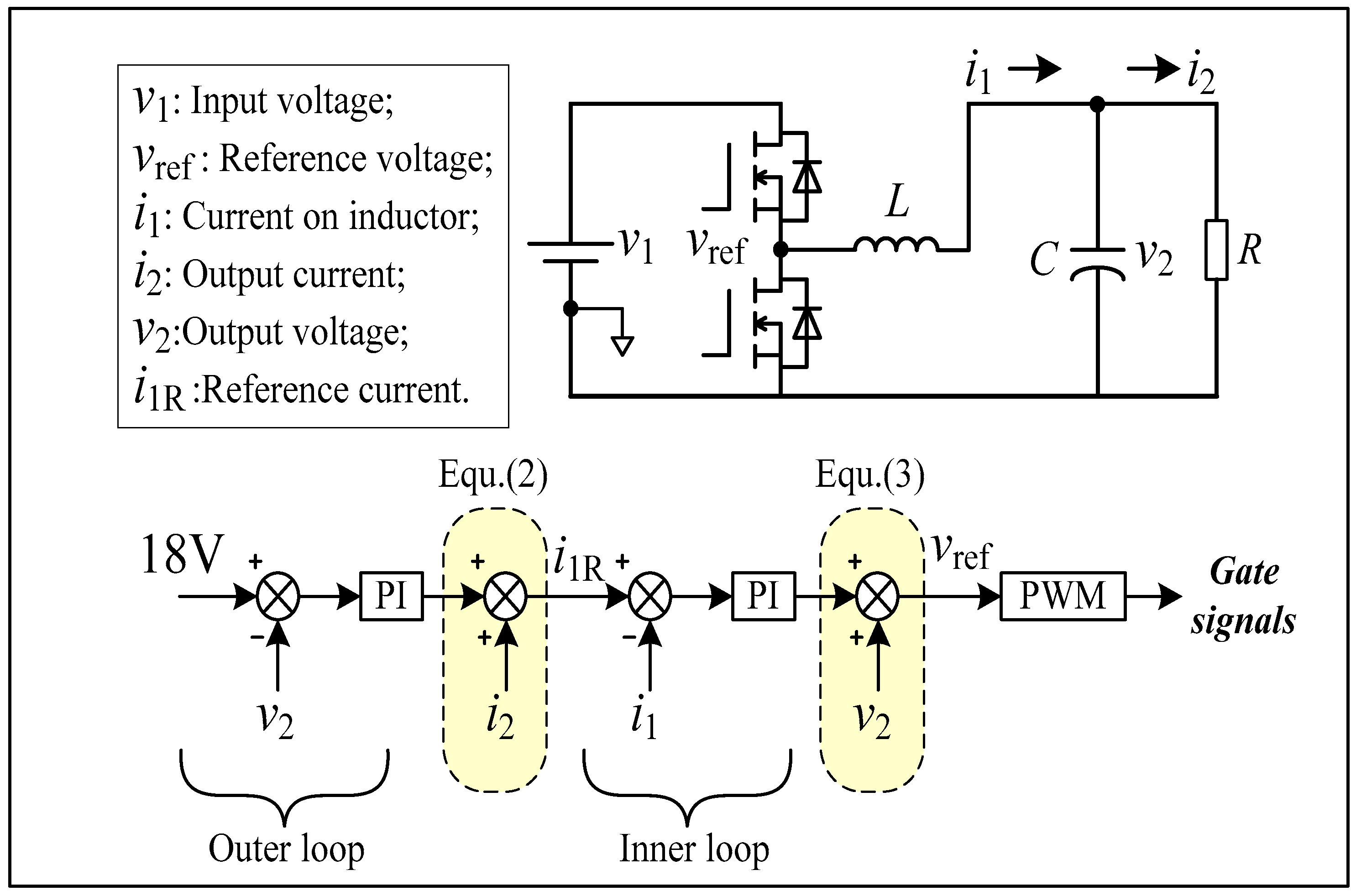

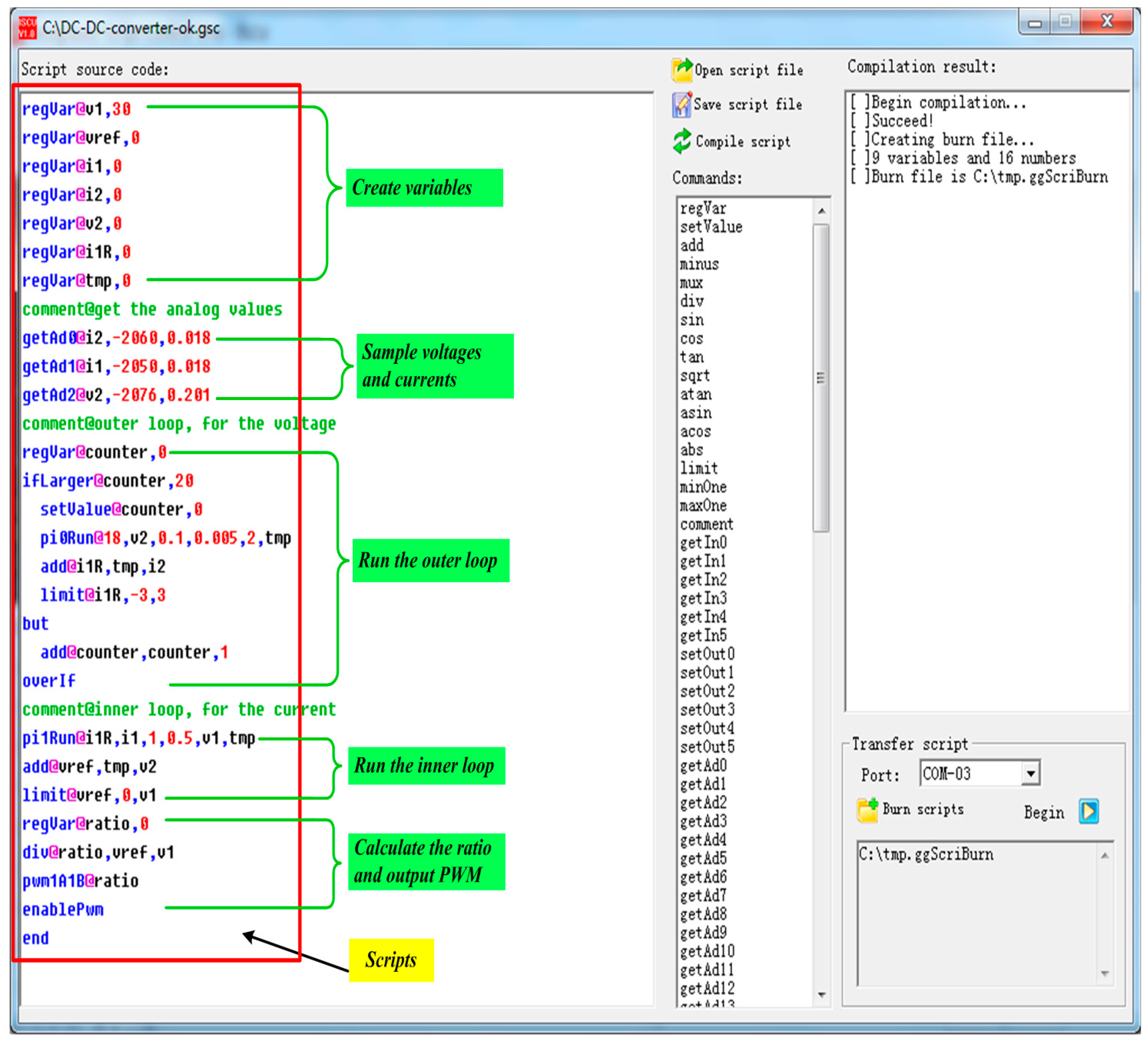

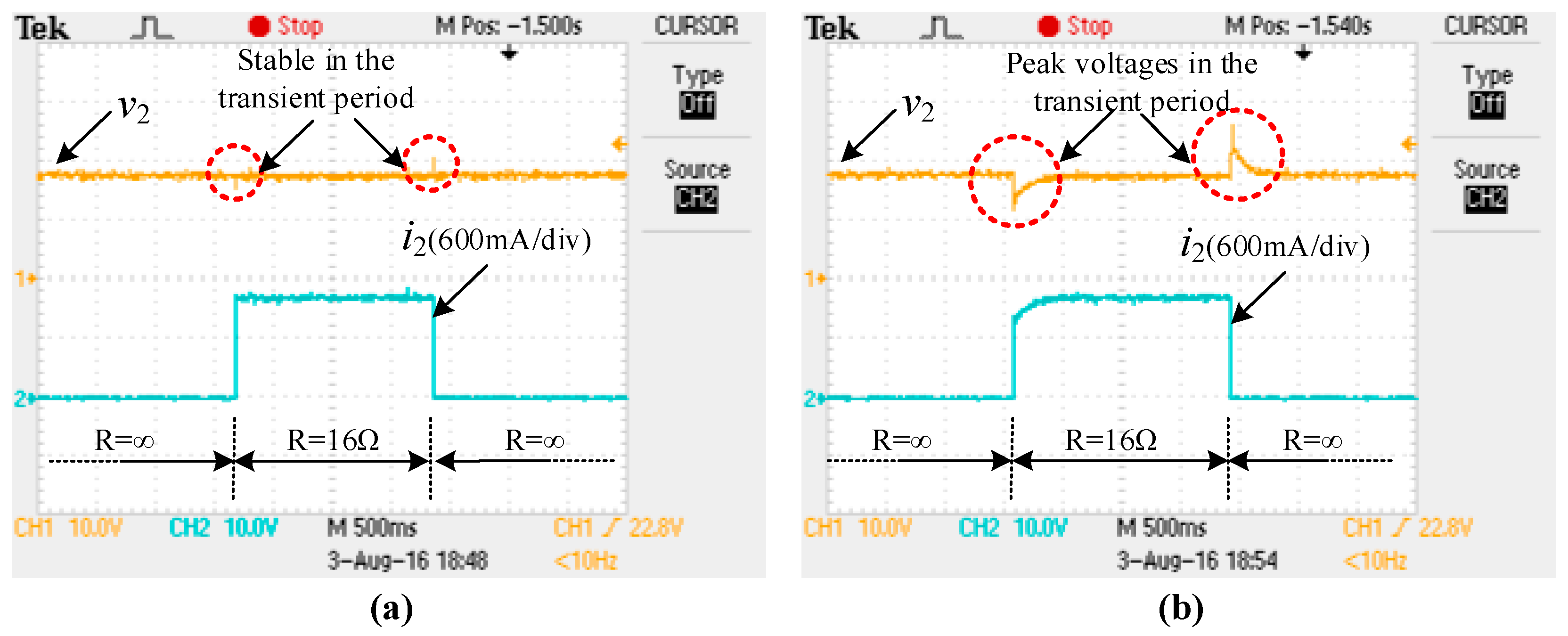

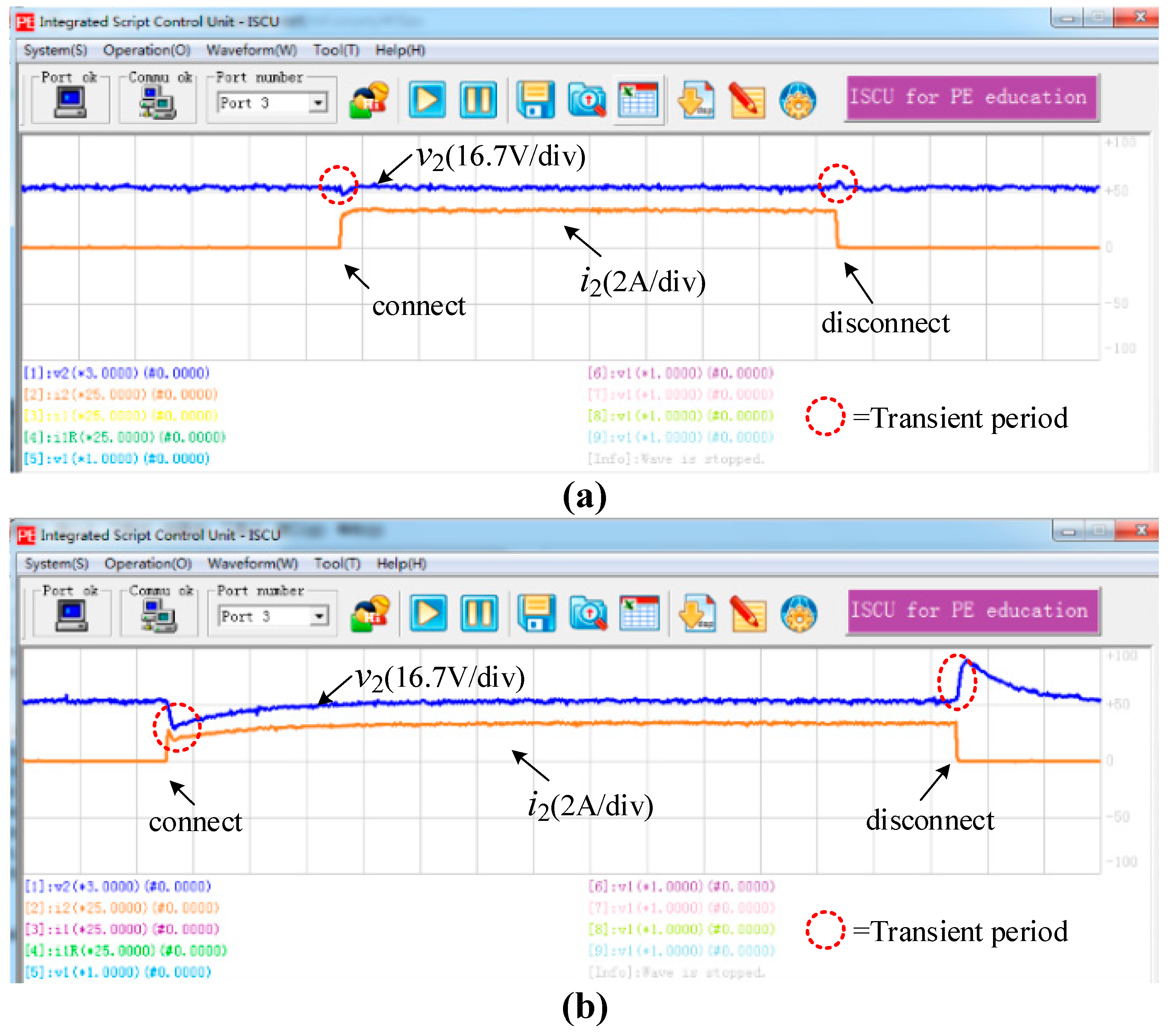

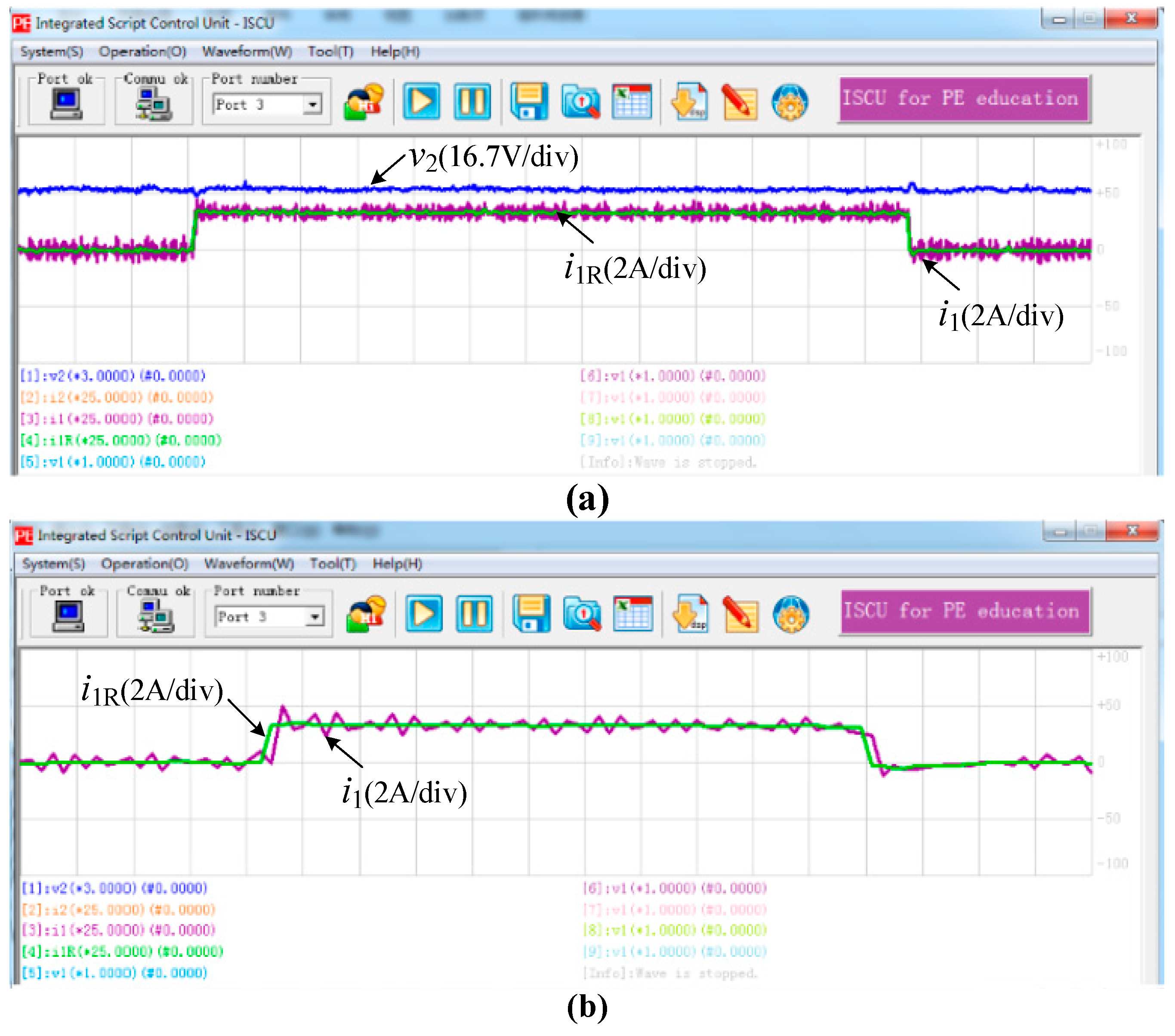

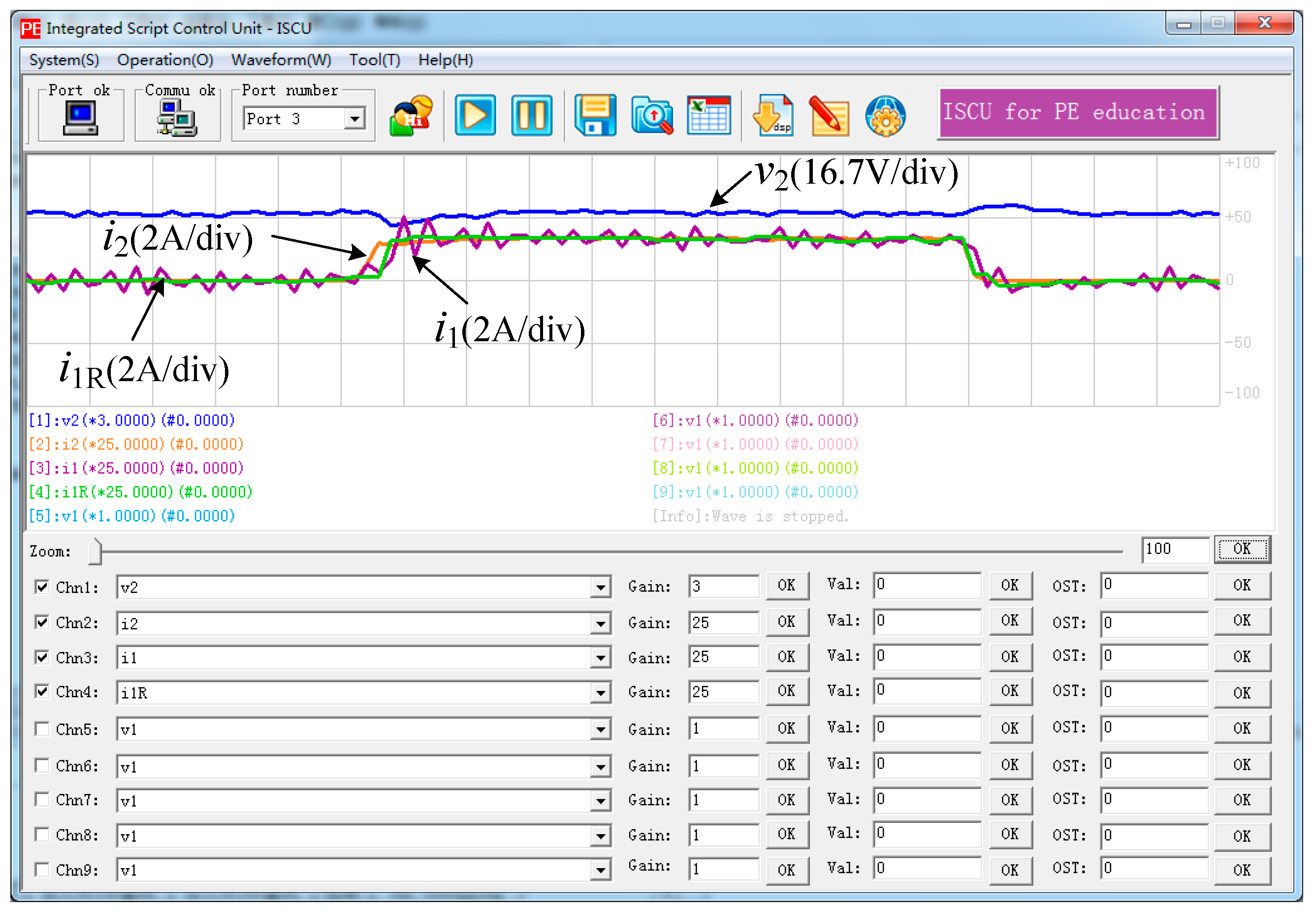

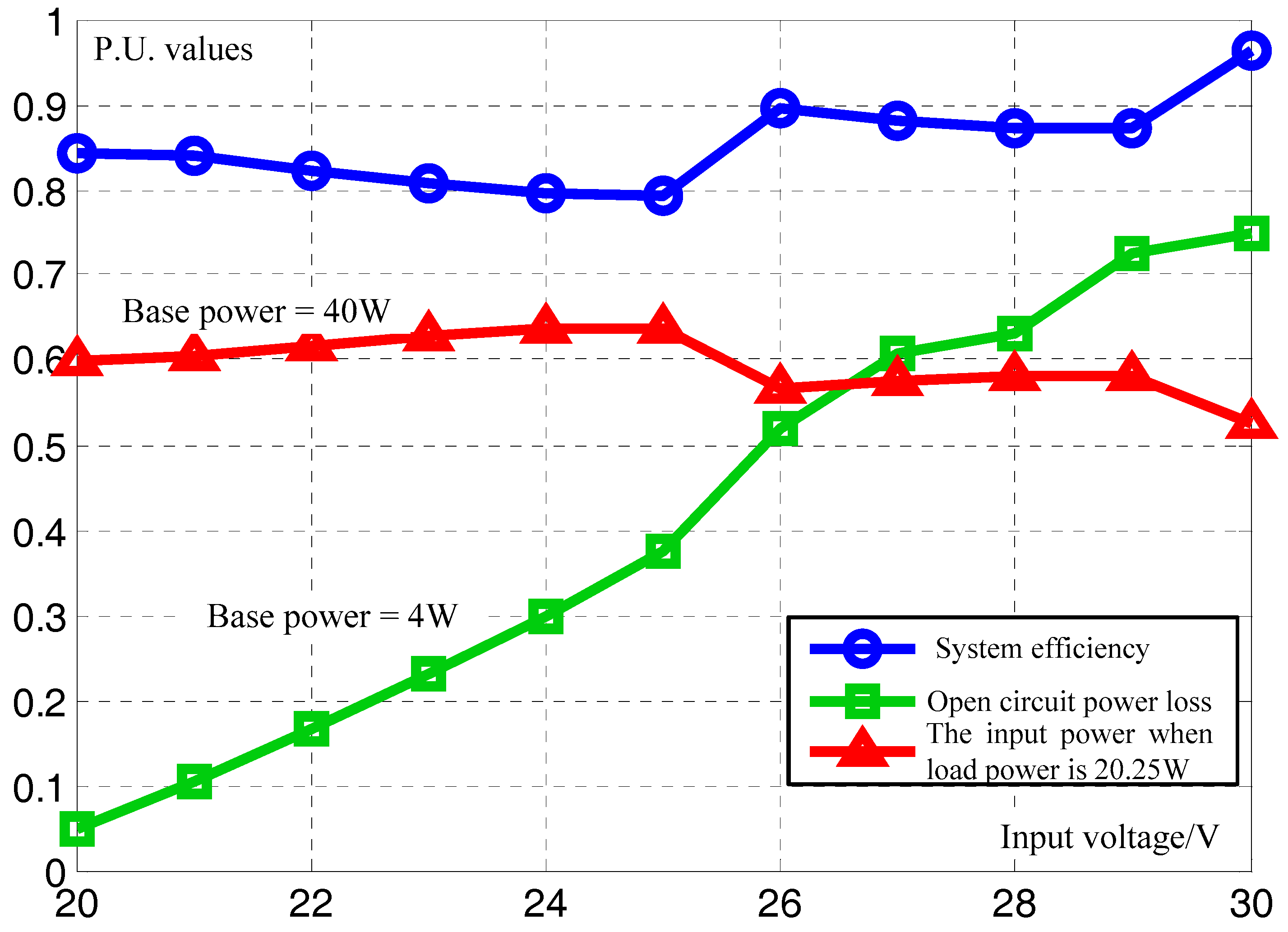

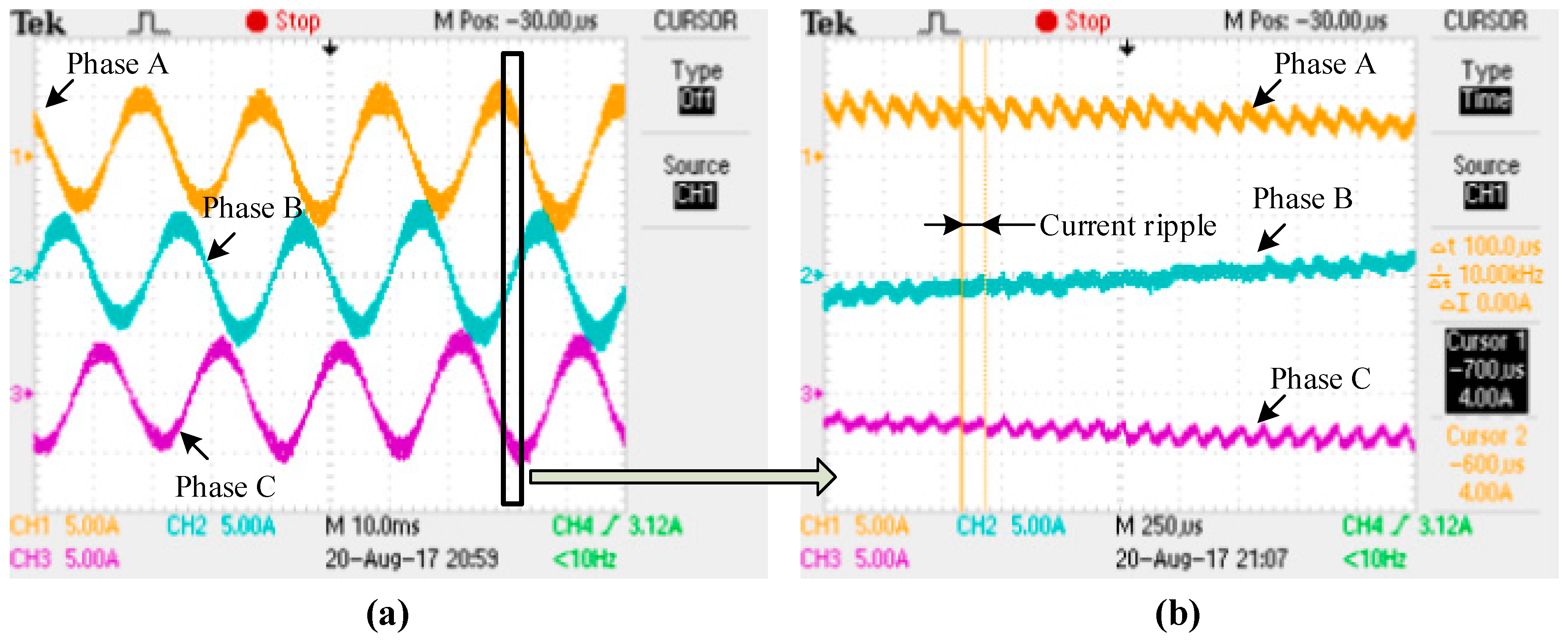

4. Experimental Results and Analysis

5. ISCU Used in Class and in Industrial Applications

- Generate the required PWM signals.

- Sample the required analog signals.

- Get the digital input signals.

- Output digital signals.

- Generate the required sinusoidal PWM signals.

6. Working Schemes and Open Source Plan

- Visit the open source library—github, and find the open documents in https://github.com/luckyharrybit/ISCU. After clicking the link, two folders named “Software and Codes” and “hardware-board” respectively could be found.

- The authors are applying for a website witch will displays all source codes. Once it’s accomplished, the information will be updated and announced in the project in github.

- Contact the authors by the following e-mails: gzgbit@126.com or gzg@bit.edu.cn.

7. Comparison with Other Toolboxes

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tomczewski, K.; Wrobel, K. Quasi-three-level converter for switched reluctance motor drives reducing current rising and falling times. IET Power Electron. 2012, 5, 1049–1057. [Google Scholar] [CrossRef]

- Sangshin, K.; Hamid, A.T. A hybrid converter system for high performance large induction motor drives. IEEE Trans. Energy Convers. 2005, 20, 504–511. [Google Scholar]

- Jin, Y.; Ali, E. Power electronic converters for 12/8 switched reluctance motor drives: A comparative analysis. In Proceedings of the 2014 IEEE Transportation Electrification Conference and Expo (ITEC 2014), Dearborn, MI, USA, 15–18 June 2014; pp. 1–6. [Google Scholar]

- Piotr, B. Power electronic converters in DC microgrid. In Proceedings of the 2007 Compatibility in Power Electronics (CPE 2007), Gdansk, Poland, 29 May–1 June 2007. [Google Scholar]

- Zhenhua, J.; Lijun, K.; Roger, A.D. Flexible multiobjective control of power converter in active hybrid fuel cell/battery power sources. IEEE Trans. Power Electron. 2005, 20, 244–253. [Google Scholar]

- Rui, L.; Dianguo, X. Parallel operation of full power converters in permanent-magnet direct-drive wind power generation system. IEEE Trans. Ind. Electron. 2011, 60, 1619–1629. [Google Scholar]

- Md, A.; Liuchen, C. Reliability comparison of power electronic converters used in grid-connected wind energy conversion system. In Proceedings of the 2012 IEEE 3rd Power Electronics for Distributed Generation Systems (PEDG 2012), Aalborg, Denmark, 25–28 June 2012; pp. 323–329. [Google Scholar]

- Lari, N.; Joonas, P.; Anssi, M.; Tuomas, M.; Juha, H.; Juha, J.; Jukka, V.; Diego, T.L.; Seppo, V.; Teuvo, S. Photovoltaic generator as an input source for power electronic converters. IEEE Trans. Power Electron. 2013, 28, 3028–3038. [Google Scholar]

- Yi, D.; Ronald, G.H. Space-vector versus nearest-level pulse width modulation for multilevel converters. IEEE Trans. Power Electron. 2015, 30, 2962–2974. [Google Scholar]

- Xinyu, W.; Jinjun, L.; Shaodi, O.; Fei, M. Research on unbalanced-load correction capability of two power electronic transformer toplogies. IEEE Trans. Power Electron. 2015, 30, 3044–3056. [Google Scholar]

- Emanuel, S.; Cosmin, P.; Martin, O. Islanding detection search sequence for distributed power generators under AC grid faults. IEEE Trans. Power Electron. 2015, 30, 3106–3121. [Google Scholar]

- Dehong, Z.; Jin, Z.; Yang, L. Predictive torque control scheme for three-phase four-switch inverter-fed induction motor drives with DC-link voltages offset suppression. IEEE Trans. Power Electron. 2015, 30, 3309–3318. [Google Scholar]

- Zhengwei, L.; Xiyou, C. TMS320F28335 based phase-shift full-bridge ZVS DC/DC converter. Convert. Tech. 2012, 34, 60–61. [Google Scholar]

- Nalin, L.G.; Santanu, M.; Kapil, J. An inductor current sensing technique for digital controllers. In Proceedings of the 2014 IEEE 40th Industrial Electronics Society (IECON 2014), Dallas, TX, USA, 29 October–1 November 2014; pp. 4171–4177. [Google Scholar]

- Florian, B.; Ruwan, P.S.C.; Farhad, S.; Sumedha, R.; Arindam, G. Application notes and recommendations on using TMS320F28335 digital signal processor to control voltage source converters. In Proceedings of the 2014 Australasian Universities Power Engineering Conference (AUPEC 2014), Perth, Australia, 28 September–1 October 2014. [Google Scholar]

- Hongjun, C.; Kai, F.; Hao, X.; Kai, D. Implementation of hybrid control for bi-directional DC-DC converter. In Proceedings of the 2014 IEEE 4th Cyber Technology in Automation, Control, and Intelligent Systems (CYBER 2014), Hong Kong, China, 4–7 June 2014; pp. 669–674. [Google Scholar]

- Mor, M.P.; Shmuel, B.Y. Digital control of resonant converters: Resolution effects on limit cycles. IEEE Trans. Power Electron. 2010, 25, 1652–1661. [Google Scholar]

- Wajiha, S.; Hrishikesh, N. DSP-based control for reliable fuel cell power systems with input ripple current compensation. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008. [Google Scholar]

- Subramanya, B.; Nagaraja, H.N. A novel DSP based non inverting buck-boost converter for PV system. In Proceedings of the 2015 IEEE Signal Processing, Informatics, Communication and Energy Systems (SPICES), Kozhikode, India, 19–21 February 2015. [Google Scholar]

- Manisha, S.; Jil, S.; Chirag, C. Design, simulation and implementation of two phase interleaved bi-directional DC-DC converter. In Proceedings of the 2015 IEEE Electrical, Electronics, Signals, Communication and Optimization (EESCO), Visakhapatnam, India, 24–25 January 2015. [Google Scholar]

- Xiaoyu, J.; Dehong, X.; Shuailin, D.; Changsheng, H. A high power density and efficiency bi-directional DC/DC converter for electric vehicles. In Proceedings of the 2015 IEEE 9th Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Korea, 1–5 June 2015; pp. 874–880. [Google Scholar]

- Manu, J.; Praveen, K.J.; Matteo, D. Analysis of a bi-directional DC-DC converter topology for low power application. In Proceedings of the 1997 IEEE Electrical and Computer Engineering, Saint Jonas, NL, Canada, 25–28 May 1997; pp. 548–551. [Google Scholar]

- Shengyen, L.; Li, W.; Teming, L.; Anton, V.P. Integration of wind power and wave power generation systems using a DC microgrid. IEEE Trans. Ind. Appl. 2015, 51, 2753–2761. [Google Scholar]

- Shigenori, I.; Hirofumi, A. A bi-directional DC/DC converter for an energy storage system. In Proceedings of the 2007 IEEE 22nd Applied Power Electronics Conference (APEC 2007), Anaheim, CA, USA, 25 February–1 March 2007; pp. 761–767. [Google Scholar]

- Huafeng, X.; Donghua, C.; Shaojun, X. A ZVS bi-directional DC-DC converter for high-low voltage conversion. In Proceedings of the 2005 IEEE 31st Industrial Electronics Society (IECON 2005), Raleigh, NC, USA, 6–10 November 2005; pp. 1154–1158. [Google Scholar]

- Zahra, A.; Sheldon, S.W. Digital control of a bidirectional DC/DC switched capacitor converter for hybrid electric vehicle energy storage system applications. IEEE Trans. Smart Grid 2014, 5, 158–166. [Google Scholar]

- Qinglin, Z.; Yunhua, X.; Xiaoyi, J.; Weiyang, W.; Lingling, C. DSP-based closed-loop control of bi-directional voltage mode high frequency link inverter with active clamp. In Proceedings of the 2005 IEEE 14th Industry Applications Conference (IAS 2005), Kowloon, China, 2–6 October 2005. [Google Scholar]

- Rajesh, K.T. Close loop control analysis with feed-forward control of Cuk converter. In Proceedings of the 2014 IEEE India Conference (INDICON 2014), Pune, India, 11–13 December 2014; pp. 928–933. [Google Scholar]

- Lijun, J.; Guangyao, Y.; Miaomiao, J.; Yifan, C.; Haipeng, Z.; Ke, Z. Study of bi-directional DC-DC converter of micro-grid hybrid energy storage system. In Proceedings of the 2015 IEEE 10th Industrial Electronics and Applications (ICIEA 2015), Auckland, New Zealand, 15–17 June 2015; pp. 1166–1169. [Google Scholar]

- Amirnaser, Y. Control of an islanded distributed energy resource unit with load compensating feed-forward. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting, Pittsburgh, PA, USA, 20–24 July 2008. [Google Scholar]

- Yonggao, Z.; Liming, L.; Pengcheng, Z.; Xiaoyuan, L.; Yong, K.; Yanli, G. Double closed loop control and analysis for shunt inverter of UPFC. In Proceedings of the 2005 IEEE Electrical Machines and Systems (ICEMS 2005), Nanjing, China, 27–29 September 2005; pp. 1118–1123. [Google Scholar]

- Wenjuan, H.; Hui, L.; Yu, W.; Yu, G. The design and simulation of a teachingvirtual platform by combining LABVIEW and Simulink for undergraduates of Electrical Engineering. In Proceedings of the 2017 IEEE 20th Electrical Machines and Systems (ICEMS 2017), Sydney, Australia, 11–14 August 2017. [Google Scholar]

- Jin-Hyuk, P.; Hae-Gwang, J.; Kyo-Beum, L. Output current ripple reduction algorithms for home energy storage systems. Energies 2013, 6, 5552–5569. [Google Scholar]

- Haoping, Y.; Tao, W. Derating design for power supply module based on saber simulation. In Proceedings of the 2016 IEEE Prognostics and System Health Management Conference (PHM-Chengdu 2016), Chengdu, China, 19–21 October 2016. [Google Scholar]

- Batunlu, C.; Alrweq, M.; Albarbar, A. Effects of Power Tracking Algorithms on Lifetime of Power Electronic Devices Used in Solar Systems. Energies 2016, 9, 884. [Google Scholar] [CrossRef]

- Morfin, O.A.; Castañeda, C.E.; Valderrabano-Gonzalez, A.; Hernandez-Gonzalez, M.; Valenzuela, F.A. A Real-Time SOSM Super-Twisting Technique for a Compound DC Motor Velocity Controller. Energies 2017, 10, 1286. [Google Scholar] [CrossRef]

| Name | Number | Supporting Function | |

|---|---|---|---|

| Digital processor (TMS320F28335) | 1 | Load scripts and execute them when power up. | |

| FLASH chip (SST39 V800 A) | 1 | Store scripts, including variables and commands. | |

| Term-inals | Digital input ports | 6 | Get digital input signals from devices outside. |

| Digital output ports | 6 | Output digital signals produced from processor. | |

| PWM ports | 12 | Output PWM signals to control the switch state. | |

| Analog-to-digital ports | 16 | Sample analog signals. | |

| External data bus | 1 | Connect with other devices and make further expansion. | |

| Serial communication interface | 1 | Doing communications between control board and other devices. | |

| Controller Area Network (CAN) interface | 1 | Realize CAN bus communications. | |

| Encoder interface | 1 | Obtain signals about the velocity of motion systems. | |

| Group | Members | Introduction |

|---|---|---|

| 1 | regVar, setValue, add, minus, mux, div, sin, cos, tan, sqrt, atan, asin, acos, abs, limit, minOne, maxOne | Math operations |

| 2 | getIn0~getIn5, setOut0~setOut5 | Digital input/output |

| 3 | enablePwm, disPwm, getPwmState, pwm1A1B~pwm6A6B | PWM control |

| 4 | getAd0~getAd15 | Analog-to-digital conversion |

| 5 | ABtoXY, XYtoAB, XYtoLR, LRtoXY, ABtoDQ, DQtoAB | Axis frame conversion |

| 6 | pi0Run~pi9Run, pi0Reset~pi9Reset | Regulators for close-loop control |

| 7 | sciTx, sciRx, readDataBus, writeDataBus | Communications |

| 8 | comment, ifx, but, overIf, loopx, overLoop, nop, end, call, func, ret (x = Larger, Small, Equal, NotLarger, NotSmaller, NotEqual) | Control the flow chart of the scripts. The user can execute some scripts under certain conditions |

| Items | Values |

|---|---|

| L | 1 mH, 15 A |

| C | 1000 μF, 63 V |

| MOSFET type | 75NF75 |

| Driver circuit | HCPL315J |

| R | 16 Ω |

| Switching frequency | 5 kHz |

| Comparative Contents | Labview | Matlab | PSIM and Saber | dSPACE | ISCU |

|---|---|---|---|---|---|

| Components | Software (+hardware) (when extra toolbox is used) | Software (+hardware) (when extra toolbox is used) | Only software | Software + hardware | Software + hardware |

| Real time control | No | Yes | No | Yes | Yes |

| Real time variable observe & modification | No | No | No | Yes | Yes |

| Cost | $3085 | $2232 | $600 | $4732 | free |

| Open source | No | No | No | No | Yes |

| Easy to learn | No | No | Medium | Medium | Yes |

| For industrial | Yes | Yes | Yes | No | Yes |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Lu, Q. Using an Integrated Script Control Unit (ISCU) to Assist the Power Electronics Education. Energies 2017, 10, 1802. https://doi.org/10.3390/en10111802

Gao Z, Lu Q. Using an Integrated Script Control Unit (ISCU) to Assist the Power Electronics Education. Energies. 2017; 10(11):1802. https://doi.org/10.3390/en10111802

Chicago/Turabian StyleGao, Zhigang, and Qi Lu. 2017. "Using an Integrated Script Control Unit (ISCU) to Assist the Power Electronics Education" Energies 10, no. 11: 1802. https://doi.org/10.3390/en10111802

APA StyleGao, Z., & Lu, Q. (2017). Using an Integrated Script Control Unit (ISCU) to Assist the Power Electronics Education. Energies, 10(11), 1802. https://doi.org/10.3390/en10111802