A Comprehensive Study of Energy Conservation in Electric-Hydraulic Injection-Molding Equipment

Abstract

:1. Introduction

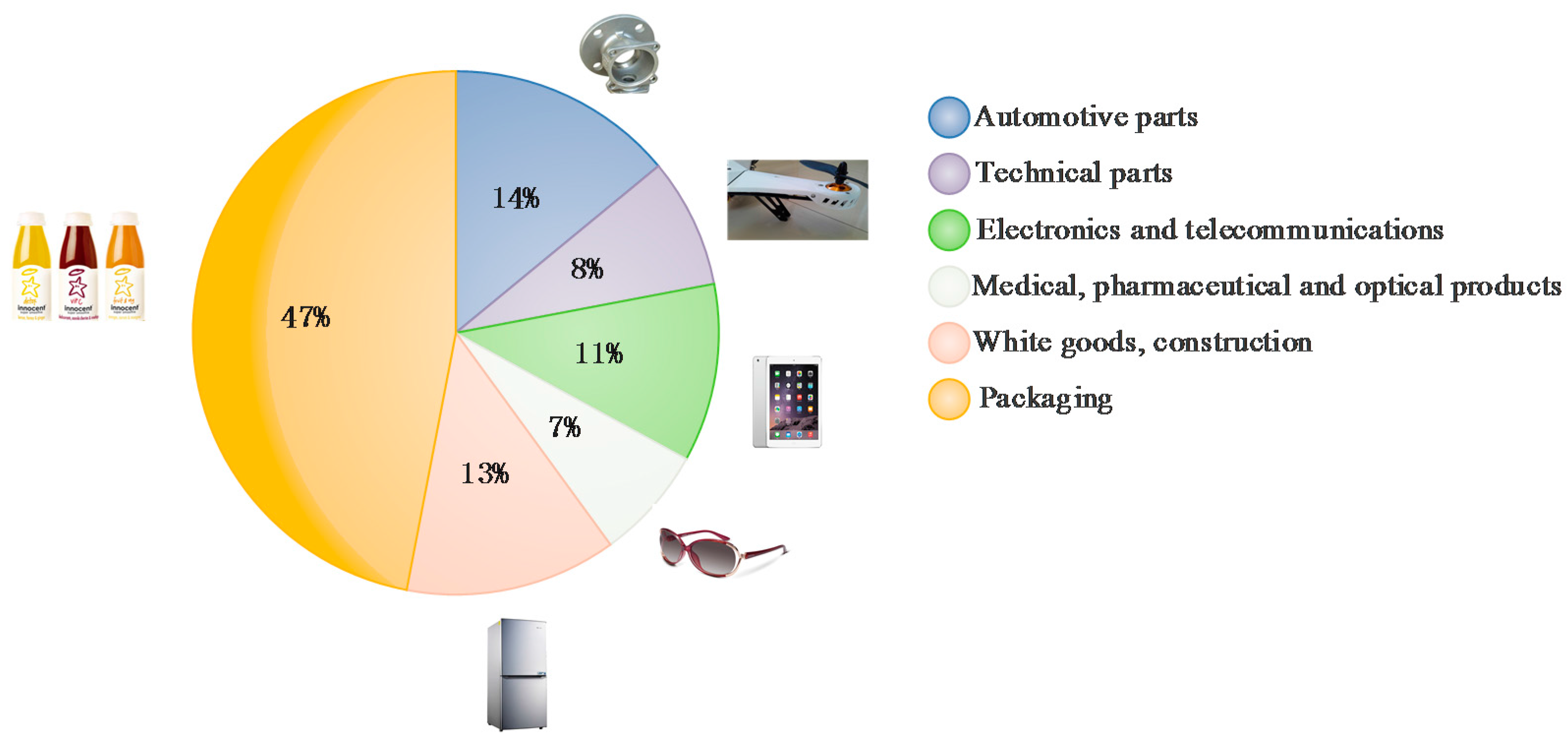

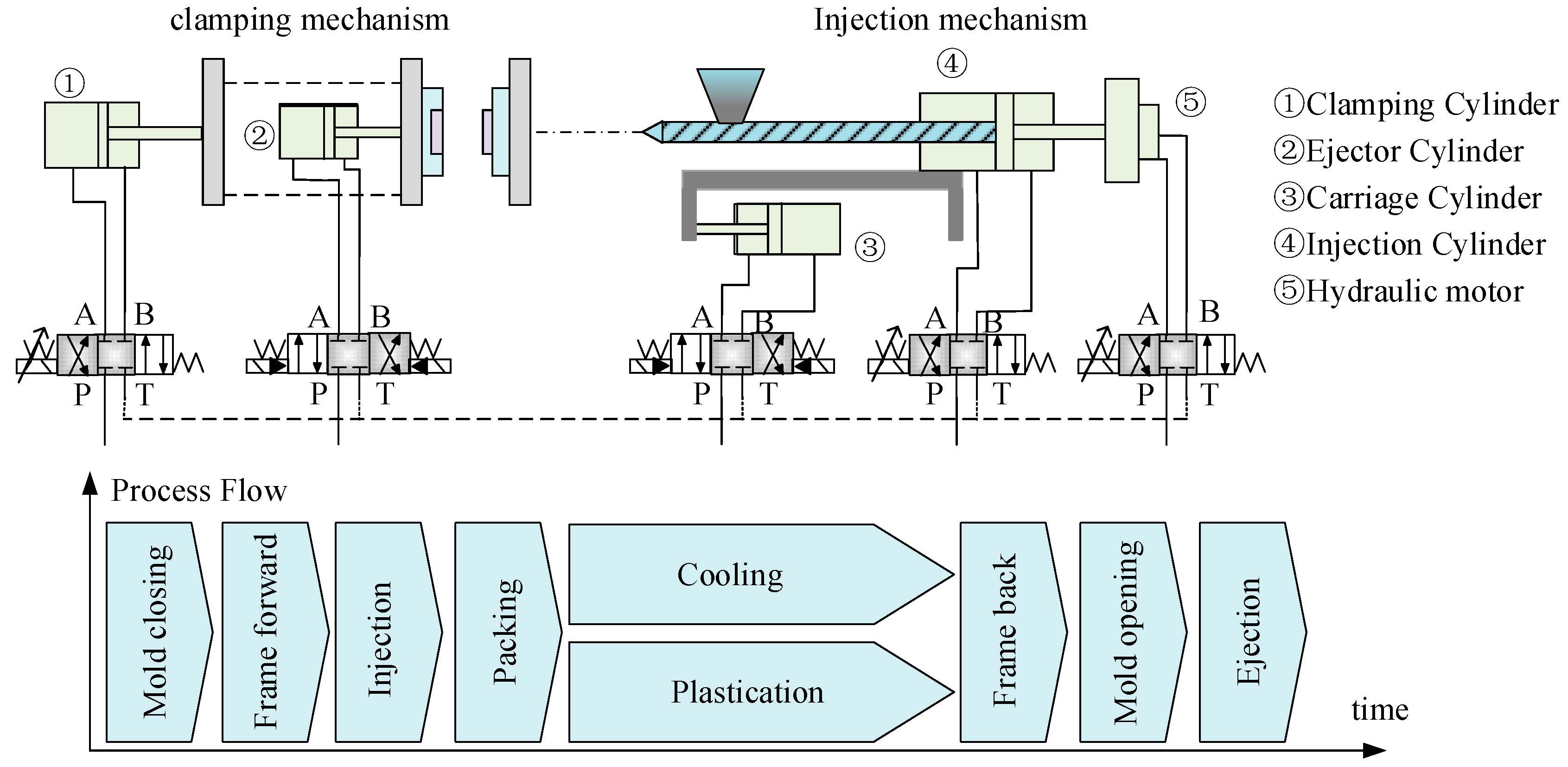

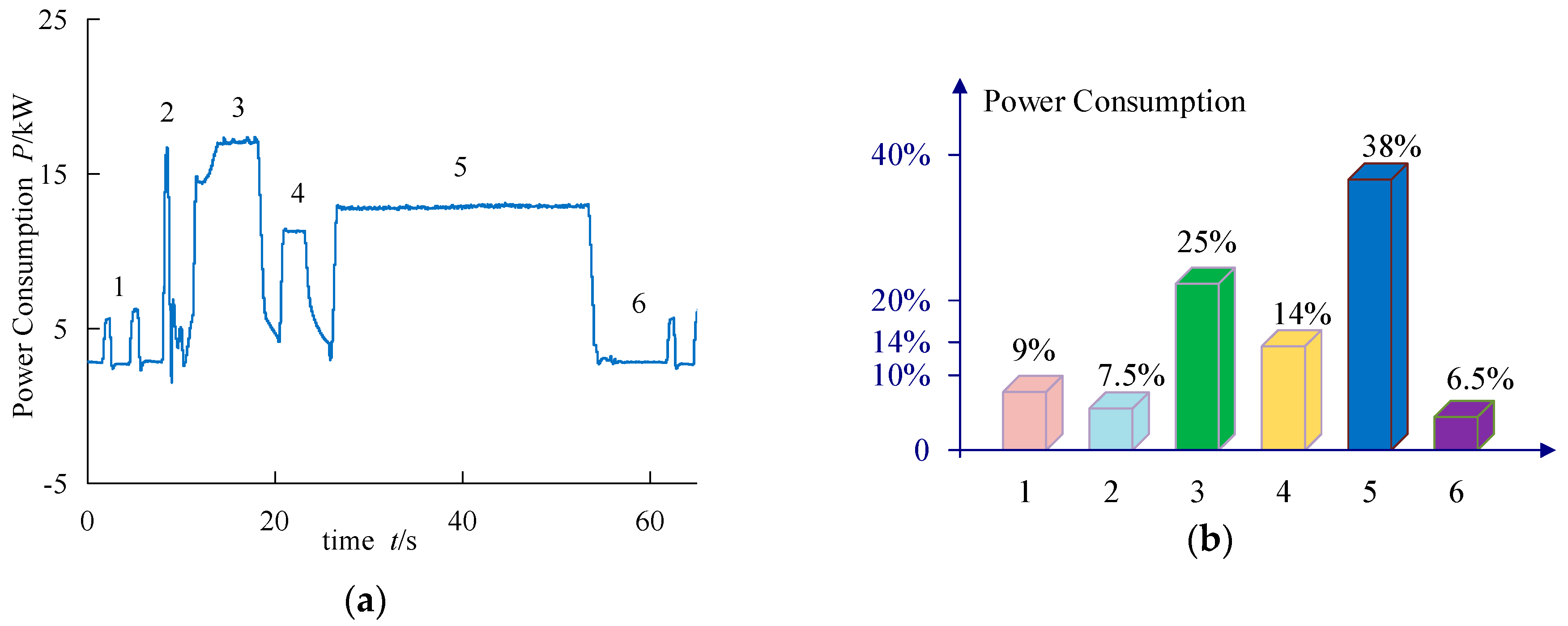

2. Evolvement and Energy Consumption Distribution of Injection-Molding Machines

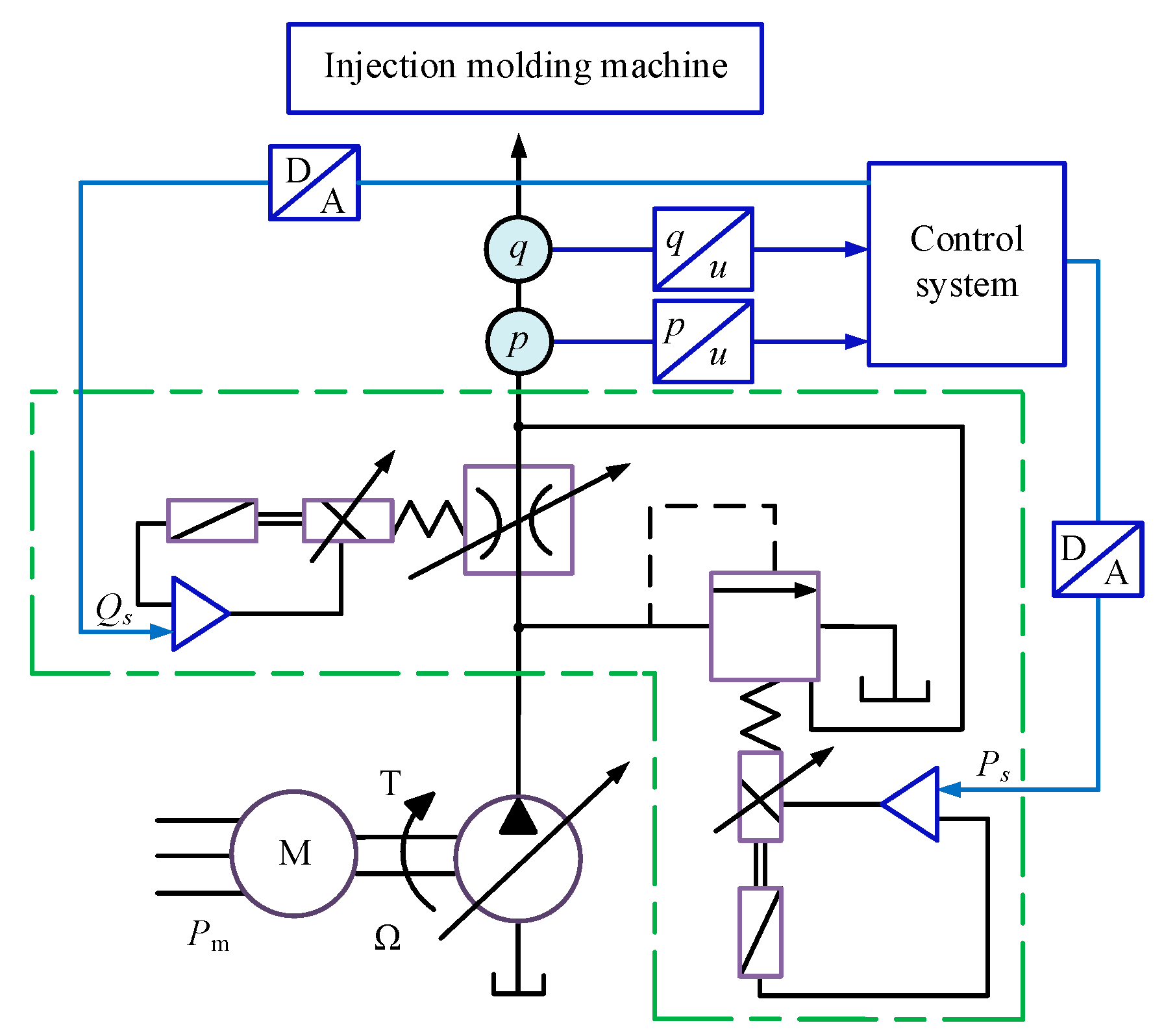

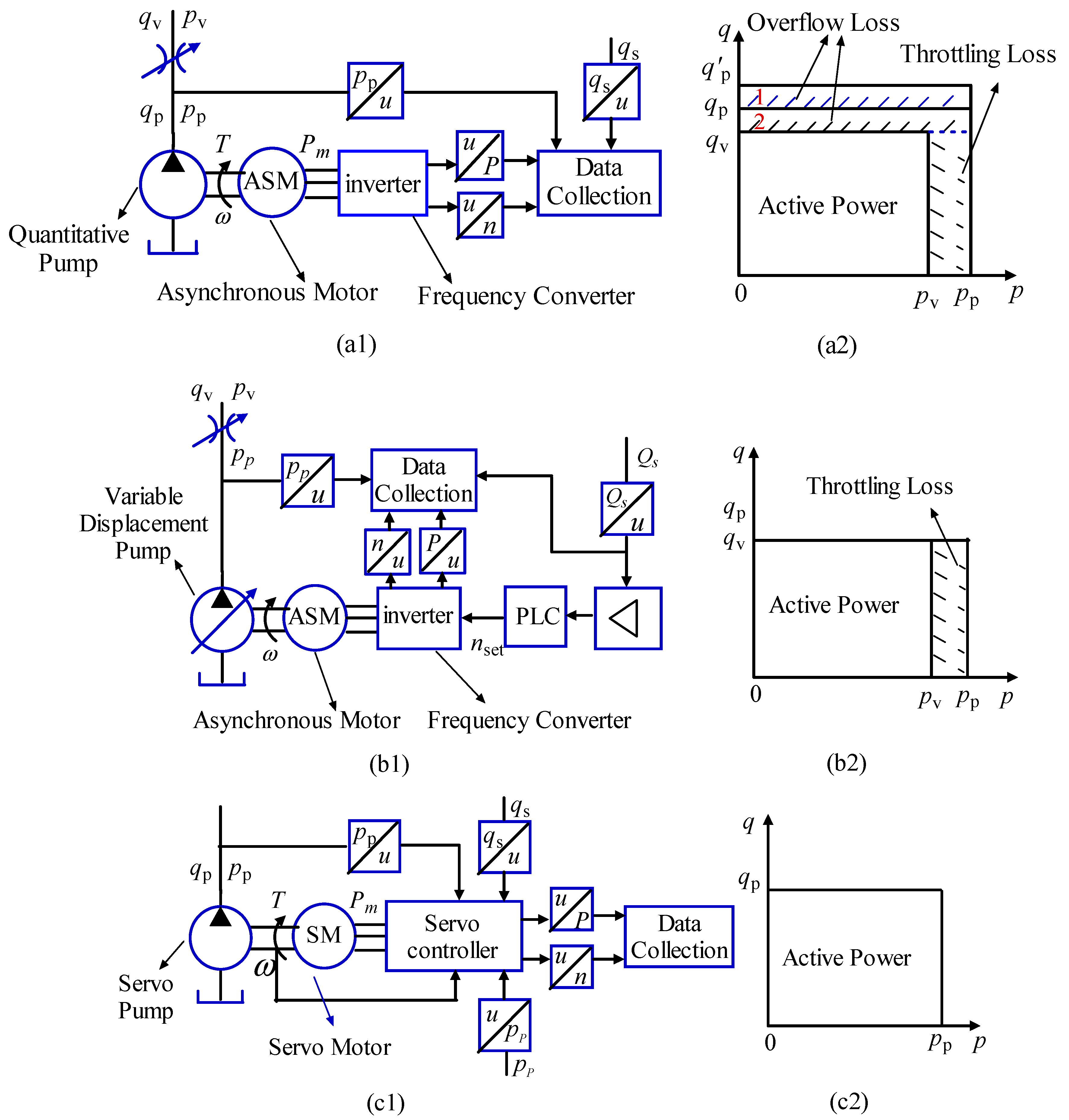

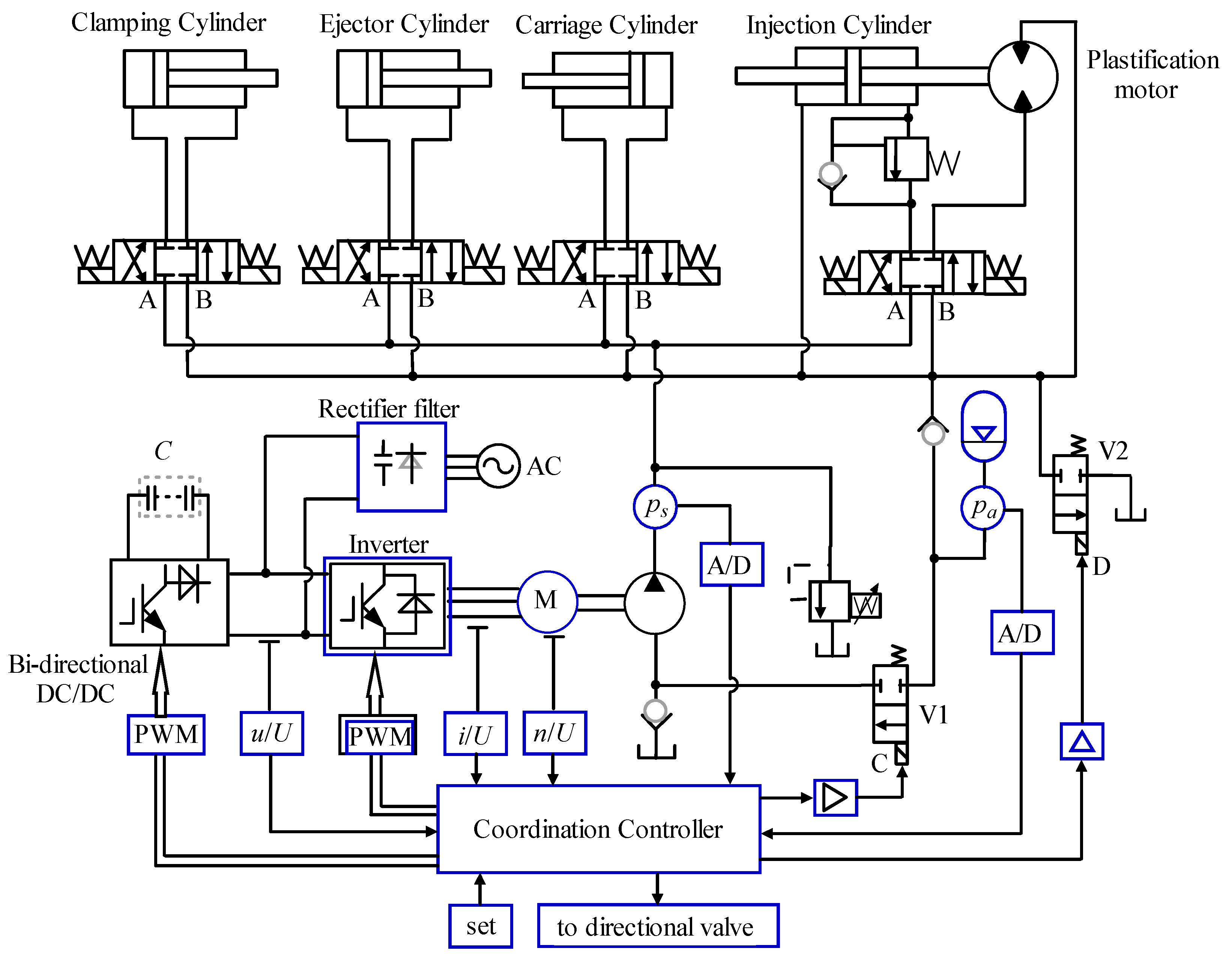

3. Drive Technology of Hydraulic IMM

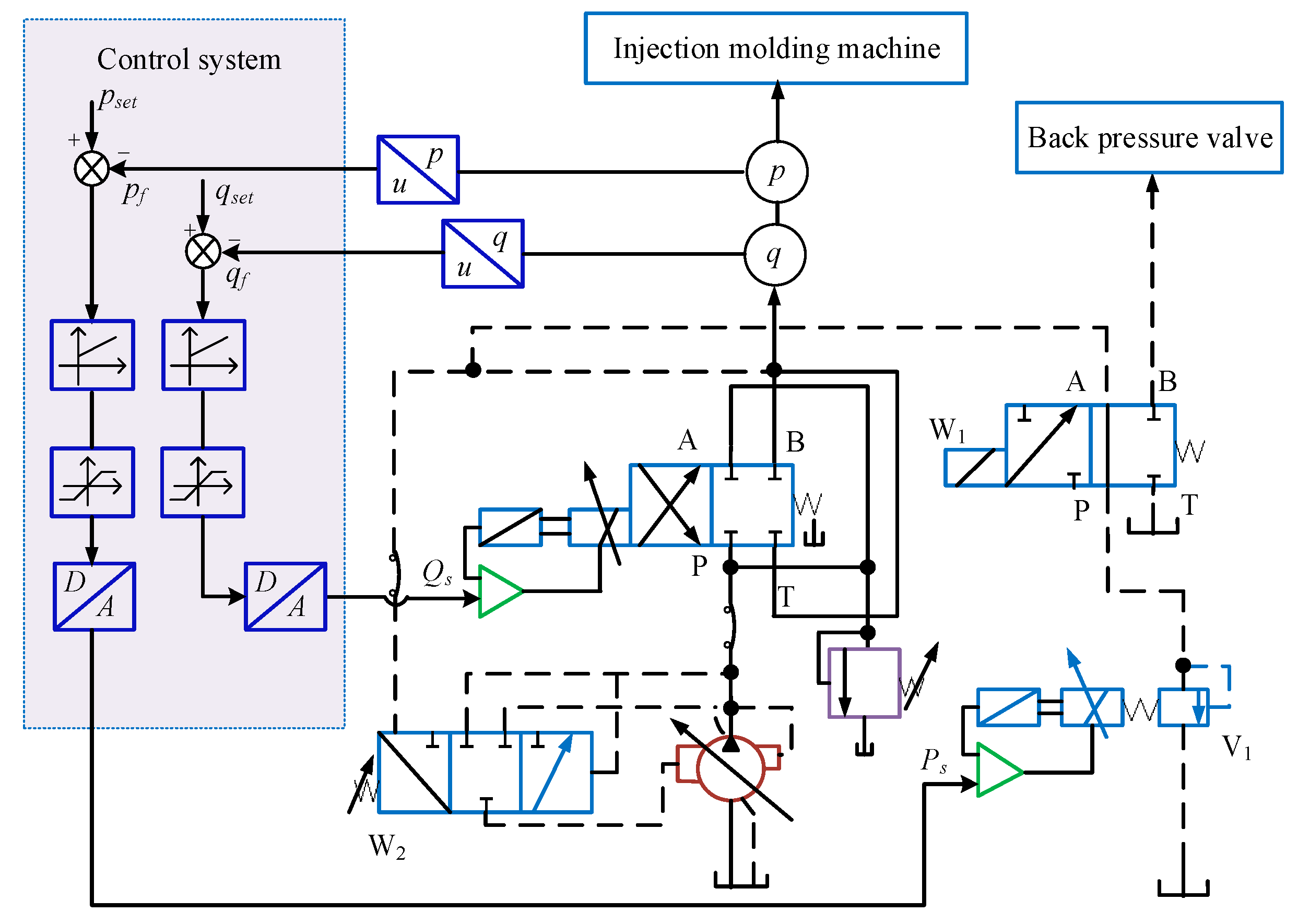

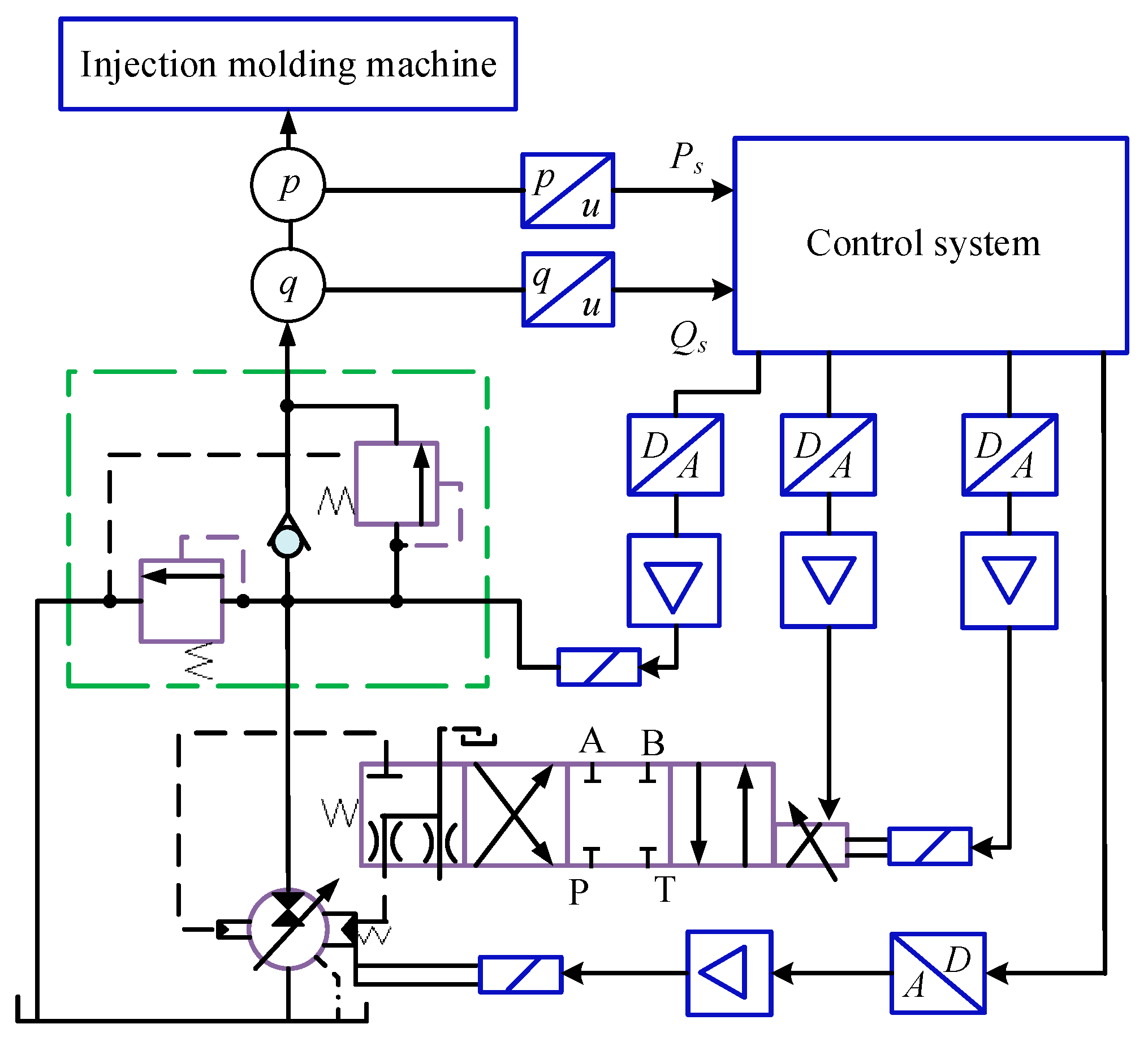

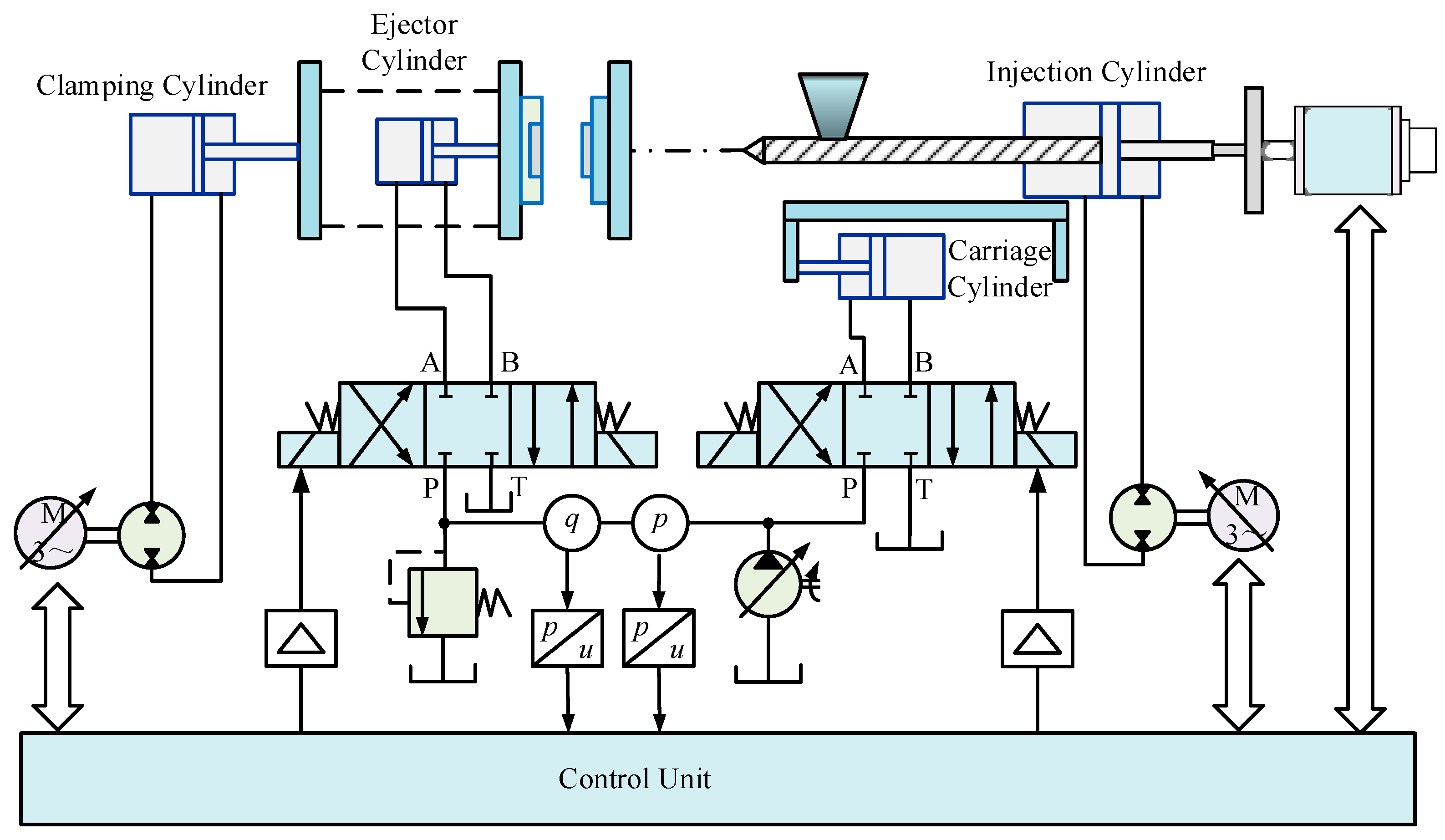

3.1. Energy Conservation Research on Hydraulic Circuits

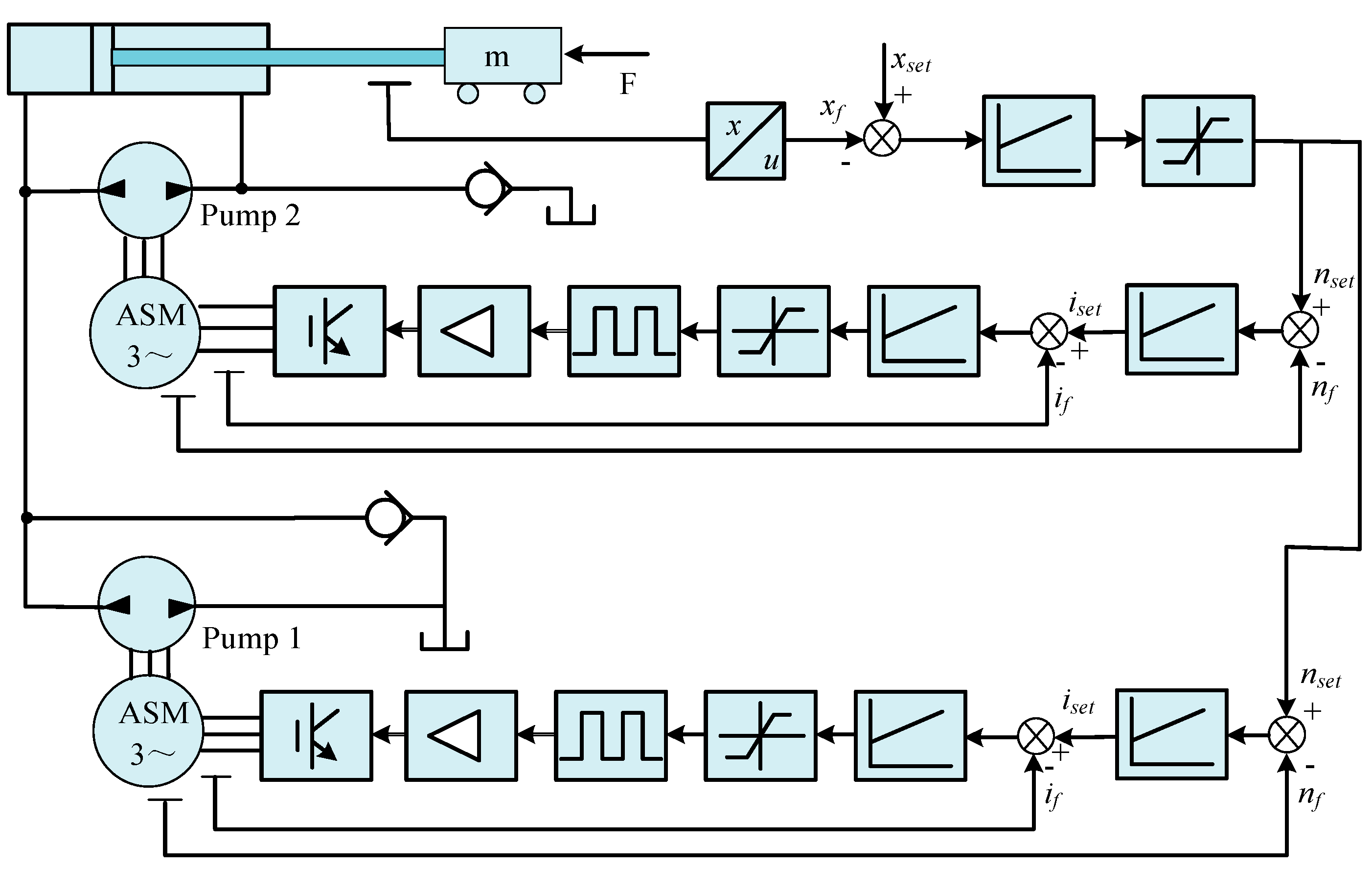

3.2. Energy Conservation Research on Electrical Circuits

4. Control Technology of IMMs

4.1. Energy Conservation Control Strategy

4.2. Energy Monitoring System

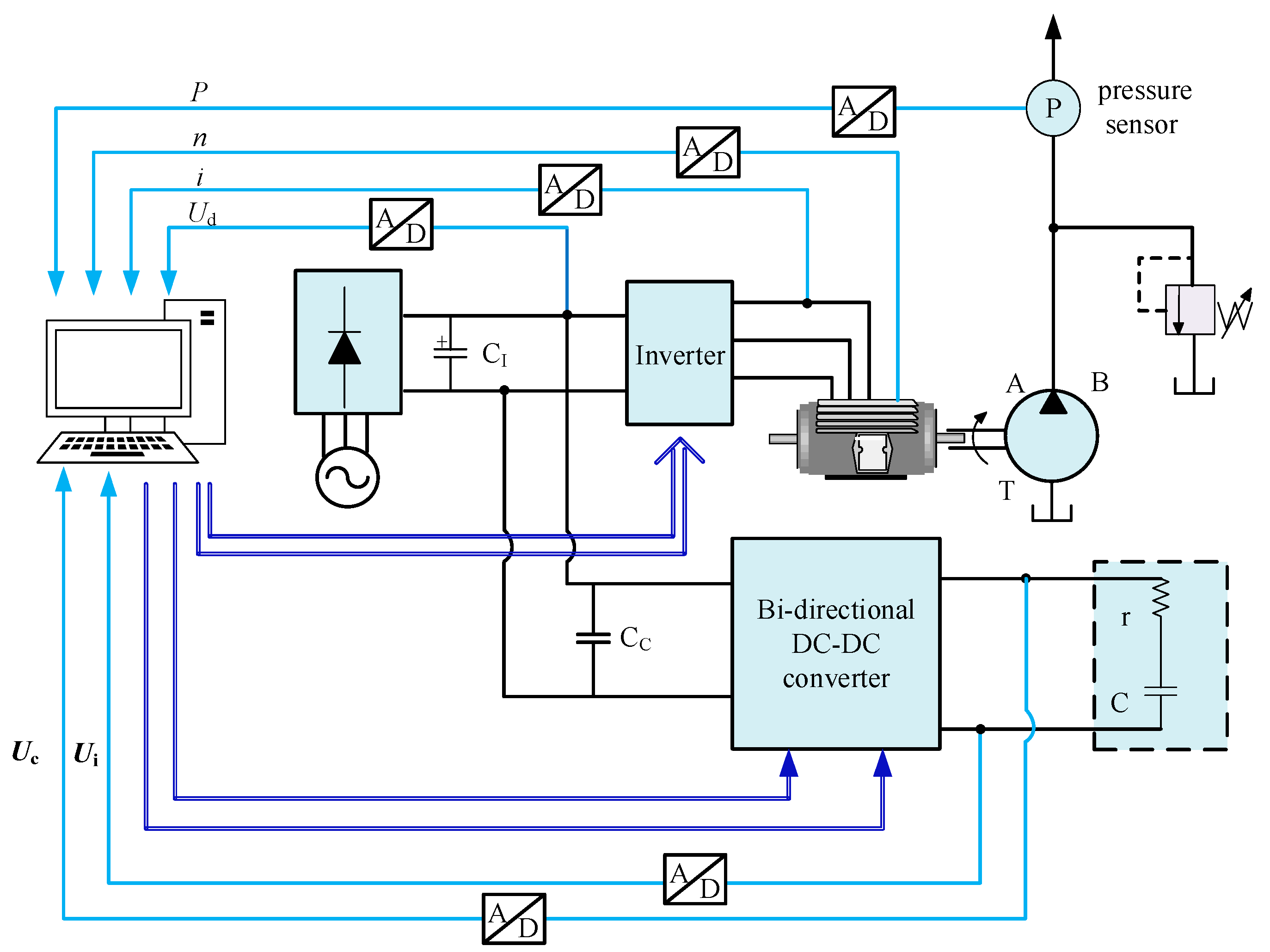

5. Energy Regeneration

5.1. Recovery and Reuse of Hydraulic Braking Energy

5.2. Recovery and Reuse of Electric Braking Energy

6. Challenges and Prospects

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviation

| IMM | injection-molding machine | ADC | analog-to-digital converter |

| P/Q | pressure and flow | PID | proportional integral derivative |

| AC | alternating current | PI | proportional integral |

| ASM | asynchronous motor | CAD | Computer-aided design |

| PLC | programmable logic controller | DC/DC | direct current to direct current |

| DC | direct current | PWM | pulse width modulation |

| SM | servo motor | A/D | analog to digital |

| DSP | digital signal processor | D/A | digital to analog |

References

- Erne, B. Injection Molding Machines Benefit from Technology-Neutral Design Approach. Available online: http://www.moog.com/literature/ICD/moogindustrialnewsletterissue34.pdf (accessed on 26 June 2013).

- Global and China Injection Molding Machine Industry Report, 2014–2016. Available online: http://www.researchinchina.com/Htmls/Report/2015/9074.html (accessed on 23 December 2016).

- Energy Management in Plastics Processing. Available online: http://www.pcn.org/Technical%20Notes%20-%20Energy%20(1%20-%208).pdf (accessed on 22 March 2017).

- Understanding Energy Consumption in Injection Moulding Machine. Available online: http://www.pitfallsinmolding.com/energyeffic1.html (accessed on 25 March 2016).

- China Plastics Injection Machine Market Panorama Survey and Development Trend Research Report during 2015–2022 Years. Available online: http://www.chyxx.com/research/201508/340721.html (accessed on 25 August 2015).

- Energy Utilization in Injection Molding. Available online: http://www.energy.ca.gov/process/pubs/energy_utilizatn_in_inj.pdf (accessed on 25 December 2016).

- In the Next Five Years, the Consumption of Injection Molding Machines Is Likely to Exceed 2 Times the Power Generation Capacity of the Three Gorges. Available online: http://www.wanguan.com/news/32112.html (accessed on 17 October 2016).

- Godec, D.; Rujnic-Sokele, M.; Šercer, M. Processing parameters influencing energy efficient injection moulding of plastics and rubbers/Utjecaj parametara prerade na energijski u inkovito injekcijsko pre anje plastike i gume. Polimeri 2013, 33, 112–117. [Google Scholar]

- Liebig, G. Comparison of the Performance of a Hybrid and an All-electric Machine. Kunststoffe/Plast. Eur. 2002, 7, 16–17. [Google Scholar]

- Schut, J.H. Does Low Constant Pressure Injection Molding Work? Available online: https://plasticsengineeringblog.com/2015/09/ (accessed on 31 August 2015).

- Akasaka, N. Design Method by use of Control Similarity Principle applied for a Load Simulator of Electric-motor Driven Injection Molding Machine. In Proceedings of the International Conference on Control, Automation and system, Seoul, Korea, 14–17 October 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Schut, J.H. Eco-Molding: More Power for Less Energy: How Much More Efficient Can Injection Molding Machines Get? Plastics Engineering: Sheboygan, WI, USA, 2015; Available online: http://read.nxtbook.com/wiley/plasticsengineering/march2015/coverstory_ecomolding.html (accessed on 5 April 2016).

- Duran-Gomez, J.L.; Enjeti, P.N.; Jouanne, A.V. An approach to achieve ride-through of an adjustable speed drive with flyback converter modules powered by super capacitors. IEEE Trans. Ind. Appl. 2002, 3, 514–522. [Google Scholar] [CrossRef]

- Rodriguez, J.R.; Dixon, J.W.; Espinoza, J.R.; Pontt, J.; Lezana, P. PWM regenerative rectifiers: State of the art. IEEE Trans. Ind. Electron. 2005, 52, 5–22. [Google Scholar] [CrossRef]

- Akiyoshi, H.; Hiraki, E.; Tanaka, T.; Okamoto, M.; Matsuo, T.; Ochi, K. Peak Power Shaving of an Electric Injection Molding Machine with Supercapacitors. IEEE Trans. Ind. Appl. 2014, 50, 1114–1120. [Google Scholar] [CrossRef]

- Quilumba, F.L.; Lee, L.K.; Lee, W.J.; Harding, A. Improving hydraulic system energy efficiency with high performance hydraulic fluids. IEEE Trans. Ind. Appl. 2014, 50, 1313–1321. [Google Scholar] [CrossRef]

- Thomas, A.R.; Speight, R.G.; Annareddy, M. Using injection moulding simulation to develop environmentally friendly products. Plast. Rubber Compos. 2013, 37, 184–189. [Google Scholar] [CrossRef]

- Chiang, M.H.; Lee, L.W.; Tsai, J.J. The concurrent implementation of high velocity control performance and high energy efficiency for hydraulic injection moulding machines. Int. J. Adv. Manuf. Technol. 2004, 23, 256–262. [Google Scholar] [CrossRef]

- Shuo, W.; Ji, Y.; Weian, Z.; Min, K. Fuzzy control of the ram velocity in energy-saving servo injection molding machines. In Proceedings of the International Technology and Innovation Conference, Xi’an, China, 12–14 October 2009; IET: London, UK, 2009. [Google Scholar] [CrossRef]

- Ren, B.; Zhang, S.Y.; Tan, J.R. Structural Scheme Optimization Design for the Stationary Platen of a Precision Plastic Injection Molding Machine. Chin. J. Mech. Eng. 2014, 27, 714–721. [Google Scholar] [CrossRef]

- Jeong, B.H.; Kim, N.H.; Lee, K.Y. Optimized Digital Proportional Integral Derivative Controller for Heating and Cooling Injection Molding System. J. Electr. Eng. Technol. 2015, 10, 1383–1388. [Google Scholar] [CrossRef]

- Socks, M. The Promise of All-Electric Injection Molding Machines: A Promise Kept? ACEEE Summer Study on Energy Efficiency in Industry 2005; Energy Efficiency in Industry: Washington, DC, USA; pp. 155–166. Available online: http://aceee.org/files/proceedings/2005/data/papers/SS05_Panel01_Paper15.pdf (accessed on 5 April 2016).

- Li, P. Modern Injection Molding Machine Control, 1st ed.; China Light Industry Press: Beijing, China, 2004; pp. 23–27. ISBN 7501932824. [Google Scholar]

- Madan, J.; Mani, M.; Kevin, W.L. Characterizing Energy Consumption of the Injection Molding Process. In Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference, Madison, WI, USA, 10–14 June 2013. [Google Scholar]

- Competition Bubbles Up Again in Physical Foam Molding. Available online: https://plasticsengineeringblog.com/2016/04/14/competition-bubbles-up-again-in-physical-foam-molding/ (accessed on 8 April 2016).

- Zhang, H.J. Research on Variable Speed Pump—Controlled Differential Cylinder and Low Energy Consumption Injection Molding Machine. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2011. [Google Scholar]

- Energy Efficiency in Plastics Processing Practical Worksheets for Industry. Available online: http://www.tangram.co.uk/TI-Energy%20Worksheets%20(Plastics)%20-%20Tangram.PDF (accessed on 20 April 2016).

- Liu, H.B.; Zhu, X.H.; Zhu, Z.D.; Sun, H.P. The Energy-saving Application for Injection Molding Machine. Chin. Hydraul. Pneum. 2007, 8, e1001055. [Google Scholar] [CrossRef]

- Moog-Plastics-Injection-Molding-Overview-en. Available online: http://www.moog.com/literature/ICD/Moog-Plastics-InjectionMolding-Overview-en.pdf (accessed on 18 April 2017).

- Wen, S.P.; Jiang, J.Q. The latest development and application of energy saving control technique for injection molding machine. Eng. Plast. Appl. 2006, 34, 59–62. (In Chinese) [Google Scholar] [CrossRef]

- Electrohydraulic Control in Plastic Parts Production. Available online: http://www.hydraulicspneumatics.com/200/TechZone/HydraulicValves/Article/False/45407/TechZone-HydraulicValves (accessed on 25 April 2017).

- Quan, L.; Li, F.L. Energy saving principle and latest technology of electro hydraulic control system for injection molding machine. Mach. Tool Hydraul. 1999, 5, 6–7. (In Chinese) [Google Scholar] [CrossRef]

- Hong, S.P.; Nguyen, T.T. Optimization of injection molding process for car fender in consideration of energy efficiency and product quality. J. Comput. Des. Eng. 2014, 1, 256–265. [Google Scholar] [CrossRef]

- Quan, L. Injection Molding Machine System Drived by Mechatronics and Electro-Hydraulic Compound Control. CN 200610012479.6, 7 March 2006. [Google Scholar]

- Concise Technologies. Energy Saving and Other Benefits of AC Drive Systems for Injection Molding. Available online: http://www.conciseusa.com/eng_sav/ (accessed on 20 April 2016).

- Frequency Inverters. Inverter in Injection Molding Machine Advantages. Available online: http://www.frequencyinverters.org/inverter-in-injection-molding-machine-advantages-609325.html (accessed on 15 April 2016).

- Yu, D.; Lu, G.; Zhou, Y.; Zhang, T.; Yu, D. MATLAB Modeling and Analysis of the Electro-Hydraulic Control System of Injection Molding Machine. Available online: https://link.springer.com/chapter/10.1007/978-3-642-54236-7_69 (accessed on 20 April 2016).

- Muharnmad, B.N.; Wang, S.P. Optimization Based on Convergence Velocity and Reliability for Hydraulic Servo System. Chin. J. Aeronaut. 2009, 22, 407–412. [Google Scholar] [CrossRef]

- Chol, S.H.; Räcklebe, S.; Helduser, S. Position tracking control of a clamp-cylinder for energy-saving injection moulding machines with electric-hydrostatic drives. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2009, 223, 479–491. [Google Scholar] [CrossRef]

- Smart Watt. 3 Ways to Increase Energy Efficiency in Injection Molding. Available online: http://news.smartwattinc.com/blog/3-ways-to-increase-energy-efficiency-in-injection-molding (accessed on 6 May 2016).

- Rahmfeld, R. Development and Control of Energy Saving Hydraulic Servo Drives for Mobile Systems; VDI: Duisburg, Gemany, 2002; pp. 1–127. ISBN 9783183527120. [Google Scholar]

- Helduser, S. Moderne hydraulische Antriebe und Steuerungen am Beispiel von Kunststoff -Spritzgieß- maschinen. Ölhydraulik Pneum. 1995, 10, 720–725. [Google Scholar]

- Helduser, S. Innovationen im Maschinenbau durch fluidtechnische Komponenten und Systeme. Ölhydraulik Pneum. 1996, 6, 380–395. [Google Scholar]

- Helduser, S. Electric-hydrostatic drive—An innovative energy-saving power and motion control system. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 1999, 213, 427–437. [Google Scholar] [CrossRef]

- Practical Optimization: A Gentle Introduction. Available online: http://www.sce.carleton.ca/faculty/chinneck/po.html (accessed on 2 March 2016).

- Neubert, T.; Helduser, S. Principle to closed loop control differential cylinder with double speed variable pumps and single loop control signal. Chin. J. Mech. Eng. 2004, 17, 85–88. [Google Scholar] [CrossRef]

- Imamura, T.; Sawada, Y.; Ichikawa, M.; Nakamura, H. Energy-saving hybrid hydraulic system comprising highly efficient IPM motor and inverter, for injection molding and manufacturing machine. In Proceedings of the JFPS International Symposium on Fluid Power, Toyama, Japan, 15–18 September 2008; pp. 117–120. [Google Scholar] [CrossRef]

- Chiang, M.H.; Chen, C.C. The high response and high efficiency velocity control of a hydraulic injection molding machine using a variable rotational speed electro-hydraulic pump-controlled system. Int. J. Adv. Manuf. Technol. 2009, 43, 841–851. [Google Scholar] [CrossRef]

- Wang, S.; Ying, J.; Chen, Z.C.; Feng, Y. A new fuzzy self-tuning method for controlling packing pressure of a high-accuracy injection molding machine. Zhejiang Daxue Xuebao Gongxue Ban J. Zhejiang Univ. 2011, 45, 1370–1375. [Google Scholar] [CrossRef]

- Cheng, G.; Hua, P. Fuzzy control of injection pressure of injection molding machines based on a nonlinear function. J. Zhejiang Univ. Eng. Sci. 2011, 45, 1382–1386. [Google Scholar] [CrossRef]

- Peng, Y. Application and Control Strategy of Servo Motor Driven Constant Pump Hydraulic System in Precision Injection Molding. J. Mech. Eng. 2011, 47, 800–809. [Google Scholar] [CrossRef]

- Zhang, H.J.; Quan, L.; Li, B. Comparative Study on Energy Efficiency of the Electro-hydraulic Control System in Injection Molding Machine. J. Mech. Eng. 2012, 48, 180. [Google Scholar] [CrossRef]

- Chiang, M.H.; Yeh, Y.P.; Yang, F.L.; Chen, Y.N. Integrated control of clamping force and energy-saving in hydraulic injection moulding machines using decoupling fuzzy sliding-mode control. Int. J. Adv. Manuf. Technol. 2005, 27, 53–62. [Google Scholar] [CrossRef]

- Wang, M.S.; Chang, C.M. DSP-Based adaptive fuzzy velocity/pressure control of injection molding machines. J. Chin. Inst. Eng. 2007, 30, 819–827. [Google Scholar] [CrossRef]

- Wei, Z.; Feng, Y.X.; Tan, J.R.; Wang, J.L.; Li, Z.K. Multi-objective performance optimal design of large-scale injection molding machine. Int. J. Adv. Manuf. Technol. 2009, 41, 242–249. [Google Scholar] [CrossRef]

- Lin, J.; Lian, R.J. Hybrid self-organizing fuzzy and radial basis-function neural-network controller for gas-assisted injection molding combination systems. Mechatronics 2010, 20, 698–711. [Google Scholar] [CrossRef]

- Liu, T.; Jiang, J. Energy control strategy research of parallel hydraulic hybrid vehicle. Dongnan Daxue Xuebao 2010, 40, 111–116. [Google Scholar] [CrossRef]

- Wang, S.; Ying, J.; Chen, Z.C.; Cai, K. Grey fuzzy PI control for packing pressure during injection molding process. J. Mech. Sci. Technol. 2011, 25, 1061–1068. [Google Scholar] [CrossRef]

- Feng, G.; Qi, J.B.; Zhang, C.G.; Zhang, Y. Research on Fuzzy-PID Compound Control in Inverter-Driven Energy-Saving Technology for Injection Molding Machine. Adv. Mater. Res. 2012, 538–541, 1057–1060. [Google Scholar] [CrossRef]

- Lu, N.Y.; Gong, G.X.; Yang, Y.; LU, Jian-Hua. Multi-objective process parameter optimization for energy saving in injection molding process. J. Zhejiang Univ. Sci. A 2012, 13, 382–394. [Google Scholar] [CrossRef]

- Qi, F.; Li, S.; Zhou, Y.; Zhou, Z. Design of Servo Control System of Precision Injection for Electro-Hydraulic Hybrid Injection Machine. Available online: https://link.springer.com/chapter/10.1007/978-3-642-54236-7_66 (accessed on 20 April 2016).

- Xu, B.; Cheng, M.; Yang, H.Y.; Zhang, J.H. An energy-saving hydraulic servo system with safety consideration for pipe fatigue tests. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2014, 228, 486–499. [Google Scholar] [CrossRef]

- Peng, Y.G.; Wang, J.; Wei, W. Model predictive control of servo motor driven constant pump hydraulic system in injection molding process based on neurodynamic optimization. J. Zhejiang Univ. Sci. 2014, 15, 139–146. [Google Scholar] [CrossRef]

- Monitor on Energy Consumption with Rexroth Software Rexroth IndraMotion MTX System Software includes An Energy and Power Monitor. Available online: https://www.boschrexroth.com/en/xc/company/press/index2-1714 (accessed on 15 August 2016).

- Energy Monitoring System of Injection Molding Machine Can Save 28%~60% Electricity. Available online: http://www.starmasterhk.com/down/winstar6e.pdf (accessed on 15 August 2016).

- Weissman, A.; Ananthanarayanan, A.; Gupta, S.K.; Sriram, R.D. A Systematic Methodology for Accurate Design-Stage Estimation of Energy Consumption for Injection Molded Parts. In Proceedings of the ASME 2010 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Montreal, QC, Canada, 15–18 August 2010. [Google Scholar] [CrossRef]

- Pang, C.K.; Le, C.V.; Gan, O.P.; Xiang, M.C.; Zhang, D.H.; Luo, M.; Chan, H.L.; Lewis, F.L. Intelligent energy audit and machine management for energy-efficient manufacturing. In Proceedings of the 2011 IEEE 5th International Conference on Cybernetics and Intelligent Systems (CIS), Qingdao, China, 17–19 September 2011. [Google Scholar] [CrossRef]

- Chee, X.M.; Le, C.V.; Zhang, D.H.; Luo, M.; Pang, C.K. Intelligent identification of manufacturing operations using in-situ energy measurement in industrial injection moulding machines. In Proceedings of the IECON 2011—37th Annual Conference on IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011. [Google Scholar] [CrossRef]

- Mianehrow, H.; Abbasian, A. Energy monitoring of plastic injection molding process running with hydraulic injection molding machines. J. Clean. Prod. 2017, 148, 804–810. [Google Scholar] [CrossRef]

- Martowibowo, S.Y.; Kaswadi, A. Optimization and Simulation of Plastic Injection Process using Genetic Algorithm and Moldflow. Chin. J. Mech. Eng. 2017, 30, 398–406. [Google Scholar] [CrossRef]

- Jarosch, P.; Wortberg, J.; Kamps, T. Comparison of drive concepts on injection molding machines under production conditions. In Proceedings of the ANTEC 2004—Annual Technical Conference Proceedings, Chicago, IL, USA, 16–20 May 2004. [Google Scholar]

- Quan, L.; Liu, S. Improve the kinetic performance of the pump controlled clamping unit in plastic injection molding machine with adaptive control strategy. Chin. J. Mech. Eng. 2006, 19, 9–13. [Google Scholar] [CrossRef]

- Robin, K. Part 3: Reducing energy costs-Focus on injection molding. Mod. Plast. Worldw. 2006, 83, 36–37. [Google Scholar]

- Azuddin, M.; Choudhury, I.A.; Taha, Z. Development and performance evaluation of a low-cost custom-made vertical injection molding machine. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 79–86. [Google Scholar] [CrossRef]

- Xu, M. Analysis and Design of Energy Regulation Device in Energy Regulation Based Variable Speed Electro-hydraulic Control System. J. Mech. Eng. 2010, 46, 136–142. [Google Scholar] [CrossRef]

- Yang, Z.; Wei, B.; Qu, J. Application of accumulator to entire hydraulic injection molding machine and its energy-saving effect analysis. J. Sichuan Univ. 2010, 42, 243–248. [Google Scholar]

- Haitian Mars Series. Available online: http://www.acwei.com/wp-content/uploads/2012/07/MARS-GENERAL-BROCHURE.pdf (accessed on 15 August 2017).

- Hu, X.F.; Wang, L.; Gong, C.; Xiao, L.; Chen, X. Harmonic analysis and suppression strategies of grid current for renewable energy grid integration system. Proc. CSEE 2010, 30, 167–170. [Google Scholar]

- Giorgetti, F.; Pastena, L.; Tarantino, A.; Velotto, F. Energy saving by onboard storage. In Proceedings of the International Symposium on Power Electronic, Electrical Drives, Automation and Motion, Taormina, Italy, 23–26 May 2006. [Google Scholar] [CrossRef]

- Cheng, Y.; Mierlo, J.V.; Lataire, P. Methods of Configuring and Managing Super Capacitor Energy Storage as Peak Power Unit. Eur. Power Electron. Drives 2008, 18, 42–49. [Google Scholar] [CrossRef]

- Cao, B.; Cao, J.; Li, J.W.; Xu, H.; Xu, P. Ultracapacitor with applications to electric vehicle. J. Xian Jiaotong Univ. 2008, 42, 1317–1322. [Google Scholar] [CrossRef]

- Brabetz, L.; Ayeb, M.; Tellmann, D. Efficient Vehicle Power Supply by Adaptive Energy, Charge and Heat Management of an Alternator—Super Capacitor System. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2009, 2, 359–366. [Google Scholar] [CrossRef]

- Rao, J.; Li, Y. Control strategies of a new hybrid multilevel inverter with energy storage. Trans. China Electrotech. Soc. 2009, 24, 103–109. [Google Scholar] [CrossRef]

- Mishima, T.; Hiraki, E.; Nakaoka, M. A High Frequency-Link Bidirectional DC-DC Converter for Super Capacitor-Based Automotive Auxiliary Electric Power Systems. J. Power Electron. 2010, 10, 27–33. [Google Scholar] [CrossRef]

- Takahashi, K.; Okamoto, M.; Hiraki, E.; Tanaka, T. Simulation analysis of energy-saving effect of an energy recovery system for electric motor drive system in the injection molding machine. In Proceedings of the Power Electronics and Motion Control Conference, Ohrid, Macedonia, 6–8 September 2010; Volume 398. [Google Scholar] [CrossRef]

- Xu, A.; Xie, S.; Yao, Y. Regenerating Energy Storage System Based on Ultra-Capacitor for Urban Railway Vehicles. Trans. China Electrotech. Soc. 2010, 25, 117–123. [Google Scholar]

- Liu, G.; Song, D.; Chen, H.; Chen, M. Modeling and Control Strategy of Parallel Hybrid System in Hydraulic Excavator. J. Tongji Univ. 2010, 38, 1079–1084. [Google Scholar] [CrossRef]

- De, D.; Klumpner, C.; Patel, C.; Ponggorn, K.; Rashed, M.; Asher, G. Modelling and control of a multi-stage interleaved DC-DC converter with coupled inductors for super-capacitor energy storage system. IET Power Electron. 2013, 6, 1360–1375. [Google Scholar] [CrossRef]

- Deng, Z.; Zhou, F.; Jin, L.; Lü, Z.; Rong, P. Power Optimal Control of Elevator Brake Energy Recovery System Based on Super-Capacitor Energy Storage and Adaptive Power-Prediction Model. Trans. China Electrotech. Soc. 2013, 28, 205–213. [Google Scholar] [CrossRef]

- Tian, M.J.; Wu, J.Y.; Hao, L.L.; Xiong, F.; Zhang, J.R.; Zhang, J. Adaptive Energy Control Strategy for Hybrid Energy Storage System Based on Multiport DC/DC Converters. Power Syst. Technol. 2015, 39, 3378–3385. [Google Scholar] [CrossRef]

- Wu, W.; Xie, S.J.; Zhang, Z.; Xu, J.M. Analysis and Design of Control Strategy for MMC-BDC Based Ultra-capacitors Energy Storage Systems. Proc. Chin. Soc. Electr. Eng. 2016, 34, 4568–4575. (In Chinese) [Google Scholar] [CrossRef]

| Control Schemes | Clamp Closing (7s) | Frame Forward (8s) | Injection (7s) | Pack, Hold (4s) | Plastification and Cooling (30s) | Clamp Opening (5s) | Total Power Consumption (61s) |

|---|---|---|---|---|---|---|---|

| Scheme 1 | 6 | 5.2 | 17.4 | 10 | 13/13 | 4.5 | 69.1 |

| Scheme 2 | 4.8 | 4.6 | 17.4 | 4 | 5/2.5 | 4 | 42.3 |

| Scheme 3 | 3.2 | 1.7 | 6 | 2 | 3.6/3.6 | 1.6 | 21.7 |

| Scheme 4 | 2.1 | 0.5 | 6 | 0.9 | 3.6/0.6 | 0.5 | 14.2 |

| Scheme 5 | 0.5 | 1.1 | 6 | 0.4 | 1.6/0.1 | 0.7 | 10.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Ren, L.; Gao, Y.; Jin, B. A Comprehensive Study of Energy Conservation in Electric-Hydraulic Injection-Molding Equipment. Energies 2017, 10, 1768. https://doi.org/10.3390/en10111768

Zhang H, Ren L, Gao Y, Jin B. A Comprehensive Study of Energy Conservation in Electric-Hydraulic Injection-Molding Equipment. Energies. 2017; 10(11):1768. https://doi.org/10.3390/en10111768

Chicago/Turabian StyleZhang, Hongjuan, Lu Ren, Yan Gao, and Baoquan Jin. 2017. "A Comprehensive Study of Energy Conservation in Electric-Hydraulic Injection-Molding Equipment" Energies 10, no. 11: 1768. https://doi.org/10.3390/en10111768

APA StyleZhang, H., Ren, L., Gao, Y., & Jin, B. (2017). A Comprehensive Study of Energy Conservation in Electric-Hydraulic Injection-Molding Equipment. Energies, 10(11), 1768. https://doi.org/10.3390/en10111768