Abstract

The development of robust mathematical models could provide the necessary tools for a more rapid, efficient, and reliable spouted bed technology development. Computer simulations can be very useful to aid this design and scale-up process: firstly, they can contribute to obtain a fundamental insight into their complex dynamic behavior by understanding the elementary physical principles such as drag, friction, dissipation etc.; secondly, the simulations can be used as a design tool where the ultimate goal is to have a numerical model with predictive capabilities for gas-particle flows at engineering scale. Clearly, one single simulation method will not be able to achieve this goal, but a hierarchy of methods modelling phenomena on different length and time scales can achieve this. The most fruitful approach will be when they are simultaneously followed, so that they can mutually benefit from each other. In this sense, this paper presents a review of the current state of the art of modelling on spouted and spout-fluid beds through an analysis of recent literature following a multiscale approach (molecular and particle, lab, plant and industrial scale). The main features of the different scales together with their current limits are discussed and specific topics are highlighted as paths that still need to be explored. In summary, the paper aims to define the theoretical setline and the basis of improvement that would lead to a robust multiscale model with solid links between micro and macroscopic phenomena. If done with the correct balance between accuracy and computational costs it will gear SB towards their reliable and successful implementation.

1. Framework of the Experimental Applications of the Technology

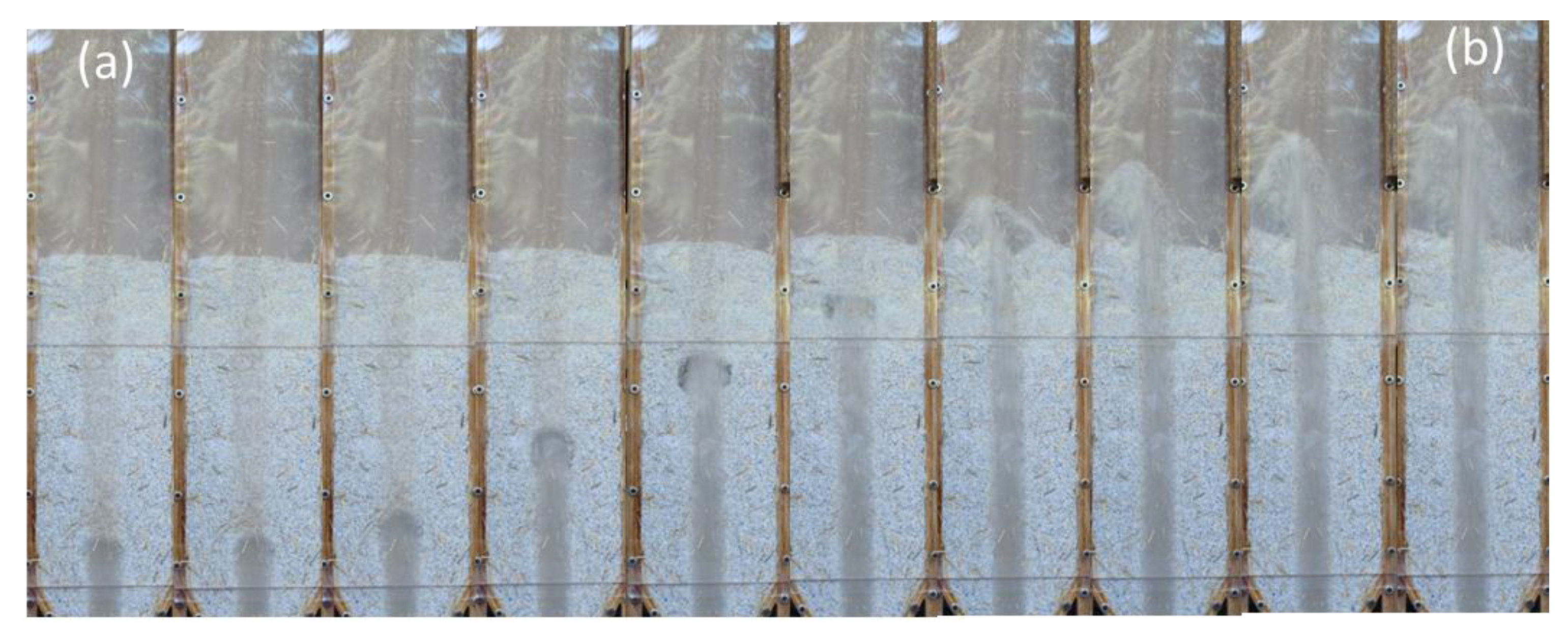

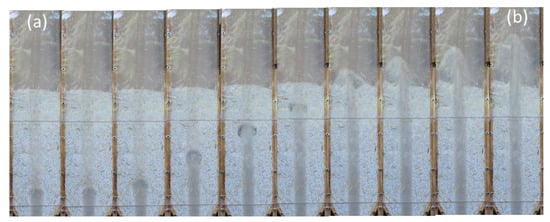

Spouted and Spout-Fluid Beds (SB) have been object of intense research during the past decades. The terms spouting and spouted bed were given by [1] at the National Research Council (NRC) of Canada to describe an innovative device based on fluidization technologies. Gishler and Mathur described this technology as “a flowing mechanism for solids and gas different from fluidisation but it achieves the same purpose for coarse particles as fluidisation does for fine materials”. In contrast with traditional fluidization [2], the fluid flow enters into the spouted bed through a single central inlet orifice creating three well differentiated zones: the central core of the reactor through which air flows is the spout, the surrounding annular region is the annulus and the solids above the bed surface entrained by the spout and going down the annulus form the so-called fountain. As an example, Figure 1 shows the different stages of spouting from the static bed situation (a) to a fully developed spouting regime (b) where the three previously mentioned zones can be easily identified.

Figure 1.

Stages of spouting: from static bed (a) to a fully developed spouting regime (b).

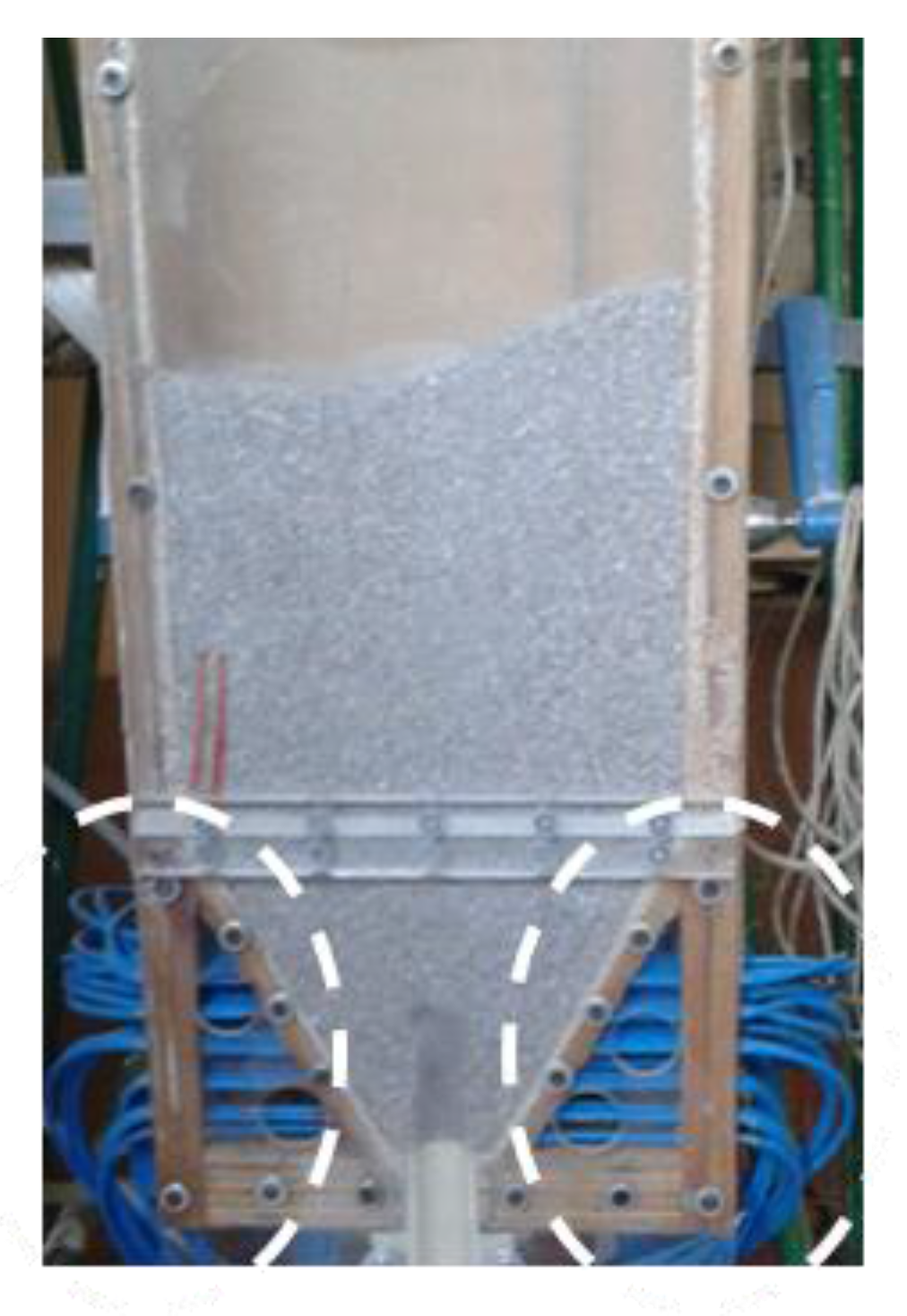

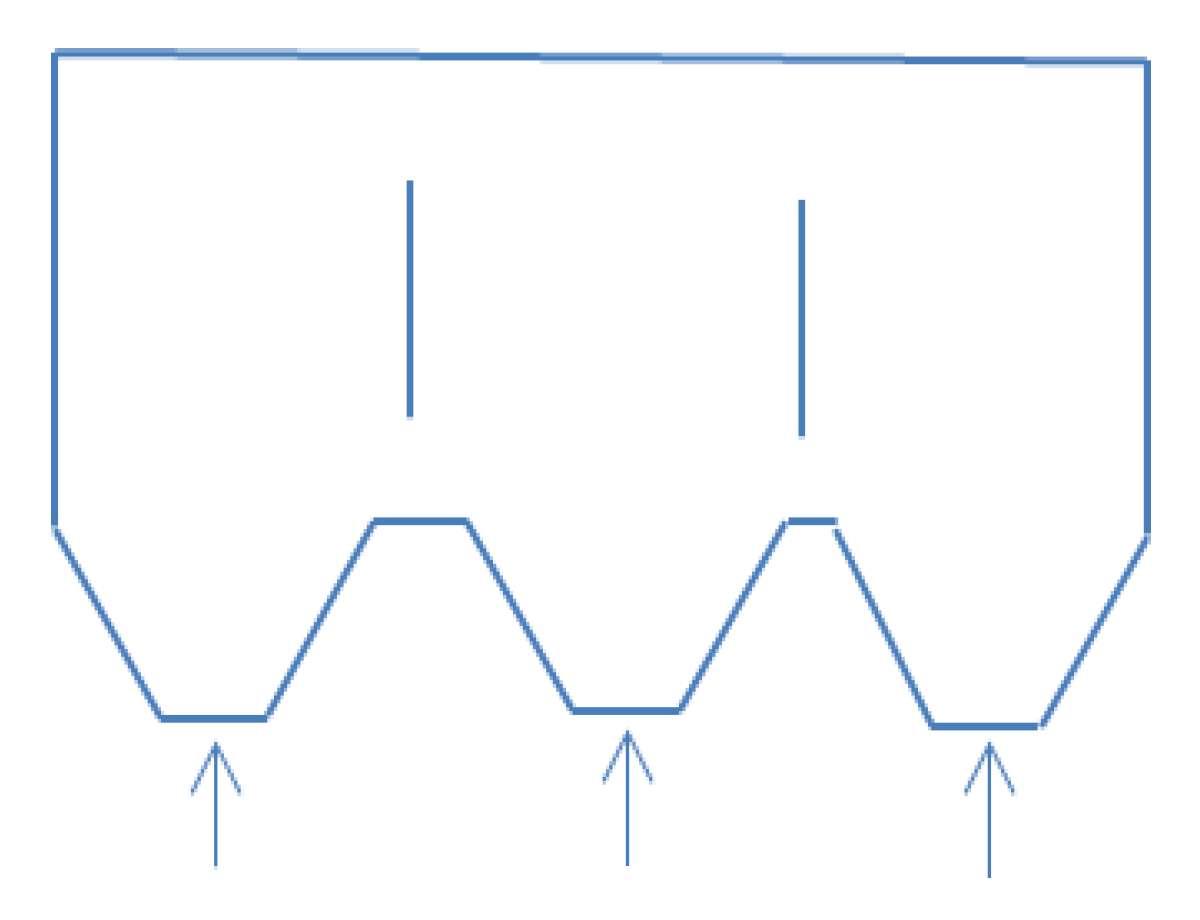

Spout-fluid beds are a type of spouted bed in which, in addition to the central orifice, an auxiliary fluid flows through a series of holes in a surrounding distributor as shown in Figure 2 (white circles). This configuration makes a hybrid reactor that shares some characteristics of both spouting and fluidisation, which is especially useful for coarse, sticky or agglomerating solids.

Figure 2.

Spout-fluid configuration.

Due to this particular configuration, the overall bed becomes a composite of a dilute phase central core and a dense phase annular region where a systematic cyclic pattern of solids movement is established giving rise to a unique system more suitable for certain applications than conventional fluidization techniques. Indeed, the existence of the described differentiated zones or the fact that usually coarse particles are present in the system leads to the need of finding different modelling approaches respect to those already existing for other types of fluid-solid configurations.

SBs were first applied as an alternative for the drying of badly slugged and moist wheat particles [1,3]. The vigorous movement of particles inside the reactor enabled the drying of the grain without damaging it. Soon, more applications were studied, and interest in these devices has been triggered in recent years being currently applied in a broad range of industrial applications, mostly related to drying processes, due to the high fluid-solid contact achieved.

Drying of barley malt [4], paddy rice [5] or mixtures of agricultural wastes [6] are the most traditional applications of SB as well as their use with pastes, slurries [7,8] and sludge from industry wastewaters [9]. In particular, SB have been widely applied in food industry for drying fruits and vegetables like red guava [10], acerola juice [11], cashew apple juice [12], peppermint [13], carrot cubes [14] or papaya seeds for oil production [15]. More recent developments have resulted in the coupling of SB with additional techniques to increase the drying efficiency of the process. For example [16], studied a solar-assisted SB for the drying of pea while the application of microwave assisted technologies shows an increasing trend for a number of materials as fish [17], coffee beans [18], potato [19] and apple cubes [20], mushrooms [21] and green soybean [22].

SB devices are also extensively applied for coating of solids such as soybean seeds [23], nuclear fuel [22,23,24,25,26], group B iron powders [27], aerogels [28], urea [29] or polymethyl methacrylate [30]. Spouted beds are also used as chemical reactors to carry out, for example, benzyl alcohol polymerisation reactions [31], the production of hydrogen from the reforming of ethylene glycol with olivine [32], the synthesis of ceramic polymer composites [33,34,35], wastewater treatments [36,37,38] and electrochemical reactions [39,40].

Finally, thermo-chemical reactions are becoming an increasing field of application for SB reactors [41]. Pyrolysis of biomass [42,43,44,45,46,47], waste plastic [48,49], scrap tires [50,51] and sludge [52,53,54,55] have been tested and validated at lab and pilot scale. Also, the combustion of wood charcoal [56], biomass [57,58,59], sludge from the paper industry [60] or eventually toxic wastes [61] has been object of several studies as well as the gasification of coal [62,63], biomass [64,65,66,67], sewage sludge [68], flame retardants textile products [69] and mixtures of biomass with plastics [46] or coal [70].

However, even though the extensive research performed mainly at lab scale and, more recently, in fully developed pilot plants [63,67,68,71,72,73], there is still a lack of technical information regarding specific scaled-up solutions. To the knowledge of the authors, only one industrial-scale prototype has been developed for the continuous drying of paddy able to handle 3500 kg/h and temperatures up to 160 °C [74]. In this framework, modelling activities play a key role for the successful development of the technology. If well-developed, they are able to provide important information for the design and scale-up stage by describing in deep detail all the involved phenomena from a general and a more specific point of view.

For the specific case of SB, one of its main features should be to provide fundamental insights into its complex and particular fluid dynamic behaviour based on its characteristic elementary theoretical principles for drag, friction or dissipation phenomena. Moreover, modelling is a design tool whose ultimate goal is to obtain a numerical model with predictive capabilities in large scale applications. This description cannot be achieved with the application of a single method, but with the coupling of a hierarchy of methods able to describe different time and length scales. The most fruitful method will be that in which all the scales are solved simultaneously so they all benefit from each other.

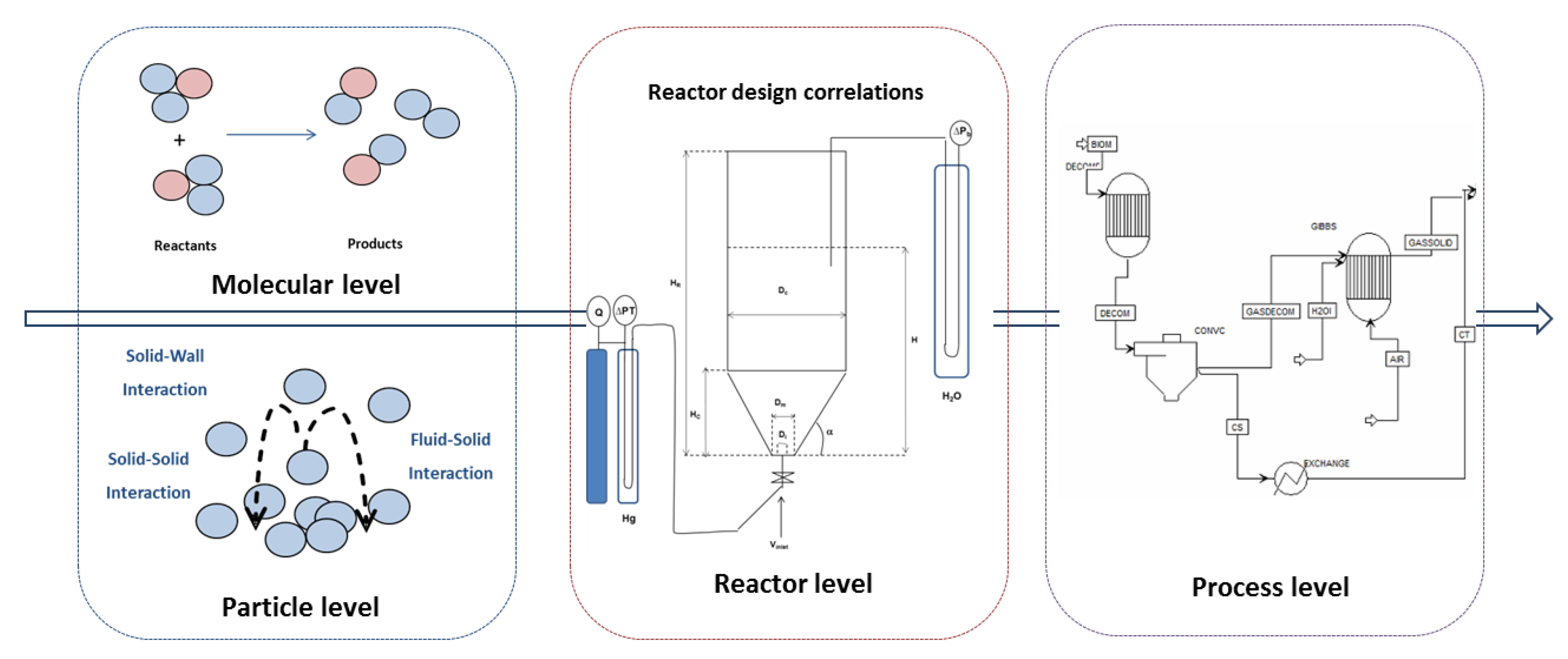

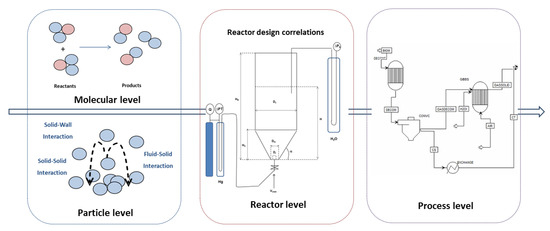

In this sense, and for the purpose of this review, four different scales have been analysed and discussed according to the traditionally distinguished scales [75]. First of all, molecular and particle scale (10−9–10−1 m) is applied to study the kinetics, particle-fluid interactions (drag forces) and particle-particle interactions (collisions described by solid pressures and viscosities). The inclusion of the kinetic theory of granular flow permits the description of the system in a larger scale and the achievement of correlations to design SB devices (lab scale: 0.1–1 m). These correlations, together with the information of a precise framework and application, are used to define the operational parameters at plant scale (1–10 m). Even though high efforts have been performed in each of the mentioned scales, industrial scale (10 m) is still far beyond the capabilities of the current state of modelling.

More precisely, Figure 3 shows a scheme of the methodology of analysis performed in this work and the involved levels of study that will be studied in detail in the following sections.

Figure 3.

Multiscale analysis strategy.

Interactions between phases (fluid-solid, solid-solid, solid-walls) together with chemical reactions and their kinetics represent the core of the technology. Optimised mass and heat transfer rates are the result of the high contact between phases and, in this sense, the study of parameters like distribution of phases and their velocity profiles become essential to understand in great detail the involved phenomena. However, this area is to be explored with large number of incognita still to be resolved. In order to evaluate the current status, Section 2 presents a state of the art of modelling at molecular and particle scale and the coupling of mass and energy transfer phenomena with kinetic reactions.

In a successive level of detail, the description of the reactor (size, characteristic parameters, presence of auxiliary devices) plays a decisive role in its scale-up. The obtaining of correlations that permit to calculate the main design parameters (minimum spouting velocity or maximum pressure drops) in a larger scale is crucial. In this framework, Section 3 provides the main theoretical and operational mathematical descriptions of the reactor and a review of the most adequate developed correlations which are, however, highly dependent on the type of reactor or feedstock used for its obtaining.

The study of process applications in terms of applied operational conditions and their optimization to maximise efficiencies while minimising resources and costs is dealt in Section 4 with an insight to the main process software used in chemical engineering.

Finally, Section 5 presents an incipient modelling methodology based on the application of neural networks for the prediction of the main SB parameters in a non-mechanistic. Although in its early stages, the increase of experimental data could boost their application in a wider framework.

Verification is of high importance in modelling activities. In this sense, all the examined works refer to models that have been validated with experimental data either from activities carried out by the same authors or with data already available in literature.

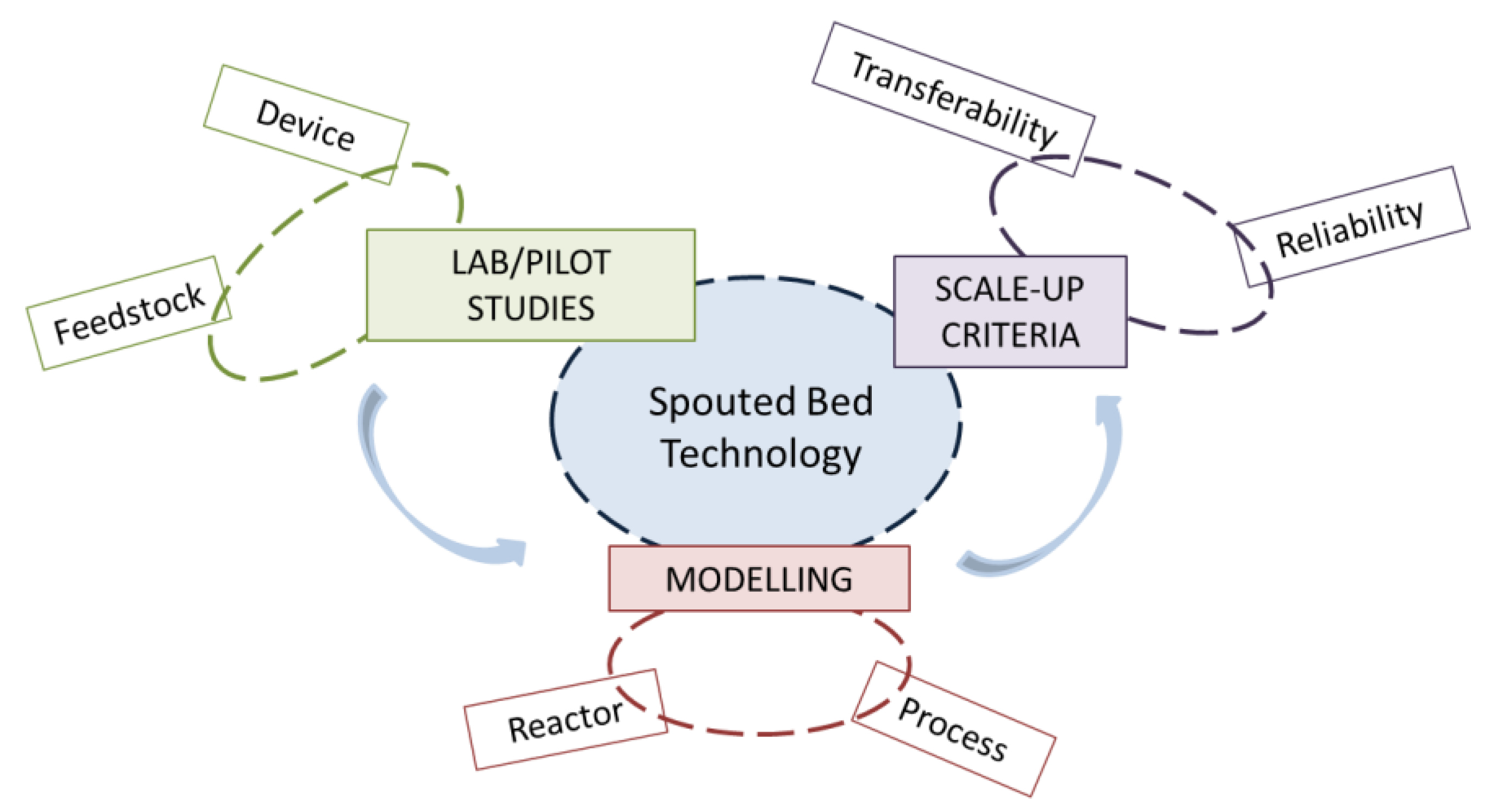

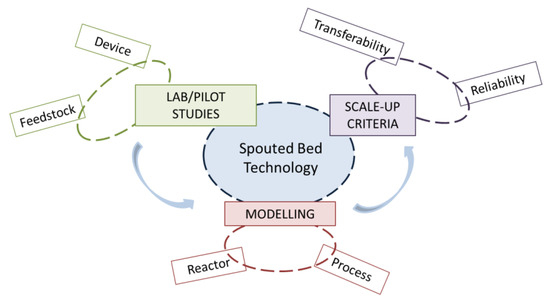

In summary, SB seem a promising technology with few pilot plants already working but still lack of consolidated industrial applications. The definition of a robust and reliable model capable to be transferred to novel environments with successful results will be in high part the key of a successful commercial establishment (Figure 4).

Figure 4.

Levels of development of SB technology.

Within this framework, the main objectives of this work are:

- -

- To set the current baseline of modelling in SB through the application of a multiscale analysis methodology, focusing the attention on the most recent works available in literature;

- -

- To identify the critical aspects and remaining uncertainties where efforts still need to be done to achieve a better comprehension of phenomena;

- -

- To suggest potential paths to be explored to foster the development of the technology.

In summary, the paper aims to contribute in the definition of the role of modelling for the complete establishment of the SB technology towards their reliable and successful implementation.

2. Molecular and Particle Scale Modelling

Kinetic rates and mechanisms at molecular level and the complex phenomena taking place at particle scale must be thoroughly understood when developing new processes. Especially when chemical reactions are involved, it is important to know how molecules behave and react in order to obtain the desired products, and how solid particles move and mix within the reactor volume. The ultimate goal will be to couple kinetic models with methods able to resolve the local balances of mass, momentum and energy in an efficient way. That way, the whole set of phenomena that take place within the device may be considered simultaneously, reproducing them with great accuracy and detail. As explained in the following sections, examples of this coupling are scarce.

2.1. Kinetic Modelling

Kinetic models provide essential information to quantify the conversion degrees and rates of specific reactions and to define the involved reaction mechanisms. As described in Section 1, a wide range of applications can be found for SB reactors and thus, a wide variety of related kinetic expressions are available in literature. However, only few works deal with the insertion of these expressions into more complex models which take into account the actual design and operational conditions of the reactor. It is clear that extensive experimental activities are required in order to achieve reliable kinetic laws. Also, the fact that kinetic models contain very specific parameters related to a specific process limits their applicability. In any case, the lack of implemented solutions using the already available expressions evidences a black hole in research on SB reactors.

One of the few works dealing with the implementation of kinetic rates on SB modelling was done by Kechagiopoulos et al. [76]. In it, the methane steam reforming was studied and its kinetic rates were added to the mass and energy balances. The model differentiated the spout and the annulus taking into account their different fluid dynamic properties and balances at each separate zone. As closure equations, interchange of mass and energy through the spout-annulus interface were considered. The model was further used to assess the influence of different factors (inlet velocity, temperature, bed height) on the efficiency of the process and the results proved that SB were good performing reactors for highly endothermic reactions.

A multiscale model to describe the yeast drying in a conical spouted bed was developed by Spreutels et al. [77] where the drying kinetics of a single pellet were combined with a gas–solid flow model with good agreement with the experimental results.

One of the main applications for SB nowadays is their use as reactors to carry out thermo-chemical reactions. Extensive research has been performed in order to obtain the kinetic parameters which better define the conversion reactions for biomass [78,79,80,81], biochar [82], plastics [48,80,83] or waste tires [84]. More precisely, the kinetic law required for large scale autothermal operation for the development of a conical SB reactor to obtain bio-oil was addressed by [85]. The study confirmed that, although the conditions of work applied in thermogravimetric analysis (TGA) are very different from those in real scale applications (heating rate, gas residence time, biomass particle size), the results from the kinetic models showed good agreement with the experimental values validating this approach as suitable for large scale conditions.

A SB reactor was used to experimentally calculate the kinetic rate of the pyrolysis of polyethylene terephthalate (PET) in the temperature range of 450–560 °C at two particle sizes (0.1–1.0 mm and 1.0–3.0 mm) in order to study potential heat and mass transfer limitations [83]. The similarity between the kinetic results revealed that heat and mass transfer limitations had been minimized. The results were compared with those obtained by isothermal Thermogravimetric Analysis (TGA) confirming the validity of the calculated kinetic expressions. A conical SB reactor was also used to obtain the kinetic expressions defining the catalytic cracking of the volatiles compounds formed in the flash pyrolysis of high density polyethylene (HDPE) on a catalyst based on HZSM-5 zeolite [86]. The catalyst deactivation was also considered inside the expression and was found to be dependent on the product concentration in the reaction medium. The model presented good agreement with experimental results and enabled the possibility to minimise the catalyst deactivation step.

In any case, the application of the calculated kinetic laws using lab-scale facilities for industrial scale applications, even though the mentioned successful applications, is still quite controversial, as several of the most important parameters could get very different values when the reactor is scaled-up (i.e., residence time, composition and dimensions of feed, …). A correct assessment of the diffusional and heat transfer limitations will be required in each specific case to ensure a correct kinetic definition of the system for any feedstock and condition of work. In addition, a lack of kinetic equations representing the reactions involving the production of tar and high hydrocarbon compounds in SB reactors is evident and represents a path that needs to be explored.

2.2. Modelling Based on the Eulerian-Lagrangian Approach

The two most applied approaches for the simulations of granular materials are the Discrete Element Method (DEM) and the Two Fluid Model (TFM), also known as Eulerian-Lagrangian and Eulerian-Eulerian approach respectively. The former considers both the solid and the gas phase as interpenetrating continua and is feasible for industrial-scale facilities, but is highly dependent on parameters. The second tracks the trajectory of each discrete particle, thus representing the most natural choice at this scale, but is more computationally complex and can be used up to lab-scale devices within an acceptable calculation time.

The DEM approach was first proposed by Cundall and Strack [87]. The solid phase is constituted by discrete particles, each of them being tracked separately solving the Newtonian equations of motion. Due to its nature, it allows the obtainment of a significant amount of insights regarding the local behaviour of particles. Moreover, being more realistic from a physical point of view, it requires a limited amount of closure equations [88] (usually those accounting for the drag and the collisions). Works in which the same experiments are simulated through different approaches [89,90,91,92] show that the Eulerian-Lagrangian approach is the most accurate in reproducing the motion of particles.

The Lagrangian approach permits to avoid relying on a model accounting for the behaviour of granular materials; the development of a model satisfyingly describing the motion and mechanisms of granular materials is still an open challenge: it was indeed included in the 125 big questions [91] in a special issue celebrating the 125th year of publication of Science (“Can we develop a general theory of the dynamics of turbulent flows and the motion of granular materials?”). Its main drawback, however, is the substantial computational complexity it entails. Even with the achievements of modern computers, this approach is still only applied on a scale of 0.1–1 m, i.e., not at industrial scale [93]. Industrial-scale facilities usually contain up to trillions of solid particles, whereas DEM simulations usually consider about 105 particles; the largest DEM simulation analysed by the authors for this review evaluated the behaviour of 4.5 million particles, it employed 16 CPU and still required months of computational time [94]. However, Golshan et al. reported that for systems with a low number of particles, the Lagrangian approach may require less computational time than the Eulerian approach [91].

Recently, DEM has been employed for the simulation of SB by several researchers, as can be seen in Table 1. In general terms, all the reviewed works of this paper refer to simulations validated with experimental data and have been carried out at room temperature, unless stated otherwise.

Table 1.

Works on CFD-DEM modelling of SB.

Previous literature works summarising the state of art on CFD modelling of SB [139,140] highlighted the lack of a deep comprehension of the physical behaviour of the solid phase and the absence of a common agreement between researchers on the most accurate models and parameters for several simulated physical features, emphasising the role of turbulence. This feature, as shown in the following paragraphs, is still open in more recent works.

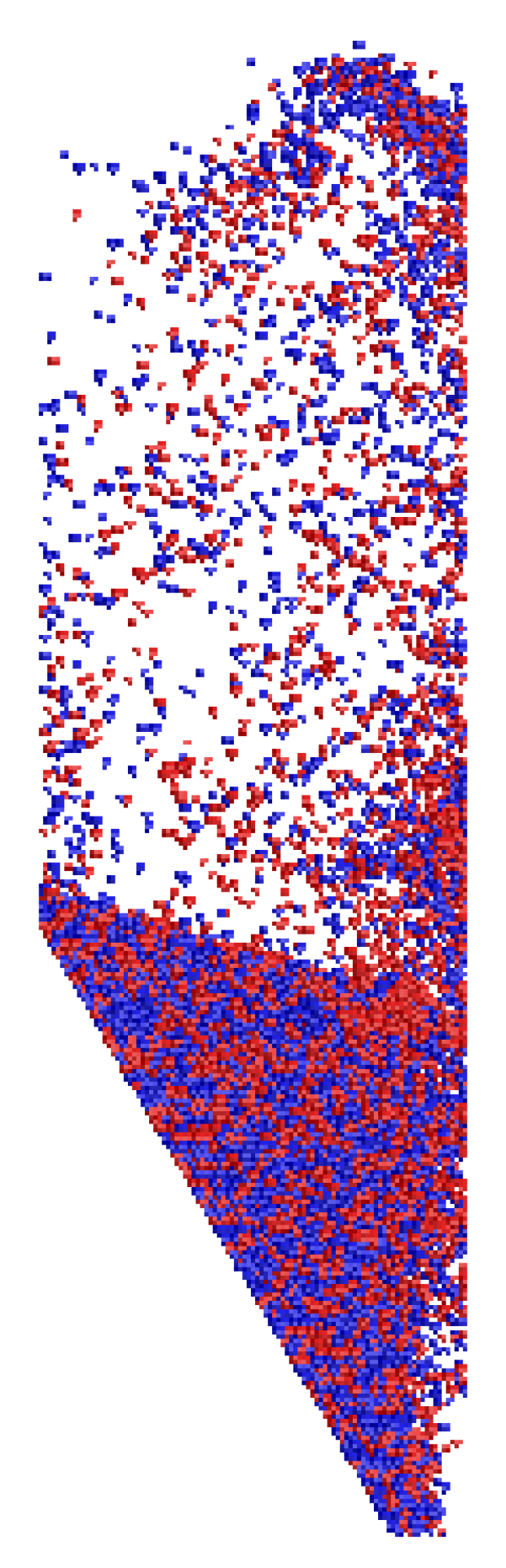

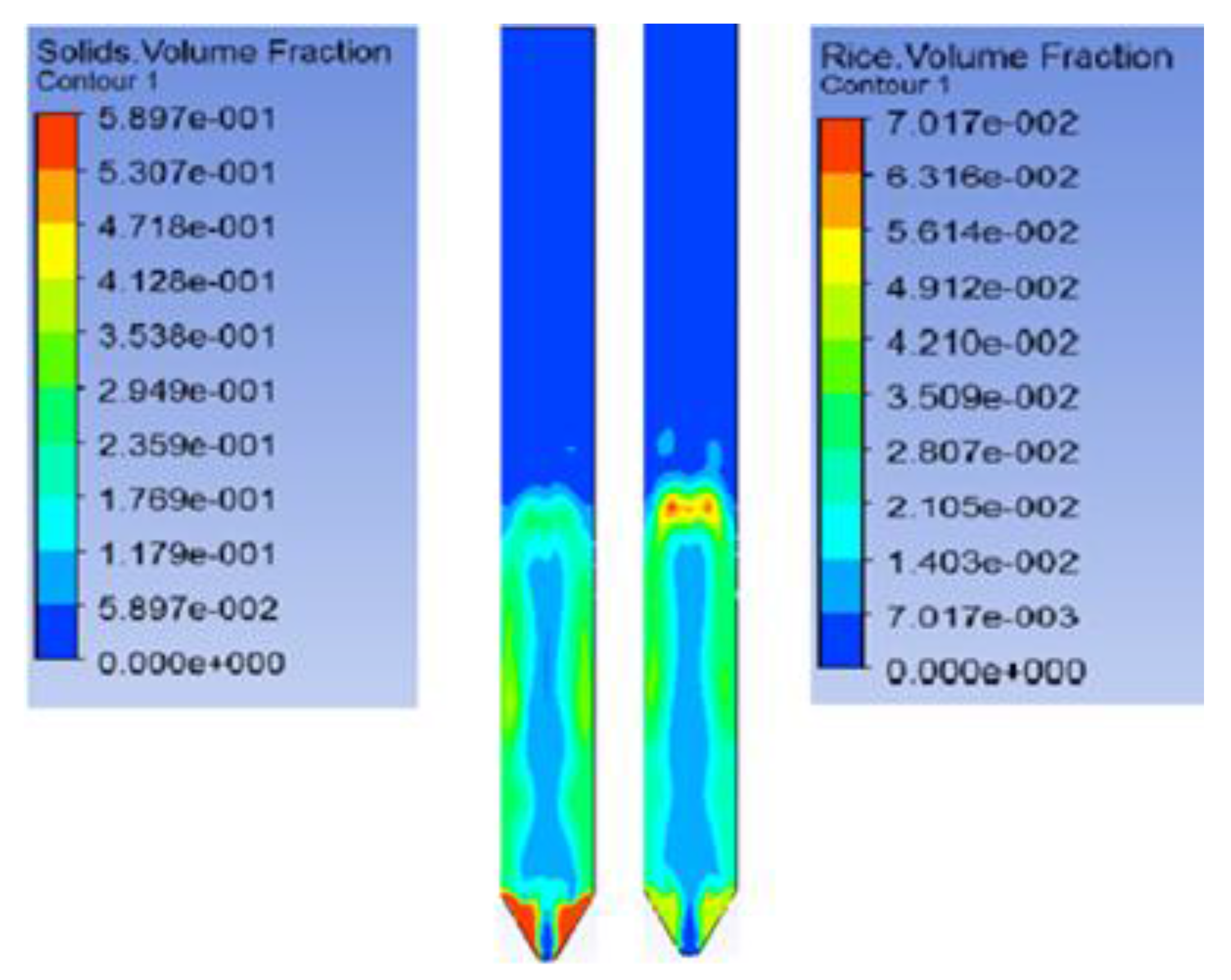

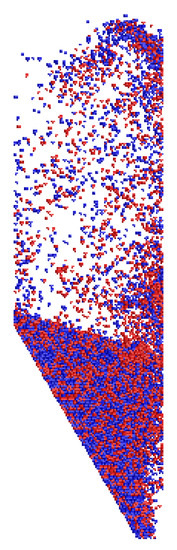

Regarding the employed software, Table 2 summarises the selected choices (where stated) to perform DEM calculations; from the existing multiple options it can be assumed that none of them is more used respect to others and the choice is up to the demand of each case. As an example, a DEM simulation of a binary mixture of glass beads using ANSYS FLUENT 17.0 is reported in Figure 5.

Table 2.

Software used for DEM modelling in SB.

Figure 5.

Spouting of a binary mixture of glass particles in ANSYS FLUENT 17.0.

In order to achieve convergence, the cells of the computational grid must be bigger than the simulated particles. As a consequence, especially for coarse particles (common in spouted beds), the computational grid cannot be very fine, possibly compromising the accuracy of the calculation for the fluid phase. In particular, Liu and colleagues [88] suggested that the diameter of the computational cell should be set to 5–10 times the diameter of the biggest particle, while Li and co-workers [112] showed that a ratio between the grid size and the particles diameter inferior to 1.67 generated problems in the calculation of particles motion. Alobaid [90] proposed that the ratio between the dimensions of cell and diameter should be between 2 and 3; indeed, this offset method was employed for the simulation of a lab-scale spouted-fluid bed, confirming its accuracy [126]. In another work [122], the employment of two different grids for the fluid and solid phase with different sizes was proposed to improve the accuracy of the calculation.

Performing calculations in irregular geometries can be challenging when a coarse mesh is used; in fact, spout-fluid beds have no inclined walls and that permits the use of a more regular mesh. In this sense, spout-fluid beds are more abundant in DEM simulations compared with those performed with TFM, as it can be seen in Table 1 and Section 3.2. A group of researchers from the Zhejiang University employed a geometry with a zig zag wall instead of an inclined one in two different works [103,104] to reproduce the experiments performed in a spouted bed with a conical base by Vieira Neto et al. [143].

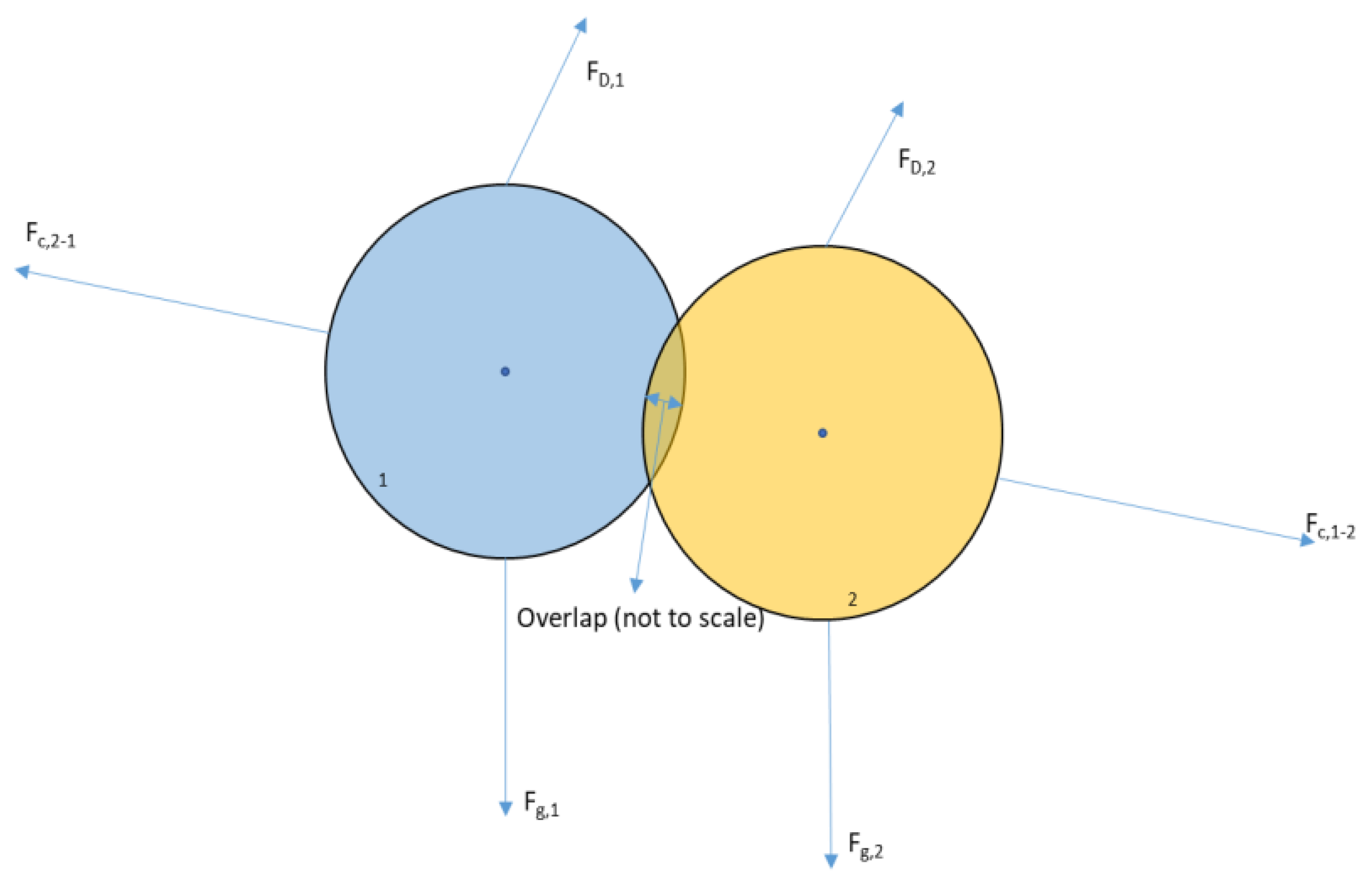

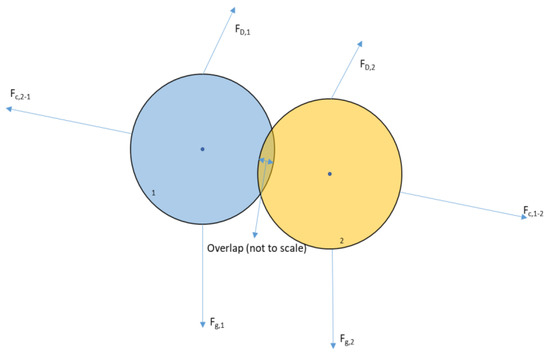

A common feature of all DEM works regards the calculation of collisions between particles, where three approaches exist: the soft-spheres approach, the hard-spheres approach and the statistical approach. The soft-spheres approach [87] is the most widespread, with almost all works on DEM modelling of spouted beds employing it (including all of the works reported in the following sections unless stated otherwise). It considers that particles deform when colliding, but instead of actually deforming them (which would require additional equations), it lets them slightly overlap and calculates the effect of the collision as a function of the overlapping. The main forces influencing the trajectories of particles are gravity (Fg), drag (FD) and the collision forces (Fc); they are schematised in Figure 6.

Figure 6.

Main forces acting on two colliding particles in the soft sphere approach.

There are several mathematical approaches [144] with the so-called spring-dashpot model commonly used which considers a spring and a dashpot accounting for the repulsive force and the collision inelasticity, respectively. A number of parameters must be specified for the spring-dashpot model; most notably, the spring constant has a relevant role: the higher it is, the smaller the time step must be [88] extending the computational time of the simulation. The value of the constant depends on the material and is hard to measure experimentally. Di Renzo and Di Maio [145] developed a complex non-linear model to predict the value of the constant yielding values between 105 and 108 N/m; however, previous works by Tsuji and others [146,147] showed that increasing the value over certain orders of magnitude has little effect on the accuracy of the simulation, and suggested setting it to 800 N/m. Other works proved that, for non-cohesive particles, simulations are insensitive to the value of the spring constant [148,149], and thus setting it to a low value does not hinder the simulation accuracy. In most works, the value of the constant is reported to be between 102 and 106 N/m.

The two other approaches are less common. The hard-spheres approach considers collisions as quasi-instantaneous, binary and punctual [150]. The statistical approach, instead, considers specific particle properties in a continuum framework, and collisions are thus calculated in a statistic way [151]. Hoomans [152] found out that, if the spring stiffness is high enough, the hard and soft spheres models produce very similar results.

The hypotheses behind DEM and its models (as the drag law), take into account both the behavior of a single particle, and the influence of the surrounding ones. Indeed, this leads to different effects, such as the different velocities and volume fraction of particles in the three characteristic zones of SBs (spout, annulus and fountain). In the reported works, comments on these features were sometimes addressed, usually pointing out the different behaviour of the particles and the exchanges between two adjacent zones. In other rare cases, the authors reported observations on the formation of bubbles or on the movement of clusters of particles. Nonetheless, more effort should be put on this direction, given the potential of DEM for the assessment of the local behaviour of solids; for example, no work addressed phenomena such as the rotation of clouds of particles or the effect of the particles volume fraction on the velocity of the gas phase.

Finally, another possible feature of particles can be cohesiveness (for wet/sticky particles). However. All discussed works consider non-cohesive particles, if not stated otherwise. DEM simulation of granular systems still has a number of open questions [153] as it will be discussed in the following sub-sections. Nonetheless, the development of more complete models has permitted the study of several features of SB achieving an initial and successful insight on the fluid dynamic characteristics of the technology.

2.2.1. Optimisation of Drag Laws

Several drag correlations which account for the interaction between the fluid and the solid phase have been developed throughout the years. However, there is still no consensus regarding which one can reproduce more accurately every feature of the motion of particles in spouted beds and its choice is not explained by the authors in most DEM works. The selected models in the works considered for this review (where stated) are reported in Table 3.

Table 3.

Drag models used in DEM simulations.

Although the Gidaspow drag model represented the most common choice, other models were often selected and indeed some works focused their attention on the comparison of drag laws to define the most suitable one.

More recently, Pietsch et al. [129] reported that Koch and Hill’s [156] and Beetstra’s [157] drag laws, based on Lattice-Boltzmann simulations, were the most adequate to reproduce the motion of particles in their prismatic spouted bed. Zhang and Li [98] argued that the drag coefficient is a 2nd order tensor, which can be reduced to a homogeneous function. They implemented several drag models and defined the one by Dahl and Hrenya [161] as the most accurate for a spouted bed.

Li and co-workers [112] assessed the most adequate drag law for a spout-fluid bed. The van der Hoef [166] and Gidaspow [154] laws produced the best results regarding the bubble formation whereas the van der Hoef and Beetstra were the most adequate for the spout-fluidisation regime. However, none of the studied relationship was free of flaws.

The validity of three drag laws (Gidaspow, Syamal-O’Brien and Wen-Yu) was tested in a spout-fluid bed by Zhou and others [111]: they reported that all three laws could accurately reproduce the spouting evolution of the bed, but the bed height was always underestimated. They identified Gidaspow law as the most accurate drag model, although pointing out that much work still has to be done in this field.

The Beetstra drag model was employed for the simulation of a spout-fluid bed with draft plates by Sutkar et al. [121]. They obtained a satisfactory agreement thanks to the hypothesis that the annulus motion might be better reproduced with the inclusion of a rolling friction model.

From the above considerations, it is clear that an agreement on the most suitable drag model is definitely lacking in DEM simulations. Similarly to the main drag law, additional drag models can simulate the effect of secondary physical phenomena; the most common ones are the Saffman force and the Magnus lift effect which are taken into account in some works [90,116,118,141,167], and neglected in others [101,106,112,120,129].

2.2.2. Definition of Particles

When specifying the properties of particles, two problems arise, one related to the number of particles, and the other to their shape. Researchers may try to diminish the number of particles in order to reduce the computational complexity. One of the most common approach consists in employing the so-called parcels instead of actual particles; they are computational particles which have different diameters than those of the actual particles whose behaviour are reproducing. Drag and other effects are calculated according to the theoretical diameter, but collisions according to the diameter of the parcel. Big parcels may however require a coarse mesh, lowering the accuracy of the simulation.

Lu and colleagues [168] employed simulations of a bubbling fluidised bed to show that when parcels account for several real particles, the mesh size is significantly coarse and some sub-grid features of the motion of the solids might be not reproduced, unless structure dependent sub-grid drag models are used, such as the energy-minimisation multi-scale (EMMS)/bubbling drag model [169]: these are different from (semi-)empirical drag models and Direct Numerical Simulations-based correlations, which are homogeneous, because they take into account the effect of heterogeneous structure, such as bubbles and clusters.

Four different scaling approaches and a full scale approach were tested in the simulation of a spout-fluid bed by Banerjee and Agarwal [114]: one based on parcels, one proposed by Glicksman et al. [170], one proposed by Link et al. [171], and one based on the terminal particle velocity, proposed by the authors. Banerjee and Agarwal [114] found that their method was both the most reliable in reproducing the behaviour of particles and the most efficient in reducing the number of simulated particles, thus optimising the computational time. Some of the aforementioned scaling approaches were also tested through DEM simulations in spout-fluid beds by other researchers: Sutkar et al. [127] reported the validity and efficacy of the Link et al. one in significantly reducing the computational time, and Ebrahimi and colleagues [128] verified the suitability of the Glicksman et al., both in a pseudo-2D and a 3D case, which also led to speed up the simulation.

Another commonly employed approach to reduce the total number of particles consists in decreasing the depth of the bed. This was done by Qiu and co-workers [99] who compared a slot-rectangular spouted bed simulating it both in 3D and quasi-3D. The results were similar although a few differences could be pointed out: increasing the depth, the pressure drop and minimum spouting velocity decreased at first and then reached an asymptotic value; bubbling internal jet regime and steady spouting regime could not be observed in the quasi-3D model; the maximum spring height and spout diameter were higher in the 3D simulation. In another study, Marchelli et al. [106] observed that the onset spouting velocity of homogeneous and binary mixtures of particles could be well predicted by means of a pseudo 2D geometry employing parcels which are bigger or smaller than the actual particles.

In several processes, particles are not perfect spheres and defining their exact shape is of key importance for the accuracy of the calculation. Nonetheless, developing and solving laws for non-spherical particles is extremely complex and, even though some examples exist in literature, not all CFD programs offer the possibility of simulating them [172]. In an attempt to account for different shapes, the Haider and Levenspiel drag law [163] takes into account the increased surface area of non-spherical particles (when compared to spherical particles of equal volume) increasing the drag coefficient of particles.

A typical compromise between complexity and physical plausibility is the application of the ‘multi-sphere method’, where non spherical particles are defined as two or more intersecting spheres. The first reported study in which the multi-sphere method was applied for a spouted bed is by Ren and colleagues [107], who simulated corn-shaped particles constituted by four or seven spherical elements, highlighting that the first choice allowed better reproduction of experimental data (minimum spouting velocity and fountain height). The developed methodology was employed [108] for the study of mixing of binary mixtures of corn-shaped and spherical particles (see Section 2.2.5). The same group [102] also applied this method to simulate cylindroid particles by comparing the results produced by an own-developed drag law [165] able to predict the fluid dynamics and pressure drop of non-spherical particles with those obtained with the Wen-Yu drag law. Also, when compared to spherical particles, cylindrical particles produced a more irregular fountain, especially for high values of the static bed height.

When considering a realistic system, it cannot be neglected that particles may feature a wide size and shape distribution. In reacting systems, particles can shrink as reactions proceed. This may create a problem as taking into account small particles results in an increase of the total number of particles. Also, the lower the diameter of the smallest particle is, the lower the time step of the simulations must be set (when using a linear spring-dashpot collision model, the collision time is roughly proportional to , with dp being the diameter of particles). Both of these options result in an increase of the computational time and one should always choose a compromise between the physical plausibility and the feasibility of the simulation.

In a 2014 article, Berger and Hrenya stated that “DEM is far from being able to simulate realistically wide size distributions” [173], suggesting the use of continuum models for granular materials (such as the Eulerian-Eulerian one) for the scope. In fact, although the literature reviewed for this work was broad, no research dealing with multi-dispersed particulate systems in spouted beds was found which evidences a lack in PSD theoretical studies for SB.

2.2.3. Turbulence Modelling

The role of turbulence was not extensively discussed in most works regarding the CFD modelling of SB. Navier-Stokes equations were in most cases solved in their Reynolds-averaged form (RANS, Reynolds Averaged Navier Stokes), with the k-ε model being the most common choice to calculate the turbulent viscosity; however, in many cases turbulence was entirely neglected. In addition, common turbulence models consider additional differential equations that must be solved, increasing the complexity of the calculations. Approaches which rely on less simplifying hypotheses, such as the Large Eddy Simulations (LES), are even more demanding. In this sense, clarifying the necessity of turbulence modelling in spouted beds is of great relevance. A summary of the approaches to turbulence in the considered articles is presented in Table 4.

Table 4.

Turbulence models used for DEM modelling in SB.

Some researchers [114] commented on neglecting turbulence stating that its effect is negligible when the volume fraction of the solid phase exceeds 0.001 [174]. Others [175], instead, run simulations to prove that the turbulence kinetic energy is very high in the interface zone between the spout and the annulus, and not employing a turbulence model hinders the accuracy of the results.

Yang et al. [135] concluded that the influence of the turbulence model in a double slot spouted column was significant in the spout and fountain regions. Wang et al. [119] compared gas-solid heat transfer in a spout fluid bed, comparing the effects of including a turbulence model (not specified) or neglecting it; they showed that the inclusion of the model leads to more accurate results, but the difference is negligible, highlighting that the Stokes number of particle is low and thus turbulent diffusion does not affect heat transfer significantly. Saidi et al. [120] simulated a spout-fluid bed, neglecting the turbulence effects and obtaining good similarities with experimental data, including pressure drops. They observed that column thickness had an effect on the vertical flux of particles, hence confirming that the wall effect has a significant influence in thin beds.

A drawback of common turbulence models is that they contain empirical parameters (six for the k-ε model) and there is no consensus on their optimal value. For this reason, some researchers [109,123] employed the Large Eddy Simulation (LES) approach, which contains less parameters; in particular, Wang et al. [123] highlighted the better accuracy of the LES approach, commenting on the intensity of turbulence in various zones of a pseudo-2D spout-fluid column.

In another rare exception, Sutkar and colleagues [127] simulated turbulence in a spout-fluid bed employing a sub-grid scale (SGS) model proposed by Vreman [176], which entails less simplyfing hypotheses.

2.2.4. Study of the Fluidisation Behaviour

Predicting the fluidisation behaviour of solids is usually the main goal when modelling a spouted bed. To assess the validity of the simulation, results were usually compared with experimental voidage, velocity or pressure profiles.

The spouting behaviour of high-density particles (like those employed in nuclear operations) was studied by Li and colleagues [101] employing a pseudo 2D geometry, assessing the dependency of many variables on particle density. Most notably, they observed that minimum spouting velocity and peak pressure drop were proportional to ρp0.67 and ρp1.2 (with ρp being the density of particles) and that dense particles had a wider range of stable spouting state and a dual dominant frequency. Marchelli et al. [106] studied the effect of diameter, density and sphericity of particles on the onset spouting velocity in a pseudo 2D model, observing that the reliability of the predictions was comparable to the results obtained with the Mathur-Ghisler equation. In another work, the spouting of 6 mm particles in a spouted bed was simulated by Yang et al. [110]; they observed that the flux of solids was dramatically higher in the axial than in the radial direction and the spout diameter increased with the gas velocity and with bed elevation. Also, the spout and annulus exchanged mass through all the interface, with the exchange being more intense with an increase of the gas velocity.

Rong and Zhan [141] employed a user defined function to insert DEM in an early version of FLUENT and validated their model with experimental analyses. Saidi and Tabrizi used DEM to prove that the use of an additional background gas flow in a spout-fluid bed eliminates dead zones [177]. Yang and collaborators [115] assessed the influence of several parameters on the solid dispersion in a spout-fluid bed, reporting that the increasing on the spouting and fluidisation velocities promoted it in the spout and fountain region in vertical and lateral directions, but had no effects on the annulus. Similar results could be obtained decreasing the particle size and the bed height or increasing the bed depth and the total gas flow rate.

The spouting behaviour of cohesive particles must be modelled with adequate hypotheses. Several models to calculate cohesive forces among particles can be found in literature. Different causes of cohesiveness can be taken into account, but they are complex and entail several parameters, hence not being very practical in their application. For this reason, Xu et al. [116] proposed a much simpler model, where cohesive forces were calculated multiplying a parameter (which varied from 0 to 20) by the gravitational force acting on each particle. When spouting developed, a cohesive force of ten times the gravitational force (roughly the force acting on wet particles) caused significant agglomeration of particles and when it was further doubled, the spout collapsed. The cohesive force reduced the velocity of particles, their concentration in the fountain and their recirculation flux. Zhang and Li [96] proposed a more detailed approach, which took into account both capillary and viscous forces, and applied it to monodispersed particles in a spouted bed. They validated it by comparison with several features observed in experiments, such as the fact that the frequency, velocity and fountain height were higher for wet rather than for dry particles. Moreover, they employed the resources of CFD to show that the granular temperature of wet particles was higher than that of the dry ones in the spout and fountain zones, while it is unchanged in the annulus.

2.2.5. Particle Mixing

Spouted beds feature excellent mixing properties. When compared to standard fluidised beds [178], segregation phenomena in heterogeneous mixtures are significantly hindered, provided that the adequate operating conditions are selected [3,179]. Nevertheless, the mixing of particles differing in diameter, density and shape must be carefully evaluated prior to undergoing a desired process. In this framework, a validated CFD model is a powerful tool to assess the quality of solids mixing in spouted beds, offering detailed insights about zones where segregation might arise, especially if DEM is used to simulate the interactions between particles.

Wen and colleagues [100] evaluated different mixing indexes. Among them, the neighbour distance method was considered the most suitable one, even though it should be modified in order to account for particles with different diameter.

Mixing might change whether particles are wet or dry, and Zhu et al. [142] studied the influence of both conditions using a monodispersed mixture of particles in a spouted bed. The Mikami model [180] was applied for wet solids and, as a result, an increase in the spouting velocity accelerated the mixing process whereas an increase in particle moisture decreased the velocity of particles, velocity gradient and mixing rate.

Mixing is influenced by the difference in physical properties of particles. Ren and co-workers [167] studied the effect of the density ratio in a spouted bed, finding out that the more this ratio was increased, the worse and more time demanding the mixing became. Similar features could be seen if the trajectories of two tracers were followed. However, the light tracer travelled to averagely higher positions in the fountain and had average longer cycle times, spending more time in the annulus, probably because it landed at higher radial distance from the centre. The same effect was observed by Marchelli et al. [106] for a binary mixture of glass particles of different diameters.

In the only study of mixing of non-spherical particles in a spouted bed, Ren and co-workers [108] employed the multi-sphere method (see Section 2.2.2) to assess the behaviour of corn-shaped and spherical particles. They observed that monodispersed mixtures of spherical particles feature a faster mixing, while in equi-volumetric binary mixtures the quality of mixing is affected by the difference in properties, with size influencing it more significantly than shape; differences in shape, size and density concur in diversifying the trajectories of particles in the fountain region, hence hindering the mixing.

Karimi and Dehkordi [118] analysed the influence of diameter and density of binary mixtures in a spout-fluid bed. They confirmed that segregation was more severe when the difference of diameter and/or density of the two kinds of particles was greater and, in that case, a more intense gas flow rate is needed to achieve a good mixing state; in spout-fluid beds, axial segregation only occurred over a certain value of the bed height, while radial segregation had a more significant influence due to the presence of dead zones next to the gas inlet. In any case, the bed never reached a fully segregated state.

2.2.6. Heat Transfer and Chemical Reactions

As described in Section 1, spouted beds are employed for coating and drying particles, and also as chemical reactors, mainly for catalytic, polymerisation and thermochemical processes. The inclusion of such physical and chemical phenomena in a CFD model is possible but complex, and increases the time needed to perform simulations.

Even though its importance, few works can be found in literature as reported by Zhong et al. [181] in a recent review on CFD simulation of Dense Particulate Reaction Systems (DPRS). The authors grouped the existing barriers for the wide use of DEM for DPRS in three points: the unsuitability of the current computational capacity for the simulation of industrial facilities, which would take years of simulation time to reproduce 30 s of a reactor’s behavior; the current limitations in simulating non-spherical particles, fragmentation of particles and the evolution of their physical properties, such as density, porosity and composition and the lack of a more comprehensive model, which would permit to consider relevant secondary phenomena, such as the production of tar, char and pollutants or the erosion of the wall.

The correct inclusion of the energy balance equations is of key importance in the study of thermochemical processes. Wang et al. [119] modelled the cooling of particles, initially at 150 °C, when spouted by air flow at ambient temperature. The increase in the rate of the fed gas promoted the convective gas-solid and conductive solid-solid heat transfer in the jet, but hindered them in the annulus region; the temperature of particles was lower in upper sections of the bed, while that of the gas phase behaved oppositely.

In order to develop a preliminary model of coal-direct chemical-looping combustion with ANSYS FLUENT, Banerjee and Agarwal [132] successfully simulated a spouted bed reactor in which gaseous methane reacted with solid Fe-based oxygen carriers. The model had previously [136] been validated by comparison with cold-flow experiments, and the features of CFD modelling were exploited to improve the design of the reactor, enhancing the solid recirculation and avoiding dead zones. In the latter work, they pointed out that the output of the process strongly depended on the fluidisation quality: dense Fe2O3 particles did not allow the obtainment of a good fluidisation regime, which was instead achieved with 60% Fe2O3 supported on MgAl2O4. It is interesting to highlight that their model required 24 h of calculation time to simulate 200 ms of the reactor, showing the high time-consuming demand of these simulations.

Xie and collaborators [109] developed a complete 3D CFD-DEM model of a spouted bed gasifier, modelling turbulence with the Large Eddy Simulation (LES) model to successfully simulate the gasification of woody biomass. The results showed that high temperatures lead to instability in the gas-solid fluid dynamic regime and that part of the solids are oxidised in the higher part of the reactor, increasing the volume fractions of hydrogen and carbon dioxide.

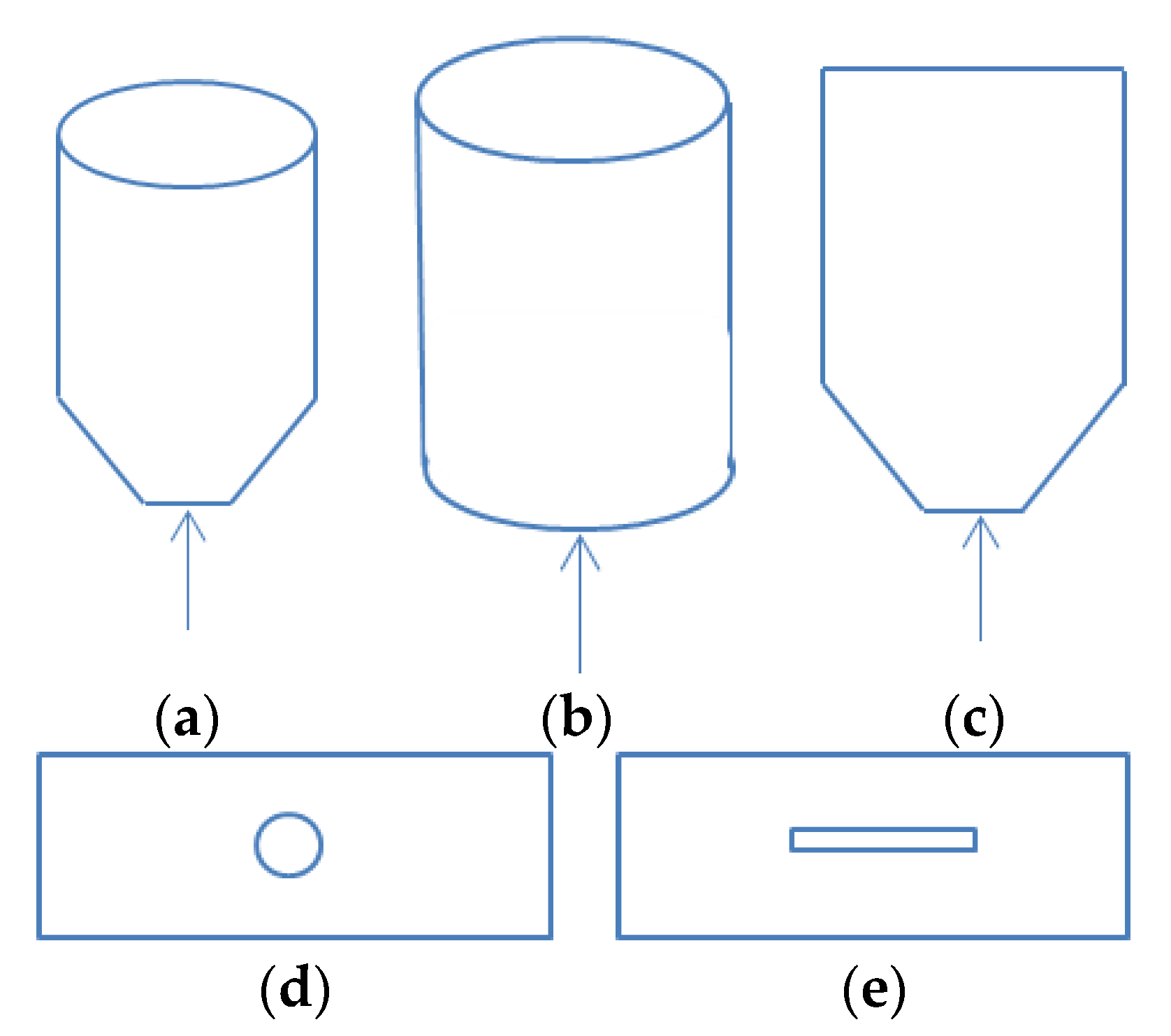

2.2.7. DEM Applied to Auxiliary Devices

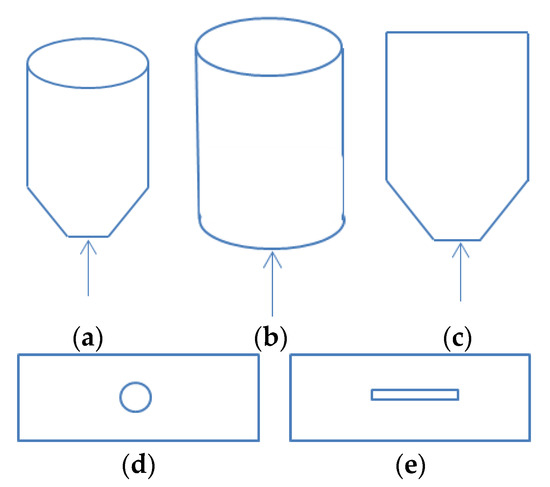

Several configurations or auxiliary devices can be included in SB to improve their spouting behaviour. The most commonly applied geometries are shown in Figure 7: conical (a), cylindrical (b) or prismatic (c) with the arrow indicating the inflow gas. The injection of gas can also be performed according to different base configurations as the traditional orifice of circular cross section (Figure 7d) or through a rectangular slot (Figure 7e).

Figure 7.

Different geometries applied in SB: conical (a); cylindrical (b) or prismatic (c); Injection of gas through circular cross section (d) or rectangular slot (e).

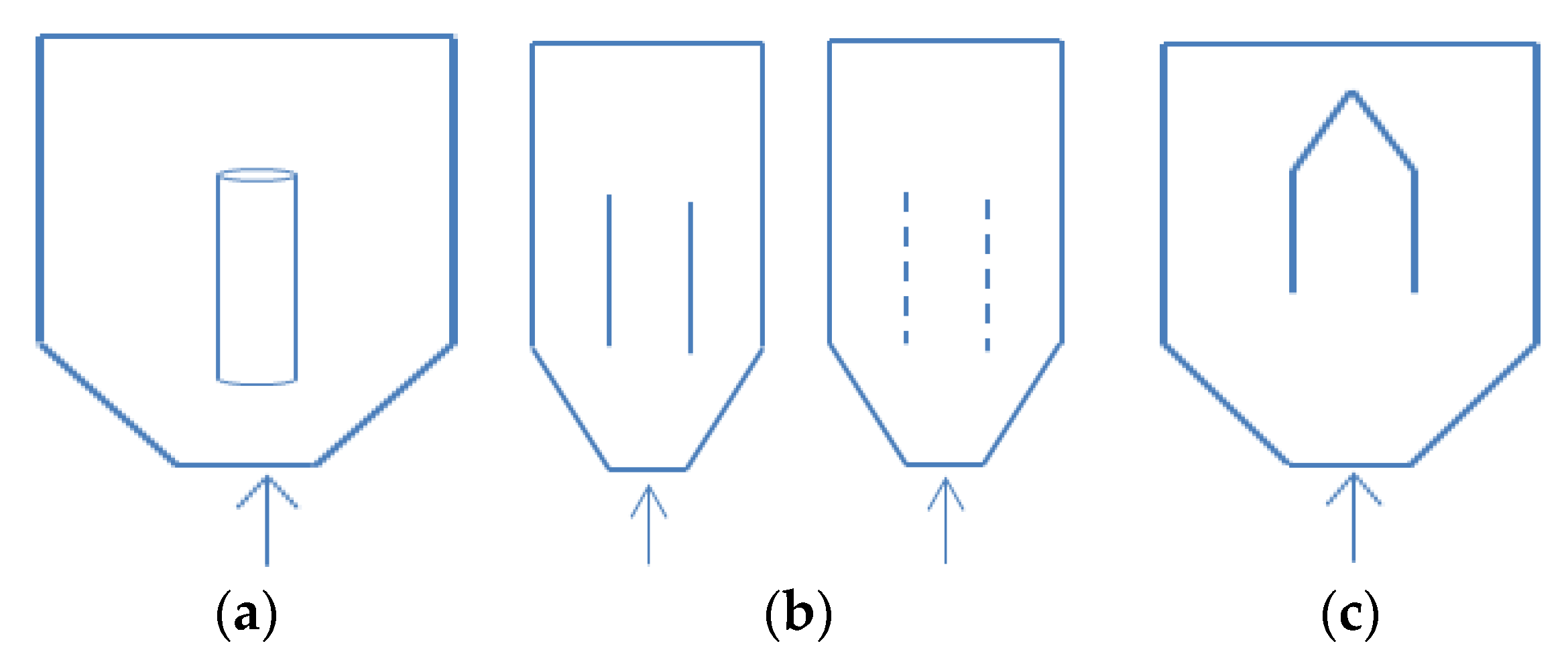

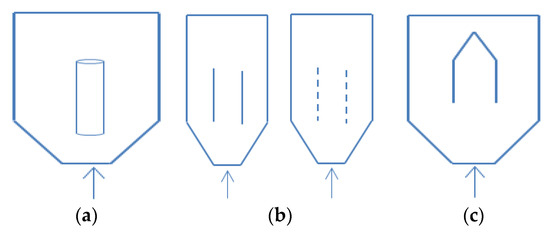

In addition, several auxiliary devices are used to improve spouting phenomena. Most notably, a draft tube which encloses the spout region can be added in order to make the flow more stable and gain a better control of the particle circulation pattern. Figure 8 shows a scheme with the most applied devices: porous/non-porous draft tubes (a), porous/non-porous draft plates (b) or the recently proposed fountain confiners (c) specifically used to improve the stabilization of the process with fine particles.

Figure 8.

Scheme of possible auxiliary devices used with SB: porous/non-porous draft tubes (a); porous/non-porous draft plates (b) or the recently proposed fountain confiners (c).

An analysis with Fast Fourier Transform (FFT) allowed Pietsch and co-workers [129] to observe that the spouting behaviour (initially instable) of a 3D prismatic spouted bed with two horizontal gas inlets could be enhanced by the addition of two draft plates. This is mostly promising for processes with liquid injections. Similarly, Salikov et al. [133] modelled a prismatic spout-fluid bed with two horizontal gas inlets obtaining similar flow features. Fries and colleagues [138] compared three different granulators, one of them a prismatic spouted bed, and evaluated their fluid dynamics and collision intensity in order to predict the properties of the produced particles.

The circulation of solids within a spouted bed with and without a draft tube was investigated by Luo and colleagues [104] who highlighted the substantial differences observed: the solids dispersion took place in different zones, being more intense when the draft tube is used. They also showed that the extension of the draft tube over the bed surface makes the solid circulation more vigorous.

A model of a slot-rectangular spouted bed was developed and validated by Saidi et al. [97]. They observed that the particle fluxes were higher when the bed height was increased and that, in higher horizontal sections of the bed, the spout shape became less rectangular and more circular.

The effect of the angle of the inclined wall of a slot-rectangular spouted bed was studied by Golshan and others [95], who employed a pseudo 2D open-source model previously developed by Zhao et al. [175]. They assessed how the angle affected the minimum spouting velocity, proposing a new correlation for its calculation. They also observed that an increase of the angle (i.e., making the device wider) enhanced the velocity of particles and solid flux in the central zone and proposed a novel curved bed which displays improved particles circulation performance.

Wang et al. [130] simulated a dual-column slot-rectangular spouted bed featuring a suspended partition, which kept the two fountains separated; they obtained good similarity with their experimental results, pointing out that the initial position of the suspended partition had little influence on the stable spouting conditions and that increasing the gap below the partition enhanced the solids transfer between the two columns. The simulations considered about 97,000 to 140,000 particles and, in order to reproduce 20 s, up to 2 months of calculation time were needed. Yang et al. [135,137] studied a double-slot spouted column too, employing 112 CPUs to simulate the behaviour of more than 2.5 million particles; the model had already been validated for a single slot spouted bed [105], by comparison of the pressure drop and velocity profiles. For the double-slot device they observed that, thanks to the partition plate, there is little exchange of information between the two partitions, which display good symmetry properties. In addition, doubling the chambers causes an increase in the pressure drop and minimum spouting velocity.

Deb and Tafti [124] modelled a spout-fluid bed to investigate the effect of employing one, two or three separate gas inlets; they reported that pressure drop is lower when only one inlet is used, and examined several methods to assess the mixing quality as a function of the number of jets used and the superficial gas velocity.

Adding draft plates to a spout-fluid bed increased the symmetry of the spouting channel, reduced the instability of the pressure drop and decreased the gas leakage from the spout to the annulus as explained by Yang and collaborators [113]. However, if the plates were too long, solid recirculation rate was reduced concluding that the optimal length must be a trade-off between the positive and negative effects. Sutkar et al. [127] studied a spout-fluid bed with draft plates, with the aim of validating a scaling approach; the bed was considered composed either of glass or of γ-alumina particles, and a good matching with experimental data was obtained in the reproduction of the motion of particles within the device.

Draft tubes might get damaged during operation when subjected to severe operating conditions or collisions with solids. In order to account for this effect, Yang and colleagues [103] included the Finnie erosion model [182] in their simulation of a spouted bed with a draft tube: they observed that, regardless the tube configuration, erosion is more pronounced in the upper region of the tube. They also proved that the increase of the tube height over the bed surface enhanced erosion whilst the reduction of the entrainment distance minimised it. Regarding the fluid dynamics, they observed that the insertion of a draft tube regularized the movement of particles inside the reactor. Moreover, there was less leakage of gas in the annulus and the solid vertical flux was promoted by increasing the length of the tube above the bed surface or increasing the entrainment zone.

Zhang and colleagues [131] reproduced a spouted bed employed as a pneumatic transporter of oil shale semi-coke particles. The model was validated by comparisons of the pressure drops, velocity and volume fraction distributions, and the feasibility of the process was proved.

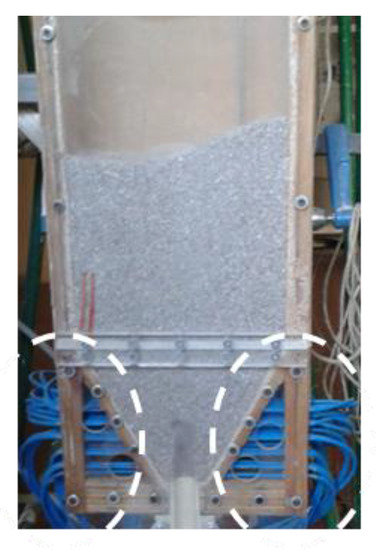

3. Lab Scale Modelling

Spouted beds can be more practically modelled through a methodology established on a lab scale. This methodology may be mainly based on correlations or CFD models based on the Two Fluid Model (TFM) approach.

In general, correlations are easy to use and, in many cases, very reliable. However, the complexity of the fluid dynamics of SB has hindered the development of robust correlations for SB based on theoretical considerations; indeed, most of them are developed in order to fit the highest number of experimental data. Also, the TFM approach, compared to the DEM approach, provides less details on a particle scale, but it is a more practical tool to model lab scale (or larger) devices due to its lower computational cost. As its main drawback, its sensitivity to physical parameters is highly significant.

3.1. Modelling Based on Semi-Empirical Correlations and Dimensional Similitude

Due to the complex fluid dynamic nature of SB, their design and performance are still not completely well-understood. Indeed, a key factor for their successful scale-up is the correct assessment and control of the main operational parameters.

The minimum spouting velocity (Ums) is probably the most important parameter for SB. In terms of industrial design, the operational characteristics of the air blower according to the gas inlet requirements are one of the main factors that need to be evaluated as they are closely related to the reliability of the system, as well as to the costs of operation. In practical terms, Ums is defined as the minimum gas inflow required for maintaining stable spouting conditions and it is closely dependent on the geometrical characteristics of the reactor and the physical properties of the solid phase. For this reason, extensive research is dedicated to obtain a reliable equation for a wide range of operational conditions. However, most of them have been only validated for a specific range of study and fail to predict most of the design variables when conditions are changed, especially for large devices which tend to be less stable and therefore, harder to control and operate.

Due to the large range of parameters affecting the spouting process, a great number of correlations for Ums have been developed according to the specific characteristics of the device and process. Ums for conical, cylindrical and flat reactors is well represented (about ±10%) by the Mathur-Ghisler equation [1], applied for ambient conditions and diameter of reactor (D) lower than 0.5 m. As stated before, almost all equations proposed in literature apply to D < 0.5 m. One of the few equations proposed for larger diameters is the equation by Fane and Mitchell [183] which, in essence, is an empirical modification of Mathur and Ghisler equation based on measurements on a device with D = 1.07 m, highlighting the lack of information regarding Ums in large units. Moreover, few correlations [50,184] have been developed with a varying temperature, which in practice varies the density and viscosity of the inflow gas. A summary of the most applied equations is presented in Table 5.

Table 5.

Most applied correlations for Ums.

The applicability of the equation of Mathur-Gishler for mixtures was also evaluated and the expression was found valid if the average particle diameter and average particle density is calculated by and respectively, with being the mass fraction of species i.

More recently, an experimental campaign using five types of biomass and a device with non-porous and open-sided draft tubes was carried out by Saldarriaga et al. [187] to obtain correlations valid for the calculation of Ums using particles of low density and different sphericity values.

Other important parameters to be defined in the design of SB are the maximum and stable pressure drops. The pressure drop of a system is closely related to its energy requirements. Its correct assessment is crucial to optimise the operational conditions and the associated costs. As a rough approximation, the maximum pressure drop is 1.5–2.5 times higher than the stable value. Once again, the currently available correlations lack of a wide framework of valid conditions where they can be successfully applied and so, their use is restricted to the range of parameters from which they were obtained. Table 6 gathers the most widely applied equations for the calculation of the maximum (ΔPM) and stable (ΔPS) pressure drops.

Table 6.

Most applied correlations for ΔPM and ΔPS.

Although relatively often neglected over other fluid dynamic parameters, the fountain area in SB is an important design input. It defines the required total height of the device and the freeboard area above the static bed. Furthermore, the fountain is even more important in SB reactors as reactions might be occurring in that region and, depending on the fountain temperature or amount of solids/gas present, unselective reactive pathways might become activated, consuming/producing preferential products.

Fountain height increases with increasing air inflow and decreases with increasing particle size and shape factor and the diameter of the spout is usually much higher than the inlet diameter. As an example, one of the few correlations for their calculation are the following [192]:

Averaged cycle times and fountain heights were successfully predicted by the one-dimensional model by Olazar et al. [193] using Ums and the pressure drop evolution as inputs. These parameters are of great importance in the definition of operational times (especially for batch experiments) and for the geometric factors of the reactor. Moreover, the simplicity of the model permits the coupling of fluid dynamic properties with kinetic ones for a more complete reactor design. Even though this model successfully predicted the solid and gas velocity profiles, it failed to describe the particle velocity along the spout. This weakness was overcome by Niksiar et al. [194] through the application of a streamtube modelling approach which permitted the obtainment of a more accurate prediction of the radial distribution of gas and particle velocities inside the SB.

Finally, the maximum bed height (Hm) is defined as the highest bed able to be spouted and represents the limit of material which can be processed by a SB. McNab and Bridgewater [195] proved valid the following equation:

with b = 1.11, which gave the best fitting to experimental data in gas spouted-beds at room temperature. At different operational conditions, Hm decreases with increasing temperature and with decreasing pressure.

At larger scale, only the equation of Lefroy and Davidson [196] is an alternative to estimate Hm in columns with D > 0.5 m.

Another strategy for scale-up activities is to use a set of dimensionless groups to be matched to maintain the fluid dynamic similarity between reactors. This dimensional similitude methodology is widely employed in different fluid dynamic applications as aircraft and ship design, and has become popular in scaling of fluidized beds. With this purpose He et al. [197] proposed the following dimensionless parameters (extrapolated from fluidised reactors) for a bed of fixed geometry:

where g·dp/U2 is the Froude number, ρp·dp·U/µ is the Reynolds number, ρ/ρp is the ratio of fluid density to particle density, H/dp is the ratio of bed height to particle diameter, D/dp is the ratio of column diameter to particle diameter, is the sphericity of particles, is the inertial friction angle of particle and ε0 is the loose packed voidage.

These groups are the same as those proposed by Glicksman [198] with the addition of ε0 and ϕ to take into account the more frequent particle–particle interactions and the greater compression and friction forces in SB relative to conventional fluidized beds.

Following this approach, studies have been conducted to expand the dimensionless-groups of spouted beds by adding the restitution coefficient (es, which accounts for the inelasticity of particles collision) or the friction of particles [199]. This parameter becomes crucial due to the important role that the interparticle collisions play in the fountain and spout regions.

As an evaluation of this approach, the scale-up methodology was carried out using sophisticated optical fibre probes that measured simultaneously the local velocity of solids, normal and shear stresses and turbulent kinetic energy [200]. The study evidenced the need of local measurements of hydrodynamic parameters for the correct scale up procedures. In addition, a recent work by Aradhya et al. suggested that current dimensionless groups are not sufficient to explain the complete hydrodynamics of the spouted bed system [201]. A new mechanistic methodology of scale-up for gas-solid spouted beds was proposed considering the similarity in local hydrodynamics based on maintaining similar radial profiles of gas holdup in the scaled-up units.

This approach however is only suitable for ‘cold’ scale-up (i.e., modelling of hydrodynamics) and it can only be extrapolated to other physical phenomena such as heat transfer if it is possible to match other key dimensionless groups. However, it is unlikely to be suitable for situations with more complex phenomena as substantial temperature or concentration gradients or chemical reactions.

3.2. Modelling Based on the Eulerian-Eulerian Approach

Spouted beds can be efficiently simulated at a lab-scale through CFD models employing the so-called Eulerian-Eulerian approach or Two-Fluid Model (TFM). In this approach, both the fluid and the solid phases are treated as mutually interpenetrating continua, and their behaviour is predicted through the numerical solution of mass, momentum and energy balance equations. Obviously, such a hypothesis for the solid phase is most appropriate if the particles composing it are very small, so that that their macroscopic behaviour can be roughly compared to that of a continuum. The balances must be coupled in order to predict the momentum exchange between the two phases, and further equations must be specified to describe turbulence, interfacial forces, solid stress and other factors.

The advantage of this approach is its relatively low computational complexity, which allows its employment even on a physical scale of 1–10 m, i.e., at plant level. The drawbacks are the loss of information regarding the local behaviour of particles and the significant amount and influence of parameters and closure equations required for an accurate reproduction of the experimental findings. The works considered in this review are summarised in Table 7. As discussed in Section 2, all the presented models have been validated with experimental data obtained at room temperature, unless stated otherwise.

Table 7.

Works on CFD-TFM modelling of SB.

Overall, as already stated in Section 2.2, TFM has been employed less than DEM for spout-fluid beds but still appears to be the first choice for spouted beds.

The Kinetic Theory of Granular Flow (KTGF) has been used in all simulations of spouted bed reactors employing an Eulerian approach, with no exceptions; details about its theoretical development can be found in the work of Gidaspow [233]. In short, it relies on the definition of solid ‘pressure’, ‘viscosity’ and the ‘granular temperature’. KTGF can recreate the behaviour of spouted beds with great accuracy provided each parameter is properly specified. However, Sun et al. [117] employed DEM to simulate a spout-fluidised bed and evaluated the translational, rotational and configurational temperature of particle. The results showed that KTGF was incapable of accurately predict solid pressure, shear viscosity, granular conductivity and kinetic energy dissipation when the volume fraction of particles was high.

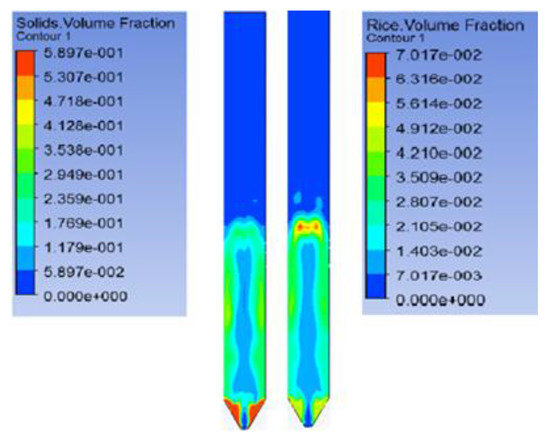

Contrarily to DEM simulations, all of the works discussed in the following paragraphs employ (where stated) the commercial CFD program ANSYS FLUENT; an example of a work performed with FLUENT and the TFM approach is shown in Figure 9. There is only one work employing ANSYS CFX, different from all the others as it regards the simulation of a SB containing water [217].

Figure 9.

Volume fraction of sand (left) and rice straw (right) in a spouted bed.

3.2.1. Optimisation of Drag Laws and Coefficients

Drag models and coefficients cannot be experimentally measured but affect critically the behaviour of the solid phase. Similarly to DEM, a universally accepted set has not been identified yet, and an optimisation must be performed for each scenario. Table 8 summarises the selected drag models for the works presented in this review (where stated).

Table 8.

Drag laws used in TFM simulations.

There are much less options than in DEM and it is evident that the Gidaspow and Syamlal-O’Brien drag models were the preferred choices, with other models being rare exceptions.

As in DEM works, extensive research was devoted to the identification of the most suitable model for drag and other coefficients. Moreover, given the complexity of the KTGF, identifying the most suitable values for the parameters involved was mandatory in order to successfully perform simulations.

Hosseini and co-workers [227] employed the KTGF to model a cylindrical spouted bed and analysed the influence of a great number of simulation variables. Drag and solid shear viscosity had the most relevant influence and the use of the representative unit cell (RUC) drag model and the Syamlal et al. viscosity model was suggested. Moreover, the use of an algebraic equation for the granular temperature was accurate enough if an adequate restitution coefficient was specified. They also pointed out that the higher the restitution coefficient was, the lower the fountain height tended to be.

For a spouted bed, Wang et al. [210] noted that the Huilin-Gidaspow drag coefficient under-predicted the bed pressure drop and fountain height, suggesting the implementation of a modified drag model to take into account more appropriately the effect of the wall on the flow.

The specularity coefficient takes into account the friction between particles and the wall: it is an empirical parameter, whose limit values are 0 for perfect specular collisions and 1 for perfectly diffuse collision, depending on the roughness of the wall. Bettega and his colleagues [234] performed simulations in a pseudo-cylindrical (half-column) spouted bed, highlighting that the specularity coefficient had a strong influence on the motion of the solid phase, but not on the static pressure, velocity of the particles in the bed and solid fraction in the spout. Fattahi et al. [228] emphasised the relevance of the specularity coefficient too, identifying the most appropriate value for their case of study at 0.025 and encouraging the development of a correlation of this coefficient with different operational conditions.

Drag laws and specularity coefficient were also studied by Setarehshenas and co-workers [205] for a conical spouted bed containing heavy zirconia particles with the aim of optimising the simulation procedure. Gidaspow was found the best fitting drag law and the use of a tetrahedral mesh could reduce the calculation time without ruining the accuracy. The specularity coefficient significantly affected the behaviour of particles with an optimal value of 0.05. The particle-wall restitution coefficient did not influence the simulation: setting it as 1 or employing a no-slip boundary condition produced the same results.

The relevance of the specularity coefficient also depends on the geometry: Hosseini and colleagues [220] modelled a pseudo 2D spouted bed both in a 2D and a 3D approach. They highlighted that the latter yielded more accurate results but was significantly more sensitive to changes to the particle-wall restitution coefficient and the specularity coefficient (with best values found to be 0.2 and 0.05 respectively); nonetheless, they stressed out that the use of a complete 3D model was the best choice to accurately reproduce the bed behaviour.

3.2.2. Turbulence Modelling

Turbulence was not extensively discussed in most works and when considered, the k-ε turbulence model [239] was mostly employed. As it can be seen in Table 9, almost half of the works did not include a turbulence model.

Table 9.

Turbulence models.

Riera and co-workers [217] simulated a multi-phase spouted column to test the validity of three turbulence models: the k-ε model, the k-ω model [240] and the SST model [241]. They observed that the k-ε and k-ω models yielded similar results for an air-water mixture, while the SST model was the most adequate for the air-water-sand mixture.

For some researchers, the inclusion of turbulence complicates the model without significant benefits: Omar Reza et al. [203] argued in fact that the Reynolds number for particles inside the column can be estimated to be about 70. They performed simulations both in laminar conditions and with the k-ε dispersed turbulent model finding out that, in the bed region, the velocity and distribution of gas and particles were almost identical, but the behaviour of gas differed in the zone above the bed. In this case, Syamlal-O’Brien drag model best reproduced the experiments and a decrease in the value of the restitution coefficient made the volume-averaged velocities of gas and particles oscillate at a higher period.

3.2.3. Study of the Fluidisation Behaviour

Assessing the spouting behaviour of solids for different operating conditions is one of the main goals of CFD models, and it is especially useful for solids whose use is not completely established, such as irregular solids as corn [223].

After the validation of their model, using particles with diameter 1.44 mm, Tabatabaei and colleagues [221] employed it to obtain the complete regime map of a slot-rectangular spouted bed containing particles of diameter 3.77 mm; the momentum exchange between the solid and gas phases was calculated through a drag law they previously developed [238], which is a modification of the Di Felice [162] drag law. Jin and others [207,214] simulated the fluid dynamics of a spouted bed used as food Microwave Vacuum Dryer, obtaining that both the jet penetration depth and the pressure drop have an almost linear dependence on the spouting velocity.

Following an unusual CFD-based Equivalent Reactor Network (ERN) model, Du and colleagues [211] modelled the fluid dynamics of a spouted bed reactor employed as polyethylene gasifier to identify the separate fluid dynamics zone it features, and then considered each of them as a separate block in Aspen Plus© v7.3 (see Section 4).

Jin and co-workers [207] simulated the fluid dynamic behaviour of lettuce particles in a spouted bed in view of a microwave-vacuum drying application. The simulations confirmed that an increasing mass of lettuce required an increasing air flow rate to obtain the same flow pattern; moreover, it was observed that the penetration depth was proportional to the gas flow rate and that the pressure drop shifted from negative to positive values as the spouting velocity was increased. Şentürk Lüle et al. [25] proved that the TFM was able to reproduce a spouted bed operating with heavy zirconia particles (with density 6050 kg/m3), similarly to what happens in spouted nuclear fuel coaters.

3.2.4. Particle Mixing

Several groups employed the TFM approach to assess the mixing behaviour of binary or even ternary particles mixtures. As in the studies performed with the DEM approach, a common conclusion of most of these works was that, for each mixture, there was a value of gas velocity above which segregation was extremely mitigated or eliminated. This is not stated again in the following paragraphs, and only further findings are reported.

Usually, when segregation occurred, fine particles mainly circulated in the inner circle, and coarse particles in the outer, due to the difference in the gas-solid drag coefficient. This was observed by Du et al. [204] in a spouted bed; they showed that this effect was more visible for particles with different density rather than those with different diameter; all of their analysis were performed with particles with diameter of 0.39 mm as the first solid phase.

The behaviour of a binary mixture of particles with different density and diameter at various relative volume fractions was also studied by Wang and colleagues [230], who developed a 3D model of a two-jets spout-fluidised bed. Their work highlighted that segregation was mainly caused by the slight difference of velocity of the two solids around bubbles, while the circulating movement of particles caused by the two jets enhances the mixing. They concluded that segregation phenomena occurred more significantly for mixtures comprising equal volumetric amounts of the two solids, and that segregation was prevented when the two volumetric fractions were largely different. The difference in diameter was taken into account by Santos et al. [208], who reproduced the behaviour of a binary mixture of glass particles in a spouted bed. Larger particles were mostly present in the spout and in the middle of the annulus, with their concentration reaching a minimum between these two zones and near the wall.

Regarding more irregular solids, Bove and his collaborators [209] simulated the spouting behaviour of a mixture of silica and rice straw with the aim of gasifying the latter. They obtained good results in the reproduction of the fountain height but not highly accurate in the prediction of the pressure drop. Similarly, Melo and others [206] studied the behaviour of mixtures of sand and low density polyethylene (LDPE)/Al composites at several volumetric ratios for future pyrolysis applications. They employed the Gidaspow drag model and the dispersed k-ε turbulence model and good results were obtained, with errors in the pressure drop up to 35%.

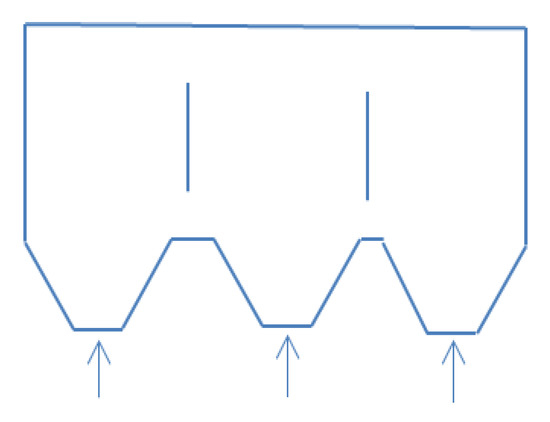

A good mixing between solids is of key relevance for every process, but this is especially true when SB are used as plain mixers: Liu et al. [232] tested the effectiveness of an industrial-scale spout-fluid mixer of biomass and inert material with the aid of a CFD model. The mixer also had lateral gas inlets and could process 18.75 t/h of biomass in a continuous manner. A mixing effectiveness of more than 80% was achieved provided the optimal values for the spouting and the lateral gas flows were set. However, when the spouting velocity was increased, mixing was hindered because the trajectories of solids, fed from the upper part of the device, were affected; mixing also worsened if the lateral gas flow was higher than half of the spouting gas flow.

Eulerian-Eulerian simulations of solids with size distribution, as it can be the case of biomass, is more feasible than with the Eulerian-Lagrangian approach as the limitations related to the mesh size and time step do not apply. Nonetheless, no articles dealing with TFM simulation of such systems in spouted beds were found during the review period. Contributions to this interesting and useful research topic could represent a significant advance in the knowledge of spouted beds specially when applied to chemical processes.

3.2.5. Correlations, Dimensioning and Scale-Up Studies