Design and Production of Animated Image Photovoltaic Modules

Abstract

:1. Introduction

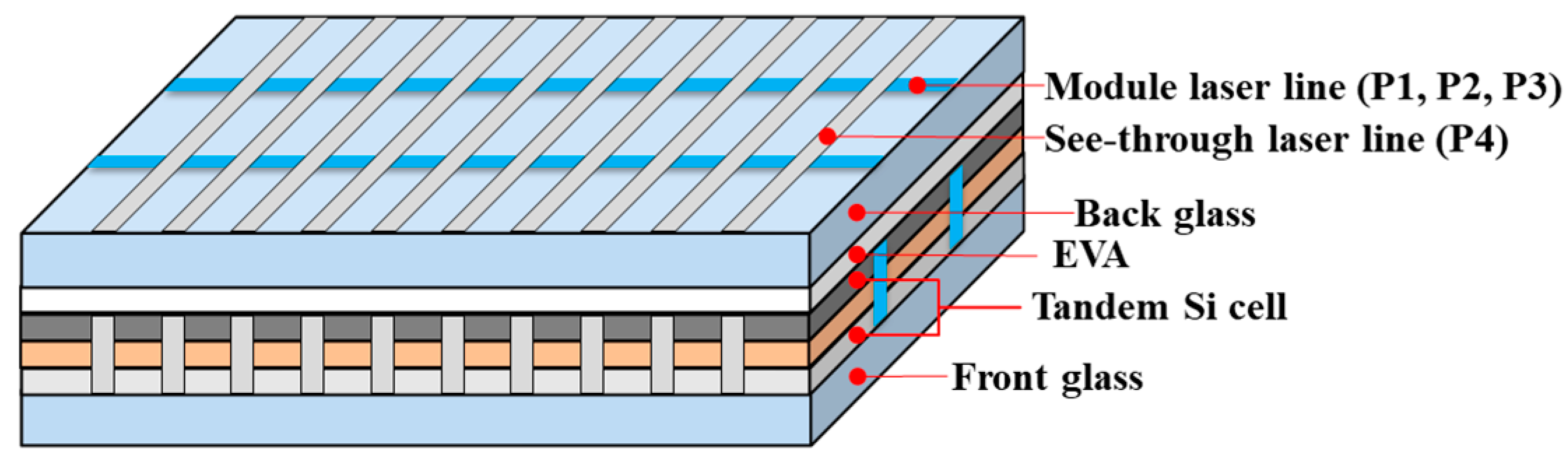

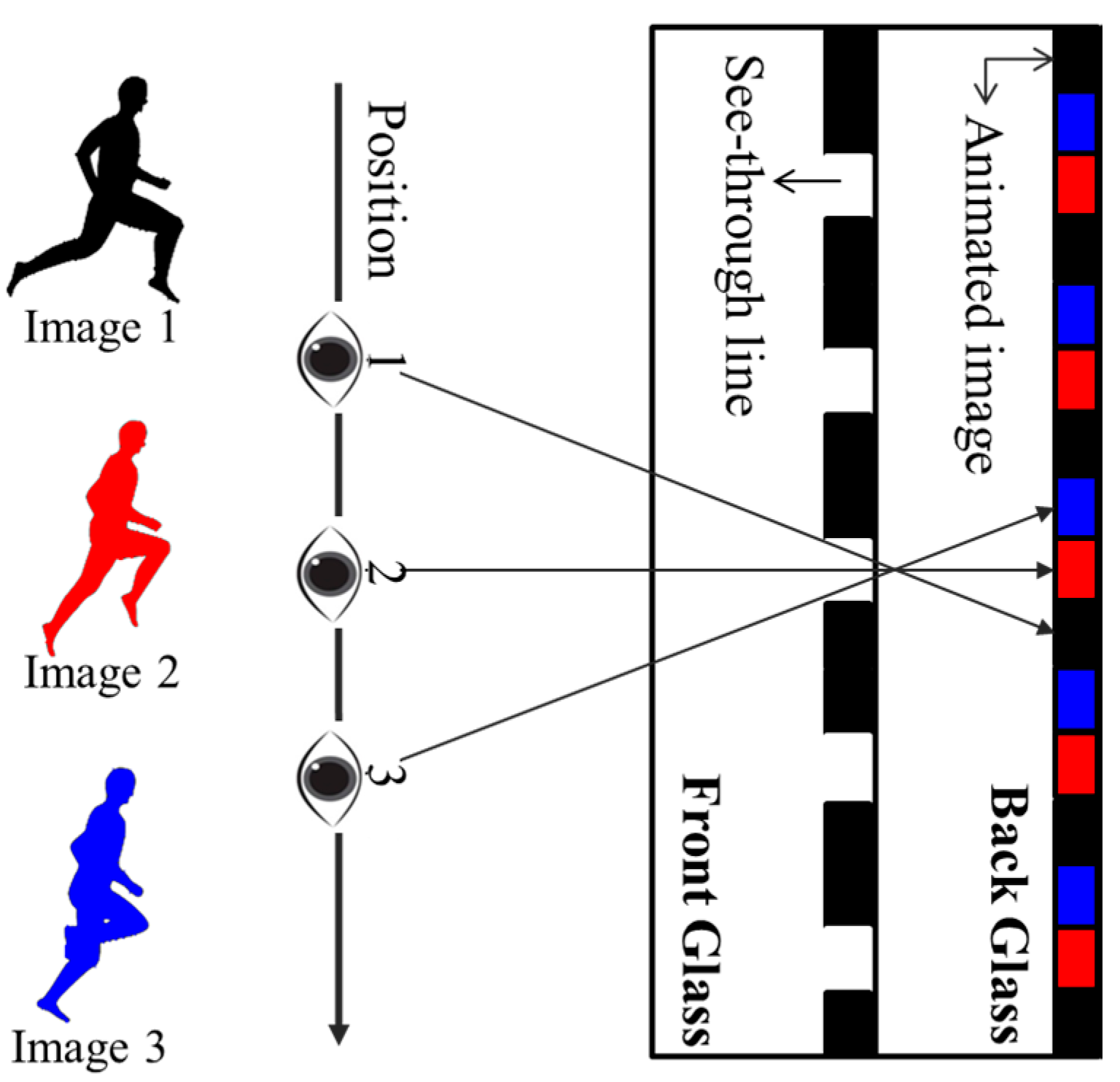

2. Materials and Methods

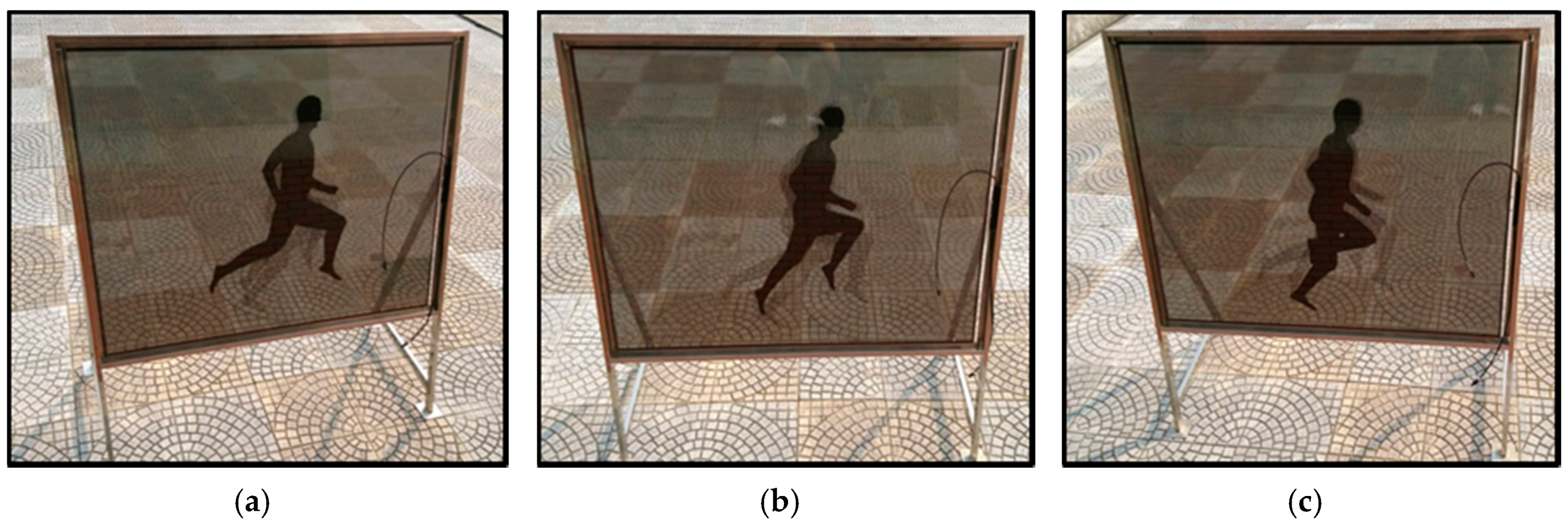

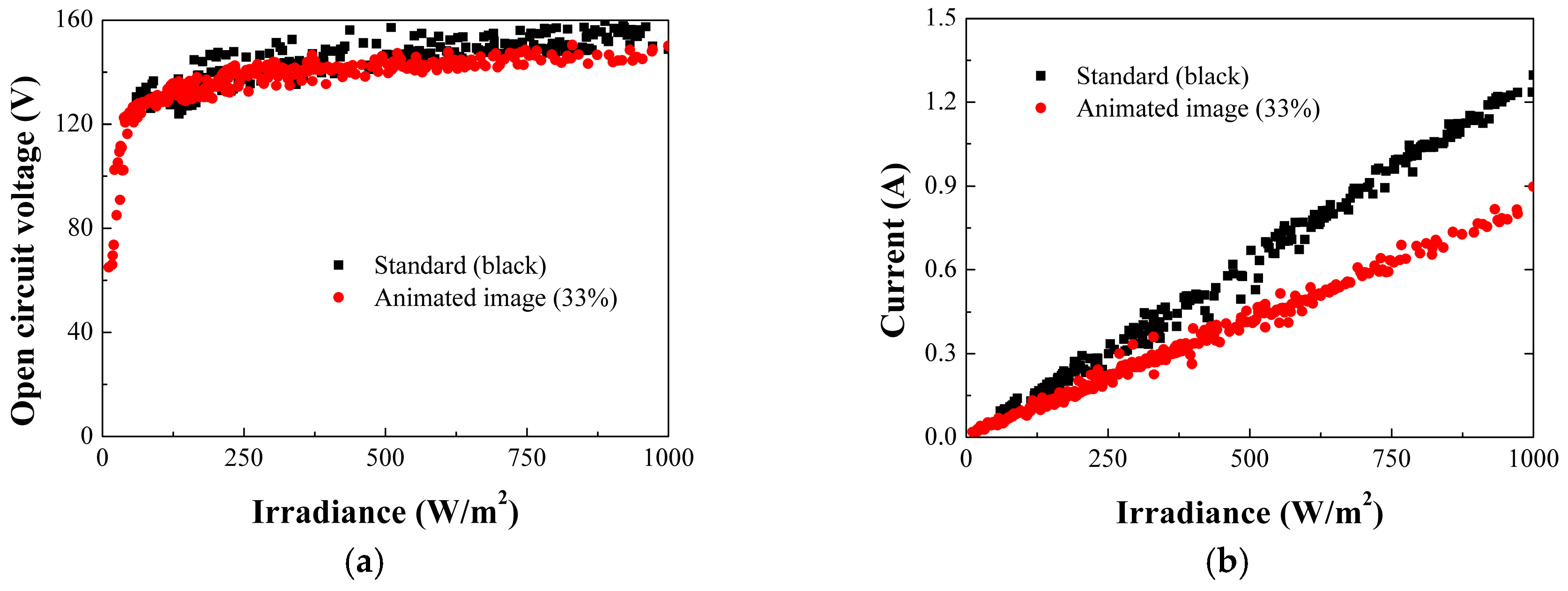

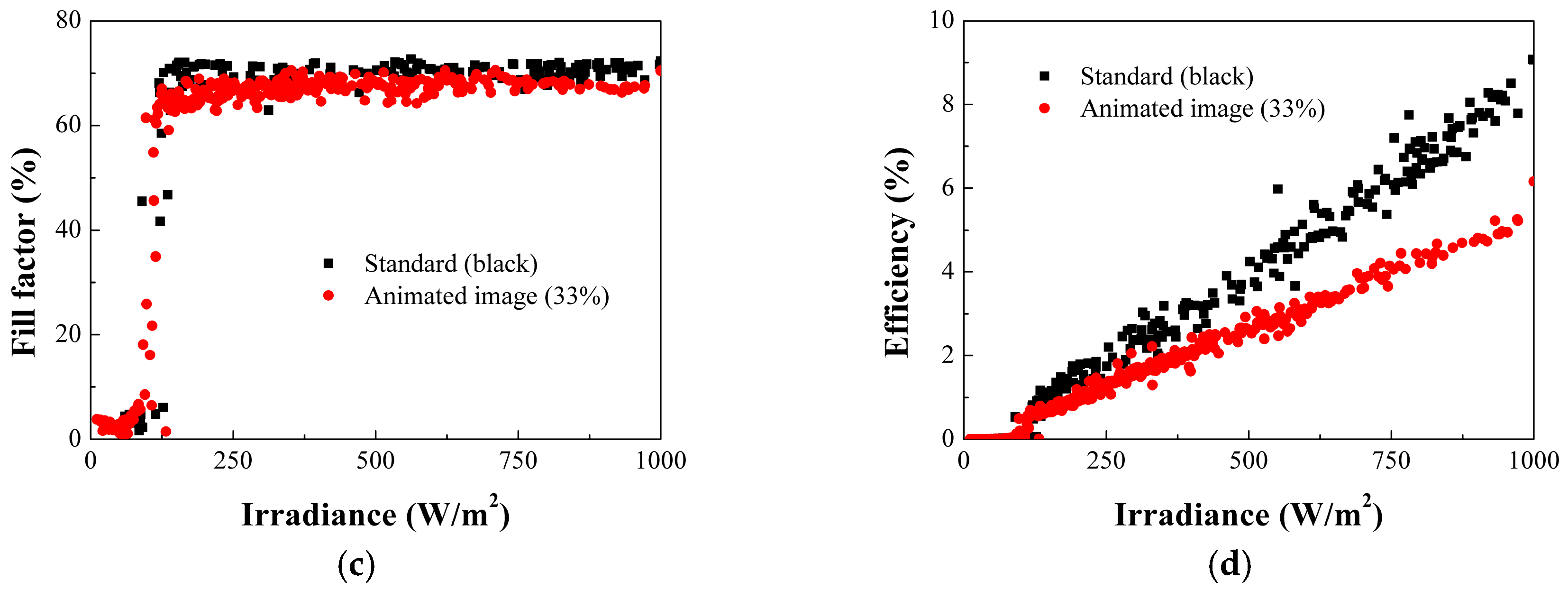

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Solar Power Energy. Global Market Outlook for Solar Power 2017–2021; Solar Power Report; SolarPower Europe: Brussels, Belgium, 2017. [Google Scholar]

- Lee, H.M.; Yoon, J.H.; Kim, S.C.; Shin, U.C. Operational Power Performance of South-facing Vertical BIPV Window System Applied in Office Building. Sol. Energy 2017, 145, 66–77. [Google Scholar] [CrossRef]

- Lim, J.W.; Kim, G.; Shin, M.; Yun, S.J. Colored a-Si:H Transparent Solar Cells Employing Ultrathin Transparent Multi-layered Electrodes. Sol. Energy Mater. Sol. Cells 2017, 163, 164–169. [Google Scholar] [CrossRef]

- Myong, S.Y.; Jeon, S.W. Design of Esthetic Color for Thin-film Silicon Semi-transparent Photovoltaic Modules. Sol. Energy Mater. Sol. Cells 2015, 143, 442–449. [Google Scholar] [CrossRef]

- Wade, N. Art and Illusionists, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-319-25229-2. [Google Scholar]

- Je, U.; Kim, J.; Cho, H.; Lim, H.; Park, C.; Kim, G.; Park, S.; Park, Y.; Kim, K.; Woo, T.; et al. Indirect Measurement of High Grid Strip Densities over Nyquist Sampling Rate Based on the Moiré Pattern Analysis for Quality Assurance in Grid Manufacturing. Measurement 2016, 91, 634–640. [Google Scholar] [CrossRef]

- Gauntt, D.M.; Barnes, G.T. Grid Line Artifact Formation: A Comprehensive Theory. Med. Phys. 2006, 33, 1668–1677. [Google Scholar] [CrossRef] [PubMed]

- Vasarely, V. Vasarely: Plastic Arts of the 20th Century, 1st ed.; Editions Du Griffon: Neuchatel, Switzerland, 1965; ISBN 9780302002568. [Google Scholar]

- Seder, R.B. Moveable Animated Display Device. U.S. Patent US 7151541 B2, 19 December 2006. [Google Scholar]

- Avagliano, S.; Bianco, N.; Manca, O.; Naso, V. Combined Thermal and Optical Analysis of Laser Back-scribing for Amorphous-silicon Photovoltaic Cells Processing. Int. J. Heat Mass Transf. 1999, 42, 645–656. [Google Scholar] [CrossRef]

- Ichikawa, Y. FabricationTechnology for Large-area a-Si Solar Cells. Sol. Energy Mater. Sol. Cells 1994, 34, 321–328. [Google Scholar] [CrossRef]

- Berg, R.B.; Calwer, H.; Marklstorfer, P.; Meckes, R.; Schulze, F.W.; Ufert, K.D.; Vogt, H. 7% Stable Efficiency Large Area a-Si: H Solar Modules by Module Design Improvement. Sol. Energy Mater. Sol. Cells 1993, 31, 253–261. [Google Scholar]

- Wang, J.; Wang, H.; Du, J.; Sun, R.; Xu, C.; Zhang, Y.; Wang, D.; Liu, T.; Huang, Y.; Jia, H.; et al. Performance Improvement of Amorphous Silicon See-through Solar Modules with High Transparency by the Multi-line ns-laser Scribing Technique. Opt. Lasers Eng. 2013, 51, 1206–1212. [Google Scholar] [CrossRef]

- Bovatsek, J.; Tamhankar, A.; Patel, R.S.; Bulgakova, N.M.; Bonse, J. Thin Film Removal Mechanisms in ns-laser Processing of Photovoltaic Materials. Thin Solid Films 2010, 518, 2897–2904. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Thin-Film Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval, 2nd ed.; International Electrotechnical Commission: Geneva, Switzerland, 2008. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, Y.-C.; Wu, H.-Y.; Hsu, C.-H.; Jiang, Y.-L.; Lien, S.-Y. Design and Production of Animated Image Photovoltaic Modules. Energies 2017, 10, 1712. https://doi.org/10.3390/en10111712

Ou Y-C, Wu H-Y, Hsu C-H, Jiang Y-L, Lien S-Y. Design and Production of Animated Image Photovoltaic Modules. Energies. 2017; 10(11):1712. https://doi.org/10.3390/en10111712

Chicago/Turabian StyleOu, Yu-Chih, Hsin-Yu Wu, Chia-Hsun Hsu, Yeu-Long Jiang, and Shui-Yang Lien. 2017. "Design and Production of Animated Image Photovoltaic Modules" Energies 10, no. 11: 1712. https://doi.org/10.3390/en10111712

APA StyleOu, Y.-C., Wu, H.-Y., Hsu, C.-H., Jiang, Y.-L., & Lien, S.-Y. (2017). Design and Production of Animated Image Photovoltaic Modules. Energies, 10(11), 1712. https://doi.org/10.3390/en10111712