1. Introduction

End stroke cushioning in a hydraulic cylinder is important because it avoids mechanical shocks by reducing the piston velocity at the end of the cycle. However, the cushioning system has to be carefully designed in order to minimize the operating cycle time, allowing faster machine operating cycles for productivity increase. A proper cushioning system reduces machine noise for less downtime and lowers the machine maintenance costs [

1].

Cushioning can be done with external control, but for mobile applications, this is not generally appropriate, as it requires a complex set-up of mechanical and hydraulic components [

2,

3]. Alternatively, in this case of mobile applications, internal end-stroke cushioning systems are preferably used.

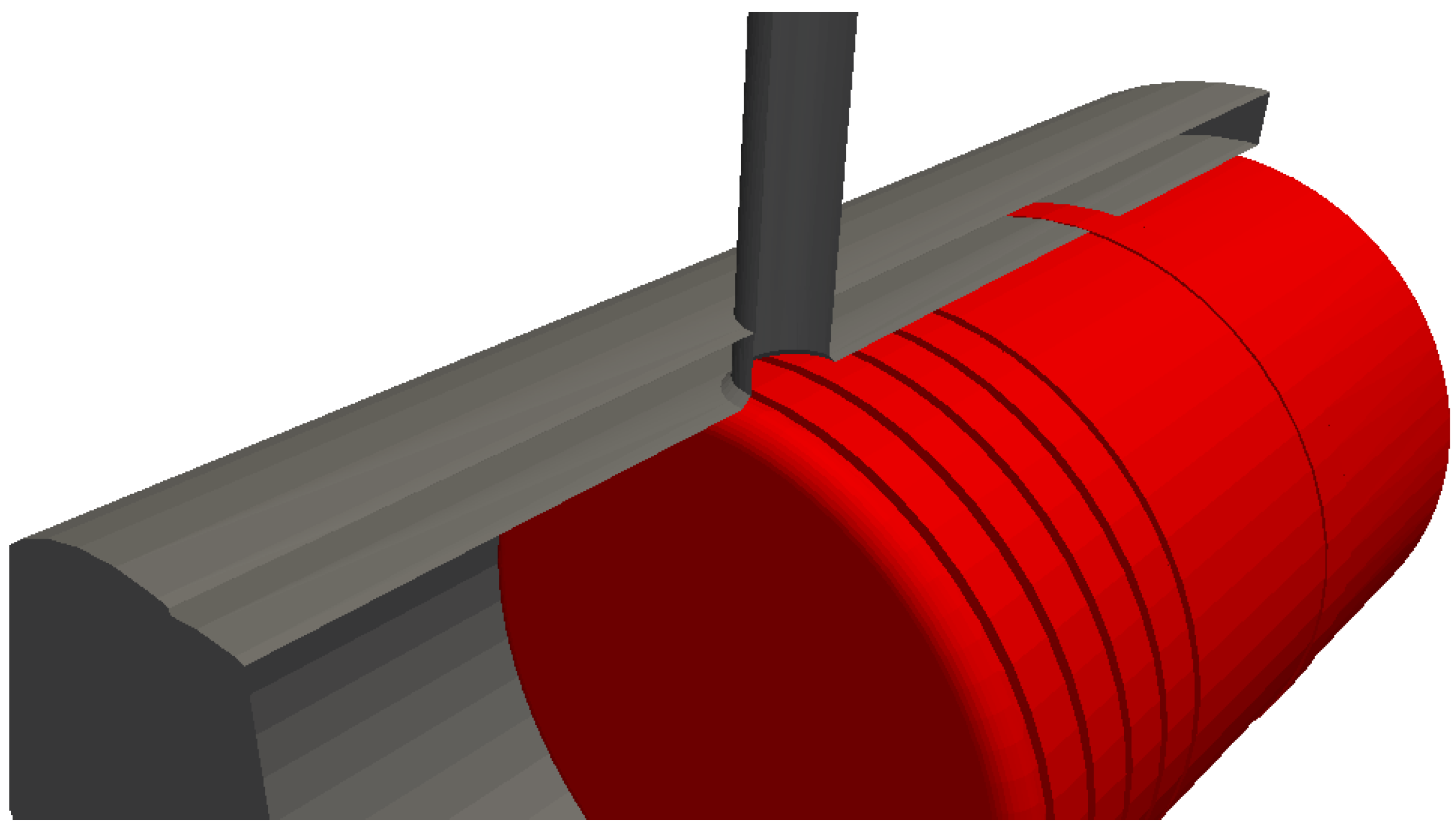

There are two main types of stroke-end hydraulic cylinder cushioning. On the one hand, it is usual to include a spear with a profile that fits conveniently in a hole drilled at the end of the cylinder. Throttling is then performed in this orifice in order to control the velocity of the piston and the pressure in the cylinder chamber. On the other hand, machining can be performed in the piston with a given number of grooves that control the oil flow rate and the pressure loss.

The first case has been extensively studied. Borgui et al. [

4] present a numerical model, supported by experimental results, obtained by the analysis of a considerable number of geometries. Schwartz et al. [

5] presented a similar work to Borghi et al. Both works demonstrate the complexity of the cushioning system and the sensitivity to the main geometric parameters. The recent work by Prahallad and Raveender [

6] analyses different geometries used in end-stroke cushioning systems. Gao et al. [

7] use the commercial simulation software of mechatronic systems AMESIM to optimize a cushioning system with a step-shaped spear.

The second type of internal cushioning, with groove machining in the piston, has not received much attention. The effect of grooves in friction reduction in pistons is well documented [

8,

9], but the effect on stability or cushioning performance has not been extensively studied.

Viscous flow in cylinder gaps has been thoroughly studied in the context of piston pumps. Recently, Zawistowski and Kleiber [

10] made an extensive review of simulation methods in this field, remarking on the contributions of Bergada et al. [

11,

12] and Hao and Qi [

13], who solved Reynolds equations for flow leakage in piston pumps. Ivantysynova and Huang [

14] considered elastohydrodynamic effects. Similarly, the effect of grooves in the piston has been numerically analyzed from the point of view of stability in piston pumps by Khumar and Bergada [

15].

Very recently, Algar et al. [

16] published an experimental test of cushioning performance of a cylinder with two grooves in the piston, finding that the three dimensional piston displacement plays an important role as a self-adjusting element.

The purpose of this work is to present a method to estimate the value of the pressure-drop coefficients for the flow through piston grooves towards the outlet port. Special attention is paid to the role of eccentricity on the cushioning performance, as a result of the research reported by Algar et al. [

16]. This method is aimed at providing the model to be introduced in a dynamic system simulation of the cushion system of a cylinder. The long-term project objective is to develop a dynamic system simulation for the accurate design of a grooved-piston cushioning cylinder in order to improve and optimize operating cycles of cylinders for mobile applications, enhancing the efficiency and reducing noise.

The work is organized as follows. In the next section, the numerical simulation is described, comprising the geometry, the meshing and the numerical model.

Section 3 describes the experimental test bench.

Section 4 presents the results obtained from the numerical simulation. In

Section 5, the results are discussed and the main conclusions are drawn.

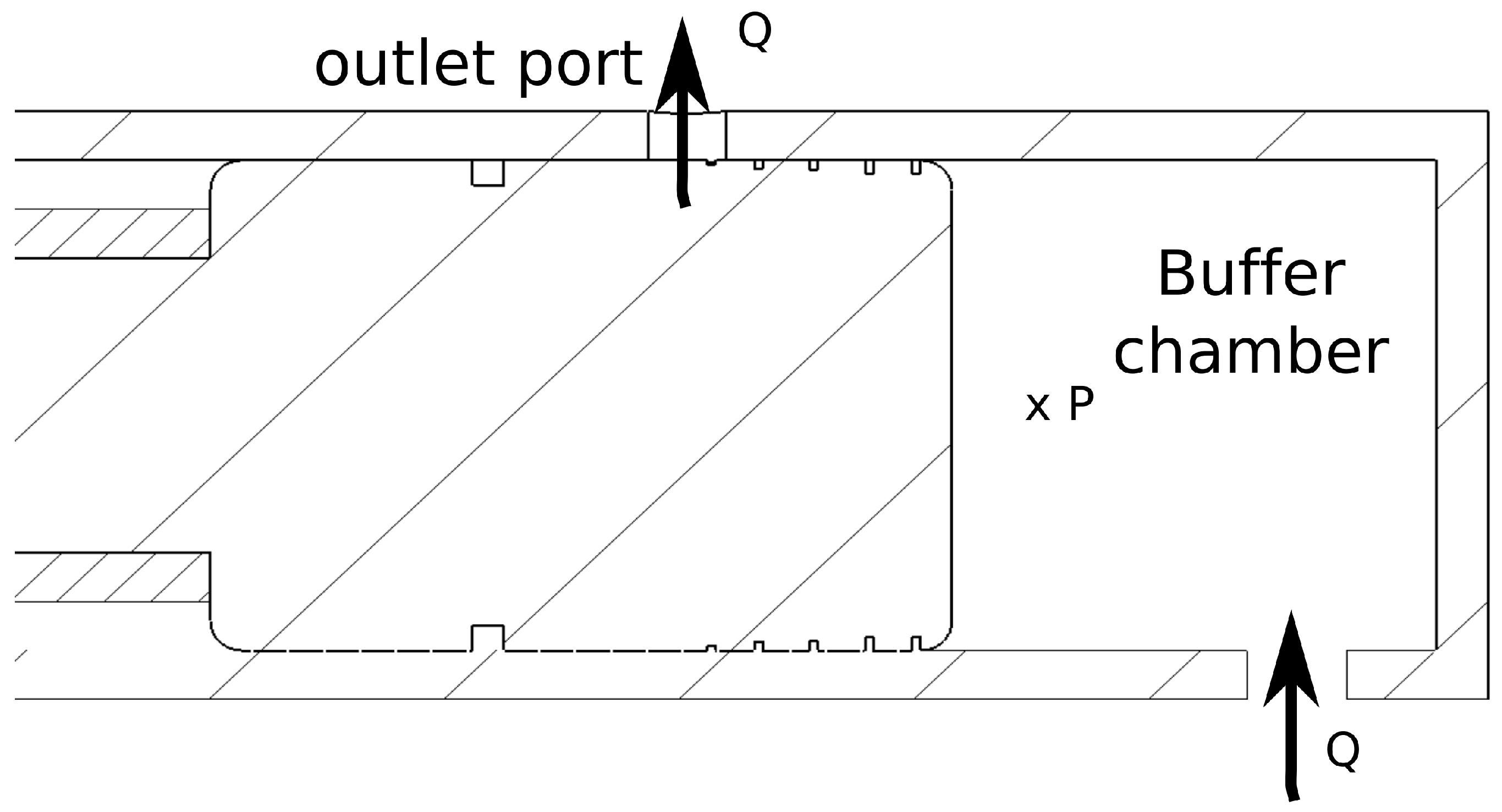

3. Experimental Test Bench

The numerical results have been compared and contrasted with the experimental measurements. A cylinder with a piston identical to the simulated geometries was exposed to a certain flow rate, and the pressure in the buffer chamber was measured. As in the numerical simulations, the piston was kept static, with a mechanical constraint, for the defined positions R12, R23, R34, R45 and R5. The flow rate was introduced in the buffer chamber through an additional inlet port, as schematically presented in

Figure 5. For the centered piston experiments, the concentricity was imposed with two modified wear rings installed behind the seal. For the attached piston experiments, the wear rings were taken off and the piston was mechanically forced against the outlet port with a wedge.

The mechanical constraint of the piston in the experimental tests posed a question with respect to the velocity condition of the piston in the numerical experiments. In real acting pistons, and also in the present numerical simulations, this is essentially Poiseuille flow with some Couette component due to piston drag. Nevertheless, as the velocity ratio between the piston and the mean flow in the gap was the surface ratio between the piston and the gap surface, which, for our case, was around 80, the effect of the piston drag has been neglected. A rough estimation of the pressure-drop variation due to the velocity in the piston gave around 0.5%.

The pressure and flow rate were acquired with a Parker Service Master Easy, equipped with a pressure transducer PD-1500 and a hydraulic flow meter SCFT-0116-PD. The pressure transducer, installed in the buffer chamber and in the outlet port, had a measurement range of between 0 and 400 bar and an accuracy of 0.5% full scale, that is, 2 bar. The measurement range of the flow meter was between 4 and 60 L/min with an accuracy of 1% full scale, that is, 0.6 L/min. The temperature of the experiments was set at C. The oil was class 32S, with a viscosity of and a density of at this temperature. The temperature was monitored with the temperature sensor for the Parker Service Master Easy SCT-150-04-02. This sensor measured the temperature in the hydraulic flow meter, which was located just behind the outlet port of the cylinder. The temperature of the oil was controlled with a heat exchanger in an auxiliary circuit. Therefore, it could be assumed that the variation in the temperature of the oil flowing through the grooves was negligible. Additionally, it should be noted that the experimental rig was disassembled and reassembled, and the repeatability of experimental measurements had not been tested. Similarly, as a result of roundness uncertainty, experimental measurements can be affected by a particular orientation of the piston inside the cylinder. These issues have not been considered in the present work.

4. Results

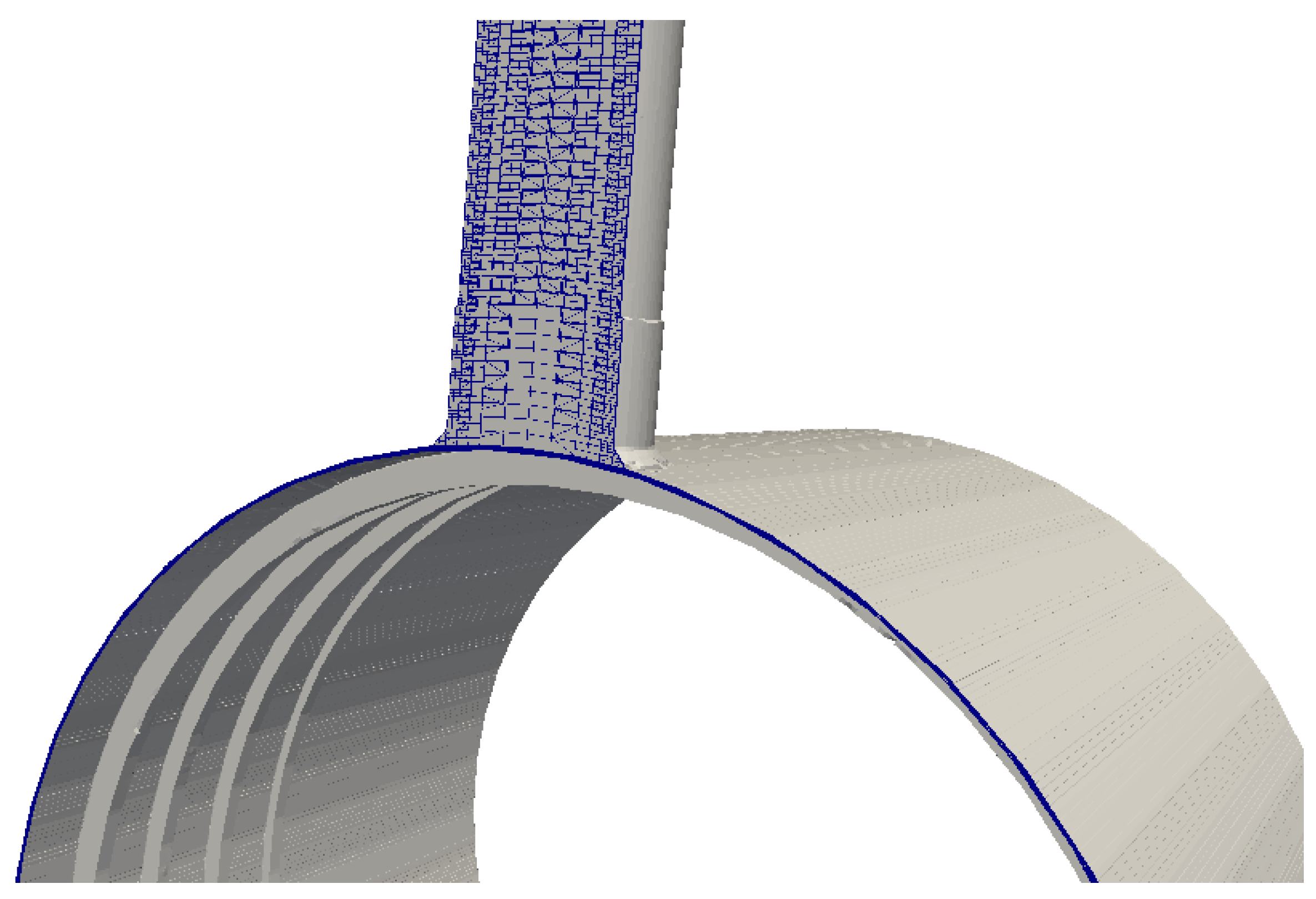

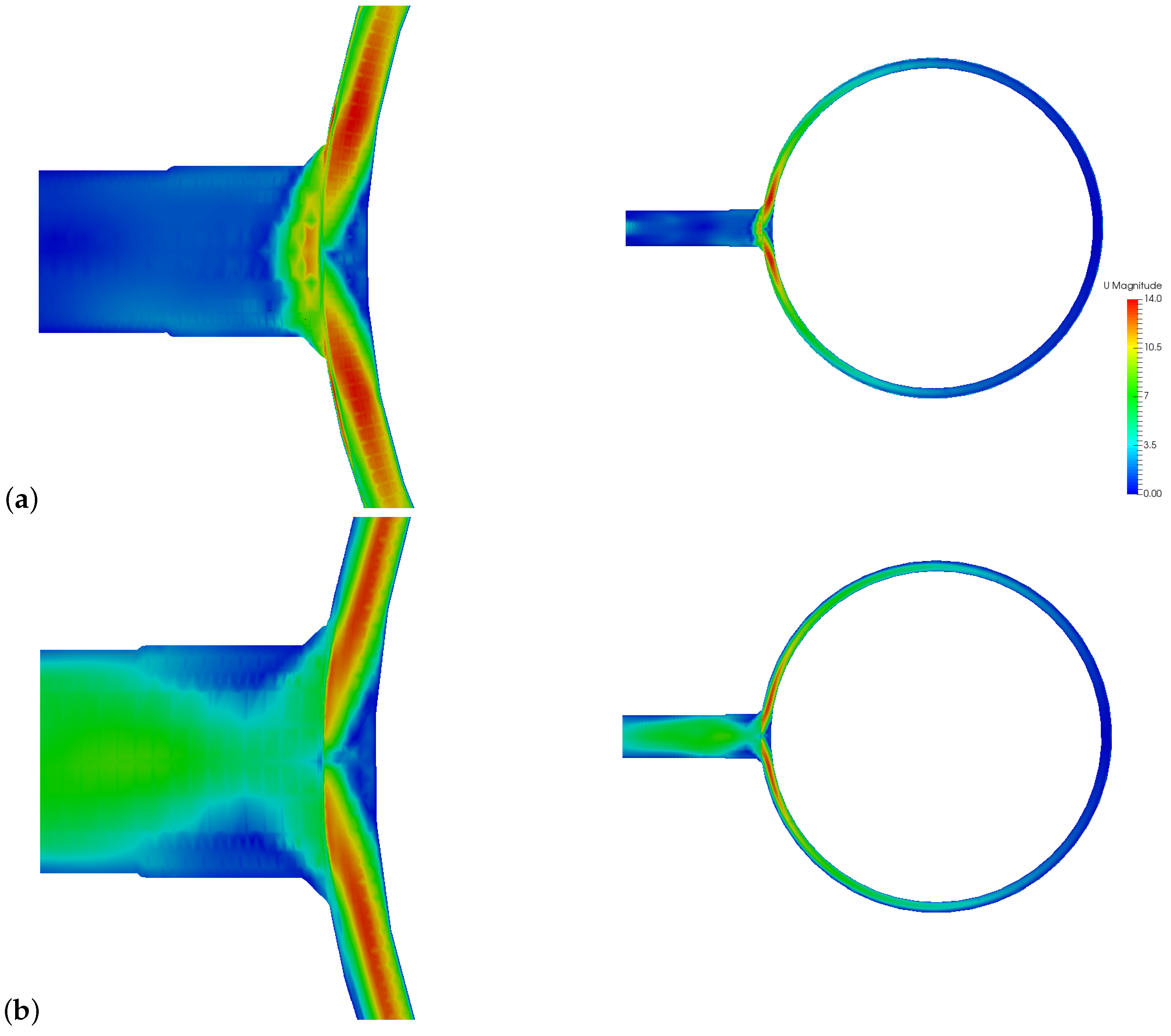

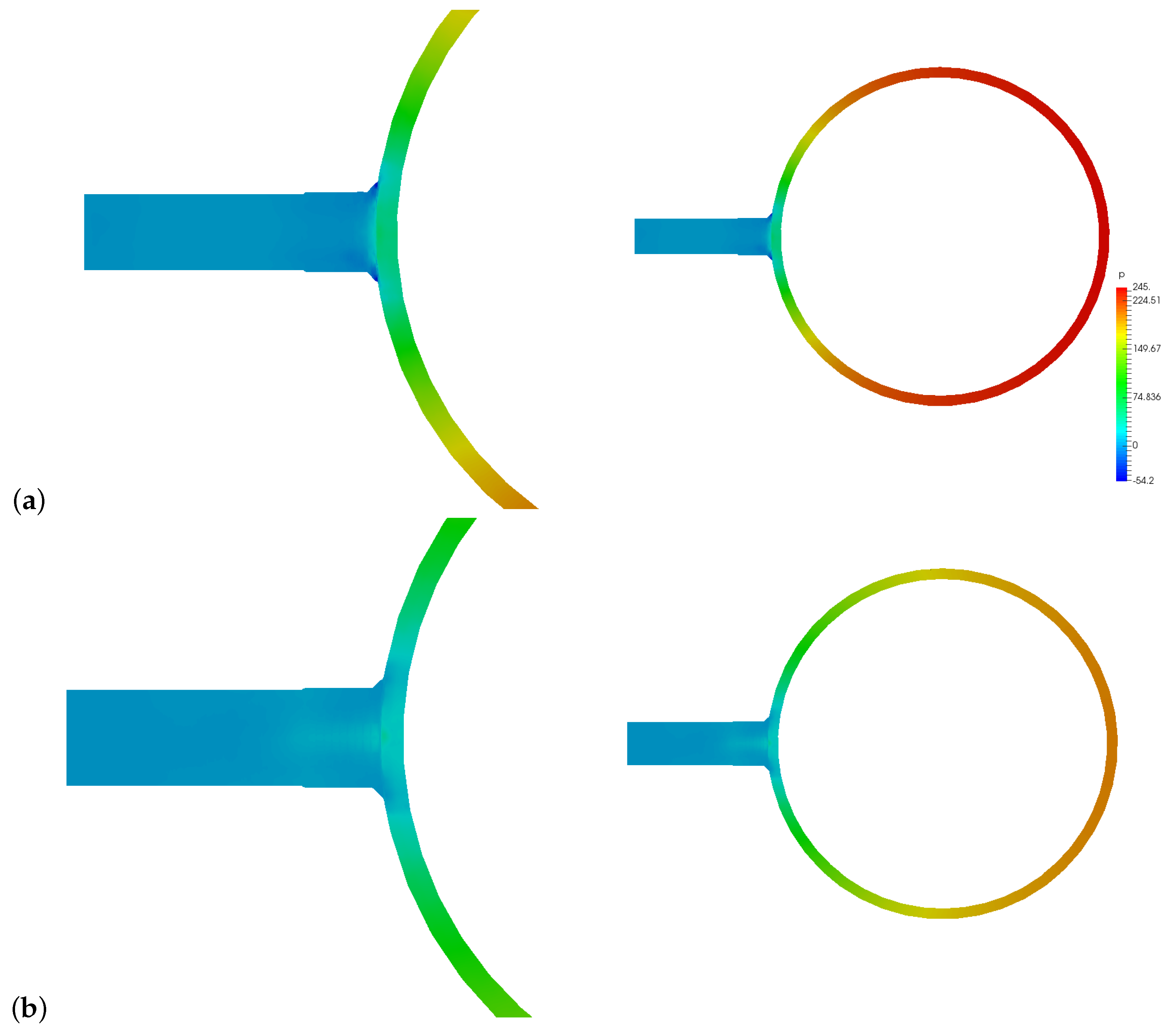

The distribution of the pressure and velocity magnitude has been plotted for all the grooves in all the piston positions, that is, grooves 1 and 2 for R12, grooves 2 and 3 for R23, grooves 3 and 4 for R34, grooves 4 and 5 for R45 and, finally, groove 5 for R5. These distributions have been extracted for the centered and off-centered piston. For the sake of illustration, the pressure and velocity contours are shown for the centered piston position R12 in

Figure 6a,b and

Figure 7a,b. These plots reveal that both the pressure and velocity magnitude take a constant value in almost half the circle, in the opposite side of the outlet port.

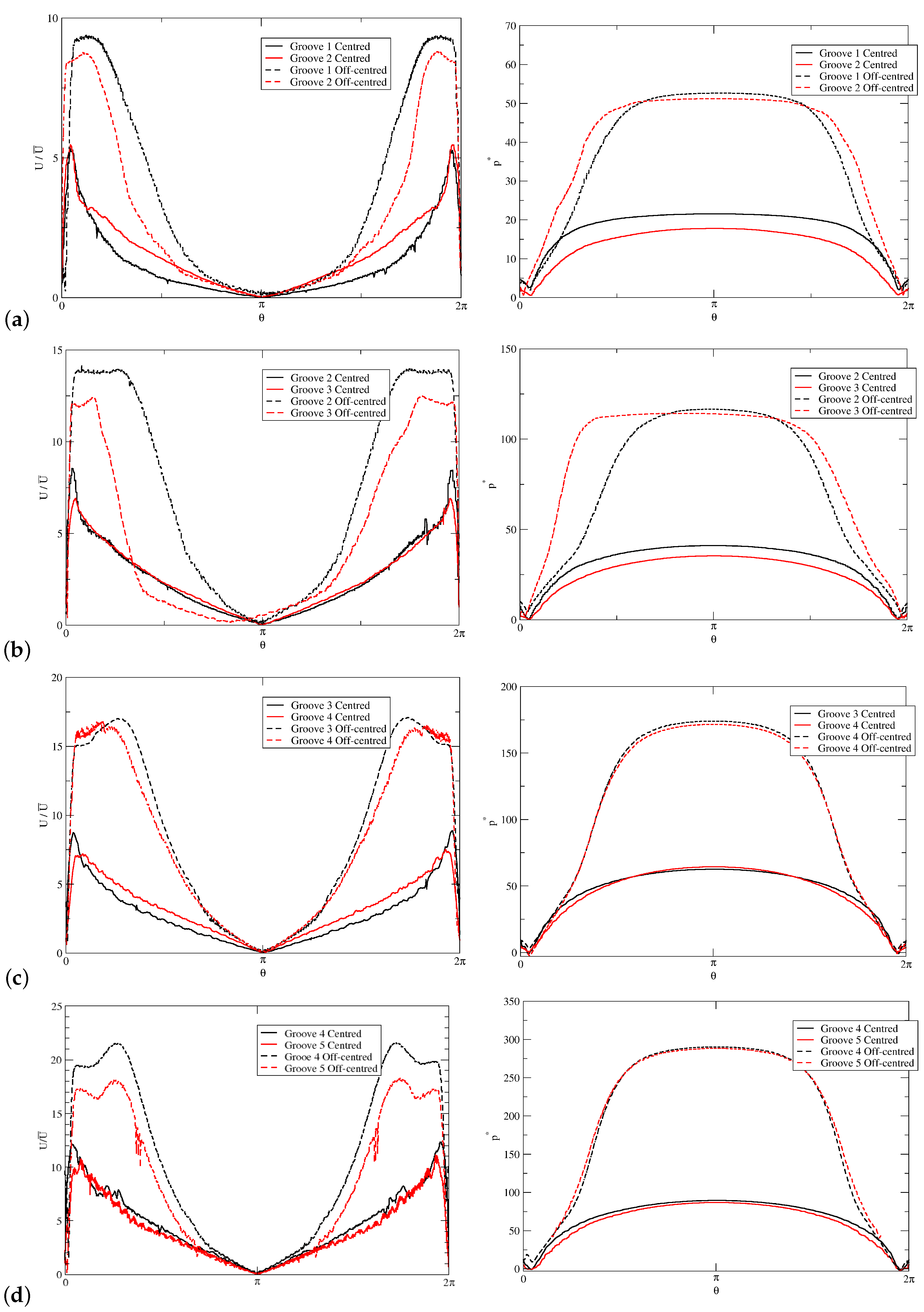

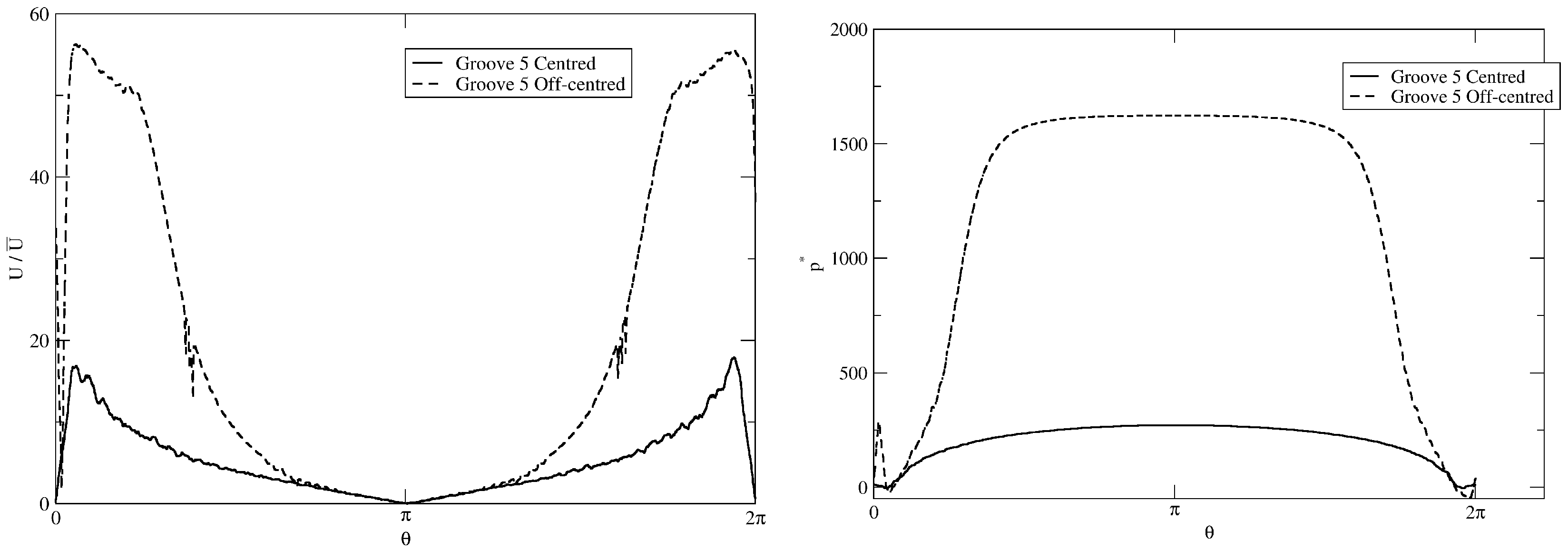

Figure 8 and

Figure 9 show the pressure and velocity distribution for all the grooves for the centered and off-centered piston in all the analyzed positions.

The velocity has been normalized with the average velocity in the outlet port, and the pressure has been normalized with the dynamic pressure in the outlet port. The graphs are plotted versus the polar angle, where 0 and

are the positions of the outlet port. The flow behaviour was clearly different for the centered and off-centered piston. Several points can be highlighted. First, the fluid velocity is much higher in grooves when the piston is radially displaced. When the piston is attached to the cylinder, all the flow is drawn through the grooves. When the piston is centered, this flow rate is distributed between the grooves and the gap between the cylinder and piston.

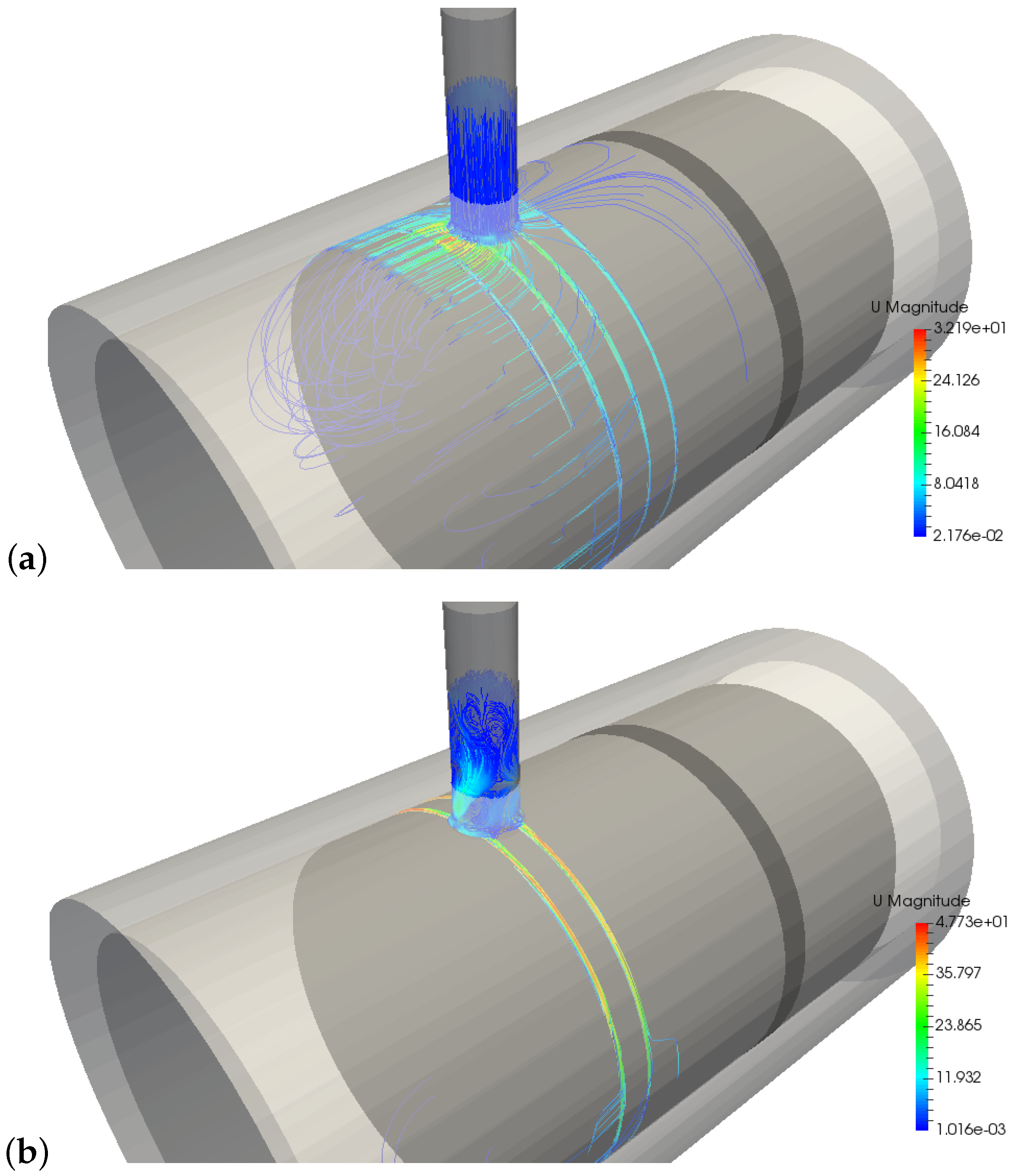

Figure 10a,b shows the streamlines with the velocity for flow at position R34.

Figure 10a shows the streamlines for the centered piston. It shows how fluid reaches the outlet port both through the grooves and the gap, particularly in the zone next to the outlet port. Part of the flow is even fed through grooves 2 and 5.

Figure 10b shows streamlines for the attached piston. The fluid dynamic behaviour is completely different. The low is null in the gap, except in the opposite side of the outlet port, feeding only grooves 3 and 4 that lead fluid to the outlet port. Consequently the velocity is higher and so is the pressure drop. Second, the pressure is also much greater in grooves when the piston is attached to the cylinder. That indicates that, as expected, the pressure drop is larger through the grooves than in the gap. This pressure presents a central plateau that is more extended and flat for the attached piston.

Flow coefficients, defined as

where

Q is the flow rate;

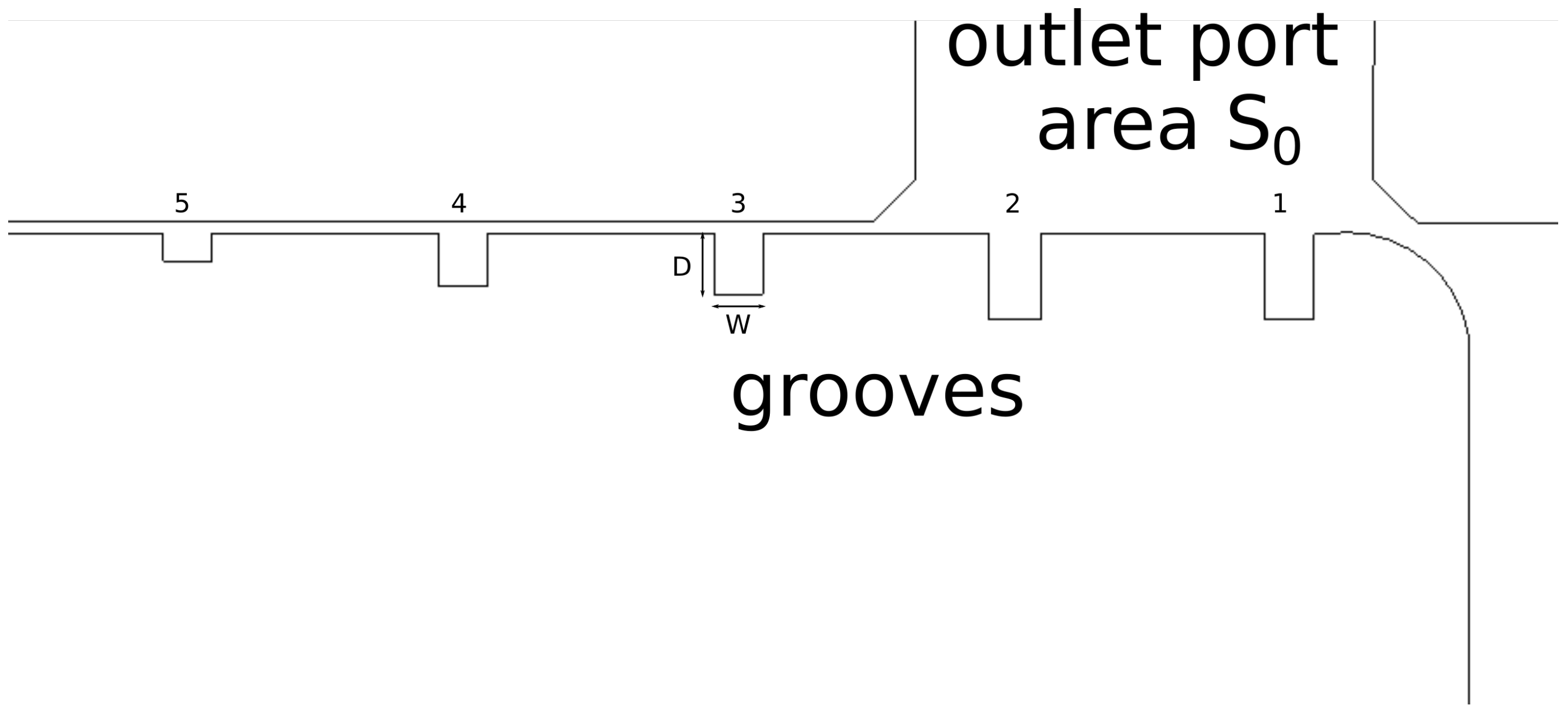

is the outlet port area, as depicted in

Figure 2;

is the difference in pressure between the outlet port and buffer chamber in the cylinder; and

is the density of the fluid, have been analyzed and compared with experimental measurements. The results are listed in

Table 2 and

Table 3. Additionally, Reynolds numbers, as defined in Equation (

3), are presented for experimental measurements. For all the numerical results, Reynolds number is 167. The error for the CFD results has been estimated from uncertainty due to mesh convergence. As this gives an uncertainty of 9% for the pressure drop, this leads to an estimated error of 5% for

.

The Reynolds number was kept constant in the CFD simulations for the sake of simplicity. In the case of the experimental measurements, the value of the flow rate and, consequently, of the Reynolds number was limited by the capacity of the pressure transducer. Because pressure loss was appreciably higher for positions R45 and R5, the flow rate had to be reduced in order to adequately measure the pressure in the buffer chamber.

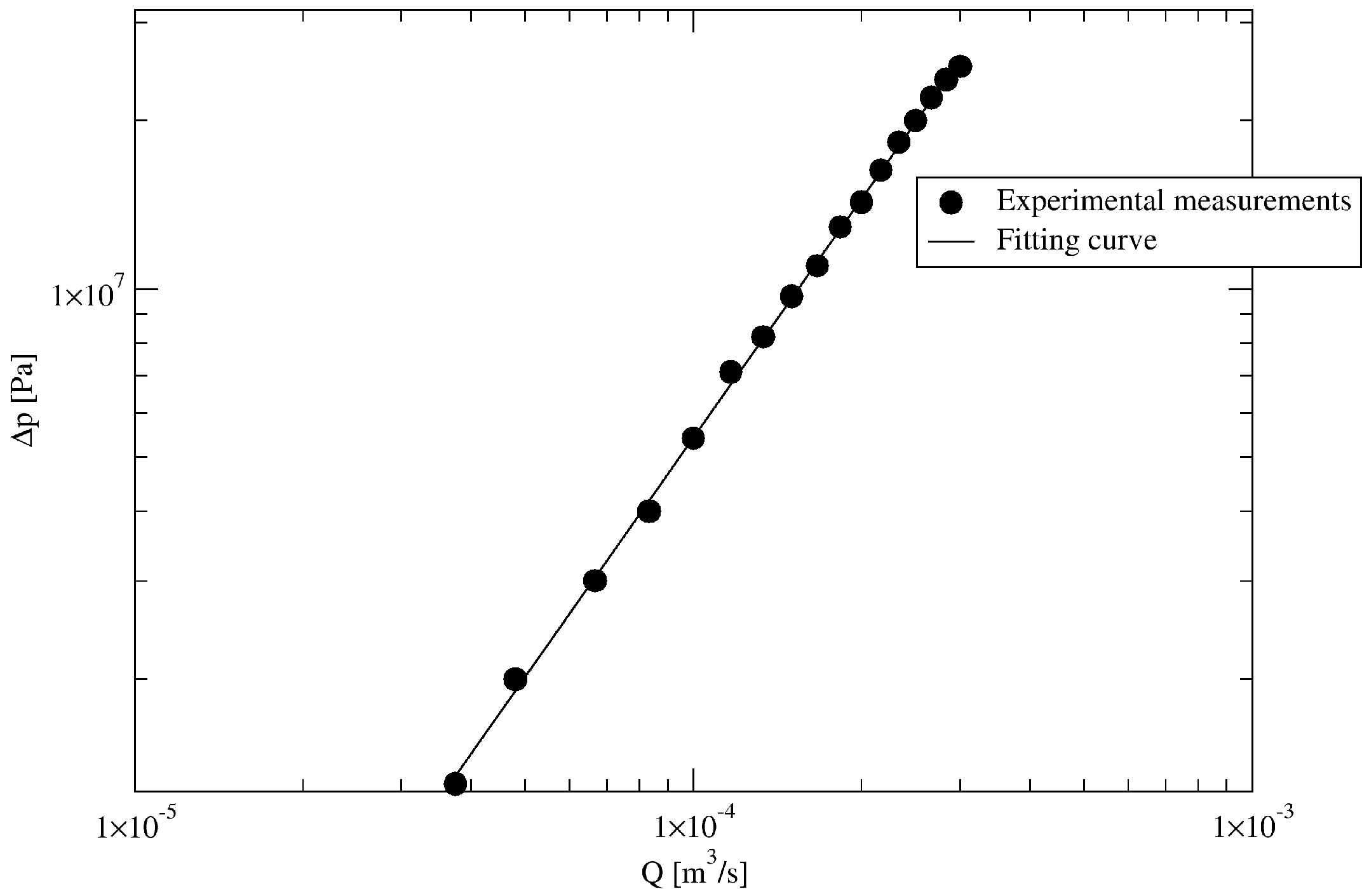

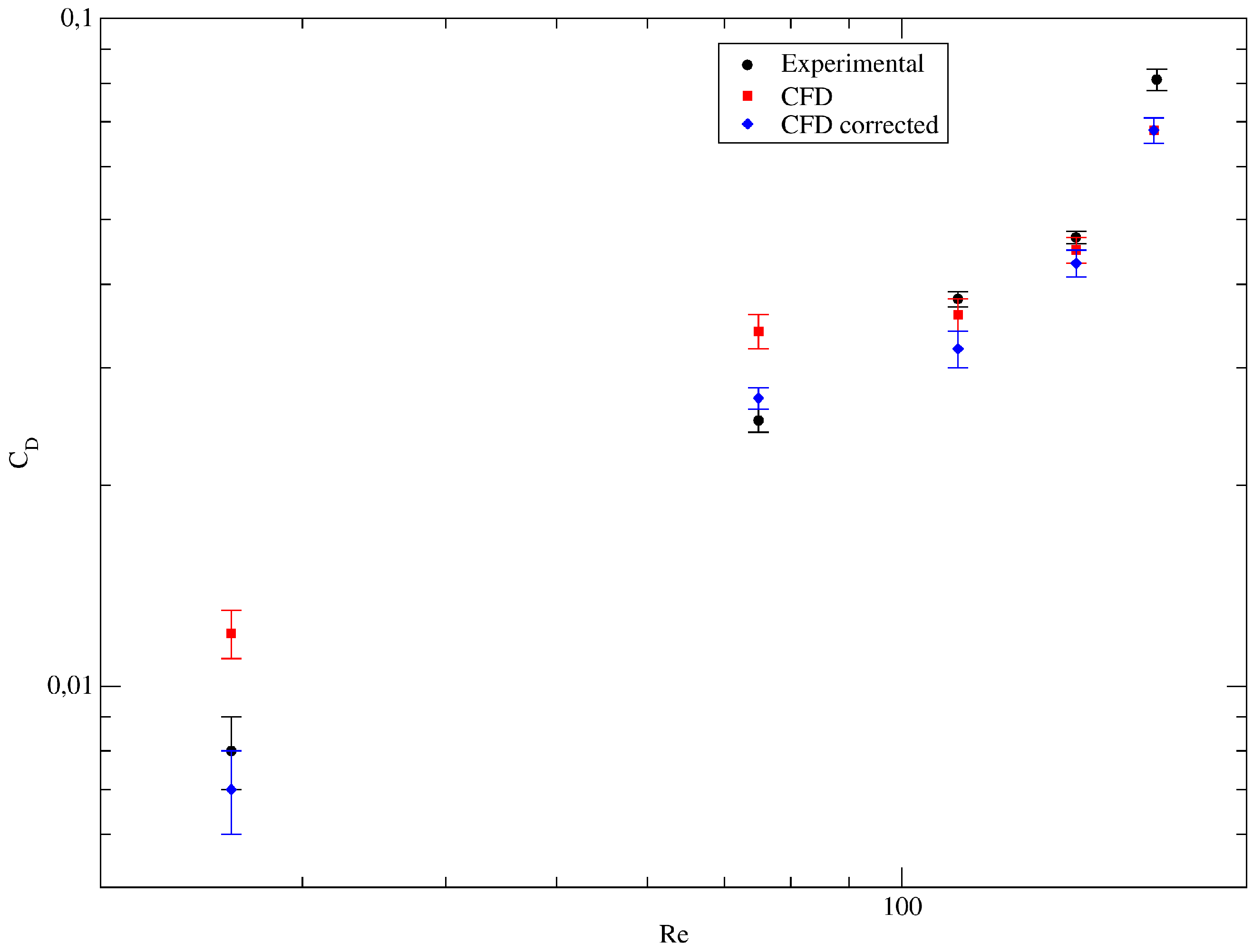

As a consequence of the increase in the pressure loss, the values of the flow coefficients decreased with the position of the piston. Nevertheless, a significant discrepancy between the CFD calculation and experimental measurements was found, essentially as a result of the difference in the Reynolds numbers. In order to correct the numerical calculation, a correlation between the pressure drop and flow rate was estimated from experimental tests. These results, presented in

Figure 11, suggest that the pressure drop scales with the flow rate as

Using this correlation with Equation (

6), this yields

This correlation can be used to correct the numerical flow-rate coefficients. The corrected results are listed in

Table 4 and are also plotted, along with the non-corrected

, in

Figure 12. The deviation for R23 and R34 has been increased, but now the agreement is very good between R45 and R5, for a lower Reynolds number. In general, the deviation from experimental measurements was bounded, with a maximum underestimation of 16%. This deviation was considered acceptable, given that the error in the measured gap height, due to roundness uncertainty in the cylinder and piston, was around 6%; hence, this led to an error of around 10% in the numerical

estimation.

5. Discussion and Conclusions

Numerical CFD simulations were conducted for the analysis of the pressure drop in a groove-machined piston for the cushioning system of a hydraulic cylinder. The aim of the work is to provide a method to estimate the values for a certain design of a piston groove pattern. This method has been used in a dynamical system simulation that is able to predict the behaviour of the cushioning performance of the cylinder.

The numerical results, obtained with a constant value of Re = 167 have been compared with experimental measurements. The value of the numerical Reynolds number was constant, because the estimated value of the flow-rate coefficient had to be used in the dynamic simulation with an a priori unknown Reynolds number. The proposed method is to numerically estimate a

value with a given Re and then to correct it for a certain velocity condition in the cushioning process. The experimental Reynolds number was bounded by the limitation of the pressure transducer used. The agreement was acceptable for similar Reynolds numbers, in positions R23 and R34 for the attached piston, considering that, according to the definition of the flow-rate coefficient (Equation (

6)) and the confidence level estimated in the grid independence analysis, the uncertainty in the values of

was about 5%. For the centered piston, the agreement was only good for R34. For R12, both the attached- and centered-piston simulation underestimate the value of the flow coefficient, at 23% and 16%. The reason for this disagreement was likely the more complex flow in the rounded corner, which led the flow towards the outlet port (see

Figure 2 for position R12 of piston). As a future work for the improvement of the method, a better mesh that could resolve the boundary layer and the flow separation in this zone could likely allow for a better estimation of

for position R12. For positions R45 and R5, with low Reynolds numbers, the value of

was highly overestimated, due to the difference in the Reynolds number. These estimations of

can be corrected if the correlation between the pressure drop and flow rate is known. This correlation was experimentally obtained for a range of the Reynolds number between 12 and 92 for position R45 with the piston attached to the cylinder, yielding the expression of Equation (8) that allows for correcting

with the Reynolds number. This correction gives an excellent agreement for R45 and R5 while it worsens the agreement between R23 and R34. Nevertheless, the overall results are better than the uncorrected estimations. This method for the pressure-drop coefficient estimation can contribute to the development of a dynamic system simulation and to the proposing of an enhanced design method for a cylinder cushioning system.