Dependence of Total Production Costs on Production and Infrastructure Parameters in the Polish Hard Coal Mining Industry

Abstract

:1. Introduction

1.1. Financial Specificity of Hard Coal Mining

- The description of the previous and current situation in Polish coalmining industry;

- The review of literature on costs in Polish coalmining;

- The case studies analysis including examining the relationships between main production and infrastructure parameters and production costs;

- The indication of irregularities in examined relationships and the ways of removing them that are oriented at improving efficiency in Polish coalmining.

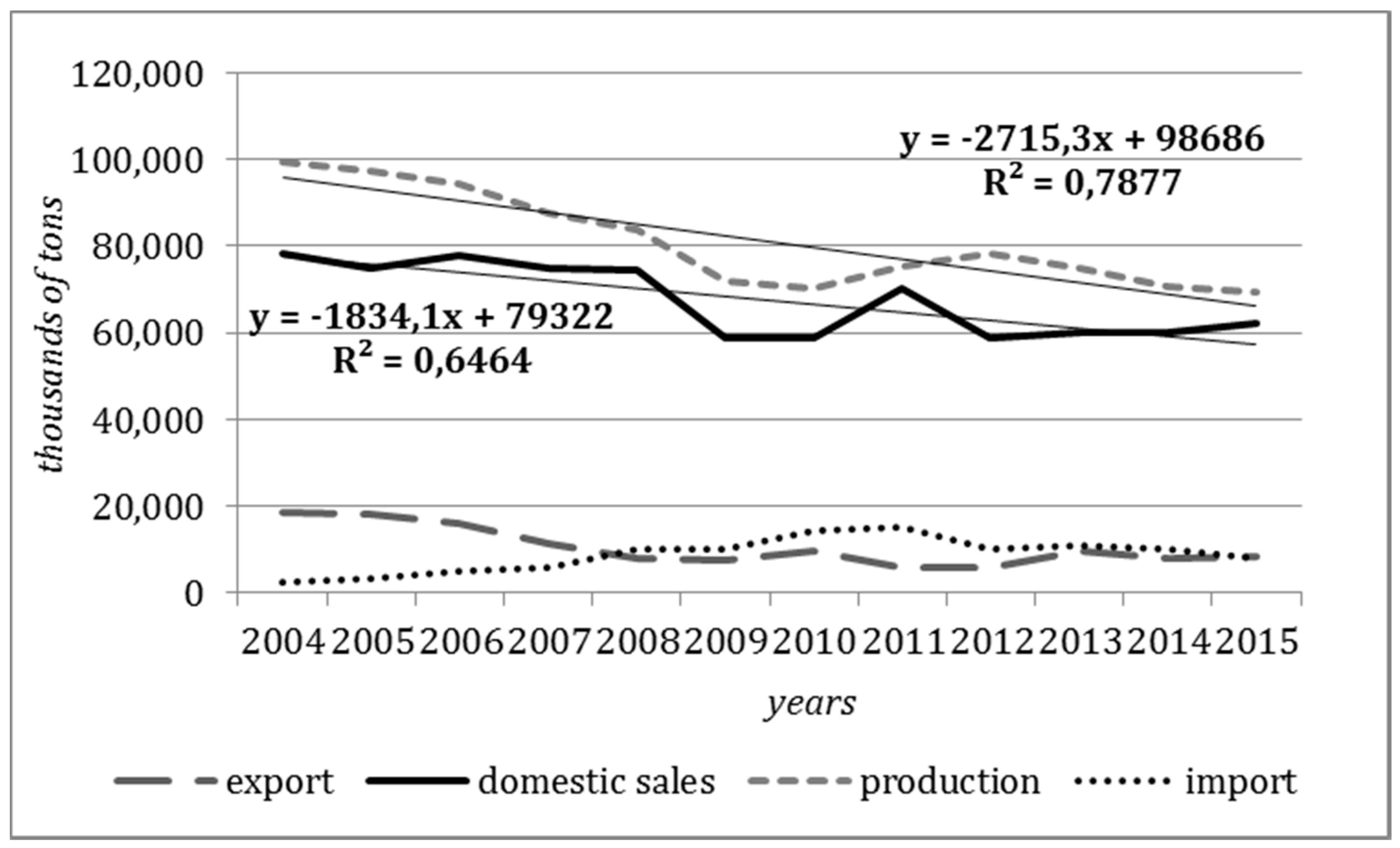

1.2. Insights from Coal Mining in Poland

1.3. Literature Studies on Costs in Coal Mining in the Context of Research Intends

2. Methods and Materials

- cov(x,y)—covariance between variables x and y;

- s(x)—standard deviation of the variable x;

- s(y)—standard deviation of the variable y.

- α0 … αm—parameters of the model;

- x1 … xmt—independent variable; and

- yt—dependent variable.

- R: multiply by the Pearson’s correlation coefficient, which measures the strength of the linear association of the independent variables to the dependent variable (R∊<0;1>);

- R2: multiply by the coefficient of determination, which measures the fit of the model and the proportion of the variability of the dependent variable that is explained by the model (R2∊<0;1>; 0—means a lack of fitting and 1 means perfect fitting);

- R2 adjusted: multiply by the adjusted coefficient of determination, which defines the fit of the model independent from the number of variables and the size of the sample (R2∊<0;1>; 0—means a lack of fitting and 1 means perfect fitting);

- p: indicates if the results are statistically significant α = 0.05 (if p > α then reject H0; if p < α then fail to reject H0; H0: βi = 0 and H1: βi ≠ 0); and

- SE: standard error of the estimate assesses the difference between the value of the dependent variable and the value of dependent variable estimated by the model (the closer that the value of SE is to zero, the better is the fit of the model).

3. Results

3.1. Production Costs in the Polish Hard Coal Mining Industry

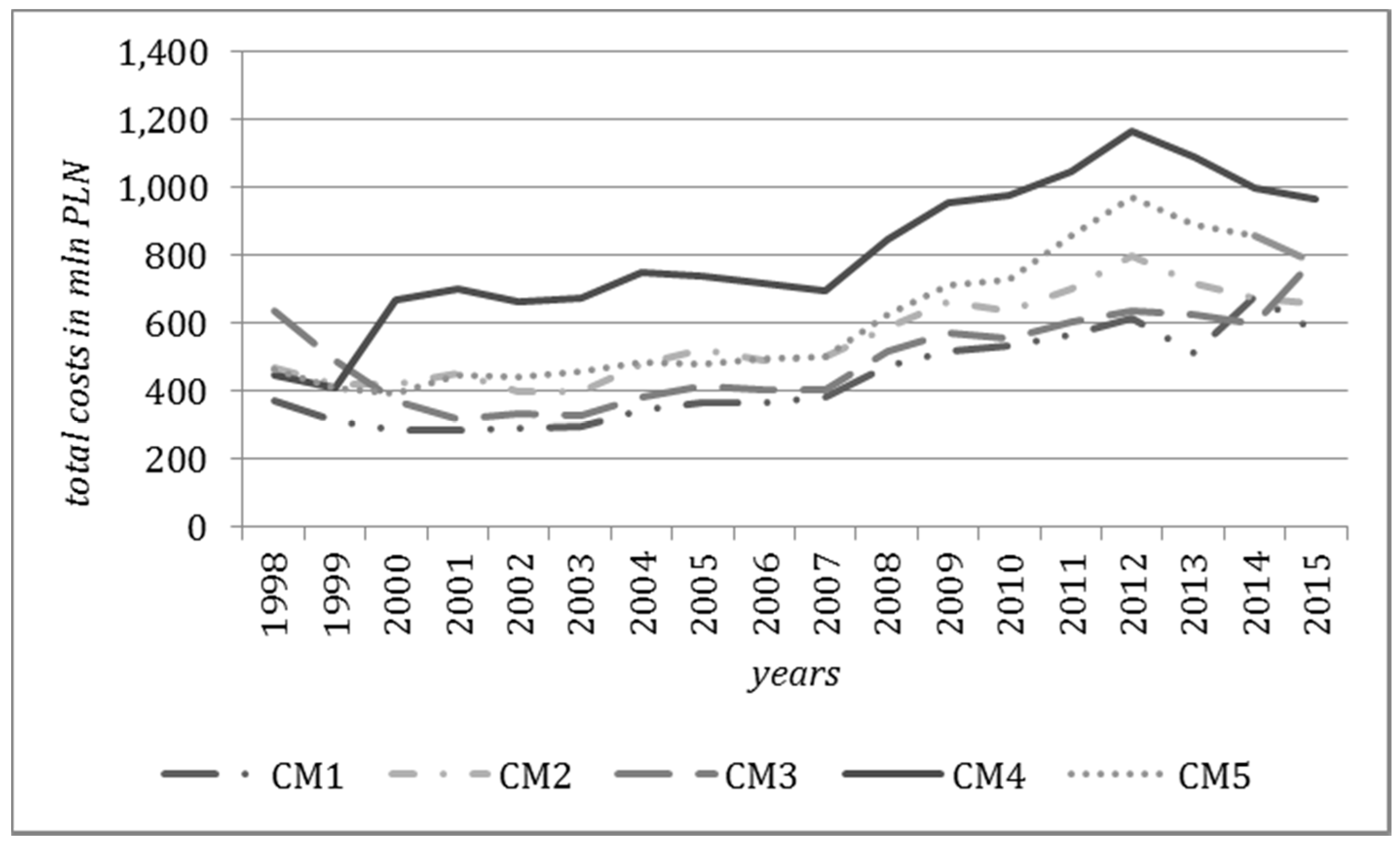

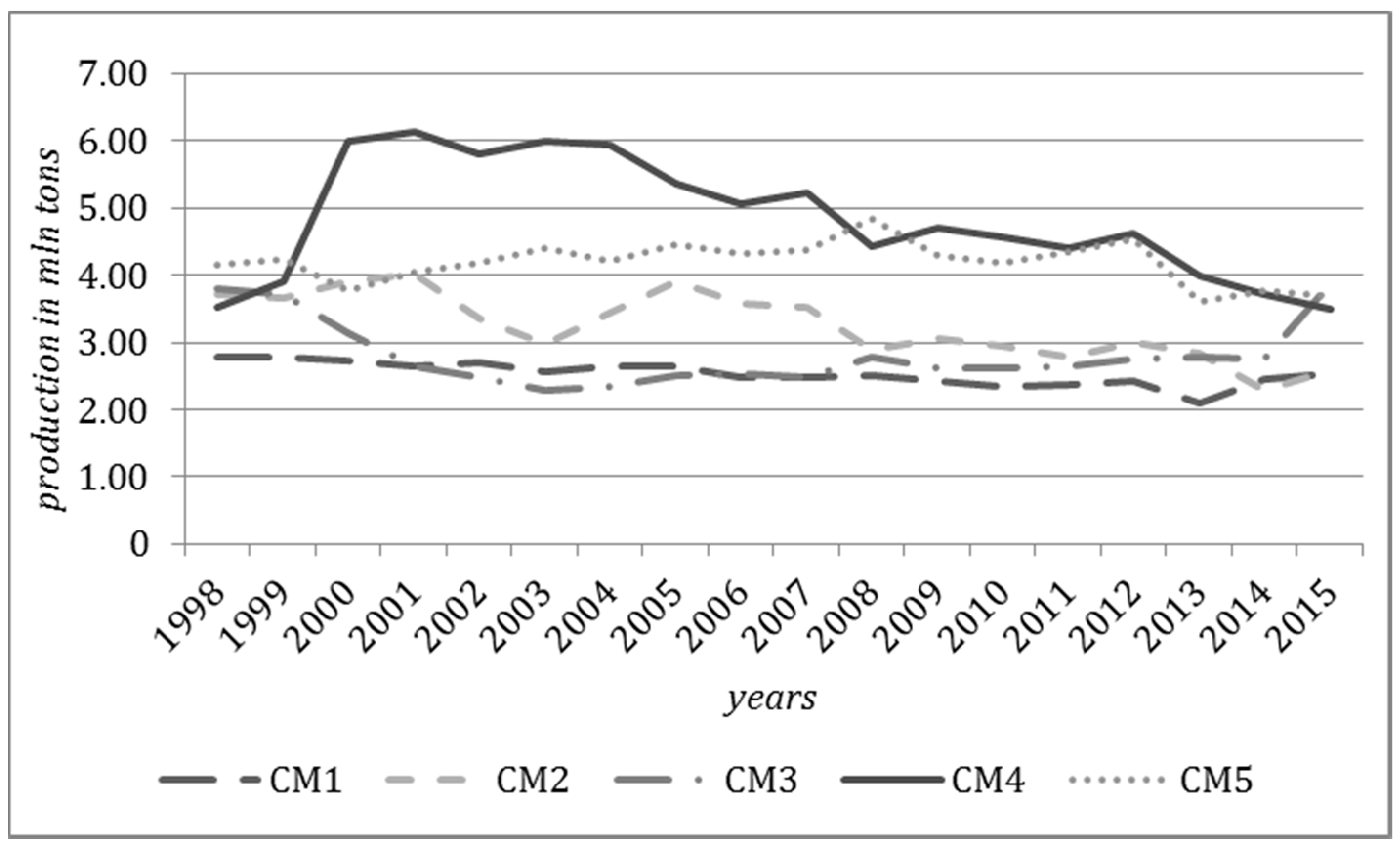

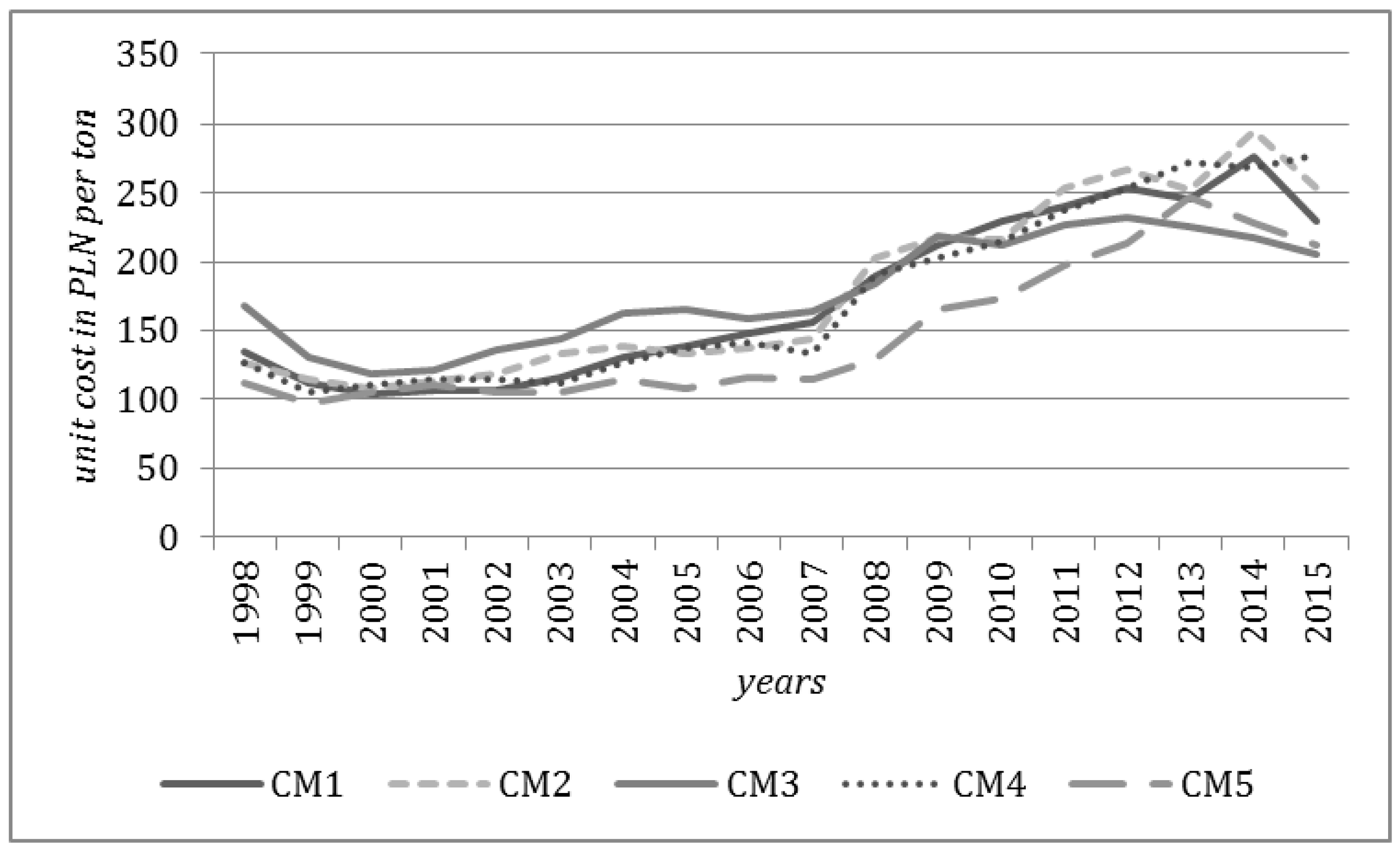

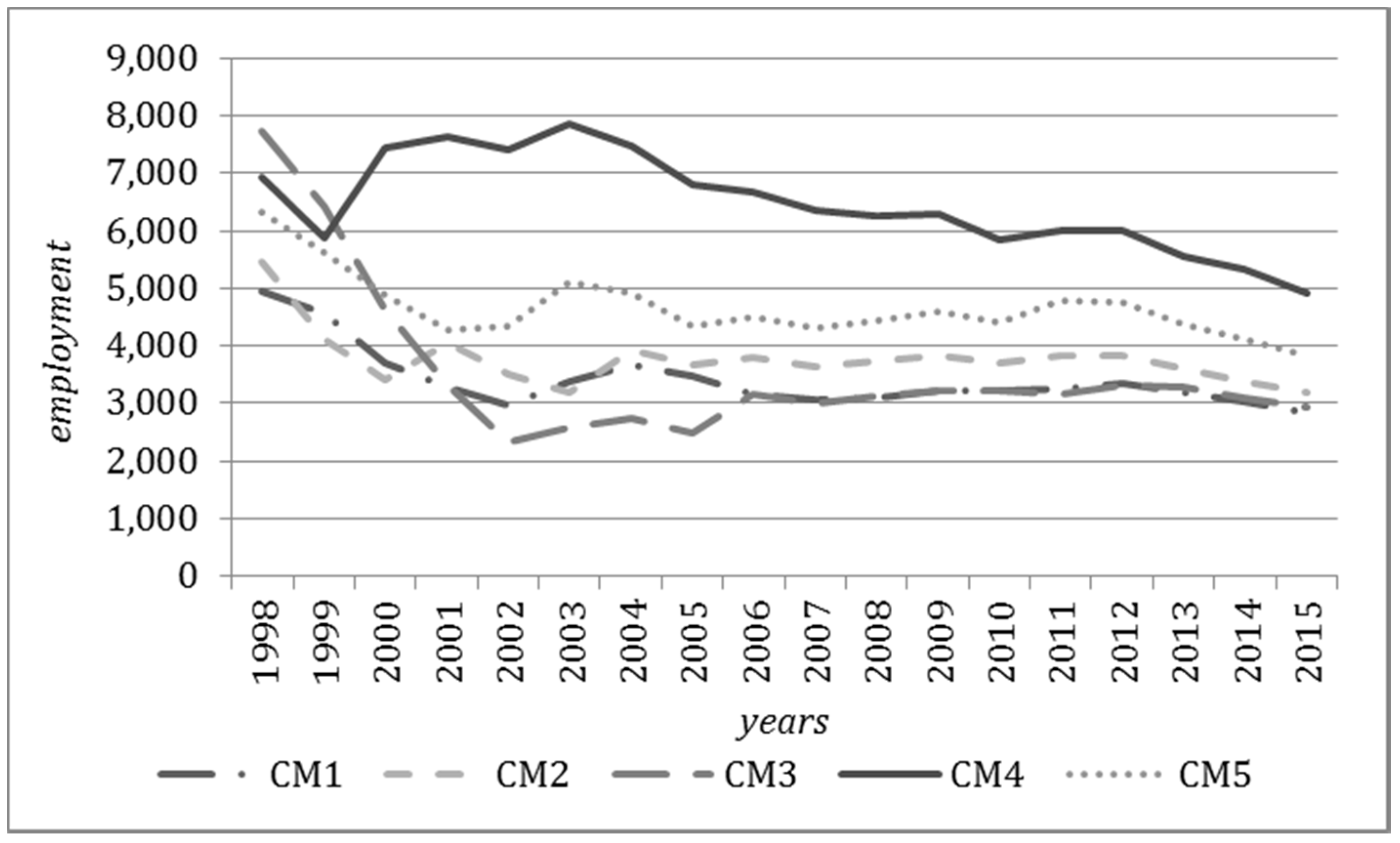

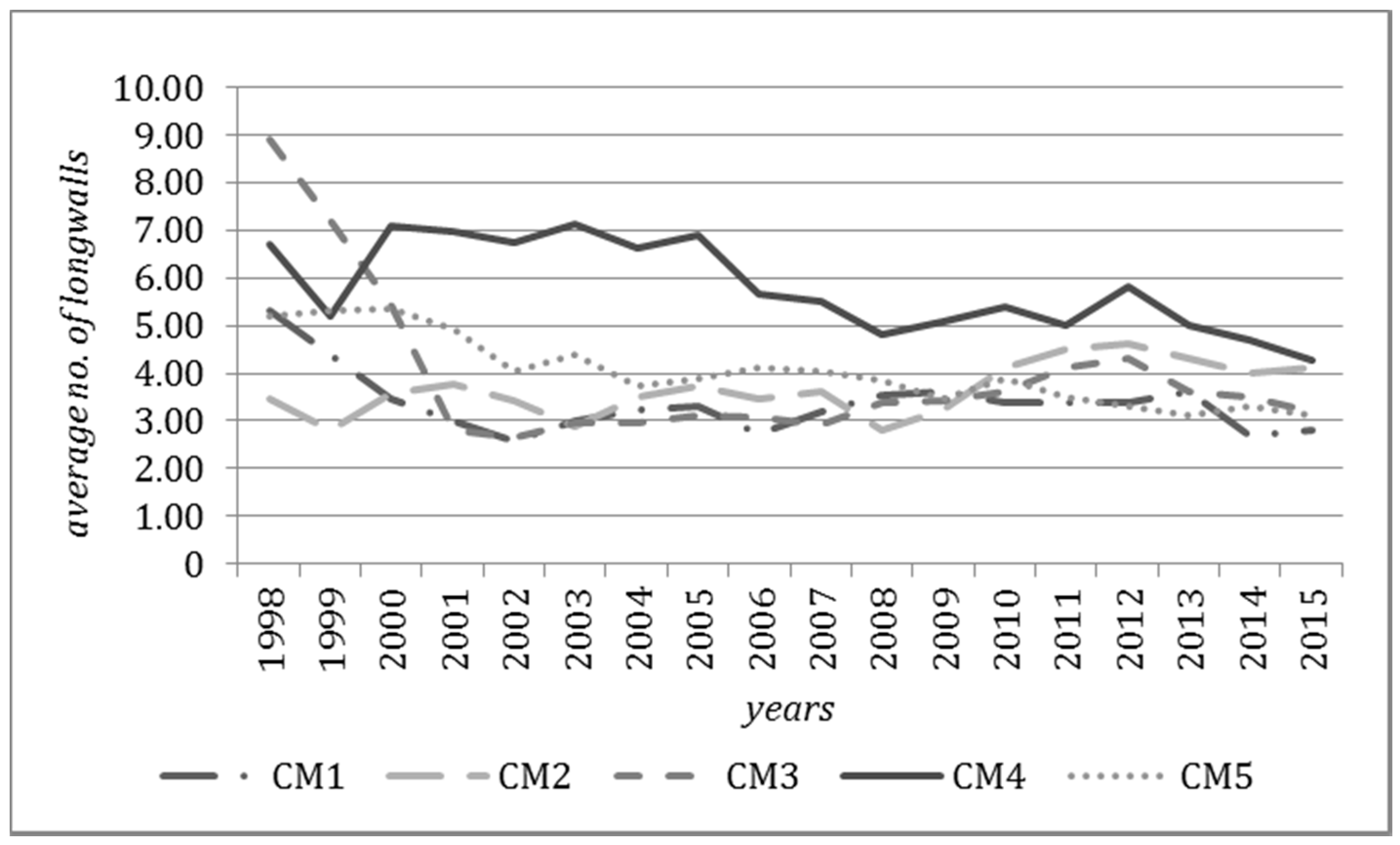

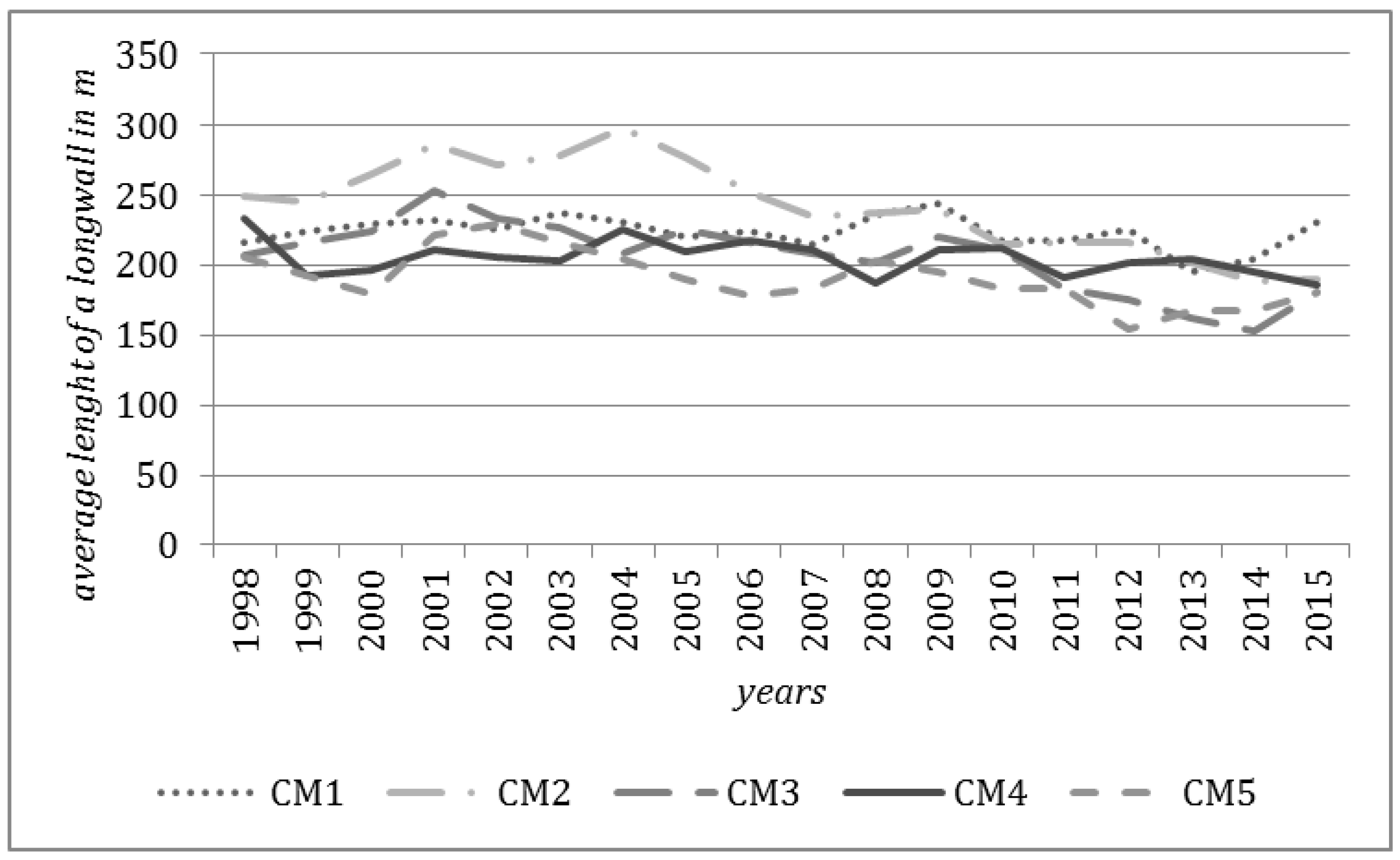

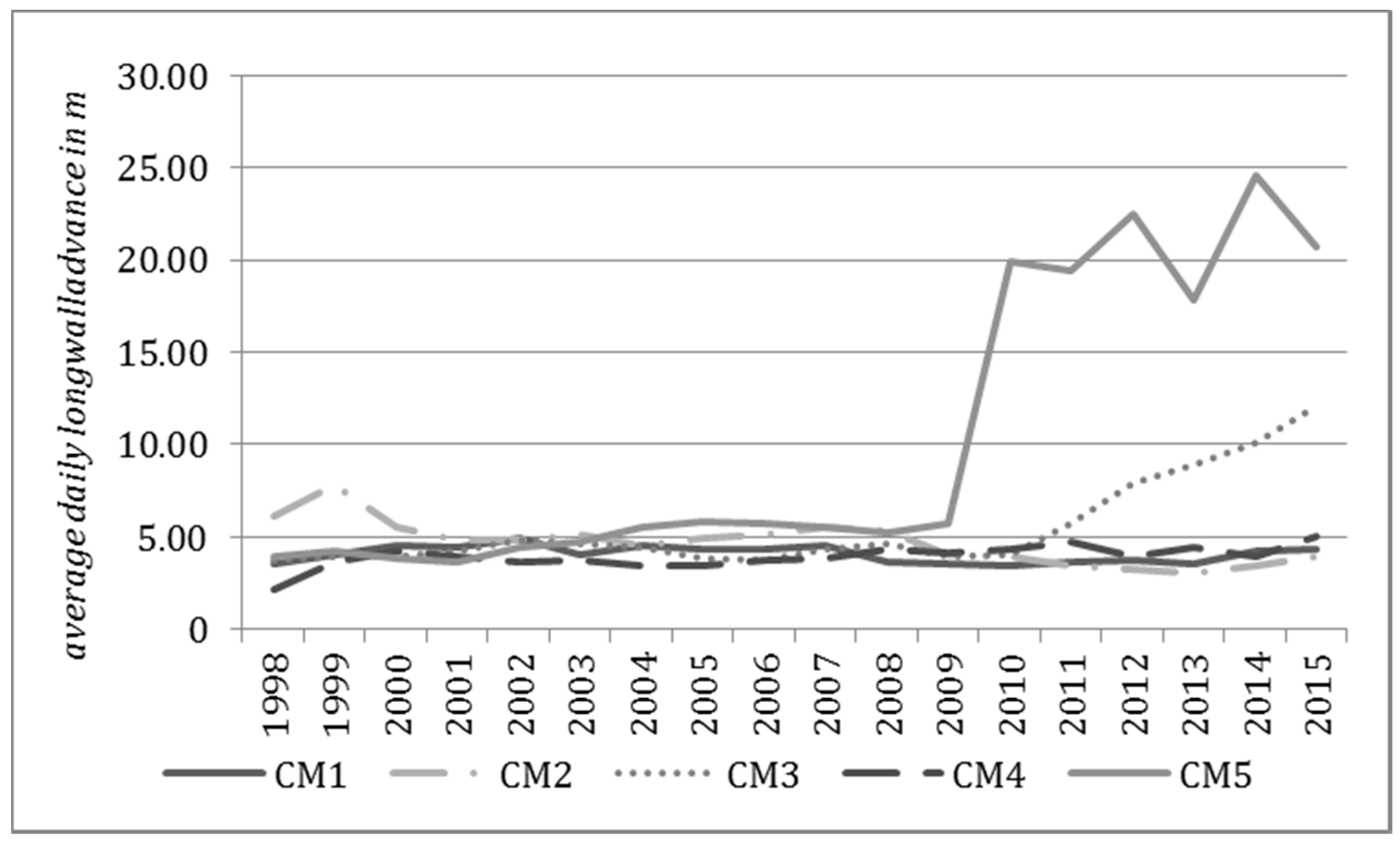

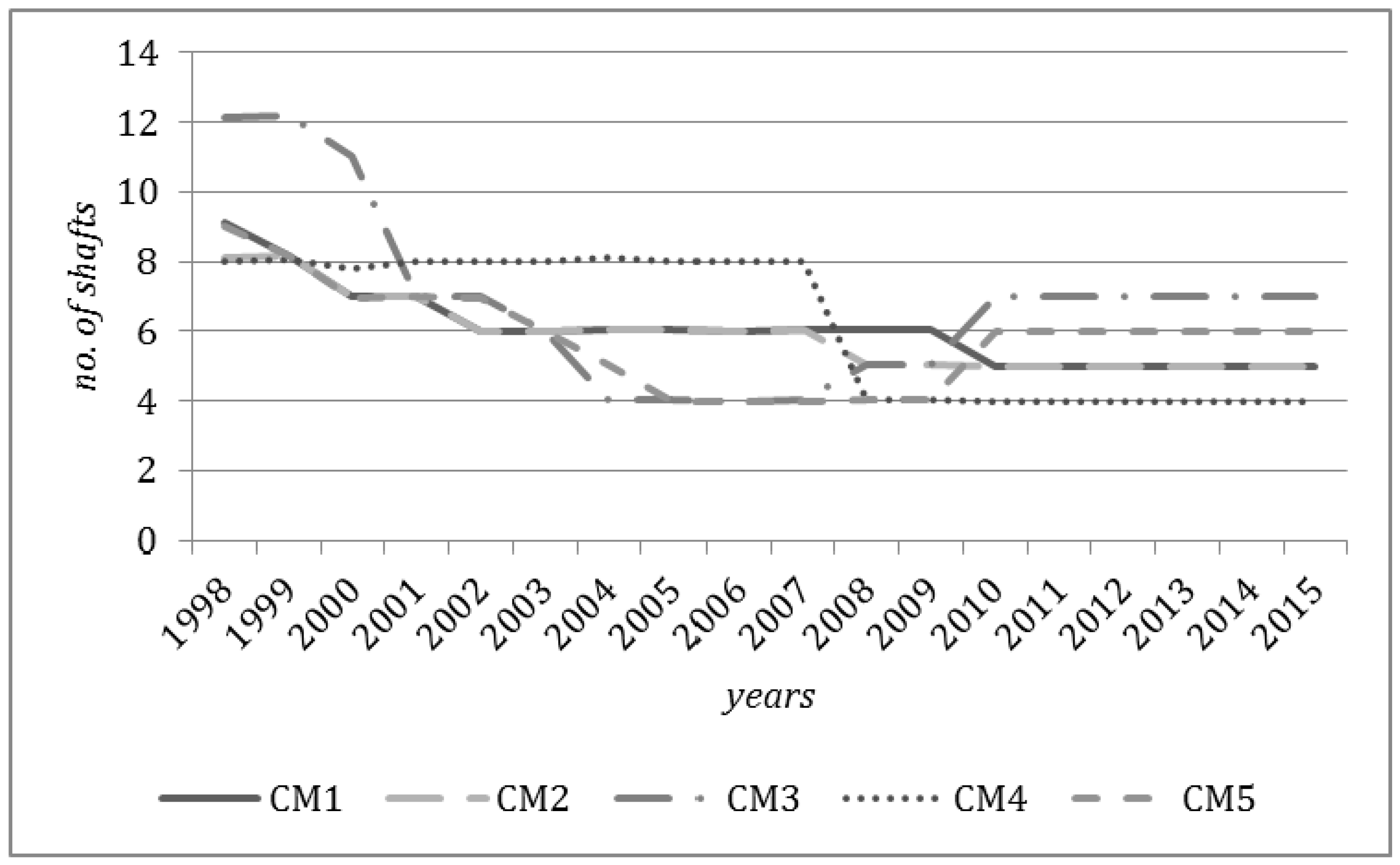

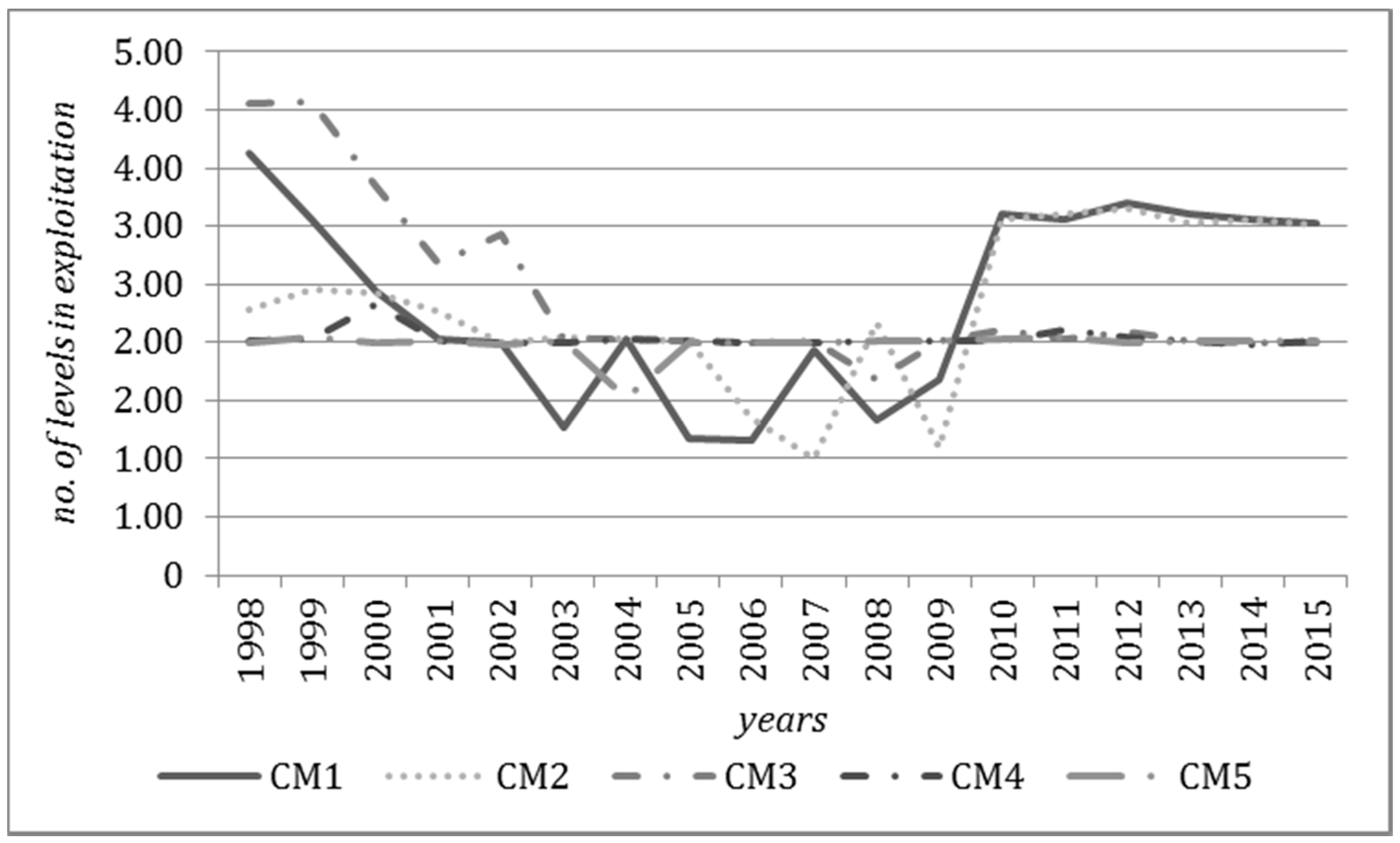

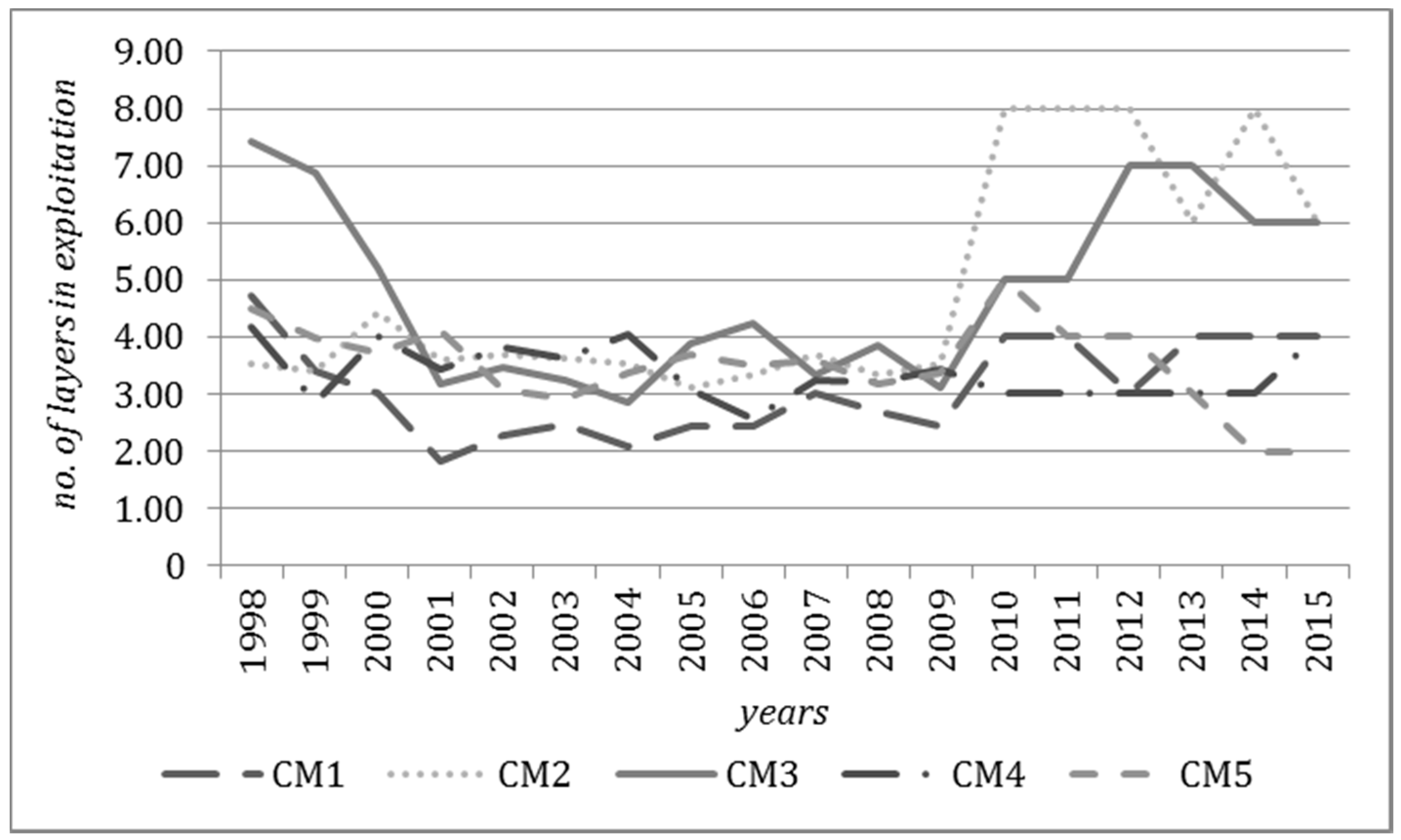

3.2. Total and Unit Costs in the Context of Infrastructure Parameters of the Examined Coal Mines

3.3. Dependence of the Total Production Costs on the Production and Infrastructure Parameters

- CM1: employment, number of levels in exploitation, number of shafts, and average daily longwall advance;

- CM2: production, number of shafts, average length of a longwall, and average preparatory work advance;

- CM3: employment, number of levels in exploitation, and average length of a longwall;

- CM4: employment, average number of longwalls, number of shafts, average daily longwall advance, and average preparatory work advance; and

- CM5: production, employment, average number of longwalls, average daily longwall advance, and average preparatory work advance.

4. Discussion

5. Conclusions

- The relationships between the production parameters (employment and production level) in examined coalmines are economically irrational. The total production costs increase even when the employment and production level decreases.

- The concentration of mining production (demonstrating mostly in longwalls reducing) and increasing of the length of a longwall influences the total production costs reduction only in some examined coalmines.

- Increase in dynamic infrastructure parameters improving the productivity (average daily longwall advance) and average preparatory work advance does not increase the total production costs.

- The examined hard coalmines should restore economically rational relationships between technical and production variables and the total production cost with a focus on the parameter of employment.

- The concentration of production and the efforts to improve productivity will not be efficient if employment and wages—which represent 60% of the total production costs—are not lowered.

- The use of the inappropriate approach to wages is due to the prioritization of human resources in Polish hard coalmining enterprises, which is strengthened by the nonnegotiable demands of the trade unions.

- Further restructuring of survived coalmines have to include: (1) increasing productivity, which can be achieved through improvement of employment structure (increasing the share of production employees in the total employment); (2) introducing the motivation system in which the salaries will be partly depended on productive and financial results; (3) increasing current and future investment expenditures in the most efficient activities; and (4) reviewing the infrastructure for its usability.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Michalak, A. The cost of capital in the effectiveness assessment of financial management in a company. Oecon. Copernic. 2016, 7, 317–329. [Google Scholar] [CrossRef]

- Nawrocki, T. The use of fuzzy logic in the enterprises business efficiency assessment. In The Essence and Measurement of Organizational Efficiency; Dudycz, T., Osbert-Pociecha, G., Brycz, B., Eds.; Springer Proceedings in Business and Economics, Poland; Springer: Cham, Switzerland, 2015; pp. 229–248. [Google Scholar]

- Zieliński, M. Efektywność—Ujęcie ekonomiczne i społeczne. Zesz. Naukowe Politech. Śląskiej Ser. Organ. Zarz. 2013, 66, 137–148. [Google Scholar]

- Bluszcz, A. European economies in terms of energy dependence. Qual. Quant. 2016, 2, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Chong, T.; Yi, S.; Heng, C. Application of set pair analysis method on occupational hazard of coal mining. Saf. Sci. 2017, 92, 10–16. [Google Scholar] [CrossRef]

- Karan, S.K.; Samadder, S.R. Reduction of spatial distribution of risk factors for transportation of contaminants released by coal mining activities. J. Environ. Manag. 2016, 180, 280–290. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, X.; Wang, D. Mining-induced void distribution and application in the hydro-thermal investigation and control of an underground coal fire: A case study. Process Saf. Environ. Prot. 2016, 102, 734–756. [Google Scholar] [CrossRef]

- Wolny, M. The Concept of Risk Dominance in MADM with No Inter-Criteria Information. Mult. Criteria Decis. Mak. 2015, 10, 185–194. [Google Scholar]

- Trojnar, A.; Więckol-Ryk, A.; Niemiec, B. Koszty profilaktyki zagrożenia tąpaniami w kopalniach węgla kamiennego. Wiad. Górnicze 2014, 4, 209–220. [Google Scholar]

- Michalak, A.; Turek, M. A method of pricing an asset lost in a mining catastrophe. Arch. Min. Sci. 2012, 57, 799–814. [Google Scholar]

- Brodny, J. Analysis of operation of new construction of the frictional joint with the resistance wedge. Arch. Min. Sci. 2012, 57, 209–227. [Google Scholar]

- Liu, H.; Cheng, Y. The elimination of coal and gas outburst disasters by long distance lower protective seam mining combined with stress-relief gas extraction in the Huaibei coal mine area. J. Nat. Gas Sci. Eng. 2015, 27, 346–353. [Google Scholar] [CrossRef]

- Hendryx, M. The public health impacts of surface coal mining. Extr. Ind. Soc. 2015, 2, 820–826. [Google Scholar] [CrossRef]

- Hota, P.; Behera, B. Coal mining in Odisha: An analysis of impacts on agricultural production and human health. Extr. Ind. Soc. 2015, 2, 683–693. [Google Scholar] [CrossRef]

- Álvarez, R.; Ordóñez, A.; De Miguel, E.; Loredo, C. Prediction of the flooding of a mining reservoir in NW Spain. J. Environ. Manag. 2015, 184, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L. Control of coal and gas outbursts in Huainan mines in China. J. Rock Mech. Geotech. Eng. 2016, 8, 559–567. [Google Scholar] [CrossRef]

- Verma, A.; Olateju, B.; Kumar, A. Greenhouse gas abatement costs of hydrogen production from underground coal gasification. Energy 2016, 85, 556–568. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, J. Fugitive Methane Emissions from Indian Coal Mining and Handling Activities: Estimates, Mitigation and Opportunities for its Utilization to Generate Clean Energy. Energy Procedia 2016, 90, 336–348. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Spearing, A.J.S.; Miao, X.; Guo, S.; Sun, Q. Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int. J. Min. Sci. Technol. 2016, 12, 17–27. [Google Scholar] [CrossRef]

- Cui, L.; Cheng, F.; Zhou, J. Preparation of high purity AlCl3·6H2O crystals from coal mining waste based on iron (III) removal using undiluted ionic liquids. Sep. Purif. Technol. 2016, 167, 45–54. [Google Scholar] [CrossRef]

- Ściążko, M.; Chmielniak, T. Zero-Emisyjny Kompleks Energio-Chemiczny—Unikalny Przykład Działania Proekologicznego Wykorzystującego Węgiel Kamienny; Szkoła Eksploatacji Podziemnej: Kraków, Poland, 2010; pp. 36–50. [Google Scholar]

- Fei, W.B.; Li, Q.; Wei, C.; Song, R.R.; Jing, M.; Li, X.C. Interaction analysis for CO2 geological storage and underground coal mining in Ordos Basin, China. Eng. Geol. 2015, 196, 194–209. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Fugiel, A.; Czaplicka-Kolarz, K.; Turek, M. Model of environmental life cycle assessment for coal mining operations. Sci. Total Environ. 2016, 562, 61–72. [Google Scholar] [CrossRef] [PubMed]

- Calvo, J.A.P.; Pérez, A.M.J. Optimal extraction policy when the environmental and social costs of the opencast coal mining activity are internalized: Mining District of the Department of El Cesar (Colombia) case study. Energy Econ. 2016, 59, 159–166. [Google Scholar] [CrossRef]

- Krzemień, A.; Sánchez, A.S.; Fernández, P.R.; Zimmermann, K.; Coto, F.G. Towards sustainability in underground coal mine closure contexts: A methodology proposal for environmental risk management. J. Clean. Prod. 2016, 139, 1044–1056. [Google Scholar] [CrossRef]

- Salmi, E.F.; Nazem, M.; Karakus, M. The effect of rock mass gradual deterioration on the mechanism of post-mining subsidence over shallow abandoned coal mines. Int. J. Rock Mech. Min. Sci. 2017, 91, 59–71. [Google Scholar] [CrossRef]

- Yaylacı, E.D.; Düzgün, H.S. Indicator-based sustainability assessment for the mining sector plans: Case of Afşin-Elbistan Coal Basin. Int. J. Coal Geol. 2016, 165, 190–200. [Google Scholar] [CrossRef]

- Yu, X. Coal mining and environmental development in southwest China. Environ. Dev. 2017, 21, 77–86. [Google Scholar] [CrossRef]

- Bluszcz, A.; Kijewska, A. Challenges of sustainable development in the mining and metallurgy sector in Poland. Metalurgija 2014, 54, 441–444. [Google Scholar]

- Bustos, B.; Folchi, M.; Fragkou, M. Coal mining on pastureland in Southern Chile; Challenging recognition and participation as guarantees for environmental justice. Geoforum 2017, 84, 292–304. [Google Scholar] [CrossRef]

- Bao, N.; Wu, L.; Ye, B.; Yang, K.; Zhou, W. Assessing soil organic matter of reclaimed soil from a large surface coal mine using a field spectroradiometer in laboratory. Geoderma 2017, 288, 47–55. [Google Scholar] [CrossRef]

- De Klerk, A.R.; Oberholster, P.J.; van Wyk, J.H.; Truter, J.C.; Schaefer, L.M.; Botha, A.-M. The effect of rehabilitation measures on ecological infrastructure in response to acid mine drainage from coal mining. Ecol. Eng. 2016, 95, 463–474. [Google Scholar] [CrossRef]

- Lechner, A.M.; Kassulke, O.; Unger, C. Spatial assessment of open cut coal mining progressive rehabilitation to support the monitoring of rehabilitation liabilities. Resour. Policy 2016, 50, 234–243. [Google Scholar] [CrossRef]

- Lima, A.T.; Mitchell, K.; O’Connell, D.W.; Verhoeven, J.; Van Cappellen, P. The legacy of surface mining: Remediation, restoration, reclamation and rehabilitation. Environ. Sci. Policy 2016, 66, 227–233. [Google Scholar] [CrossRef]

- Dong, J.; Cheng, Y.-P.; Chang, T.-Y.; Zhang, J.-J.; Guo, S.-F. Coal mine methane control cost and full cost: The case of the Luling Coal Mine, Huaibei coalfield, China. J. Nat. Gas Sci. Eng. 2015, 26, 290–302. [Google Scholar] [CrossRef]

- Frantál, B. Living on coal: Mined-out identity, community displacement and forming of anti-coal resistance in the Most region, Czech Republic. Resour. Policy 2016, 49, 385–393. [Google Scholar] [CrossRef]

- Fugiel, A.; Burchart-Korol, D.; Czaplicka-Kolarz, K.; Smoliński, A. Environmental impact and damage categories caused by air pollution emissions from mining and quarrying sectors of European countries. J. Clean. Prod. 2017, 143, 159–168. [Google Scholar] [CrossRef]

- McDuie-Ra, D.; Kikon, D. Tribal communities and coal in Northeast India: The politics of imposing and resisting mining bans. Energy Policy 2016, 99, 261–269. [Google Scholar] [CrossRef]

- Mishra, S.K.; Hitzhusen, F.J.; Sohngen, B.L.; Guldmann, J.M. Costs of abandoned coal mine reclamation and associated recreation benefits in Ohio. J. Environ. Manag. 2012, 100, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Zafrilla, J.R. The mining industry under the thumb of politicians: The environmental consequences of the Spanish Coal Decree. J. Clean. Prod. 2014, 84, 715–722. [Google Scholar] [CrossRef]

- Valero, A.; Domínguez, A.; Valero, B. Exergy cost allocation of by-products in the mining and metallurgical industry. Resour. Conserv. Recycl. 2015, 102, 128–142. [Google Scholar] [CrossRef]

- Vegas, I.; Cano, M.; Arribas, I.; Frías, M.; Rodríguez, O. Physical-mechanical behavior of binary cements blended with thermally activated coal mining waste. Constr. Build. Mater. 2015, 99, 169–174. [Google Scholar] [CrossRef]

- Limanskiy, A.V.; Vasilyeva, M.A. Using of low-grade heat mine water as a renewable source of energy in coal-mining regions. Ecol. Eng. 2016, 91, 41–43. [Google Scholar] [CrossRef]

- Oliveira, C.M.; Machado, C.M.; Duarte, G.W.; Peterson, M. Beneficiation of pyrite from coal mining. J. Clean. Prod. 2016, 139, 821–827. [Google Scholar] [CrossRef]

- Cardoso, A. Behind the life cycle of coal: Socio-environmental liabilities of coal mining in Cesar, Colombia. Ecol. Econ. 2015, 120, 71–82. [Google Scholar] [CrossRef]

- Fernández, S.; Poschenrieder, C.; Marcenò, C.; Gallego, J.R.; Jiménez-Gámez, D.; Bueno, A.; Afif, E. Phytoremediation capability of native plant species living on Pb-Zn and Hg-As mining wastes in the Cantabrian range, north of Spain. J. Geochem. Explor. 2017, 174, 10–20. [Google Scholar] [CrossRef]

- Galloux, J.; Chekli, L.; Phuntsho, S.; Tijing, L.D.; Jeong, S.; Zhao, Y.X.; Gao, B.Y.; Park, S.H.; Shon, H.K. Coagulation performance and floc characteristics of polytitanium tetrachloride and titanium tetrachloride compared with ferric chloride for coal mining wastewater treatment. Sep. Purif. Technol. 2015, 152, 94–100. [Google Scholar] [CrossRef]

- Norman, H. Coal Mining and Coal Seam Gas on Gomeroi country: Sacred lands, economic futures and shifting alliances. Energy Policy 2016, 99, 242–251. [Google Scholar] [CrossRef]

- Sorin, M.; Mirela, I.; Diana, C. Considerations on the Cost of Electricity Production in the Context of Integration Operating Activities Underground and Production of Coal in Thermal Power Stations Electricity in the Jiu Valley Mining Area. Procedia Econ. Financ. 2017, 23, 371–377. [Google Scholar] [CrossRef]

- Gorczyńska, A. The impact of the crisis on the course of cross-border consolidation processes. Equilibrum 2011, 6, 17–21. [Google Scholar]

- Ma, J.; Dai, H. A methodology to construct warning index system for coal mine safety based on collaborative management. Saf. Sci. 2017, 93, 86–95. [Google Scholar] [CrossRef]

- Korski, J.; Tobór-Osadnik, K.; Wyganowska, M. Reasons of problems of the Polish hard coal mining in connection with restructuring changes in the period 1988–2014. Resour. Policy 2016, 48, 25–31. [Google Scholar] [CrossRef]

- Connor, L.H. Energy futures, state planning policies and coal mine contests in rural New South Wales. Energy Policy 2016, 99, 233–241. [Google Scholar] [CrossRef]

- Diana, C.; Sorin, M.; Mirela, I.; Laura, M.; Sabina, I. Creating Competitive Advantage in Coal Mining Industry in Romania: A New Challenge. Procedia Econ. Financ. 2015, 23, 428–433. [Google Scholar] [CrossRef]

- Malarz, K.; Kowalska-Styczeń, A.; Kułakowski, K. The working group performance modeled by a bi-layer cellular automaton. Simul.-Trans. Soc. Model. Simul. Int. 2016, 92, 179–193. [Google Scholar] [CrossRef]

- Betz, M.R.; Partridge, M.D.; Farren, M.; Lobao, L. Coal mining, economic development, and the natural resources curse. Energy Econ. 2015, 50, 105–116. [Google Scholar] [CrossRef]

- Sierpińska, M.; Bąk, P. Characteristic of the capital gaining sources and financing the activity of coal mine enterprises. Part 1: Sources of the own capital. Miner. Resour. Manag. 2007, 23, 93–108. [Google Scholar]

- Sierpińska, M.; Bąk, P. The role of corporate bonds in financing mining sector companies during an economic downturn. Miner. Resour. Manag. 2013, 29, 141–155. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, A. Possible strategies for hard coal mining in Poland as a result of production function analysis. Resour. Policy 2016, 50, 27–33. [Google Scholar] [CrossRef]

- Sobczyk, E.J.; Kicki, J.; Sobczyk, W.; Szuwarzyński, M. Support of mining investment choice decisions with the use of multi-criteria method. Resour. Policy 2017, 51, 94–99. [Google Scholar] [CrossRef]

- Yu, S.; Gao, S.; Sun, H. A dynamic programming model for environmental investment decision-making in coal mining. Appl. Energy 2016, 166, 273–281. [Google Scholar] [CrossRef]

- Wodarski, K.; Bijańska, J. Risk management in the planning of development projects in the industrial enterprises. Metalurgija 2014, 3, 276–278. [Google Scholar]

- Turek, M. Postęp dobowy ścian ważnym składnikiem procesu restrukturyzacji technicznej. Prz. Górniczy 2008, 64, 3–9. [Google Scholar]

- Turek, M.; Skrzyński, K.; Smoliński, A. Wpływ wybranych parametrów technicznych i organizacyjnych kopalń węgla kamiennego na wielkość jednostkowego kosztu wydobycia. Prace Naukowe GIG. Górnictwo i Środowisko 2007, I, 207–220. [Google Scholar]

- Turek, M.; Skrzyński, K.; Smoliński, A. The relation between the technical and organizational parameters of collieries: Data set analysis. Glückauf 2009, 10, 516–521. [Google Scholar]

- Sojda, A.; Jakowska-Suwalska, K. Wielokryterialna metoda oceny przedsiębiorstwa górniczego. Zesz. Naukowe Politech. Śląskiej Ser. Organ. Zarz. 2014, 74, 147–157. [Google Scholar]

- Gawlik, L. Budowa i weryfikacja modelu ekonometrycznego dla określenia liniowej zależności pomiędzy kosztami wydobycia a wielkością wydobycia. Miner. Resour. Manag. 2008, 24, 27–44. [Google Scholar]

- Gawlik, L.; Kasztelewicz, Z. Zależność kosztów produkcji węgla w kopalni węgla brunatnego Konin” od poziomu jego sprzedaży. Prace Naukowe Inst. Górnictwa Politech. Wroc. 2015, 112, 231–242. [Google Scholar]

- Gawlik, L. Koszty stałe i zmienne pozyskania węgla kamiennego jako element zarządzania produkcją. Polityka Energ. 2007, 10, 471–482. [Google Scholar]

- Gawlik, L. Koszty zmienne w kosztach wytwarzania węgla w kopalniach węgla kamiennego. Polityka Energ. 2010, 13, 131–144. [Google Scholar]

- Jurdziak, L. Cena węgla brunatnego jako wyznacznik podziału zysku w układach kopalń i elektrowni część III—Obliczenia cen i zysków dla hipotetycznych danych. Prace Nauk. Inst. Górnictwa Politech. Wroc. 2007, 118, 69–80. [Google Scholar]

- Lisowski, A. Podstawy Ekonomicznej Efektywności Podziemnej Eksploatacji Złóż; Wydawnictwo GiG, Wydawnictwo PWN: Katowice, Poland; Warszawa, Poland, 2001. [Google Scholar]

- Magda, R. Możliwości obniżania cen zbytu węgla w zależności od przyjętego poziomu średniej akumulacji jednostkowej ze sprzedaży. Wiad. Górnicze 2014, 65, 47–52. [Google Scholar]

- Magda, R. Ocena wpływu ograniczenia stopnia wykorzystania zdolności produkcyjnej w ścianach wydobywczych na jednostkowy koszt własny. Prz. Górniczy 2013, 9, 110–113. [Google Scholar]

| Specification | Hard Coal Mines | ||||

|---|---|---|---|---|---|

| CM1 | CM2 | CM3 | CM4 | CM5 | |

| Production | −0.7756 * | −0.8842 * | −0.0266 | −0.6473 * | −0.4005 |

| Employment | −0.4301 | −0.2711 | −0.2268 | −0.8297 * | −0.4143 |

| Average number of longwalls | −0.1276 | 0.6361 * | −0.1311 | −0.7668 * | −0.7757 * |

| No. of levels in exploitation | 0.4233 | 0.5573 * | −0.5655 * | −0.2910 | 0.1393 |

| No. of layers in exploitation | 0.5407 * | 0.8152 * | 0.3599 | −0.2960 | −0.3364 |

| No. of shafts | −0.7127 * | −0.7999 * | −0.2427 | −0.9314 * | −0.0778 |

| Average length of a longwall | −0.4066 | −0.8621 * | −0.7904 * | −0.4135 | −0.6859 * |

| Average daily longwall advance | −0.5490 * | −0.7789 * | 0.5668 * | 0.5827 * | 0.9187 * |

| Average preparatory work advance | 0.0443 | 0.2987 | −0.1919 | 0.7803 * | −0.7888 * |

| Specification | Full Model | Limited Model | ||||

|---|---|---|---|---|---|---|

| R | 0.9542 | 0.9346 | ||||

| R2 | 0.9105 | 0.8734 | ||||

| R2 adjusted | 0.8099 | 0.8344 | ||||

| F | F(9.8) = 9.0496 | F(4.13) = 22.426 | ||||

| p | p < 0.0025 | p < 0.00001 | ||||

| SE | 26.12 | 24.376 | ||||

| Variables | Parameters | Parameters | ||||

| b ** | b | p | b ** | b | p | |

| Production | 0.1832 | 0.0001 | 0.6302 | - | - | - |

| Employment | −0.5067 | −0.06 | 0.2265 | −0.2062 | −0.230 | 0.4394 |

| Average number of longwalls | 0.2406 | 22.35 | 0.5969 | - | - | - |

| No. of levels in exploitation | 0.4548 | 34.45 | 0.0915 | 0.3924 | 29.73 | 0.0074 |

| No. of layers in exploitation | −0.1860 | −13.22 | 0.5628 | - | - | - |

| No. of shafts | −0.5500 | −28.78 | 0.1432 | −0.5423 | −28.48 | 0.0411 |

| Average length of a longwall | −0.1508 | −0.77 | 0.5284 | - | - | - |

| Average daily longwall advance | −0.6009 | −80.08 | 0.1218 | −0.4201 | −55.99 | 0.0031 |

| Average preparatory work advance | −0.2204 | −34.84 | 0.1768 | - | - | - |

| Specification | Full Model | Limited Model | ||||

|---|---|---|---|---|---|---|

| R | 0.9831 | 0.9713 | ||||

| R2 | 0.9665 | 0.9434 | ||||

| R2 adjusted | 0.9288 | 0.9126 | ||||

| F | F(9.8) = 25.635 | F(6.11) = 30.598 | ||||

| p | p < 0.00006 | p < 0.00000 | ||||

| SE | 17.125 | 18.967 | ||||

| Variables | Parameters | Parameters | ||||

| b ** | b | p | b ** | b | p | |

| Production | −0.1868 | −0.0000 | 0.4345 | −0.2359 | 0.00 | 0.3488 |

| Employment | 0.1296 | 0.02 | 0.1837 | - | - | - |

| Average number of longwalls | 0.0783 | 9.30 | 0.7807 | −0.0706 | −8.38 | 0.7986 |

| No. of levels in exploitation | 0.0636 | 6.19 | 0.6109 | 0.0918 | 3.06 | 0.6595 |

| No. of layers in exploitation | 0.0316 | 1.05 | 0.8792 | - | - | - |

| No. of shafts | −0.5238 | −31.84 | 0.0971 | −0.0345 | −2.10 | 0.8573 |

| Average length of a longwall | −0.2809 | −0.54 | 0.1661 | −0.4543 | −0.88 | 0.0220 |

| Average daily longwall advance | −0.0172 | −0.95 | 0.9575 | - | - | - |

| Average preparatory work advance | 0.1703 | 17.72 | 0.1841 | −0.3667 | −20.21 | 0.2111 |

| Specification | Full Model | Limited Model | ||||

|---|---|---|---|---|---|---|

| R | 0.9014 | 0.8754 | ||||

| R2 | 0.8125 | 0.7663 | ||||

| R2 adjusted | 0.6016 | 0.6945 | ||||

| F | F(9.8) = 3.8528 | F(4.13) = 10.661 | ||||

| p | p < 0.0354 | p < 0.00047 | ||||

| SE | 24.551 | 21.500 | ||||

| Variables | Parameters | Parameters | ||||

| b ** | b | p | b ** | b | p | |

| Production | 0.2672 | 0.00 | 0.6975 | - | - | - |

| Employment | −0.4726 | −0.01 | 0.6246 | 0.4218 | 0.0118 | 0.2414 |

| Average number of longwalls | 0.4474 | 10.50 | 0.7020 | - | - | - |

| No. of levels in exploitation | −1.0413 | −55.25 | 0.0926 | −0.7399 | −39.26 | 0.0530 |

| No. of layers in exploitation | 0.2692 | 6.69 | 0.5756 | - | - | - |

| No. of shafts | 0.2976 | 4.47 | 0.6289 | - | - | - |

| Average length of a longwall | −0.4238 | −0.63 | 0.4801 | −0.5845 | −0.8701 | 0.0630 |

| Average daily longwall advance | −0.2534 | −3.94 | 0.7390 | −0.0324 | −0.5033 | 0.8984 |

| Average preparatory work advance | 0.1757 | 7.645 | 0.5728 | - | - | - |

| Specification | Full Model | Limited Model | ||||

|---|---|---|---|---|---|---|

| R | 0.9777 | 0.9756 | ||||

| R2 | 0.9559 | 0.9518 | ||||

| R2 adjusted | 0.9034 | 0.9317 | ||||

| F | F(9.8) = 19.284 | F(5.12) = 47.414 | ||||

| p | p < 0.00017 | p < 0.0000 | ||||

| SE | 19.727 | 16.843 | ||||

| Variables | Parameters | Parameters | ||||

| b ** | b | p | b ** | b | p | |

| Production | −0.1385 | −0.0000 | 0.6418 | - | - | - |

| Employment | −0.4793 | −0.0364 | 0.1599 | −0.5519 | −0.0420 | 0.2010 |

| Average number of longwalls | 0.4219 | 28.72 | 0.1090 | 0.3571 | 24.31 | 0.0074 |

| No. of levels in exploitation | −0.0417 | −34.39 | 0.6828 | - | - | - |

| No. of layers in exploitation | 0.0068 | 0.9132 | 0.9471 | - | - | - |

| No. of shafts | −0.3964 | −12.50 | 0.1015 | −0.4220 | −13.31 | 0.0226 |

| Average length of a longwall | 0.0795 | 0.3992 | 0.5492 | - | - | - |

| Average daily longwall advance | 0.3537 | 36.90 | 0.1976 | 0.2077 | 21.67 | 0.0723 |

| Average preparatory work advance | 0.3070 | 38.15 | 0.0819 | 0.3251 | 40.39 | 0.0145 |

| Specification | Full Model | Limited Model | ||||

|---|---|---|---|---|---|---|

| R | 0.9761 | 0.9611 | ||||

| R2 | 0.9527 | 0.9237 | ||||

| R2 adjusted | 0.8995 | 0.9237 | ||||

| F | F(9.8) = 17.898 | F(5.12) = 29.080 | ||||

| p | p < 0.00022 | p < 0.00000 | ||||

| SE | 16.158 | 16.746 | ||||

| Variables | Parameters | Parameters | ||||

| b ** | b | p | b ** | b | p | |

| Production | −0.2490 | −0.0000 | 0.1073 | −0.2414 | −0.0000 | 0.0300 |

| Employment | 0.0920 | 0.0081 | 0.6408 | 0.1562 | 0.0137 | 0.1725 |

| Average number of longwalls | −0.7014 | −48.36 | 0.0161 | −0.3996 | −27.55 | 0.0300 |

| No. of levels in exploitation | 0.1445 | 63.74 | 0.1659 | - | - | - |

| No. of layers in exploitation | 0.0915 | 6.12 | 0.4463 | - | - | - |

| No. of shafts | 0.2042 | 7.07 | 0.5112 | - | - | - |

| Average length of a longwall | −0.1554 | −0.4028 | 0.3993 | - | - | - |

| Average daily longwall advance | 0.4506 | 2.91 | 0.2480 | 0.7741 | 5.00 | 0.0307 |

| Average preparatory work advance | 0.1863 | 4.97 | 0.5958 | 0.1639 | 4.37 | 0.5513 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jonek-Kowalska, I.; Turek, M. Dependence of Total Production Costs on Production and Infrastructure Parameters in the Polish Hard Coal Mining Industry. Energies 2017, 10, 1480. https://doi.org/10.3390/en10101480

Jonek-Kowalska I, Turek M. Dependence of Total Production Costs on Production and Infrastructure Parameters in the Polish Hard Coal Mining Industry. Energies. 2017; 10(10):1480. https://doi.org/10.3390/en10101480

Chicago/Turabian StyleJonek-Kowalska, Izabela, and Marian Turek. 2017. "Dependence of Total Production Costs on Production and Infrastructure Parameters in the Polish Hard Coal Mining Industry" Energies 10, no. 10: 1480. https://doi.org/10.3390/en10101480

APA StyleJonek-Kowalska, I., & Turek, M. (2017). Dependence of Total Production Costs on Production and Infrastructure Parameters in the Polish Hard Coal Mining Industry. Energies, 10(10), 1480. https://doi.org/10.3390/en10101480