Study on Debinding and Sintering Processes for Ceramics Fabricated Using Digital Light Processing (DLP) 3D Printing

Abstract

:1. Introduction

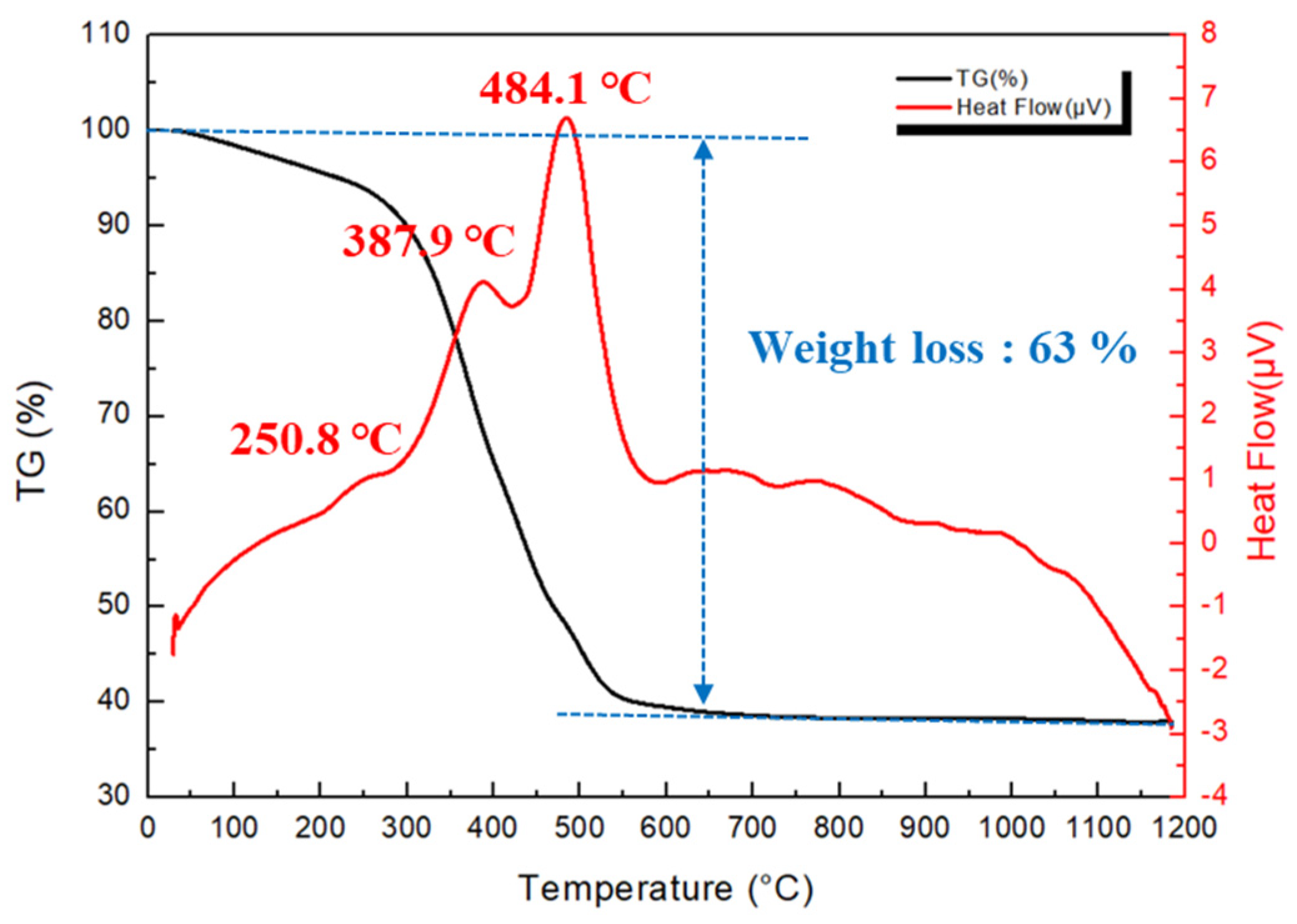

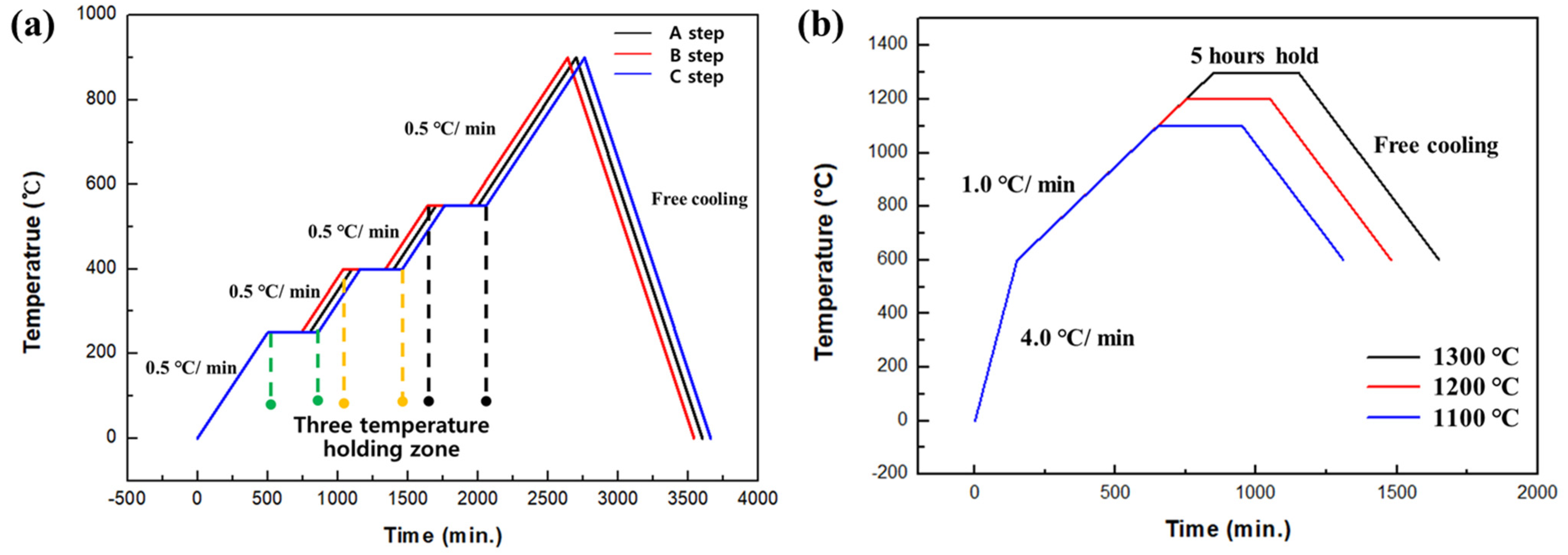

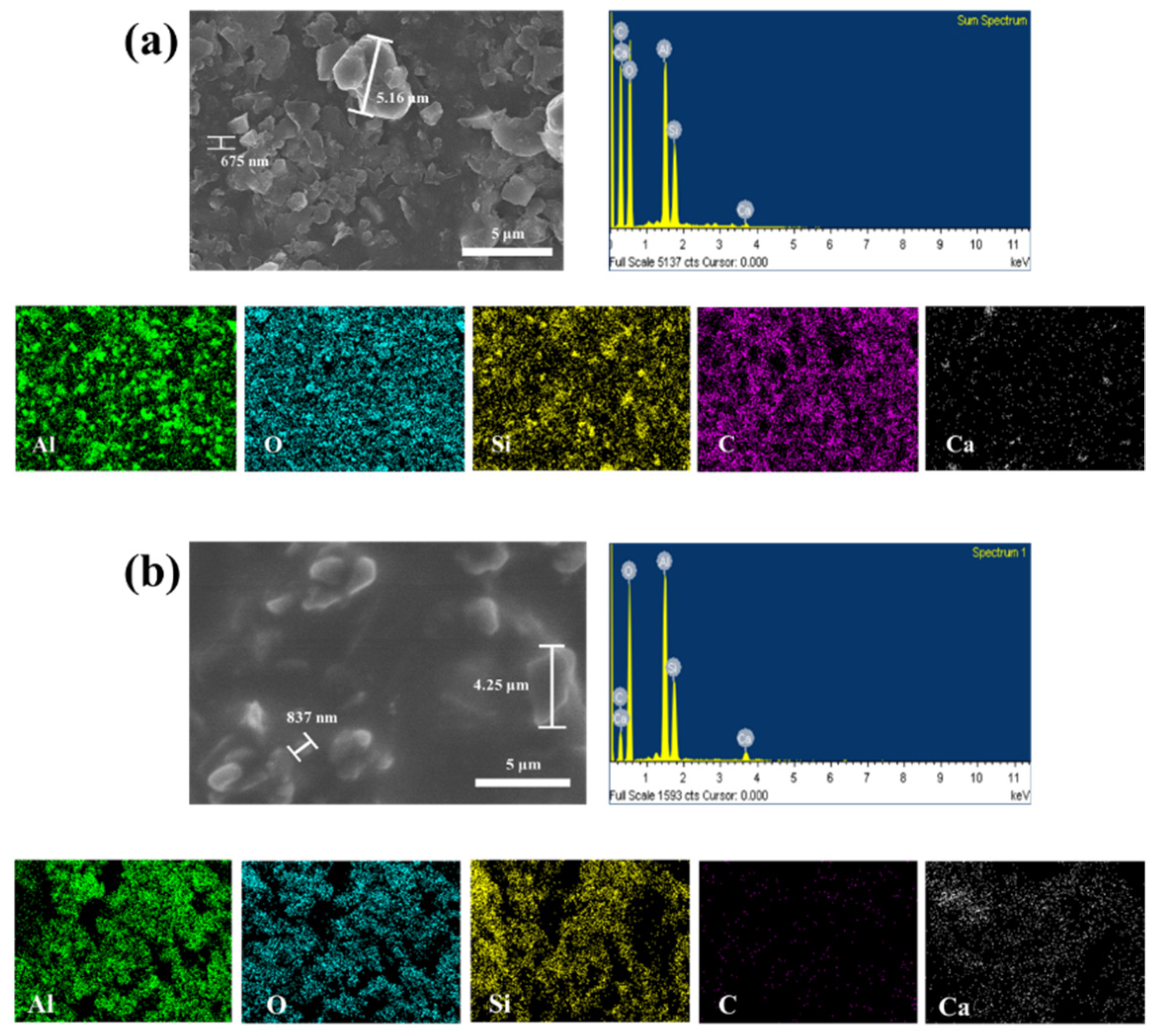

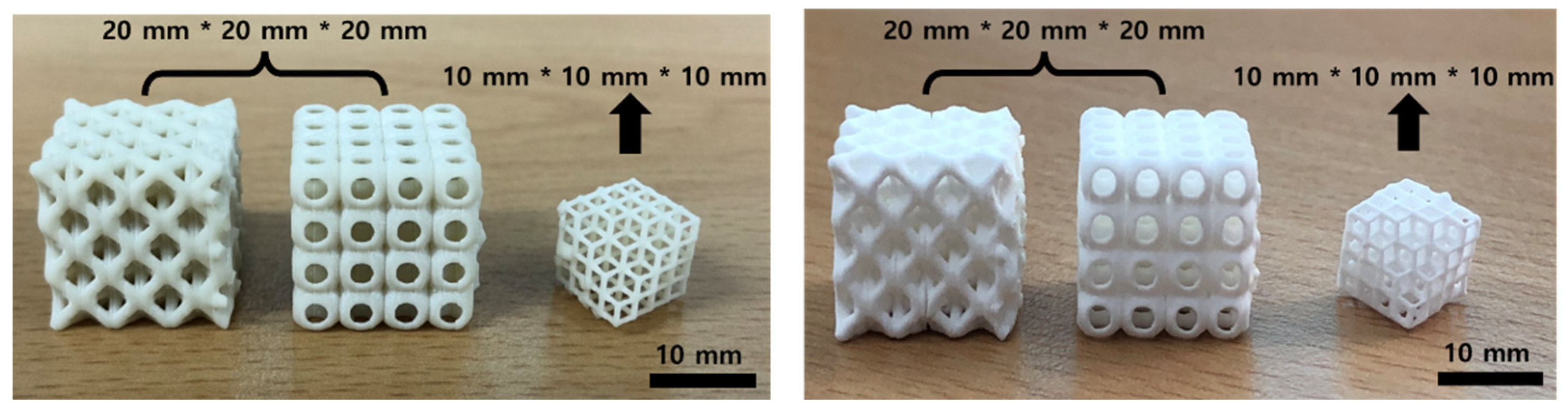

2. Experiment

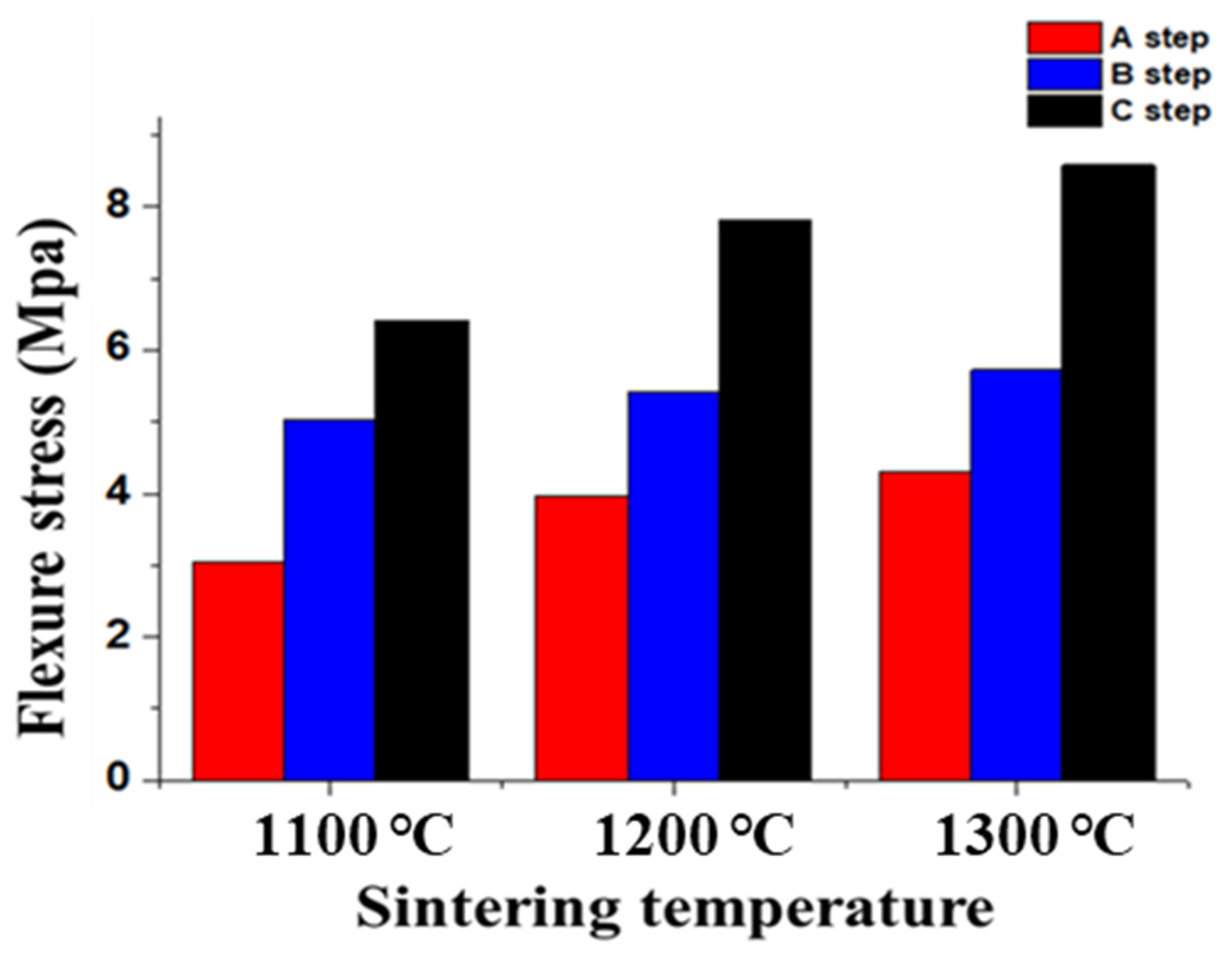

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Varghese, G.; Moral, M.; Castro-García, M.; López-López, J.J.; Marín-Rueda, J.R.; Yagüe-Alcaraz, V.; Hernández-Afonso, L.; CarlosRuiz-Morales, J.; Canales-Vázquez, J. Fabrication and characterisation of ceramics via low-cost DLP 3D printing. Boletín Soc. Española Cerámica Vidr. 2018, 57, 9–18. [Google Scholar] [CrossRef]

- Li, S.; Duan, W.; Zhao, T.; Han, W.; Wang, L.; Dou, R.; Wang, G. The fabrication of SiBCN ceramic components from preceramic polymers by digital light processing (DLP) 3D printing technology. J. Eur. Ceram. Soc. 2018, 38, 4597–4603. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, Z.; Liu, C.; Zhu, J.; Caoo., J.; Yuan, J.; Wang, P.; Liu, C.; Lao, C.; Chen, Z. Dimensional retention of photocured ceramic units during 3D printing and sintering processes. Ceram. Int. 2021, 47, 11097–11108. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, W.; Sun, J.; Liu, J.; Bai, J. Development and evaluation of Al2O3-ZrO2 composite processed by digital light 3D printing. Ceram. Int. 2020, 46, 8682–8688. [Google Scholar] [CrossRef]

- Fan, J.; Xu, X.; Niu, S.; Zhou, Y.; Li, X.; Guo, Y.; Luo, Y. Anisotropy management on microstructure and mechanical property in 3D printing of silica-based ceramic cores. J. Eur. Ceram. Soc. 2022, 42, 4388–4395. [Google Scholar] [CrossRef]

- Mamatha, S.; Biswas, P.; Ramavath, P.; Das, D.; Johnson, R. Effect of parameters on 3D printing of alumina ceramics and evaluation of properties of sintered parts. J. Asian Ceram. Soc. 2021, 9, 858–864. [Google Scholar] [CrossRef]

- Chen, R.; Duan, W.; Wang, G.; Liu, B.; Zhao, Y.; Li, S. Preparation of broadband transparent Si3N4-SiO2 ceramics by digital light processing (DLP) 3D printing technology. J. Eur. Ceram. Soc. 2021, 41, 5495–5504. [Google Scholar] [CrossRef]

- Kovacev, N.; Li, S.; Essa, K. Effect of the preparation techniques of phothopolymerizabel ceramic slurry and printing parameters on the accuracy of 3D printed lattice structures. J. Eur. Ceram. Soc. 2021, 41, 7734–7743. [Google Scholar] [CrossRef]

- Truxova, V.; Safka, J.; Seidl, M.; Kovalenko, I.; Volesky, L.; Ackermann, M. Ceramic 3D printing: Comparison of SLA and DLP technologies. MM Sci. J. 2020, 3905–3911. [Google Scholar] [CrossRef]

- Wang, K.; Qiu, M.; Jiao, C.; Gu, J.; Xie, D.; Wang, C.; Tang, X.; Wei, Z.; Shen, L. Study on defect-free debinding green body of ceramic formed by DLP technology. Ceram. Int. 2020, 46, 2438–2446. [Google Scholar] [CrossRef]

- Shuai, X.; Zeng, Y.; Li, P.; Chen, J. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. J. Mater. Sci. 2020, 55, 6771–6782. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J.; Li, J. Influence of debinding holding time on mechanical properties of 3D-printed alumina ceramic cores. Ceram. Int. 2021, 47, 4884–4894. [Google Scholar] [CrossRef]

- Sun, L.; Dong, P.; Zeng, Y.; Chen, J. Fabrication of hollow lattice alumina ceramic with good mechanical properties by Digital Light Processing 3D printing technology. Ceram. Int. 2021, 47, 26519–26527. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, W.; Wu, H.; Song, X.; Chen, Y.; Cheng, L.; He, F.; Chen, S.; Wu, S. Preparation of a defect-free alumina cutting tool via additive manufacturing based on stereolithography—Optimization of the drying and debinding processes. Ceram. Int. 2016, 42, 11598–11602. [Google Scholar] [CrossRef]

- Kang, K.H.; Jeon, S.H.; Hyun, M.H.; Lee, D.K. Synthsis of Cubic and Rod Shapes CaCO₃ by Hydrothermal Method. J. Korea Acad. Ind. 2016, 17, 255–261. [Google Scholar]

- Shamsudin, R.; Abdul Azam, F.A.; Abdul Hamid, M.A.; Ismail, H. Bioactivity and Cell Compatibility of β-Wollastonite Derived from Rice Husk Ash and Limestone. Materials 2017, 10, 1188. [Google Scholar] [CrossRef] [Green Version]

- Anbalagan, G.; Prabakaran, A.; Gunasekaran, S. Spectroscopic characterization of indian standard sand. J. Appl. Spectrosc. 2010, 77, 86–94. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Khodair, Z.T.; Khadom, A.A. Preparation and investigation of the structural properties of α-Al2O3 nanoparticles using the sol-gel method. Chem. Data Collect. 2020, 29, 100531. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, Z.; Hu, Y.; He, J.; Tian, M.; Zhou, J.; Zhou, Q.; Chen, S.; Chen, D.; Chen, P.; et al. Novel insights into the hydroxylation behaviors of α-quartz (101) surface and its effects on the adsorption of sodium oleate. Minerals 2019, 9, 450. [Google Scholar] [CrossRef]

- Redemaker, H.; Launspach, M. Detection of interaction between biomineralising proteins and calcium carbonate microcrystals. Beilstein J. Nanotechnol. 2011, 2, 222–227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Núñez-Rodríguez, L.A.; Encinas-Romero, M.A.; Gómez-Álvarez, A.; Valenzuela-García, J.L.; Tiburcio-Munive, G.C. Evaulation of Bioactive Properties of α and β Wollastonite Bioceramics Soaked in a Simulated Body Fluid. J. Biomater. Nanobiotechnology 2018, 9, 263–276. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J. Effect of sintering temperature in argon atmosphere on microstructrue and properties of 3D printed alumina ceramic cores. J. Adv. Ceram. 2020, 9, 220–231. [Google Scholar] [CrossRef] [Green Version]

- Grigoriev, S.N.; Fedorov, S.V.; Hamdy, K. Materials, properties, manufacturing methods and cutting performance of innovative ceramic cutting tools—A review. Manuf. Rev. 2019, 6, 19. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.F.; Ohji, T.; Kanszki, S.; Díaz, A.; Hampshire, S. Microstructure and mechanical properties of silicon nitride ceramics with controlled porosity. J. Am. Ceram. Soc. 2002, 85, 1512–1516. [Google Scholar] [CrossRef]

- Santoliquido, O.; Camerota, F.; Ortona, A. The influence of topology on DLP 3D printing, debinding and sintering of ceramic periodic architectures designed to replace bulky components. Open Ceram. 2021, 5, 100059. [Google Scholar] [CrossRef]

| Ceramic Slurry Component (CCTP17W) | Mass Percentage (wt %) |

|---|---|

| Al₂O₃ | 20–40 |

| SiO₂ (Quartz) | 5–15 |

| Kaolin | 5–15 |

| Ceramic frit | 1–10 |

| Calcium inosilicate | 1–10 |

| Borosilicate frit | 1–10 |

| Urethane acrylate resin | 10–30 |

| Alkox.Pentaerythritol tetracrylate | 10–30 |

| Urethane acrylate | 5–15 |

| 2-Propenoic Acid | <0.1 |

| 2,6-di-tert-butyl-p-cresol | 0.1–1 |

| Dibutyltin dilaurate | <0.15 |

| 2,4,6-Trimethylbenzoyldiphenylphosphine oxide | 0.12–2 |

| 2,5-thiophenedylbis (5-tert-butyl-1, 3-benzoxazole) | 0.001–1 |

| Silica, amorphous, fumed, cryst, -free | 0.1–2 |

| Sample | Weight Loss Rate after Debinding (%) | X, Y, and Z Linear Shrinkage (%) | Density (g/cm3) |

|---|---|---|---|

| 1100 °C | 60 | 16.9/20/15.1 | 1.10 |

| 1200 °C | 60 | 20.8/20/21.2 | 1.14 |

| 1300 °C | 60 | 22.1/21.6/28.5 | 1.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sim, J.-H.; Koo, B.-K.; Jung, M.; Kim, D.-S. Study on Debinding and Sintering Processes for Ceramics Fabricated Using Digital Light Processing (DLP) 3D Printing. Processes 2022, 10, 2467. https://doi.org/10.3390/pr10112467

Sim J-H, Koo B-K, Jung M, Kim D-S. Study on Debinding and Sintering Processes for Ceramics Fabricated Using Digital Light Processing (DLP) 3D Printing. Processes. 2022; 10(11):2467. https://doi.org/10.3390/pr10112467

Chicago/Turabian StyleSim, Jae-Ho, Bon-Keup Koo, Minhun Jung, and Dong-Soo Kim. 2022. "Study on Debinding and Sintering Processes for Ceramics Fabricated Using Digital Light Processing (DLP) 3D Printing" Processes 10, no. 11: 2467. https://doi.org/10.3390/pr10112467

APA StyleSim, J.-H., Koo, B.-K., Jung, M., & Kim, D.-S. (2022). Study on Debinding and Sintering Processes for Ceramics Fabricated Using Digital Light Processing (DLP) 3D Printing. Processes, 10(11), 2467. https://doi.org/10.3390/pr10112467