Preparation and In Vitro Analysis of Craniofacial Titanium Implants Surfaces Produced by Additive 3D Printing and Conventional Manufacturing

Abstract

:1. Introduction

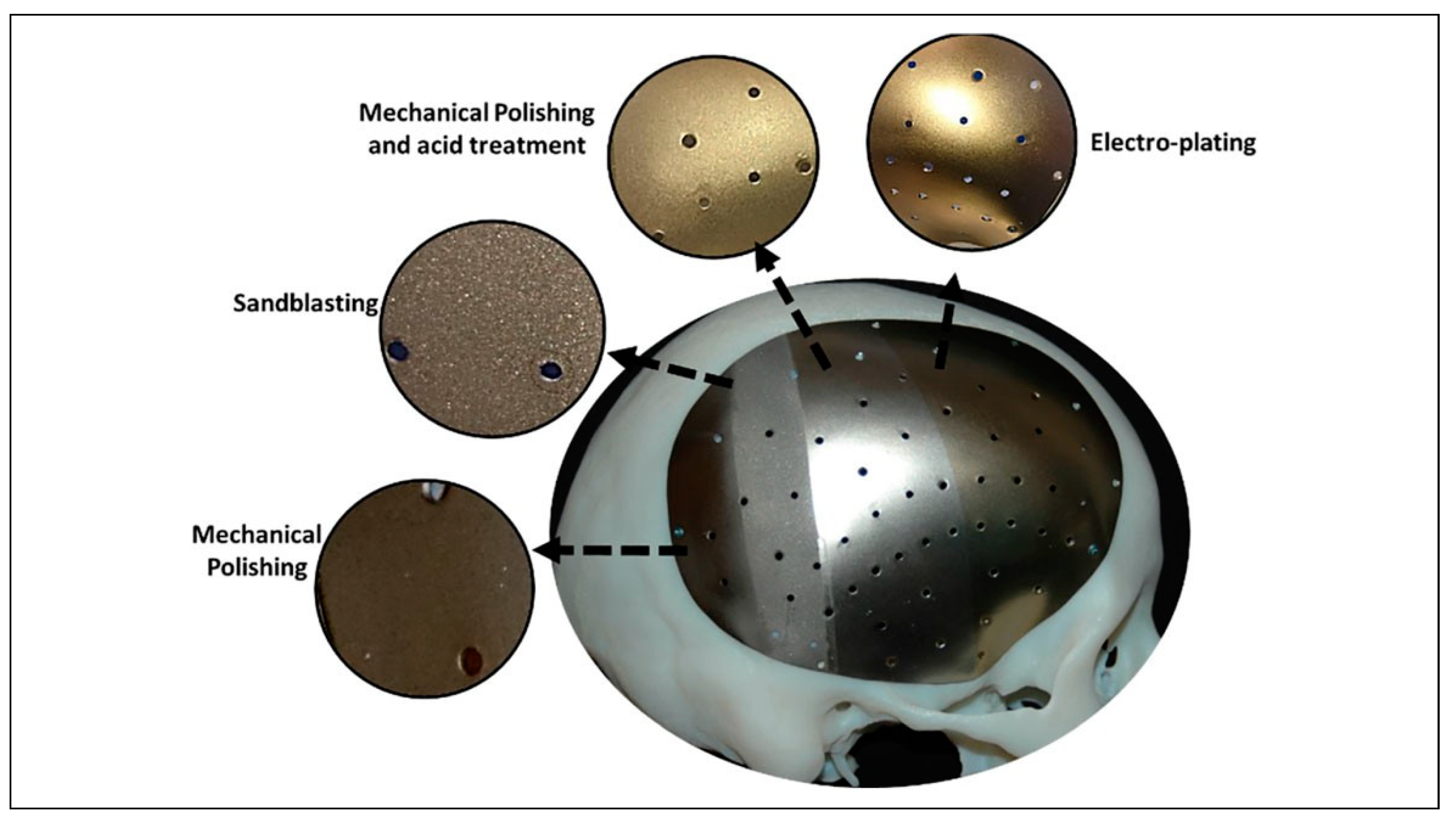

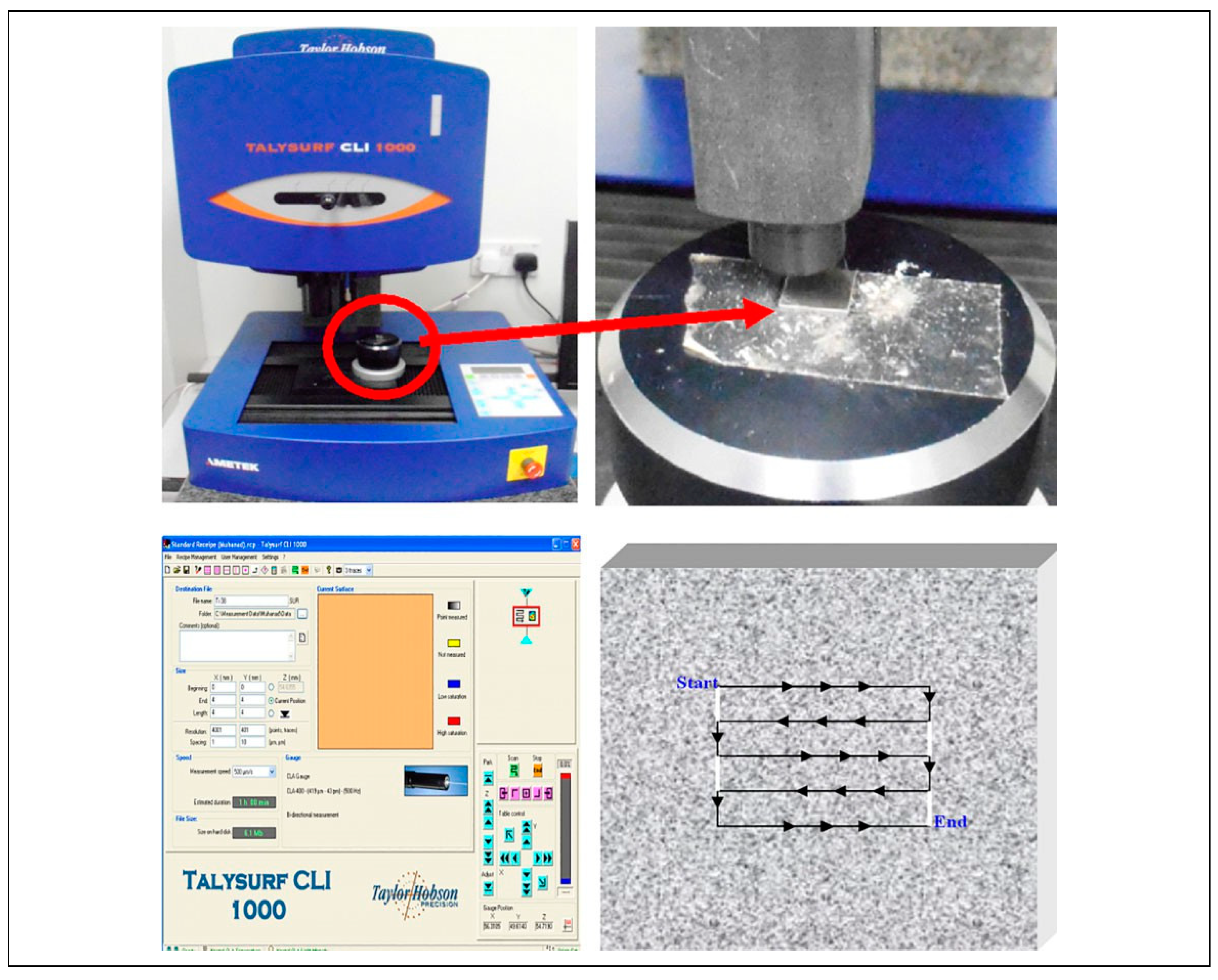

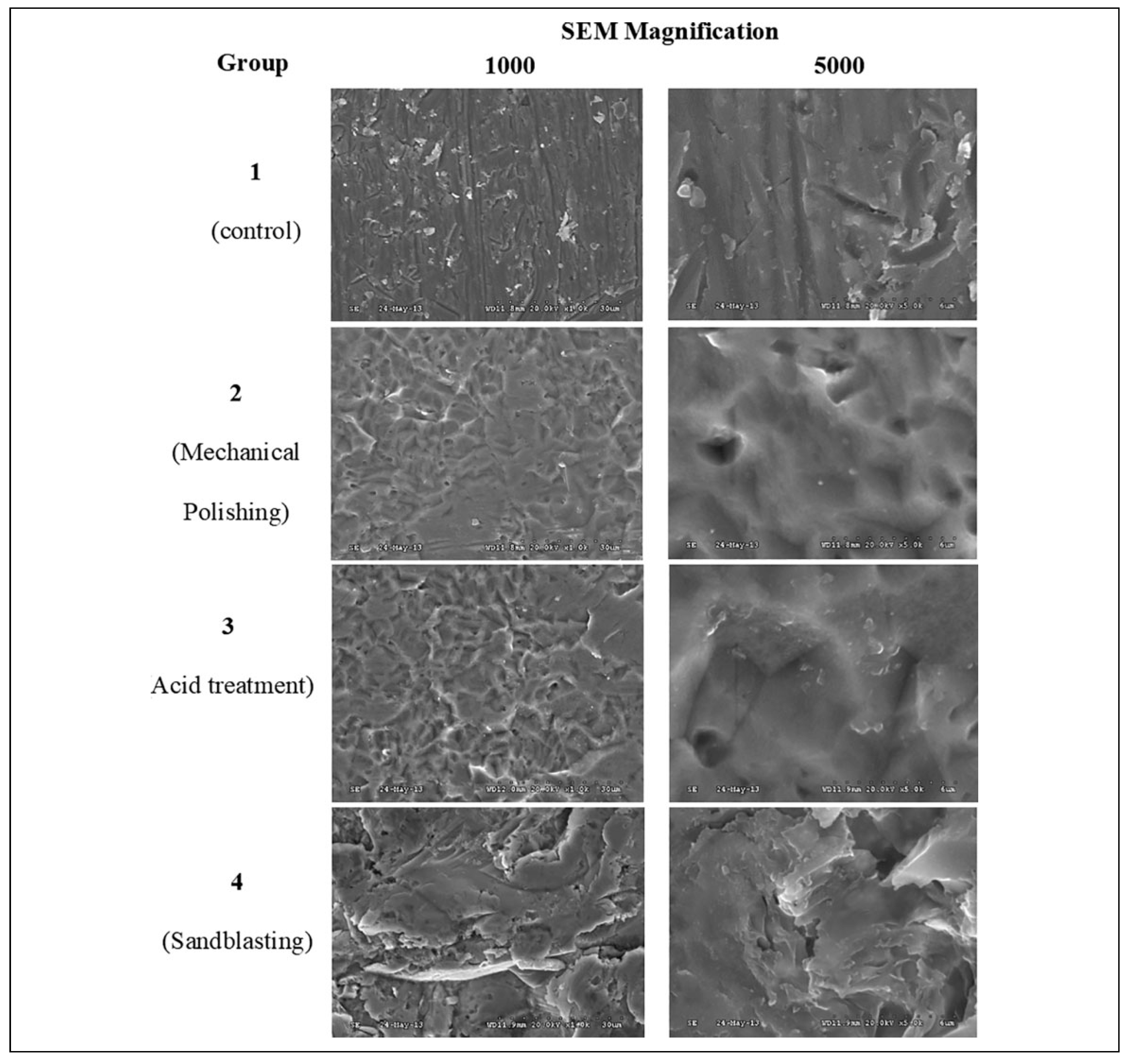

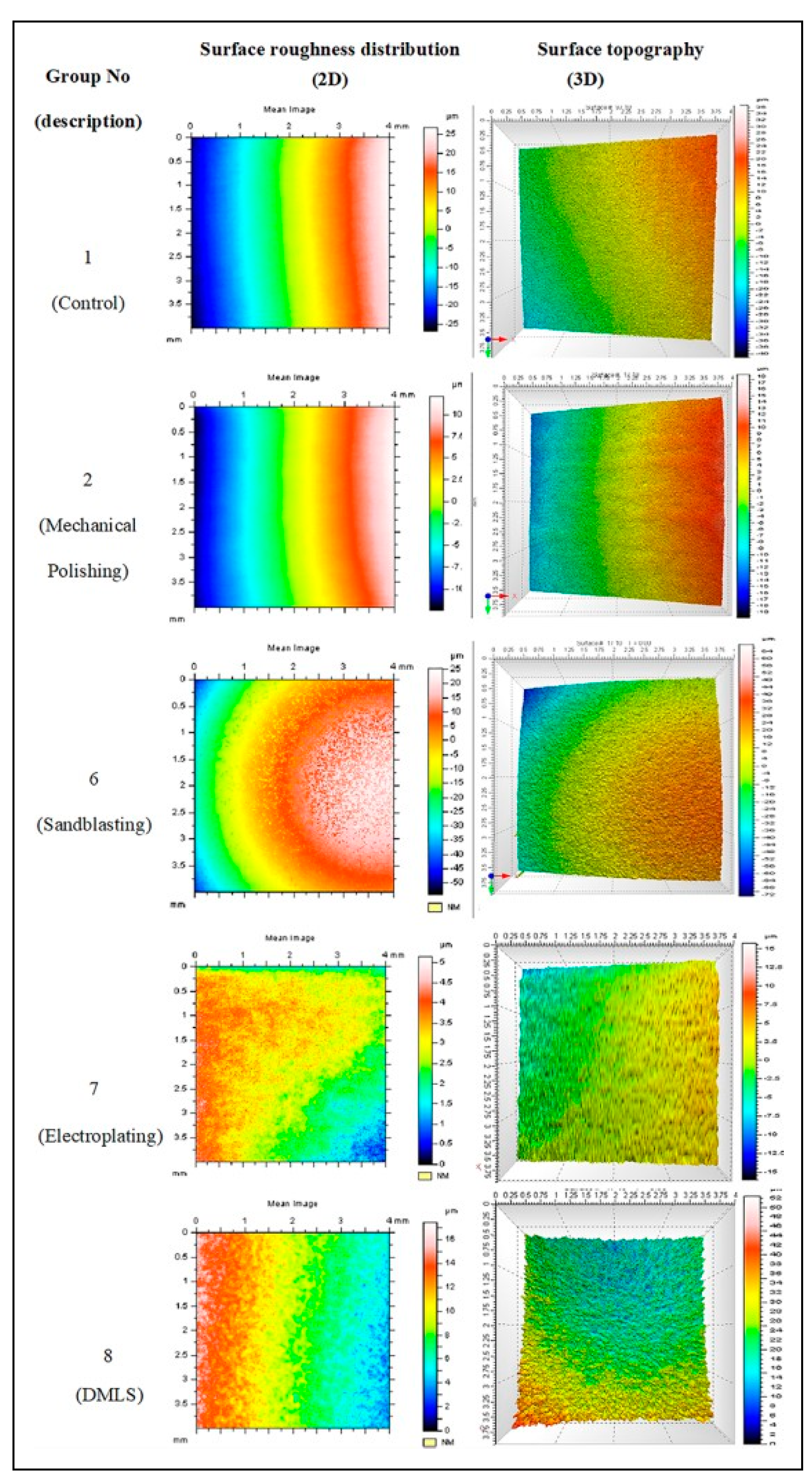

2. Materials and Methods

Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Ethical Approval

Funding

Conflicts of Interest

References

- Ninomi, M. Metallic biomaterials. J. Artif. Organs 2008, 11, 3–110. [Google Scholar] [CrossRef]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 8–1277. [Google Scholar] [CrossRef]

- Parthasarathy, J. 3D modelling, custom implants and its future perspectives in craniofacial surgery. Ann. Maxillofac. Surg. 2014, 4, 1–18. [Google Scholar] [CrossRef]

- Le Guehennec, L.; Soueidan, A.; Layrolle, P.; Amouriq, Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent. Mater. 2007, 23, 7–854. [Google Scholar] [CrossRef] [PubMed]

- Eufinger, H.; Wehmöller, M.; Machtens, E.; Heuser, L.; Harders, A.; Kruse, D. Reconstruction of craniofacial bone defects with individual alloplastic implants based on CAD/CAM-manipulated CT-data. J. Craniomaxillofac. Surg. 1995, 23, 3–181. [Google Scholar] [CrossRef] [PubMed]

- Derand, P.; Rannar, L.E.; Hirsch, J.M. Imaging, virtual planning, design, and production of patient-specific implants and clinical validation in craniomaxillofacial surgery. Craniomaxillofac. Trauma. Reconstr. 2012, 5, 3–144. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electronbeam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 3–385. [Google Scholar] [CrossRef]

- Day, R.E.; Guy, D.T.; Kop, A.M.; Morrison, D.A. The Royal Perth Hospital method for the design and manufacture of titanium cranioplasty plates. Br. J. Oral Maxillofac. Surg. 2012, 50, 4–377. [Google Scholar] [CrossRef]

- Foley, B.D.; Thayer, W.P.; Honeybrook, A.; McKenna, S.; Press, S. Mandibular reconstruction using computer-aided design and computer-aided manufacturing: An analysis of surgical results. J. Oral Maxillofac. Surg. 2013, 71, e111–e119. [Google Scholar] [CrossRef]

- Sharma, S.D.; Lim, B.; Bentley, R.P. Preservation of the temporalis muscle during cranioplasty. Br. J. Oral Maxfac Surg. 2012, 50, e36–e37. [Google Scholar] [CrossRef]

- Wiggins, A.; Austerberry, R.; Morrison, D.; Ho, K.M.; Honeybul, S. Cranioplasty with custom-made titanium plates—14 years experience. Neurosurgery 2013, 72, 248–256; discussion 256. [Google Scholar] [CrossRef]

- Gerbino, G.; Zavattero, E.; Zenga, F.; Bianchi, F.A.; Garzino-Demo, P.; Berrone, S. Primary and secondary reconstruction of complex craniofacial defects using polyetheretherketone custom-made implants. J. Craniomaxillofac. Surg. 2015, 43, 8–1363. [Google Scholar] [CrossRef]

- Gerbino, G.; Zavattero, E.; Zenga, F.; Bianchi, F.A.; Garzino-Demo, P.; Berrone, S. Technical concept of patient-specific, ultrahigh molecular weight polyethylene orbital wall implant. J. Craniomaxillofac. Surg. 2013, 41, 4–290. [Google Scholar]

- Brie, J.; Chartier, T.; Chaput, C.; Delage, C.; Pradeau, B.; Caire, F.; Boncoeur, M.-P.; Moreau, J.-J. A new custom made bioceramic implant for the repair of large and complex craniofacial bone defects. J. Craniomaxillofac. Surg. 2013, 41, 5–407. [Google Scholar] [CrossRef]

- Ciocca, L.; Mazzoni, S.; Fantini, M.; Persiani, F.; Marchetti, C.; Scotti, R. CAD/CAM guided secondary mandibular reconstruction of a discontinuity defect after ablative cancer surgery. J. Craniomaxillofac. Surg. 2012, 40, e511–e515. [Google Scholar] [CrossRef]

- Watson, J.; Hatamleh, M.; Alwahadni, A.; Srinivasan, D. Correction of facial and mandibular asymmetry using a computer aided design/computer aided manufacturing prefabricated titanium implant. J. Craniomaxillofac. Surg. 2014, 25, 3–1101. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.S.; Chen, M.; Pan, C.B.; Tao, Q.; Wang, J.G.; Wang, C.; Zhang, B.; Huang, H.Z. Immediate reconstruction of bilateral mandible defects: Management based on computeraided design/computer-aided manufacturing rapid prototyping technology in combination with vascularized fibular osteomyocutaneous flap. J. Oral Maxillofac. Surg. 2011, 69, 1792–1797. [Google Scholar] [CrossRef]

- Hirsch, D.L.; Garfein, E.S.; Christensen, A.M.; Weimer, K.A.; Saddeh, P.B.; Levine, J.P. Use of computer-aided design and computer-aided manufacturing to produce orthognathically ideal surgical outcomes: A paradigm shift in head and neck reconstruction. J. Oral Maxillofac. Surg. 2009, 67, 10–2122. [Google Scholar] [CrossRef]

- Keller, J.C.; Draughn, R.A.; Wightman, J.P.; Dougherty, W.J.; Meletiou, S.D. Characterization of sterilized CP titanium implant surfaces. Int. J. Oral Maxillofac. Impl. 1990, 5, 4–367. [Google Scholar]

- Marinucci, L.; Balloni, S.; Becchetti, E.; Belcastro, S.; Guerra, M.; Calvitti, M.; Lilli, C.; Calvi, E.M.; Locci, P. Effect of titanium surface roughness on human osteoblast proliferation and gene expression in vitro. Int. J. Oral Maxillofac. Impl. 2006, 21, 5–725. [Google Scholar]

- Martin, J.Y.; Schwartz, Z.; Hummert, T.W.; Schraub, D.M.; Simpson, J.; Lankford, J., Jr.; Dean, D.D.; Cochran, D.L.; Boyan, B. Effect of titanium surface roughness on proliferation, differentiation, and protein synthesis of human osteoblast-like cells (MG63). J. Biomed. Mater. Res. 1995, 29, 389–401. [Google Scholar] [CrossRef] [PubMed]

- Ku, C.H.; Pioletti, D.P.; Browne, M.; Gregson, P.J. Effect of different Ti-6Al-4V surface treatments on osteoblasts behaviour. Biomaterials 2002, 23, 1447–1454. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.A.; Bhatt, V.; Balakrishnan, M.; Hashem, M.; Vellappally, S.; Aziz A Al Kheraif, A.; Halawany, H.S.; Abraham, N.B.; Jacob, V.; Anil, S. Bioactivity and surface characteristics of titanium implants following various surface treatments: An in vitro study. J. Oral Implantol. 2015, 41, e183–e188. [Google Scholar] [CrossRef]

- Rosa, A.L.; Beloti, M.M. Effect of cpTi surface roughness on human bone marrow cell attachment, proliferation, and differentiation. Braz. Den, J. 2003, 14, 16–21. [Google Scholar] [CrossRef]

- Anselme, K.; Linez, P.; Bigerelle, M.; Le Maguer, D.; Le Maguer, A.; Hardouin, P.; Hildebrand, H.; Iost, A.; Leroy, J. The relative influence of the topography and chemistry of TiAl6V4 surfaces on osteoblastic cell behaviour. Biomaterials 2000, 21, 1567–1577. [Google Scholar] [CrossRef]

- Ask, M.; Lausmaa, J.; Kasemo, B. Preparation and surface spectroscopic characterization of oxide films on Ti6Al4V. Appl. Surf. Sci. 1988, 35, 283–301. [Google Scholar] [CrossRef]

- Puippe, J.C. Surface treatment of titanium implants. Euro Cells Mater. 2003, 5, 32–33. [Google Scholar]

- Hatamleh, M.M.; Wu, X.; Alnazzawi, A.; Watson, J.; Watts, D. Surface characteristics and biocompatibility of cranioplasty titanium implants following different surface treatments. Dent. Mater. 2018, 34, 676–683. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of advanced manufactured titanium implants—A review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef]

- Tuomi, J.T.; Björkstrand, R.V.; Pernu, M.L.; Salmi, M.V.; Huotilainen, E.I.; Wolff, J.E.; Vallittu, P.K.; Mäkitie, A.A. In vitro cytotoxicity and surface topography evaluation of additive manufacturing titanium implant materials. J. Mater. Sci. Mater. Med. 2017, 28, 53. [Google Scholar] [CrossRef]

- Deleanu, L.; Cantaragiu, A.; Georgescu, C.; Botan, M. Influence of measurements of 3D roughness parameters. Mech. Test. Diagn. 2011, 1, 42–53. [Google Scholar]

| Group (n = 10) | Sa | Sp | Sv | Sz |

|---|---|---|---|---|

| 1 | 12.55 a | 29.74 a | 30.61 a | 60.35 a |

| 2 | 4.03 6.00 b | 7.32 14.26 b | 8.20 14.90 b | 15.37 29.16 b |

| 3 | 1.69 4.88 b | 3.23 14.86 b | 3.71 15.88 b | 6.82 30.74 b |

| 4 | 1.72 11.98 a | 4.56 34.91 c | 3.27 56.64 c | 7.65 107.05d |

| 5 | 4.95 2.72 c | 9.54 12.02 b | 13.24 9.59 b | 51.82 23.83 b |

| 6 | 0.88 13.95 a | 5.71 43.56 c | 2.86 62.67 c | 13.40 106.23d |

| 7 | 4.33 2.31 c | 15.42 9.07 b | 8.03 10.39 b | 18.59 19.46 b |

| 8 | 1.16 4.29 b | 3.26 23.23 a | 2.73 19.55 b | 5.55 42.75 c |

| 2.09 | 6.18 | 2.72 | 7.78 |

© 2020 by the author. Published by MDPI on behalf of the AO Foundation. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hatamleh, M.M. Preparation and In Vitro Analysis of Craniofacial Titanium Implants Surfaces Produced by Additive 3D Printing and Conventional Manufacturing. Craniomaxillofac. Trauma Reconstr. 2021, 14, 224-230. https://doi.org/10.1177/1943387520970792

Hatamleh MM. Preparation and In Vitro Analysis of Craniofacial Titanium Implants Surfaces Produced by Additive 3D Printing and Conventional Manufacturing. Craniomaxillofacial Trauma & Reconstruction. 2021; 14(3):224-230. https://doi.org/10.1177/1943387520970792

Chicago/Turabian StyleHatamleh, Muhanad M. 2021. "Preparation and In Vitro Analysis of Craniofacial Titanium Implants Surfaces Produced by Additive 3D Printing and Conventional Manufacturing" Craniomaxillofacial Trauma & Reconstruction 14, no. 3: 224-230. https://doi.org/10.1177/1943387520970792

APA StyleHatamleh, M. M. (2021). Preparation and In Vitro Analysis of Craniofacial Titanium Implants Surfaces Produced by Additive 3D Printing and Conventional Manufacturing. Craniomaxillofacial Trauma & Reconstruction, 14(3), 224-230. https://doi.org/10.1177/1943387520970792