Production, Use and Recycling of Fruit Cultivating Bags in China

Abstract

:1. Introduction

2. Current Situation of Fruits Production in China

2.1. Overall Production Status

2.2. Spatial Pattern of Fruit Industry and Production Status of Main Fruits

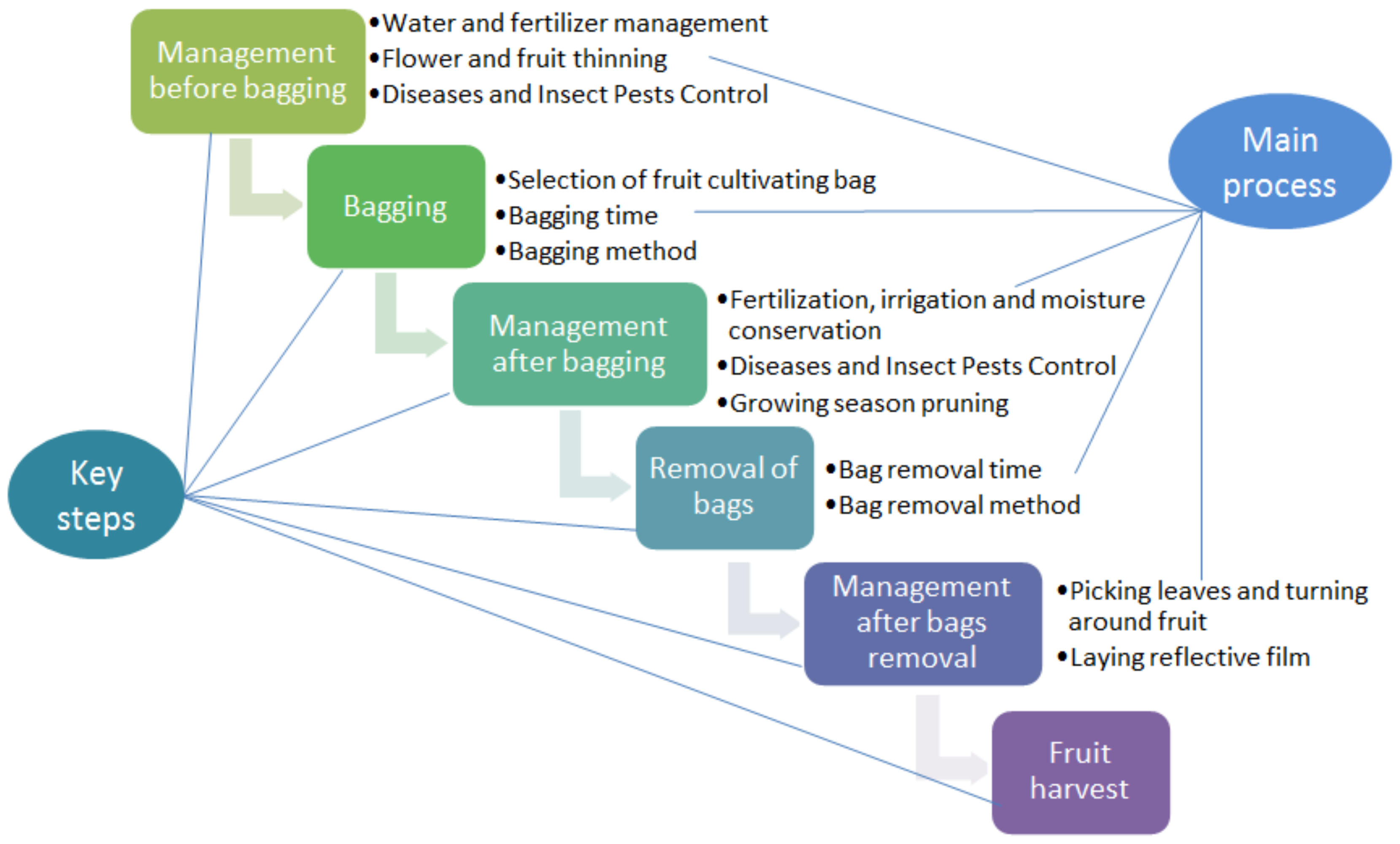

3. Overview of Fruit Bagging Technology

4. Production and Use of Fruit Cultivating Bags

4.1. Classification of Fruit Cultivating Bags

4.2. Production and Use of Fruit Cultivating Bags

4.2.1. Plastic Film Bags

4.2.2. Paper-Film Composite Bags

4.2.3. Paper Bags

4.2.4. Other Types of Fruit Bags

5. Discussion on the Present Situation and Strategy of Recycling Waste Fruit Cultivating Bags

5.1. Current Situation of Recycling Waste Fruit Cultivating Bags

5.2. Recycling Strategies for Waste Fruit Cultivating Bags

- (1)

- Sorting and recycling of waste fruit bags

- (2)

- Improving fruit farmer awareness of recycling fruit bags

- (3)

- Improving the level of mechanized operation

- (4)

- Establish a comprehensive recycling system for waste fruit bags

- (5)

- Exploring and implementing fruit non-bagging production technology [86]. Although fruit bagging has many advantages, it also has negative problems such as resource consumption, environmental pollution, labor cost and economic cost increase. For example, ➀ at present, apple bags used by Chinese fruit farmers are generally paper bags, and their production materials are wood pulp paper (WPP). In general, about 5 paper bags are required for 1 kg of apples, and each paper bag is calculated as 5 g WPP. Hence, if 1 kg of apples is produced, about 25 g of WPP is required, and 25 kg of WPP is required for 1 ton of apples. In 2020, China’s apple total yield was 44.1 million tons, and 80% of apples were bagged with paper bags. It would take 1.1 million tons of WPP to bag apples, which would be a huge resource consumption. ➁ In addition, bagging and bag removal operations are completed manually. The bagging farming time is short, and the problems of an aging rural population and difficult and expensive employment are becoming more and more prominent. It is estimated that the labor cost and paper bag cost of an apple from bagging (paper bag) to picking is about 0.2 Renminbi (Yuan). According to this calculation, the labor cost and paper bag cost of 1 kg of apples (5 paper bags) are 1 Renminbi (Yuan), accounting for 40–50% of the orchard expenditure. If the apple yield of 30,000 kg per hectare is calculated, the total cost is 30,000 Renminbi (Yuan). ➂ If the removed fruit bags are not handled in time, they will fall all over the ground and seriously pollute the environment.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Buthelezi, N.M.D.; Mafeo, T.P.; Mathaba, N. Preharvest bagging as an alternative technique for enhancing fruit quality: A review. HortTechnology 2021, 31, 1–10. [Google Scholar] [CrossRef]

- Kasso, M.; Bekele, A. Post-harvest loss and quality deterioration of horticultural crops in Dire Dawa Region, Ethiopia. J. Saudi Soc. Agric. Sci. 2018, 17, 88–96. [Google Scholar] [CrossRef] [Green Version]

- Maung, K.L.; Yin, Y.M.; Khine, M.P.; Chan, K.N.; Khai, A.A. Current knowledge of mango and fruit fly (Diptera: Tephritidae) control in myanmar: A review. Adv. Entomol. 2021, 9, 49–58. [Google Scholar] [CrossRef]

- Li, C.J.; Zhu, H.M.; Li, C.Y.; Qian, H.; Yao, W.R.; Guo, Y.H. The present situation of pesticide residues in China and their removal and transformation during food processing. Food Chem. 2021, 354, 129552. [Google Scholar] [CrossRef]

- Frank, D.L. Evaluation of fruit bagging as a pest management option for direct pests of apple. Insects 2018, 9, 178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, R.R.; Pal, R.K.; Sagar, V.R.; Parmanick, K.K.; Paul, V.; Gupta, V.K.; Kumar, K.; Rana, M.R. Impact of pre-harvest fruit-bagging with different coloured bags on peel colour and the incidence of insect pests, disease and storage disorders in ‘Royal Delicious’ apple. J. Hortic. Sci. Biotechnol. 2014, 89, 6013. [Google Scholar] [CrossRef]

- Sharma, R.R.; Sanikommu, V.R.R.; Jhalegar, J. Pre-harvest fruit bagging: A useful approach for plant protection and improved post-harvest fruit quality—A review. J. Hortic. Sci. Biotechnol. 2014, 89, 101–113. [Google Scholar] [CrossRef]

- Ahmed, T.; Hasan, M.M.; Hassan, K.; Ahmed, J.D.; Ahmed, K.S.D.; Azam, A.; Mondal, M.F. Fruit bagging of custard apple (Annona reticulata) as an eco-friendly protection approach against mealybug (Phenacoccus solenopsis) infestation in the north-eastern Bangladesh. Int. J. Trop. Insect Sci. 2022, 42, 723–732. [Google Scholar] [CrossRef]

- Sharma, R.R.; Sanikommu, V.R. Chapter 16—Preharvest fruit bagging for better protection and postharvest quality of horticultural produce. In Preharvest Modulation of Postharvest Fruit and Vegetable Quality; Academic Press: Cambridge, MA, USA, 2018; pp. 455–489. [Google Scholar]

- Jia, H.J.; Araki, A.; Okamoto, G. Influence of fruit bagging on aroma volatiles and skin coloration of ‘Hakuho’ peach (Prunus persica Batsch). Postharvest Biol. Technol. 2005, 35, 61–68. [Google Scholar] [CrossRef]

- Zha, Q.; Xi, X.J.; He, Y.N.; Jiang, A.L. Bagging affecting sugar and anthocyanin metabolism in the ripening period of grape berries. Not. Bot. Horti Agrobot. Cluj-Napoca 2019, 47, 1194–1205. [Google Scholar] [CrossRef]

- Sharma, R.R.; Pal, R.K.; Asrey, R.; Sagar, V.R.; Rana, M.R. Pre-harvest fruit bagging influences fruit color and quality of apple cv. Delicious. Agric. Sci. 2013, 4, 443–448. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.M.; Anwar, R.; Yousef, A.F.; Li, B.; Luvisi, A.; De Bellis, L.; Aprile, A.; Chen, F. Influence of Bagging on the Development and Quality of Fruits. Plants 2021, 10, 358. [Google Scholar] [CrossRef] [PubMed]

- Paul, J.R.; Prasad, K.; Lalrinngheta, J.; Mukhim, C.; Akshatha, H. Improving fruit quality by bagging technology. Food Sci. Rep. 2021, 2, 49–53. [Google Scholar]

- Deng, X.X. Thoughts on the development of China’s fruit industry. J. Fruit Sci. 2021, 38, 121–127. [Google Scholar]

- Yuan, B.; Yue, F.Z.; Cui, Y.H.; Chen, C. The role of fine management techniques in relation to agricultural pollution and farmer income: The case of the fruit industry. Environ. Res. Lett. 2022, 17, 034001. [Google Scholar] [CrossRef]

- Xia, Y.; Huang, J.H.; Jiang, F.; He, J.Y.; Pan, X.B.; Lin, X.J.; Hu, H.Q.; Fan, G.C.; Zhu, S.F.; Hou, B.H. The effectiveness of fruit bagging and culling for risk mitigation of fruit flies affecting citrus in China: A preliminary report. Fla. Entomol. 2019, 102, 79–84. [Google Scholar]

- Wang, G.P.; Xue, X.M.; Wang, J.Z. Research progress and development trend of apple bagging technology in China. J. Hebei Agric. Sci. 2021, 25, 44–48. [Google Scholar]

- Zhang, Q.Q.; Si, R.S.; Shi, F.J.; Huo, X.X. The evolution trend of Chinese fruit production concentration level. Chin. J. Agric. Resour. Reg. Plan. 2021, 42, 96–108. [Google Scholar]

- Department of Rural Social and Economic Investigation, National Bureau of Statistics. China Rural Statistical Yearbook (1985–2021); China Statistics Press: Beijing, China, 2022. [Google Scholar]

- Zhu, X.M.; Zhang, B. Study on spatio-temporal evolution of competition pattern of geographical indication fruit industry in China. For. Econ. 2022, 44, 78–96. [Google Scholar]

- Wang, J.K. Optimization strategy of export trade of Chinese fruits under the change of Chinese fruit industry structure. Adv. J. Food Sci. Technol. 2015, 8, 589–592. [Google Scholar] [CrossRef]

- Endo, M. Studies on the daily change of fruit size of the Japanese pear: VII. Effect of bagging with different paper bag types on fruit growth and quality with special reference to diurnal fluctuation in fruit size. J. Jpn. Soc. Hortic. Sci. 1976, 44, 381–394. [Google Scholar] [CrossRef] [Green Version]

- Kubo, Y.; Taira, S.; Ishio, S.; Sugiura, A.; Tomana, T. Color development of 4 apple cultivars grown in the southwest of Japan, with special reference to fruit bagging. J. Jpn. Soc. Hortic. Sci. 1988, 57, 191–199. [Google Scholar] [CrossRef] [Green Version]

- Nagasawa, K.; Sato, S.; Ishiwata, H. Some characteristics of peach fruits cultured by non-bagging condition. Tech. Bull. Fac. Hortic. Chiba Univ. 1954, 2, 17–24. [Google Scholar]

- Sharma, R.R.; Sagar, V.R.; Dhiman, M.R.; Parmanick, K.K.; Kumar, K. Response of ‘Royal Delicious’ apple to the staggered pre-harvest fruit-bagging. Indian J. Hortic. 2016, 73, 109. [Google Scholar] [CrossRef]

- Sharma, R.R.; Asrey, R.; Sagar, V.R.; Sethi, S. Influence of pre-harvest fruit bagging on Golden Delicious apple (Malus × domestica). Indian J. Agric. Sci. 2017, 87, 1170–1173. [Google Scholar]

- Gethe, A.S.; Pujari, C.V.; Patil, R.V.; Hiray, S.A.; Lalge, P.M. Impact of pre-harvest fruit bagging on fruit yield and biochemical properties of pomegranate cv. Phule Bhagwa supe. Int. J. Chem. Stud. 2021, 9, 2238–2242. [Google Scholar]

- Gethe, A.S.; Hiray, S.A.; Pujari, C.V.; Patil, R.V. Effect of pre-harvest fruit bagging on physical and physiological properties of pomegranate (Punica granatum, L.) cv. Phule Bhagwa Super. Int. J. Curr. Microbiol. Appl. Sci. 2021, 10, 227–236. [Google Scholar]

- Sharma, R.R.; Nagaraja, A.; Goswami, A.K.; Thakre, M.; Varghese, E. Influence of on-the-tree fruit bagging on biotic stresses and postharvest quality of rainy-season crop of ‘Allahabad Safeda’ guava (Psidium guajava L.). Crop Prot. 2020, 135, 105216. [Google Scholar] [CrossRef]

- Kiran, A.S.; Kavitha, C.; Soorianathasundaram, K.; Sritharan, N. Impact of fruit bagging with different coloured non-woven polypropylene bags on yield attributes in grapes. J. Dairy. Foods Home Sci. 2020, 39, 359–362. [Google Scholar] [CrossRef]

- La, N. Bagging of fruit bunches: An eco-friendly approach for quality production and protection from physiological disorder in litchi. Agiculture Food E-Newsl. 2020, 2, 1–3. [Google Scholar]

- Leisso, R.; Jarrett, B.; Mendrey, K.; Miller, Z. Bagging apple fruit for codling moth control in Western Montana. HortTechnology 2021, 31, 1–4. [Google Scholar] [CrossRef]

- Campbell, D.; Sarkhosh, A.; Brecht, J.K.; Gillett-Kaufman, J.L.; Treadwell, D. Bagging organic peaches reduces physical injuries and storage decay with minimal effects on fruit quality. HortScience 2020, 56, 1–7. [Google Scholar] [CrossRef]

- Campbell, D.; Brecht, J.K.; Sarkhosh, A.; Liburd, O.E. Photoselective-light impacts on fruit bagging microclimate, quality, and nutrients of peach. HortScience 2021, 56, 1354–1362. [Google Scholar] [CrossRef]

- Hossain, M.M.; Chowdhury, S.; Rahim, M.A. Preharvest fruit bagging time regulates postharvest quality and shelf life of dragon fruit (Hylocereus spp.). Int. J. Minor Fruits Med. Aromat. Plants 2021, 7, 36–44. [Google Scholar] [CrossRef]

- Chowdhury, S.; Hossain, M.M.; Rahim, M.A.; Ferdous, T. Postharvest quality and shelf life of dragon fruit (Hylocereus spp.) as influenced by preharvest fruit bagging materials. J. Agric. Food Environ. 2020, 1, 33–40. [Google Scholar] [CrossRef]

- Hossain, M.J.; Hossain, R.G.; Mehedi, M.; Hossain, M.M. Effects of preharvest fruit bagging on postharvest quality and shelf life of mango cv. amrapali. J. Bangladesh Agric. Univ. 2020, 18, 61–67. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hossain, M.M.; Rahim, M.A.; Rubel, M.; Islam, M.Z. Effect of pre-harvest fruit bagging on post-harvest quality of guava cv. Swarupkathi. Fundam. Appl. Agric. 2018, 3, 363–371. [Google Scholar]

- Mamay, M. The influence of calyx removal and fruit bagging on carob moth, Ectomyelois ceratoniae Zeller (Lepidoptera: Pyralidae), infestation in pomegranate. Crop Prot. 2021, 147, 105708. [Google Scholar] [CrossRef]

- Legua, P.; Martínez-Nicolás, J.J.; Guirao, P.; Hernández, F.; Núñez-Gómez, D.; Melgarejo, P. Influence of fruit bagging technique on the morphometric and biochemical characteristics of two pomegranate varieties (Punica granatum L.). Food Chem. Mol. Sci. 2022, 4, 100112. [Google Scholar] [CrossRef] [PubMed]

- Secretaria, L.; Bayogan, E.R.; Lubaton, C.D.; Nortate, A.; Ekman, J. Postharvest quality of ‘carabao’ mango as affected by spun-bound bagging materials. Chiang Mai Univ. J. Nat. Sci. 2021, 20, 2021007. [Google Scholar] [CrossRef]

- Karar, H.; Ahmad, M.; Ullah, H.; Wajid, M.; Raza, H. Original research effectiveness of fruit bagging for the control of insect-pests complex and its impact on quality of mango fruits. J. Hortic. Sci. Technol. 2019, 2, 45–48. [Google Scholar] [CrossRef]

- Ryu, M.R.; Kim, G.Y.; Yang, Y.J. Postharvest quality of ‘Whangkeumbae’ pear affected by preharvest fruit bagging. Korean J. Hortic. Sci. Technol. 2008, 26, 149–153. [Google Scholar]

- Karajeh, M.R. Pre-harvest bagging of grape clusters as a non-chemical physical control measure against certain pests and diseases of grapevines. Org. Agric. 2018, 8, 259–264. [Google Scholar] [CrossRef]

- Tuan, N.; Hung, N.; Anh, B.; Kien, T.; Viet, D. Effect of bagging time on fruit yield and quality of red pitaya (Hylocereus spp.) fruit in Vietnam. Int. J. Plant Soil Sci. 2017, 19, 1–7. [Google Scholar] [CrossRef]

- Nascimento, W.; Müller, C.H.; Araújo, C.D.S.; Flores, B.C. Fruit bagging of Pouteria caimito aiming protection against the attack of fruit fly. Rev. Bras. De Frutic. 2011, 33, 48–52. [Google Scholar] [CrossRef]

- Raga, A.; Sousa, E.M.D.; Braga, S.; Louzeiro, L. Susceptibility of bagged guavas to the attack of fruit flies (tephritidae). J. Exp. Agric. Int. 2020, 42, 82–87. [Google Scholar] [CrossRef]

- Wang, H.; Wang, S.; Fan, M.M.; Zhang, S.H.; Sun, L.L.; Zhao, Z.Y. Metabolomic insights into the browning of the peel of bagging ‘Rui Xue’ apple fruit. BMC Plant Biol. 2021, 21, 209. [Google Scholar] [CrossRef]

- Wang, L.B.; Ma, M.; Zhang, S.L.; Wu, Z.F.; Li, J.; Luo, W.Q.; Guo, L.; Lin, W.; Zhang, S.L. Characterization of genes involved in pear ascorbic acid metabolism and their response to bagging treatment during ‘Yali’ fruit development. Sci. Hortic. 2021, 285, 110178. [Google Scholar] [CrossRef]

- Yuan, Z.H.; Yin, Y.L.; Feng, L.J.; Zhao, X.Q.; Hou, L.F.; Zhang, Y.X. Evaluation of pomegranate bagging and fruit cracking in Shandong, China. Acta Hortic. 2012, 940, 125–129. [Google Scholar] [CrossRef]

- Zhi, C.; Ali, M.M.; Zhang, J.; Shi, M.; Ma, S.; Chen, F. Effect of Paper and Aluminum Bagging on Fruit Quality of Loquat (Eriobotrya japonica Lindl.). Plants 2021, 10, 2704. [Google Scholar] [CrossRef]

- Li, S.G.; Tao, S.H.; Zhang, J.; Wu, L.N.; Huan, C.; Zheng, X.L. Effect of calcium treatment on the storability and disease resistance in pre-harvest bagging mango fruit during room temperature storage. J. Food Process. Preserv. 2020, 44, 14803. [Google Scholar] [CrossRef]

- Zhu, C.H.; Li, J.X.; Zhou, D.G.; Peng, M.X.; Guo, J.; Gao, J.Y.; Yu, J.Q. Effect of bagging on fruit development and quality in off-season lemon. Southwest China J. Agric. Sci. 2011, 24, 202–205. [Google Scholar]

- Ran, H.J.; Fan, S.Y.; Zeng, K.F.; Deng, L.L. Effect of preharvest bagging treatment on postharvest degreening behavior and storage characteristics of satsuma mandarin (Citrus unshiu Marc.) fruit. Food Sci. 2020, 41, 221–226. [Google Scholar]

- Sun, X.; Kai, S.; Liu, J.; Zhang, J.; Zang, L. Effects of different bagging period on the microenvironment and qulity of sweet cherry over whole branch by non-woven fabric. Chin. Agric. Sci. Bull. 2009, 25, 160–164. [Google Scholar]

- Yang, W.H.; Zhu, X.C.; Bu, J.H.; Hu, G.B.; Wang, H.C.; Huang, X.M. Effects of bagging on fruit development and quality in cross-winter off-season longan. Sci. Hortic. 2009, 120, 194–200. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Y.; Li, W.; Yang, C.; Lin, Y.; Wang, Y.; Chen, C.; Wan, C.; Chen, J.; Gan, Z. The Effects of Bagging on Color Change and Chemical Composition in ‘Jinyan’ Kiwifruit (Actinidia chinensis). Horticulturae 2022, 8, 478. [Google Scholar] [CrossRef]

- Wang, Y.; Song, Q.M.; Wang, F.; Tang, S.Y.; Pan, T.T.; Zhang, Y.P.; Hu, D.Y. Bagging and non-bagging treatment on the dissipation and residue of four mixed application pesticides on banana fruit. J. Sci. Food Agric. 2020, 101, 3472–3480. [Google Scholar] [CrossRef]

- Deng, H.Y.; Huang, L.F.; Liang, G.D.; He, Q.G.; Wu, Z.J. Effect of bagging treatment on fruit quality of pitaya in high temperature and high humidity areas. Chin. J. Trop. Crops 2020, 41, 167–174. [Google Scholar]

- Liu, H.P.; Bu, J.H.; Lin, J.B.; Hu, G.B. Research progress on bagging of litchi fruit. Trop. Agric. Eng. 2015, 39, 19–24. [Google Scholar]

- State Administration for Market Regulation. National Public Service Platform for Standard Information. Available online: http://std.samr.gov.cn (accessed on 10 August 2022).

- Peng, C.; Deng, L.P.; Meng, W.C.; Chang, X.X.; Zhang, Z.W.; Luo, J.L.; Qiu, J.S.; Lu, Y.S. Effect of bagging on fruit appearance and aromatic components of prunus salicina var. cordata. Chin. Agric. Sci. Bull. 2022, 38, 45–51. [Google Scholar]

- Taobao Marketplace. Available online: https://item.taobao.com/item.htm?spm=a230r.1.14.33.274f1546rFvnX8&id=639282502113&ns=1&abbucket=16#detail (accessed on 12 August 2022).

- Taobao Marketplace. Available online: https://item.taobao.com/item.htm?spm=a230r.1.14.190.22607cfeuEJMVH&id=40010852886&ns=1&abbucket=16#detail (accessed on 12 August 2022).

- Taobao Marketplace. Available online: https://item.taobao.com/item.htm?spm=a230r.1.14.68.1eb15838wsk4KA&id=592374979041&ns=1&abbucket=16#detail (accessed on 12 August 2022).

- Taobao Marketplace. Available online: https://item.taobao.com/item.htm?spm=a230r.1.14.21.7a0b1c3a2H4JXk&id=633981132746&ns=1&abbucket=16#detail (accessed on 12 August 2022).

- Taobao Marketplace. Available online: https://item.taobao.com/item.htm?spm=a1z10.1-c.w4004-1793242006.30.7a143f698vQFC2&id=566024245075 (accessed on 12 August 2022).

- Taobao Marketplace. Available online: https://item.taobao.com/item.htm?spm=a1z10.5-c.w4002-15905271393.10.16351f8dfRuBBt&id=588530198810 (accessed on 12 August 2022).

- Sarker, D.; Rahman, M.; Barman, J. Efficacy of different bagging materials for the control of mango fruit fly. Bangladesh J. Agric. Res. 2009, 34, 165–168. [Google Scholar] [CrossRef]

- Zou, Y.Q.; Lin, Z.Z.; Xu, R.W.; Cheng, Y.J. Development and evaluation of a coating substitute for individual polyethylene film packaging of citrus fruit. Sci. Agric. Sin. 2022, 55, 2398–2412. [Google Scholar]

- He, J.; Cheng, X.T.; Gao, Y.; Zhang, X.N.; Jia, X.H. Comparison of quality and storability among bagged and non-bagged fruits of three apple varieties. China Fruits 2022, 6, 6–9. [Google Scholar]

- Song, Y.L.; Wang, H.; Liu, L.; Gao, Q.; Gao, Y.J. Making fruit bag paper with direct black dye instead of carbon black. J. Tianjin Univ. Sci. Technol. 2020, 35, 35–39. [Google Scholar]

- Chen, Y.G.; Wang, Y.; Song, J.; Tang, Z.H. Study on the physical characters of the bagging bags for apple growing and their application. J. Fruit Sci. 2000, 17, 249–254. [Google Scholar]

- Zhang, M.Y. A survey of the properties of fruit-bagged paper. J. Northwest Inst. Light Ind. 1999, 2, 66–69. [Google Scholar]

- Zhang, M.Y.; Luo, Y.; Lin, T. Development and application of coatings in the production of coated fruit bag paper. Pap. Pap. Mak. 2012, 31, 19–22. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB 19341-2003: Fruit Cultivating Bag Paper; China Standards Press: Beijing, China, 2003. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB 19341-2015: Fruit Cultivating Bag Paper; China Standards Press: Beijing, China, 2015. [Google Scholar]

- Liu, X.M.; Xu, L.J.; Chen, T.; Wang, J.C.; Zhu, S.F.; Lei, L. Effects of types of covering pouch on quality of Jumeigui grapes. Fujian J. Agric. Sci. 2017, 32, 1228–1233. [Google Scholar]

- Meng, F.X.; Duan, Y.J.; Fang, H.D.; Yang, Y.J.; Lv, Z.Y.; Guo, S.P.; Liu, H.G. Effects of different fruit bags and bagging methods on fruit quality of ‘Renong 1′ mango. Acta Agric. Jiangxi 2020, 32, 30–34. [Google Scholar]

- Xia, H.M.; Zhen, W.B.; Chen, D.Y.; Zeng, W. An ordinary multilayer fruit paper bag supplying device for fruit bagging. HortScience 2019, 54, 1644–1649. [Google Scholar] [CrossRef]

- Song, Y.L. Study on Recycling Technology of Waste Fruit Bag Paper; Tianjin University of Science & Technology: Tianjin, China, 2019. [Google Scholar]

- Liu, L. Study on New Wet Strength Dissociating Agent and Its Mechanism of Action; Tianjin University of Science and Technology: Tianjin, China, 2020. [Google Scholar]

- Wang, Y.X.; Zhang, Y.H.; Pu, Y.; Zhang, J.T.; Wang, F.C. Design of a new fruit tree bagging machine. IOP Conf. Ser. Mater. Sci. Eng. 2018, 452, 042099. [Google Scholar] [CrossRef]

- Xia, H.M.; Zhen, W.B.; Chen, D.Y.; Zeng, W. Rigid-flexible coupling contact action simulation study of the open mechanism on the ordinary multilayer fruit paper bag for fruit bagging. Comput. Electron. Agric. 2020, 173, 105414. [Google Scholar] [CrossRef]

- Sun, Y.X.; Song, L.Q.; Zhao, L.L.; Zhang, X.Y.; Liu, D.L.; Zhao, J.; Liu, X.Q.; Tang, Y. Breeding of a new early-ripening, yellow and bagging-free apple cultivar Yanxiangyu. J. Fruit Sci. 2022, 39, 499–501. [Google Scholar]

| Type | Standard Number | Standard Name | Year |

|---|---|---|---|

| Agricultural industry standard | NY/T 1505-2007 | Rules of bagging for fruit producing-Apple | 2008 |

| NY/T 1998-2011 | Rules of bagging for fruit producing-Table grape | 2011 | |

| NY/T 2314-2013 | Rules of bagging for fruit producing-Lemon | 2013 | |

| Local standard | DB32/T 930-2006 | Rules of cultivated technology of bagged grapes in whole orchard | 2007 |

| DB32/T 1101-2007 | Rules of cultivated technology of bagged pears in whole orchard | 2007 | |

| DB32/T 1102-2007 | Rules of cultivated technology of bagged apples in whole orchard | 2007 | |

| DB32/T 1335-2009 | Rules of cultivated technology of bagged juicy peach in whole orchard | 2009 | |

| DB32/T 1412-2009 | Rules of bagging technique for ‘Cuiguan’ pear | 2009 | |

| DB45/T 722-2011 | Technical standard for mango fruit bagging | 2011 | |

| DB42/T 930-2013 | Regulations of bagging technology for sand pear (Pyrus pyrifolia Nakai) | 2013 | |

| DB41/T 1775-2019 | Technical standard for peach fruit bagging | 2019 | |

| DB/T 360-2021 | Technical standard for grape fruit bagging | 2021 | |

| Group standard | T/SDAS 150-2020 | Technical standard for apple fruit bagging | 2020 |

| T/SDAS 77-2019 | Technical standard for pear fruit bagging | 2019 | |

| Enterprise standard | Q/AHTZ.N 04-2022 | Technical specifications for pomegranate fruit bagging | 2022 |

| Q/YD 10005-2021 | Rules for intensive cultivation of Yue Duo apple dwarf rootstock | 2021 |

| Type | Characteristic | Application Object |

|---|---|---|

| plastic film bags | Advantage: (1) There is a wire on the top for sealing and a plurality of small holes on the bottom for ventilation. (2) Cheap, tiny and easy to use. (3) There is no need to remove bags when harvesting fruits, and they can be transported and sold with bags. Shortcoming: (1) Although there are air holes at the bottom, the moisture permeability and air permeability are still poor. (2) The fruit has a poor coloring effect and is prone to sunburn. | apple |

| single-layer paper bags | Advantage: (1) The paper bag material is effectively waterproof. Water does not penetrate inward but forms water droplets on the surface of the bag and then rolls down. (2) There is a vent at the bottom corner, which can ensure the air permeability of the fruit. (3) The paper bag is provided with wire, which can be used for sealing. Shortcoming: The fruit coloring effect was slightly poor. | grape, loquat, peach, pear and citrus |

| double-layer paper bags | Advantage: The advantages are the same as single-layer fruit bags. At the same time, because of the use of double-layer paper, the fruit coloring effect is better. Shortcoming: (1) The price of double-layer paper bags is higher. (2) Sometimes, in order to improve the fruit coloring effect, the outer bag and the inner bag need to be removed twice, which is labor-intensive and costly. | apple, pear, peach, mango |

| paper-film composite bags | Advantage: (1) There is a wire on the top for sealing. (2) The inner membrane surface is uniformly distributed with pores to ensure air permeability and moisture permeability. Shortcoming: The fruit coloring effect was slightly poor. | apple, pear and loquat |

| nylon bags | Advantage: (1) The effect of insect and bird prevention is good. (2) Good ventilation and light transmission. Shortcoming: Poor water resistance, not suitable for fruits requiring coloring. | dragon fruit, grape, mango |

| non-woven bags | Advantage: (1) It has good ventilation and waterproof effect. (2) The materials used are degradable and pollution-free and can be reused. Shortcoming: Poor water resistance and high price. | grape, litchi |

| Indicator | Unit | Parameter Specification | ||||||

|---|---|---|---|---|---|---|---|---|

| Excellent | First-Class | Qualified | ||||||

| Inner | Outer | Inner | Outer | Inner | Outer | |||

| Weight | g/m2 | Inner bag paper: 26.0 28.0 30.0 32.0 Outer bag paper: 36.0 40.0 45.0 50.0 56.0 | ||||||

| Weight deviation ≤ | % | 4.0 | 5.0 | 5.0 | ||||

| Deviation of profile basis weight ≤ | g/m2 | 1.0 | 1.5 | 1.5 | ||||

| Tensile index (longitudinal) ≥ | N·m/g | 65.0 | 60.0 | 60.0 | 55.0 | 50.0 | 50.0 | |

| Wet tensile index(longitudinal) ≥ | N·m/g | 20.0 | 24.0 | 15.0 | 22.0 | 10.0 | 18.0 | |

| Tearing index ≥ | Longitudinal | mN·m2/g | 3.60 | 4.60 | 3.20 | 4.00 | 2.80 | 3.50 |

| Transverse | mN·m2/g | 5.20 | 6.20 | 4.60 | 5.50 | 4.00 | 5.00 | |

| Air permeability ≥ | μm/(Pa·s) | 3.0 | 2.0 | 1.0 | ||||

| Water absorption (front) ≤ | g/m2 | 20.0 | 10.0 | 23.0 | 13.0 | 25.0 | 15.0 | |

| Decolorization test a (water) | — | Negative | — | Negative | — | Negative | — | |

| Heavy metal a ≤ | Pb | mg/kg | 5.0 | — | 5.0 | — | 5.0 | — |

| As | mg/kg | 1.0 | — | 1.0 | — | 1.0 | — | |

| Moisture content | % | 7.0 ± 2.0 | ||||||

| Type | Standard Number | Standard Name | Year |

|---|---|---|---|

| Agricultural industry standard | NY/T 1555-2007 | Fruit cultivating paper bag for apple | 2008 |

| Local standard | DB61/T 292-2001 | Fruit cultivating paper bag for apple | 2001 |

| Group standard | T/MYXGY 001-2018 | Fruit cultivating paper bag for apple and peach | 2018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Gu, F.; Wu, F.; Wang, B.; Shi, L.; Hu, Z. Production, Use and Recycling of Fruit Cultivating Bags in China. Sustainability 2022, 14, 14144. https://doi.org/10.3390/su142114144

Yang H, Gu F, Wu F, Wang B, Shi L, Hu Z. Production, Use and Recycling of Fruit Cultivating Bags in China. Sustainability. 2022; 14(21):14144. https://doi.org/10.3390/su142114144

Chicago/Turabian StyleYang, Hongguang, Fengwei Gu, Feng Wu, Bokai Wang, Lili Shi, and Zhichao Hu. 2022. "Production, Use and Recycling of Fruit Cultivating Bags in China" Sustainability 14, no. 21: 14144. https://doi.org/10.3390/su142114144

APA StyleYang, H., Gu, F., Wu, F., Wang, B., Shi, L., & Hu, Z. (2022). Production, Use and Recycling of Fruit Cultivating Bags in China. Sustainability, 14(21), 14144. https://doi.org/10.3390/su142114144