Modeling Impacts of COVID-19 in Supply Chain Activities: A Grey-DEMATEL Approach

Abstract

1. Introduction

- What are the various impacts of COVID-19 on supply chain activities?

- How can the causal interrelationships among the various COVID-19 impacts be revealed?

- Do the outcomes provide better insights for industrial practitioners to formulate strategies in overcoming the COVID-19 impacts?

2. Literature Review

2.1. Supply Chain Management

2.2. COVID-19 Impacts on Supply Chain Activities

2.3. Research Gaps

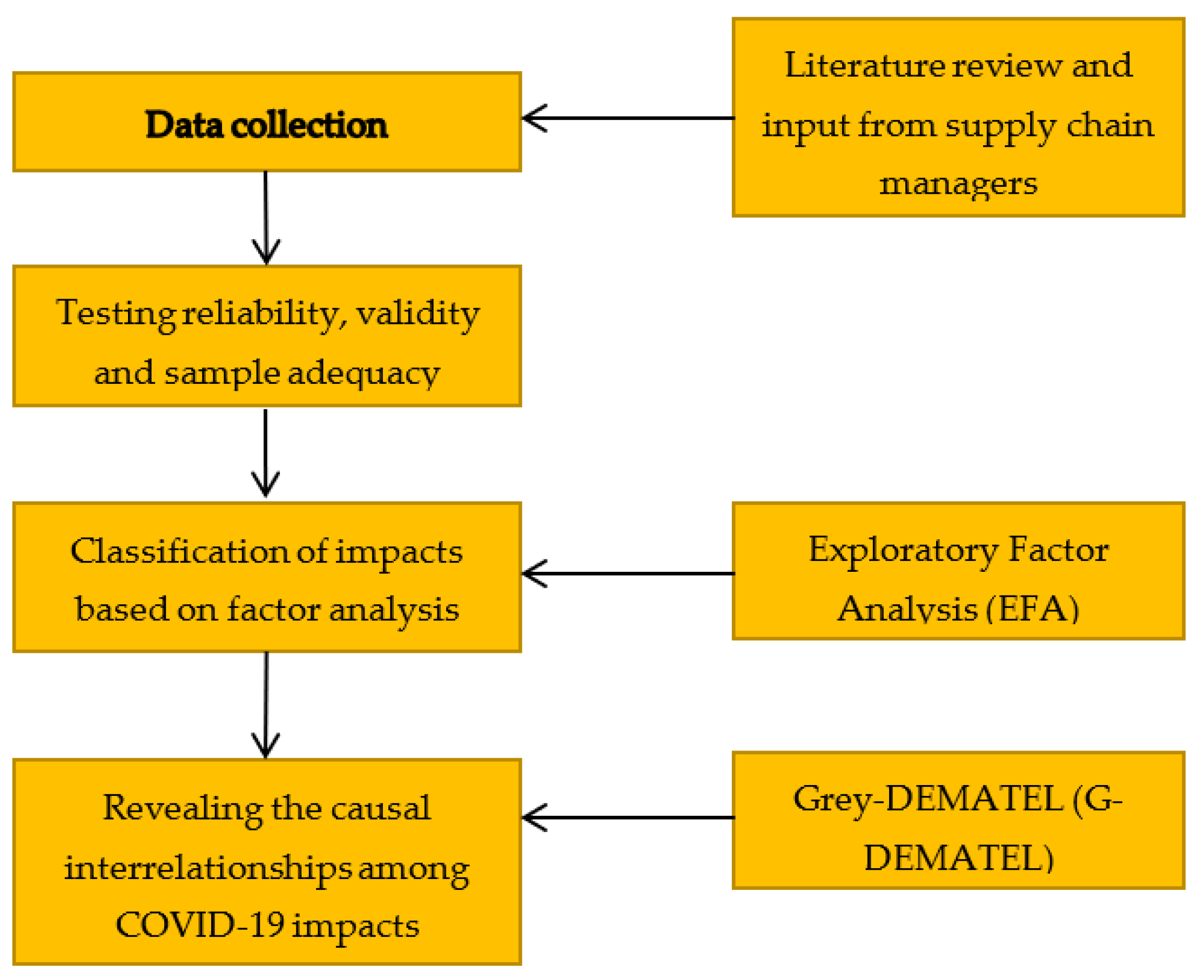

3. Research Methodology

3.1. Data Collection

- First, a literature review was carried out to collect research articles for this study. Articles were identified in scientific databases such as SCOPUS, Web of Science, Google Scholar, EBSCO, and ScienceDirect. Several keywords such as ‘COVID-19 AND developing countries’, ‘Impact of COVID-19 in supply chains’, ‘COVID-19 AND sustainability’, ‘COVID-19 AND SDGs’, and ‘COVID-19 AND global trade’ were used for the collection of the articles. In the initial stage, 100+ articles were taken from a variety of journals. Next, a screening process was introduced to find the most relevant papers. The articles included in the literature review were selected based on the following inclusion criteria: (i) articles published in English only considered, (ii) must be peer-reviewed, and (iii) articles focusing on the COVID-19 impacts on supply chains were considered. The exclusion criteria included conference proceedings, short communications, and duplicative works. After the final screening, only 33 articles were found to match the criteria to conceptualize this study’s supply chain disruption risk constructs and variables. Therefore, these articles were acknowledged in this study.

- However, to identify the impacts in a real-life scenario, in-depth interviews with supply chain managers were conducted from November 2020 to May 2021. Fifty-five supply chain managers engaged in global trade were approached for the interviews via email and, out of 55, only 32 were interviewed. The interview started with a basic introduction of COVID-19 and how it has affected industrial activities. Finally, the interview focused on identifying the COVID-19 impacts on supply chain activities. From these interviews, few impacts were identified.

- Finally, a workshop was conducted with the 32 supply chain managers (6—import/export specialist, 8—demand planning manager, 8—transportation planner, 6—distribution manager, and 4—business analyst). These 32 managers were from the automobile sector, leather sector, agricultural sector, handicraft sector, and textile sector. Managers from these sectors were chosen as these sectors were considered to be a lifeline source of income for semiskilled and economically marginalized people. Similar to other sectors, during COVID-19, these sectors were forced to shut down their activities. Such a shut down hardly impacted the socioeconomic conditions of the people who relied on these sectors. The profiles of the managers and their respective companies are given in Table 1 and Table 2. The companies considered in this study are located in Chennai and companies from this region were selected as this region significantly contributes to the gross domestic product (GDP) of India and has been a job provider for semiskilled people. Here, a list of 25 COVID-19 impacts on the supply chain was identified from the literature review and interviews were carried out with the managers. They were asked to mark the impacts that appeared to be significant from their view and the neglect impacts that they felt were insignificant. By consolidating the responses of the 32 managers, 20 common impacts were selected. The finalized COVID-19 impacts considered for this study are given in Table 3.

3.2. Testing Reliability, Validity, and Sampling Adequacy

3.3. Exploratory Factor Analysis (EFA)

3.4. Grey-DEMATEL

4. Results and Discussions

Comparison with Other Studies

5. Implications of the Study

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| S. No | COVID-19 Impacts | Likert’s Scale (5—Completely Agree, 4—Agree, 3—Neutral, 2—Disagree, 1—Completely Disagree) |

|---|---|---|

| 1 | Technical workforce shortage (OM1) | |

| 2 | Stalled industrial activity (OM2) | |

| 3 | Difficulty in demand forecasting (OM3) | |

| 4 | Reduced production capacity (OM4) | |

| 5 | Disproportionateness between supply and demand (OM5) | |

| 6 | Obsolescence of machines (SM1) | |

| 7 | Production disruption and backlog (SM2) | |

| 8 | Disruption in supply (SM3) | |

| 9 | Pilling up of inventory (SM4) | |

| 10 | Increased transportation cost (DM1) | |

| 11 | Lack of supplier engagement (DM2) | |

| 12 | Increased lead time to delivery (PM1) | |

| 13 | Lack of international trade (PM2) | |

| 14 | Supply chain collapse (RM1) | |

| 15 | Lack of physical distribution channel (RM2) | |

| 16 | Ripple effect on supply chain operations (RM3) | |

| 17 | Mass layoffs (IM1) | |

| 18 | Lockdown restriction (IM2) | |

| 19 | Distress on Return of investment (LM1) | |

| 20 | Reduced cash inflow (LM2) |

Appendix B

| Area of Impacts | OM | SM | DM | PM | RM | IM | LM |

|---|---|---|---|---|---|---|---|

| OM | 0 | ||||||

| SM | 0 | ||||||

| DM | 0 | ||||||

| PM | 0 | ||||||

| RM | 0 | ||||||

| IM | 0 | ||||||

| LM | 0 |

Appendix C

| COVID-19 Impacts | OM1 | OM2 | OM3 | OM4 | OM5 | SM1 | SM2 | SM3 | SM4 | DM1 | DM2 | PM1 | PM2 | RM1 | RM2 | RM3 | IM1 | IM2 | LM1 | LM2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OM1 | 0 | |||||||||||||||||||

| OM2 | 0 | |||||||||||||||||||

| OM3 | 0 | |||||||||||||||||||

| OM4 | 0 | |||||||||||||||||||

| OM5 | 0 | |||||||||||||||||||

| SM1 | 0 | |||||||||||||||||||

| SM2 | 0 | |||||||||||||||||||

| SM3 | 0 | |||||||||||||||||||

| SM4 | 0 | |||||||||||||||||||

| DM1 | 0 | |||||||||||||||||||

| DM2 | 0 | |||||||||||||||||||

| PM1 | 0 | |||||||||||||||||||

| PM2 | 0 | |||||||||||||||||||

| RM1 | 0 | |||||||||||||||||||

| RM2 | 0 | |||||||||||||||||||

| RM3 | 0 | |||||||||||||||||||

| IM1 | 0 | |||||||||||||||||||

| IM2 | 0 | |||||||||||||||||||

| LM1 | 0 | |||||||||||||||||||

| LM2 | 0 |

References

- Banik, A.; Nag, T.; Chowdhury, S.R.; Chatterjee, R. Why Do COVID-19 Fatality Rates Differ Across Countries? An Explorative Cross-country Study Based on Select Indicators. Glob. Bus. Rev. 2020, 21, 607–625. [Google Scholar] [CrossRef]

- Kandel, N.; Chungong, S.; Omaar, A.; Xing, J. Health security capacities in the context of COVID-19 outbreak: An analysis of International Health Regulations annual report data from 182 countries. Lancet 2020, 395, 1047–1053. [Google Scholar] [CrossRef]

- Chowdhury, P.; Paul, S.K.; Kaisar, S.; Moktadir, M.A. COVID-19 pandemic related supply chain studies: A systematic review. Transp. Res. Part E Logist. Transp. Rev. 2021, 148, 102271. [Google Scholar] [CrossRef] [PubMed]

- Koshta, N.; Devi, Y.; Patra, S. Aerial Bots in the Supply Chain: A New Ally to Combat COVID-19. Technol. Soc. 2021, 66, 101646. [Google Scholar] [CrossRef] [PubMed]

- Rizou, M.; Galanakis, I.M.; Aldawoud, T.M.S.; Galanakis, C.M. Safety of foods, food supply chain and environment within the COVID-19 pandemic. Trends Food Sci. Technol. 2020, 102, 293–299. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Zhong, R.Y. A supply chain disruption recovery strategy considering product change under COVID-19. J. Manuf. Syst. 2021, 60, 920–927. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.; Jabbour, C.J.C.; Gunasekaran, A.; Ndubisi, N.O.; Venkatesh, M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technol. Forecast. Soc. Chang. 2021, 163, 120447. [Google Scholar] [CrossRef]

- Anser, M.K.; Khan, M.A.; Nassani, A.A.; Abro, M.M.Q.; Zaman, K.; Kabbani, A. Does COVID-19 pandemic disrupt sustainable supply chain process? Covering some new global facts. Environ. Sci. Pollut. Res. 2021, 28, 59792–59804. [Google Scholar] [CrossRef]

- Hoekman, B.; Mavroidis, P.C. WTO Reform: Back to the Past to Build for the Future. Glob. Policy 2021, 12, 5–12. [Google Scholar] [CrossRef]

- Remko, V.H. Research opportunities for a more resilient post-COVID-19 supply chain—Closing the gap between research findings and industry practice. Int. J. Oper. Prod. Manag. 2020, 40, 341–355. [Google Scholar] [CrossRef]

- Xu, Z.; Elomri, A.; Kerbache, L.; El Omri, A. Impacts of COVID-19 on Global Supply Chains: Facts and Perspectives. IEEE Eng. Manag. Rev. 2020, 48, 153–166. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, R.; Panchal, R.; Tiwari, M.K. Impact of COVID-19 on logistics systems and disruptions in food supply chain. Int. J. Prod. Res. 2021, 59, 1993–2008. [Google Scholar] [CrossRef]

- Wen, W.; Yang, S.; Zhou, P.; Gao, S.Z. Impacts of COVID-19 on the electric vehicle industry: Evidence from China. Renew. Sustain. Energy Rev. 2021, 144, 111024. [Google Scholar] [CrossRef]

- Barbier, E.B.; Burgess, J.C. Sustainability and development after COVID-19. World Dev. 2020, 135, 105082. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef] [PubMed]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2020, 41, 63–73. [Google Scholar] [CrossRef]

- Pereira, M.M.O.; Silva, M.E.; Hendry, L.C. Supply chain sustainability learning: The COVID-19 impact on emerging economy suppliers. Supply Chain Manag. Int. J. 2021, 26, 715–736. [Google Scholar] [CrossRef]

- Ranjbari, M.; Shams Esfandabadi, Z.; Zanetti, M.C.; Scagnelli, S.D.; Siebers, P.-O.; Aghbashlo, M.; Peng, W.; Quatraro, F.; Tabatabaei, M. Three pillars of sustainability in the wake of COVID-19: A systematic review and future research agenda for sustainable development. J. Clean. Prod. 2021, 297, 126660. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Prod. Plan. Control 2021, 1–18. [Google Scholar] [CrossRef]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Gurtu, A.; Johny, J. Supply Chain Risk Management: Literature Review. Risks 2021, 9, 16. [Google Scholar] [CrossRef]

- Sharma, V.; Raut, R.D.; Mangla, S.K.; Narkhede, B.E.; Luthra, S.; Gokhale, R. A systematic literature review to integrate lean, agile, resilient, green and sustainable paradigms in the supply chain management. Bus. Strateg. Environ. 2021, 30, 1191–1212. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M. A decision-aid model for evaluating challenges to blockchain adoption in supply chains. Int. J. Logist. Res. Appl. 2021, 1–22. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Wittstruck, D.; Teuteberg, F. Understanding the Success Factors of Sustainable Supply Chain Management: Empirical Evidence from the Electrics and Electronics Industry. Corp. Soc. Responsib. Environ. Manag. 2012, 19, 141–158. [Google Scholar] [CrossRef]

- Sánchez-Flores, R.B.; Cruz-Sotelo, S.E.; Ojeda-Benitez, S.; Ramírez-Barreto, M.E. Sustainable Supply Chain Management—A Literature Review on Emerging Economies. Sustainability 2020, 12, 6972. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Lepri, M.; Trianni, A. A triple bottom line balanced set of key performance indicators to measure the sustainability performance of industrial supply chains. Sustain. Prod. Consum. 2021, 26, 648–691. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Paul, J.; Sinha, O. Analyzing challenges for sustainable supply chain of electric vehicle batteries using a hybrid approach of Delphi and Best-Worst Method. Resour. Conserv. Recycl. 2021, 175, 105879. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. Core issues in sustainable supply chain management—A Delphi study. Bus. Strateg. Environ. 2008, 17, 455–466. [Google Scholar] [CrossRef]

- Stindt, D. A generic planning approach for sustainable supply chain management—How to integrate concepts and methods to address the issues of sustainability? J. Clean. Prod. 2017, 153, 146–163. [Google Scholar] [CrossRef]

- Al-Mansour, J.F.; Al-Ajmi, S.A. Coronavirus ‘COVID-19’—Supply Chain Disruption and Implications for Strategy, Economy, and Management. J. Asian Financ. Econ. Bus. 2020, 7, 659–672. [Google Scholar] [CrossRef]

- Raj, A.; Mukherjee, A.A.; de Sousa Jabbour, A.B.L.; Srivastava, S.K. Supply chain management during and post-COVID-19 pandemic: Mitigation strategies and practical lessons learned. J. Bus. Res. 2022, 142, 1125–1139. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, D.; Dolgui, A. OR-methods for coping with the ripple effect in supply chains during COVID-19 pandemic: Managerial insights and research implications. Int. J. Prod. Econ. 2021, 232, 107921. [Google Scholar] [CrossRef]

- Guan, D.; Wang, D.; Hallegatte, S.; Davis, S.J.; Huo, J.; Li, S.; Bai, Y.; Lei, T.; Xue, Q.; Coffman, D.; et al. Global supply-chain effects of COVID-19 control measures. Nat. Hum. Behav. 2020, 4, 577–587. [Google Scholar] [CrossRef] [PubMed]

- Heubl, B. News—Analysis. Pandemic: How coronavirus wreaks havoc in the global tech sector. Eng. Technol. 2020, 15, 12–14. [Google Scholar] [CrossRef]

- Şahin, A.; Tasci, M.; Yan, J. The Unemployment Cost of COVID-19: How High and How Long? Econ. Comment. (Federal Reserv. Bank Cleveland) 2020, 1–7. [Google Scholar] [CrossRef]

- International Labour Organization (ILO). COVID-19 and the World of Work; International Labour Organization: Geneva, Switzerland, 2020; pp. 1–22. [Google Scholar]

- Nicita, A.; Oganivtsev, V.; Shirotori, M. Global Supply Chains: Trade and Economic Policies for Developing Countries; United Nations Conference on Trade and Development: Geneva, Switzerland, 2013; pp. 9–34. [Google Scholar]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T. Skills needed in supply chain-human agency and social capital analysis in third party logistics. Manag. Decis. 2018, 56, 143–159. [Google Scholar] [CrossRef]

- Narasimha, P.T.; Jena, P.R.; Majhi, R. Impact of COVID-19 on the Indian seaport transportation and maritime supply chain. Transp. Policy 2021, 110, 191–203. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P.; Moktadir, M.A.; Lau, K.H. Supply chain recovery challenges in the wake of COVID-19 pandemic. J. Bus. Res. 2021, 136, 316–329. [Google Scholar] [CrossRef]

- Din, A.U.; Han, H.; Ariza-Montes, A.; Vega-Muñoz, A.; Raposo, A.; Mohapatra, S. The Impact of COVID-19 on the Food Supply Chain and the Role of E-Commerce for Food Purchasing. Sustainability 2022, 14, 3074. [Google Scholar] [CrossRef]

- Seuring, S.; Brandenburg, M.; Sauer, P.C.; Schünemann, D.-S.; Warasthe, R.; Aman, S.; Qian, C.; Petljak, K.; Neutzling, D.M.; Land, A.; et al. Comparing regions globally: Impacts of COVID-19 on supply chains—A Delphi study. Int. J. Oper. Prod. Manag. 2022, 42, 1077–1108. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M.; Paul, S.K. Key Challenges to Sustainable Humanitarian Supply Chains: Lessons from the COVID-19 Pandemic. Sustainability 2021, 13, 5850. [Google Scholar] [CrossRef]

- Miller, F.A.; Young, S.B.; Dobrow, M.; Shojania, K.G. Vulnerability of the medical product supply chain: The wake-up call of COVID-19. BMJ Qual. Saf. 2021, 30, 331–335. [Google Scholar] [CrossRef] [PubMed]

- The Lancet Public Health Will the COVID-19 pandemic threaten the SDGs? Lancet Public Health 2020, 5, e460. [CrossRef]

- Wang, Q.; Huang, R. The impact of COVID-19 pandemic on sustainable development goals—A survey. Environ. Res. 2021, 202, 111637. [Google Scholar] [CrossRef] [PubMed]

- Ameli, M.; Shams Esfandabadi, Z.; Sadeghi, S.; Ranjbari, M.; Zanetti, M.C. COVID-19 and Sustainable Development Goals (SDGs): Scenario analysis through fuzzy cognitive map modeling. Gondwana Res. 2022, in press. [Google Scholar] [CrossRef]

- Qalati, S.A.; Ostic, D.; Fan, M.; Dakhan, S.A.; Vela, E.G.; Zufar, Z.; Sohu, J.M.; Mei, J.; Thuy, T.T.H. The General Public Knowledge, Attitude, and Practices Regarding COVID-19 During the Lockdown in Asian Developing Countries. Int. Q. Community Health Educ. 2021, 0272684X2110049. [Google Scholar] [CrossRef]

- Mahajan, K.; Tomar, S. COVID-19 and Supply Chain Disruption: Evidence from Food Markets in India. Am. J. Agric. Econ. 2021, 103, 35–52. [Google Scholar] [CrossRef]

- Barman, A.; Das, R.; De, P.K. Impact of COVID-19 in food supply chain: Disruptions and recovery strategy. Curr. Res. Behav. Sci. 2021, 2, 100017. [Google Scholar] [CrossRef]

- Chowdhury, M.T.; Sarkar, A.; Paul, S.K.; Moktadir, M.A. A case study on strategies to deal with the impacts of COVID-19 pandemic in the food and beverage industry. Oper. Manag. Res. 2020, 15, 166–178. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef]

- Zhu, G.; Chou, M.C.; Tsai, C.W. Lessons Learned from the COVID-19 Pandemic Exposing the Shortcomings of Current Supply Chain Operations: A Long-Term Prescriptive Offering. Sustainability 2020, 12, 5858. [Google Scholar] [CrossRef]

- Taqi, H.M.M.; Ahmed, H.N.; Paul, S.; Garshasbi, M.; Ali, S.M.; Kabir, G.; Paul, S.K. Strategies to Manage the Impacts of the COVID-19 Pandemic in the Supply Chain: Implications for Improving Economic and Social Sustainability. Sustainability 2020, 12, 9483. [Google Scholar] [CrossRef]

- Hald, K.S.; Coslugeanu, P. The preliminary supply chain lessons of the COVID-19 disruption—What is the role of digital technologies? Oper. Manag. Res. 2021, 15, 282–297. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Foropon, C.; Tiwari, M.; Dwivedi, Y.; Schiffling, S. An investigation of information alignment and collaboration as complements to supply chain agility in humanitarian supply chain. Int. J. Prod. Res. 2021, 59, 1586–1605. [Google Scholar] [CrossRef]

- Rai, S.S.; Rai, S.; Singh, N.K. Organizational resilience and social-economic sustainability: COVID-19 perspective. Environ. Dev. Sustain. 2021, 23, 12006–12023. [Google Scholar] [CrossRef]

- Frohlich, M.T. Techniques for improving response rates in OM survey research. J. Oper. Manag. 2002, 20, 53–62. [Google Scholar] [CrossRef]

- Kirkire, M.S.; Rane, S.B.; Abhyankar, G.J. Structural equation modelling—FTOPSIS approach for modelling barriers to product development in medical device manufacturing industries. J. Model. Manag. 2020, 15, 967–993. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Srivastava, R.K. Analysis of external barriers to remanufacturing using grey-DEMATEL approach: An Indian perspective. Resour. Conserv. Recycl. 2018, 136, 79–87. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K.; Shankar, R.; Prakash Garg, C.; Jakhar, S. Modelling critical success factors for sustainability initiatives in supply chains in Indian context using Grey-DEMATEL. Prod. Plan. Control 2018, 29, 705–728. [Google Scholar] [CrossRef]

- Kumar, A.; Luthra, S.; Mangla, S.K.; Kazançoğlu, Y. COVID-19 impact on sustainable production and operations management. Sustain. Oper. Comput. 2020, 1, 1–7. [Google Scholar] [CrossRef]

- Pahl, S.; Brandi, C.; Schwab, J.; Stender, F. Cling together, swing together: The contagious effects of COVID-19 on developing countries through global value chains. World Econ. 2021, 45, 539–560. [Google Scholar] [CrossRef]

- Aljanabi, A.R.A. The impact of economic policy uncertainty, news framing and information overload on panic buying behavior in the time of COVID-19: A conceptual exploration. Int. J. Emerg. Mark. 2021. ahead of printing. [Google Scholar] [CrossRef]

- Van Barneveld, K.; Quinlan, M.; Kriesler, P.; Junor, A.; Baum, F.; Chowdhury, A.; Junankar, P.; Clibborn, S.; Flanagan, F.; Wright, C.F.; et al. The COVID-19 pandemic: Lessons on building more equal and sustainable societies. Econ. Labour Relations Rev. 2020, 31, 133–157. [Google Scholar] [CrossRef]

- Zimon, G.; Babenko, V.; Sadowska, B.; Chudy-Laskowska, K.; Gosik, B. Inventory Management in SMEs Operating in Polish Group Purchasing Organizations during the COVID-19 Pandemic. Risks 2021, 9, 63. [Google Scholar] [CrossRef]

- McMaster, M.; Nettleton, C.; Tom, C.; Xu, B.; Cao, C.; Qiao, P. Risk Management: Rethinking Fashion Supply Chain Management for Multinational Corporations in Light of the COVID-19 Outbreak. J. Risk Financ. Manag. 2020, 13, 173. [Google Scholar] [CrossRef]

- Zimmerling, A.; Chen, X. Innovation and possible long-term impact driven by COVID-19: Manufacturing, personal protective equipment and digital technologies. Technol. Soc. 2021, 65, 101541. [Google Scholar] [CrossRef]

- Piccinini, D.; Giunchi, C.; Olivieri, M.; Frattini, F.; Di Giovanni, M.; Prodi, G.; Chiarabba, C. COVID-19 lockdown and its latency in Northern Italy: Seismic evidence and socio-economic interpretation. Sci. Rep. 2020, 10, 16487. [Google Scholar] [CrossRef]

- Ozili, P.K. COVID-19 pandemic and economic crisis: The Nigerian experience and structural causes. J. Econ. Adm. Sci. 2020, 37, 401–418. [Google Scholar] [CrossRef]

- Hailu, G. Economic thoughts on COVID-19 for Canadian food processors. Can. J. Agric. Econ. Can. d’agroeconomie 2020, 68, 163–169. [Google Scholar] [CrossRef]

- Singh, G.; Aiyub, A.S.; Greig, T.; Naidu, S.; Sewak, A.; Sharma, S. Exploring panic buying behavior during the COVID-19 pandemic: A developing country perspective. Int. J. Emerg. Mark. 2021. ahead of printing. [Google Scholar] [CrossRef]

- Arya, B.; Horak, S.; Bacouel-Jentjens, S.; Ismail, K. Leading entrepreneurial sustainability initiatives in emerging economies. Int. J. Emerg. Mark. 2021. ahead of printing. [Google Scholar] [CrossRef]

- Dang, H.-A.H.; Viet Nguyen, C. Gender inequality during the COVID-19 pandemic: Income, expenditure, savings, and job loss. World Dev. 2021, 140, 105296. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, M.; Sodani, P.R.; Das, S. Effect of COVID-19 on Economy in India: Some Reflections for Policy and Programme. J. Health Manag. 2020, 22, 169–180. [Google Scholar] [CrossRef]

- Roy, S.; Dutta, R.; Ghosh, P. Identifying key indicators of job loss trends during COVID-19 and beyond. Soc. Sci. Humanit. Open 2021, 4, 100163. [Google Scholar] [CrossRef]

- Gualtieri, G.; Brilli, L.; Carotenuto, F.; Vagnoli, C.; Zaldei, A.; Gioli, B. Quantifying road traffic impact on air quality in urban areas: A Covid19-induced lockdown analysis in Italy. Environ. Pollut. 2020, 267, 115682. [Google Scholar] [CrossRef]

- Eregowda, T.; Chatterjee, P.; Pawar, D.S. Impact of lockdown associated with COVID19 on air quality and emissions from transportation sector: Case study in selected Indian metropolitan cities. Environ. Syst. Decis. 2021, 41, 401–412. [Google Scholar] [CrossRef]

- Park, C.-Y.; Villafuerte, J.; Abiad, A.; Narayanan, B.; Banzon, E.; Samson, J.; Aftab, A.; Tayag, M.C. An Updated Assessment of the Economic Impact of COVID-19; Asian Development Bank: Manila, Philippines, 2020; p. 133. [Google Scholar]

- Chatterjee, S.; Chaudhuri, R. Supply chain sustainability during turbulent environment: Examining the role of firm capabilities and government regulation. Oper. Manag. Res. 2021. [Google Scholar] [CrossRef]

| Characteristics | n | % | ||

|---|---|---|---|---|

| Managers (n = 32) | Job title | Import/export specialist | 6 | 18.75 |

| Demand planning manager | 8 | 25 | ||

| Transportation manager | 8 | 25 | ||

| Distribution manager | 6 | 18.75 | ||

| Business analyst | 4 | 12.5 | ||

| Experience | Up to 10 years | 8 | 25 | |

| 10–15 years | 6 | 18.75 | ||

| 16–20 years | 8 | 25 | ||

| 20–25 years | 10 | 31.25 | ||

| Educational qualification | Graduate | 14 | 43.75 | |

| Post-graduate | 10 | 31.25 | ||

| Doctorate | 8 | 25 | ||

| Features | Company 1 (Automobile Sector) | Company 2 (Agricultural Sector) | Company 3 (Leather Sector) | Company 4 (Handicraft Sector) | Company 5 (Textile Sector) |

|---|---|---|---|---|---|

| Year of establishment | 1998 | 2000 | 2001 | 2000 | 2003 |

| Workforce strength | >100 | 100–150 | 80–100 | 50–100 | 100–150 |

| Products | Gears, chain sprocket | Pulses, cereals, nuts | Belt, jacket, shoes | Decorative items | Shirts and pants |

| Annual turnover (in INR) | 100 crores | 60 crores | 50 crores | 30 crores | 60 crores |

| COVID-19 Impacts | Definition | References |

|---|---|---|

| Technical workforce shortage | Restricted movement of labor results in technical workforce shortages | [11,51,52] |

| Stalled industrial activity | Lack of workforce and demand halted industrial activity | Input from managers |

| Difficulty in demand forecasting | Being unsure about the buying capacity of people, it is difficult to predict the demands | [53] |

| Reduced production capacity | Insufficient demand in the market results in a reduction of production capacity | [3] |

| Disproportionateness between supply and demand | Supply and demand equation has been collapsed due to panic buying | [54] |

| Obsolescence of machines | Prolonged suspension of production made the machine obsolete | Input from managers |

| Production disruption and backlog | Industries were unable to complete the earlier committed assignments | [54] |

| Disruption in supply | Lockdown restriction prohibited the movement of supply | [54] |

| Pilling up of inventory | Absence of market demand increased the inventory | [54,55] |

| Increased transportation cost | Limited transportation option is directly proportional to increased transportation cost | [54,56] |

| Lack of supplier engagement | Citing uncertainty in the global market, most of the suppliers disengage from the supply chain network | [3,57] |

| Increased lead time to delivery | Collapsed supply chain network increase the delivery time | [53] |

| Lack of international trade | Segmented lockdown restricted global trade | [55] |

| Supply chain collapse | Individual lockdown by different countries collapsed the supply chain network | [11] |

| Lack of physical distribution channel | Disengagement of suppliers creates a void in the supply chain network | [58] |

| Ripple effect on supply chain operations | Suspension of supply chain activity in one end creates catastrophe at the other end | [3] |

| Mass layoffs | Absence of industrial activity leads to mass layoffs | [52,55,58] |

| Lockdown restriction | Imposed to control COVID-19 outbreak | [51] |

| Distress on Return of investment | Stalled industrial activity raised a question on the return of investment | [52] |

| Reduced cash inflow | Absence of supply and demand activity reduced cash inflow | [55] |

| COVID-19 Impacts | Mean | Standard Deviation | Corrected Item-Total Correlation | Squared Multiple Correlation | Cronbach’s Alpha If Item Deleted |

|---|---|---|---|---|---|

| Technical workforce shortage | 4.3833 | 0.92226 | 0.251 | 0.312 | 0.755 |

| Stalled industrial activity | 4.3500 | 0.87962 | 0.198 | 0.277 | 0.758 |

| Difficulty in demand forecasting | 4.0500 | 1.03211 | 0.125 | 0.307 | 0.763 |

| Reduced production capacity | 4.0667 | 1.17699 | 0.366 | 0.514 | 0.746 |

| Disproportionateness between supply and demand | 4.1500 | 1.17639 | 0.234 | 0.573 | 0.757 |

| Obsolescence of machines | 4.1833 | 1.01667 | 0.221 | 0.428 | 0.757 |

| Production disruption and backlog | 4.1500 | 1.07080 | 0.402 | 0.518 | 0.744 |

| Disruption in supply | 4.0167 | 1.15702 | 0.291 | 0.607 | 0.752 |

| Pilling up of inventory | 4.0833 | 1.09377 | 0.184 | 0.525 | 0.760 |

| Increased transportation cost | 4.1833 | 1.03321 | 0.313 | 0.462 | 0.750 |

| Lack of supplier engagement | 4.1000 | 1.05284 | 0.557 | 0.478 | 0.733 |

| Increased lead time to delivery | 4.1667 | 1.07619 | 0.304 | 0.319 | 0.751 |

| Lack of international trade | 4.3000 | 0.92608 | 0.410 | 0.518 | 0.745 |

| Supply chain collapse | 4.3000 | 0.84973 | 0.539 | 0.553 | 0.738 |

| Lack of physical distribution channel | 4.0000 | 1.14980 | 0.104 | 0.442 | 0.767 |

| Ripple effect on supply chain operations | 4.0833 | 1.12433 | 0.458 | 0.621 | 0.739 |

| Mass layoffs | 4.0667 | 1.08716 | 0.363 | 0.499 | 0.747 |

| Lockdown restriction | 4.0167 | 1.17158 | 0.339 | 0.402 | 0.749 |

| Distress on Return of investment | 4.1667 | 1.07619 | 0.260 | 0.393 | 0.754 |

| Reduced cash inflow | 3.9000 | 1.13047 | 0.569 | 0.565 | 0.730 |

| Area of Impacts | COVID-19 Impacts | Factor Loadings |

|---|---|---|

| Organization management (OM) Cronbach 0.655 | Distress on return of investment (OM1) | 0.695 |

| Mass layoffs (OM2) | 0.644 | |

| Difficulty in demand forecasting (OM3) | 0.594 | |

| Production disruption and backlog (OM4) | 0.505 | |

| Technical workforce shortage (OM5) | 0.422 | |

| Supply management (SM) Cronbach 0.782 | Supply chain collapse (SM1) | 0.755 |

| Disruption in supply (SM2) | 0.559 | |

| Reduced production capacity (SM3) | 0.550 | |

| Increased lead time to delivery (SM4) | 0.529 | |

| Disruption management (DM) Cronbach 0.846 | Ripple effect on supply chain operations (DM1) | 0.749 |

| Reduced cash inflow (DM2) | 0.670 | |

| Production management (PM) Cronbach 0.765 | Stalled industrial activity (PM1) | 0.774 |

| Lack of international trade (PM2) | 0.636 | |

| Relationship management (RM) Cronbach 0.627 | Obsolescence of machines (RM1) | 0.740 |

| Lack of physical distribution channel (RM2) | 0.563 | |

| Disproportionateness between supply and demand (RM3) | 0.532 | |

| Inventory management (IM) Cronbach 0.796 | Lockdown restriction (IM1) | 0.467 |

| Pilling up of inventory (IM2) | 0.867 | |

| Logistics management (LM) Cronbach 0.823 | Lack of supplier engagement (LM1) | 0.735 |

| Increased transportation cost (LM2) | 0.508 |

| Linguistics Terms | Score | Grey Numbers |

|---|---|---|

| Very high influence (VH) | 4 | (0.75, 1.00) |

| High influence (H) | 3 | (0.50, 0.75) |

| Low influence (L) | 2 | (0.25, 0.50) |

| Very low influence (VL) | 1 | (0.00, 0.25) |

| No influence (N) | 0 | (0, 0) |

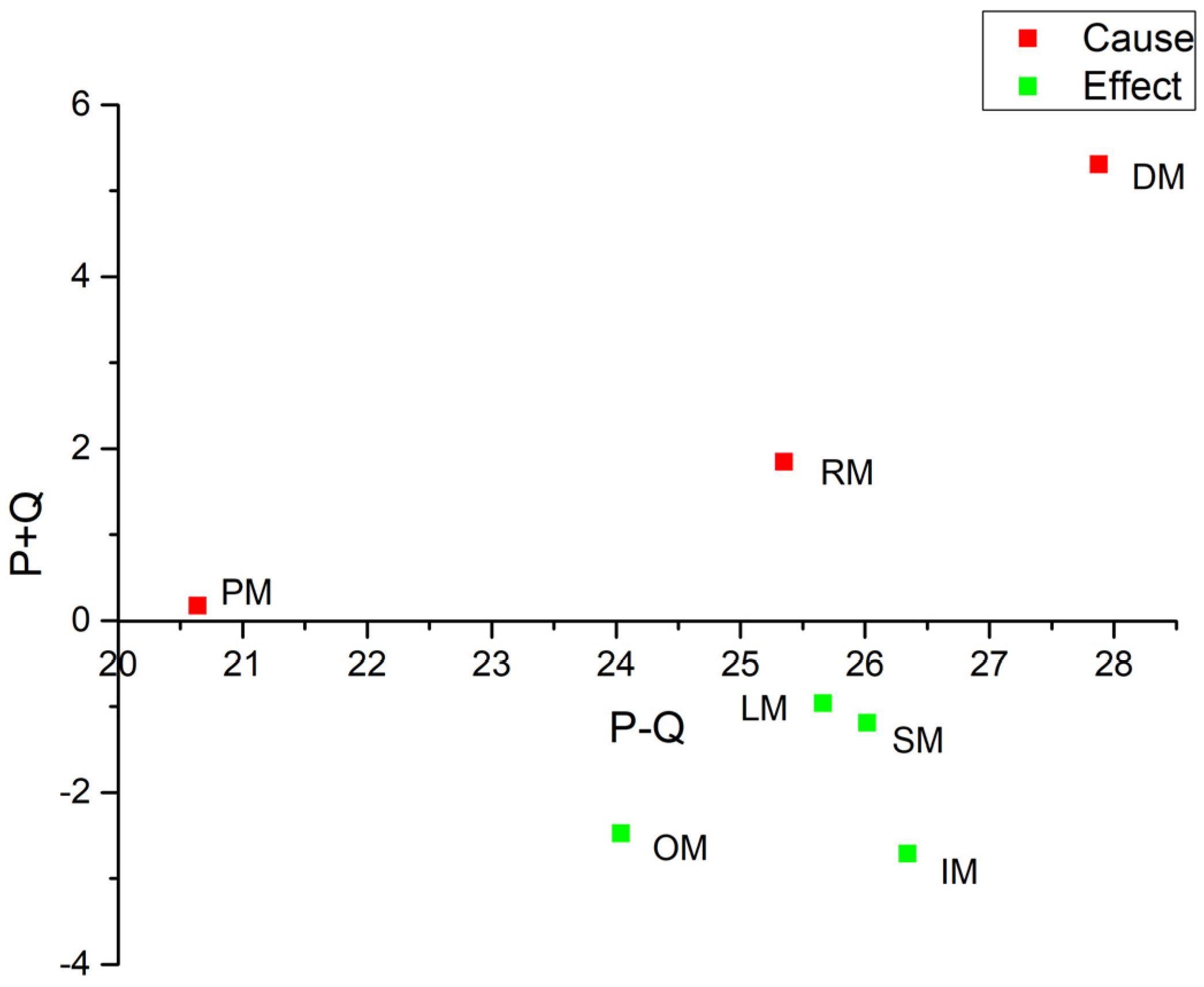

| Area of Impacts | Cause/Effect | Weight | ||||

|---|---|---|---|---|---|---|

| OM | 10.78 | 13.26 | 24.04 | −2.47 | Effect | 0.1367 |

| SM | 12.41 | 13.60 | 26.02 | −1.19 | Effect | 0.1473 |

| DM | 16.59 | 11.28 | 27.88 | 5.31 | Cause | 0.1605 |

| PM | 10.41 | 10.23 | 20.64 | 0.18 | Cause | 0.1167 |

| RM | 13.60 | 11.75 | 25.35 | 1.85 | Cause | 0.1438 |

| IM | 11.82 | 14.53 | 26.34 | −2.71 | Effect | 0.1498 |

| LM | 12.35 | 13.31 | 25.66 | −0.96 | Effect | 0.1452 |

| COVID-19 Impacts | Cause/Effect | Weight | ||||

|---|---|---|---|---|---|---|

| OM1 | 8.41 | 9.86 | 18.27 | −1.45 | Effect | 0.0460 |

| OM2 | 9.36 | 8.78 | 18.14 | 0.58 | Cause | 0.0455 |

| OM3 | 7.05 | 13.15 | 20.20 | −6.09 | Effect | 0.0529 |

| OM4 | 9.22 | 10.82 | 20.04 | −1.60 | Effect | 0.0504 |

| OM5 | 11.53 | 8.05 | 19.58 | 3.47 | Cause | 0.0499 |

| SM1 | 10.18 | 7.72 | 17.89 | 2.46 | Cause | 0.0453 |

| SM2 | 13.29 | 8.80 | 22.09 | 4.50 | Cause | 0.0565 |

| SM3 | 8.87 | 9.92 | 18.78 | −1.05 | Effect | 0.0472 |

| SM4 | 8.65 | 9.33 | 17.98 | −0.68 | Effect | 0.0451 |

| DM1 | 14.19 | 9.84 | 24.03 | 4.35 | Cause | 0.0613 |

| DM2 | 5.30 | 12.25 | 17.55 | −6.95 | Effect | 0.0473 |

| PM1 | 9.28 | 9.22 | 18.50 | 0.06 | Cause | 0.0464 |

| PM2 | 10.13 | 9.71 | 19.84 | 0.43 | Cause | 0.0498 |

| RM1 | 10.78 | 7.26 | 18.04 | 3.51 | Cause | 0.0461 |

| RM2 | 11.32 | 9.73 | 21.04 | 1.59 | Cause | 0.0529 |

| RM3 | 7.40 | 11.64 | 19.04 | −4.24 | Effect | 0.0489 |

| IM1 | 10.91 | 9.17 | 20.08 | 1.74 | Cause | 0.0506 |

| IM2 | 8.24 | 10.30 | 18.54 | −2.06 | Effect | 0.0468 |

| LM1 | 12.33 | 10.11 | 22.44 | 2.22 | Cause | 0.0566 |

| LM2 | 10.45 | 11.25 | 21.70 | −0.80 | Effect | 0.0545 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M. Modeling Impacts of COVID-19 in Supply Chain Activities: A Grey-DEMATEL Approach. Sustainability 2022, 14, 14141. https://doi.org/10.3390/su142114141

Karuppiah K, Sankaranarayanan B, Ali SM. Modeling Impacts of COVID-19 in Supply Chain Activities: A Grey-DEMATEL Approach. Sustainability. 2022; 14(21):14141. https://doi.org/10.3390/su142114141

Chicago/Turabian StyleKaruppiah, Koppiahraj, Bathrinath Sankaranarayanan, and Syed Mithun Ali. 2022. "Modeling Impacts of COVID-19 in Supply Chain Activities: A Grey-DEMATEL Approach" Sustainability 14, no. 21: 14141. https://doi.org/10.3390/su142114141

APA StyleKaruppiah, K., Sankaranarayanan, B., & Ali, S. M. (2022). Modeling Impacts of COVID-19 in Supply Chain Activities: A Grey-DEMATEL Approach. Sustainability, 14(21), 14141. https://doi.org/10.3390/su142114141