Development of PZN-PMN-PZT Piezoelectric Ceramics with High d33 and Qm Values

Abstract

1. Introduction

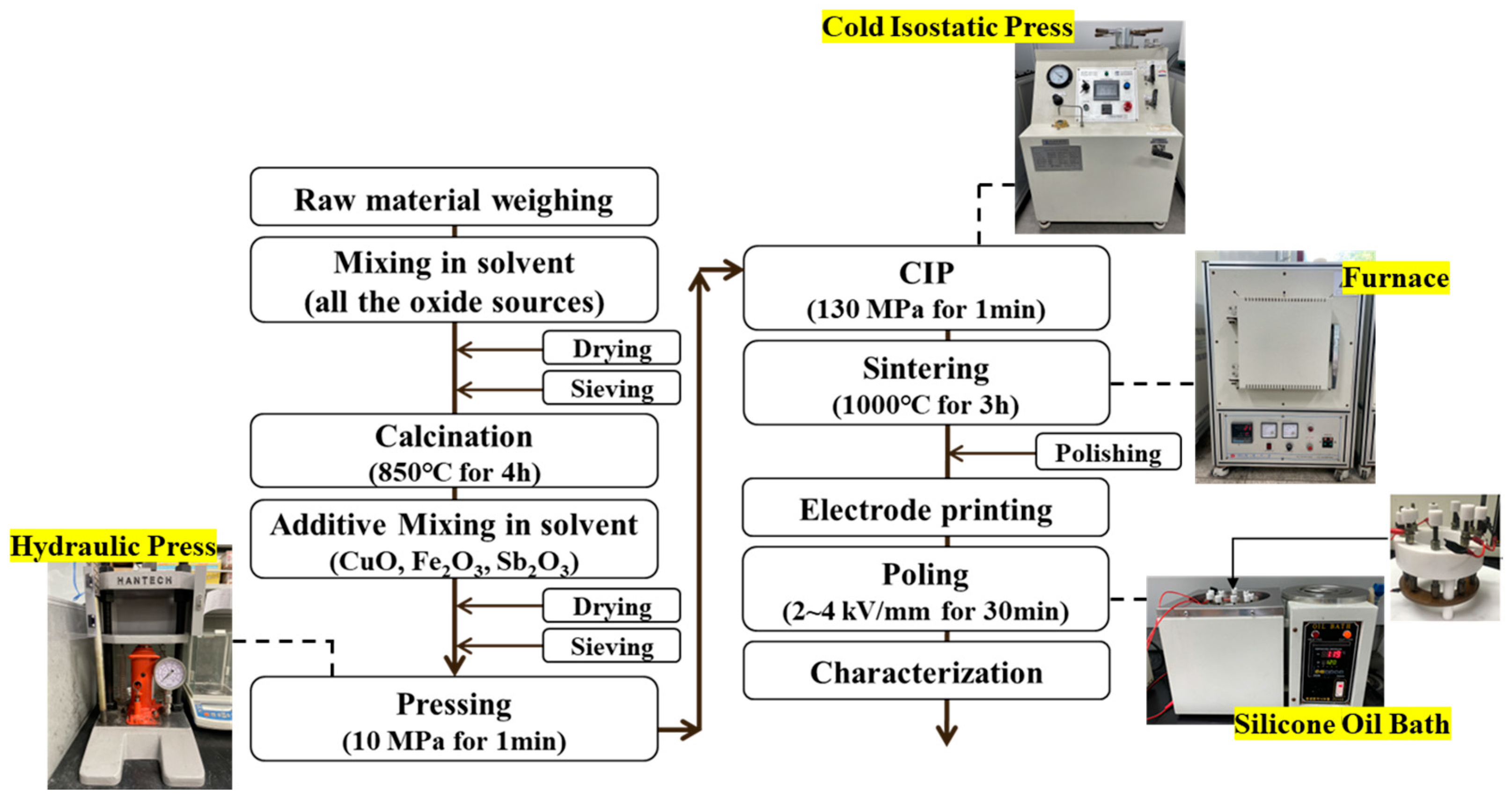

2. Materials and Methods

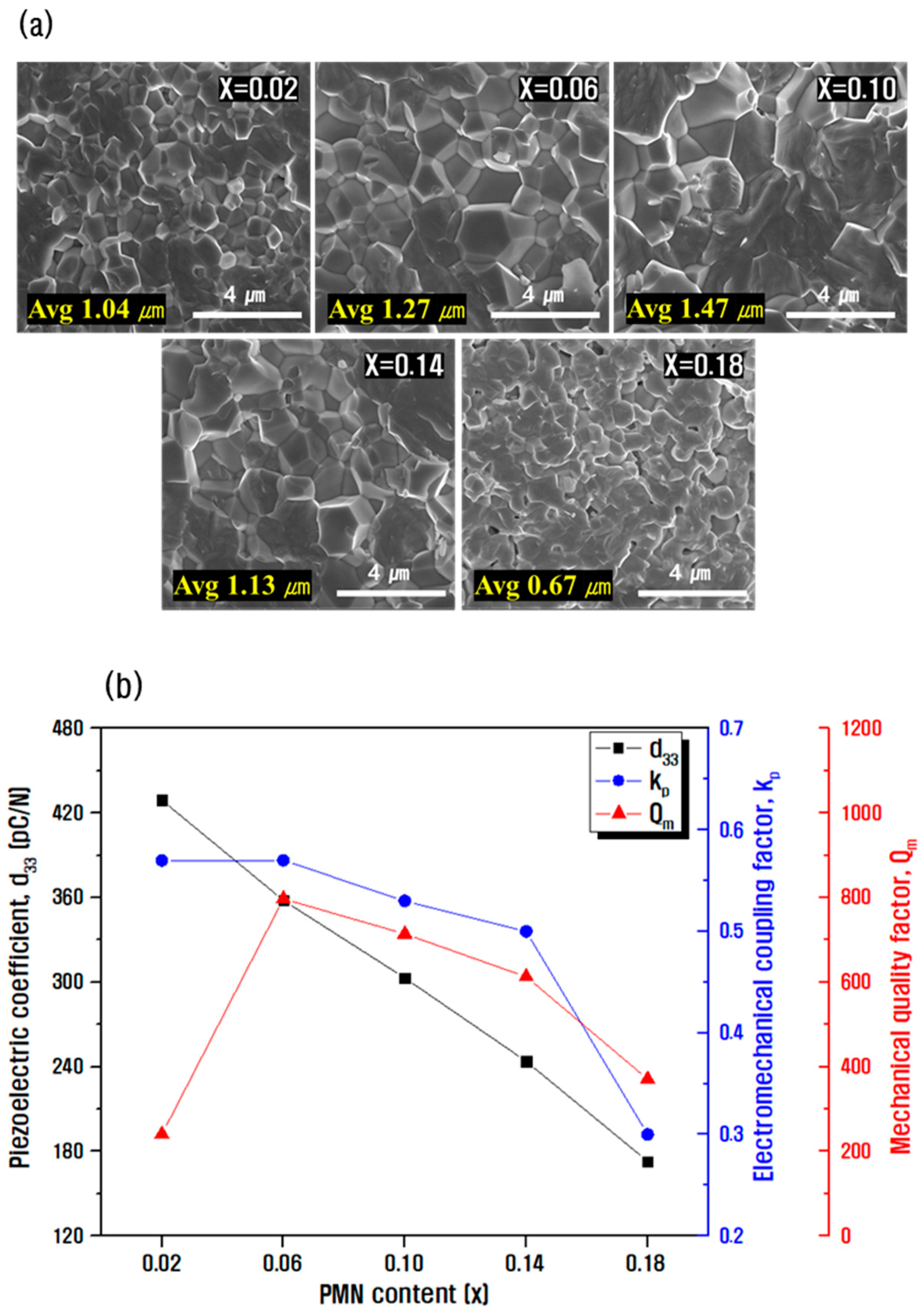

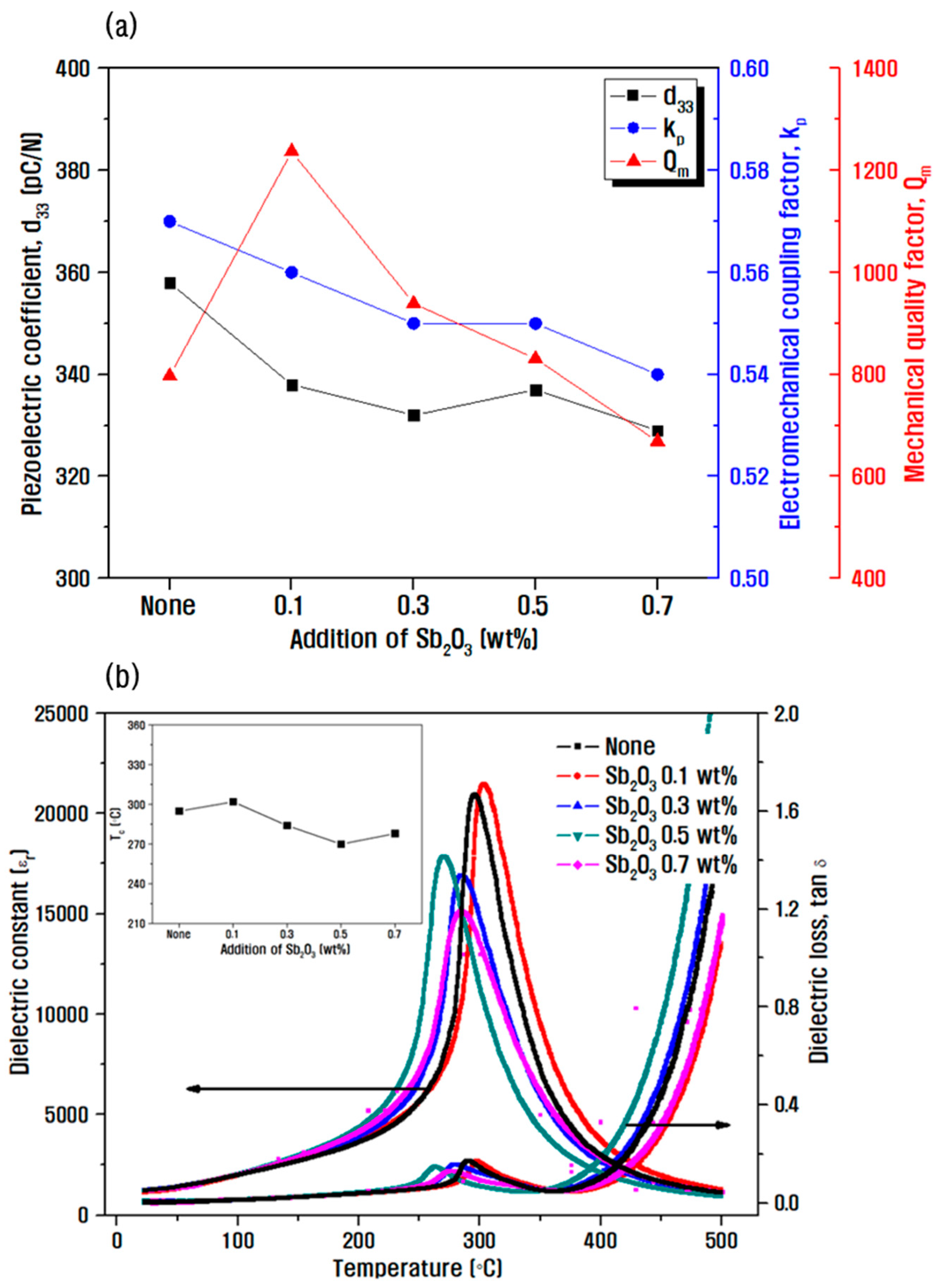

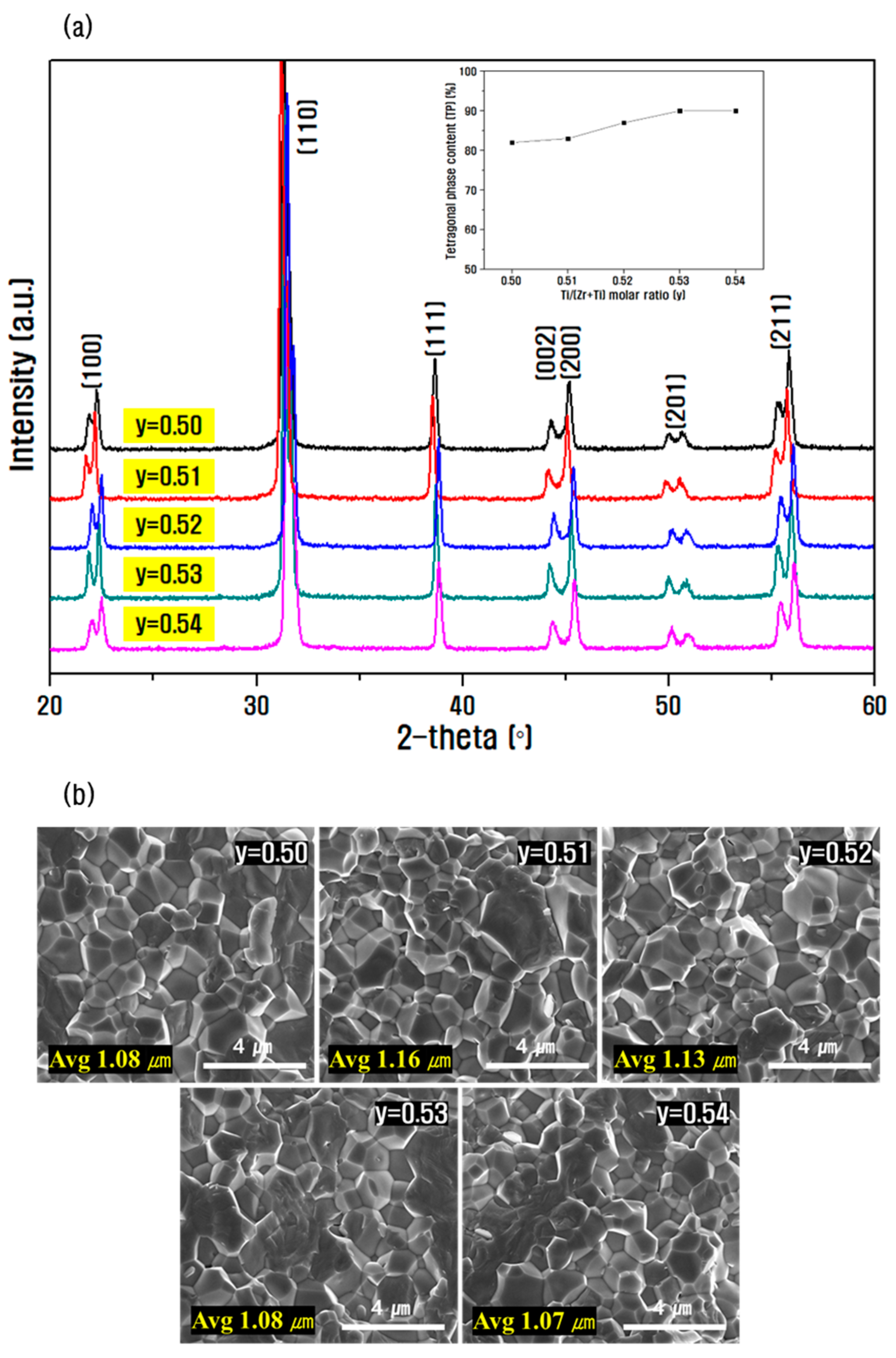

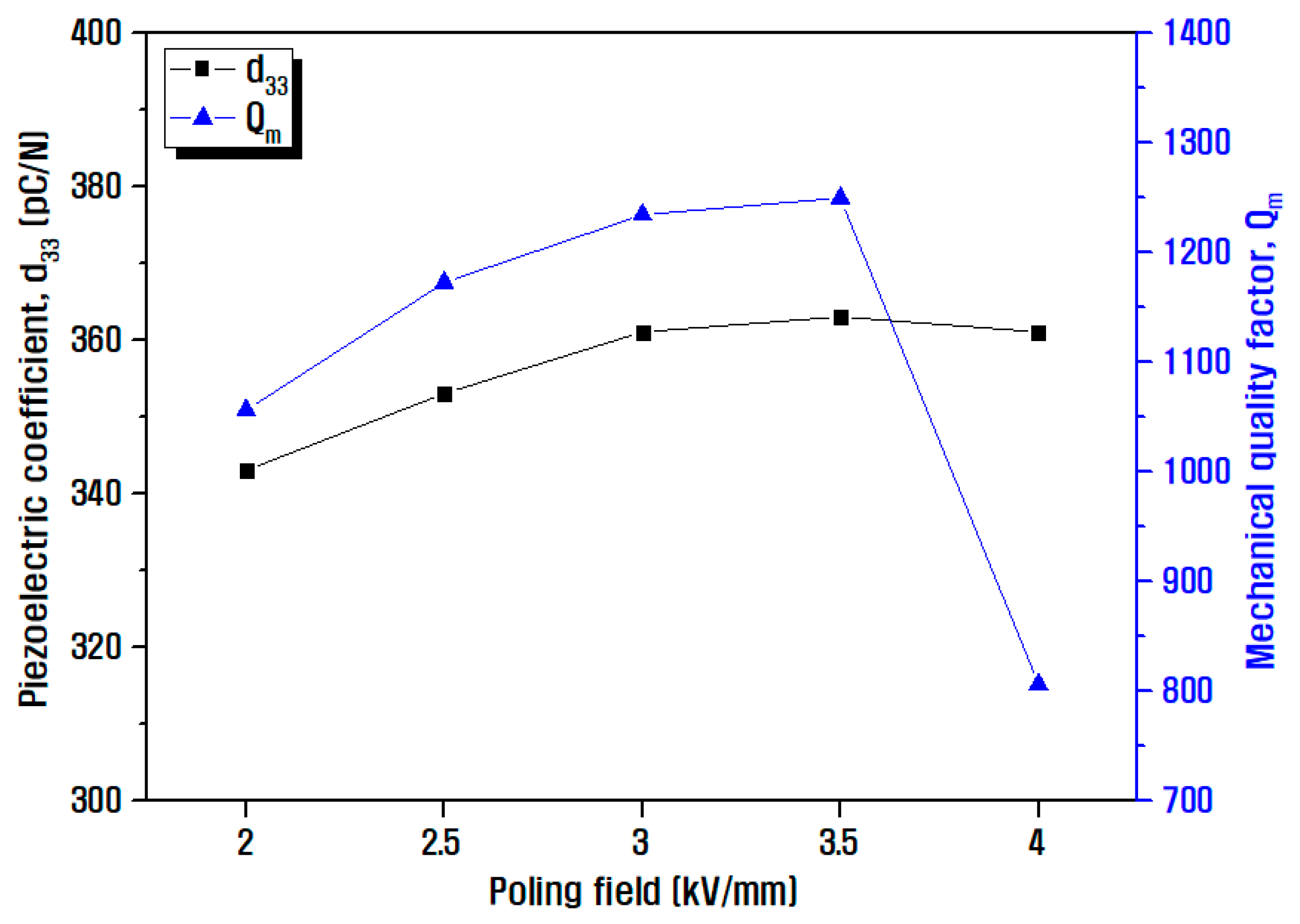

3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, M.; Hou, Y.; Zhu, M.; Zhang, M.; Yan, H. Shift of Morphotropic Phase Boundary in High-Performance Fine-Grained PZN-PZT Ceramics. J. Eur. Ceram. Soc. 2014, 34, 2275–2283. [Google Scholar] [CrossRef]

- Lee, T.G.; Lee, H.J.; Kim, D.H.; Xu, H.B.; Park, S.-J.; Park, J.S.; Nahm, S.; Kang, C.Y.; Yoon, S.J. Relation between Structure and Piezoelectric Properties of (1-x-y)PbZrO3-XPbTiO3-YPb(Ni1/3Nb2/3)O3 Ceramics near Triple Point Composition. J. Eur. Ceram. Soc. 2016, 36, 4049–4057. [Google Scholar] [CrossRef]

- Butnoi, P.; Manotham, S.; Jaita, P.; Sweatman, D.; Pisitpipathsin, N.; Tunkasiri, T. Electric Field–Induced Strain Behavior and Ferroelectric Properties of Lead Zirconate Titanate-Barium Calcium Zirconate Titanate Ceramics. Integr. Ferroelectr. 2018, 187, 156–164. [Google Scholar] [CrossRef]

- Kweon, S.; Lee, K.; Park, Y.; Yoon, M. Low-temperature sintering of (1-x)Pb(Zr0.53Ti0.47)O3-xBiYO3 ceramics with nano-powder for Piezo-Speaker. Jpn. J. Appl. Phys. 2019, 58, 51008. [Google Scholar] [CrossRef]

- Nam, C.H.; Park, H.Y.; Seo, I.T.; Choi, J.H.; Nahm, S.; Lee, H.G. Effect of CuO on the Sintering Temperature and Piezoelectric Properties of MnO2-Doped 0.75Pb(Zr0.47Ti0.53)O3-0.25Pb(Zn1/3Nb2/3)O3 Ceramics. J. Alloys Compd. 2011, 509, 3686–3689. [Google Scholar] [CrossRef]

- Dinh, N.; Luan, T.; Vuong, L.D.; Chanh, B.C. Microstructure, Ferroelectric and Piezoelectric Properties of PZT-PMnSbN Ceramics. Int. J. Mater. Chem. 2013, 3, 51–58. [Google Scholar] [CrossRef]

- Dinh Gio, P.; Vuong, L.D.; Thanh Hoa, H.T. Electrical Properties of CuO-Doped PZT-PZN-PMnN Piezoelectric Ceramics Sintered at Low Temperature. J. Mater. Sci. Chem. Eng. 2014, 2, 20–27. [Google Scholar] [CrossRef]

- Wu, Q.-C.; Hao, M.-M.; Zeng, Z.-Q.; Wang, X.-C.; Lv, W.-Z.; Fan, G.-F. Nonlinear Dielectric Effect of Fe2O3-Doped PMS–PZT Piezoelectric Ceramics for High-Power Applications. Ceram. Int. 2017, 43, 10866–10872. [Google Scholar] [CrossRef]

- Zeng, X.; Ding, A.; Liu, T.; Deng, G.; Zheng, X. Dielectric and Piezoelectric Properties of PZN-PZT Ceramics with Neodymium Doping. Integr. Ferroelectr. 2006, 80, 265–272. [Google Scholar] [CrossRef]

- Chen, C.Y.; Hu, Y.; Lin, H.L. A Novel Low Temperature Sintering Process for PMnN-PZT Ceramics. Mater. Chem. Phys. 2006, 99, 26–29. [Google Scholar] [CrossRef]

- Photankham, W.; Kongpimai, J.; Phewphong, S.; Wattanasarn, H.; Samapisut, S.; Namthaisong, A. Effect of PFN Addition on Microstructure and Piezoelectric Properties of PZT58/42 Ceramics. Integr. Ferroelectr. 2018, 187, 80–88. [Google Scholar] [CrossRef]

- Tapaonoi, C.; Tashiro, S.; Igarashi, H. Piezoelectric Properties of Fine-Grained Lead Zirconate Titanate Ceramics Modified with Pb(Sb1/2Nb1/2)O3. Jpn. J. Appl. Phys. 1994, 33, 5336–5340. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, H.C. Design and Preparation of Self-Oscillating Actuators Using Piezoelectric Ceramics with High Coupling Factors and Mechanical Quality Factors. Micromachines 2022, 13, 158. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.P.; Hou, Y.D.; Ge, H.Y.; Zhu, M.K.; Yan, H. Effect of NiO Additive on Microstructure, Mechanical Behavior and Electrical Properties of 0.2PZN-0.8PZT Ceramics. J. Eur. Ceram. Soc. 2013, 33, 1447–1456. [Google Scholar] [CrossRef]

- Vuong, L.D. Effect of Li2CO3 Addition on the Sintering Behavior and Physical Properties of PZT-PZN-Pmnn Ceramics. Int. J. Mater. Sci. Appl. 2013, 2, 89. [Google Scholar] [CrossRef][Green Version]

- Zheng, M.; Hou, Y.; Zhu, M.; Zhang, M.; Yan, H. Comparative Study of Microstructure, Electric Properties and Conductivity for NiO and PNN Modified Pb(Zn1/3Nb2/3)O3-PbZrO3-PbTiO3 Ceramics. Mater. Res. Bull. 2014, 51, 426–431. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, X.; Zhu, J.; Zeng, X.; Feng, X.; Liao, J. Composition Design, Phase Transitions and Electrical Properties of Sr2+-Substituted xPZN-0.1PNN-(0.9-x)PZT Piezoelectric Ceramics. Ceram. Int. 2016, 42, 4080–4089. [Google Scholar] [CrossRef]

- Chen, C.Y.; Hu, Y.; Lin, H.L.; Wei, W.Y. Influence of the Sintering Temperature on Phase Development in PMnN-PZT Ceramics. Ceram. Int. 2007, 33, 263–268. [Google Scholar] [CrossRef]

- Kalem, V.; Timucin, M. Structural, Piezoelectric and Dielectric Properties of PSLZT-PMnN Ceramics. J. Eur. Ceram. Soc. 2013, 33, 105–111. [Google Scholar] [CrossRef]

- Kumar, A.; Yoon, J.Y.; Thakre, A.; Peddigari, M.; Jeong, D.Y.; Kong, Y.M.; Ryu, J. Dielectric, Ferroelectric, Energy Storage, and Pyroelectric Properties of Mn-Doped (Pb0.93La0.07) (Zr0.82Ti0.18)O3 Anti-Ferroelectric Ceramics. J. Korean Ceram. Soc. 2019, 56, 412–420. [Google Scholar] [CrossRef]

- Chaudhari, V.A.; Bichile, G.K. Structural and Impedance Spectroscopic Studies on PbZrxTi1-XO3 Ceramics. Phys. B Condens. Matter 2010, 405, 534–539. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, S.H.; Yoon, C.B.; Kim, H.E.; Lee, K.W. Low-Temperature Sintering of MnO2-Doped PZT-PZN Piezoelectric Ceramics. J. Electroceramics 2007, 18, 311–315. [Google Scholar] [CrossRef][Green Version]

- Huang, X.; Peng, J.; Zeng, J.; Zheng, L.; Li, G.; Karaki, T. The High Piezoelectric Properties and High Temperature Stability in Mn Doped Pb(Mg0.5W0.5)O3-Pb(Zr,Ti)O3 Ceramics. Ceram. Int. 2019, 45, 6523–6527. [Google Scholar] [CrossRef]

- Deng, B.; Wei, Q.; He, C.; Wang, Z.; Yang, X.; Long, X. Effect of Pb(Mn1/3Sb2/3)O3 Addition on the Electrical Properties of BiScO3-PbTiO3 Piezoelectric Ceramics. J. Alloys Compd. 2019, 790, 397–404. [Google Scholar] [CrossRef]

- Li, X.; Zhao, X.; Ren, B.; Luo, H.; Ge, W.; Jiang, Z.; Zhang, S. Microstructure and Dielectric Relaxation of Dipolar Defects in Mn-Doped (1-X)Pb(Mg1/3Nb2/3)O3-XPbTiO3 Single Crystals. Scr. Mater. 2013, 69, 377–380. [Google Scholar] [CrossRef]

- Liu, H.; Nie, R.; Yue, Y.; Zhang, Q.; Chen, Q.; Zhu, J.; Yu, P.; Xiao, D.; Wang, C.; Wang, X. Effect of MnO2 Doping on Piezoelectric, Dielectric and Ferroelectric Properties of PNN–PZT Ceramics. Ceram. Int. 2015, 41, 11359–11364. [Google Scholar] [CrossRef]

- Kim, I.; Kim, M.; Jeong, S.; Song, J.; Joo, H.; Thang, V.V.; Muller, A. Properties of Step-down Multilayer Piezo Stack Transformers Using PNN-PMN-PZT Ceramics with CeO2 Addition. J. Korean Phys. Soc. 2011, 58, 580–584. [Google Scholar] [CrossRef]

- Peng, Z.H.; Zheng, D.Y.; Zhou, T.; Yang, L.; Zhang, N.; Fang, C. Effects of Co2O3 Doping on Electrical Properties and Dielectric Relaxation of PMS–PNN–PZT Ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 5961–5968. [Google Scholar] [CrossRef]

- Menasra, H.; Necira, Z.; Bouneb, K.; Maklid, A.; Boutarfaia, A. Microstructure and Dielectric Properties of Bi Substituted PLZMST Ceramics. Mater. Sci. Appl. 2013, 4, 293–298. [Google Scholar] [CrossRef][Green Version]

- Zhuo, Z.; Ling, Z.; Liu, Y. Phase Composition and Piezoelectric Properties of Pb(Sb1/2Nb1/2)–PbTiO3–PbZrO3 Ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 9524–9530. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, Y.; Wang, Y.; Meng, H. Study on Pb(Mg1/3Ta2/3)O3-Pb(Mn1/3Sb2/3)O3-Pb(ZrxTi 1-x)O3 High Power Piezoelectric Ceramics near the Morphotropic Phase Boundary. J. Alloys Compd. 2010, 508, 364–369. [Google Scholar] [CrossRef]

- Kahoul, F.; Hamzioui, L.; Boutarfaia, A. The Influence of Zr/Ti Content on the Morphotropic Phase Boundary and on the Properties of PZT-SFN Piezoelectric Ceramics. Energy Procedia 2014, 50, 87–96. [Google Scholar] [CrossRef][Green Version]

- Mirzaei, A.; Bonyani, M.; Torkian, S. Effect of Nb Doping on Sintering and Dielectric Properties of PZT Ceramics. Process. Appl. Ceram. 2016, 10, 175–182. [Google Scholar] [CrossRef]

- Lonkar, C.M.; Kharat, D.K.; Kumar, H.H.; Prasad, S.; Ghosh, M.; Kumbhar, C.S. Effect of Zr/Ti Ratio on Piezoelectric Properties of Pb(Ni1/3Sb2/3)O3-Pb(ZrTi)O3 Ceramics. Ceram. Int. 2011, 37, 3509–3514. [Google Scholar] [CrossRef]

- Chen, H.; Fan, C. Fabrication and Properties of PYN-PMN-PZT Quaternary Piezoelectric Ceramics for High-Power, High-Temperature Applications. Mater. Lett. 2010, 64, 654–656. [Google Scholar] [CrossRef]

- Hamzioui, L.; Kahoul, F.; Guemache, A.; Aillerie, M.; Boutarfaia, A. Effect of Zr/Ti Ratio on Piezoelectric and Dielectric Propertiesof 0.1Pb[Fe1/2Nb1/2]O3-0.9Pb[ZrxTi1−x]O3 Ceramics. Trans. Indian Ceram. Soc. 2021, 80, 60–63. [Google Scholar] [CrossRef]

- Vuong, L.D.; Gio, P.D.; Chuong, T.V.; Thi, D.; Trang, H.; Hung, D.V. Effect of Zr/Ti Ratio Content on Some Physical Properties of Low Temperature Sintering PZT−PZN−PMnN Ceramics. Int. J. Mater. Chem. 2013, 3, 39–43. [Google Scholar] [CrossRef]

- Peng, G.; Chen, C.; Zhang, J.; Zheng, D.; Hu, S.; Zhang, H. Effects of PNN/PZT Ratios on Phase Structure, Electric Properties and Relaxation Behavior of PZN–PNN–PZT Ceramics. J. Mater. Sci. Mater. Electron. 2016, 27, 3145–3151. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, Q.; Ma, W.; Zhang, Y.; Liu, H. The Effect of Poling Condition on the Piezoelectric Properties of 0.3PNN-0.7PZT Ceramics in the Vicinity of MPB. J. Mater. Sci. Mater. Electron. 2012, 23, 688–691. [Google Scholar] [CrossRef]

- Li, C.X.; Yang, B.; Zhang, S.T.; Zhang, R.; Cao, W.W. Effects of sintering temperature and poling conditions on the electrical properties of Ba0.70Ca0.30TiO3 diphasic piezoelectric ceramics. Ceram. Int. 2013, 39, 2967–2973. [Google Scholar] [CrossRef]

| PMN Content (x) | Lattice Parameters | Tetragonality (c/a) | Density (g/cm3) | Relative Density (%) | ||

|---|---|---|---|---|---|---|

| a(Å) | c(Å) | Theoretical | Experimental | |||

| 0.02 | 4.038 | 4.118 | 1.019 | 8.10 | 8.02 | 99.0 |

| 0.06 | 4.040 | 4.118 | 1.019 | 8.09 | 7.96 | 98.4 |

| 0.10 | 4.038 | 4.114 | 1.018 | 8.11 | 7.78 | 95.9 |

| 0.14 | 4.048 | 4.094 | 1.011 | 8.11 | 7.68 | 94.7 |

| 0.18 | 4.088 | 4.092 | 1.000 | 7.96 | 7.32 | 92.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-W.; Lee, H.-C. Development of PZN-PMN-PZT Piezoelectric Ceramics with High d33 and Qm Values. Materials 2022, 15, 7070. https://doi.org/10.3390/ma15207070

Kim S-W, Lee H-C. Development of PZN-PMN-PZT Piezoelectric Ceramics with High d33 and Qm Values. Materials. 2022; 15(20):7070. https://doi.org/10.3390/ma15207070

Chicago/Turabian StyleKim, So-Won, and Hee-Chul Lee. 2022. "Development of PZN-PMN-PZT Piezoelectric Ceramics with High d33 and Qm Values" Materials 15, no. 20: 7070. https://doi.org/10.3390/ma15207070

APA StyleKim, S.-W., & Lee, H.-C. (2022). Development of PZN-PMN-PZT Piezoelectric Ceramics with High d33 and Qm Values. Materials, 15(20), 7070. https://doi.org/10.3390/ma15207070