Development of Biodegradable PLA/PBAT-Based Filaments for Fertilizer Release for Agricultural Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

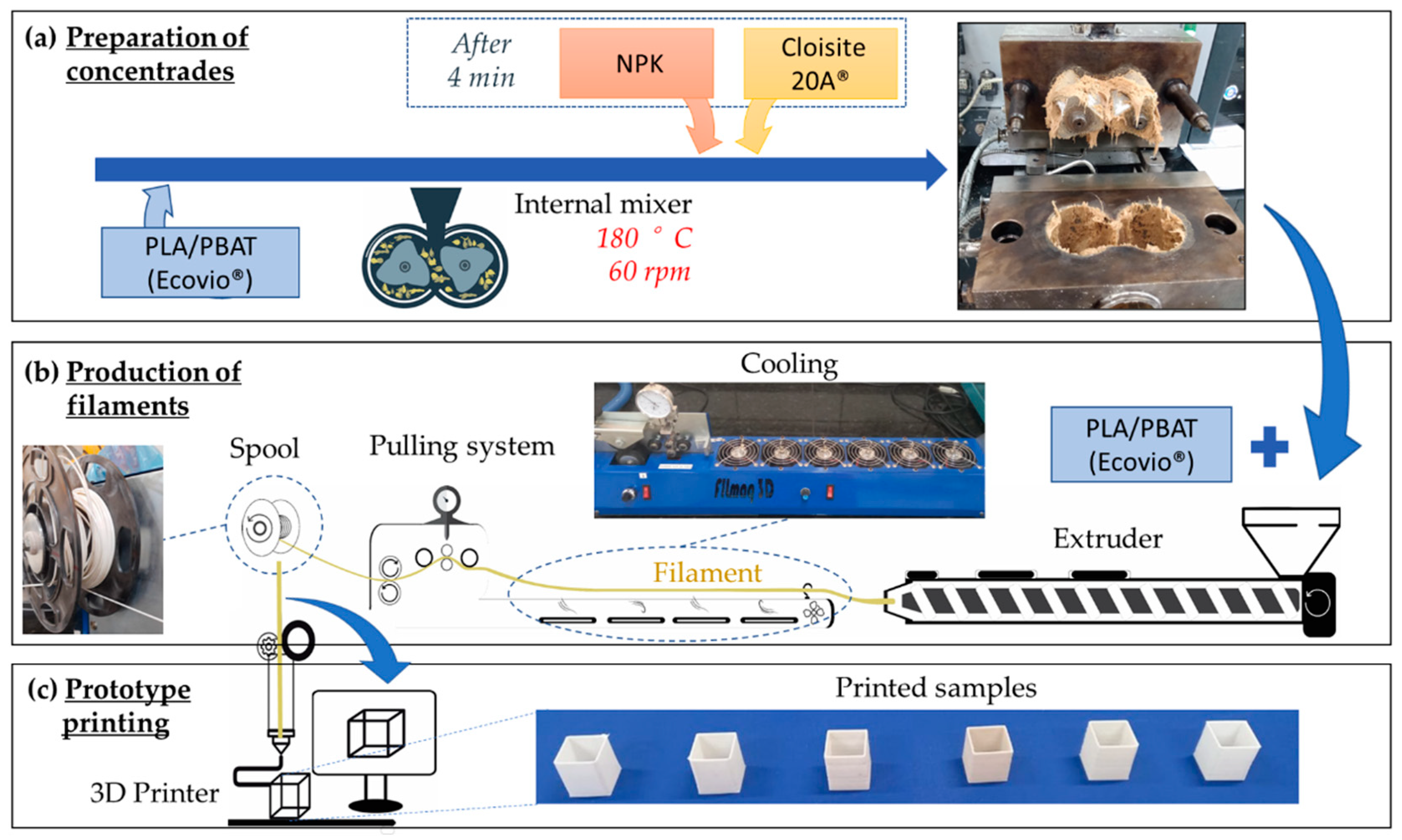

2.2. Preparation of Composites and Production of Filaments

2.3. Prototype Printing

2.4. Characterization

2.5. Release Rate in Water and Release Kinetics

3. Results and Discussion

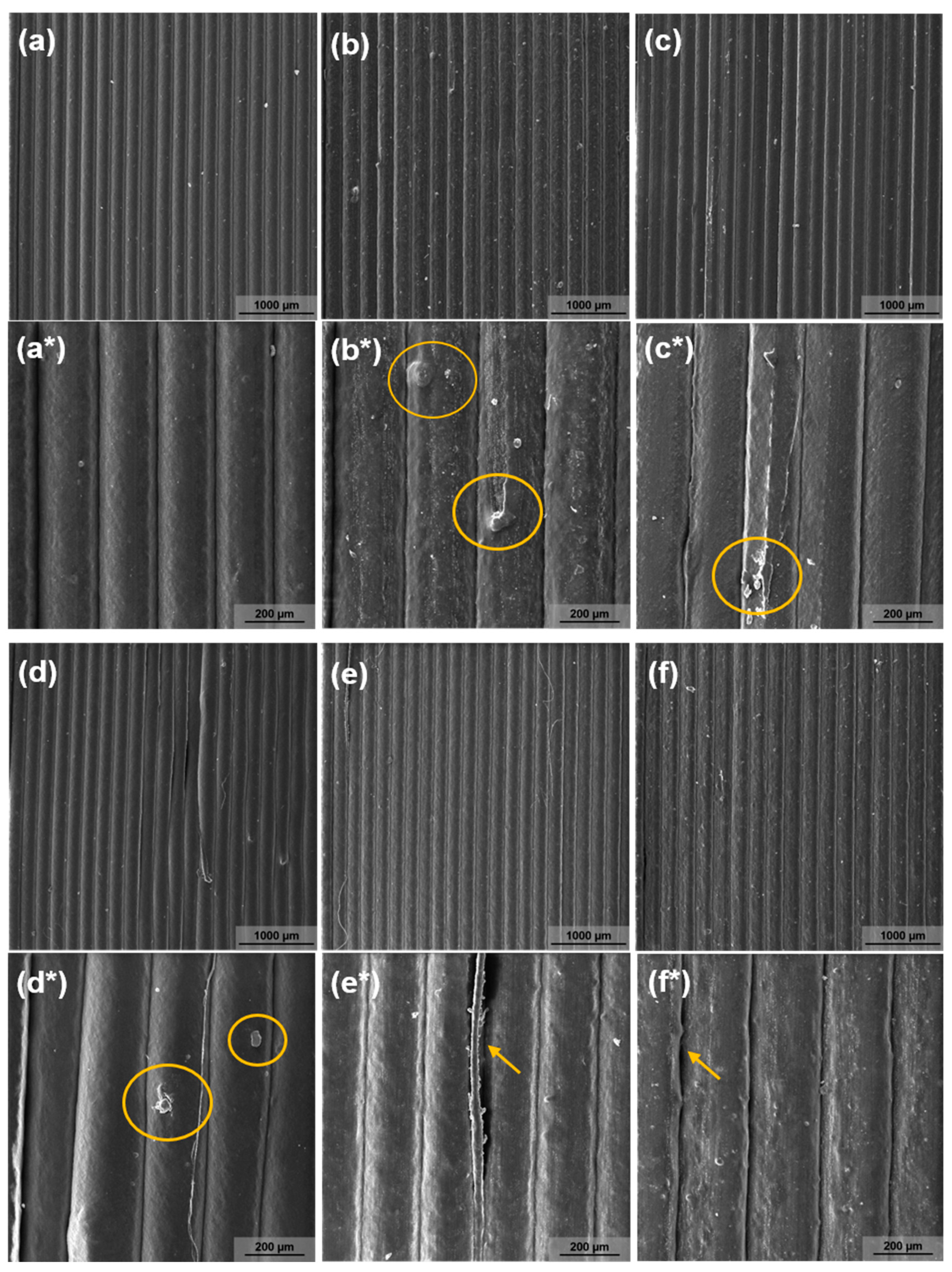

3.1. Morphological Analysis

3.2. XRD Analisys

3.3. Thermal Analysis

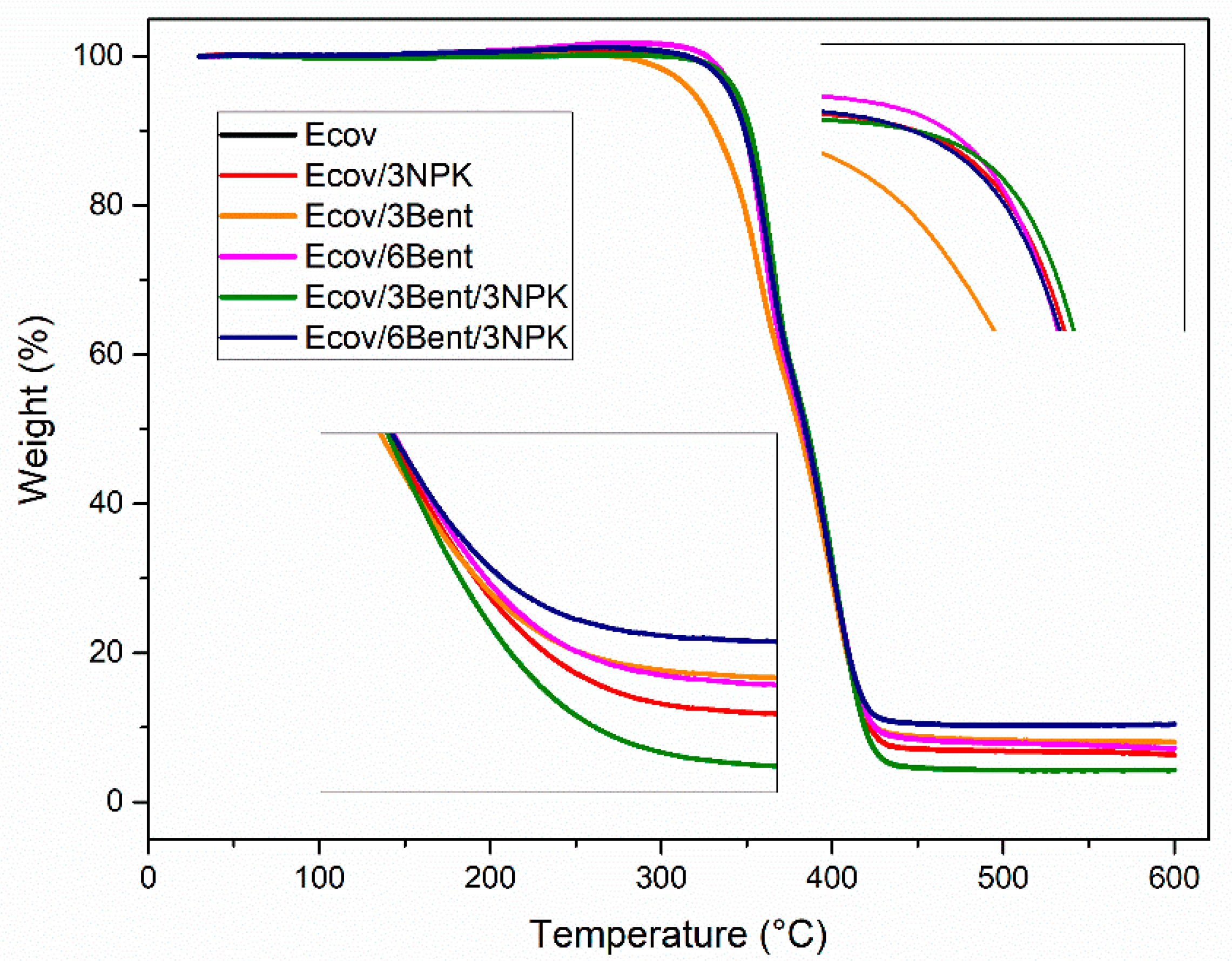

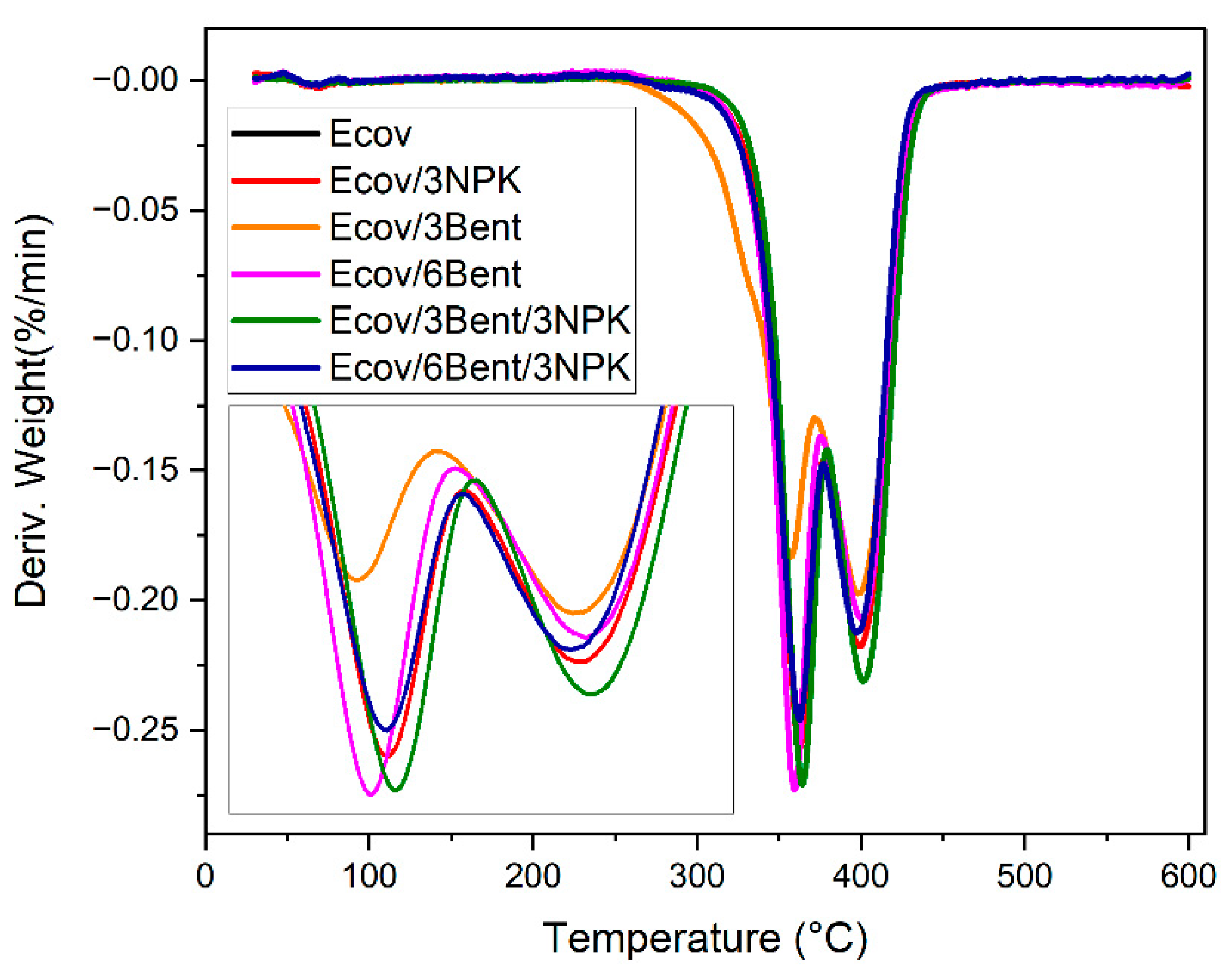

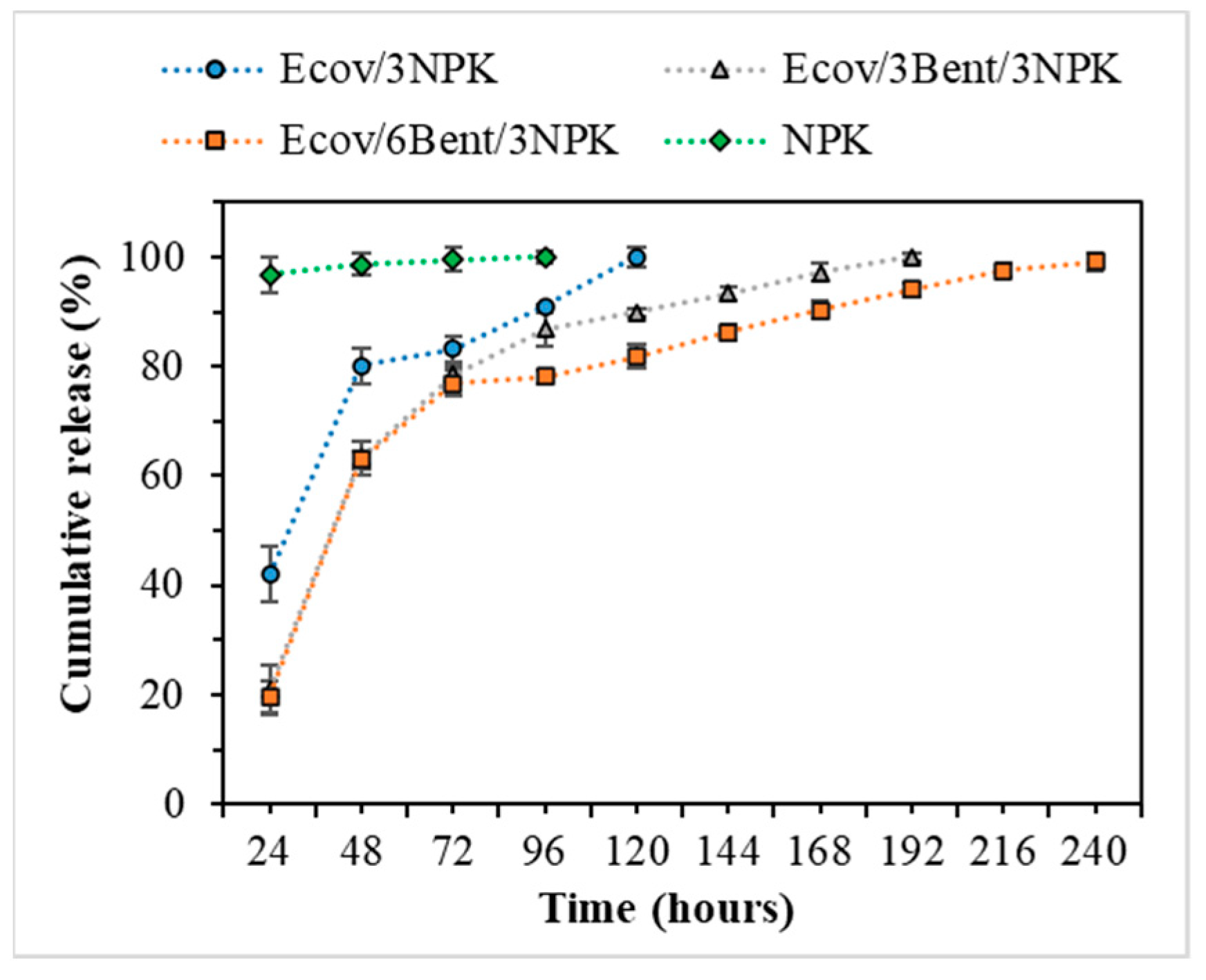

3.4. NPK Release

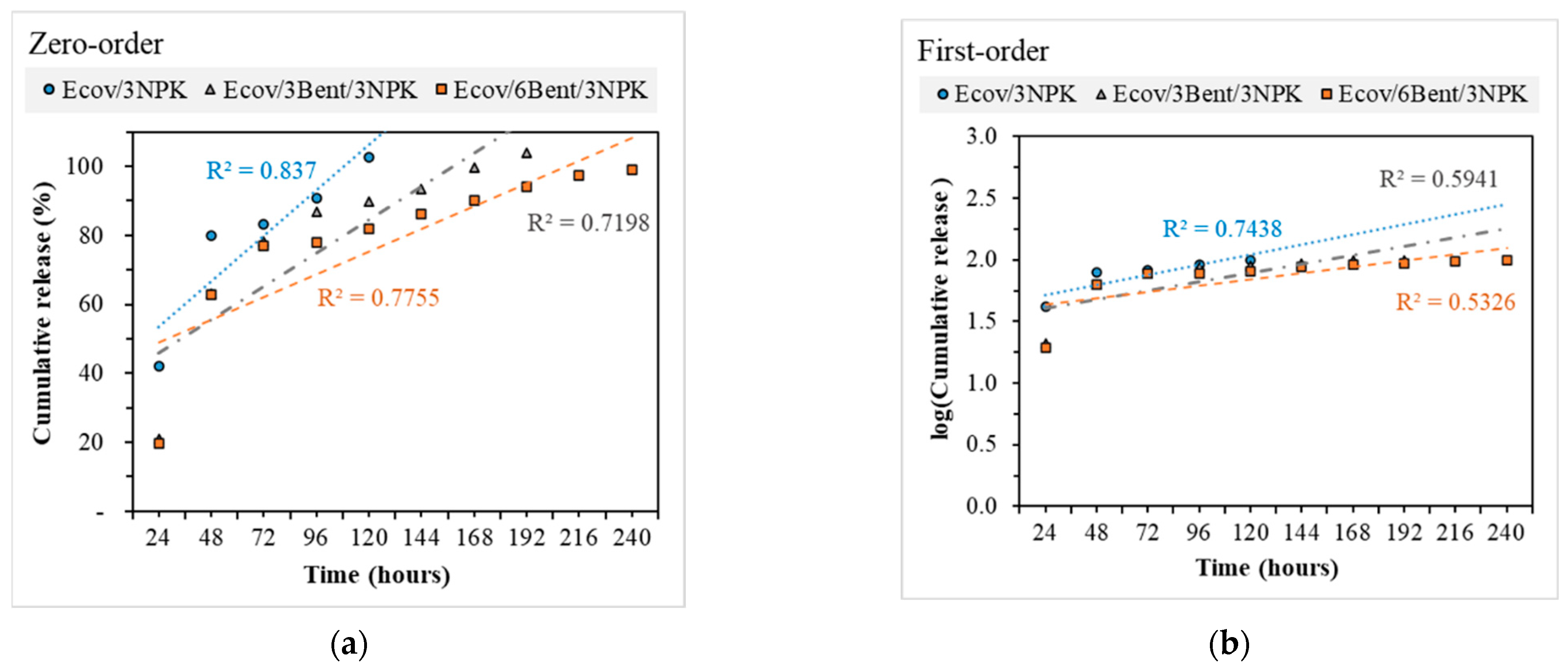

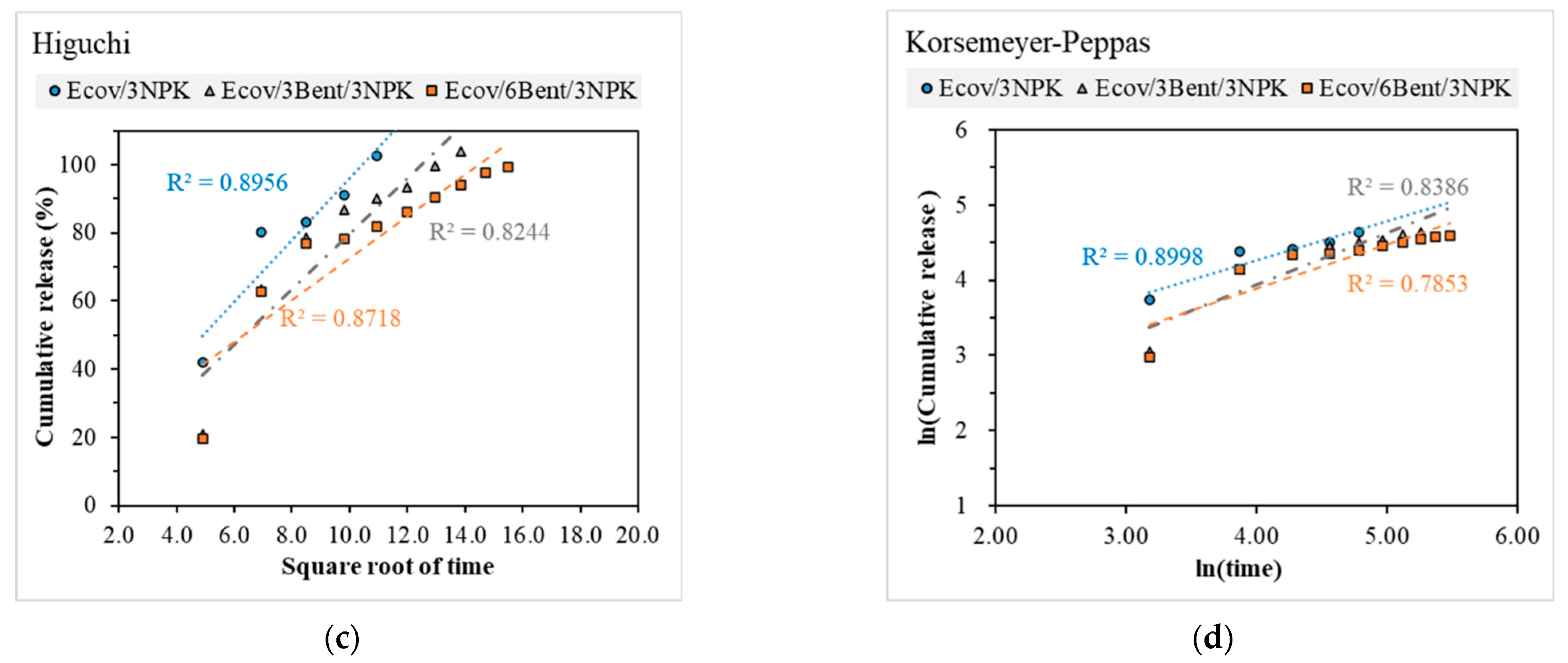

3.5. Release Kinetics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- FAO. World Fertilizer Trends and Outlook to 2022. Food and Agriculture Organization of the United Nations. 2019. Available online: https://www.fao.org/3/ca6746en/ca6746en.pdf (accessed on 1 June 2022).

- Fertilizer Market by Type (Organic and Inorganic), Form (Solid and Liquid), Application (Agriculture, Horticulture, Gardening, and Others), and Regional Analysis (North America, Europe, Asia-Pacific, and LAMEA): Global Opportunity Analysis and Industry Forecast, 2021–2028. Available online: https://www.researchdive.com/6194/fertilizer-market (accessed on 2 June 2022).

- Singh, V.K.; Gautam, P.; Nanda, G.; Dhaliwal, S.S.; Pramanick, B.; Meena, S.S.; Alsanie, W.F.; Gaber, A.; Sayed, S.; Hossain, A. Soil test based fertilizer application improves productivity, profitability and nutrient use efficiency of rice (Oryza sativa L.) under direct seeded condition. Agronomy 2021, 11, 1756. [Google Scholar] [CrossRef]

- Lakshmi, P.; Singh, S.; Pramanick, B.; Kumar, M.; Laik, R.; Kumari, A.; Shukla, A.; Latef, A.A.; Ali, O.; Hossain, A. Long-term zinc fertilization in calcareous soils improves wheat (Triticum aestivum L.) productivity and soil zinc status in the rice–wheat cropping system. Agronomy 2021, 11, 1306. [Google Scholar] [CrossRef]

- Fertahi, S.; Ilsouk, M.; Zeroual, Y.; Oukarroum, A.; Barakat, A. Recent trends in organic coating based on biopolymers and biomass for controlled and slow release fertilizers. J. Control. Release 2021, 330, 341–361. [Google Scholar] [CrossRef] [PubMed]

- Lawrencia, D.; Wong, S.; Low, D.; Goh, B.; Goh, J.; Ruktanonchai, U.; Soottitantawat, A.; Lee, L.; Tang, S. Controlled release fertilizers: A review on coating materials and mechanism of release. Plants 2021, 10, 238. [Google Scholar] [CrossRef]

- Vejan, P.; Khadiran, T.; Abdullah, R.; Ahmad, N. Controlled release fertilizer: A review on developments, applications and potential in agriculture. J. Control. Release 2021, 339, 321–334. [Google Scholar] [CrossRef]

- Chen, J.; Fan, X.; Zhang, L.; Chen, X.; Sun, S.; Sun, R. Research progress in lignin-based slow/controlled release fertilizer. ChemSusChem 2020, 13, 4356–4366. [Google Scholar] [CrossRef]

- Gil-Ortiz, R.; Naranjo, M.; Ruiz-Navarro, A.; Atares, S.; García, C.; Zotarelli, L.; San Bautista, A.; Vicente, O. Enhanced agronomic efficiency using a new controlled-released, polymeric-coated nitrogen fertilizer in rice. Plants 2020, 9, 1183. [Google Scholar] [CrossRef]

- Daitx, T.S.; Giovanela, M.; Carli, L.N.; Mauler, R.S. Biodegradable polymer/clay systems for highly controlled release of NPK fertilizer. Polym. Adv. Technol. 2019, 30, 631–639. [Google Scholar] [CrossRef]

- de Carvalho Arjona, J.; das Graças Silva-Valenzuela, M.; Wang, S.-H.; Valenzuela-Diaz, F. Biodegradable Nanocomposite Microcapsules for Controlled Release of Urea. Polymers 2021, 13, 722. [Google Scholar] [CrossRef]

- Chiaregato, C.G.; Souza, C.F.; Faez, R. The fertilizer release into water and soil as the biodegradation process in the sustainable material enhancing the fertilizer efficiency. Environ. Technol. Innov. 2021, 22, 101417. [Google Scholar] [CrossRef]

- França, D.; Angelo, L.M.; Souza, C.F.; Faez, R. Biobased poly(3-hydroxybutyrate)/starch/cellulose nanofibrils for nutrients coatings. ACS Appl. Polym. Mater. 2021, 3, 3227–3237. [Google Scholar] [CrossRef]

- Nooeaid, P.; Chuysinuan, P.; Pitakdantham, W.; Aryuwananon, D.; Techasakul, S.; Dechtrirat, D. Eco-friendly polyvinyl alcohol/polylactic acid core/shell structured fibers as controlled-release fertilizers for sustainable agriculture. J. Polym. Environ. 2021, 29, 552–564. [Google Scholar] [CrossRef]

- Beig, B.; Niazi, M.B.K.; Jahan, Z.; Hussain, A.; Zia, M.H.; Mehran, M.T. Coating materials for slow release of nitrogen from urea fertilizer: A review. J. Plant Nutr. 2020, 43, 1510–1533. [Google Scholar] [CrossRef]

- Wei, H.; Wang, H.; Chu, H.; Li, J. Preparation and characterization of slow-release and water-retention fertilizer based on starch and halloysite. Int. J. Biol. Macromol. 2019, 133, 1210–1218. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Biswas, D.R.; Datta, S.C.; Dwivedi, B.S.; Bhattacharyya, R.; Kumar, R.; Bandyopadhyay, K.K.; Saha, M.; Chawla, G.; Saha, J.K.; et al. Preparation of novel biodegradable starch/poly(vinyl alcohol)/bentonite grafted polymeric films for fertilizer encapsulation. Carbohydr. Polym. 2021, 259, 117679. [Google Scholar] [CrossRef]

- dos Santos, A.C.; Henrique, H.M.; Cardoso, V.L.; Reis, M.H. Slow release fertilizer prepared with lignin and poly(vinyl acetate) bioblend. Int. J. Biol. Macromol. 2021, 185, 543–550. [Google Scholar] [CrossRef]

- Bauli, C.R.; Lima, G.F.; de Souza, A.G.; Ferreira, R.R.; Rosa, D.S. Eco-friendly carboxymethyl cellulose hydrogels filled with nanocellulose or nanoclays for agriculture applications as soil conditioning and nutrient carrier and their impact on cucumber growing. Colloids Surf. A Physicochem. Eng. Asp. 2021, 623, 126771. [Google Scholar] [CrossRef]

- Eddarai, E.; El Mouzahim, M.; Boussen, R.; Bellaouchou, A.; Guenbour, A.; Zarrouk, A. Chitosan-kaolinite clay composite as durable coating material for slow release NPK fertilizer. Int. J. Biol. Macromol. 2022, 195, 424–432. [Google Scholar] [CrossRef]

- Vo, P.T.; Nguyen, H.T.; Trinh, H.T.; Nguyen, V.M.; Le, A.-T.; Tran, H.Q.; Nguyen, T.T.T. The nitrogen slow-release fertilizer based on urea incorporating chitosan and poly(vinyl alcohol) blend. Environ. Technol. Innov. 2021, 22, 101528. [Google Scholar] [CrossRef]

- Cardoso, P.H.M.; Coutinho, R.R.T.P.; Drummond, F.R.; Da Conceição, M.D.N.; Thiré, R.M.D.S.M. Evaluation of Printing Parameters on Porosity and Mechanical Properties of 3D Printed PLA/PBAT Blend Parts. Macromol. Symp. 2020, 394, 2000157. [Google Scholar] [CrossRef]

- Singamneni, S.; Behera, M.P.; Truong, D.; Le Guen, M.J.; Macrae, E.; Pickering, K. Direct extrusion 3D printing for a softer PLA-based bio-polymer composite in pellet form. J. Mater. Res. Technol. 2021, 15, 936–949. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Investigating the effects of extrusion temperatures and material extrusion rates on FFF-printed thermoplastics. Int. J. Adv. Manuf. Technol. 2021, 117, 2679–2699. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J. Manuf. Process. 2019, 37, 266–273. [Google Scholar] [CrossRef]

- Teoh, J.H.; Tay, S.M.; Fuh, J.; Wang, C.-H. Fabricating scalable, personalized wound dressings with customizable drug loadings via 3D printing. J. Control. Release 2022, 341, 80–94. [Google Scholar] [CrossRef] [PubMed]

- Dhakal, K.N.; Krause, B.; Lach, R.; Wutzler, A.; Grellmann, W.; Le, H.H.; Das, A.; Wießner, S.; Heinrich, G.; Adhikari, R. Electrically conductive nanocomposites based on poly(lactic acid)/flexible copolyester blends with multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2022, 139, 51554. [Google Scholar] [CrossRef]

- Freitas, A.L.P.D.L.; Filho, L.R.T.; Calvão, P.S.; de Souza, A.M.C. Effect of montmorillonite and chain extender on rheological, morphological and biodegradation behavior of PLA/PBAT blends. Polym. Test. 2017, 62, 189–195. [Google Scholar] [CrossRef]

- Daitx, T.D.S.; De Lima, V.S.; Gryczak, M.; Petzhold, C.L.; Carli, L.N.; Mauler, R.S. Poly(hydroxybutyrate)-based systems behavior on the controlled release of NPK fertilizers. Polym. Adv. Technol. 2020, 31, 2579–2587. [Google Scholar] [CrossRef]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A.; et al. Hybridization of MMT/lignocellulosic fiber reinforced polymer nanocomposites for structural applications: A review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Martins, R.C.; Ribeiro, S.P.D.S.; Rezende, M.J.C.; Nascimento, R.S.V.; Nascimento, M.A.C.; Batistella, M.; Lopez-Cuesta, J.M. Flame-Retarding Properties of Injected and 3D-Printed Intumescent Bio-Based PLA Composites: The Influence of Brønsted and Lewis Acidity of Montmorillonite. Polymers 2022, 14, 1702. [Google Scholar] [CrossRef]

- Stephen, R.; Pal, K.; Thomas, S. Polymer Matrix-Based Nanocomposites: Preparation and Properties. In Handbook of Polymer and Ceramic Nanotechnology; Springer: Cham, Switzerland, 2021; pp. 317–331. [Google Scholar] [CrossRef]

- Alam, A.; Masood, F.; Perveen, K.; Yasin, T.; Hameed, A. Enhanced thermal properties of sepiolite/poly-3-hydroxyoctanoate nanocomposites as biodegradable packaging materials. Mater. Today Commun. 2022, 31, 103290. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Gulino, E.F. Opuntia Ficus Indica based green composites for NPK fertilizer controlled release produced by compression molding and Fused Deposition Modeling. Compos. Part A Appl. Sci. Manuf. 2022, 159, 107030. [Google Scholar] [CrossRef]

- Irfan, S.A.; Razali, R.; KuShaari, K.; Mansor, N.; Azeem, B.; Versypt, A.N.F. A review of mathematical modeling and simulation of controlled-release fertilizers. J. Control. Release 2018, 271, 45–54. [Google Scholar] [CrossRef] [PubMed]

- Ritger, P.L.; Peppas, N.A. A simple equation for description of solute release I. Fickian and non-fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. J. Control. Release 1987, 5, 23–36. [Google Scholar] [CrossRef]

- Siepmann, J.; Peppas, N.A. Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (HPMC). Adv. Drug Deliv. Rev. 2012, 64, 163–174. [Google Scholar] [CrossRef]

- Falcão, G.A.M.; Almeida, T.G.; Bardi, M.A.G.; Carvalho, L.H.; Canedo, E.L. PBAT/organoclay composite films—Part 2: Effect of UV aging on permeability, mechanical properties and biodegradation. Polym. Bull. 2019, 76, 291–301. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Spiridaki, M.; Kechagias, J.D. Mechanical Performance of Fused Filament Fabricated and 3D-Printed Polycarbonate Polymer and Polycarbonate/Cellulose Nanofiber Nanocomposites. Fibers 2021, 9, 74. [Google Scholar] [CrossRef]

- Skowyra, J.; Pietrzak, K.; Alhnan, M.A. Fabrication of extended-release patient-tailored prednisolone tablets via fused deposition modelling (FDM) 3D printing. Eur. J. Pharm. Sci. 2015, 68, 11–17. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, R.; Ray, S.S.; Ghosh, A.K. Rheology and foaming behaviour of styrene–ethylene–butylene–styrene nanocomposites. Colloid Polym. Sci. 2021, 299, 481–496. [Google Scholar] [CrossRef]

- Zagho, M.M.; Khader, M.M. The impact of clay loading on the relative intercalation of poly(vinyl alcohol)-clay composites. J. Mater. Sci. Chem. Eng. 2016, 4, 20–31. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Wu, Q.; Sun, X.; Yue, Y.; Tubana, B.; Yang, R.; Cheng, H.N. Novel alginate-cellulose nanofiber-poly(vinyl alcohol) hydrogels for carrying and delivering nitrogen, phosphorus and potassium chemicals. Int. J. Biol. Macromol. 2021, 172, 330–340. [Google Scholar] [CrossRef]

- Olad, A.; Zebhi, H.; Salari, D.; Mirmohseni, A.; Tabar, A.R. Slow-release NPK fertilizer encapsulated by carboxymethyl cellulose-based nanocomposite with the function of water retention in soil. Mater. Sci. Eng. C 2018, 90, 333–340. [Google Scholar] [CrossRef] [PubMed]

- Kartini, I.; Lumbantobing, E.T.; Suyanta, S.; Sutarno, S.; Adnan, R. Bioplastic composite of carboxymethyl cellulose/NPK fertilizer. In Key Engineering Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2020; Volume 840, pp. 156–161. [Google Scholar] [CrossRef]

- Thiyagu, T.T.; Gokilakrishnan, G.; Uvaraja, V.C.; Maridurai, T.; Prakash, V.R.A. Effect of SiO2/TiO2 and ZnO Nanoparticle on Cardanol Oil Compatibilized PLA/PBAT Biocomposite Packaging Film. Silicon 2022, 14, 3795–3808. [Google Scholar] [CrossRef]

- Gomez-Gamez, A.; Yebra-Rodriguez, A.; Peñas-Sanjuan, A.; Soriano-Cuadrado, B.; Jimenez-Millan, J. Influence of clay percentage on the technical properties of montmorillonite/polylactic acid nanocomposites. Appl. Clay Sci. 2020, 198, 105818. [Google Scholar] [CrossRef]

- Arruda, L.C.; Magaton, M.; Bretas, R.E.S.; Ueki, M.M. Influence of chain extender on mechanical, thermal and morphological properties of blown films of PLA/PBAT blends. Polym. Test. 2015, 43, 27–37. [Google Scholar] [CrossRef]

- Wu, C.-S. Utilization of peanut husks as a filler in aliphatic–aromatic polyesters: Preparation, characterization, and biodegradability. Polym. Degrad. Stab. 2012, 97, 2388–2395. [Google Scholar] [CrossRef]

- Mondal, D.; Bhowmick, B.; Mollick, M.M.R.; Maity, D.; Ranjan Saha, N.; Rangarajan, V.; Rana, D.; Sen, R.; Chattopadhyay, D. Antimicrobial activity and biodegradation behavior of poly(butylene adipate-co-terephthalate)/clay nanocomposites. J. Appl. Polym. Sci. 2014, 131, 40079. [Google Scholar] [CrossRef]

- Baldanza, V.A.R.; Souza, F.G.; Filho, S.T.; Franco, H.A.; Oliveira, G.E.; Caetano, R.M.J.; Hernandez, J.A.R.; Leite, S.G.F.; Sousa, A.M.F.; Silva, A.L.N. Controlled-release fertilizer based on poly(butylene succinate)/urea/clay and its effect on lettuce growth. J. Appl. Polym. Sci. 2018, 135, 46858. [Google Scholar] [CrossRef]

- Souza, J.L.; de Campos, A.; França, D.; Faez, R. PHB and montmorillonite clay composites as KNO3 and NPK support for a controlled release. J. Polym. Environ. 2019, 27, 2089–2097. [Google Scholar] [CrossRef]

- Souza, J.D.L.; Chiaregato, C.G.; Faez, R. Green composite based on PHB and montmorillonite for KNO3 and NPK delivery system. J. Polym. Environ. 2017, 26, 670–679. [Google Scholar] [CrossRef]

- Li, G.; Xia, Y.; Mu, G.; Yang, Q.; Zhou, H.; Lin, X.; Gao, Y.; Qian, F. Phase Structure Analysis and Composition Optimization of Poly(Lactic Acid)/Poly(Butylene Adipate-co-terephthalate) Blends. J. Macromol. Sci. Part B 2022, 61, 413–424. [Google Scholar] [CrossRef]

- Spada, J.C.; Seibert, S.F.; Tessaro, I.C. Impact of PLA Poly(Lactic Acid) and PBAT Poly(butylene adipate-co-terephthalate) coating on the properties of composites with high content of rice husk. J. Polym. Environ. 2021, 29, 1324–1331. [Google Scholar] [CrossRef]

- Kim, S.; Roy, S.; Yoon, K.S.; Rhim, J. Preparation of low-density polyethylene- and poly (lactide)/poly (butylene adipate-co-terephthalate)-based antibacterial films integrated with elemental sulfur and sulfur nanoparticles. Packag. Technol. Sci. 2021, 34, 505–516. [Google Scholar] [CrossRef]

- He, H.; Liu, B.; Xue, B.; Zhang, H. Study on structure and properties of biodegradable PLA/PBAT/organic-modified MMT nanocomposites. J. Thermoplast. Compos. Mater. 2019, 35, 503–520. [Google Scholar] [CrossRef]

- González-Ausejo, J.; Gámez-Pérez, J.; Balart, R.; Lagarón, J.M.; Cabedo, L. Effect of the addition of sepiolite on the morphology and properties of melt compounded PHBV/PLA blends. Polym. Compos. 2019, 40, E156–E168. [Google Scholar] [CrossRef]

- Taleb, K.; Pillin, I.; Grohens, Y.; Saidi-Besbes, S. Polylactic acid/Gemini surfactant modified clay bio-nanocomposites: Morphological, thermal, mechanical and barrier properties. Int. J. Biol. Macromol. 2021, 177, 505–516. [Google Scholar] [CrossRef]

- Alves, J.L.; Rosa, P.D.T.V.E.; Realinho, V.; Antunes, M.; Velasco, J.I.; Morales, A.R. The effect of Brazilian organic-modified montmorillonites on the thermal stability and fire performance of organoclay-filled PLA nanocomposites. Appl. Clay Sci. 2020, 194, 105697. [Google Scholar] [CrossRef]

- Tan, L.-C.; He, Y.; Qu, J.-P. Structure and properties of Polylactide/Poly(butylene succinate)/Organically Modified Montmorillonite nanocomposites with high-efficiency intercalation and exfoliation effect manufactured via volume pulsating elongation flow. Polymer 2019, 180, 121656. [Google Scholar] [CrossRef]

- Hussain, R.; Devi, R.R.; Maji, T.K. Controlled release of urea from chitosan microspheres prepared by emulsification and cross-linking method. Iran. Polym. J. 2012, 21, 473–479. [Google Scholar] [CrossRef]

- Calabria, L.; Vieceli, N.; Bianchi, O.; de Oliveira, R.V.B.; Filho, I.D.N.; Schmidt, V. Soy protein isolate/poly(lactic acid) injection-molded biodegradable blends for slow release of fertilizers. Ind. Crops Prod. 2012, 36, 41–46. [Google Scholar] [CrossRef]

- Schaffazick, S.R.; Guterres, S.S.; Freitas, L.D.L.; Pohlmann, A.R. Physicochemical characterization and stability of the polymeric nanoparticle systems for drug administration. Química Nova 2003, 26, 726–737. [Google Scholar] [CrossRef]

- De Melo, N.F.S.; Grillo, R.; Rosa, A.H.; Fraceto, L.F.; Filho, N.L.D.; De Paula, E.; De Araújo, D.R. Development and characterization of poli (L-lactide) nanocapsules containing benzocaine. Química Nova 2010, 33, 65–69. [Google Scholar] [CrossRef]

- Costa, P.J.C.D. Avaliação in vitro da lioequivalência de formulações farmacêuticas. Rev. Bras. Ciências Farm. 2002, 38, 141–153. [Google Scholar] [CrossRef]

- Gulino, E.F.; Citarrella, M.C.; Maio, A.; Scaffaro, R. An innovative route to prepare in situ graded crosslinked PVA graphene electrospun mats for drug release. Compos. Part A: Appl. Sci. Manuf. 2022, 155, 106827. [Google Scholar] [CrossRef]

- Frish Stern, H.L.D.A. Critical Reviews in Solid State and Materials Science; CRC Press: Boca Raton, FL, USA, 1983; Volume 11, pp. 123–187. [Google Scholar]

- Sankar, C.; Mishra, B. Development and in vitro evaluations of gelatin A microspheres of Ketorolac tromethamine for intranasal administration. Acta Pharm. 2003, 53, 101–110. [Google Scholar]

- Wen, P.; Han, Y.; Wu, Z.; He, Y.; Ye, B.-C.; Wang, J. Rapid synthesis of a corncob-based semi-interpenetrating Polymer network slow-release nitrogen fertilizer by microwave irradiation to control water and nutrient losses. Arab. J. Chem. 2017, 10, 922–934. [Google Scholar] [CrossRef]

- Wen, P.; Wu, Z.; He, Y.; Ye, B.-C.; Han, Y.; Wang, J.; Guan, X. Microwave-assisted synthesis of a semi-interpenetrating Polymer network slow-release nitrogen fertilizer with water absorbency from cotton stalks. ACS Sustain. Chem. Eng. 2016, 4, 6572–6579. [Google Scholar] [CrossRef]

| Identification | Bentonite (% w/w) | NPK (% w/w) |

|---|---|---|

| Ecov | - | - |

| Ecov/3NPK | - | 3 |

| Ecov/3Bent | 3 | - |

| Ecov/6Bent | 6 | - |

| Ecov/3Bent/3NPK | 3 | 3 |

| Ecov/6Bent/3NPK | 6 | 3 |

| Identification | Diameter (mm) |

|---|---|

| Ecov | 1.75 ± 0.05 |

| Ecov/3NPK | 1.74 ± 0.07 |

| Ecov/3Bent | 1.76 ± 0.06 |

| Ecov/6Bent | 1.75 ± 0.08 |

| Ecov/3Bent/3NPK | 1.77 ± 0.07 |

| Ecov/6Bent/3NPK | 1.77 ± 0.08 |

| Filling Density | No filling |

| Higher and Lower Layers | 0 |

| Number of Walls | 2 |

| Printing Speed | 30 mm/s |

| Travelling Speed | 50 mm/s |

| Printing Temperature | 170 °C |

| Print Table Temperature | 45 °C |

| Filament Diameter | 1.75 ± 0.10 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, T.C.P.; Fortes, A.G.d.S.; de Abreu, I.R.; de Carvalho, L.H.; de Almeida, Y.M.B.; Alves, T.S.; Barbosa, R. Development of Biodegradable PLA/PBAT-Based Filaments for Fertilizer Release for Agricultural Applications. Materials 2022, 15, 6764. https://doi.org/10.3390/ma15196764

da Silva TCP, Fortes AGdS, de Abreu IR, de Carvalho LH, de Almeida YMB, Alves TS, Barbosa R. Development of Biodegradable PLA/PBAT-Based Filaments for Fertilizer Release for Agricultural Applications. Materials. 2022; 15(19):6764. https://doi.org/10.3390/ma15196764

Chicago/Turabian Styleda Silva, Thyago Camelo Pereira, Allef Gabriel da Silva Fortes, Iago Rodrigues de Abreu, Laura Hecker de Carvalho, Yeda Medeiros Bastos de Almeida, Tatianny Soares Alves, and Renata Barbosa. 2022. "Development of Biodegradable PLA/PBAT-Based Filaments for Fertilizer Release for Agricultural Applications" Materials 15, no. 19: 6764. https://doi.org/10.3390/ma15196764

APA Styleda Silva, T. C. P., Fortes, A. G. d. S., de Abreu, I. R., de Carvalho, L. H., de Almeida, Y. M. B., Alves, T. S., & Barbosa, R. (2022). Development of Biodegradable PLA/PBAT-Based Filaments for Fertilizer Release for Agricultural Applications. Materials, 15(19), 6764. https://doi.org/10.3390/ma15196764