The Development of a Digital Twin Framework for an Industrial Robotic Drilling Process

Abstract

:1. Introduction

2. Robotic Drilling

3. The History of the Digital Twin from Concept Idea to Building Frameworks

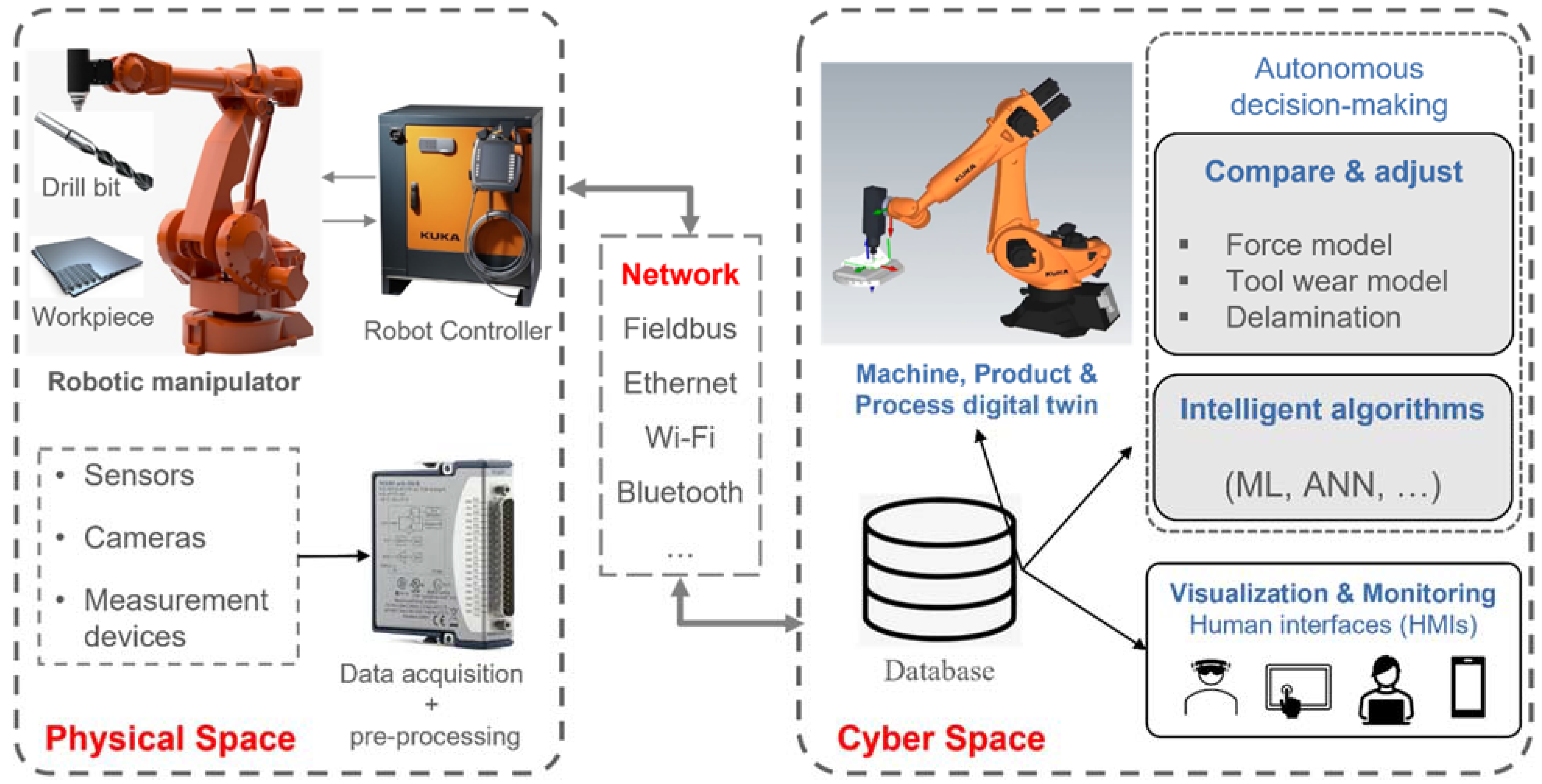

4. Digital Twin Architecture for Robotic Drilling

4.1. Generic Framework

- Machine Digital Twin: This is typically a rigid body dynamics model of the robot manipulator incorporating the end effector and drilling module. The digital twin communicates with the drilling module to record real-time process parameters such as drilling torque, speed, temperature, etc. The drill bit is explicitly incorporated within the machine digital twin.

- Product Digital Twin: In its simplest form this is a computer-aided design (CAD) model of the drilled component, containing information such as: number and location of drilled holes, hole diameter, component geometry, hole quality and residual stress. Some of this information is known a priori, e.g., number of holes, but some are determined either post-manufacture, e.g., hole quality, or through the process digital twin, e.g., residual stress.

- Process Digital Twin: The process digital twin determines the rate of material removal, hole quality, residual stress generated, tool wear and other key parameters. The process digital twin can be used in conjunction with an artificial neural network or other machine learning method for in-line prediction or smart decision making.

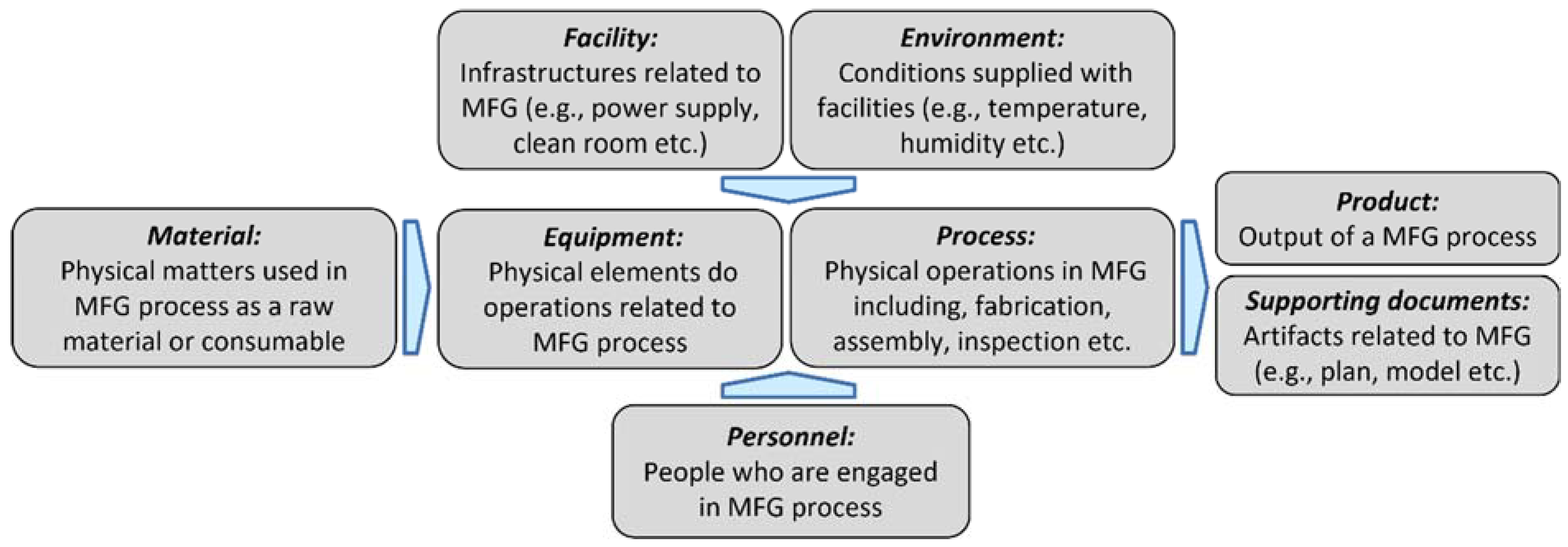

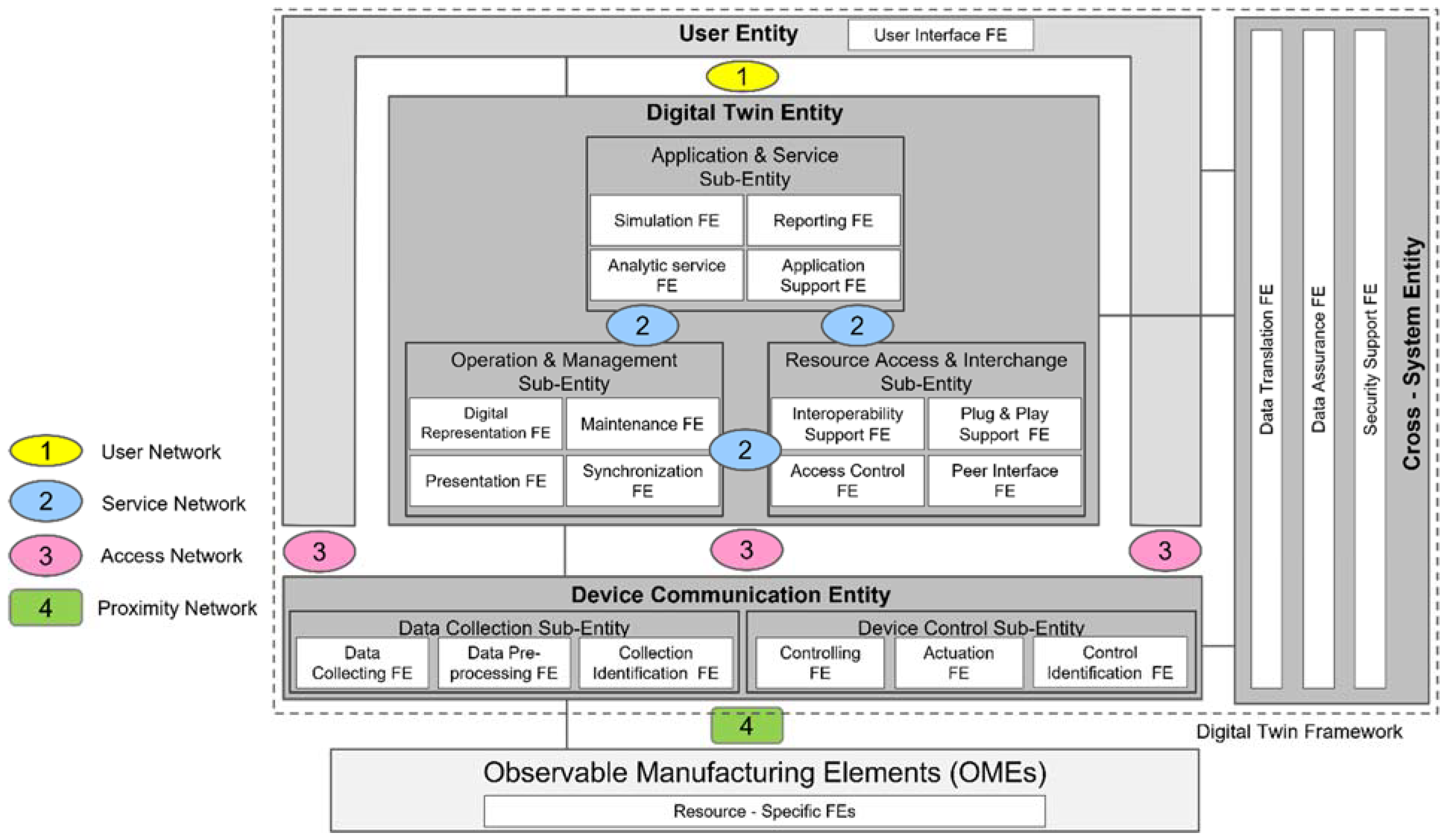

4.2. Digital Twin Framework for Manufacturing Based on ISO 23247

- ISO 10303-238: Product data representation and exchange, model based integrated manufacturing [43]

- ISO 10303-242: Product data representation and exchange, managed model-based 3D engineering [44]

- ISO 13399: Cutting tool data representation and exchange [45]

- ISO 23952: Quality information framework, and integrated model for manufacturing quality information [46]

- MTConnect: Protocol for exchange of information between shop floor devices [37]

- IEC 62541 (OPC-UA): Protocol for machine to machine information exchange [47]

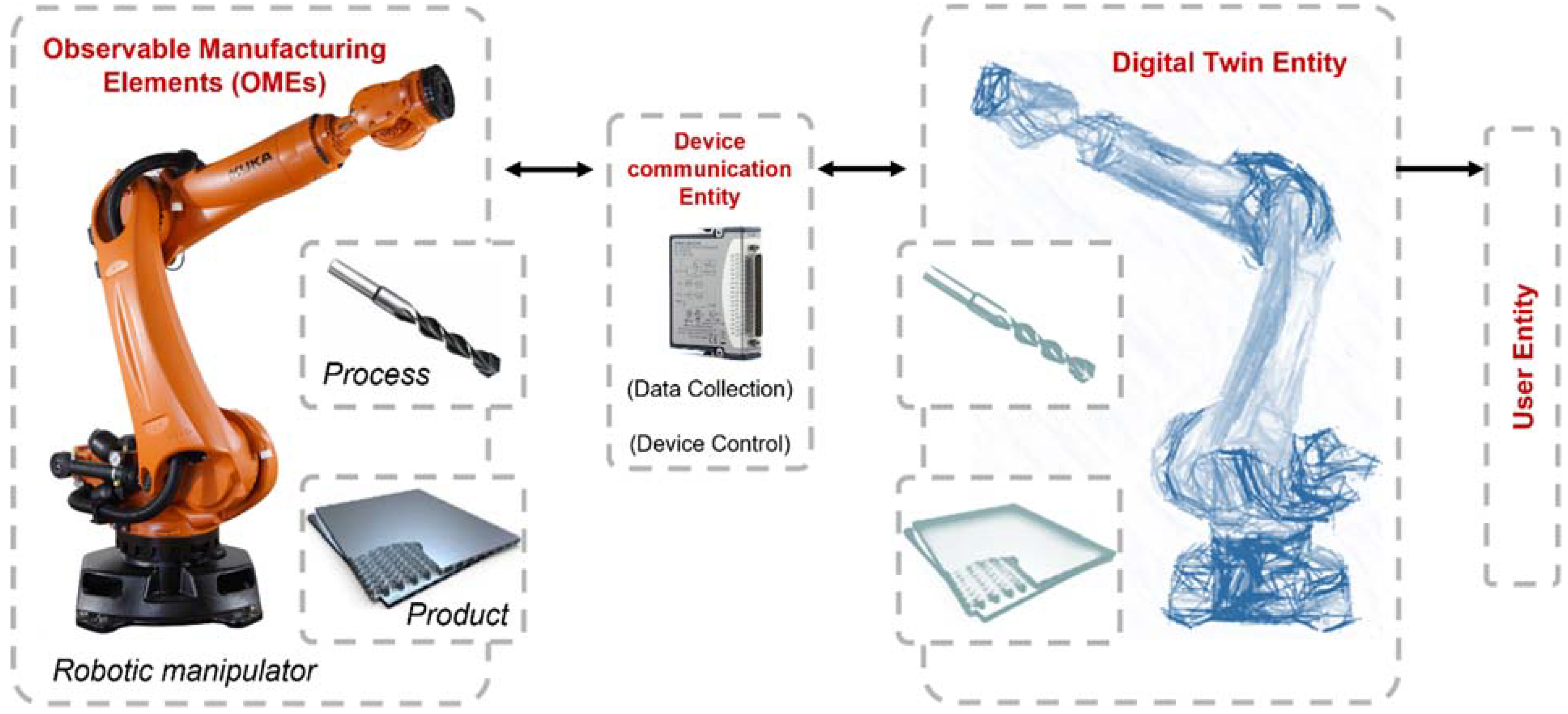

5. Digital Twin Architecture for ISO 23247: A Case Study of Robotic Drilling

- 1-

- Equipment:

- 2-

- Materials:

- 3-

- Product:

- 4-

- Process:

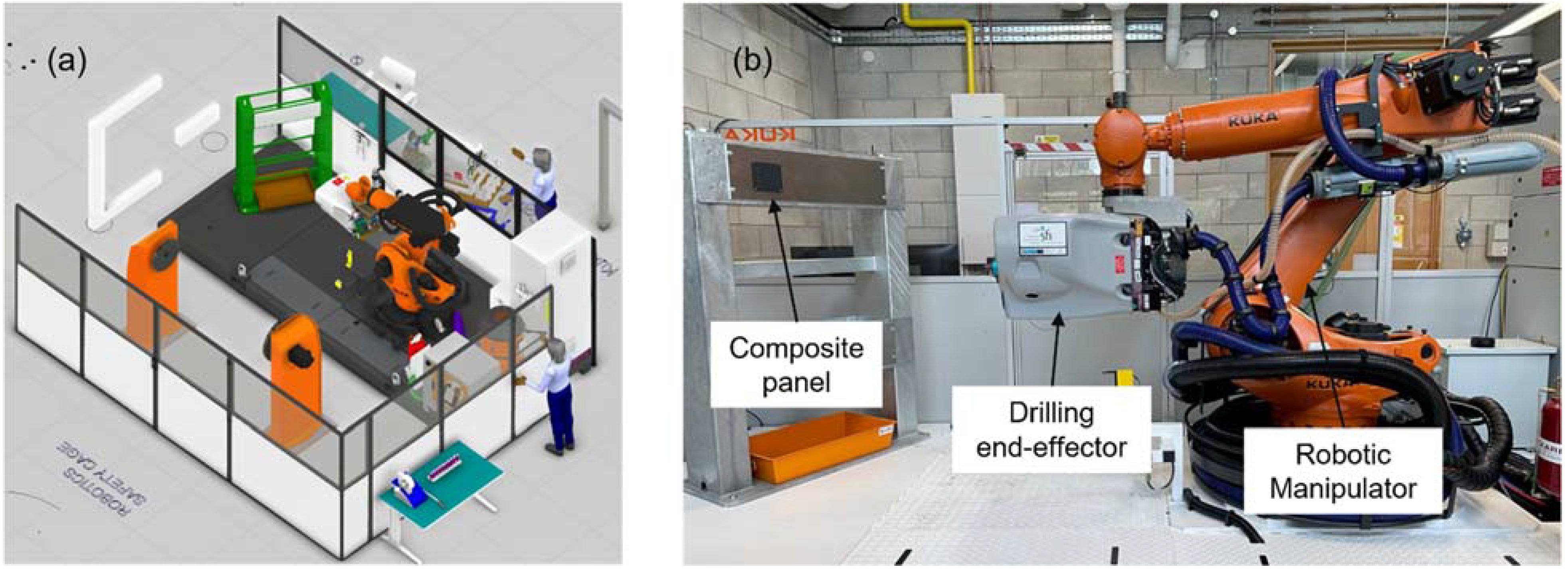

6. Experimental Procedure for Robotic Drilling

- Personnel: Operators, engineers, maintenance staff, research & development staff.

- Facilities: Ventilation, heating, air pump, illumination, vacuum pump, oil/lubrication pump.

- Environment: Temperature, luminance, humidity.

- Supporting documents: Drilling process plan, CAD/CAM files, process measured values, quality control.

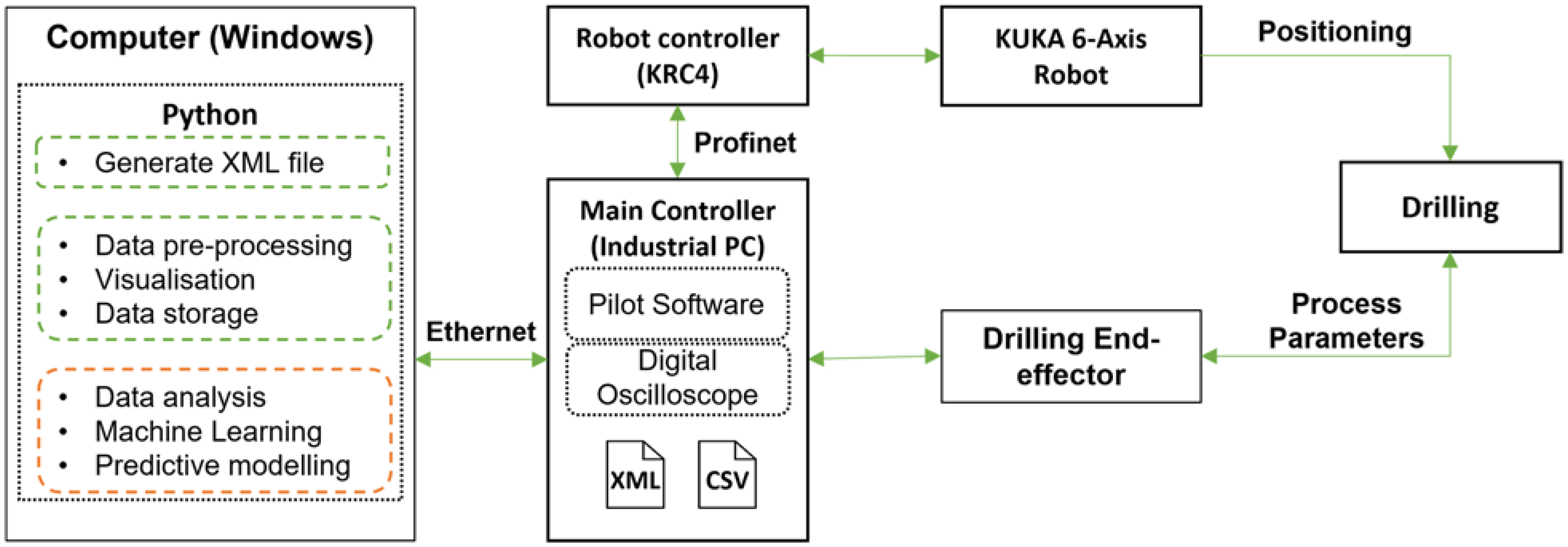

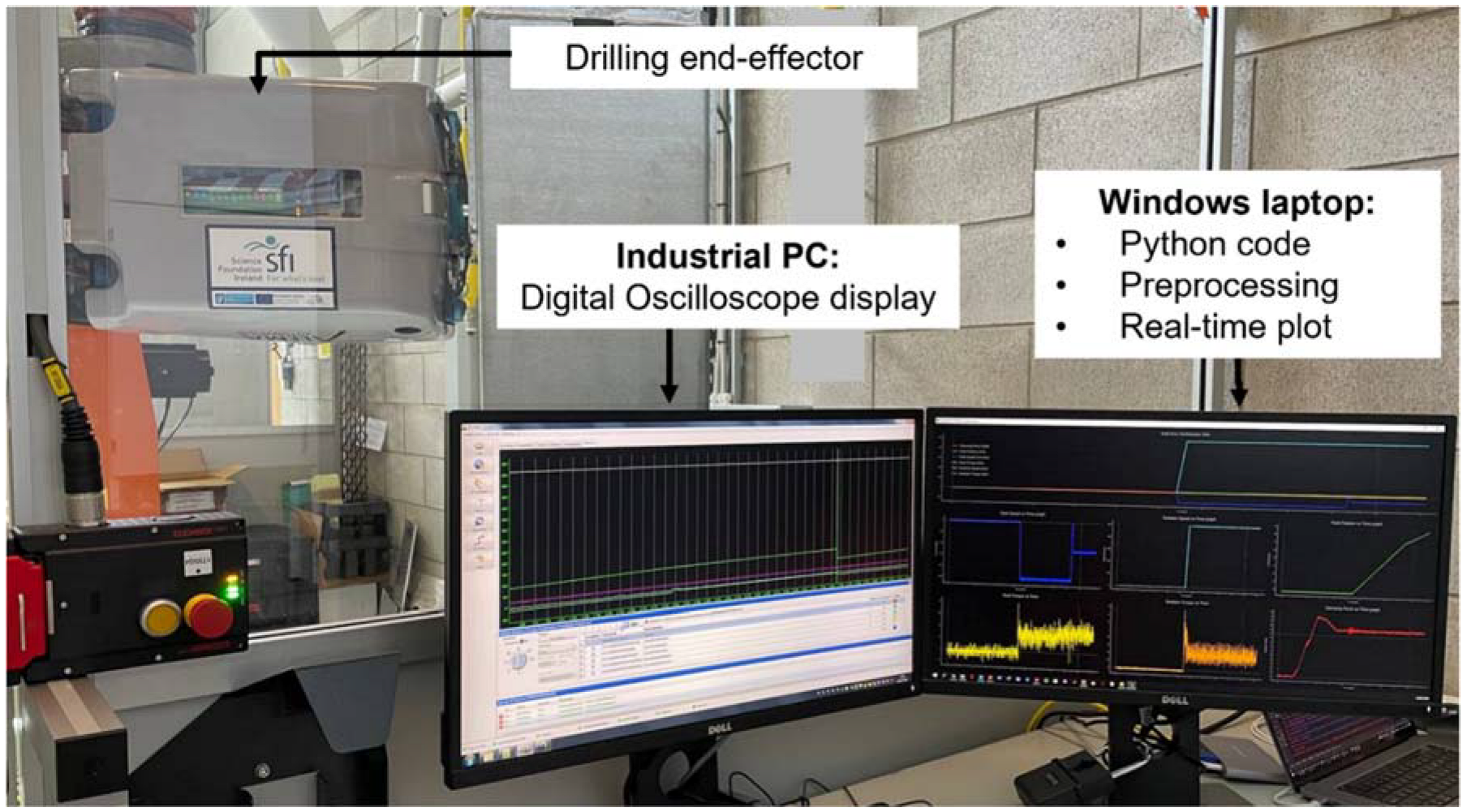

7. Device Communication Entity

8. Advantages of Proposed Framework

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tao, J.; Qin, C.; Xiao, D.; Shi, H.; Ling, X.; Li, B.; Liu, C. Timely chatter identification for robotic drilling using a local maximum synchrosqueezing-based method. J. Intell. Manuf. 2020, 31, 1243–1255. [Google Scholar] [CrossRef]

- Tao, J.; Qin, C.; Xiao, D.; Shi, H.; Liu, C. A pre-generated matrix-based method for real-time robotic drilling chatter monitoring. Chin. J. Aeronaut. 2019, 32, 2755–2764. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.K.; Huang, H.; Xu, X. Digital twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput.-Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Roucoules, L.; Anwer, N. Coevolution of digitalisation, organisations and product development cycle. CIRP Ann. 2021, 70, 519–542. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- ISO 23247-1; Automation Systems and Integration—Digital Twin Framework For Manufacturing—Part 1: Overview and General Principles. ISO: Geneva, Switzerland, 2021.

- Pan, Z.; Zhang, H.; Zhu, Z.; Wang, J. Chatter analysis of robotic machining process. J. Mater. Process. Technol. 2006, 173, 301–309. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Industrial robotic machining: A review. Int. J. Adv. Manuf. Technol. 2019, 103, 1239–1255. [Google Scholar] [CrossRef]

- Verl, A.; Valente, A.; Melkote, S.; Brecher, C.; Ozturk, E.; Tunc, L.T. Robots in machining. CIRP Ann. 2019, 68, 799–822. [Google Scholar] [CrossRef]

- Susemihl, H.; Brillinger, C.; Stürmer, S.P.; Hansen, S.; Boehlmann, C.; Kothe, S.; Wollnack, J.; Hintze, W. Referencing Strategies for High Accuracy Machining of Large Aircraft Components with Mobile Robotic Systems; 0148-7191; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Bogue, R. Finishing robots: A review of technologies and applications. Ind. Robot. Int. J. 2009, 36, 6–12. [Google Scholar] [CrossRef]

- Sabourin, M.; Paquet, F.; Hazel, B.; Côté, J.; Mongenot, P. Robotic approach to improve turbine surface finish. In Proceedings of the 2010 1st International Conference on Applied Robotics for the Power Industry, Montreal, QC, Canada, 5–7 October 2010; pp. 1–6. [Google Scholar]

- Ozturk, E.; Barrios, A.; Sun, C.; Rajabi, S.; Munoa, J. Robotic assisted milling for increased productivity. CIRP Ann. 2018, 67, 427–430. [Google Scholar] [CrossRef]

- Frommknecht, A.; Kuehnle, J.; Effenberger, I.; Pidan, S. Multi-sensor measurement system for robotic drilling. Robot. Comput.-Integr. Manuf. 2017, 47, 4–10. [Google Scholar] [CrossRef]

- Möller, C.; Schmidt, H.C.; Koch, P.; Böhlmann, C.; Kothe, S.-M.; Wollnack, J.; Hintze, W. Machining of large scaled cfrp-parts with mobile cnc-based robotic system in aerospace industry. Procedia Manuf. 2017, 14, 17–29. [Google Scholar] [CrossRef]

- Bi, S.; Liang, J. Robotic drilling system for titanium structures. Int. J. Adv. Manuf. Technol. 2010, 54, 767–774. [Google Scholar] [CrossRef]

- Schneider, U.; Drust, M.; Ansaloni, M.; Lehmann, C.; Pellicciari, M.; Leali, F.; Gunnink, J.W.; Verl, A. Improving robotic machining accuracy through experimental error investigation and modular compensation. Int. J. Adv. Manuf. Technol. 2016, 85, 3–15. [Google Scholar] [CrossRef]

- Posada, J.D.; Schneider, U.; Pidan, S.; Geravand, M.; Stelzer, P.; Verl, A. High accurate robotic drilling with external sensor and compliance model-based compensation. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 3901–3907. [Google Scholar]

- Olsson, T.; Haage, M.; Kihlman, H.; Johansson, R.; Nilsson, K.; Robertsson, A.; Björkman, M.; Isaksson, R.; Ossbahr, G.; Brogårdh, T. Cost-efficient drilling using industrial robots with high-bandwidth force feedback. Robot. Comput.-Integr. Manuf. 2010, 26, 24–38. [Google Scholar] [CrossRef]

- Grieves, M. Origins of the digital twin concept. FLA Inst. Technol. 2016. [Google Scholar] [CrossRef]

- Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Draft modeling, simulation, information technology and processing roadmap. Natl. Aeronaut. Space Adm. 2010, 11, 1–32. [Google Scholar]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future nasa and us air force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Panetta, K. Gartners Top 10 Technology Trends 2017. Available online: https://www.gartner.com/smarterwithgartner/gartners-top-10-technology-trends-2017 (accessed on 20 June 2022).

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Xiong, M.; Wang, H. Digital twin applications in aviation industry: A review. Int. J. Adv. Manuf. Technol. 2022, 121, 5677–5692. [Google Scholar] [CrossRef]

- Fang, X.; Wang, H.; Liu, G.; Tian, X.; Ding, G.; Zhang, H. Industry application of digital twin: From concept to implementation. Int. J. Adv. Manuf. Technol. 2022, 121, 4289–4312. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, R.; Liu, S.; Lv, Q.; Bao, J.; Li, J. A digital twin-driven human–robot collaborative assembly-commissioning method for complex products. Int. J. Adv. Manuf. Technol. 2021, 118, 3389–3402. [Google Scholar] [CrossRef]

- Maruyama, T.; Ueshiba, T.; Tada, M.; Toda, H.; Endo, Y.; Domae, Y.; Nakabo, Y.; Mori, T.; Suita, K. Digital twin-driven human robot collaboration using a digital human. Sensors 2021, 21, 8266. [Google Scholar] [CrossRef]

- Laudante, E.; Greco, A.; Caterino, M.; Fera, M. Human–robot interaction for improving fuselage assembly tasks: A case study. Appl. Sci. 2020, 10, 5757. [Google Scholar] [CrossRef]

- Lv, Q.; Zhang, R.; Sun, X.; Lu, Y.; Bao, J. A digital twin-driven human-robot collaborative assembly approach in the wake of COVID-19. J. Manuf. Syst. 2021, 60, 837–851. [Google Scholar] [CrossRef]

- Liu, C.; Vengayil, H.; Zhong, R.Y.; Xu, X. A systematic development method for cyber-physical machine tools. J. Manuf. Syst. 2018, 48, 13–24. [Google Scholar] [CrossRef]

- Liu, S.; Bao, J.; Lu, Y.; Li, J.; Lu, S.; Sun, X. Digital twin modeling method based on biomimicry for machining aerospace components. J. Manuf. Syst. 2021, 58, 180–195. [Google Scholar] [CrossRef]

- Liu, C.; Vengayil, H.; Lu, Y.; Xu, X. A cyber-physical machine tools platform using opc ua and mtconnect. J. Manuf. Syst. 2019, 51, 61–74. [Google Scholar] [CrossRef]

- Fujishima, M.; Ohno, K.; Nishikawa, S.; Nishimura, K.; Sakamoto, M.; Kawai, K. Study of sensing technologies for machine tools. CIRP J. Manuf. Sci. Technol. 2016, 14, 71–75. [Google Scholar] [CrossRef]

- MTConnect Institute. Mtconnect Standard; MTConnect Institute: McLean, VA, USA, 2008. [Google Scholar]

- OPC Foundation. The Opc Unified Architecture; OPC Foundation: Scottsdale, AZ, USA, 2008. [Google Scholar]

- Hinchy, E.; O’Dowd, N.P.; McCarthy, C.T. Using open-source microcontrollers to enable digital twin communication for smart manufacturing. Procedia Manuf. 2019, 38, 1213–1219. [Google Scholar] [CrossRef]

- ISO 23247-2; Automation Systems and Integration—Digital Twin Framework for Manufacturing—Part 2: Reference Architecture. ISO: Geneva, Switzerland, 2021.

- ISO 23247-3; Automation Systems and Integration—Digital Twin Framework for Manufacturing—Part 3: Digital Representation of Manufacturing Elements. ISO: Geneva, Switzerland, 2021.

- ISO 23247-4; Automation Systems and Integration—Digital Twin Framework for Manufacturing—Part 4: Information Exchange. ISO: Geneva, Switzerland, 2021.

- ISO 10303-238; Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 238: Application Protocol: Model Based Integrated Manufacturing. ISO: Geneva, Switzerland, 2020.

- ISO 10303-242; Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 242: Application Protocol: Managed Model-Based 3d Engineering. ISO: Geneva, Switzerland, 2020.

- ISO 13399-1; Cutting Tool Data Representation and Exchange—Part 1: Overview, Fundamental Principles and General Information Model. ISO: Geneva, Switzerland, 2006.

- ISO 23952; Automation Systems and Integration—Quality Information Framework (qif)—An Integrated Model for Manufacturing Quality Information. ISO: Geneva, Switzerland, 2020.

- IEC 62541-1; Opc Unified Architecture—Part 1: Overview and Concepts. IEC: Geneva, Switzerland, 2020.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farhadi, A.; Lee, S.K.H.; Hinchy, E.P.; O’Dowd, N.P.; McCarthy, C.T. The Development of a Digital Twin Framework for an Industrial Robotic Drilling Process. Sensors 2022, 22, 7232. https://doi.org/10.3390/s22197232

Farhadi A, Lee SKH, Hinchy EP, O’Dowd NP, McCarthy CT. The Development of a Digital Twin Framework for an Industrial Robotic Drilling Process. Sensors. 2022; 22(19):7232. https://doi.org/10.3390/s22197232

Chicago/Turabian StyleFarhadi, Ahmad, Stephen K. H. Lee, Eoin P. Hinchy, Noel P. O’Dowd, and Conor T. McCarthy. 2022. "The Development of a Digital Twin Framework for an Industrial Robotic Drilling Process" Sensors 22, no. 19: 7232. https://doi.org/10.3390/s22197232