Rheological Behavior of Passion Fruit (Passiflora edulis) Peel Extract

Abstract

:1. Introduction

2. Results and Discussion

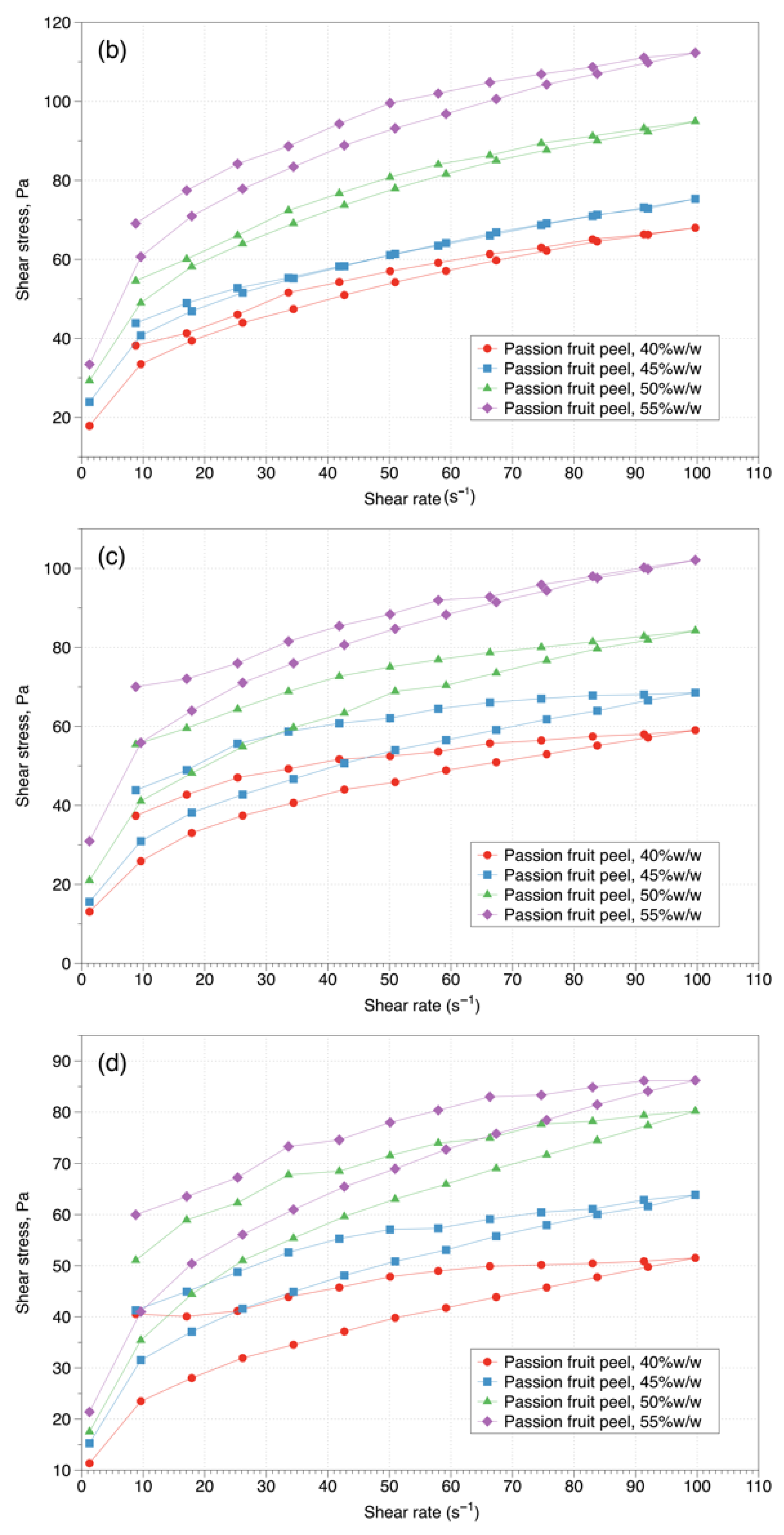

2.1. The Behavior to the Flow of Passion Fruit Peel Extract

2.2. Viscoelasticity of Passion Fruit Peel Extracts

3. Conclusions

4. Materials and Methods

4.1. Raw Material

4.2. Preparation of Passion Fruit Peel Extract

4.3. The Behavior to the Flow of Passion Fruit Peel Extract

4.4. Temperature Sweep Test for Passion Fruit Peel Extract

4.5. Experimental Design

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeraik, M.L.; Serteyn, D.; Deby-Dupont, G.; Wauters, J.N.; Tits, M.; Yariwake, J.H.; Angenot, L.; Franck, T. Evaluation of the antioxidant activity of passion fruit (Passiflora edulis and Passiflora alata) extracts on stimulated neutrophils and myeloperoxidase activity assays. Food Chem. 2011, 128, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Laboissière, L.H.E.S.; Deliza, R.; Barros-Marcellini, A.M.; Rosenthal, A.; Camargo, L.M.A.Q.; Junqueira, R.G. Effects of high hydrostatic pressure (HHP) on sensory characteristics of yellow passion fruit juice. Innov. Food Sci. Emerg. Technol. 2007, 8, 469–477. [Google Scholar] [CrossRef]

- Wijeratnam, S.W. Passion Fruit; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 230–234. [Google Scholar] [CrossRef]

- Coelho, E.M.; Gomes, R.G.; Machado, B.A.S.; Oliveira, R.S.; dos Santos Lima, M.; de Azêvedo, L.C.; Guez, M.A.U. Passion fruit peel flour—Technological properties and application in food products. Food Hydrocoll. 2017, 62, 158–164. [Google Scholar] [CrossRef]

- de Oliveira, C.F.; Giordani, D.; Lutckemier, R.; Gurak, P.D.; Cladera-Olivera, F.; Marczak, L.D.F. Extraction of pectin from passion fruit peel assisted by ultrasound. LWT-Food Sci. Technol. 2016, 71, 110–115. [Google Scholar] [CrossRef]

- López-Vargas, J.H.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, Physico-chemical, Technological, Antibacterial and antioxidant properties of dietary fiber powder obtained from yellow passion fruit (Passiflora edulis var. flavicarpa) co-products. Food Res. Int. 2013, 51, 756–763. [Google Scholar] [CrossRef]

- Seixas, F.L.; Fukuda, D.L.; Turbiani, F.R.B.; Garcia, P.S.; Petkowicz, C.L.d.O.; Jagadevan, S.; Gimenes, M.L. Extraction of pectin from passion fruit peel (Passiflora edulis f.flavicarpa) by microwave-induced heating. Food Hydrocoll. 2014, 38, 186–192. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.F.; Vega-Vega, V.; Rosas-Domínguez, C.; Palafox-Carlos, H.; Villa-Rodriguez, J.A.; Siddiqui, M.W.; Dávila-Aviña, J.E.; González-Aguilar, G.A. Agro-industrial potential of exotic fruit byproducts as a source of food additives. Food Res. Int. 2011, 44, 1866–1874. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S. Chapter 2—Classification, Technological Properties, and Sustainable Sources. In Dietary Fiber: Properties, Recovery, and Applications; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 27–58. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Ibarz, A. Operaciones Unitarias en la Ingeniería de Alimentos; Mundi-Prensa: Madrid, España, 2005. [Google Scholar]

- Díaz-Ocampo, R.; Sánchez, R.; Franco, J.M. Rheology of commercial and model borojó jam formulations. Int. J. Food Prop. 2014, 17, 791–805. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: Dallas, TX, USA, 1992. [Google Scholar]

- Matos, A.; Aguilar, D. Influencia de la Temperatura y Concentración sobre el Comportamiento Reológico de la Pulpa de Tuna (Opuntia ficus Indica). Rev. Investig. Cienc. Tecnol. Aliment. 2010, 1, 8. Available online: https://revistas.upeu.edu.pe/index.php/ri_alimentos/article/view/820/788 (accessed on 3 February 2022).

- De Mello, F.R.; Bernardo, C.; Dias, C.O.; Züge, L.C.B.; Silveira, J.L.M.; Amante, E.R.; Candido, L.M.B. Evaluation of the chemical characteristics and rheological behavior of pitaya (Hylocereus undatus) peel. Fruits 2014, 69, 381–390. [Google Scholar] [CrossRef]

- Ocampo, R.D.; Zapateiro, L.G.; Gómez, J.M.F.; Torres, C.V. Caracterización bromatológica, fisicoquímica microbiológica y reológica de la pulpa de borojó (Borojoa patinoi Cuatrec). Cienc. Tecnol. 2012, 5, 17–24. [Google Scholar] [CrossRef]

- Vandresen, S.; Quadri, M.G.N.; de Souza, J.A.R.; Hotza, D. Temperature effect on the rheological behavior of carrot juices. J. Food Eng. 2009, 92, 269–274. [Google Scholar] [CrossRef]

- Santos, M.; Correia, C.; Petkowicz, C.; Candido, L. Evaluation of the Technological Potential of Gabiroba [Campomanesia xanthocarpa Berg] Fruit. J. Nutr. Food Sci. 2012, 2, 1–7. [Google Scholar] [CrossRef]

- Andrade, R.D.; Torres, R.; Montes, E.J.; Pérez, O.A.; Restan, L.E.; Peña, R.E. Efecto de la temperatura en el comportamiento reológico de la pulpa de níspero (Achras sapota L.). Rev. Fac. Agron. 2009, 26, 599–612. [Google Scholar]

- Deng, Z.; Pan, Y.; Chen, W.; Chen, W.; Yun, Y.; Zhong, Q.; Zhang, W.; Chen, H. Effects of cultivar and growth region on the structural, emulsifying and rheological characteristic of mango peel pectin. Food Hydrocoll. 2020, 103, 105707. [Google Scholar] [CrossRef]

- Wang, W.; Ma, X.; Jiang, P.; Hu, L.; Zhi, Z.; Chen, J.; Ding, T.; Ye, X.; Liu, D. Characterization of pectin from grapefruit peel: A comparison of ultrasound-assisted and conventional heating extractions. Food Hydrocoll. 2016, 61, 730–739. [Google Scholar] [CrossRef]

- Yang, X.; Nisar, T.; Hou, Y.; Gou, X.; Sun, L.; Guo, Y. Pomegranate peel pectin can be used as an effective emulsifier. Food Hydrocoll. 2018, 85, 30–38. [Google Scholar] [CrossRef]

- Barbieri, S.F.; Petkowicz, C.L.d.; de Godoy, R.C.B.; de Azeredo, H.C.M.; Franco, C.R.C.; Silveira, J.L.M. Pulp and Jam of Gabiroba (Campomanesia xanthocarpa Berg): Characterization and Rheological Properties. Food Chem. 2018, 263, 292–299. [Google Scholar] [CrossRef]

- Villacorta, L.M.; Vásquez, C.P.; Jara, R.S. Efecto de la temperatura y concentración de sólidos solubles sobre las propiedades reológicas de la pulpa de guanábana (Annona muricata L.). Pueblo Cont. 2012, 23, 113–124. Available online: http://journal.upao.edu.pe/PuebloContinente/article/view/356/323 (accessed on 3 February 2022).

- Dutta, D.; Dutta, A.; Raychaudhuri, U.; Chakraborty, R. Rheological characteristics and thermal degradation kinetics of beta-carotene in pumpkin puree. J. Food Eng. 2006, 76, 538–546. [Google Scholar] [CrossRef]

- Andrade, R.; Ortega, F.A.; Montes, E.J.; Torres, R.; Pérez, O.A.; Castro, M.; Gutiérrez, L.A. Caracterización Fisicoquímica y reológica de la pulpa de guayaba (Psidium guajava L.) variedades híbrido de Klom Sali, Puerto Rico, D14 y red. Vitae 2009, 16, 13–18. [Google Scholar]

- Andrade, R.; Torres, R.; Montes, E.J.; Pérez, O.A.; Bustamante, C.E.; Mora, B.B. Efecto de la temperatura en el comportamiento reológico de la pulpa de zapote (Calocarpum sapota Merr). Rev. Tec. Fac. Ing. Univ. Zulia 2010, 33, 138–144. [Google Scholar]

- Ortega, F.A.; Salcedo, E.; Arrieta, R.; Torres, R. Efecto de la temperatura y concentración sobre las propiedades reológicas de la pulpa de mango variedad Tommy Atkins. Rev. ION 2015, 28, 79–92. [Google Scholar] [CrossRef]

- Abboud, K.Y.; Iacomini, M.; Simas, F.F.; Cordeiro, L.M.C. High methoxyl pectin from the soluble dietary fiber of passion fruit peel forms weak gel without the requirement of sugar addition. Carbohydr. Polym. 2020, 246, 116616. [Google Scholar] [CrossRef] [PubMed]

- Lundberg, B.; Pan, X.; White, A.; Chau, H.; Hotchkiss, A. Rheology and composition of citrus fiber. J. Food Eng. 2014, 125, 97–104. [Google Scholar] [CrossRef]

- Gómez-Díaz, D.; Navaza, J.M.; Quintáns-Riveiro, L.C. Intrinsic viscosity and flow behaviour of arabic gum aqueous solutions. Int. J. Food Prop. 2008, 11, 773–780. [Google Scholar] [CrossRef]

- Rasidek, N.A.M.; Nordin, M.F.M.; Iwamoto, K.; Rahman, N.A.; Nagatsu, Y.; Tokuyama, H. Rheological flow models of banana peel pectin jellies as affected by sugar concentration. Int. J. Food Prop. 2018, 21, 2087–2099. [Google Scholar] [CrossRef]

- Muñoz-Puentes, E.; Rubio, L.A.; Cabeza, M.S. Comportamiento de flujo y caracterización fisicoquímica de pulpas de durazno. Sci. Agropecu. 2012, 3, 107–116. [Google Scholar]

- Koocheki, A.; Ghandi, A.; Razavi, S.M.; Mortazavi, S.A.; Vasiljevic, T. The rheological properties of ketchup as a function of different hydrocolloids and temperature. Int. J. Food Sci. Technol. 2009, 44, 596–602. [Google Scholar] [CrossRef]

- Mubarok, A.Z.; Ananda, F.Y. Effect of concentration of porang flour and temperature on rheological properties of tomato ketchup. IOP Conf. Ser. Earth Environ. Sci. 2020, 475, 012034. [Google Scholar] [CrossRef]

- do Nascimento, G.E.; Iacomini, M.; Cordeiro, L.M.C. A comparative study of mucilage and pulp polysaccharides from tamarillo fruit (Solanum betaceum Cav.). Plant Physiol. Biochem. 2016, 104, 278–283. [Google Scholar] [CrossRef] [PubMed]

- Ramos, A.M.; Ibarz, A. Comportamiento viscoelástico de pulpa de membrillo en función de la concentración de sólidos solubles. Food Sci. Technol. 2006, 26, 214–219. [Google Scholar] [CrossRef]

- Lozano, E.J.; Andrade, R.D.; Salcedo, J.G. Functional and rheological properties of Yam (Dioscorea rotundata) mucilage. Adv. J. Food Sci. Technol. 2018, 15, 134–142. [Google Scholar] [CrossRef]

| Peel Content in the Extract, %w/w | T, °C | k, Pa sn | n | Thixotropy, % | R2 |

|---|---|---|---|---|---|

| 40 | 5 | 23.90 ± 2.45 | 0.261 ± 0.006 | 2.45 ± 0.05 | 0.995 |

| 10 | 24.35 ± 2.62 | 0.252 ± 0.007 | 1.03 ± 0.01 | 0.996 | |

| 25 | 19.14 ± 0.61 | 0.237 ± 0.009 | 1.74 ± 0.02 | 0.996 | |

| 40 | 17.10 ± 2.39 | 0.230 ± 0.011 | 0.20 ± 0.01 | 0.997 | |

| 45 | 5 | 24.10 ± 2.07 | 0.250 ± 0.031 | 2.36 ± 0.01 | 0.996 |

| 10 | 25.72 ± 2.85 | 0.277 ± 0.008 | 1.65 ± 0.02 | 0.996 | |

| 25 | 20.94 ± 2.86 | 0.222 ± 0.015 | 0.84 ± 0.01 | 0.996 | |

| 40 | 17.51 ± 1.90 | 0.261 ± 0.003 | 1.51 ± 0.01 | 0.996 | |

| 50 | 5 | 29.85 ± 2.49 | 0.245 ± 0.011 | 0.04 ± 0.01 | 0.996 |

| 10 | 29.47 ± 1.49 | 0.236 ± 0.016 | 1.22 ± 0.01 | 0.996 | |

| 25 | 23.36 ± 1.17 | 0.287 ± 0.004 | 0.04 ± 0.01 | 0.995 | |

| 40 | 22.97 ± 2.93 | 0.235 ± 0.007 | 1.72 ± 0.02 | 0.996 | |

| 55 | 5 | 39.10 ± 3.16 | 0.228 ± 0.016 | 2.55 ± 0.03 | 0.996 |

| 10 | 38.47 ± 1.53 | 0.023 ± 0.017 | 0.65 ± 0.02 | 0.996 | |

| 25 | 35.60 ± 3.23 | 0.263 ± 0.017 | 1.05 ± 0.01 | 0.998 | |

| 40 | 31.33 ± 2.12 | 0.240 ± 0.006 | 0.51 ± 0.01 | 0.995 |

| Peel Content in the Extract, %w/w | k0, Pa sn | Ea, J mol−1 K−1 | R2 |

|---|---|---|---|

| 5 | 0.87 ± 0.15 | 7714.8 ± 0.8 | 0.944 |

| 10 | 1.03 ± 2.62 | 7423.1 ± 0.7 | 0.878 |

| 25 | 2.08 ± 0.61 | 6163.7 ± 0.9 | 0.901 |

| 40 | 5.55 ± 2.39 | 4545.0 ± 0.01 | 0.966 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrieta-Durango, C.; Henao-Rivas, L.; Andrade-Pizarro, R. Rheological Behavior of Passion Fruit (Passiflora edulis) Peel Extract. Gels 2022, 8, 566. https://doi.org/10.3390/gels8090566

Arrieta-Durango C, Henao-Rivas L, Andrade-Pizarro R. Rheological Behavior of Passion Fruit (Passiflora edulis) Peel Extract. Gels. 2022; 8(9):566. https://doi.org/10.3390/gels8090566

Chicago/Turabian StyleArrieta-Durango, Carlos, Luis Henao-Rivas, and Ricardo Andrade-Pizarro. 2022. "Rheological Behavior of Passion Fruit (Passiflora edulis) Peel Extract" Gels 8, no. 9: 566. https://doi.org/10.3390/gels8090566

APA StyleArrieta-Durango, C., Henao-Rivas, L., & Andrade-Pizarro, R. (2022). Rheological Behavior of Passion Fruit (Passiflora edulis) Peel Extract. Gels, 8(9), 566. https://doi.org/10.3390/gels8090566