A Review on Characteristics, Techniques, and Waste-to-Energy Aspects of Municipal Solid Waste Management: Bangladesh Perspective

Abstract

:1. Introduction

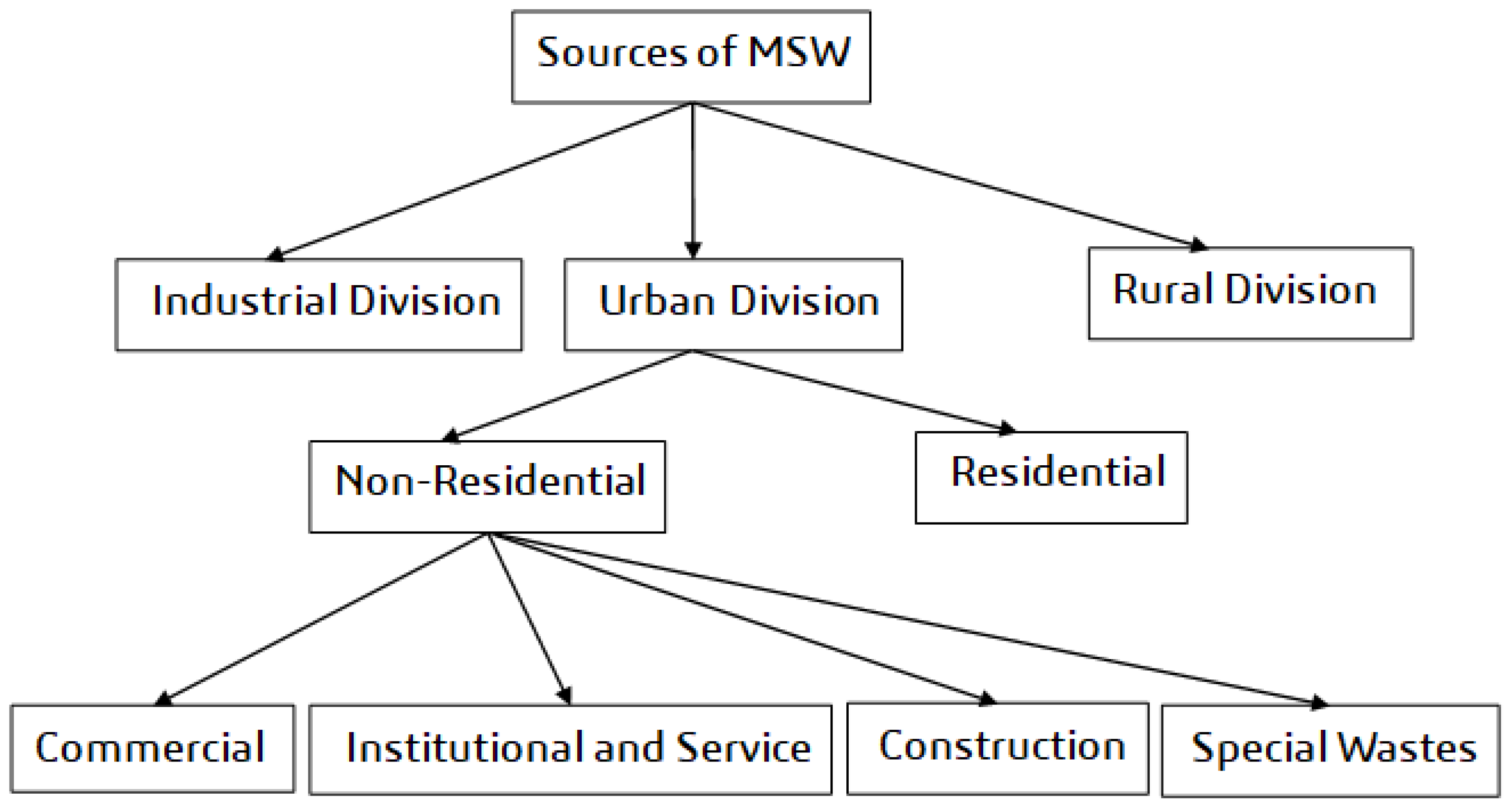

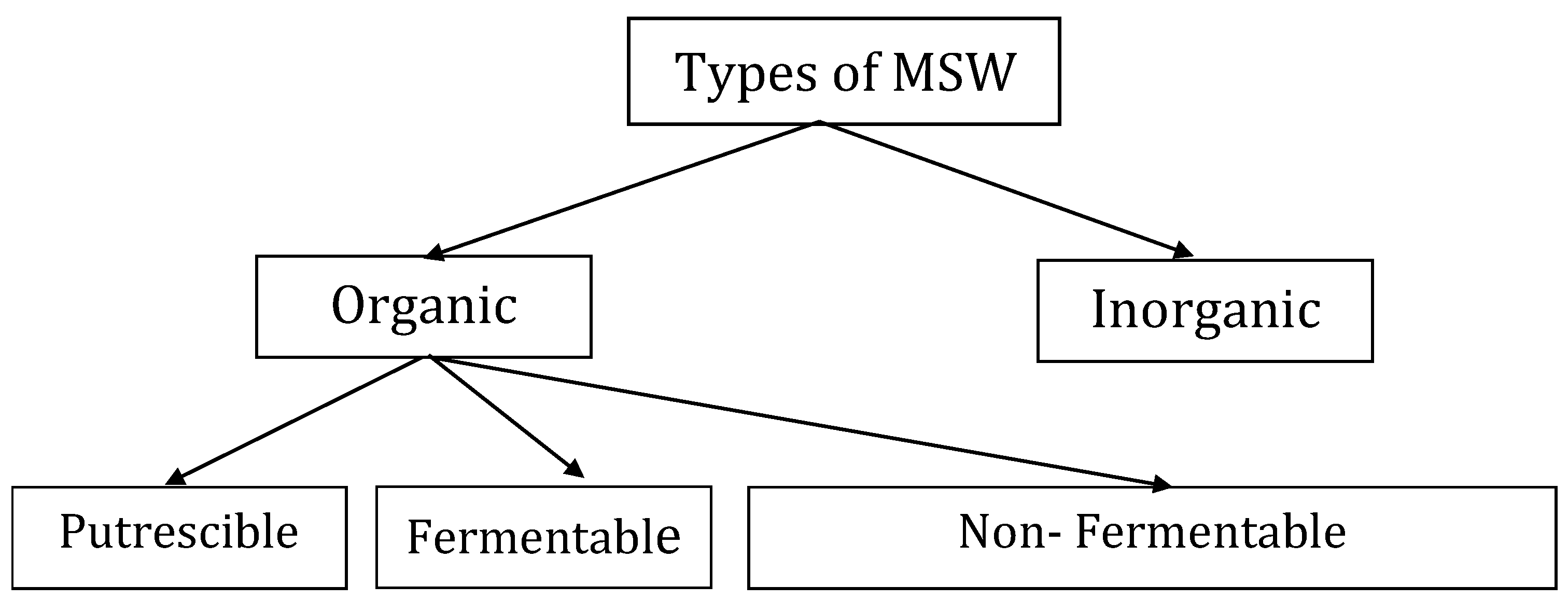

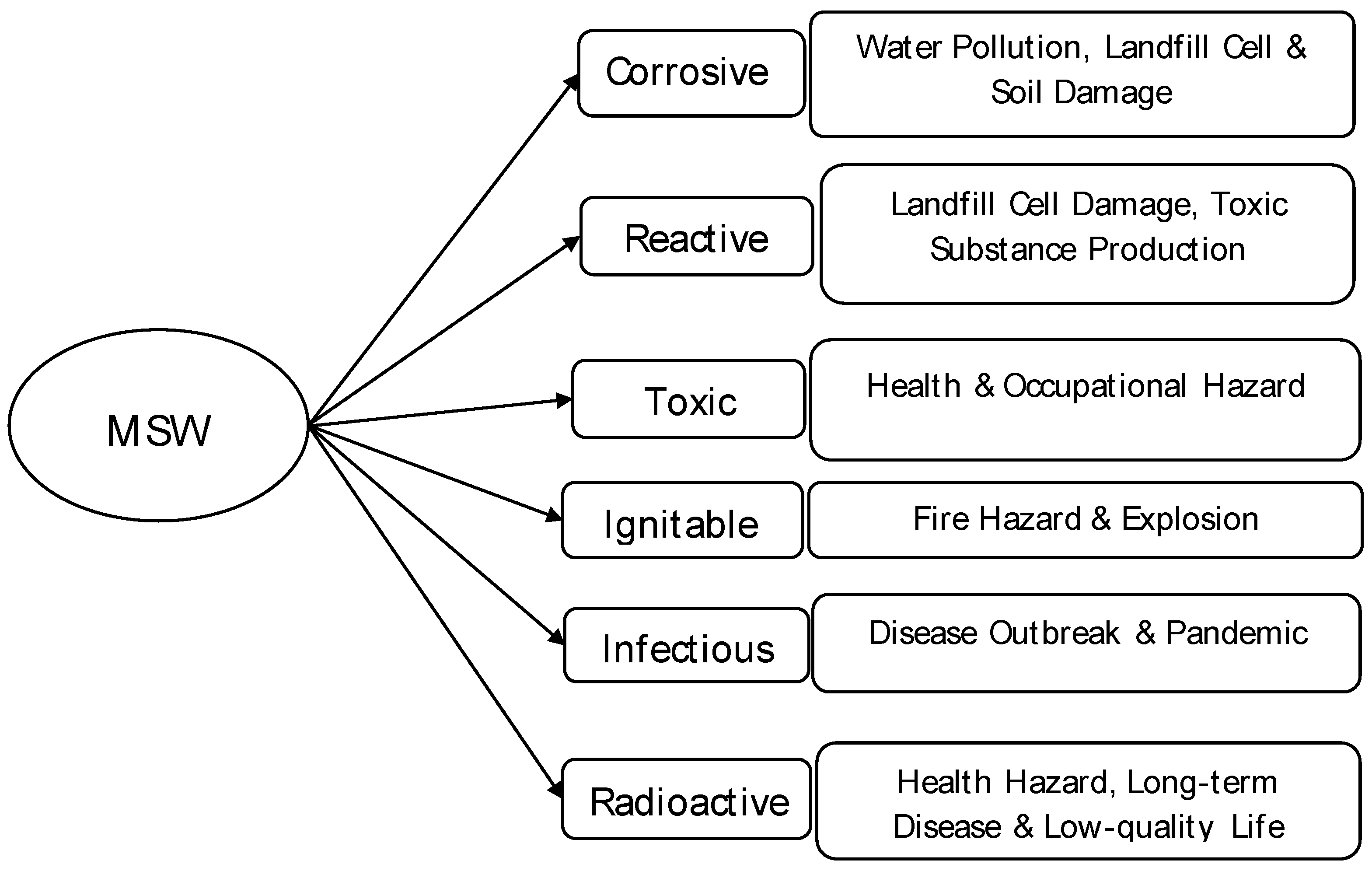

2. MSW Characteristics

3. MSW Collection and Transportation

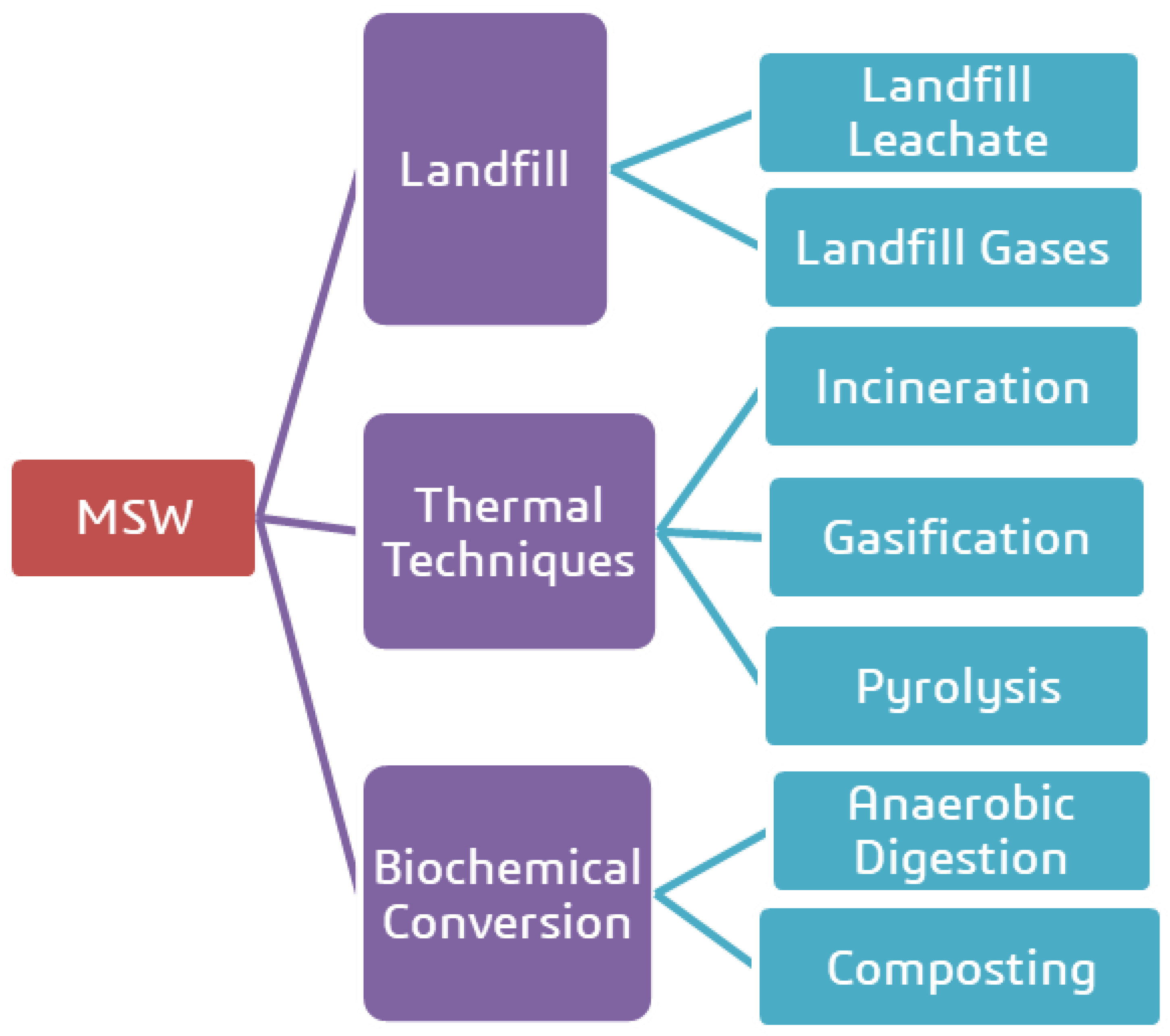

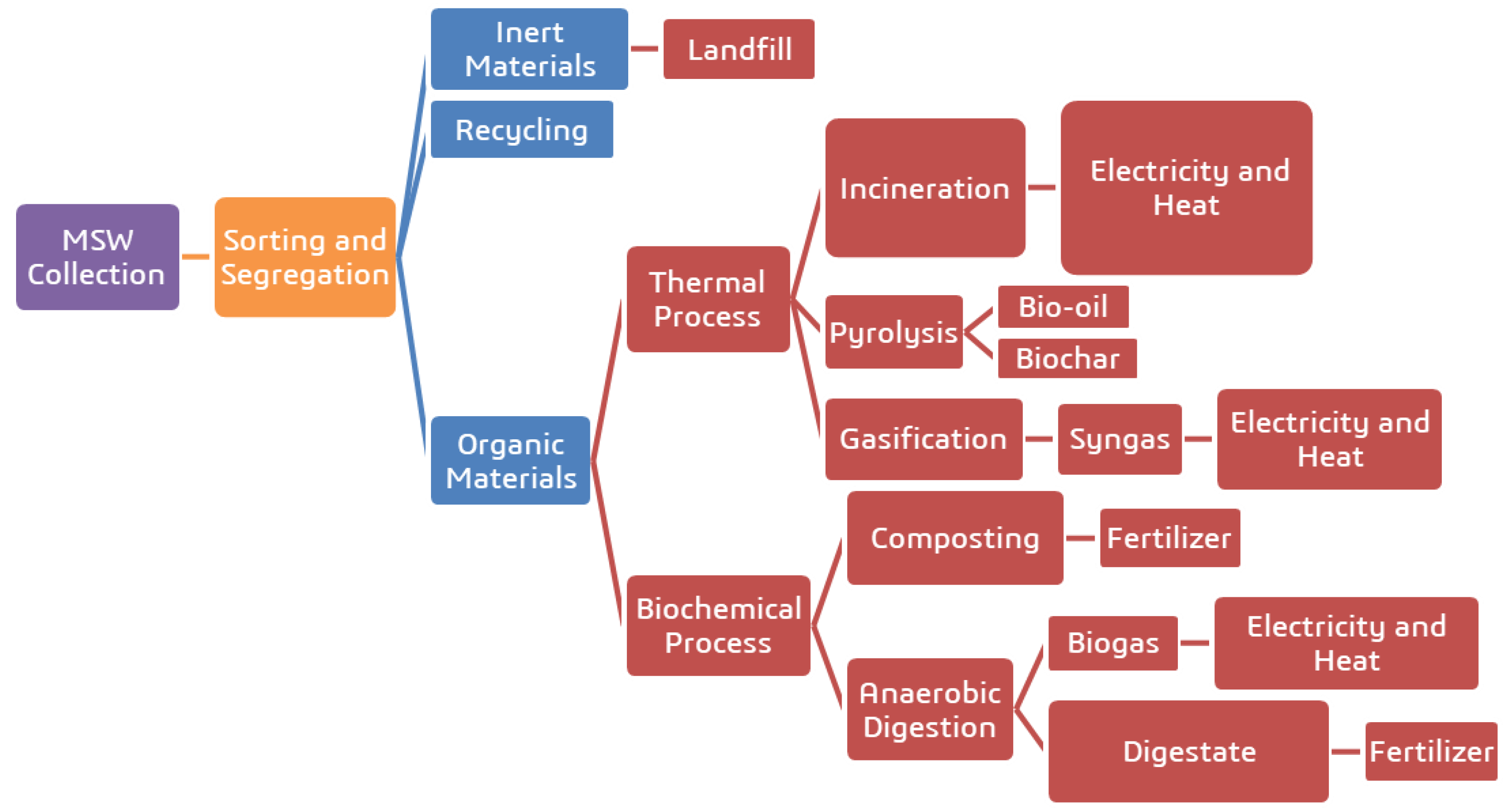

4. MSW Management Techniques

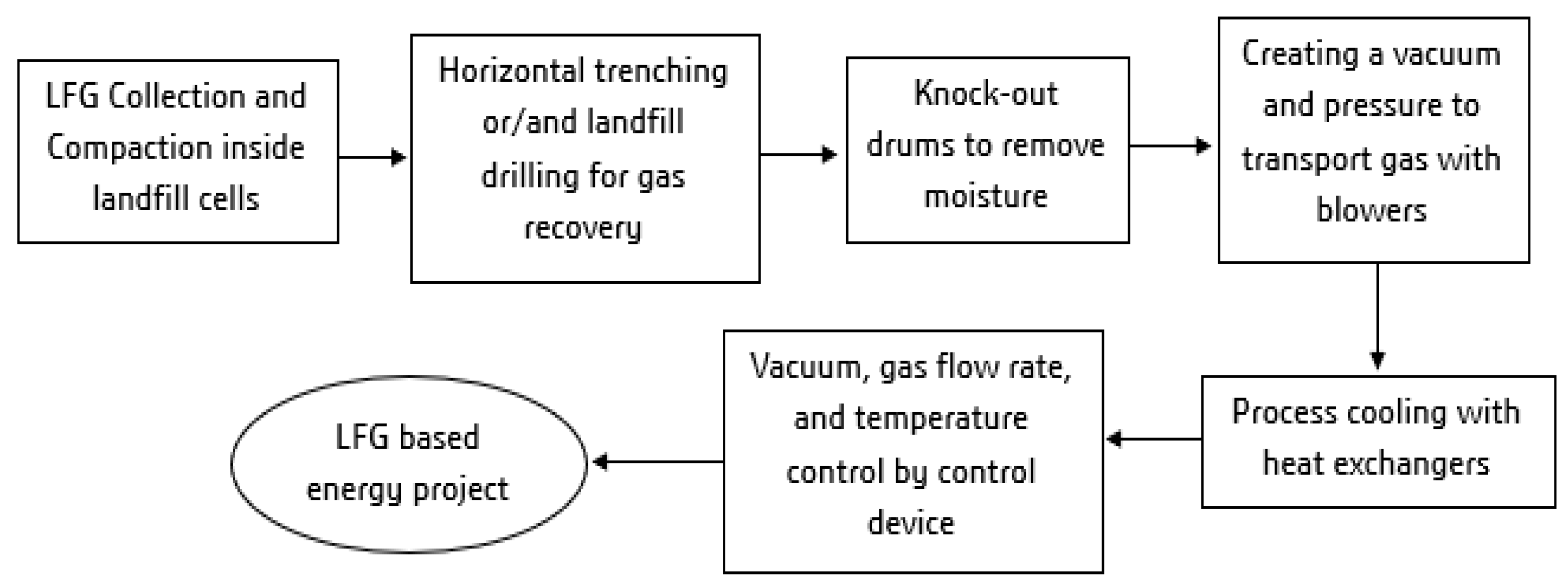

4.1. Landfilling

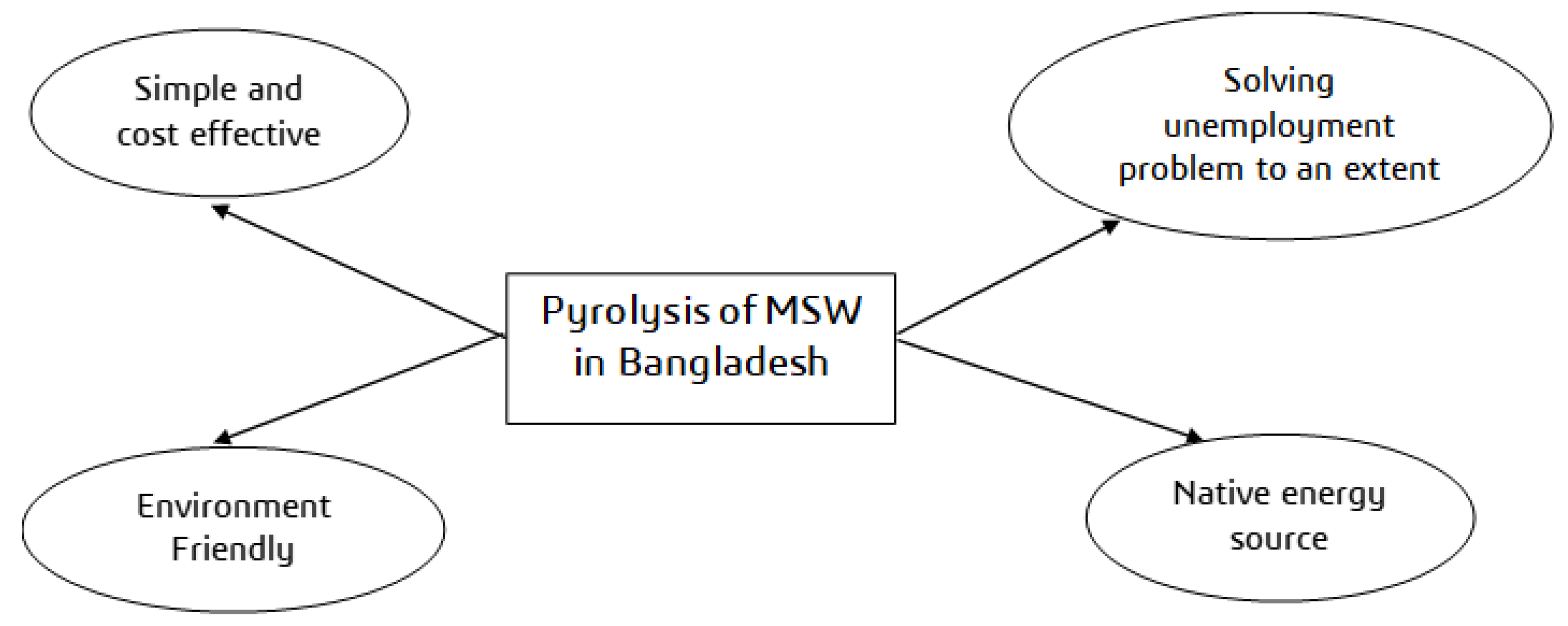

4.2. Thermal Process

4.3. Biochemical Conversion

5. Benefits, Challenges, and Cost Analysis of the WTE Projects

5.1. Benefits of WTE Projects

5.1.1. Prevention of Unsupervised Landfills

5.1.2. Reduction in GHG Emissions

5.1.3. Promotes Recycling

5.2. Challenges in WTE Projects

5.2.1. Inefficient Waste Management

5.2.2. Unwanted Emissions

5.2.3. Occupational Hazard

5.2.4. High Capital and Operating Costs

5.3. Relative Cost Analysis of Energy Production

6. Possible Strategies for Valuable Fund Recovery from MSW in Bangladesh

| Component | Generated MSW (tons/day) | Recycling Rate (%) |

|---|---|---|

| Plastic | 124 | 83 |

| Paper | 260 | 65 |

| Glass | 46 | 53 |

| Metal | 27 | - |

| Compostable | 2211 | 0 |

| Others | 99 | 95 |

7. Prospectives and Challenges

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pop, M.; Bucur, I.; Zoldan, D.; Imre, K.; Nichita, I.; Cristina, G.; Tîrziu, A.; Tîrziu, E. Chemical and Microbiological Air Quality in a Municipal Solid Waste Landfill and Its Surroundings, in South-Eastern Romania. Sustainability 2022, 14, 156. [Google Scholar] [CrossRef]

- Khan, A.H.; Sharholy, M.; Alam, P.; Al-Mansour, A.I.; Ahmad, K.; Kamal, M.A.; Alam, S.; Pervez, M.N.; Naddeo, V. Evaluation of cost benefit analysis of municipal solid waste management systems. J. King Saud Univ.-Sci. 2022, 34, 101997. [Google Scholar] [CrossRef]

- Gabay, M. Resource Conservation and Recovery Act: Management of Pharmaceutical Waste. Hosp. Pharm. 2012, 47, 769–770. [Google Scholar] [CrossRef]

- Gundupalli, S.P.; Hait, S.; Thakur, A. A review on automated sorting of source-separated municipal solid waste for recycling. Waste Manag. 2017, 60, 56–74. [Google Scholar] [CrossRef] [PubMed]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development; The World Bank: Washington, DC, USA, 2018; 292p. [Google Scholar]

- Jerin, D.T.; Sara, H.H.; Radia, M.A.; Hema, P.S.; Hasan, S.; Urme, S.A.; Audia, C.; Hasan, M.T.; Quayyum, Z. An overview of progress towards implementation of solid waste management policies in Dhaka, Bangladesh. Heliyon 2022, 8, e08918. [Google Scholar] [CrossRef]

- Kawai, K.; Tasaki, T. Revisiting estimates of municipal solid waste generation per capita and their reliability. J. Mater. Cycles Waste Manag. 2016, 18, 1–13. [Google Scholar] [CrossRef]

- Habib, M.A.; Ahmed, M.M.; Aziz, M.; Beg, M.R.A.; Hoque, M.E. Municipal Solid Waste Management and Waste-to-Energy Potential from Rajshahi City Corporation in Bangladesh. Appl. Sci. 2021, 11, 3744. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of end-of-life vehicles: Assessing trends and performances in Europe. Technol. Forecast. Soc. Change 2020, 152, 119887. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Fedrizzi, P. Web-GIS oriented systems viability for municipal solid waste selective collection optimization in developed and transient economies. Waste Manag. 2013, 33, 785–792. [Google Scholar] [CrossRef]

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef]

- Kumar, A.; Agrawal, A. Recent trends in solid waste management status, challenges, and potential for the future Indian cities—A review. Curr. Res. Environ. Sustain. 2020, 2, 100011. [Google Scholar] [CrossRef]

- Schluep, M. Chapter 29—Informal Waste Recycling in Developing Countries. In Handbook of Recycling; Worrell, E., Reuter, M.A., Eds.; Elsevier: Boston, MA, USA, 2014; pp. 439–444. [Google Scholar]

- Iyamu, H.O.; Anda, M.; Ho, G. A review of municipal solid waste management in the BRIC and high-income countries: A thematic framework for low-income countries. Habitat Int. 2020, 95, 102097. [Google Scholar] [CrossRef]

- Faccio, M.; Persona, A.; Zanin, G. Waste collection multi objective model with real time traceability data. Waste Manag. 2011, 31, 2391–2405. [Google Scholar] [CrossRef] [PubMed]

- Alagöz, A.Z.; Kocasoy, G. Improvement and modification of the routing system for the health-care waste collection and transportation in İstanbul. Waste Manag. 2008, 28, 1461–1471. [Google Scholar] [CrossRef]

- Hirpe, L.; Yeom, C. Municipal Solid Waste Management Policies, Practices, and Challenges in Ethiopia: A Systematic Review. Sustainability 2021, 13, 11241. [Google Scholar] [CrossRef]

- Mmereki, D.; Baldwin, A.; Li, B. A comparative analysis of solid waste management in developed, developing and lesser developed countries. Environ. Technol. Rev. 2016, 5, 120–141. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Ahsan, A.; Alamgir, M.; El-Sergany, M.M.; Shams, S.; Rowshon, M.K.; Daud, N.N. Assessment of Municipal Solid Waste Management System in a Developing Country. Chin. J. Eng. 2014, 2014, 561935. [Google Scholar] [CrossRef]

- Sukholthaman, P.; Shirahada, K. Technological challenges for effective development towards sustainable waste management in developing countries: Case study of Bangkok, Thailand. Technol. Soc. 2015, 43, 231–239. [Google Scholar] [CrossRef]

- Ashikuzzaman, M.; Howlader, M.H. Sustainable Solid Waste Management in Bangladesh: Issues and Challenges. Sustain. Waste Manag. Chall. Dev. Ctries. 2019, 35–55. [Google Scholar] [CrossRef]

- Pervez, M.N.; Mondal, M.I.H.; Cai, Y.; Zhao, Y.; Naddeo, V. Textile waste management and environmental concerns. In Fundamentals of Natural Fibres and Textiles; Mondal, M.I.H., Ed.; Woodhead Publishing: Cambridge, UK, 2021; pp. 719–739. [Google Scholar]

- Abedin, M.; Jahiruddin, M. Waste generation and management in Bangladesh: An overview. Asian J. Med. Biol. Res. 2015, 2015, 114–120. [Google Scholar] [CrossRef]

- Ng, W.P.Q.; Lam, H.L.; Varbanov, P.S.; Klemeš, J. Waste-to-Energy (WTE) network synthesis for Municipal Solid Waste (MSW). Energy Convers. Manag. 2014, 85, 866–874. [Google Scholar] [CrossRef]

- Fan, H.; Hossain, M.I.; Sultanuzzaman, M.R. Technological Innovation, Infrastructure and Industrial Growth in Bangladesh: Empirical Evidence from ARDL and Granger Causality Approach. Asian Econ. Financ. Rev. 2018, 8, 964–985. [Google Scholar] [CrossRef]

- Iqbal, M.R.; Piumali, A.B.K.T.; Priyankara, N.H.; Alagiyawanna, A.M.N.; Kurukulasuriya, L.C.; Kawamoto, K. Characterization of Physicochemical and Mechanical Properties of Dumped Municipal Solid Waste in Sri Lanka as Affected by the Climate Zone and Dumping Age. Sustainability 2022, 14, 4706. [Google Scholar] [CrossRef]

- Buenrostro, O.; Bocco, G.; Cram, S. Classification of sources of municipal solid wastes in developing countries. Resour. Conserv. Recycl. 2001, 32, 29–41. [Google Scholar] [CrossRef]

- Ziraba, A.K.; Haregu, T.N.; Mberu, B. A review and framework for understanding the potential impact of poor solid waste management on health in developing countries. Arch. Public Health 2016, 74, 55. [Google Scholar] [CrossRef]

- Mukherjee, C.; Denney, J.; Mbonimpa, E.G.; Slagley, J.; Bhowmik, R. A review on municipal solid waste-to-energy trends in the USA. Renew. Sustain. Energy Rev. 2020, 119, 109512. [Google Scholar] [CrossRef]

- Alam, O.; Qiao, X. An in-depth review on municipal solid waste management, treatment and disposal in Bangladesh. Sustain. Cities Soc. 2020, 52, 101775. [Google Scholar] [CrossRef]

- dos Muchangos, L.S.; Tokai, A.; Hanashima, A. Analyzing the structure of barriers to municipal solid waste management policy planning in Maputo city, Mozambique. Environ. Dev. 2015, 16, 76–89. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; The World Bank Group: Washington, DC, USA, 2012. [Google Scholar]

- Mohee, R.; Mauthoor, S.; Bundhoo, Z.M.; Somaroo, G.; Soobhany, N.; Gunasee, S. Current status of solid waste management in small island developing states: A review. Waste Manag. 2015, 43, 539–549. [Google Scholar] [CrossRef]

- Bohdziewicz, J.; Kwarciak, A. The application of hybrid system UASB reactor-RO in landfill leachate treatment. Desalination 2008, 222, 128–134. [Google Scholar] [CrossRef]

- Islam, K.M.N. Municipal Solid Waste to Energy Generation in Bangladesh: Possible Scenarios to Generate Renewable Electricity in Dhaka and Chittagong City. J. Renew. Energy 2016, 2016, 1712370. [Google Scholar] [CrossRef]

- Hemidat, S.; Achouri, O.; El Fels, L.; Elagroudy, S.; Hafidi, M.; Chaouki, B.; Ahmed, M.; Hodgkinson, I.; Guo, J. Solid Waste Management in the Context of a Circular Economy in the MENA Region. Sustainability 2022, 14, 480. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2021, 19, 1433–1456. [Google Scholar] [CrossRef]

- Lee, C.C.; Huffman, G.L. Incineration of solid waste. Environ. Prog. 1989, 8, 143–151. [Google Scholar] [CrossRef]

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- Deus, R.M.; Mele, F.D.; Bezerra, B.S.; Battistelle, R.A.G. A municipal solid waste indicator for environmental impact: Assessment and identification of best management practices. J. Clean. Prod. 2020, 242, 118433. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. Sustainable waste management: Waste to energy plant as an alternative to landfill. Energy Convers. Manag. 2017, 131, 18–31. [Google Scholar] [CrossRef]

- Suthar, S.; Rayal, P.; Ahada, C.P.S. Role of different stakeholders in trading of reusable/recyclable urban solid waste materials: A case study. Sustain. Cities Soc. 2016, 22, 104–115. [Google Scholar] [CrossRef]

- Lu, J.S.; Chang, Y.; Poon, C.S.; Lee, D.J. Slow pyrolysis of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef]

- Malkow, T. Novel and innovative pyrolysis and gasification technologies for energy efficient and environmentally sound MSW disposal. Waste Manag. 2004, 24, 53–79. [Google Scholar] [CrossRef]

- Paritosh, K.; Yadav, M.; Mathur, S.; Balan, V.; Liao, W.; Pareek, N.; Vivekanand, V. Organic Fraction of Municipal Solid Waste: Overview of Treatment Methodologies to Enhance Anaerobic Biodegradability. Front. Energy Res. 2018, 6, 75. [Google Scholar] [CrossRef]

- Şimşek, K.; Alp, S. Evaluation of Landfill Site Selection by Combining Fuzzy Tools in GIS-Based Multi-Criteria Decision Analysis: A Case Study in Diyarbakır, Turkey. Sustainability 2022, 14, 9810. [Google Scholar] [CrossRef]

- Narayana, T. Municipal solid waste management in India: From waste disposal to recovery of resources? Waste Manag. 2009, 29, 1163–1166. [Google Scholar] [CrossRef]

- Kalyani, K.A.; Pandey, K.K. Waste to energy status in India: A short review. Renew. Sustain. Energy Rev. 2014, 31, 113–120. [Google Scholar] [CrossRef]

- Sohoo, I.; Ritzkowski, M.; Sultan, M.; Farooq, M.; Kuchta, K. Conceptualization of Bioreactor Landfill Approach for Sustainable Waste Management in Karachi, Pakistan. Sustainability 2022, 14, 3364. [Google Scholar] [CrossRef]

- Wiszniowski, J.; Robert, D.; Surmacz-Gorska, J.; Miksch, K.; Weber, J.V. Landfill leachate treatment methods: A review. Environ. Chem. Lett. 2006, 4, 51–61. [Google Scholar] [CrossRef]

- Youcai, Z. Chapter 1—Leachate Generation and Characteristics. In Pollution Control Technology for Leachate from Municipal Solid Waste; Youcai, Z., Ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 1–30. [Google Scholar]

- Tałałaj, I.A.; Biedka, P.; Bartkowska, I. Treatment of landfill leachates with biological pretreatments and reverse osmosis. Environ. Chem. Lett. 2019, 17, 1177–1193. [Google Scholar] [CrossRef]

- Kjeldsen, P.; Barlaz, M.A.; Rooker, A.P.; Baun, A.; Ledin, A.; Christensen, T.H. Present and Long-Term Composition of MSW Landfill Leachate: A Review. Crit. Rev. Environ. Sci. Technol. 2002, 32, 297–336. [Google Scholar] [CrossRef]

- Chelliapan, S.; Arumugam, N.; Din, M.F.M.; Kamyab, H.; Ebrahimi, S.S. Chapter 11—Anaerobic treatment of municipal solid waste landfill leachate. In Bioreactors; Singh, L., Yousuf, A., Mahapatra, D.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 175–193. [Google Scholar]

- Alvarez-Vazquez, H.; Jefferson, B.; Judd, S.J. Membrane bioreactors vs. conventional biological treatment of landfill leachate: A brief review. J. Chem. Technol. Biotechnol. 2004, 79, 1043–1049. [Google Scholar] [CrossRef]

- Akter, S.; Suhan, M.B.K.; Islam, M.S. Recent advances and perspective of electrocoagulation in the treatment of wastewater: A review. Environ. Nanotechnol. Monit. Manag. 2022, 17, 100643. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. An overview of landfill leachate treatment via activated carbon adsorption process. J. Hazard. Mater. 2009, 171, 54–60. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Lo, W.-H.; Chan, G.Y.S. Physico-chemical treatments for removal of recalcitrant contaminants from landfill leachate. J. Hazard. Mater. 2006, 129, 80–100. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Lu, H.; Liu, J.; Wang, W.; Zhang, X. Hydraulic and mechanical behavior of landfill clay liner containing SSA in contact with leachate. Environ. Technol. 2018, 39, 1307–1315. [Google Scholar] [CrossRef]

- Demirel, B.; Scherer, P. The roles of acetotrophic and hydrogenotrophic methanogens during anaerobic conversion of biomass to methane: A review. Rev. Environ. Sci. Bio/Technol. 2008, 7, 173–190. [Google Scholar] [CrossRef]

- Bove, R.; Lunghi, P. Electric power generation from landfill gas using traditional and innovative technologies. Energy Convers. Manag. 2006, 47, 1391–1401. [Google Scholar] [CrossRef]

- Joshi, R.; Ahmed, S.; Ng, C. Status and challenges of municipal solid waste management in India: A review. Cogent Environ. Sci. 2016, 2, 1139434. [Google Scholar] [CrossRef]

- Qin, J.; Zhao, R.; Chen, T.; Zi, Z.; Wu, J. Co-combustion of municipal solid waste and coal gangue in a circulating fluidized bed combustor. Int. J. Coal Sci. Technol. 2018, 6, 218–224. [Google Scholar] [CrossRef]

- Lu, J.W.; Zhang, S.; Hai, J.; Lei, M. Status and perspectives of municipal solid waste incineration in China: A comparison with developed regions. Waste Manag. 2017, 69, 170–186. [Google Scholar] [CrossRef]

- Yang, J.; Li, Z.; Wei, R.; Zhou, D.; Long, H.; Li, J.; Xu, C. Co-Combustion of Food Solid Wastes and Pulverized Coal for Blast Furnace Injection: Characteristics, Kinetics, and Superiority. Sustainability 2022, 14, 7156. [Google Scholar] [CrossRef]

- Fitzgerald, G.C. 5—Pre-processing and treatment of municipal solid waste (MSW) prior to incineration. In Waste to Energy Conversion Technology; Klinghoffer, N.B., Castaldi, M.J., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 55–71. [Google Scholar]

- Abdulyekeen, K.A.; Umar, A.A.; Patah, M.F.A.; Daud, W.M.A.W. Torrefaction of biomass: Production of enhanced solid biofuel from municipal solid waste and other types of biomass. Renew. Sustain. Energy Rev. 2021, 150, 111436. [Google Scholar] [CrossRef]

- Panepinto, D.; Zanetti, M. Technical and Environmental Comparison among Different Municipal Solid Waste Management Scenarios. Sustainability 2021, 13, 3167. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Chen, W.-H. Pyrolysis characteristics and kinetics of microalgae via thermogravimetric analysis (TGA): A state-of-the-art review. Bioresour. Technol. 2017, 246, 88–100. [Google Scholar] [CrossRef] [PubMed]

- Malav, L.C.; Yadav, K.K.; Gupta, N.; Kumar, S.; Sharma, G.K.; Krishnan, S.; Rezania, S.; Kamyab, H.; Pham, Q.B.; Yadav, S.; et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. J. Clean. Prod. 2020, 277, 123227. [Google Scholar] [CrossRef]

- Agarwal, M.; Tardio, J.; Venkata Mohan, S. Critical analysis of pyrolysis process with cellulosic based municipal waste as renewable source in energy and technical perspective. Bioresour. Technol. 2013, 147, 361–368. [Google Scholar] [CrossRef]

- Motasemi, F.; Afzal, M.T. A review on the microwave-assisted pyrolysis technique. Renew. Sustain. Energy Rev. 2013, 28, 317–330. [Google Scholar] [CrossRef]

- Jayawardhana, Y.; Kumarathilaka, P.; Mayakaduwa, S.; Weerasundara, L.; Bandara, T.; Vithanage, M. Characteristics of Municipal Solid Waste Biochar: Its Potential to be Used in Environmental Remediation. In Utilization and Management of Bioresources; Springer: Singapore, 2018. [Google Scholar]

- Abdeljaber, A.; Zannerni, R.; Masoud, W.; Abdallah, M.; Rocha-Meneses, L. Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment. Sustainability 2022, 14, 3899. [Google Scholar] [CrossRef]

- Belgiorno, V.; De Feo, G.; Della Rocca, C.; Napoli, D.R. Energy from gasification of solid wastes. Waste Manag. 2003, 23, 1–15. [Google Scholar] [CrossRef]

- Cárdenas-Talero, J.L.; Silva-Leal, J.A.; Pérez-Vidal, A.; Torres-Lozada, P. The Influence of Municipal Wastewater Treatment Technologies on the Biological Stabilization of Sewage Sludge: A Systematic Review. Sustainability 2022, 14, 5910. [Google Scholar] [CrossRef]

- Tambone, F.; Genevini, P.; D’Imporzano, G.; Adani, F. Assessing amendment properties of digestate by studying the organic matter composition and the degree of biological stability during the anaerobic digestion of the organic fraction of MSW. Bioresour. Technol. 2009, 100, 3140–3142. [Google Scholar] [CrossRef] [PubMed]

- Angelidaki, I.; Karakashev, D.; Batstone, D.J.; Plugge, C.M.; Stams, A.J. Chapter sixteen—Biomethanation and Its Potential. In Methods in Enzymology; Rosenzweig, A.C., and Ragsdale, S.W., Eds.; Academic Press: Cambridge, MA, USA, 2011; pp. 327–351. [Google Scholar]

- Mathioudakis, D.; Karageorgis, P.; Papadopoulou, K.; Astrup, T.F.; Lyberatos, G. Environmental and Economic Assessment of Alternative Food Waste Management Scenarios. Sustainability 2022, 14, 9634. [Google Scholar] [CrossRef]

- Valladão, A.B.G.; Freire, D.M.G.; Cammarota, M.C. Enzymatic pre-hydrolysis applied to the anaerobic treatment of effluents from poultry slaughterhouses. Int. Biodeterior. Biodegrad. 2007, 60, 219–225. [Google Scholar] [CrossRef]

- López, M.; Soliva, M.; Martínez-Farré, F.X.; Fernández, M.; Huerta-Pujol, O. Evaluation of MSW organic fraction for composting: Separate collection or mechanical sorting. Resour. Conserv. Recycl. 2010, 54, 222–228. [Google Scholar] [CrossRef]

- Saha, J.K.; Panwar, N.; Singh, M.V. An assessment of municipal solid waste compost quality produced in different cities of India in the perspective of developing quality control indices. Waste Manag. 2010, 30, 192–201. [Google Scholar] [CrossRef]

- Hargreaves, J.C.; Adl, M.S.; Warman, P.R. A review of the use of composted municipal solid waste in agriculture. Agric. Ecosyst. Environ. 2008, 123, 1–14. [Google Scholar] [CrossRef]

- Jorge-Mardomingo, I.; Jiménez-Hernández, M.E.; Moreno, L.; de la Losa, A.; de la Cruz, M.T.; Casermeiro, M.Á. Application of high doses of organic amendments in a Mediterranean agricultural soil: An approach for assessing the risk of groundwater contamination. CATENA 2015, 131, 74–83. [Google Scholar] [CrossRef]

- Abu Qdais, H.A.; Hamoda, M.F. Enhancement of Carbon and Nitrogen Transformations During Composting of Municipal Solid Waste. J. Environ. Sci. Health Part A 2004, 39, 409–420. [Google Scholar] [CrossRef] [PubMed]

- Herrera, F.; Castillo, J.E.; Chica, A.F.; Bellido, L.L. Use of municipal solid waste compost (MSWC) as a growing medium in the nursery production of tomato plants. Bioresour. Technol. 2008, 99, 287–296. [Google Scholar] [CrossRef]

- Hicklenton, P.R.; Rodd, V.; Warman, P.R. The effectiveness and consistency of source-separated municipal solid waste and bark composts as components of container growing media. Sci. Hortic. 2001, 91, 365–378. [Google Scholar] [CrossRef]

- Perera, F. Pollution from Fossil-Fuel Combustion is the Leading Environmental Threat to Global Pediatric Health and Equity: Solutions Exist. Int. J. Environ. Res. Public Health 2018, 15, 16. [Google Scholar] [CrossRef]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Nubi, O.; Morse, S.; Murphy, R.J. Electricity Generation from Municipal Solid Waste in Nigeria: A Prospective LCA Study. Sustainability 2022, 14, 9252. [Google Scholar] [CrossRef]

- Prawisudha, P.; Namioka, T.; Yoshikawa, K. Coal alternative fuel production from municipal solid wastes employing hydrothermal treatment. Appl. Energy 2012, 90, 298–304. [Google Scholar] [CrossRef]

- Ghazali, N.; Muthusamy, K.; Wan Ahmad, S. Utilization of Fly Ash in Construction. IOP Conf. Ser. Mater. Sci. Eng. 2019, 601, 012023. [Google Scholar] [CrossRef]

- Tareen, W.U.K.; Dilbar, M.T.; Farhan, M.; Ali Nawaz, M.; Durrani, A.W.; Memon, K.A.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B.; Amir, M.; et al. Present Status and Potential of Biomass Energy in Pakistan Based on Existing and Future Renewable Resources. Sustainability 2020, 12, 249. [Google Scholar] [CrossRef]

- Nair, R.B.; Lennartsson, P.R.; Taherzadeh, M.J. 8—Bioethanol Production From Agricultural and Municipal Wastes. In Current Developments in Biotechnology and Bioengineering; Wong, J.W.C., Tyagi, R.D., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 157–190. [Google Scholar]

- Moya, D.; Aldás, C.; López, G.; Kaparaju, P. Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using Waste-To-Energy Technologies. Energy Procedia 2017, 134, 286–295. [Google Scholar] [CrossRef]

- Sharholy, M.; Ahmad, K.; Mahmood, G.; Trivedi, R.C. Municipal solid waste management in Indian cities—A review. Waste Manag. 2008, 28, 459–467. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Huang, G.; Xu, Y.; Gong, Q. Waste-to-Energy in China: Key Challenges and Opportunities. Energies 2015, 8, 14182–14196. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Y.; Chen, G.; Zuo, J.; Yan, B.; Yin, P. Effectiveness of waste-to-energy approaches in China: From the perspective of greenhouse gas emission reduction. J. Clean. Prod. 2017, 163, 99–105. [Google Scholar] [CrossRef]

- Korai, M.S.; Mahar, R.B.; Uqaili, M.A. The feasibility of municipal solid waste for energy generation and its existing management practices in Pakistan. Renew. Sustain. Energy Rev. 2017, 72, 338–353. [Google Scholar] [CrossRef]

- de Araújo, A.S.F.; de Melo, W.J.; Singh, R.P. Municipal solid waste compost amendment in agricultural soil: Changes in soil microbial biomass. Rev. Environ. Sci. Bio/Technol. 2010, 9, 41–49. [Google Scholar] [CrossRef]

- Shiralipour, A.; McConnell, D.B.; Smith, W.H. Uses and benefits of MSW compost: A review and an assessment. Biomass Bioenergy 1992, 3, 267–279. [Google Scholar] [CrossRef]

- Braber, K. Anaerobic digestion of municipal solid waste: A modern waste disposal option on the verge of breakthrough. Biomass Bioenergy 1995, 9, 365–376. [Google Scholar] [CrossRef]

- Danthurebandara, M.; Van Passel, S.; Nelen, D.; Tielemans, Y.; Van Acker, K. Environmental and socio-economic impacts of landfills. In Proceedings of the Linnaeus Eco-Tech 2012, Kalmar, Sweden, 26–28 November 2012; pp. 40–52. [Google Scholar]

- Hutchinson, D. Emission inventories. In Air Quality Management; Hester, R.E., Harrison, R.M., Eds.; The Royal Society of Chemistry: London, UK, 1997; pp. 19–40. [Google Scholar]

- Psomopoulos, C.S.; Bourka, A.; Themelis, N.J. Waste-to-energy: A review of the status and benefits in USA. Waste Manag. 2009, 29, 1718–1724. [Google Scholar] [CrossRef]

- Islam, K.M.N. Municipal solid waste to energy generation: An approach for enhancing climate co-benefits in the urban areas of Bangladesh. Renew. Sustain. Energy Rev. 2018, 81, 2472–2486. [Google Scholar] [CrossRef]

- Fernández-Gonzalez, J.M.; Grindlay, A.L.; Serrano-Bernardo, F.; Rodríguez-Rojas, M.I.; Zamorano, M. Economic and environmental review of Waste-to-Energy systems for municipal solid waste management in medium and small municipalities. Waste Manag. 2017, 67, 360–374. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.T.; Mohaddespour, A.; Nasr, A.T.; Carter, S. Municipal solid waste-to-energy processing for a circular economy in New Zealand. Renew. Sustain. Energy Rev. 2021, 145, 111080. [Google Scholar] [CrossRef]

- Adipah, S.; Kwame, O. A Novel Introduction of Municipal Solid Waste Management. J. Environ. Sci. Public Health 2018, 03, 147–157. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Edwards, J.; Othman, M.; Burn, S. A review of policy drivers and barriers for the use of anaerobic digestion in Europe, the United States and Australia. Renew. Sustain. Energy Rev. 2015, 52, 815–828. [Google Scholar] [CrossRef]

- Austin, J.S. 11—Air quality equipment and systems for waste to energy (WTE) conversion plants. In Waste to Energy Conversion Technology; Klinghoffer, N.B., Castaldi, M.J., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 204–226. [Google Scholar]

- Dowen, S.; Bremmer, J.; Angel, B.M.; Larracas, A. Waste Gasification & Pyrolysis: High Risk, Low Yield Processes for Waste Management. J. Environ. Prot. 2017, 11, 5. [Google Scholar]

- EIA, U. Cost and Performance Characteristics of New Generating Technologies, Annual Energy Outlook 2022; U.S. Energy Information Administration, Office of Electricity, Coal, Nuclear and Renewables Analysis: Washington, DC, USA, 2022.

- Li, S.; Jin, H.; Gao, L.; Zhang, X.; Ji, X. Techno-economic performance and cost reduction potential for the substitute/synthetic natural gas and power cogeneration plant with CO2 capture. Energy Convers. Manag. 2014, 85, 875–887. [Google Scholar] [CrossRef]

- Huiru, Z.; Yunjun, Y.; Liberti, F.; Pietro, B.; Fantozzi, F. Technical and economic feasibility analysis of an anaerobic digestion plant fed with canteen food waste. Energy Convers. Manag. 2019, 180, 938–948. [Google Scholar] [CrossRef]

- Moon, D. The High Cost of Waste Incineration; Naayem, N., Ed.; World Bank: Washington, DC, USA, 2000. [Google Scholar]

- Bridgwater, A.V.; Peacocke, G.V.C. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Elkhalifa, S.; Mackey, H.R.; Al-Ansari, T.; McKay, G. Pyrolysis of Biosolids to Produce Biochars: A Review. Sustainability 2022, 14, 9626. [Google Scholar] [CrossRef]

- Mostakim, K.; Arefin, M.A.; Islam, M.T.; Shifullah, K.M.; Islam, M.A. Harnessing energy from the waste produced in Bangladesh: Evaluating potential technologies. Heliyon 2021, 7, e08221. [Google Scholar] [CrossRef]

- Fernández-González, J.M.; Diaz-Lopez, C.; Martín-Pascual, J.; Zamorano, M. Recycling Organic Fraction of Municipal Solid Waste: Systematic Literature Review and Bibliometric Analysis of Research Trends. Sustainability 2020, 12, 4798. [Google Scholar] [CrossRef]

- Hossain, R.; Islam, M.T.; Shanker, R.; Khan, D.; Locock, K.E.S.; Ghose, A.; Schandl, H.; Dhodapkar, R.; Sahajwalla, V. Plastic Waste Management in India: Challenges, Opportunities, and Roadmap for Circular Economy. Sustainability 2022, 14, 4425. [Google Scholar] [CrossRef]

- Yasin, N.H.M.; Mumtaz, T.; Hassan, M.A. Food waste and food processing waste for biohydrogen production: A review. J. Environ. Manag. 2013, 130, 375–385. [Google Scholar] [CrossRef]

- Bari, Q.H.; Mahbub Hassan, K.; Haque, R. Scenario of solid waste reuse in Khulna city of Bangladesh. Waste Manag. 2012, 32, 2526–2534. [Google Scholar] [CrossRef] [PubMed]

- Quazi, B.; Fukuhara, T. Recycling Practices of Solid Waste in Khulna City. Bangladesh. J. Solid Waste Technol. Manag. 2011, 37, 1–16. [Google Scholar]

- Rahman, M.; Alam, J. Solid Waste Management and Incineration Practice: A Study of Bangladesh. Int. J. Nonferrous Metall. 2020, 9, 1–25. [Google Scholar] [CrossRef]

| Components | Percentage |

|---|---|

| Paper products and cardboards | 25.9 |

| Food waste | 15.1 |

| Yard waste | 13.2 |

| Plastics | 13.1 |

| Wood | 6.2 |

| Rubber and leather | 3.2 |

| Textiles | 6.2 |

| Metals | 9.1 |

| Glass | 4.4 |

| Electronic waste | 2.0 |

| Miscellaneous inorganic wastes | 1.5 |

| City | Food and Vegetables | Paper and Paper Products | Polythene and Plastics | Textile and Woods | Rubber and Leathers | Metal and Tins | Glass and Ceramic | Others |

|---|---|---|---|---|---|---|---|---|

| Dhaka | 68.3 | 10.7 | 4.3 | 2.2 | 1.4 | 2 | 0.7 | 10.4 |

| Chittagong | 73.6 | 9.9 | 2.8 | 2.1 | 1 | 2.2 | 1 | 7.4 |

| Khulna | 78.9 | 9.5 | 3.1 | 1.3 | 0.5 | 1.1 | 0.5 | 5.0 |

| Rajshahi | 71.1 | 8.9 | 4 | 1.9 | 1.1 | 1.1 | 1.1 | 10.4 |

| Barisal | 81.1 | 7.2 | 3.5 | 1.9 | 0.1 | 1.2 | 0.5 | 4.5 |

| Sylhet | 73.8 | 8.4 | 3.4 | 2.1 | 0.6 | 1.1 | 0.7 | 9.9 |

| City | pH | Moisture Content (% Fresh Matter) | Volatile Solid (% Dry Matter) | Ash Residue (% Dry Matter) | C/N | Nitrogen (% Dry Matter) | Phosphorus (% Dry Matter) | Potassium (% Dry Matter) |

|---|---|---|---|---|---|---|---|---|

| Dhaka | 8.6 | 70 | 71 | 29 | 10.17 | 0.89 | 0.31 | 0.62 |

| Chittagong | 8.2 | 62 | 54 | 46 | 17.22 | 0.17 | 0.23 | 0.57 |

| Khulna | 7.7 | 68 | 56 | 44 | 16.08 | 1.62 | 0.41 | 1.37 |

| Rajshahi | 7.7 | 56 | 48 | 52 | 12.15 | 0.56 | 0.31 | 0.38 |

| Barisal | 7.7 | 57 | 43 | 57 | 12.44 | 1.23 | 0.4 | 1.18 |

| Sylhet | 7.7 | 69 | 65 | 35 | 11.96 | 0.9 | 0.32 | 0.42 |

| Emission (kg/MW h) | MSW | Natural Gas (NG) | Oil | Coal |

|---|---|---|---|---|

| CO2 | 380 | 515 | 758.5 | 1020 |

| SO2 | 0.36 | 0.04 | 5.44 | 16 |

| NOx | 2.45 | 0.80 | 1.80 | 2.8 |

| Type of Technology for Energy Production | Estimated Capital Investment, $/kW | References | |

|---|---|---|---|

| Conventional energy production technologies | Combined power plant with oil/gas | 950–1000 | [116] |

| Onshore wind | 1850 | ||

| Offshore wind | 5500 | ||

| Solar thermal | 7100 | ||

| Solar photovoltaic | 1200–1600 | ||

| Conventional hydropower | 2800 | ||

| Geothermal | 2800 | ||

| Advanced nuclear | 6400–6800 | ||

| Combustion turbine with NG | 700–1200 | ||

| Fuel cell | 7000 | ||

| Cogeneration with coal | 1700 | [117] | |

| Integrated gasification combined cycle with coal (IGCC) | 1570 | ||

| IGCC with carbon capture | 2200 | ||

| WTE technologies | Biomass | 4100 | [116] |

| Landfill gas | 1600 | ||

| Anaerobic digestion | 3700–7000 | [118] | |

| Incineration | 7000–10,000 | [115] | |

| Pyrolysis | 8000–11,500 | ||

| Gasification | 7500–11,000 | ||

| Plasma arc gasification | 8000–11,500 |

| Type of Technology for Energy Production | O and M Cost USD/Tonne of MSW | |

|---|---|---|

| Conventional technologies | Incineration | 60–90 |

| Anaerobic Digestion | 22–55 | |

| Sanitary landfill | 30–80 | |

| Composting | 20–60 | |

| Non-conventional technologies | Pyrolysis | 100 |

| Gasification | 40 | |

| Plasma gasification | 300 | |

| Incineration USD/Tonne | AD USD/Tonne | Composting USD/Tonne | Sanitary Landfills USD/Tonne | |

|---|---|---|---|---|

| High income countries | 125 | 110 | 63 | 73 |

| Upper middle-income countries | 102 | 75 | 45 | 45 |

| Lower middle-income countries | 70 | 50 | 25 | 27 |

| Low-income countries | - | - | 20 | 22 |

| Capacity, tonne/day | 1200 |

| Capital cost USD/tonne | 36 |

| O and M cost, USD/tonne | 60 |

| Total electricity generation, GWh | 2250–3325 |

| Total revenue USD M | 530 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, H.; Alam, S.R.; Bin-Masud, R.; Prantika, T.R.; Pervez, M.N.; Islam, M.S.; Naddeo, V. A Review on Characteristics, Techniques, and Waste-to-Energy Aspects of Municipal Solid Waste Management: Bangladesh Perspective. Sustainability 2022, 14, 10265. https://doi.org/10.3390/su141610265

Roy H, Alam SR, Bin-Masud R, Prantika TR, Pervez MN, Islam MS, Naddeo V. A Review on Characteristics, Techniques, and Waste-to-Energy Aspects of Municipal Solid Waste Management: Bangladesh Perspective. Sustainability. 2022; 14(16):10265. https://doi.org/10.3390/su141610265

Chicago/Turabian StyleRoy, Hridoy, Samiha Raisa Alam, Rayhan Bin-Masud, Tonima Rahman Prantika, Md. Nahid Pervez, Md. Shahinoor Islam, and Vincenzo Naddeo. 2022. "A Review on Characteristics, Techniques, and Waste-to-Energy Aspects of Municipal Solid Waste Management: Bangladesh Perspective" Sustainability 14, no. 16: 10265. https://doi.org/10.3390/su141610265