Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation

Abstract

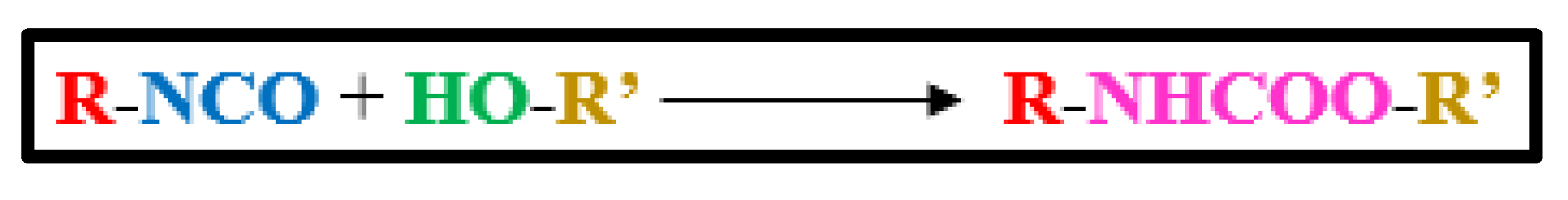

:1. Introduction

1.1. Bio-Based Polyurethane

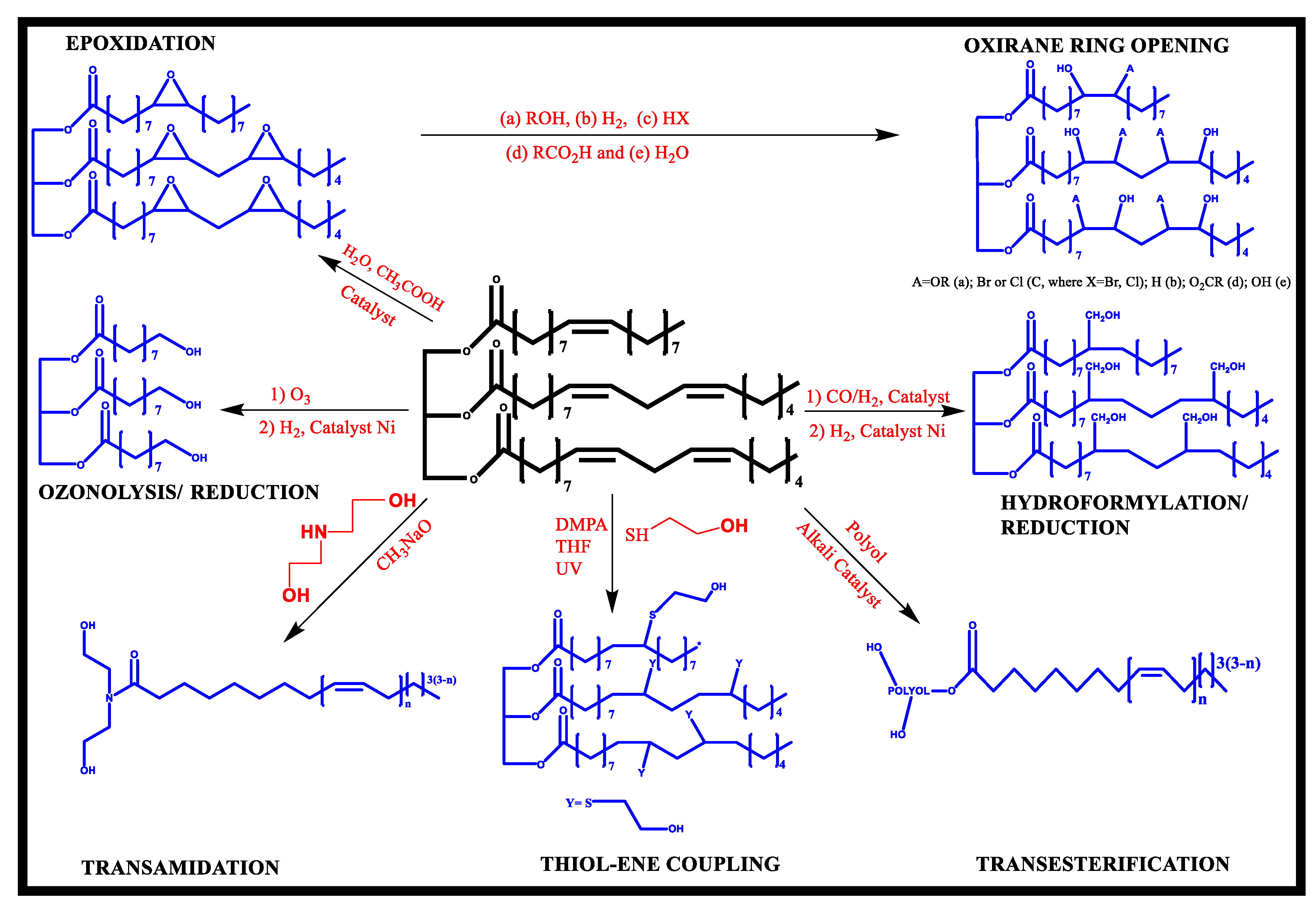

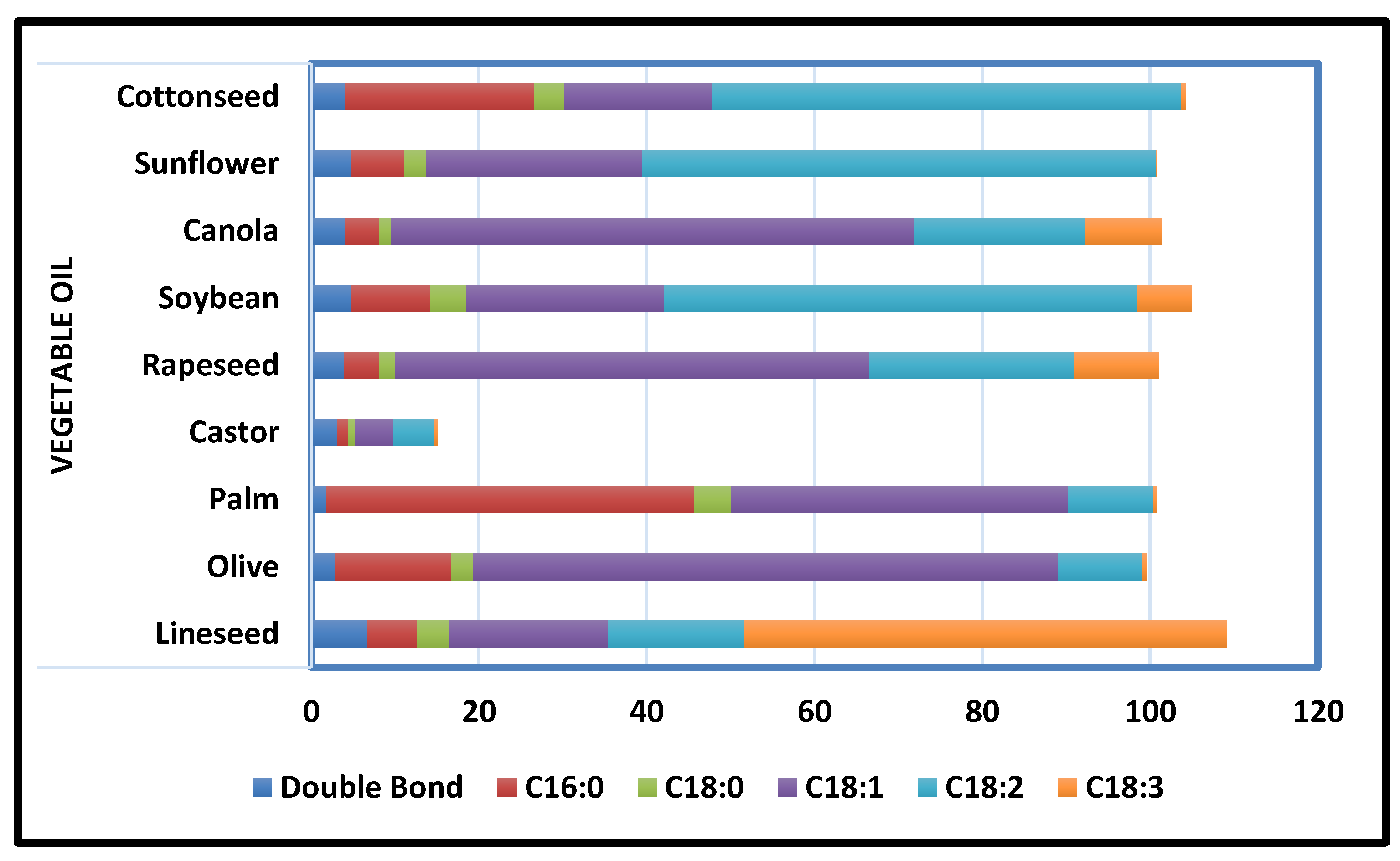

1.1.1. Vegetable Oil-Derived Monomers

1.1.2. Bio-Based Isocyanates

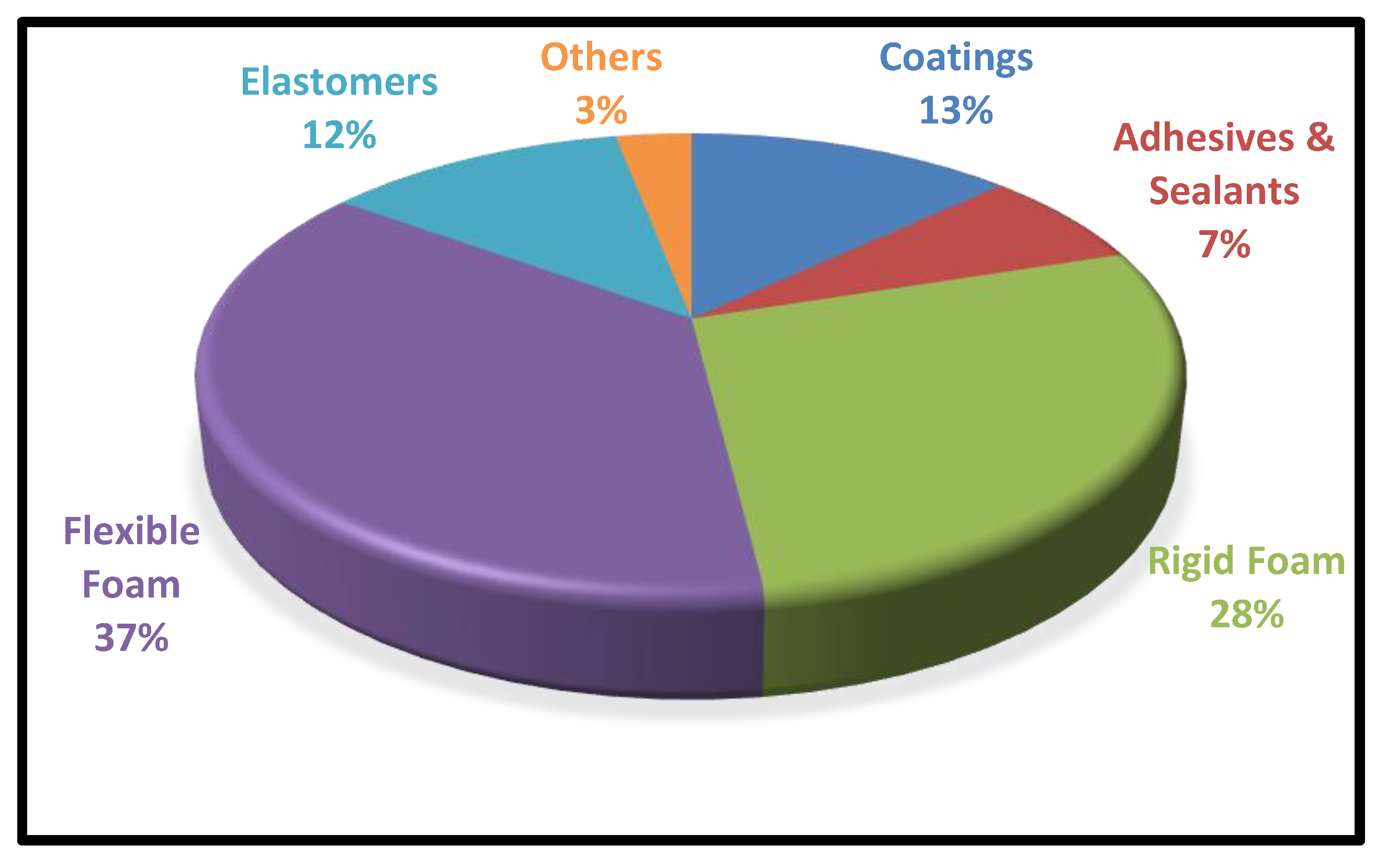

2. Polyurethanes: Types, Synthesis, and Utilities

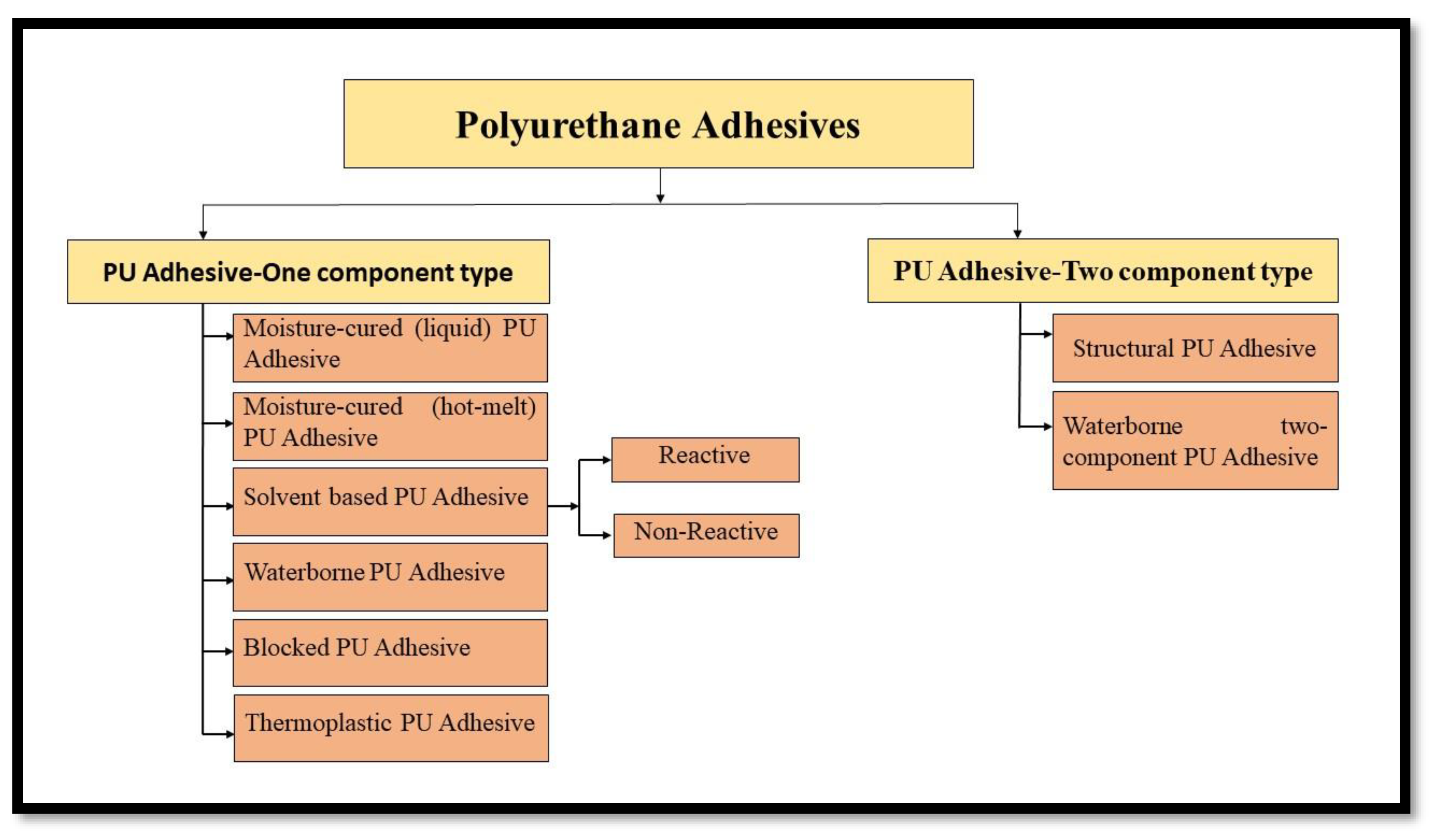

2.1. Polyurethane Adhesives

2.1.1. Protein

2.1.2. Vegetable Oils

Castor Oil

Palm Oil

Canola Oil

Jatropha Oil

Soybean Oil

2.1.3. Lignin

2.1.4. Starch

2.1.5. Polylactic Acid

2.1.6. Applications of Bio-Based PU Adhesive

2.2. Polyurethane Coatings

2.2.1. Vegetable Oil-Based Polyurethane Coatings

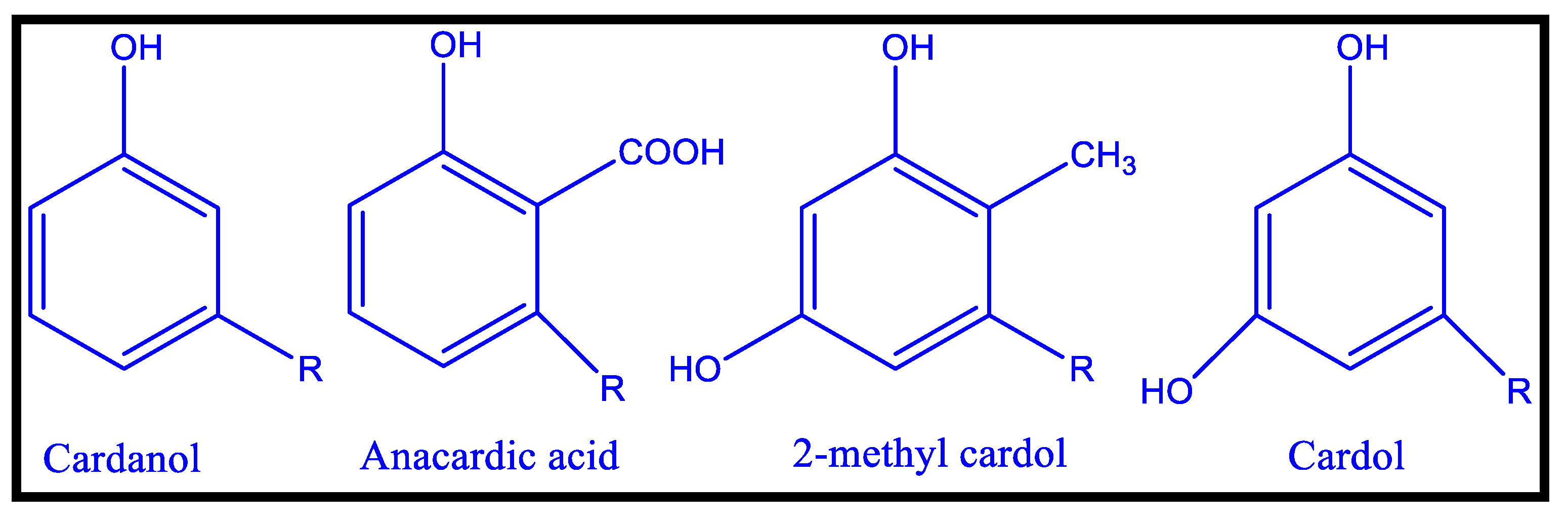

2.2.2. PU Coatings Based on Cashew Nut Shell Liquid (CNSL)

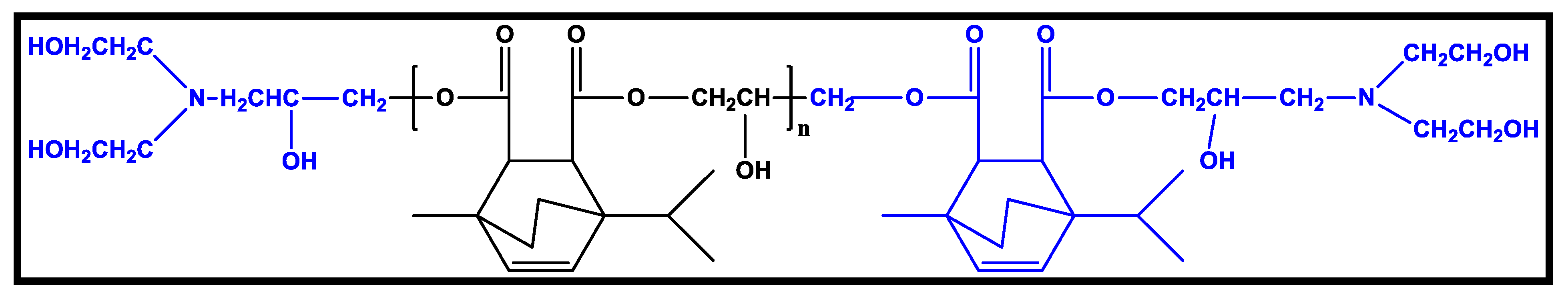

2.2.3. Polyurethane Coatings Based on Terpene

2.2.4. Polyurethane Coatings Based on Eucalyptus Tar

2.3. Polyurethane Foams

2.3.1. Vegetable Oil-Based Polyurethane Foams

2.3.2. Application of Bio-Based Polyurethane Foams

2.4. Polyurethanes Elastomers

2.4.1. Non-Implantable Devices

Wound Dressing

Films as Wound Dressing Applications

Fibrous Mat for Wound Dressing Applications

2.4.2. Implantable Devices

Long Term Implants

Short-Term Implants

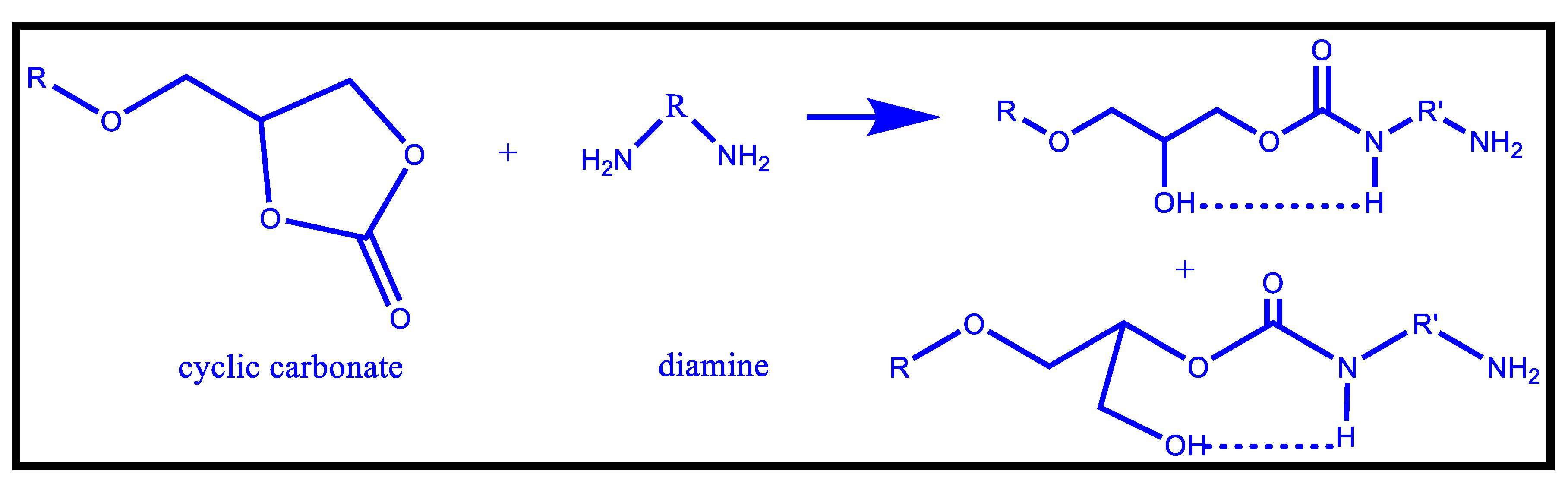

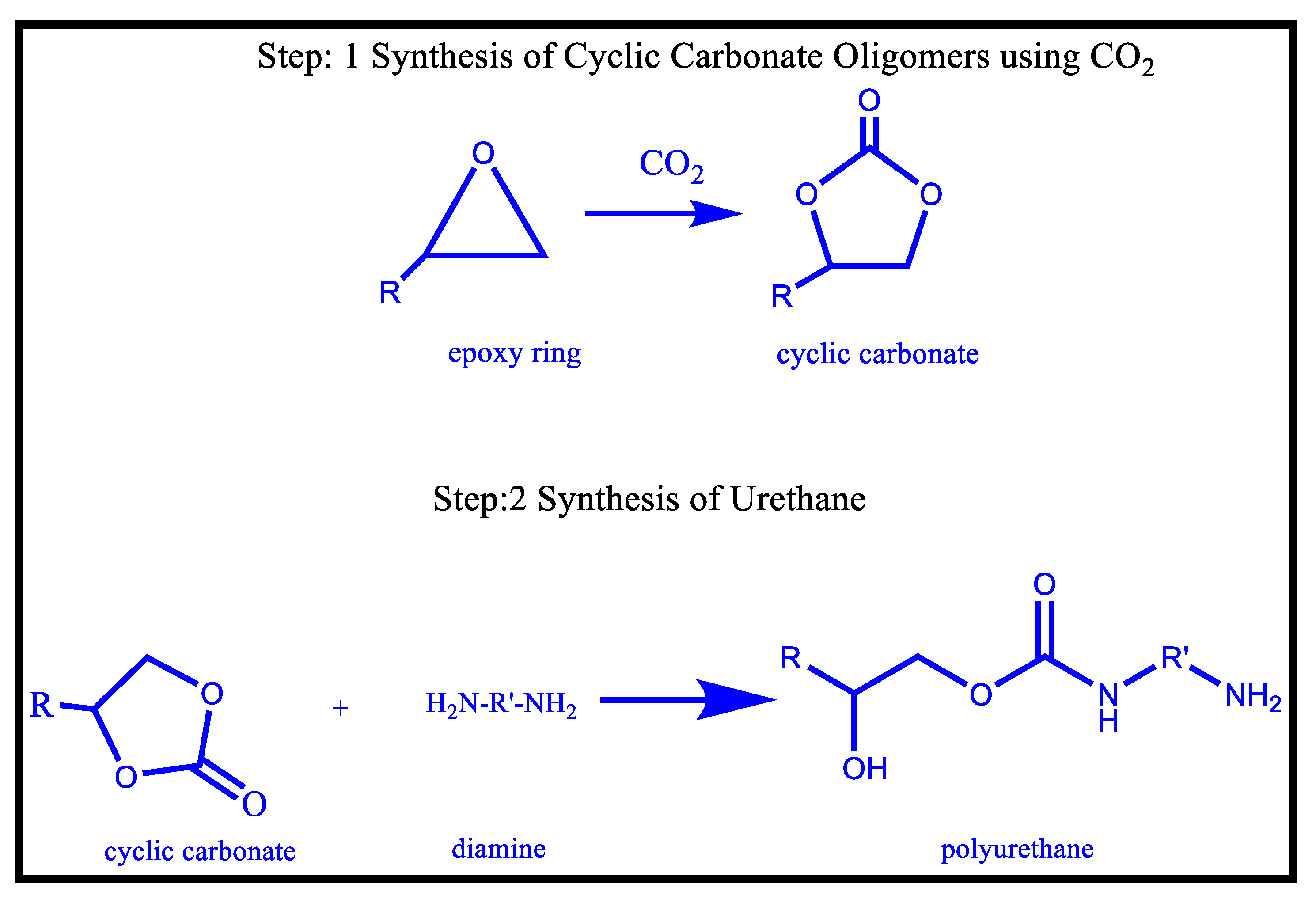

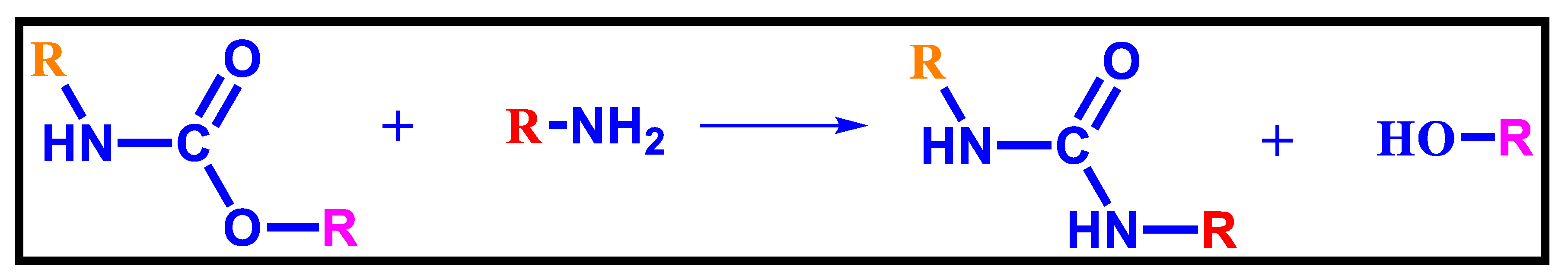

3. Non-Isocyanate Polyurethanes (NIPUs)

Applications of NIPU

4. Recycling and Disposing of Polyurethanes

- Rebonding: Flexible PU foam is cut into smaller pieces and it is used in the manufacture of sports mats and carpet lay [115].

- Regrind or Powdering: Powdered PU waste is blended with one of the virgin reagents (usually with the polyol up to 30% wt) to build new PU goods [115].

- Compression Molding: Powdered PU waste is exposed to high heat and pressures in the mold. It can enable upto approximately 100% recycled substance to be obtained [115].

4.1. Hydrolysis

4.2. Aminolysis

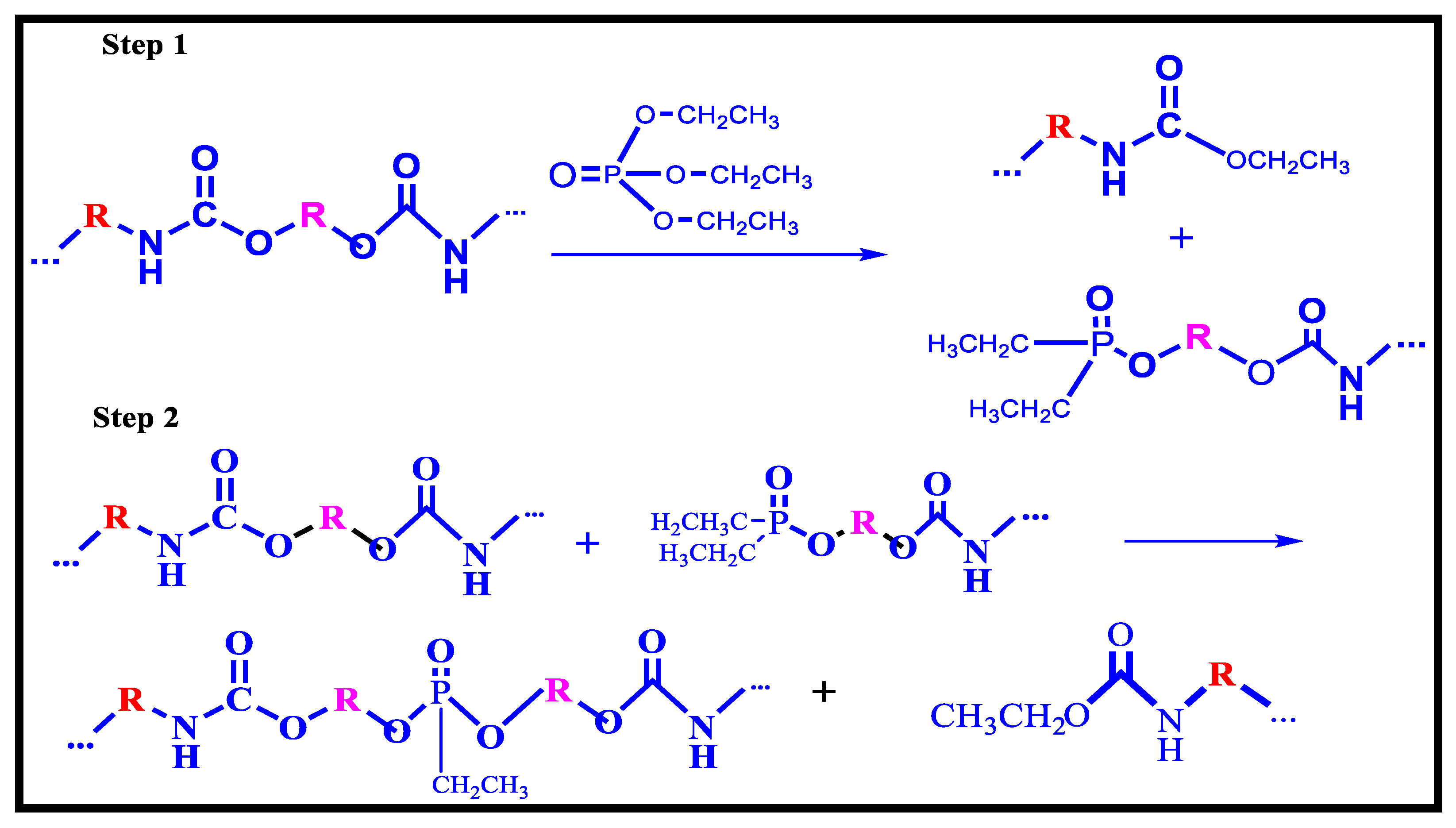

4.3. Phosphorolysis

4.4. Glycolysis

- Catalysts: The catalysts engaged are amines such as diethanolamine and ethanolamine; alkaline acetates such as sodium, potassium, or lithium acetate; hydroxides such as potassium or sodium hydroxides; metallic octoates such as stannous or lithium octoates and organometallic compounds such as titanium butoxide [115].

- Cleavage Agents: DPG, DEG, MPG, and MEG, and are some of the most commonly utilised cleavage agents, with DEG being the most common; however, crude glycerol is now the most assuring [115].

- Glycolysis agent: PU ratios: In transesterification reaction, the most frequent glycolysis agent: PU ratios used. It can be seen that the glycolysis agent to PU ratio is often more than 1, in order to ensure optimal split-phase glycolysis and, as an outcome, a good quality glycolyzate that may be used in the generation of a fresh PU product [115].

- Temperature: the best temperature for carrying out the glycolysis reaction is between 160 and 250 °C, because cooler temperatures result in a slow recovery course and a low polyol proportion, whereas higher temperatures result in excessive evaporation of cleavage agent and a rise in the extension of the secondary reactions [115].

4.5. Gasification

4.6. Pyrolysis

4.7. Hydrogenation

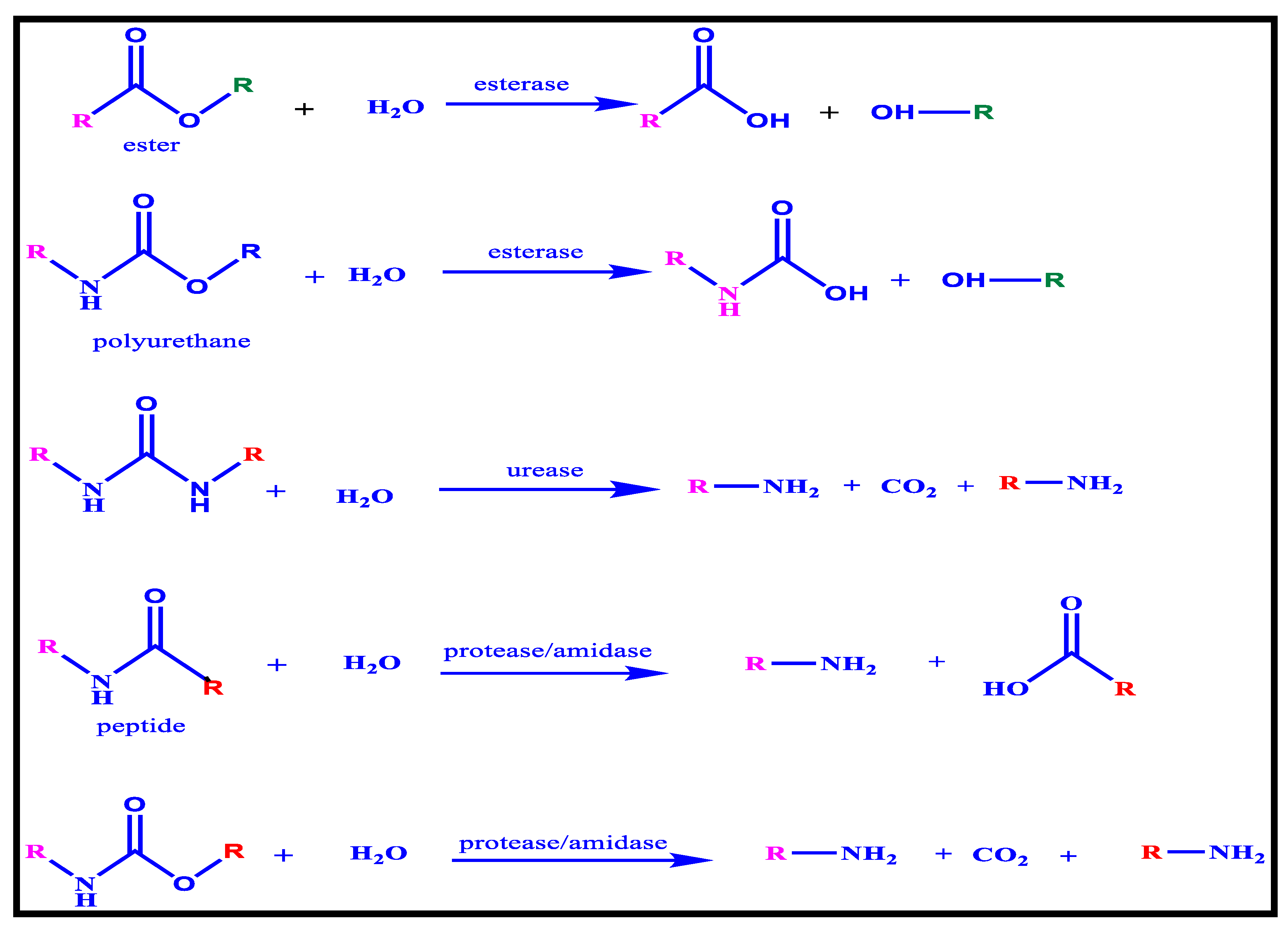

5. Biological Degradation of Polyurethane

5.1. Degradation by Fungi

5.2. Degradation by Bacteria

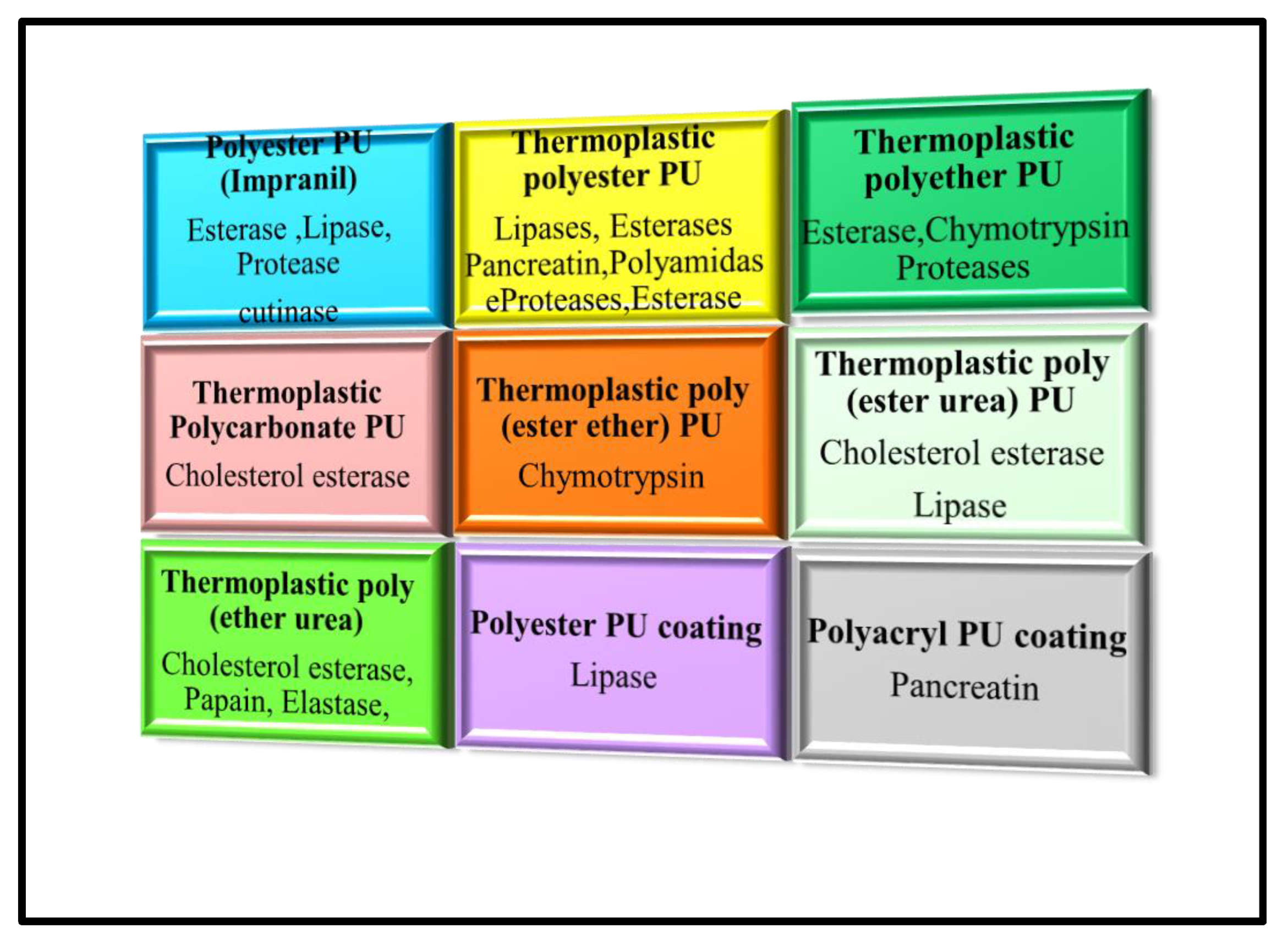

5.3. Degradation by Enzymes

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, Y.; Dewil, R.; Appels, L.; Ansart, R.; Baeyens, J.; Kang, Q. Reviewing the thermo-chemical recycling of waste polyurethane foam. J. Environ. Manag. 2020, 278, 111527. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications-a review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef] [Green Version]

- Cornille, A.; Guillet, C.; Benyahya, S.; Negrell, C.; Boutevin, B.; Caillol, S. Room temperature flexible isocyanate-free polyurethane foams. Eur. Polym. J. 2016, 84, 873–888. [Google Scholar] [CrossRef]

- Thébault, M.; Pizzi, A.; Essawy, H.A.; Barhoum, A.; Van Assche, G. Isocyanate free condensed tannin-based polyurethanes. Eur. Polym. J. 2015, 67, 513–526. [Google Scholar] [CrossRef]

- Kulkarni, R.D.; Paraskar, P.M. Synthesis of Isostearic Acid/Dimer Fatty Acid-Based Polyesteramide Polyol for the Development of Green Polyurethane Coatings. J. Polym. Environ. 2021, 29, 54–70. [Google Scholar]

- Cheng, Z.; Li, Q.; Yan, Z.; Liao, G.; Zhang, B.; Yu, Y.; Yi, C.; Xu, Z. Design and synthesis of novel aminosiloxane crosslinked linseed oil-based waterborne polyurethane composites and its physicochemical properties. Prog. Org. Coat. 2018, 127, 194–201. [Google Scholar] [CrossRef]

- Kovács, E.; Turczel, G.; Szabó, L.; Varga, R.; Tóth, I.; Anastas, P.T.; Tuba, R. Synthesis of 1,6-Hexandiol, Polyurethane Monomer Derivatives via Isomerization Metathesis of Methyl Linolenate. ACS Sustain. Chem. Eng. 2017, 5, 11215–11220. [Google Scholar] [CrossRef]

- Liang, H.; Feng, Y.; Lu, J.; Liu, L.; Yang, Z.; Luo, Y.; Zhang, Y.; Zhang, C. Bio-based cationic waterborne polyurethanes dispersions prepared from different vegetable oils. Ind. Crops Prod. 2018, 122, 448–455. [Google Scholar] [CrossRef]

- Gomez-Jimenez-Aberasturi, O.; Gomez, J.R. New approaches to producing polyols from biomass. J. Chem. Technol. Biotechnol. 2017, 92, 705–711. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, L.; Fan, Y. Preparation of Soy-Based Adhesive Enhanced by Waterborne Polyurethane: Optimization by Response Surface Methodology. Adv. Mater. Sci. Eng. 2018, 2018, 9253670. [Google Scholar] [CrossRef] [Green Version]

- Zuber, M.; Shah, S.A.A.; Jamil, T.; Asghar, M.I. Performance behavior of modified cellulosic fabrics using polyurethane acrylate copolymer. Int. J. Biol. Macromol. 2014, 67, 254–259. [Google Scholar] [CrossRef]

- Sharmin, E.; Zafar, F.; Akram, D.; Alam, M.; Ahmad, S. Recent advances in vegetable oils based environment friendly coatings: A review. Ind. Crop. Prod. 2015, 76, 215–229. [Google Scholar] [CrossRef]

- Vanbésien, T.; Monflier, E.; Hapiot, F. Hydroformylation of vegetable oils: More than 50 years of technical innovation, successful research, and development. Eur. J. Lipid Sci. Technol. 2015, 118, 26–35. [Google Scholar] [CrossRef]

- Paraskar, P.M.; Prabhudesai, M.S.; Hatkar, V.M.; Kulkarni, R.D. Vegetable oil based polyurethane coatings—A sustainable approach: A review. Prog. Org. Coat. 2021, 156, 106267. [Google Scholar] [CrossRef]

- Peyrton, J.; Chambaretaud, C.; Sarbu, A.; Avérous, L. Biobased Polyurethane Foams Based on New Polyol Architectures from Microalgae Oil. ACS Sustain. Chem. Eng. 2020, 8, 12187–12196. [Google Scholar] [CrossRef]

- Devi, K.; Nurul, P.P.; Ain, H.; Tuan Noor Maznee, T.I.; MohdNorhisham, S.; Srihanum, A.; Norhayati, M.N.; Yeong, S.K.; Hazimah, A. Green Polyurethane for Ornamental Products; MPOB Information Series, MPOB TT No. 522; MPOB: Bandar Baru Bangi, Malaysia, 2012. [Google Scholar]

- De Souza, F.M.; Kahol, P.K.; Gupta, R.K. Introduction to Polyurethane Chemistry. ACS Symp. Ser. 2021, 1380, 1–24. [Google Scholar]

- KhoonPoh, A.; Choy Sin, L.; Foon, C.; Hock, C. Polyurethane wood adhesive from palm oil-based polyester polyol. J. Adhes. Sci. Technol. 2014, 28, 1020–1033. [Google Scholar] [CrossRef]

- Ang, K.P.; Lee, C.S.; Cheng, S.F.; Chuah, C.H. Synthesis of palm oil-based polyester polyol for polyurethane adhesive production. J. Appl. Polym. Sci. 2013, 131, 6. [Google Scholar] [CrossRef]

- Li, N.; Qi, G.; Sun, X.S.; Stamm, M.J.; Wang, D. Physicochemical Properties and Adhesion Performance of Canola Protein Modified with Sodium Bisulfite. J. Am. Oil Chem. Soc. 2011, 89, 897–908. [Google Scholar] [CrossRef]

- Aung, M.M.; Yaakob, Z.; Kamarudin, S.; Abdullah, L.C. Synthesis and characterization of Jatropha (Jatropha curcas L.) oil-based polyurethane wood adhesive. Ind. Crops Prod. 2014, 60, 177–185. [Google Scholar] [CrossRef]

- Saalah, S.; Abdullah, L.; Aung, M.; Salleh, M.; Biak, D.A.; Basri, M.; Jusoh, E.; Mamat, S.; Al Edrus, S.O. Chemical and Thermo-Mechanical Properties of Waterborne Polyurethane Dispersion Derived from Jatropha Oil. Polymers 2021, 13, 795. [Google Scholar] [CrossRef]

- Wang, C.-S.; Yang, L.-T.; Ni, B.-L.; Shi, G. Polyurethane networks from different soy-based polyols by the ring opening of epoxidized soybean oil with methanol, glycol, and 1,2-propanediol. J. Appl. Polym. Sci. 2009, 114, 125–131. [Google Scholar] [CrossRef]

- Valero, M.; Gonzalez, A. Polyurethane adhesive system from castor oil modified by a transesterification reaction. J. Elastomers Plast. 2012, 44, 433–442. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, L.; Ding, M.; Tan, H.; Li, J.; Fu, Q. Preparation and rapid degradation of nontoxic biodegradable polyurethanes based on poly(lactic acid)-poly(ethylene glycol)-poly(lactic acid) and l-lysine diisocyanate. Polym. Cem. 2011, 2, 601–607. [Google Scholar] [CrossRef]

- Das, S.; Pandey, P.; Mohanty, S.; Nayak, S.K. Evaluation of biodegradability of green polyurethane/nanosilica composite synthesized from transesterified castor oil and palm oil based isocyanate. Int. Biodeterior. Biodegrad. 2017, 117, 278–288. [Google Scholar] [CrossRef]

- Rodriguez, R.; Pérez, B.; Florez, S. Effect of Different Nanoparticles on Mechanical Properties and Curing Behavior of Thermoset Polyurethane Adhesives. J. Adhes. 2014, 90, 848–859. [Google Scholar] [CrossRef]

- Mirabedini, S.; Mohseni, M.; PazokiFard, S.; Esfandeh, M. Effect of TiO2 on the mechanical and adhesion properties of RTV silicone elastomer coatings. Colloids Surf. A Physicochem. Eng. Asp. 2008, 317, 80–86. [Google Scholar] [CrossRef]

- Alinejad, M.; Henry, C.; Nikafshar, S.; Gondaliya, A.; Bagheri, S.; Chen, N.; Singh, S.K.; Hodge, D.B.; Nejad, M. Lignin-Based Polyurethanes: Opportunities for Bio-Based Foams, Elastomers, Coatings and Adhesives. Polymers 2019, 11, 1202. [Google Scholar] [CrossRef] [Green Version]

- Magalhães, S.; Alves, L.; Medronho, B.; Fonseca, A.C.; Romano, A.; Coelho, J.F.J.; Norgren, M. Brief Overview on Bio-Based Adhesives and Sealants. Polymers 2019, 11, 1685. [Google Scholar] [CrossRef] [Green Version]

- Mapari, S.; Mestry, S.; Mhaske, S.T. Developments in pressure-sensitive adhesives: A review. Polym. Bull. 2021, 78, 4075–4108. [Google Scholar] [CrossRef]

- Liu, X.; Hong, W.; Chen, X. Continuous Production of Water-Borne Polyurethanes: A Review. Polymers 2020, 12, 2875. [Google Scholar] [CrossRef]

- Fuensanta, M.; Martin-Martínez, J.M. Thermoplastic polyurethane pressure sensitive adhesives made with mixtures of polypropylene glycols of different molecular weights. Int. J. Adhes. Adhes. 2019, 88, 81–90. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Yang, J. Design strategies and applications of tissue bioadhesives. Macromol. Biosci. 2013, 13, 271–288. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Tu, W.; Hu, J. Preparation and Characterization of Two-component Waterborne Polyurethane Comprised of Water-soluble Acrylic Resin and HDI Biuret. Chin. J. Chem. Eng. 2006, 14, 99–104. [Google Scholar] [CrossRef]

- Malik, M.; Kaur, R. Mechanical and Thermal Properties of Castor Oil–Based Polyurethane Adhesive: Effect of TiO2 Filler. Adv. Polym. Technol. 2016, 37, 24–30. [Google Scholar] [CrossRef]

- Dai, J.; Liu, X.; Ma, S.; Wang, J.; Shen, X.; You, S.; Zhu, J. Soybean oil-based UV-curable coatings strengthened by crosslink agent derived from itaconic acid together with 2-hydroxyethyl methacrylate phosphate. Prog. Org. Coat. 2016, 97, 210–215. [Google Scholar] [CrossRef]

- Raydan, N.D.V.; Leroyer, L.; Charrier, B.; Robles, E. Recent Advances on the Development of Protein-Based Adhesives for Wood Composite Materials—A Review. Molecules 2021, 26, 7617. [Google Scholar] [CrossRef]

- Mubofu, E.B. Castor oil as a potential renewable resource for the production of functional materials. Sustain. Chem. Processes 2016, 4, 11. [Google Scholar] [CrossRef]

- Silva, B.B.R.; Santana, R.M.C.; Forte, M.C. A solventless castor oil-based PU adhesive for wood and foam substrates. Int. J. Adhes. Adhes. 2010, 30, 559–565. [Google Scholar] [CrossRef]

- Patel, M.R.; Shukla, J.M.; Patel, N.K.; Patel, K.H. Biomaterial based novel polyurethane adhesives for wood to wood and metal to metal bonding. Mater. Res. 2009, 12, 385–393. [Google Scholar] [CrossRef] [Green Version]

- Radojčić, D.; Ionescu, M.; Petrović, Z.S. Novel potentially biodegradable polyurethanes from bio-based polyols. Contemp. Mater. 2013, 4, 9–21. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Bio-Renewable Sources for Synthesis of Eco-Friendly Polyurethane Adhesives—Review. Open J. Polym. Chem. 2017, 7, 57–75. [Google Scholar] [CrossRef] [Green Version]

- Börcsök, Z.; Pásztory, Z. The role of lignin in wood working processes using elevated temperatures: An abbreviated literature survey. Eur. J. Wood Wood Prod. 2021, 79, 511–526. [Google Scholar] [CrossRef]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2019, 3, 8–18. [Google Scholar] [CrossRef]

- Sudoł, E.; Kozikowska, E. Mechanical Properties of Polyurethane Adhesive Bonds in a Mineral Wool-Based External Thermal Insulation Composite System for Timber Frame Buildings. Materials 2021, 14, 2527. [Google Scholar] [CrossRef]

- Calpena, E.O.; Francisca, A.A.; Sánchez, M.A.M. Adhesives in the Footwear Industry: A Critical Review. Rev. Adhes. Adhes. 2019, 7, 69–91. [Google Scholar] [CrossRef]

- Bao, Z.; Gao, M.; Sun, Y.; Nian, R.; Xian, M. The recent progress of tissue adhesives in design strategies, adhesive mechanism and applications. Mater. Sci. Eng. C 2020, 111, 110796. [Google Scholar] [CrossRef]

- Liu, L.; Lu, J.; Zhang, Y.; Liang, H.; Liang, D.; Jiang, J.; Lu, Q.; Quirino, R.L.; Zhang, C. Thermosetting polyurethanes prepared with the aid of a fully bio-based emulsifier with high bio-content, high solid content, and superior mechanical properties. Green Chem. 2018, 21, 526–537. [Google Scholar] [CrossRef]

- Chattopadhyay, D.; Kothapalli, R.V. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Sawpan, M.A. Polyurethanes from vegetable oils and applications: A review. J. Polym. Res. 2018, 25, 184. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, G.; Zhang, J.; Huang, J.; Yu, X.; Shang, Q.; An, R.; Liu, C.; Hu, L.; Zhou, Y. Rubber Seed Oil-Based UV-Curable Polyurethane Acrylate Resins for Digital Light Processing (DLP) 3D Printing. Molecules 2021, 26, 5455. [Google Scholar] [CrossRef] [PubMed]

- Patil, A.M.; Jirimali, H.D.; Gite, V.V.; Jagtap, R.N. Synthesis and performance of bio-based hyperbranched polyol in polyurethane coatings. Prog. Org. Coat. 2020, 149, 105895. [Google Scholar] [CrossRef]

- Jeon, I.-Y.; Noh, H.-J.; Baek, J.-B. Hyperbranched Macromolecules: From Synthesis to Applications. Molecules 2018, 23, 657. [Google Scholar] [CrossRef] [Green Version]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Saif, M.J. Recent trends in environmentally friendly water-borne polyurethane coatings: A review. Korean J. Chem. Eng. 2015, 33, 388–400. [Google Scholar] [CrossRef]

- Anıl, D.; Berksun, E.; Durmuş-Sayar, A.; Sevinis-Özbulut, E.B.; Ünal, S. Chapter 11—Recent advances in waterborne polyurethanes and their nanoparticle-containing dispersions. In Handbook of Waterborne Coatings; Elsevier: Amsterdam, The Netherlands, 2020; pp. 249–302. [Google Scholar]

- Zhang, Y.; Zhang, W.; Wang, X.; Dong, Q.; Zeng, X.; Quirino, R.L.; Lu, Q.; Wang, Q.; Zhang, C. Waterborne polyurethanes from castor oil-based polyols for next generation of environmentally-friendly hair-styling agents. Prog. Org. Coat. 2020, 142, 105588. [Google Scholar] [CrossRef]

- Agnol, L.D.; Dias, F.T.G.; Ornaghi, H.L.; Sangermano, M.; Bianchi, O. UV-curable waterborne polyurethane coatings: A state-of-the-art and recent advances review. Prog. Org. Coat. 2021, 154, 106156. [Google Scholar] [CrossRef]

- Ghosh, T.; Karak, N. Cashew nut shell liquid terminated self-healable polyurethane as an effective anticorrosive coating with biodegradable attribute. Prog. Org. Coat. 2019, 139, 105472. [Google Scholar] [CrossRef]

- Kathalewar, M.; Sabnis, A.; D’Mello, D. Isocyanate free polyurethanes from new CNSL based bis-cyclic carbonate and its application in coatings. Eur. Polym. J. 2014, 57, 99–108. [Google Scholar] [CrossRef]

- Lubi, M.C.; Thachil, E.T. Cashew nut shell liquid (CNSL)—A versatile monomer for polymer synthesis. Des. Monomers Polym. 2000, 3, 123–153. [Google Scholar] [CrossRef]

- Kinaci, E.; Can, E.; La Scala, J.J.; Palmese, G.R. Epoxidation of Cardanol’s Terminal Double Bond. Polymers 2020, 12, 2104. [Google Scholar] [CrossRef]

- Asif, A.H.; Mahajan, M.S.; Sreeharsha, N.; Gite, V.V.; Al-Dhubiab, B.E.; Kaliyadan, F.; Nanjappa, S.H.; Meravanige, G.; Aleyadhy, D.M. Enhancement of Anticorrosive Performance of Cardanol Based Polyurethane Coatings by Incorporating Magnetic Hydroxyapatite Nanoparticles. Materials 2022, 15, 2308. [Google Scholar] [CrossRef] [PubMed]

- Stachak, P.; Łukaszewska, I.; Hebda, E.; Pielichowski, K. Recent Advances in Fabrication of Non-Isocyanate Polyurethane-Based Composite Materials. Materials 2021, 14, 3497. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Wu, G.; Jin, C.; Kong, Z. Preparation and antimicrobial activity of terpene-based polyurethane coatings with carbamate group-containing quaternary ammonium salts. Prog. Org. Coat. 2015, 80, 150–155. [Google Scholar] [CrossRef]

- Llevot, A.; Meier, M. Perspective: Green polyurethane synthesis for coating applications. Polym. Int. 2019, 68, 826–831. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D.; Yıldız, Z. Sustainability in Polyurethane Synthesis and Bio-based Polyurethanes BT. In Sustainability in the Textile and Apparel Industries: Sourcing Synthetic and Novel Alternative Raw Materials; Springer International Publishing: Cham, Switzerland, 2020; pp. 139–156. [Google Scholar]

- Lee, S.T.; Park, C.B.; Ramesh, N.S. Polymeric foams. In Polymers, 1st ed.; CRC/Taylor & Francis: Boca Raton, FL, USA, 2006; Volume 6. [Google Scholar]

- Szpiłyk, M.; Lubczak, R.; Lubczak, J. The biodegradable cellulose-derived polyol and polyurethane foam. Polym. Test. 2021, 100, 107250. [Google Scholar] [CrossRef]

- Lin, C.S.K.; Kirpluks, M.; Priya, A.; Kaur, G. Conversion of food waste-derived lipid to bio-based polyurethane foam. Case Stud. Chem. Environ. Eng. 2021, 4, 100131. [Google Scholar] [CrossRef]

- Zhang, J.; Hori, N.; Takemura, A. Influence of NCO/OH ratio on preparation of four agricultural wastes liquefied polyols based polyurethane foams. Polym. Degrad. Stab. 2020, 179, 109256. [Google Scholar] [CrossRef]

- Jonjaroen, V.; Ummartyotin, S.; Chittapun, S. Algal cellulose as a reinforcement in rigid polyurethane foam. Algal Res. 2020, 51, 102057. [Google Scholar] [CrossRef]

- Nabipour, H.; Wang, X.; Song, L.; Hu, Y. A fully bio-based coating made from alginate, chitosan and hydroxyapatite for protecting flexible polyurethane foam from fire. Carbohydr. Polym. 2020, 246, 116641. [Google Scholar] [CrossRef]

- Thangavelu, S.A.G.; Mukherjee, M.; Layana, K.; Kumar, C.D.; Sulthana, Y.R.; Kumar, R.R.; Ananthan, A.; Muthulakshmi, V.; Mandal, A.B. Biodegradable polyurethanes foam and foam fullerenes nanocomposite strips by one-shot moulding: Physicochemical and mechanical properties. Mater. Sci. Semicond. Process. 2020, 112, 105018. [Google Scholar] [CrossRef]

- Moon, J.; Kwak, S.B.; Lee, J.Y.; Kim, D.; Ha, J.U.; Oh, J.S. Recycling of bio-polyurethane foam using high power ultrasound. Polymer 2019, 186, 122072. [Google Scholar] [CrossRef]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańska, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and eggshells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Mirski, R.; Dukarska, D.; Walkiewicz, J.; Derkowski, A. Waste Wood Particles from Primary Wood Processing as a Filler of Insulation PUR Foams. Materials 2021, 14, 4781. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, A.; Kaur, R.; Walia, R.S. PU foam derived from renewable sources: Perspective on properties enhancement: An overview. Eur. Polym. J. 2017, 95, 255–274. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, M. Function of silicon oil in the castor oil based rigid polyurethane foams. J. Polym. Eng. 2013, 33, 875–880. [Google Scholar] [CrossRef]

- Kumar, M.; Kaur, R. Effect of Different Formulations of MDI on Rigid Polyurethane Foams based on Castor Oil. Int. J. Sci. Res. Rev. 2013, 2, 29–42. [Google Scholar]

- Agrawal, A.; Kaur, R.; Walia, R.S. Investigation on flammability of rigid polyurethane foam-mineral fillers composite. Fire Mater. 2019, 43, 917–927. [Google Scholar] [CrossRef]

- Kumar, M.; Kaur, R. Glass fiber reinforced rigid polyurethane foam: Synthesis and characterization. e-Polymers 2017, 17, 517–521. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R. Development of vegetable oil-based conducting rigid PU foam. e-Polymers 2019, 19, 411–420. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. Flame retardancy of ceramic-based rigid polyurethane foam composites. J. Appl. Polym. Sci. 2019, 136, 48250. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, M. Addition of anti-flaming agents in castor oil based rigid polyurethane foams: Studies on mechanical and flammable behaviour. Mater. Res. Express 2020, 7, 015333. [Google Scholar] [CrossRef]

- Shin, E.J.; Choi, S.M. Advances in Waterborne Polyurethane-Based Biomaterials for Biomedical Applications. Adv. Exp. Med. Biology. 2018, 1077, 251–283. [Google Scholar]

- Dreifke, M.B.; Jayasuriya, A.A.; Jayasuriya, A.C. Current wound healing procedures and potential care. Mater. Sci. Eng. C 2015, 48, 651–662. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wendels, S.; Avérous, L. Biobased polyurethanes for biomedical applications. Bioact. Mater. 2021, 6, 1083–1106. [Google Scholar] [CrossRef]

- Baheiraei, N.; Gharibi, R.; Yeganeh, H.; Miragoli, M.; Salvarani, N.; Di Pasquale, E.; Condorelli, G. Electroactive polyurethane/siloxane derived from castor oil as a versatile cardiac patch, part I: Synthesis, characterization, and myoblast proliferation and differentiation. J. Biomed. Mater. Res. Part A 2016, 104, 775–787. [Google Scholar] [CrossRef]

- Tan, L.; Hu, J.; Huang, H.; Han, J.; Hu, H. Study of multi-functional electrospun composite nanofibrous mats for smart wound healing. Int. J. Biol. Macromol. 2015, 79, 469–476. [Google Scholar] [CrossRef]

- Tan, L.; Hu, J.; Zhao, H.-F. Design of bilayered nanofibrous mats for wound dressing using an electrospinning technique. Mater. Lett. 2015, 156, 46–49. [Google Scholar] [CrossRef]

- Baheiraei, N.; Yeganeh, H.; Ai, J.; Gharibi, R.; Ebrahimibarough, S.; Azami, M.; Vahdat, S.; Baharvand, H. Preparation of a porous conductive scaffold from aniline pentamer-modified polyurethane/PCL blend for cardiac tissue engineering. J. Biomed. Mater. Res. Part A 2015, 103, 3179–3187. [Google Scholar] [CrossRef]

- Guo, B.; Finne-Wistrand, A.; Albertsson, A.C. Facile Synthesis of Degradable and Electrically Conductive Polysaccharide Hydrogels. Biomacromolecules 2011, 12, 2601–2609. [Google Scholar] [CrossRef]

- Ganji, Y.; Kasra, M.; Salahshour, K.S.; Bagheri, H.M. Synthesis and characterization of gold nanotube/nanowire–polyurethane composite based on castor oil and polyethylene glycol. Mater. Sci. Eng. C 2014, 42, 341–349. [Google Scholar] [CrossRef]

- Tsai, M.-C.; Hung, K.-C.; Hung, S.-C.; Hsu, S.-H. Evaluation of biodegradable elastic scaffolds made of anionic polyurethane for cartilage tissue engineering. Colloids Surf. B Biointerfaces 2015, 125, 34–44. [Google Scholar] [CrossRef] [PubMed]

- Hung, K.-C.; Tseng, C.-S.; Dai, L.-G.; Hsu, S.-H. Water-based polyurethane 3D printed scaffolds with controlled release function for customized cartilage tissue engineering. Biomaterials 2016, 83, 156–168. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Dong, R.; Ge, J.; Guo, B.; Ma, P.X. Biocompatible, Biodegradable, and Electroactive Polyurethane-Urea Elastomers with Tunable Hydrophilicity for Skeletal Muscle Tissue Engineering. ACS Appl. Mater. Interfaces 2015, 7, 28273–28285. [Google Scholar] [CrossRef]

- Chang, C.-J.; Hsu, S.-H. The effect of high outflow permeability in asymmetric poly(dl-lactic acid-co-glycolic acid) conduits for peripheral nerve regeneration. Biomaterials 2006, 27, 1035–1042. [Google Scholar] [CrossRef]

- Hsu, S.-H.; Chang, W.-C.; Yen, C.-T. Novel flexible nerve conduits made of water-based biodegradable polyurethane for peripheral nerve regeneration. J. Biomed. Mater. Res. A 2017, 105, 1383–1392. [Google Scholar] [CrossRef]

- Rocco, K.A.; Maxfield, M.W.; Best, C.A.; Dean, E.W.; Breuer, C.K. In vivo applications of electrospun tissue-engineered vascular grafts: A review. Tissue Eng. Part B Rev. 2014, 20, 628–640. [Google Scholar] [CrossRef]

- Adolph, E.J.; Guo, R.; Pollins, A.C.; Zienkiewicz, K.J.; Cardwell, N.L.; Davidson, J.M.; Guelcher, S.A.; Nanney, L.B. Injected biodegradable polyurethane scaffolds support tissue infiltration and delay wound contraction in a porcine excisional model. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 1679–1690. [Google Scholar] [CrossRef]

- Liu, W.; Wang, T.; Yang, C.; Darvell, B.W.; Wu, J.; Lin, K.; Chang, J.; Pan, H.; Lu, W. Alkaline biodegradable implants for osteoporotic bone defects--importance of microenvironment pH. Osteoporos. Int. 2016, 27, 93–104. [Google Scholar] [CrossRef]

- González Paz, R.J.; Lligadas, G.; Ronda, J.C.; Galià, M.; Ferreira, A.M.; Boccafoschi, F.; Ciardelli, G.; Cadiz, V. Enhancement of fatty acid-based polyurethanes cytocompatibility by non-covalent anchoring of chondroitin sulfate. Macromol. Biosci. 2012, 12, 1697–1705. [Google Scholar] [CrossRef]

- Blakney, A.K.; Simonovsky, F.I.; Suydam, I.T.; Ratner, B.D.; Woodrow, K.A. Rapidly Biodegrading PLGA-Polyurethane Fibers for Sustained Release of Physicochemically Diverse Drugs. ACS Biomater. Sci. Eng. 2016, 2, 1595–1607. [Google Scholar] [CrossRef] [Green Version]

- Żółtowska, K.; Piotrowska, U.; Oledzka, E.; Kuras, M.; Zgadzaj, A.; Sobczak, M. Biodegradable Poly(ester-urethane) Carriers Exhibiting Controlled Release of Epirubicin. Pharm. Res. 2017, 34, 780–792. [Google Scholar] [CrossRef] [PubMed]

- Mahanta, A.K.; Mittal, V.; Singh, N.; Dash, D.; Malik, S.; Kumar, M.; Maiti, P. Polyurethane-Grafted Chitosan as New Biomaterials for Controlled Drug Delivery. Macromolecules 2015, 48, 2654–2666. [Google Scholar] [CrossRef]

- Yu, C.; Tan, X.; Xu, Z.; Zhu, G.; Teng, W.; Zhao, Q.; Liang, Z.; Wu, Z.; Xiong, D. Smart drug carrier based on polyurethane material for enhanced and controlled DOX release triggered by redox stimulus. React. Funct. Polym. 2020, 148, 104507. [Google Scholar] [CrossRef]

- Aluri, R.; Jayakannan, M. Development of l-Tyrosine-Based Enzyme-Responsive Amphiphilic Poly(ester-urethane) Nanocarriers for Multiple Drug Delivery to Cancer Cells. Biomacromolecules 2017, 18, 189–200. [Google Scholar] [CrossRef]

- Kathalewar, M.S.; Joshi, P.B.; Sabnis, A.S.; Malshe, V.C. Non-isocyanate polyurethanes: From chemistry to applications. RSC Adv. 2013, 3, 4110–4129. [Google Scholar] [CrossRef]

- Doley, S.; Dolui, S.K. Solvent and catalyst-free synthesis of sunflower oil based polyurethane through non-isocyanate route and its coatings properties. Eur. Polym. J. 2018, 102, 161–168. [Google Scholar] [CrossRef]

- Malik, M.; Kaur, R. Synthesis of NIPU by the carbonation of canola oil using highly efficient 5,10,15-tris(pentafluorophenyl)corrolato-manganese(III) complex as novel catalyst. Polym. Adv. Technol. 2018, 29, 1078–1085. [Google Scholar] [CrossRef]

- Carré, C.; Ecochard, Y.; Caillol, S.; Avérous, L. From the Synthesis of Biobased Cyclic Carbonate to Polyhydroxyurethanes: A Promising Route towards Renewable Non-Isocyanate Polyurethanes. ChemSusChem 2019, 12, 3410–3430. [Google Scholar] [CrossRef]

- Rokicki, G.; Parzuchowski, P.G.; Mazurek, M. Non-isocyanate polyurethanes: Synthesis, properties, and applications. Polym. Adv. Technol. 2015, 26, 707–761. [Google Scholar] [CrossRef]

- Javni, I.; Hong, D.P.; Petrović, Z.S. Polyurethanes from soybean oil, aromatic, and cycloaliphatic diamines by nonisocyanate route. J. Appl. Polym. Sci. 2013, 128, 566–571. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.M.; de Lucas, A.; Rodríguez, J.F. Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability. Waste Manag. 2018, 76, 147–171. [Google Scholar] [CrossRef] [PubMed]

- Motokucho, S.; Nakayama, Y.; Morikawa, H.; Nakatani, H. Environment-friendly chemical recycling of aliphatic polyurethanes by hydrolysis in a CO2 -water system. J. Appl. Polym. Sci. 2017, 135, 14–17. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.M.; de Lucas, A.; Rodríguez, J.F. Glycolysis of viscoelastic flexible polyurethane foam wastes. Polym. Degrad. Stab. 2015, 116, 23–35. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.; Wang, L.; Hao, J. Comparative study of nitrogen migration among the products from catalytic pyrolysis and gasification of waste rigid polyurethane foam. J. Anal. Appl. Pyrolysis 2016, 120, 144–153. [Google Scholar] [CrossRef]

- AnuarSharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Jomaa, G.; Goblet, P.; Coquelet, C.; Morlot, V. Kinetic modeling of polyurethane pyrolysis using non-isothermal thermogravimetric analysis. Thermochim. Acta 2015, 612, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Dong, Q.; Liu, S.; Xie, H.; Liu, L.; Li, J. Recycling and Disposal Methods for Polyurethane Foam Wastes. Procedia Environ. Sci. 2012, 16, 167–175. [Google Scholar] [CrossRef]

- Osman, M.; Satti, S.M.; Luqman, A.; Hasan, F.; Shah, Z.; Shah, A.A. Degradation of Polyester Polyurethane by Aspergillus sp. Strain S45 Isolated from Soil. J. Polym. Environ. 2018, 26, 301–310. [Google Scholar] [CrossRef]

- Khan, S.; Nadir, S.; Shah, Z.U.; Shah, A.A.; Karunarathna, S.C.; Xu, J.; Khan, A.; Munir, S.; Hasan, F. Biodegradation of polyester polyurethane by Aspergillus tubingensis. Environ. Pollut. 2017, 225, 469–480. [Google Scholar] [CrossRef]

- Magnin, A.; Pollet, E.; Phalip, V.; Avérous, L. Evaluation of biological degradation of polyurethanes. Biotechnol. Adv. 2020, 39, 107457. [Google Scholar] [CrossRef]

| Thermoplastic PU | Flexible PU | Rigid PU | Polyurethane Ionomers | Water-Based PU |

|---|---|---|---|---|

|  |  |  |  |

| Flexible and elastic with good abrasion, weather, and abrasion resistance. | Block copolymers with phase separation between soft and hard segments that are flexible. | Versatile and energy-saving insulator | Improved thermal and mechanical characteristics and greater dispersion in polar liquids due to increased hydrophilicity. | Coatings and adhesives which use water as solvent are called water-based polyurethane. |

| For example, automotive instruments, footwear, medical devices, film, sheet, and applications with a profile. | For example, cushion materials, carpet underlays, furniture, packaging, biomedical, and industries that use cushion materials. | For example, sound and thermal insulators. Used in commercial and residential appliances. | For example, biomedical devices, shape memory and are biocompatible. | For example, coatings, adhesives, sealants, binders |

| Property | Bio-Based Polyurethanes | Petro-Based Polyurethanes |

|---|---|---|

| Density (kg m−3) | 112–181 | 141–181 |

| Thermal Conductivity (Wm−1K−1) | 0.06–0.0540 | 0.0540 |

| Volatile Organic Compound (µg m−3) | Not detected at 61–91 °C | Not detected at 61–91 °C |

| Compressive Strength (N mm−2) | 111–171 | 58.0 |

| Tensile Strength (N mm−2) | 1.4–1.6 | 0.84 |

| Bending strength (N mm−2) | 2.7–3.5 | 1.88 |

| Bending Stress (N mm−2) | 1.55 | 1.50 |

| Water Absorption (kg m−3) | 0.3 | 0.24 |

| Animal-Based Adhesives | Advantages | Disadvantages |

|---|---|---|

| Tissue and bones | Cheap, non-toxic, sets quickly, has a high shear strength, and doesn’t discolour wood | Has low water and damp resistance and does not produce distinct adhesive lines |

| Albumin and blood | Rapid heat setting, excellent dry shear strength, microorganism resistance, and does not discolour wood | Suitable to glue thin sheets |

| Casein | Resistance to water, damp conditions, elevated temperature, high shear strength | May discolour woods, dissolves only at high pH, expensive, not suitable for exterior use |

| Plant-Based Adhesives | Advantages | Disadvantages |

| Soybean | Non-toxic, has strong dry strength, and is moderately resistant to heat, wet, and damp environments. | Denaturation of proteins in alkaline solution which is caustic and discolour wood, sensitive to microbial degradation, and not suitable for exterior applications |

| Peanut | Non-toxic, hygroscopic, superiority of colour | Low shear strength, produces blisters, small bubble-like voids, and peanut allergies limit its applications. |

| Gluten | Non-toxic, sustainable source of protein | Costly |

| S. No. | Compositions of PU Adhesive | Method of Preparation | Applications |

|---|---|---|---|

| 1. | Castor oil—pentaerythritol | Trans esterification reaction | Bonding/adhesion of wood to wood and metal to metal |

| 2. | Castor oil—polyester polyols | Trans esterification reaction | Wood adhesive |

| 3. | Castor oil—cellulose acetate | Condensation reaction | Wood-wood, steel-steel adhesion |

| 4. | Castor oil—MDI modified cellulose acetate | Condensation reaction | Wood-wood, stainless steel lubricants |

| 5. | Castor oil-based PU adhesives | Condensation/trans esterification reactions | Wood adhesives, sealants |

| 6. | Castor oil—dicarboxylic acid (maleic acid, fumaric acid, oxalic acid) | Condensation reaction | Wood Adhesives |

| PU Type | Elastomer | Coating | Rigid Foam | Flexible Foam |

|---|---|---|---|---|

| Catalyst | DEA, EA, LiAc | KAc, NaOH, | BaO, DEA, EA, NaOH, KOH, NaAc, Dibutyltindilaurate, ZnAc2 | KAc, ZnAc2 DEA, TiBut, SnOct, LiOct |

| Cleavage agent | Diethylene glycol Monopropylene glycol Monoethylene glycolPoly(ethylene glycol) Triethylene glycol | Monoethylene glycol | Dipropylene glycol, Tetraethylene glycol, Diethylene glycol | Diethylene glycol, Monoethylene glycol, Dipropylene glycol, Monopropylene glycol, Poly(ethylene glycol), Triethylene glycol, Pentane 1,5 diol, Glycerol, Butane 1,4 diol, Polyethylene glycol 400, 1,6-hexane diol, Crude glycerol |

| Glycol: PU (wt.%) | 2:1 | 1:10–1:2 | 1:1–2:1 | 1:10–2:1 |

| Temperature range (°C) | 160–190 | 190–240 | 170–200 | 160–250 |

| Potential Market for recovered products | Adhesives | Coatings | Rigid foams | Flexible foams, Rigid foams, Adhesives, Elastomers |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaur, R.; Singh, P.; Tanwar, S.; Varshney, G.; Yadav, S. Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol 2022, 2, 284-314. https://doi.org/10.3390/macromol2030019

Kaur R, Singh P, Tanwar S, Varshney G, Yadav S. Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol. 2022; 2(3):284-314. https://doi.org/10.3390/macromol2030019

Chicago/Turabian StyleKaur, Raminder, Pooja Singh, Surya Tanwar, Gunjan Varshney, and Sarla Yadav. 2022. "Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation" Macromol 2, no. 3: 284-314. https://doi.org/10.3390/macromol2030019

APA StyleKaur, R., Singh, P., Tanwar, S., Varshney, G., & Yadav, S. (2022). Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol, 2(3), 284-314. https://doi.org/10.3390/macromol2030019