On the Effects of Clothing Area Factor and Vapour Resistance on the Evaluation of Cold Environments via IREQ Model

Abstract

1. Introduction

1.1. Background

1.2. Aim of This Paper

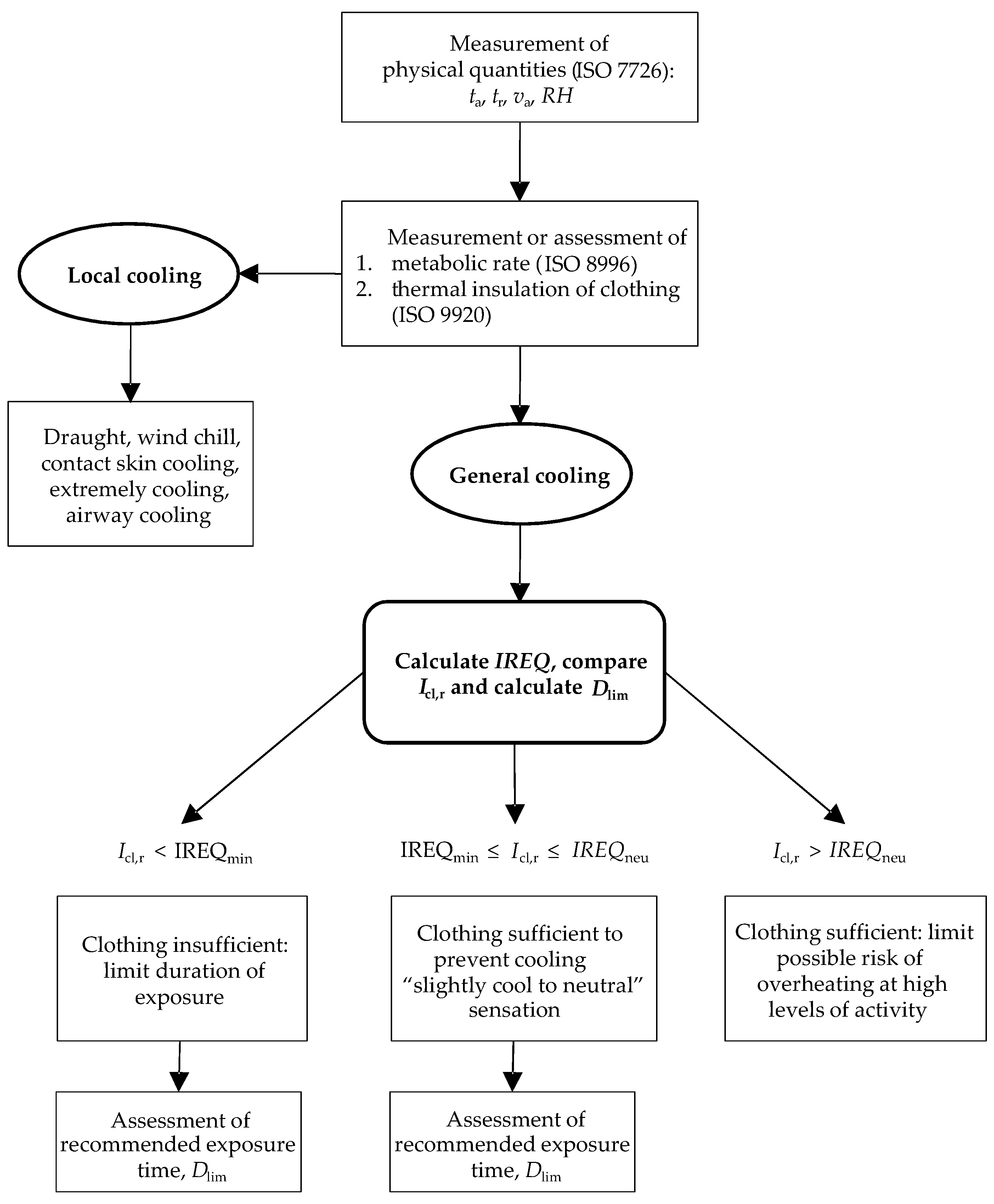

2. The IREQ Model

2.1. Model Features

- IREQ < Icl,r: there is no risk for cold. However, if IREQ << Icl,r, then there may be a risk of overheating and excess sweating, which may lead to discomfort and cold-related issues later.

- IREQ > Icl,r: worker safety is not necessarily guaranteed. More specifically, if the body heat loss is within 144 kJ m−2, there is no risk to health, provided that the extremities are properly protected. However, if this limit for heat loss is exceeded, it is necessary to assess the maximum safe exposure time.

2.2. Open Issues

3. Methods

- Identification of the equations which return the highest and lowest fcl values, respectively.

- Evaluation and comparison of IREQ and Dlim values using the equations identified in the previous step, consistently with low strain (neutral) and high strain (minimal) criteria within the range of subjective (metabolic rate and basic clothing insulation) and physical (air temperature, air velocity, relative humidity and mean radiant temperature) variables considered by ISO 11079.

- Air temperature: ta < 10 °C;

- Air velocity: 0.4 < va < 18 m/s;

- Basic clothing insulation, Icl ≥ 0.5 clo.

4. Results and Discussion

4.1. The Effect of Clothing Area Factor

4.1.1. Preliminary Observations

- Group A formulas (Equations (13), (17), (19) and (20)) that include ISO 11079 (Equation (13)), ISO 9920 (Equation (17)), and ISO 7933 (Equation (17)) return fcl values higher than 25% (50%) for Icl = 2.0 clo (Icl = 4.0 clo) if compared with Equation (16), which returns the lowest values.

- Group B formulas (Equations (15), (18) and (21)) return fcl values not higher than 10% if compared with those calculated by Equation (16).

- Group C formulas exhibit intermediate behaviour if compared with Equation (16). More particularly, Equation (14) returns fcl values not higher than 20%, whereas Equation (22) behaves like group A formulas for Icl < 1.0 clo, then reaches a maximum of 10.6% for Icl = 2 clo, and finally overestimates fcl by 6.2% for Icl = 4.0 clo.

- Equation (13), which returns the highest fcl values and is adopted by ISO 11079.

- Equation (16), which returns the lowest fcl values and is chosen as the basis for comparisons.

- Equation (22), which despite requiring further validation, is a better fit for the experimental fcl values measured on professional modular clothing system for ambulance personnel, which is meant to provide thermal comfort over a wide range of climatic conditions from hot summer days to extremely cold Nordic winters [36].

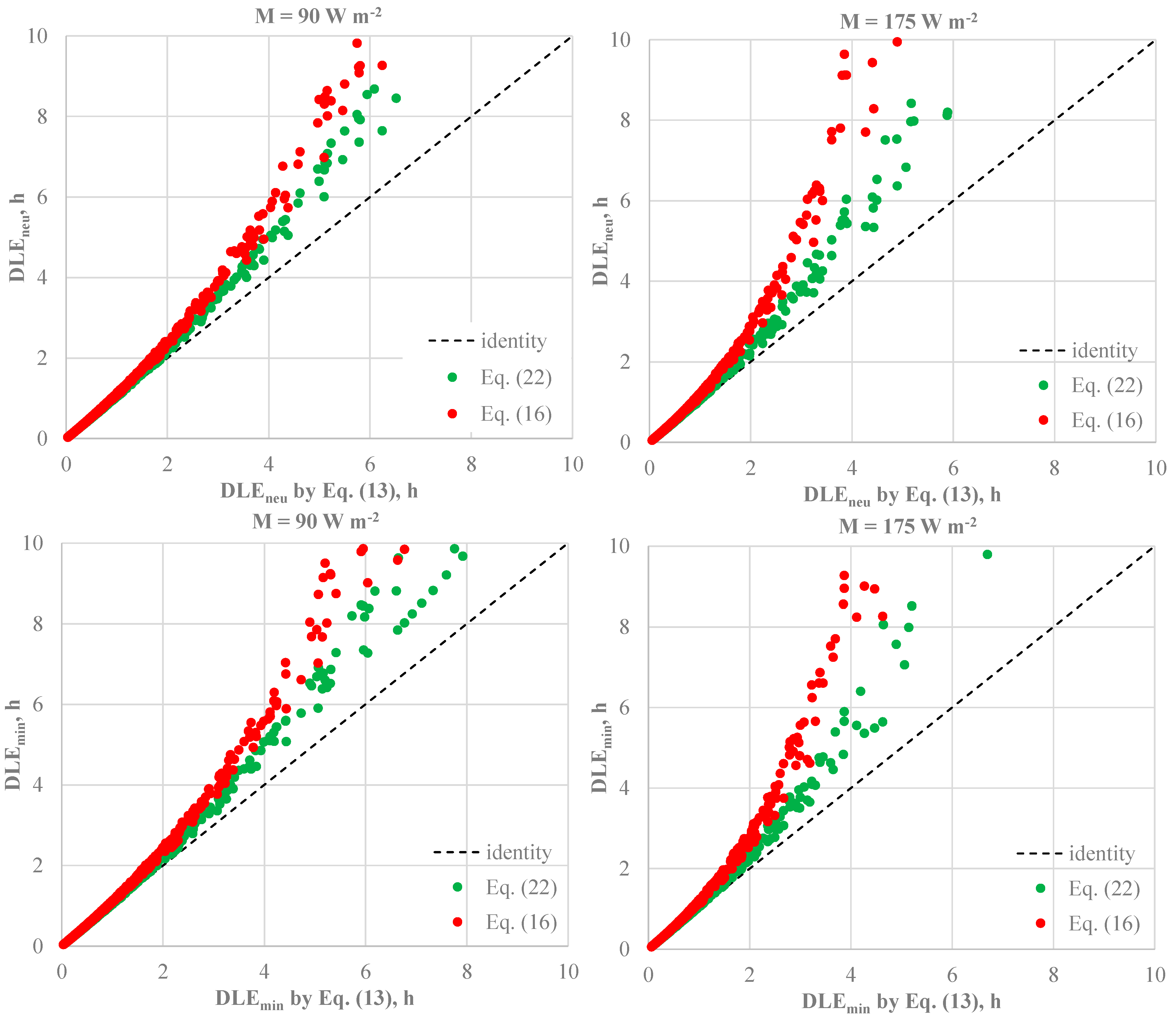

4.1.2. Effect of Clothing Area Factor on IREQ Values

- 1.

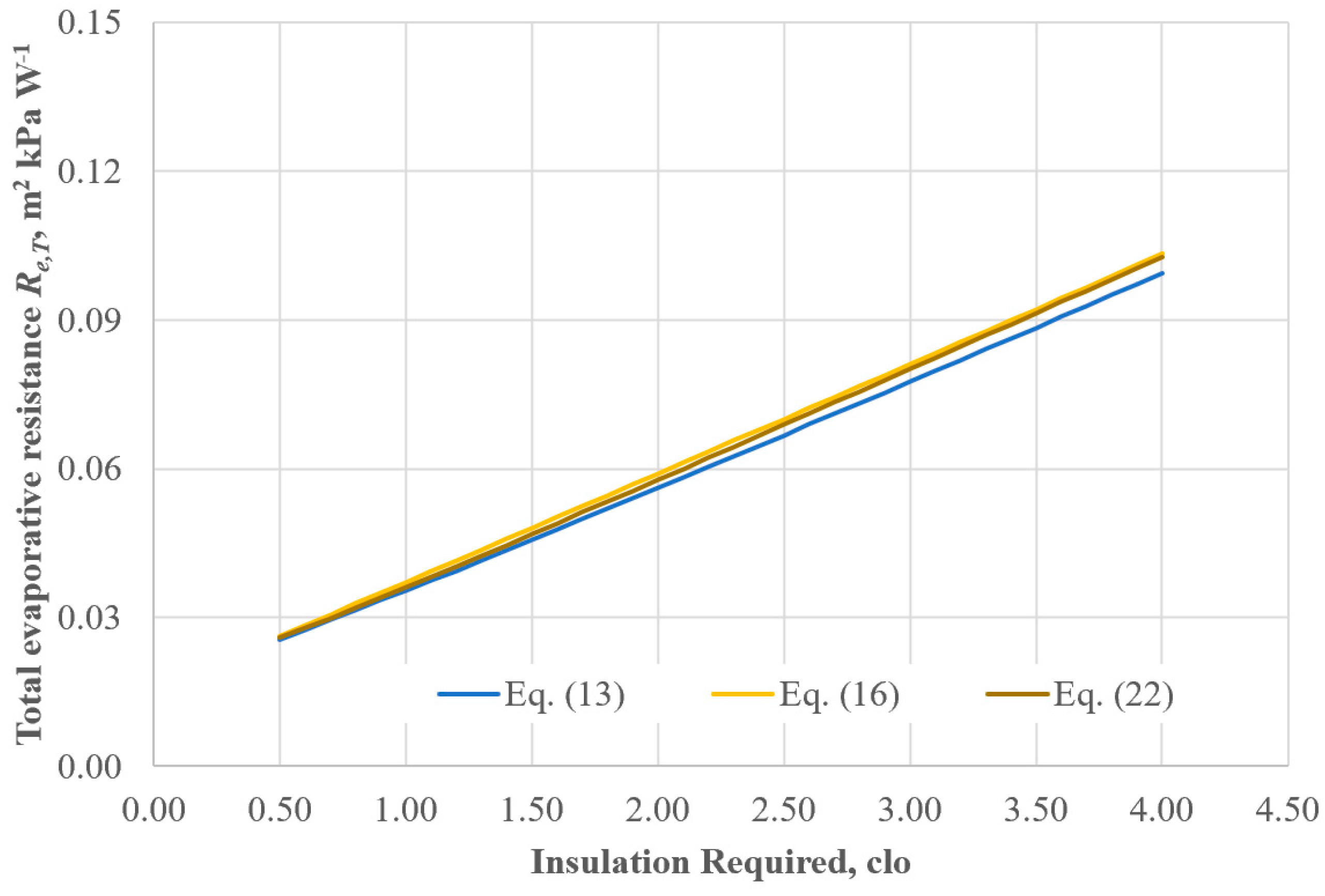

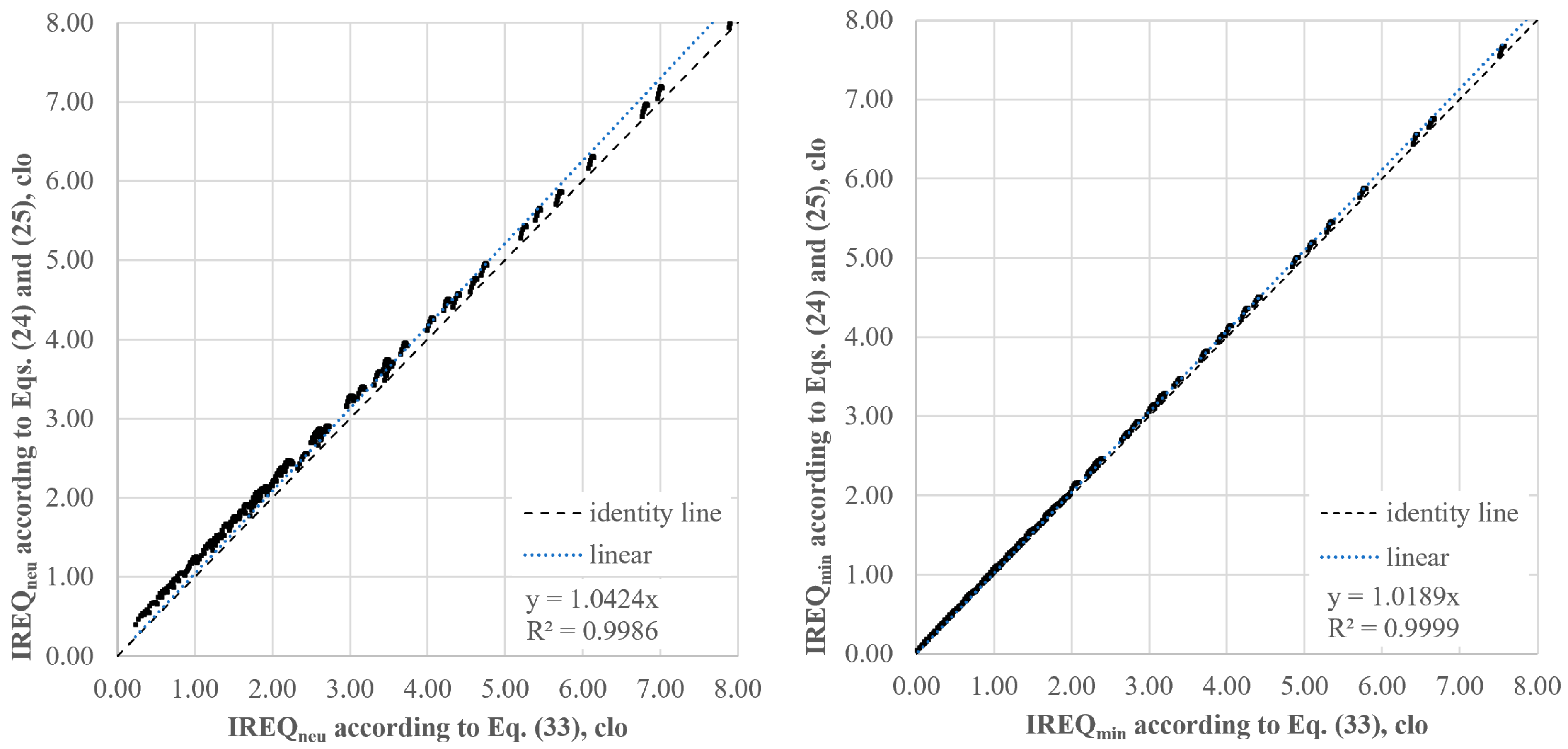

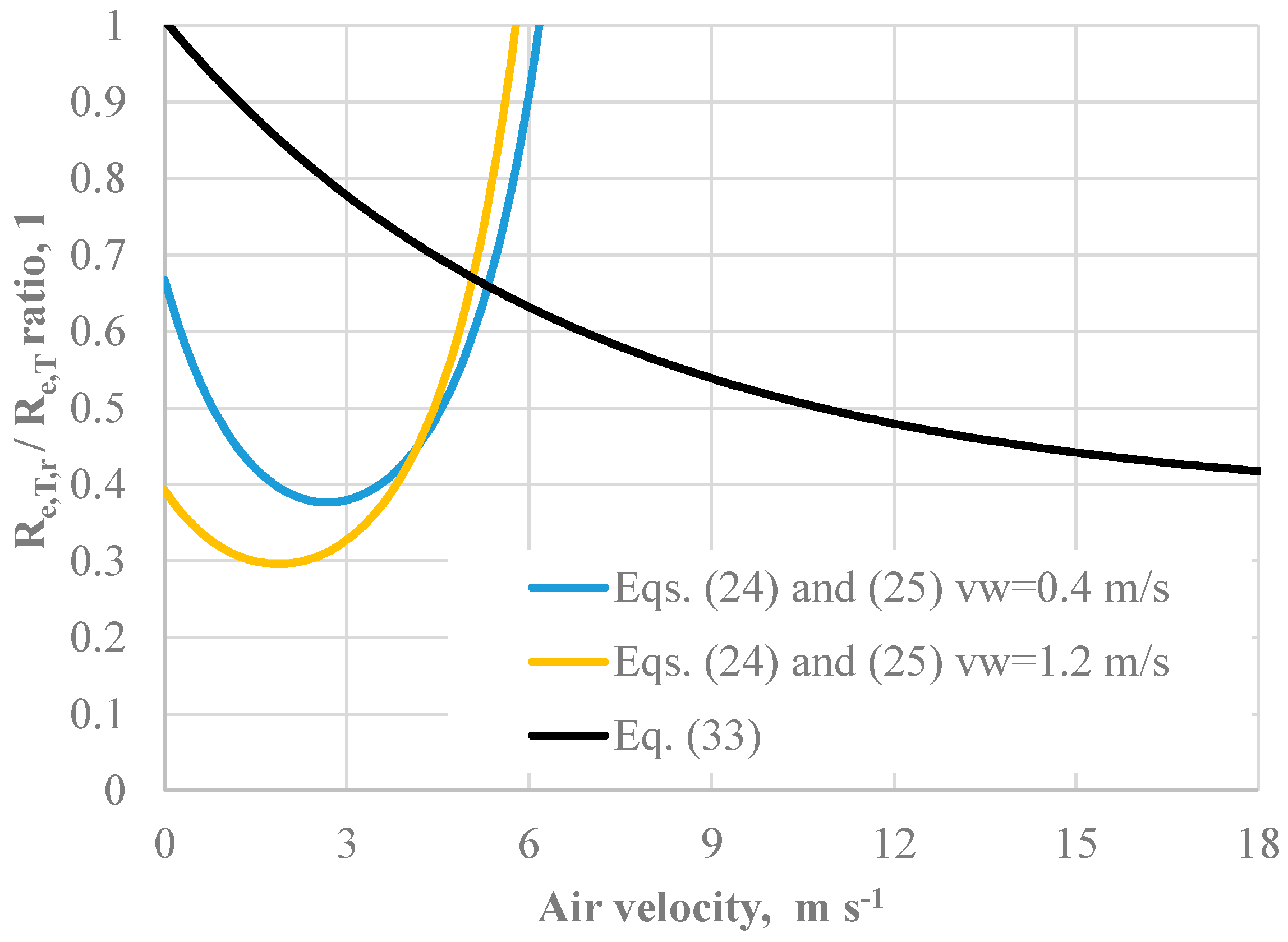

- The right side of Equation (2) (dry heat loss) is scarcely affected by the different formulas used for the evaluation of fcl. This is because the only term at the right side of Equation (2) affected by the clothing area factor is the evaporative heat flow E being related to the resultant total evaporative resistance of clothing according to Equations (5) and (32) with Icl,r = IREQ. Now, the total evaporative resistance of clothing and air boundary layer is quite unaffected by the formula adopted for fcl calculation, as shown in Figure 4.

- 2.

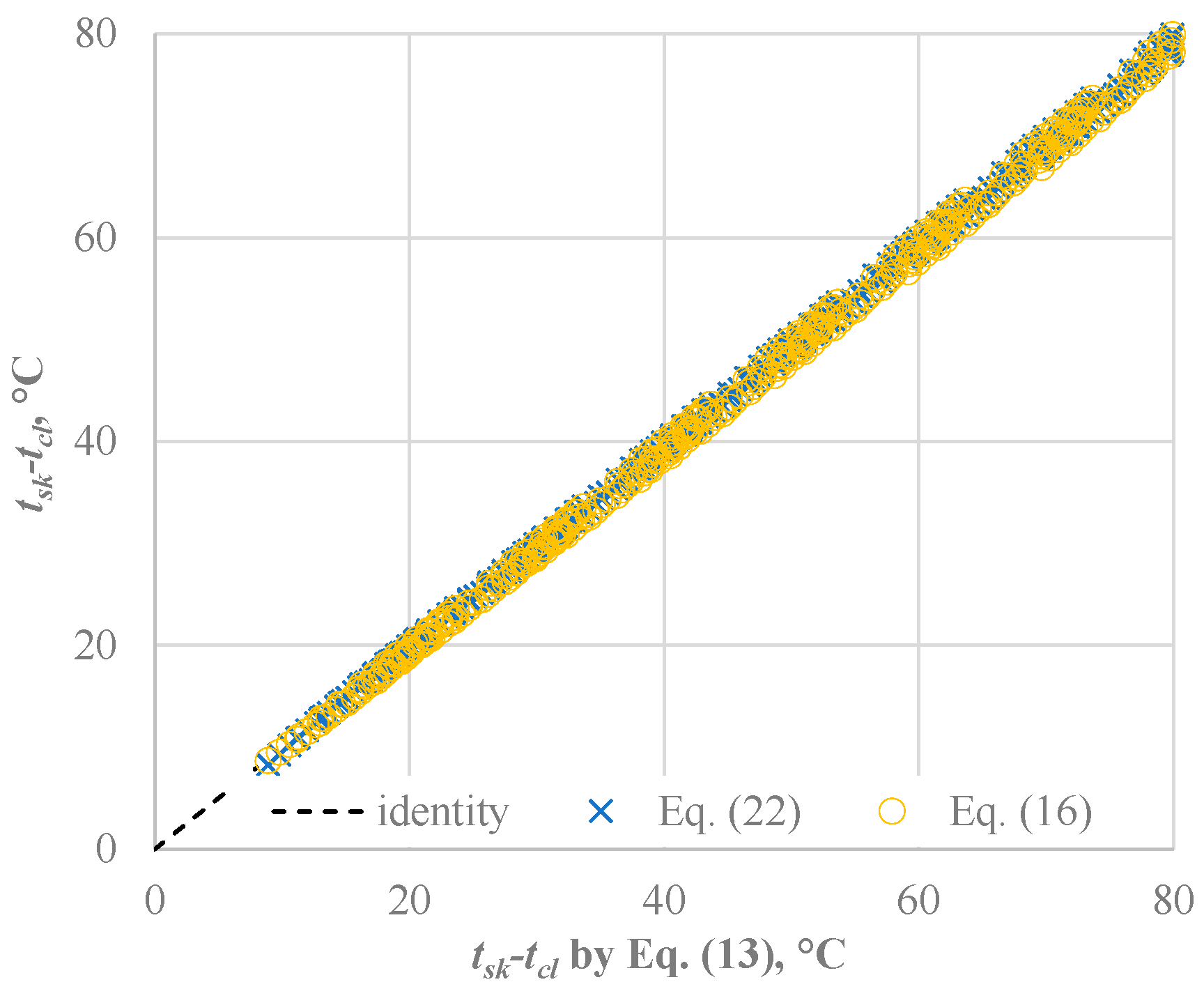

- The clothing surface temperature is scarcely affected by the errors induced by the use of the different formulas for fcl calculation as confirmed by data shown in Figure 5.

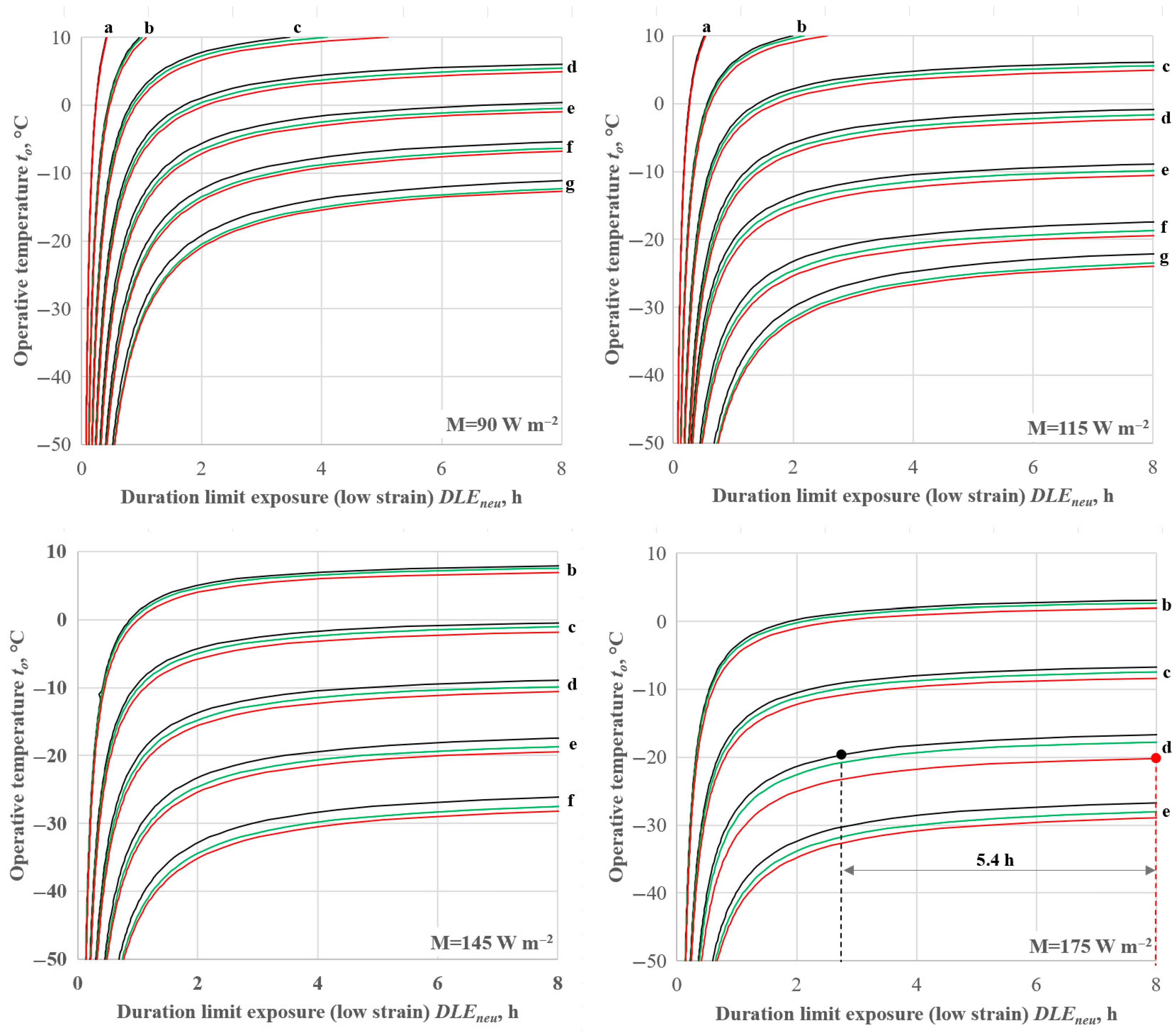

4.1.3. Effect of Clothing Area Factor on Dlim Values

4.2. The Effect of Resultant Vapour Resistance

5. Conclusions

- Despite the meaningful underestimation of the clothing area factor calculated with the most recent algorithms developed on an experimental basis, the effects on the neutral and minimum IREQ values are negligible. Different fcl formulas return the same IREQ values. This phenomenon is only an apparent inconsistency as, under equilibrium conditions (no heat accumulated in the body), the only term affecting the heat balance equation on the human body is the evaporative heat loss that is scarcely affected by fcl, especially for high clothing insulation values.

- The clothing area factor meaningfully affects the duration limit exposure under long-term risk conditions (Dlim > 2 h and Icl,r < IREQmin). More particularly, as fcl increases, both dry and latent heat losses increase with the consequent increase in the modulus of the body heat storage rate. Consequently, the most recent formula proposed by Kuklane and Toma (lower fcl, then lower dry heat loss) [36] returns higher Dlim values (up to 5 h) if compared with those calculated consistently with the actual version of ISO 11079 standard.

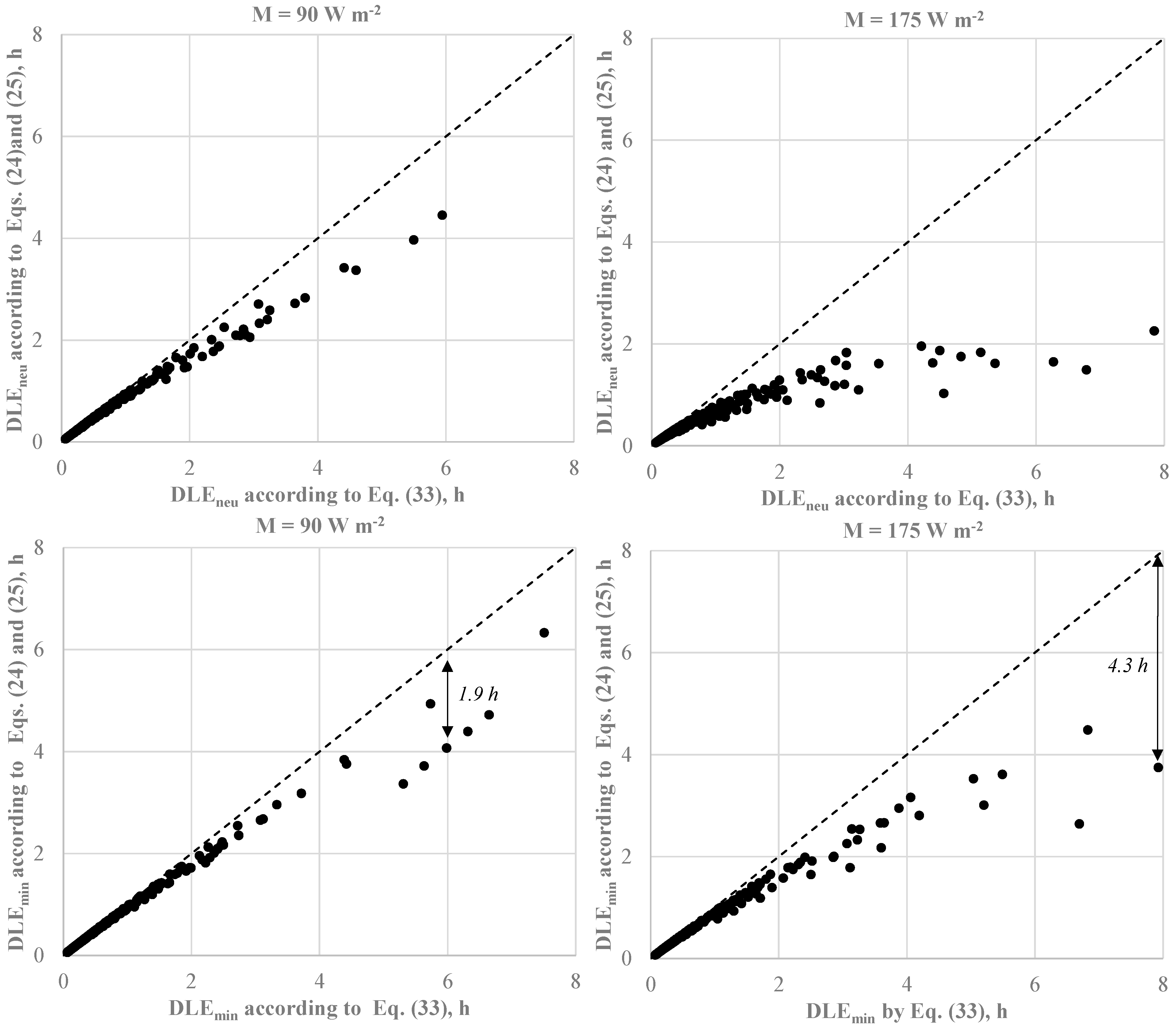

- The effect of the resultant vapour resistance calculation is similar to that observed in the case of fcl. IREQ values are not meaningfully affected even by meaningful differences in the vapour resistance and the evaporative loss, whereas Dlim values calculated using the actual version of ISO 11079 can be significantly higher than those calculated consistently with the algorithms recommended by ISO 9920 but validated for air velocity values lower than 3.5 m s−1.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Symbols

| ADu | Dubois body surface area, m2 |

| ap | air permeability of outer fabric, L s−1 m−2 |

| Ar | Effective radiating area of a body, m2 |

| C | Convective heat flow, W m−2 |

| Cres | Respiratory convective heat flow, W m−2 |

| CorrE | Correction factor for total vapour resistance, ND |

| CorrIT | Correction factor for total insulation, ND |

| DLEmin | Duration limit exposure consistent with high strain criteria, h |

| DLEneu | Duration limit exposure consistent with low strain criteria, h |

| Dlim | Duration limit exposure, h |

| E | Evaporative heat flow at the skin, W m−2 |

| Eres | Respiratory evaporative heat flow, W m−2 |

| fcl | Clothing area factor, ND |

| hc | Convective heat transfer coefficient, W m−2 K−1 |

| hr | Radiative heat transfer coefficient, W m−2 K−1 |

| Ia | Static boundary layer thermal insulation, m2 K W−1 or clo |

| Ia,r | Resultant boundary layer thermal insulation, m2 K W−1 or clo |

| Icl | Basic clothing insulation, m2 K W−1 or clo |

| Icl,r | Resultant clothing insulation, m2 K W−1 or clo |

| im | Moisture permeability index, ND |

| IREQ | Required clothing insulation, m2 K W−1 or clo |

| IREQmin | Minimal required clothing insulation, m2 K W−1 or clo |

| IREQneu | Neutral required clothing insulation, m2 K W−1 or clo |

| IT | Basic total insulation, m2 K W−1 or clo |

| IT,r | Resultant total insulation, m2 K W−1 or clo |

| K | Conductive heat flow, W m−2 |

| L | Lewis relation, K kPa−1 |

| M | Metabolic rate, W m−2 or met |

| pa | Water vapour partial pressure, kPa |

| pex | Saturated water vapour pressure at expired air temperature, kPa |

| psk,s | Saturated water vapour pressure at skin temperature, kPa |

| R | Radiative heat flow, W m−2 |

| Re,T | Total evaporative resistance of clothing and boundary air layer, m2 kPa W−1 |

| Re,T,r | Resultant evaporative resistance of clothing and boundary air layer, m2 kPa W−1 |

| RH | Relative Humidity, % |

| Qlim | Limit body heat loss, kJ m−2 or W h m−2 |

| S | Body heat storage rate, W m−2 |

| ta | Air temperature, °C |

| tcl | Clothing surface temperature, °C |

| tex | Expired air temperature, °C |

| to | Operative temperature, °C |

| tr | Mean radiant temperature, °C |

| tsk | Mean skin temperature, °C |

| va | Air velocity, m s−1 |

| var | Relative air velocity, m s−1 |

| vw | Walking speed, m s−1 |

| W | Effective mechanical power, ND |

| w | Skin wettedness, ND |

Greek Symbols

| εcl | Emissivity of clothing surface, ND |

| σ | Stefan–Boltzmann constant, W m−2 K−4 |

Abbreviations

| PHS | Predicted Heat Strain |

| PMV | Predicted Mean Vote |

| SOBANE | Screening, OBservation, Analysis, Expertise |

Appendix A

- 1.

- Since the four microclimatic quantities (air temperature, air velocity, relative humidity, and mean radiant temperature) and the metabolic rate are known, the right side of the first equation in system (A1) is a known value, except for the evaporative heat flow. With this in mind, we arbitrarily choose a trial value for IREQ (e.g., IREQ = 0.5)

- 2.

- The resultant evaporative resistance can be evaluated using Equation (27) with the assumed value for IREQ (Icl,r = IREQ). Consequently, the evaporation rate at the skin surface, given by Equation (5), can be calculated by assuming the skin wettedness values provided by Table 1. At this point, the right-hand side of Equation (2) becomes a known quantity, allowing the calculation of the clothing temperature with the following equation (see Equation (A1)):

- 3.

- The value of tcl obtained from Equation (A6) enables the calculation of the radiative heat transfer coefficient hr and the convective heat transfer coefficient hc, as given by Equations (A7) and (A8), respectively. Consequently, the convective and radiative heat fluxes can be determined using Equations (3a) and (3b).

- 4.

- The final step involves comparing the left-hand side of Equation (2), calculated as described in bullet point 3, with the right-hand side, calculated as outlined in bullet point 2. Specifically,

- (a)

- If the left-hand side exceeds the right, the trial IREQ value is increased by a small, arbitrary increment (see the adjustment factor in codes reported in the Appendix B).

- (b)

- If the right-hand side exceeds the left, the trial IREQ value is decreased by a similarly small amount.

Appendix B

Appendix B.1. Matlab Function for the Calculation of IREQ Neutral

Appendix B.2. Matlab Function for the Calculation of IREQ Minimal

Appendix B.3. Matlab Function for the Calculation of DLE Neutral

Appendix B.4. Matlab Function for the Calculation of DLE Minimal

Appendix B.5. Example of Matlab Script for Calculating IREQ Values

References

- Petersson, J.; Kuklane, K.; Gao, C. Is there a need to integrate human thermal models with weather forecasts to predict thermal stress? Int. J. Environ. Res. Public Health 2019, 16, 4586. [Google Scholar] [CrossRef]

- Ebi, K.L.; Mills, D. Winter mortality in a warming climate: A reassessment. Wiley Interdiscip. Rev. Clim. Change 2013, 4, 203–212. [Google Scholar] [CrossRef]

- Gronlund, C.J.; Sullivan, K.P.; Kefelegn, Y.; Cameron, L.; O’Neill, M.S. Climate change and temperature extremes: A review of heat-and cold-related morbidity and mortality concerns of municipalities. Maturitas 2018, 114, 54–55. [Google Scholar] [CrossRef] [PubMed]

- Mäkinen, T.M.; Hassi, J. Health Problems in Cold Work. Ind. Health 2009, 47, 207–220. [Google Scholar] [CrossRef]

- Oliveira, A.V.M.; Gaspar, A.R.; Quintela, D.A. Occupational exposure to cold thermal environments: A field study in Portugal. Eur. J. Appl. Physiol. 2008, 104, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Holmér, I.; Parsons, K.C.; Tochihara, Y.; Sawada, S. Cold Stress at Work: Preventive Research. Ind. Health 2009, 47, 205–206. [Google Scholar] [CrossRef] [PubMed]

- ISO 12894; Ergonomics of the Thermal Environment—Medical Supervision of Individuals Exposed to Extreme Hot or Cold Environments. International Standardization Organization: Geneva, Switzerland, 2001.

- Castellani, J.W.; Tipton, M.J. Cold stress effects on exposure tolerance and exercise performance. Compr. Physiol. 2015, 6, 443–469. [Google Scholar] [CrossRef]

- Parsons, K.C. Human Cold Stress; CRC Press: Boca Raton, FL, USA, 2021; 158p. [Google Scholar]

- National Institute for Occupational Safety and Health. Workplace Safety and Health Topics. 2023. Available online: https://www.cdc.gov/niosh/cold-stress/about/?CDC_AAref_Val=https://www.cdc.gov/niosh/topics/coldstress/ (accessed on 24 June 2025).

- Council of the European Community. Council Directive 89/391/EEC of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work. Off. J. Eur. Union 1989, 183, 1–8. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31989L0391 (accessed on 24 July 2025).

- Malchaire, J.B.; Gebhardt, H.J.; Piette, A. Strategy for Evaluation and Prevention of Risk due to Work in Thermal Environment. Ann. Occup. Hyg. 1999, 43, 367–376. [Google Scholar] [CrossRef]

- Palella, B.I.; Quaranta, F.; Riccio, G. On the management and prevention of heat stress for crews onboard ships. Ocean Eng. 2016, 112, 277–286. [Google Scholar] [CrossRef]

- ISO 15265; Ergonomics of Thermal Environments: Strategy of Evaluation of the Risk for the Prevention of Constraints or Discomfort Under Thermal Working Conditions Standard. International Standardization Organization: Geneva, Switzerland, 2005.

- ISO 15743; Ergonomics of the Thermal Environment—Cold Workplaces—Risk Assessment and Management. International Standardization Organization: Geneva, Switzerland, 2008.

- Holmér, I. Required Clothing Insulation (IREQ) as an Analytical Index of the Cold Stress. ASHRAE Trans. 1984, 90, 1116–1128. [Google Scholar]

- Holmér, I. Assessment of Cold Stress in Terms of Required Clothing Insulation: IREQ. Int. J. Ind. Ergon. 1988, 3, 159–166. [Google Scholar] [CrossRef]

- ISO 11079; Ergonomics of the Thermal Environment—Determination and Interpretation of Cold Stress When Using Required Clothing Insulation (IREQ) and Local Cooling Effects. International Standardization Organization: Geneva, Switzerland, 2007.

- Castellani, J.W.; Spitz, M.G.; Karis, A.J.; Martini, S.; Young, A.J.; Margolis, L.M.; Phillip Karl, J.; Murphy, N.E.; Xu, X.; Montain, S.J.; et al. Cardiovascular and thermal strain during 3–4 days of a metabolically demanding cold-weather military operation. Extrem. Physiol. Med. 2017, 6, 2. [Google Scholar] [CrossRef] [PubMed]

- Morabito, M.; Pavlinic, D.Z.; Crisci, A.; Capecchi, V.; Orlandini, S.; Mekjavic, I.B. Determining optimal clothing ensembles based on weather forecasts, with particular reference to outdoor winter military activities. Int. J. Biometeorol. 2011, 55, 481–490. [Google Scholar] [CrossRef]

- Cartwright, J.M.T.; Etter, C.V.; Gnatiuk, E.A.; Perrotta, A.S.; Wang, F.; White, M.D. Duration limits for exposure for the whole body and extremities with a military extreme cold protection clothing ensemble at an ambient temperature of −40°C. Temperature 2022, 9, 211–222. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.V.M.; Gaspar, A.R.; André, J.S.; Quintela, D.A. Subjective analysis of cold thermal environments. Appl. Ergon. 2014, 45, 534–543. [Google Scholar] [CrossRef]

- Golbabaei, F.; Azrah, K.; Goodarzi, Z.; Ahmadi, O.; Karami, E. Risk assessment of cold stress in petroleum transfer station in the northwestern regions of Iran: Subjective and field measurements. J. Therm. Biol. 2022, 110, 103335. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Lin, L.Y.; Halder, A.; Kuklane, K.; Holmér, I. Validation of standard ASTM F2732 and comparison with ISO 11079 with respect to comfort temperature ratings for cold protective clothing. Appl Ergon. 2015, 46, 44–53. [Google Scholar] [CrossRef]

- ASTM F2732-23; Standard Practice for Determining the Temperature Ratings for Cold Weather Protective Clothing. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- Liu, X.; Wang, Y.; Tian, M. Quantitative characterization of clothing’s cold protective capability to achieve thermal comfort: A systematic review. Build. Environ. 2022, 219, 109226. [Google Scholar] [CrossRef]

- Golden, F.S.C.; Tipton, M.J. Human Adaptation to Repeated Cold Immersions. J. Physiol. 1998, 396, 349–363. [Google Scholar] [CrossRef]

- Griefahn, B.; Forsthoff, A. Comparison Between Estimated Worn Clothing Insulation and Required Calculated Clothing Insulation in Moderately Cold Environments (0 °C < or = ta < or 15 °C). Appl. Ergon. 1997, 28, 295–299. [Google Scholar] [CrossRef]

- Griefahn, B.; Forsthoff, A. Limits of and Possibilities to Improve the IREQ Cold Stress Model (ISO/TR 11079). A Validation Study in the Field. Appl. Ergon. 2000, 31, 423–431. [Google Scholar] [CrossRef]

- Oliveira, A.V.M.; Gaspar, A.R.; Raimundo, A.M.; Quintela, D.A. Evaluation of Occupational Cold Environments: Field Measurements and Subjective Analysis. Ind. Healt 2014, 52, 262–274. [Google Scholar] [CrossRef]

- Austad, H.; Wiggen, Ø.; Færevik, H.; Seeberg, T. Towards a wearable sensor system for continuous occupational cold stress assessment. Ind. Health 2018, 56, 228–240. [Google Scholar] [CrossRef]

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. Notes on the Implementation of the IREQ Model for the Assessment of Extreme Cold Environments. Ergonomics 2013, 56, 707–724. [Google Scholar] [CrossRef]

- Havenith, G.; Nilsson, H.O. Correction of clothing insulation for movement and wind effects, a meta-analysis. Eur. J. Appl. Physiol. 2004, 92, 636–640. [Google Scholar] [CrossRef] [PubMed]

- ISO 9920; Ergonomics of the Thermal Environment—Estimation of the Thermal Insulation and Evaporative Resistance of a Clothing Ensemble. International Organization for Standardization: Geneva, Switzerland, 2009.

- Fanger, P.O. Thermal Comfort; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Kuklane, K.; Toma, R. Common clothing area factor estimation equations are inaccurate for highly insulating (Icl>2 clo) and non-western loose-fitting clothing ensembles. Ind. Health 2021, 59, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Kakitsuba, N. Investigation into clothing area factors for tight and loose fitting clothing in three different body positions. J. Hum. Environ. Syst. 2004, 7, 75–81. [Google Scholar] [CrossRef]

- McCullough, E.A.; Huang, J.; Deaton, S. Methods for measuring the clothing area factor. Environmental Ergonomics XI. In Proceedings of the 11th International Conference on Environmental Ergonomics, Ystad, Sweden, 22–26 May 2005; Holmér, I., Kuklane, K., Gao, C., Eds.; Lund University: Lund, Sweden, 2005; pp. 433–436. [Google Scholar]

- Psikuta, A.; Mert, E.; Annaheim, S.; Rossi, R.M. 3D body scanning technology and applications in protective clothing. In Firefighters’ Clothing and Equipment: Performance, Protection, and Comfort; Song, G., Wang, F., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 269–284. [Google Scholar]

- Meinander, H.; Anttonen, H.; Bartels, V.; Holmér, I.; Reinertsen, R.E.; Soltynski, K.; Varieras, S. Manikin measurements versus wear trials of cold protective clothing (Subzero project). Eur. J. Appl. Physiol. 2004, 92, 619–621. [Google Scholar] [CrossRef]

- Meinander, H.; Anttonen, H.; Bartels, V.; Holmér, I.; Reinertsen, R.E.; Soltynski, K.; Varieras, S. Thermal Insulation Measurements of Cold Protective Clothing Using Thermal Manikins. SUBZERO Project, Final Report (Report No. 4); Fibre Materials Science, Tampere University of Technology: Tampere, Finland, 2003. [Google Scholar]

- ISO 15831; Clothing—Physiological effects—Measurement of Thermal Insulation by Means of a Thermal Manikin. International Standardization Organization: Geneva, Switzerland, 2004.

- Havenith, G.; Kuklane, K.; Fan, J.; Hodder, S.; Ouzzahra, Y.; Lundgren, K.; Au, Y.; Loveday, D. A database of static clothing thermal insulation and vapor permeability values of non-western ensembles for use in ASHRAE standard 55, ISO 7730, and ISO 9920. ASHRAE Trans 2015, 121, 197–215. [Google Scholar]

- ISO 7933; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Heat Stress Using Calculation of the Predicted Heat Strain. International Standardization Organization: Geneva, Switzerland, 2023.

- Available online: https://www.design.lth.se/english/the-department/research-laboratories/aerosol-climate-laboratory/climate/tools/calculations-for-ireq-and-wct/ (accessed on 24 June 2025).

- Ikäheimo, T.M.; Kuklane, K.; Jaakkola, J.J.K.; Holmér, I. Cold stress. In Patty’s Industrial Hygiene, 7th ed.; Cohrssen, Ed.; Physical and Biological Agents; John Wiley & Sons: Hoboken, NJ, USA, 2021; Volume 3, 432p. [Google Scholar]

- ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort. International Standardization Organization: Geneva, Switzerland, 2005.

- Smallcombe, J.; Hodder, S.; Loveday, D.; Kuklane, K.; Mlynarczyk, M.; Halder, A.; Petersson, J.; Havenith, G. Updated database of clothing thermal insulation and vapor permeability values of western ensembles for use in ASHRAE standard 55, ISO 7730 and ISO 9920. Results of ASHRAE RP-1760. ASHRAE Trans 2021, 127, 773–799. [Google Scholar]

- ISO TR 11079; Evaluation of Cold Environments: Determination of Required Clothing Insulation (IREQ). International Standardization Organization: Geneva, Switzerland, 1993.

- Havenith, G.; Holmér, I.; den Hartog, E.A.; Parsons, K.C. Clothing evaporative heat resistance. Proposal for improved representation in standards and models. Ann. Occup. Hyg. 1999, 43, 339–346. [Google Scholar] [CrossRef]

- Havenith, G.; Holmér, I.; den Hartog, E.A.; Parsons, K.C. Clothing Evaporative Heat Resistance—Proposal for Improved Representation in Standards and Models, Environmental Ergonomics 1998; Heaney, J., Hodgdon, J., Eds.; ICEE: San Diego, CA, USA, 1998. [Google Scholar]

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G.; Malchaire, J. On the Effect of Thermophysical Properties of Clothing on the Heat Strain Predicted by PHS Model. Ann. Occup. Hyg. 2016, 60, 231–251. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Del Ferraro, S.; Lin, L.; Sotto Mayor, T.; Molinaro, V.; Ribeiro, M.; Gao, C.; Kuklane, K.; Holmér, I. Localised boundary air layer and clothing evaporative resistances for individual body segments. Ergonomics 2012, 55, 799–812. [Google Scholar] [CrossRef] [PubMed]

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. THERMODE 2023: Formulation and Validation of a new Thermo-physiological Model for Moderate Environments. Build. Environ. 2024, 252, 111272. [Google Scholar] [CrossRef]

- Ueno, S. Comparison of correction factor for both dynamic total thermal insulation and evaporative resistance between ISO 7933 and ISO 9920. J. Physiol. Anthropol. 2020, 39, 23. [Google Scholar] [CrossRef]

- The MathWorks, Inc. MATLAB version: 9.13.0 (R2022b). Available online: https://www.mathworks.com (accessed on 24 June 2025).

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. The role of Measurement Accuracy on the Heat Stress Assessment according to ISO 7933: 2004. WIT Trans. Biomed. Health 2007, 11, 115–124. [Google Scholar] [CrossRef]

- Tartarini, F.; Schiavon, S. pythermalcomfort: A Python package for thermal comfort research. SoftwareX 2020, 12, 100578. [Google Scholar] [CrossRef]

- Holmér, I.; Nilsson, H.O.; Anttonen, H. Prediction of Wind Effects on Cold Protective Clothing; RTO-MP-076 Report; Research and Technology Organization: Neuilly-sur-Seine, France, 2002. [Google Scholar]

- Nilsson, H.; Holmér, I.; Ohlsson, G.; Anttonen, H. Clothing Insulation at High Wind Speed. In Proceedings of the Problems with Cold Work, Saltsjöbaden, Sweden, 16–17 November 1998; pp. 114–117. Available online: https://www.diva-portal.org/smash/get/diva2:1001873/FULLTEXT01.pdf (accessed on 24 July 2025).

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. On the transition thermal discomfort to heat stress as a function of the PMV value. Ind. Health 2013, 51, 285–296. [Google Scholar] [CrossRef]

- ISO 7243; Ergonomics of the thermal environment—Assessment of heat stress using the WBGT (Wet Bulb Globe Temperature) Index. International Standardization Organization: Geneva, Switzerland, 2017.

- ASHRAE 55; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2023.

- Brimicombe, C.; Di Napoli, C.; Quintino, T.; Pappenberger, F.; Cornforth, R.; Cloke, H.L. Thermofeel: A python thermal comfort indices library. SoftwareX 2022, 18, 101005. [Google Scholar] [CrossRef]

| Quantity | Low Strain | High Strain |

|---|---|---|

| IREQ | Neutral (IREQneu) | Minimal (IREQmin) |

| tsk | 35.7–0.0285·M | 33.34–0.0354·M |

| w | w = 0.001·M | 0.06 |

| Dlim | Short | Long |

| Qlim (kJ m−2) | 144 | 144 |

| Equation | Equation Number | References |

|---|---|---|

| 1.0 + 1.97 Icl | (13) | [18,44] |

| 1.0 + 1.197 Icl | (14) | [45] |

| 1.0 + 0.97 Icl | (15) | [46] |

| 1.05 + 0.645 Icl | (16) | [40,41,47] |

| 1.0 + 1.81 Icl | (17) | [34] |

| 1.0 + 0.85 IT | (18) | [40,41] |

| 1.01 +1.599 Icl | (19) | [48] |

| 1.0 + 1.697 Icl | (20) | [48] |

| 1.04 + 0.85 IT | (21) | [36] |

| 1.657 Icl0.1546 | (22) | [36] |

| Variable | Units | Values | Number of Conditions |

|---|---|---|---|

| IREQ calculations | |||

| ta | °C | from −50 to 10 (step 10 °C) | 7 |

| RH | % | 50 | 1 |

| tr | °C | from −50 to 10 (step 10 °C) | 7 |

| va | m s−1 | 0.5, 1.0, 1.5, 2, 5, 10, 18 | 7 |

| M | W m−2 | 70, 90, 115, 145, 175, 200, 230, 260 | 8 |

| ap | L m−2 s−1 | 8 | 1 |

| Number of simulations | 2744 | ||

| Dlim calculations | |||

| ta (*) | °C | from −50 to 10 (step 10 °C) | 7 |

| RH | % | 50 | 1 |

| va | m s−1 | 0.5, 1.0, 1.5, 2.0, 5.0, 10, 18 | 7 |

| M | W m−2 | 90, 115, 145, 175 | 4 |

| Icl | clo | 0.5 (**), 1.0, 1.5, 2.0, 2.5, 3.0 (**), 3.5 (**) | 7 |

| ap | L s−1 m−2 | 8 | 1 |

| Number of simulations | 1225 | ||

| Variable | Units | Values | Number of Conditions |

|---|---|---|---|

| ta (*) | °C | from −50 to 10 (step 10 °C) | 7 |

| RH | % | 50 | 1 |

| va | m s−1 | from 0.5 to 3.5 (step 0.5 m s−1) | 7 |

| M | W m−2 | 90, 175 | 2 |

| Icl | clo | 0.5 (**), 1.0, 1.5, 2.0, 2.5, 3.0 (**), 3.5 (**) | 7 |

| ap | L m−2 s−1 | 8 | 1 |

| Number of simulations | 539 | ||

| to (°C) | E (W m−2) | Δ (%) | S (W m−2) | Δ (%) | E (W m−2) | Δ (%) | S (W m−2) | Δ (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Equation (33) | Equations (24) and (25) | Equation (33) | Equations (24) and (25) | Equation (33) | Equations (24) and (25) | Equation (33) | Equations (24) and (25) | |||||

| M = 90 W m−2 | M = 175 W m−2 | |||||||||||

| Icl = 1.0 clo | ||||||||||||

| −50 | 13.9 | 18.7 | 34.1 | −337 | −341 | 1.4 | 24.9 | 48.0 | 92.5 | −284 | −307 | 8 |

| −40 | 13.9 | 18.6 | 34.1 | −288 | −293 | 1.6 | 24.9 | 47.9 | 92.5 | −232 | −255 | 10 |

| −30 | 13.9 | 18.6 | 34.1 | −239 | −244 | 2.0 | 24.8 | 47.8 | 92.5 | −180 | −203 | 13 |

| −20 | 13.8 | 18.5 | 34.1 | −190 | −195 | 2.5 | 24.6 | 47.4 | 92.5 | −128 | −151 | 18 |

| −10 | 13.6 | 18.2 | 34.1 | −141 | −146 | 3.3 | 24.2 | 46.6 | 92.5 | −76 | −98.2 | 30 |

| 0 | 13.1 | 17.5 | 34.1 | −92 | −97 | 4.8 | 23.2 | 44.7 | 92.5 | −23 | −44.3 | 94 |

| 10 | 12.2 | 16.4 | 34.1 | −42 | −47 | 9.9 | 21.5 | 41.3 | 92.5 | - | - | - |

| Icl = 1.5 clo | ||||||||||||

| −50 | 10.5 | 14.1 | 34.1 | −236 | −239 | 1.5 | 18.9 | 36.3 | 92.5 | −178 | −196 | 10 |

| −40 | 10.5 | 14.1 | 34.1 | −199 | −202 | 1.8 | 18.8 | 36.3 | 92.5 | −139 | −156 | 13 |

| −30 | 10.5 | 14.1 | 34.1 | −162 | −165 | 2.2 | 18.8 | 36.2 | 92.5 | −99 | −116 | 18 |

| −20 | 10.4 | 14.0 | 34.1 | −125 | −128 | 2.9 | 18.6 | 35.9 | 92.5 | −59 | −76.6 | 29 |

| −10 | 10.3 | 13.8 | 34.1 | −88 | −91 | 4.0 | 18.3 | 35.2 | 92.5 | −20 | −36.5 | 87 |

| 0 | 9.9 | 13.3 | 34.1 | −50 | −54 | 6.7 | 17.6 | 33.8 | 92.5 | - | - | - |

| 10 | 9.3 | 12.4 | 34.1 | −12 | −15 | 25.7 | 16.2 | 31.3 | 92.5 | - | - | - |

| Icl = 2.0 clo | ||||||||||||

| −50 | 8.4 | 11.3 | 34.1 | −174 | −177 | 1.7 | 15.1 | 29.1 | 92.5 | −113 | −127 | 12 |

| −40 | 8.4 | 11.3 | 34.1 | −144 | −147 | 2.0 | 15.1 | 29.1 | 92.5 | −81 | −95 | 17 |

| −30 | 8.4 | 11.3 | 34.1 | −114 | −117 | 2.5 | 15.1 | 29.0 | 92.5 | −49 | −63 | 28 |

| −20 | 8.4 | 11.2 | 34.1 | −84 | −87 | 3.4 | 15.0 | 28.8 | 92.5 | −17 | −31 | 81 |

| −10 | 8.2 | 11.0 | 34.1 | −54 | −57 | 5.2 | 14.7 | 28.3 | 92.5 | - | - | - |

| 0 | 7.9 | 10.7 | 34.1 | −24 | −27 | 11.2 | 14.1 | 27.1 | 92.5 | - | - | - |

| 10 | 7.4 | 10.0 | 34.1 | - | - | - | 13.0 | 25.1 | 92.5 | - | - | - |

| Icl = 2.5 clo | ||||||||||||

| −50 | 7.0 | 9.4 | 34.1 | −132 | −134 | 1.8 | 12.6 | 24.2 | 92.5 | −69 | −81 | 17 |

| −40 | 7.0 | 9.4 | 34.1 | −107 | −109 | 2.2 | 12.6 | 24.2 | 92.5 | −42 | −54 | 28 |

| −30 | 7.0 | 9.4 | 34.1 | −82 | −84 | 2.9 | 12.5 | 24.2 | 92.5 | −15 | −27 | 76 |

| −20 | 7.0 | 9.3 | 34.1 | −57 | −59 | 4.2 | 12.5 | 24.0 | 92.5 | - | - | - |

| −10 | 6.9 | 9.2 | 34.1 | −32 | −34 | 7.3 | 12.2 | 23.5 | 92.5 | - | - | - |

| 0 | 6.6 | 8.9 | 34.1 | −7 | −9 | 33.5 | 11.7 | 22.6 | 92.5 | - | - | - |

| 10 | 6.2 | 8.3 | 34.1 | - | - | - | 10.9 | 20.9 | 92.5 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

d’Ambrosio Alfano, F.R.; Kuklane, K.; Palella, B.I.; Riccio, G. On the Effects of Clothing Area Factor and Vapour Resistance on the Evaluation of Cold Environments via IREQ Model. Int. J. Environ. Res. Public Health 2025, 22, 1188. https://doi.org/10.3390/ijerph22081188

d’Ambrosio Alfano FR, Kuklane K, Palella BI, Riccio G. On the Effects of Clothing Area Factor and Vapour Resistance on the Evaluation of Cold Environments via IREQ Model. International Journal of Environmental Research and Public Health. 2025; 22(8):1188. https://doi.org/10.3390/ijerph22081188

Chicago/Turabian Styled’Ambrosio Alfano, Francesca Romana, Kalev Kuklane, Boris Igor Palella, and Giuseppe Riccio. 2025. "On the Effects of Clothing Area Factor and Vapour Resistance on the Evaluation of Cold Environments via IREQ Model" International Journal of Environmental Research and Public Health 22, no. 8: 1188. https://doi.org/10.3390/ijerph22081188

APA Styled’Ambrosio Alfano, F. R., Kuklane, K., Palella, B. I., & Riccio, G. (2025). On the Effects of Clothing Area Factor and Vapour Resistance on the Evaluation of Cold Environments via IREQ Model. International Journal of Environmental Research and Public Health, 22(8), 1188. https://doi.org/10.3390/ijerph22081188