Trends in Robotics Research in Occupational Safety and Health: A Scientometric Analysis and Review

Abstract

1. Introduction

- What are the research trends and sources of publications in the past decade?

- What are the important keywords in robotics occupational safety and health research?

- What are the key publications in robotics occupational safety and health research?

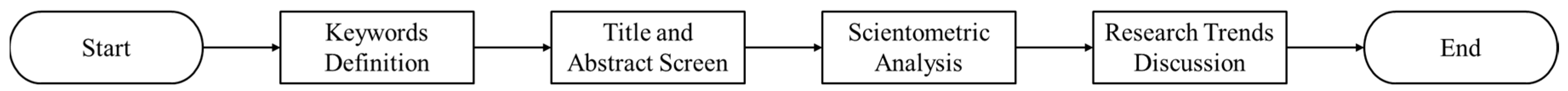

2. Research Methodology

2.1. Scientometric Analysis

2.2. Keywords and Data Collection

- Time: 2012–2022;

- Article types: journal paper, conference paper, review paper, and book chapter;

- Language: English.

3. Scientometric Analysis and Results

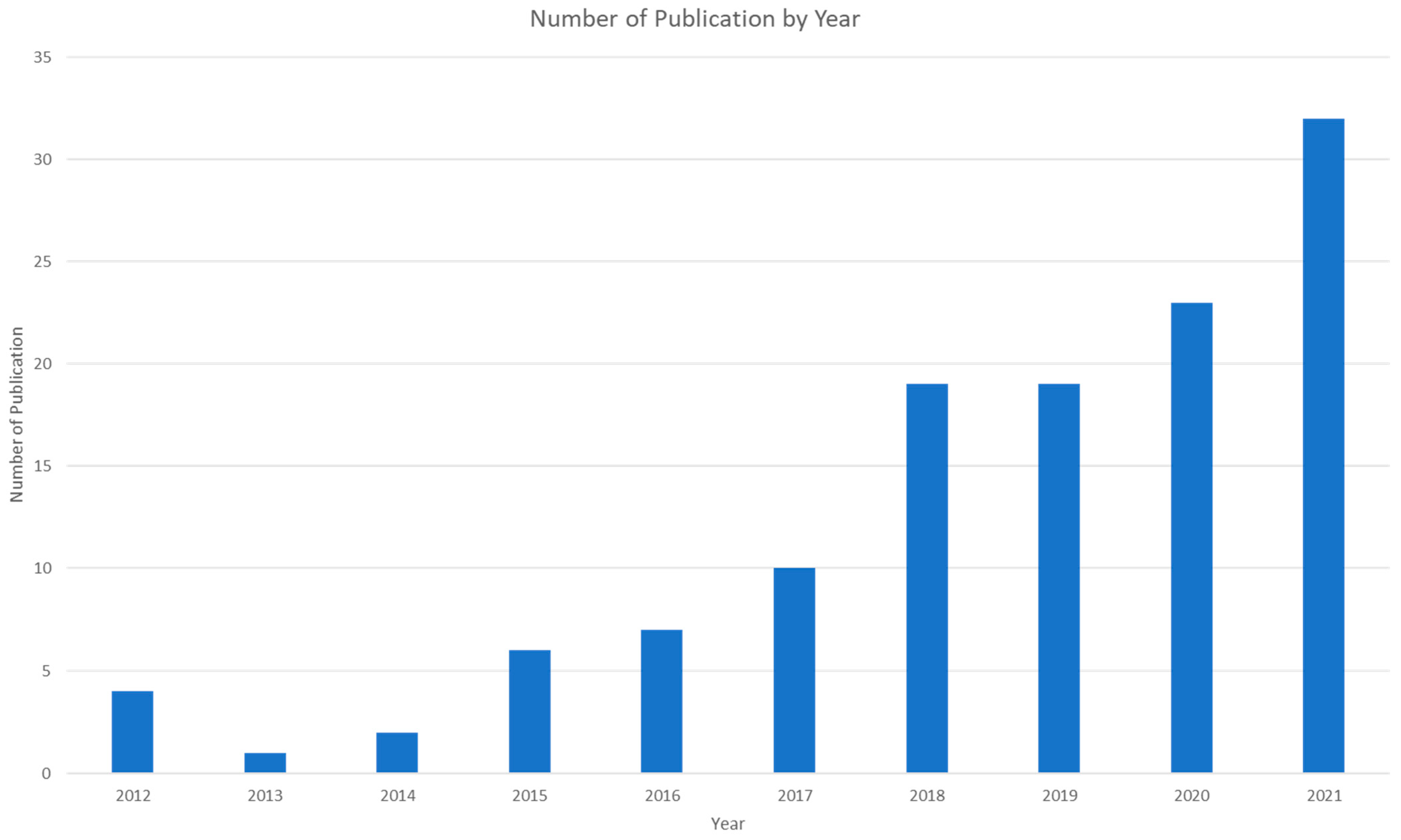

3.1. Document Analysis

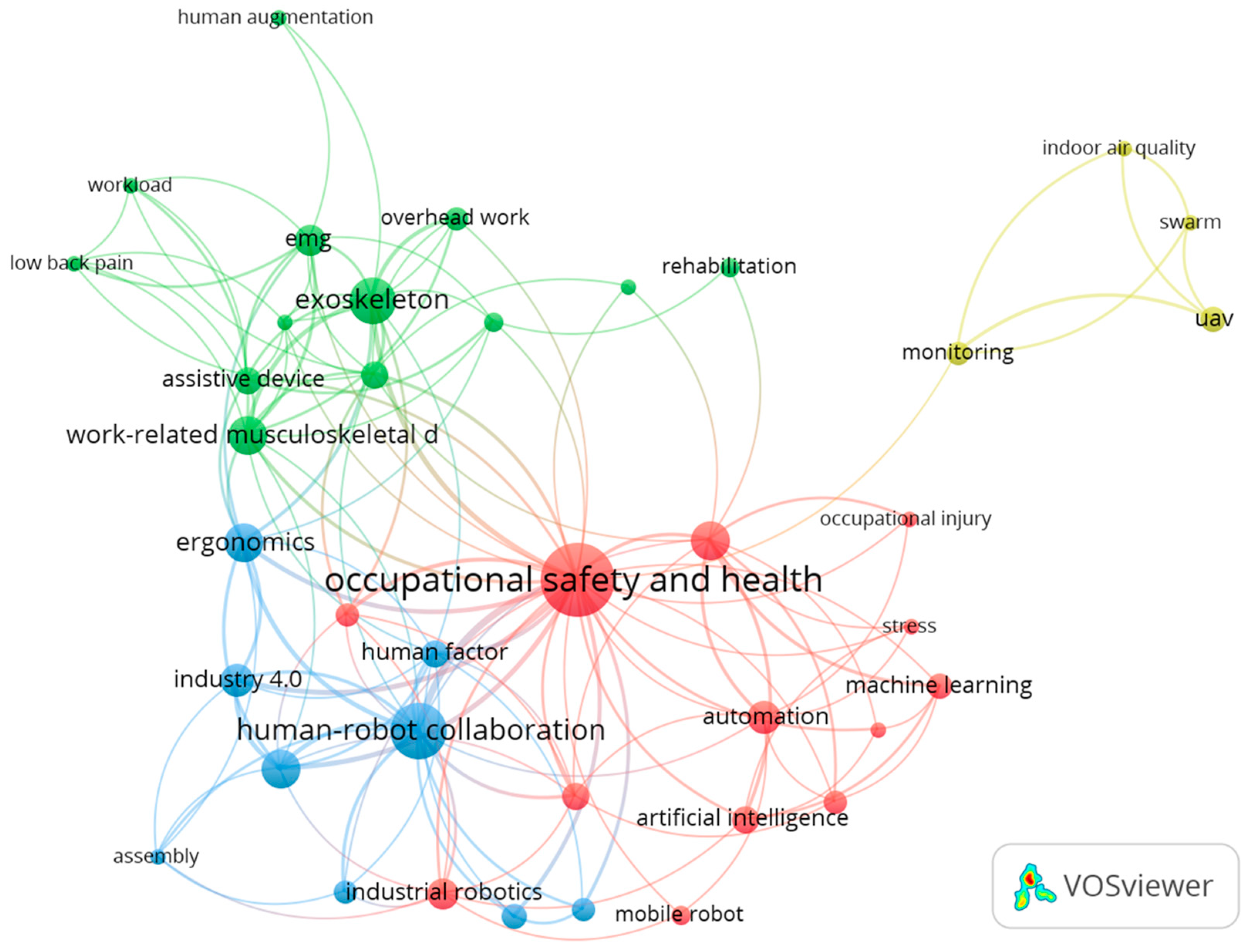

3.2. Keyword Analysis

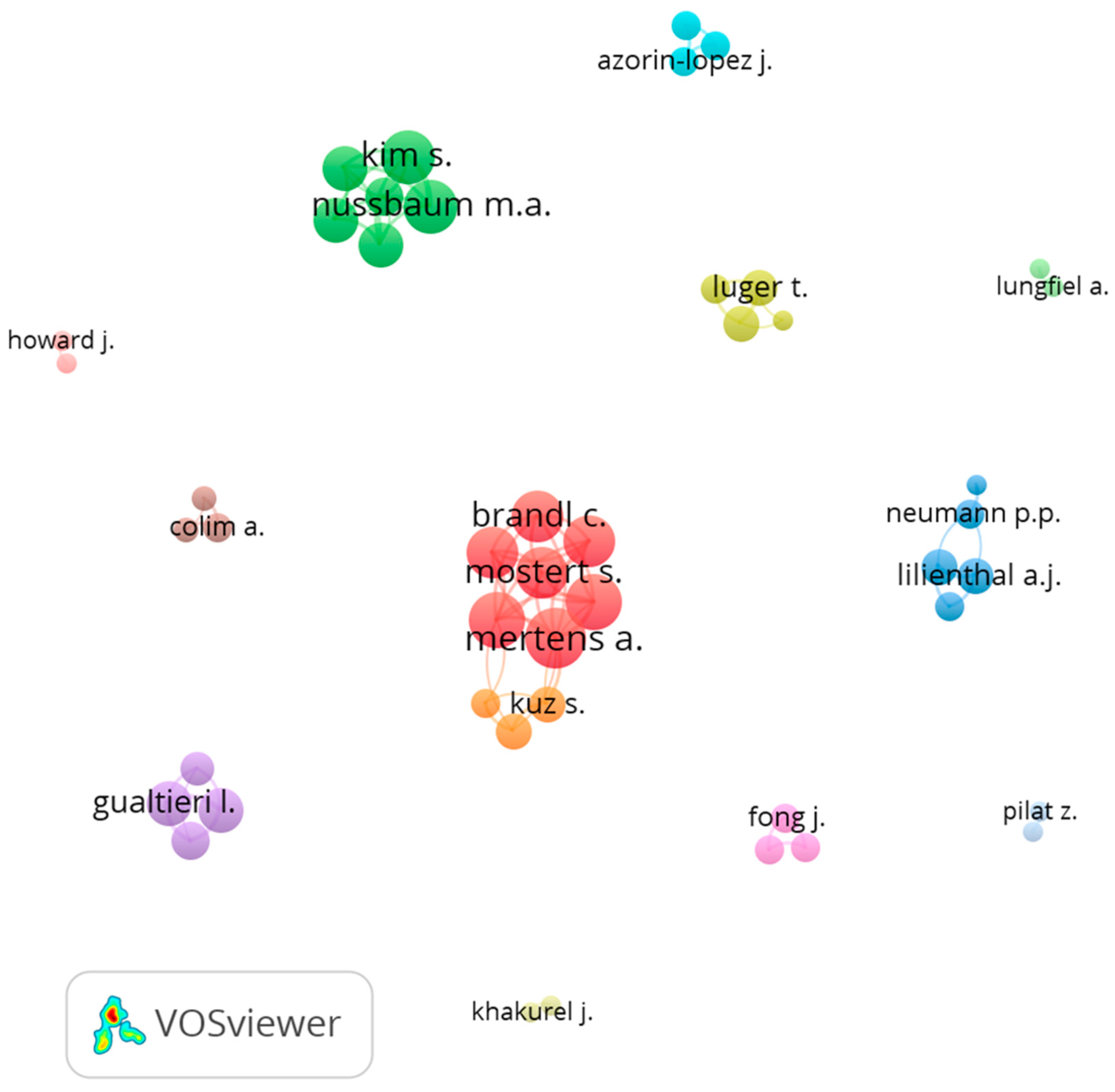

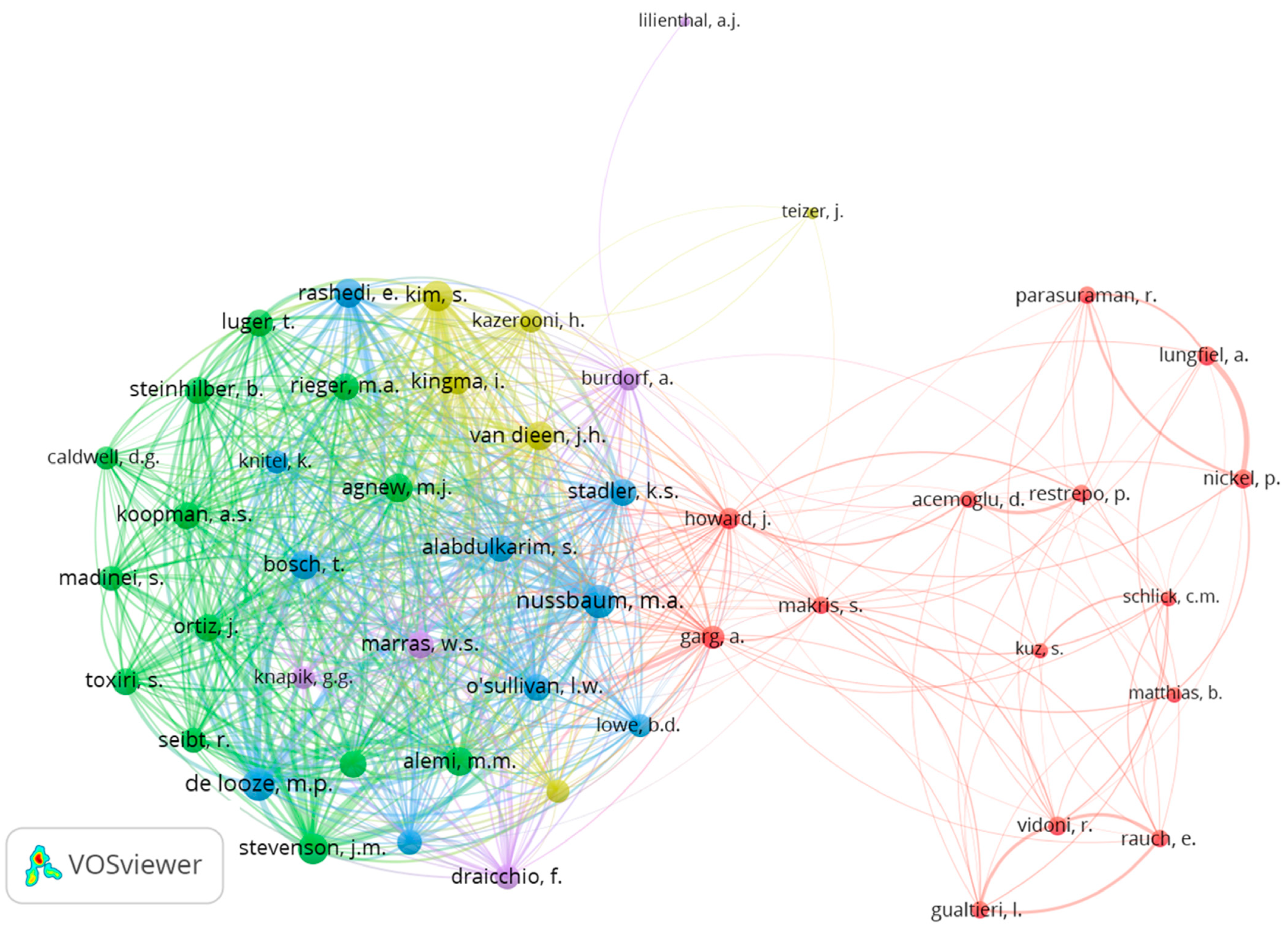

3.3. Bibliographic Coupling

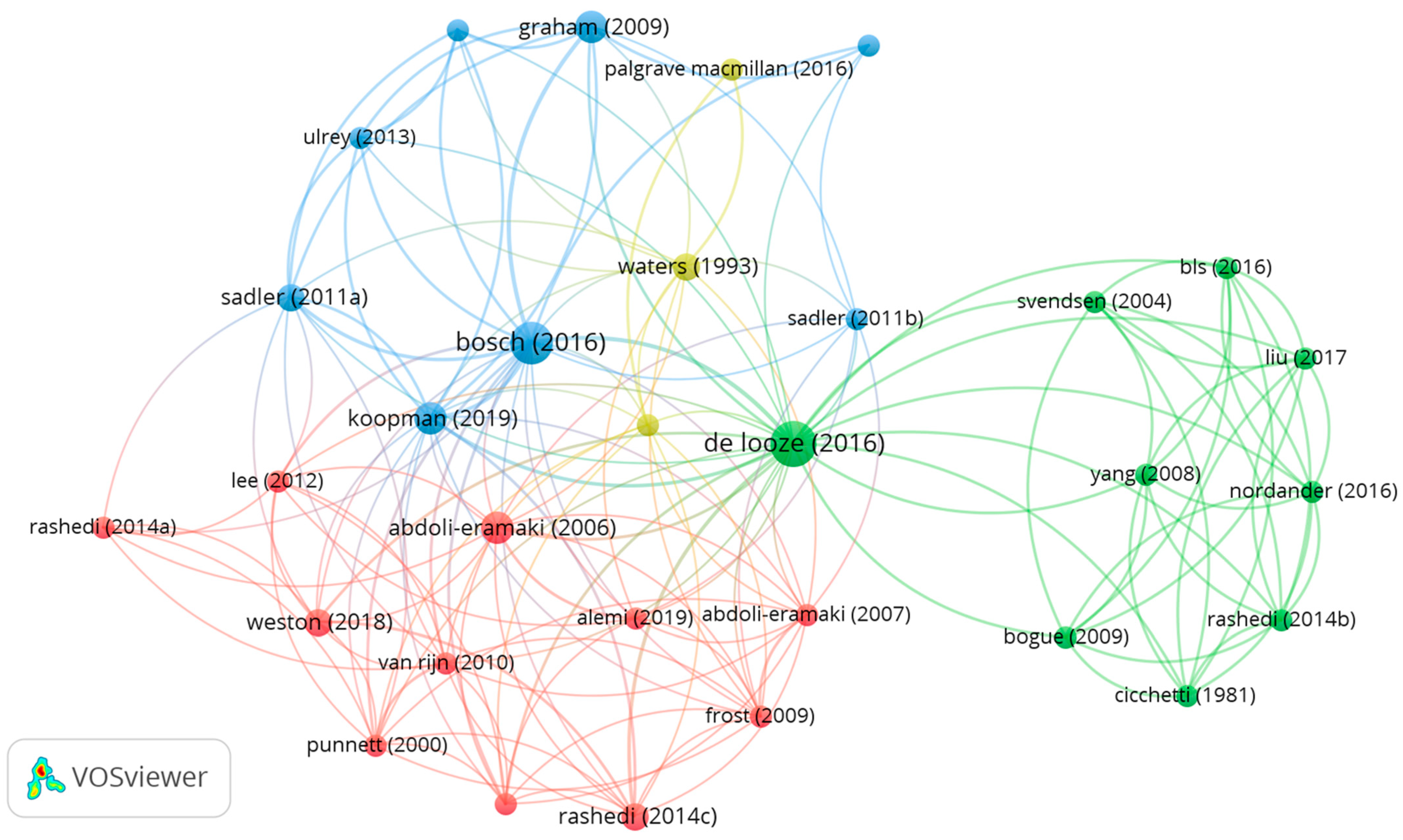

3.4. Co-Citation Analysis

4. Discussion

4.1. Research Trends

4.2. Future Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Disclaimer

References

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M.; Blanco-Novoa, O.; Froiz-Míguez, I.; Fraga-Lamas, P. Towards an Autonomous Industry 4.0 Warehouse: A UAV and Blockchain-Based System for Inventory and Traceability Applications in Big Data-Driven Supply Chain Management. Sensors 2019, 19, 2394. [Google Scholar] [CrossRef] [PubMed]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- European Commission, Directorate-General for Research Innovation; Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Liang, C.-J.; Wang, X.; Kamat, V.R.; Menassa, C.C. Human–Robot Collaboration in Construction: Classification and Research Trends. J. Constr. Eng. Manag. 2021, 147, 03121006. [Google Scholar] [CrossRef]

- Association for Advancing Automation. What Are Collaborative Robots? Available online: https://www.automate.org/a3-content/what-are-collaborative-robots (accessed on 20 January 2023).

- Nourmohammadi, A.; Fathi, M.; Ng, A.H. Balancing and scheduling assembly lines with human-robot collaboration tasks. Comput. Oper. Res. 2022, 140, 105674. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, H.; Zhang, X.; He, X.; Tan, Z. A decision model on human-robot collaborative routing for automatic logistics. Adv. Eng. Inform. 2022, 53, 101681. [Google Scholar] [CrossRef]

- Liang, C.-J.; Kamat, V.R.; Menassa, C.C. Teaching robots to perform quasi-repetitive construction tasks through human demonstration. Autom. Constr. 2020, 120, 103370. [Google Scholar] [CrossRef]

- Liang, C.-J.; McGee, W.; Menassa, C.C.; Kamat, V.R. Real-time state synchronization between physical construction robots and process-level digital twins. Constr. Robot. 2022, 6, 57–73. [Google Scholar] [CrossRef]

- Bragança, S.; Costa, E.; Castellucci, I.; Arezes, P.M. A Brief Overview of the Use of Collaborative Robots in Industry 4.0: Human Role and Safety. In Occupational and Environmental Safety and Health; Arezes, P.M., Baptista, J.S., Barroso, M.P., Carneiro, P., Cordeiro, P., Costa, N., Melo, R.B., Miguel, A.S., Perestrelo, G., Eds.; Studies in Systems, Decision and Control; Springer International Publishing: Cham, Germany, 2019; Chapter 68; pp. 641–650. [Google Scholar] [CrossRef]

- Hearl, F.J.; Murashov, V.; Howard, J.; Hsiao, H.; Sammarco, J.; Lowe, B.; Luxbacher, G. Robotics in the Workplace. In Patty’s Industrial Hygiene; Wiley Online Library: Hoboken, NJ, USA, 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot. Comput. Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Robla-Gómez, S.; Becerra, V.M.; Llata, J.R.; González-Sarabia, E.; Torre-Ferrero, C.; Pérez-Oria, J. Working Together: A Review on Safe Human-Robot Collaboration in Industrial Environments. IEEE Access 2017, 5, 26754–26773. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human–Robot Collaboration Trends and Safety Aspects: A Systematic Review. J. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- Chemweno, P.; Pintelon, L.; Decre, W. Orienting safety assurance with outcomes of hazard analysis and risk assessment: A review of the ISO 15066 standard for collaborative robot systems. Saf. Sci. 2020, 129, 104832. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Onososen, A.O.; Musonda, I. Research focus for construction robotics and human-robot teams towards resilience in construction: Scientometric review. J. Eng. Des. Technol. 2022, 21, 502–526. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Milojevic, S. Scientometrics. arXiv 2012, arXiv:1208.4566. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Adabre, M.A.; Edwards, D.J.; Hosseini, M.R.; Ameyaw, E.E. Artificial intelligence in the AEC industry: Scientometric analysis and visualization of research activities. Autom. Constr. 2020, 112, 103081. [Google Scholar] [CrossRef]

- Zhong, B.; Wu, H.; Li, H.; Sepasgozar, S.; Luo, H.; He, L. A scientometric analysis and critical review of construction related ontology research. Autom. Constr. 2019, 101, 17–31. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H. A Scientometric Review of Soft Robotics: Intellectual Structures and Emerging Trends Analysis (2010–2021). Front. Robot. AI 2022, 9, 868682. [Google Scholar] [CrossRef]

- Haghani, M.; Bliemer, M.C.; Goerlandt, F.; Li, J. The scientific literature on Coronaviruses, COVID-19 and its associated safety-related research dimensions: A scientometric analysis and scoping review. Saf. Sci. 2020, 129, 104806. [Google Scholar] [CrossRef]

- Gipp, B.; Beel, J. Citation Proximity Analysis (CPA)—A new approach for identifying related work based on Co-Citation Analysis. In Proceedings of the 12th International Conference on Scientometrics and Informetrics (ISSI’09), Rio de Janeiro, Brazil, 14–17 July 2009. [Google Scholar]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Olukolajo, M.A.; Oyetunji, A.K.; Amaechi, C.V. A Scientometric review of environmental valuation research with an altmetric pathway for the future. Environments 2023, 10, 58. [Google Scholar] [CrossRef]

- Ghaleb, H.; Alhajlah, H.H.; Bin Abdullah, A.A.; Kassem, M.A.; Al-Sharafi, M.A. A Scientometric Analysis and Systematic Literature Review for Construction Project Complexity. Buildings 2022, 12, 482. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive maintenance and intelligent sensors in smart factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Veritas Health Innovation. Covidence Systematic Review Software. Available online: www.covidence.org (accessed on 2 February 2023).

- Wang, X.V.; Wang, L. A literature survey of the robotic technologies during the COVID-19 pandemic. J. Manuf. Syst. 2021, 60, 823–836. [Google Scholar] [CrossRef]

- Savić, M.; Ivanović, M.; Jain, L.C. Co-authorship Networks: An Introduction. In Complex Networks in Software, Knowledge, and Social Systems; Savić, M., Ivanović, M., Jain, L.C., Eds.; Intelligent Systems Reference Library; Springer International Publishing: Cham, Germany, 2019; Chapter 5; pp. 179–192. [Google Scholar] [CrossRef]

- Faber, M.; Bützler, J.; Schlick, C.M. Human-robot Cooperation in Future Production Systems: Analysis of Requirements for Designing an Ergonomic Work System. Procedia Manuf. 2015, 3, 510–517. [Google Scholar] [CrossRef]

- Petruck, H.; Faber, M.; Giese, H.; Geibel, M.; Mostert, S.; Usai, M.; Mertens, A.; Brandl, C. Human-Robot Collaboration in Manual Assembly—A Collaborative Workplace. In Proceedings of the 20th Congress of the International Ergonomics Association (IEA 2018), Florence, Italy, 26–30 August 2018. [Google Scholar] [CrossRef]

- Kim, S.; Nussbaum, M.A.; Esfahani, M.I.M.; Alemi, M.M.; Alabdulkarim, S.; Rashedi, E. Assessing the influence of a passive, upper extremity exoskeletal vest for tasks requiring arm elevation: Part I–“Expected” effects on discomfort, shoulder muscle activity, and work task performance. Appl. Ergon. 2018, 70, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Nussbaum, M.A.; Esfahani, M.I.M.; Alemi, M.M.; Jia, B.; Rashedi, E. Assessing the influence of a passive, upper extremity exoskeletal vest for tasks requiring arm elevation: Part II—“Unexpected” effects on shoulder motion, balance, and spine loading. Appl. Ergon. 2018, 70, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Alabdulkarim, S.; Kim, S.; Nussbaum, M.A. Effects of exoskeleton design and precision requirements on physical demands and quality in a simulated overhead drilling task. Appl. Ergon. 2019, 80, 136–145. [Google Scholar] [CrossRef]

- Gualtieri, L.; Palomba, I.; Merati, F.A.; Rauch, E.; Vidoni, R. Design of Human-Centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study. Sustainability 2020, 12, 3606. [Google Scholar] [CrossRef]

- Bennetts, V.H.; Schaffernicht, E.; Lilienthal, A.J.; Fan, H.; Kucner, T.P.; Andersson, L.; Johansson, A. Towards occupational health improvement in foundries through dense dust and pollution monitoring using a complementary approach with mobile and stationary sensing nodes. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016. [Google Scholar] [CrossRef]

- Schaffernicht, E.; Bennetts, V.H.; Lilienthal, A.J. Mobile robots for learning spatio-temporal interpolation models in sensor networks—The Echo State map approach. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2017), Singapore, 29 May–3 June 2017. [Google Scholar] [CrossRef]

- Schmalz, T.; Schändlinger, J.; Schuler, M.; Bornmann, J.; Schirrmeister, B.; Kannenberg, A.; Ernst, M. Biomechanical and Metabolic Effectiveness of an Industrial Exoskeleton for Overhead Work. Int. J. Environ. Res. Public Health 2019, 16, 4792. [Google Scholar] [CrossRef]

- Howard, J. Artificial intelligence: Implications for the future of work. Am. J. Ind. Med. 2019, 62, 917–926. [Google Scholar] [CrossRef]

- Pearce, M.; Mutlu, B.; Shah, J.; Radwin, R. Optimizing Makespan and Ergonomics in Integrating Collaborative Robots Into Manufacturing Processes. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1772–1784. [Google Scholar] [CrossRef]

- de Melo, R.R.S.; Costa, D.B.; Álvares, J.S.; Irizarry, J. Applicability of unmanned aerial system (UAS) for safety inspection on construction sites. Saf. Sci. 2017, 98, 174–185. [Google Scholar] [CrossRef]

- Kessler, M.M. Bibliographic coupling between scientific papers. Am. Doc. 1963, 14, 10–25. [Google Scholar] [CrossRef]

- Steinhilber, B.; Luger, T.; Schwenkreis, P.; Middeldorf, S.; Bork, H.; Mann, B.; von Glinski, A.; Schildhauer, T.A.; Weiler, S.; Schmauder, M.; et al. The use of exoskeletons in the occupational context for primary, secondary, and tertiary prevention of work-related musculoskeletal complaints. IISE Trans. Occup. Ergon. Hum. Factors 2020, 8, 132–144. [Google Scholar] [CrossRef] [PubMed]

- Del Ferraro, S.; Falcone, T.; Ranavolo, A.; Molinaro, V. The effects of upper-body exoskeletons on human metabolic cost and thermal response during work tasks—A systematic review. Int. J. Environ. Res. Public Health 2020, 17, 7374. [Google Scholar] [CrossRef] [PubMed]

- Howard, J.; Murashov, V.V.; Lowe, B.D.; Lu, M. Industrial exoskeletons: Need for intervention effectiveness research. Am. J. Ind. Med. 2020, 63, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Steinhilber, B.; Seibt, R.; Rieger, M.A.; Luger, T. Postural Control When Using an Industrial Lower Limb Exoskeleton: Impact of Reaching for a Working Tool and External Perturbation. Hum. Factors: J. Hum. Factors Ergon. Soc. 2022, 64, 635–648. [Google Scholar] [CrossRef]

- Park, H.; Kim, S.; Nussbaum, M.A.; Srinivasan, D. Effects of using a whole-body powered exoskeleton during simulated occupational load-handling tasks: A pilot study. Appl. Ergon. 2022, 98, 103589. [Google Scholar] [CrossRef]

- Bär, M.; Steinhilber, B.; Rieger, M.A.; Luger, T. The influence of using exoskeletons during occupational tasks on acute physical stress and strain compared to no exoskeleton—A systematic review and meta-analysis. Appl. Ergon. 2021, 94, 103385. [Google Scholar] [CrossRef]

- Schwartz, M.; Theurel, J.; Desbrosses, K. Effectiveness of soft versus rigid back-support exoskeletons during a lifting task. Int. J. Environ. Res. Public Health 2021, 18, 8062. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; van Dieen, J.; Bruijn, S.; Koopman, A.; Van Bennekom, C.A.M.; Houdijk, H. The effect of a passive trunk exoskeleton on metabolic costs during lifting and walking. Ergonomics 2019, 62, 903–916. [Google Scholar] [CrossRef]

- Zelik, K.E.; Nurse, C.A.; Schall, M.C.; Sesek, R.F.; Marino, M.C.; Gallagher, S. An ergonomic assessment tool for evaluating the effect of back exoskeletons on injury risk. Appl. Ergon. 2022, 99, 103619. [Google Scholar] [CrossRef]

- Schwerha, D.J.; McNamara, N.; Nussbaum, M.A.; Kim, S. Adoption potential of occupational exoskeletons in diverse enterprises engaged in manufacturing tasks. Int. J. Ind. Ergon. 2021, 82, 103103. [Google Scholar] [CrossRef]

- Ranavolo, A.; Ajoudani, A.; Cherubini, A.; Bianchi, M.; Fritzsche, L.; Iavicoli, S.; Sartori, M.; Silvetti, A.; VanderBorght, B.; Varrecchia, T.; et al. The sensor-based biomechanical risk assessment at the base of the need for revising of standards for human ergonomics. Sensors 2020, 20, 5750. [Google Scholar] [CrossRef] [PubMed]

- Kopp, T.; Baumgartner, M.; Kinkel, S. Success factors for introducing industrial human-robot interaction in practice: An empirically driven framework. Int. J. Adv. Manuf. Technol. 2020, 112, 685–704. [Google Scholar] [CrossRef]

- Benos, L.; Kokkotis, C.; Tsatalas, T.; Karampina, E.; Tsaopoulos, D.; Bochtis, D. Biomechanical Effects on Lower Extremities in Human-Robot Collaborative Agricultural Tasks. Appl. Sci. 2021, 11, 11742. [Google Scholar] [CrossRef]

- Tamers, S.L.; Streit, J.; Pana-Cryan, R.; Ray, T.; Syron, L.; Flynn, M.A.; Castillo, D.; Roth, G.; Geraci, C.; Guerin, R.; et al. Envisioning the future of work to safeguard the safety, health, and well-being of the workforce: A perspective from the CDC’s National Institute for Occupational Safety and Health. Am. J. Ind. Med. 2020, 63, 1065–1084. [Google Scholar] [CrossRef] [PubMed]

- Small, H. Co-citation in the scientific literature: A new measure of the relationship between two documents. J. Am. Soc. Inf. Sci. 1973, 24, 265–269. [Google Scholar] [CrossRef]

- Kleinberg, J. Bursty and hierarchical structure in streams. In Proceedings of the 8th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Edmonton, AB, Canada, 23–26 July 2002. [Google Scholar] [CrossRef]

- de Looze, M.P.; Bosch, T.; Krause, F.; Stadler, K.S.; O’sullivan, L.W. Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics 2016, 59, 671–681. [Google Scholar] [CrossRef]

- Khakurel, J.; Melkas, H.; Porras, J. Tapping into the wearable device revolution in the work environment: A systematic review. Inf. Technol. People 2018, 31, 791–818. [Google Scholar] [CrossRef]

- Khakurel, J.; Pöysä, S.; Porras, J. The use of wearable devices in the workplace—A systematic literature review. In Proceedings of the 2nd EAI International Conference on Smart Objects and Technologies for Social Good (GOODTECHS 2016), Venice, Italy, 30 November–1 December 2016. [Google Scholar] [CrossRef]

- Sado, F.; Yap, H.J.; Ghazilla, R.A.R.; Ahmad, N. Exoskeleton robot control for synchronous walking assistance in repetitive manual handling works based on dual unscented Kalman filter. PLoS ONE 2018, 13, e0200193. [Google Scholar] [CrossRef]

- Deshpande, N.; Ortiz, J.; Sarakoglou, I.; Semini, C.; Tsagarakis, N.; Brygo, A.; Fernandez, J.; Frigerio, M.; Saccares, L.; Toxiri, S.; et al. Next-generation collaborative robotic systems for industrial safety and health. WIT Trans. Built Environ. 2018, 174, 187–200. [Google Scholar] [CrossRef]

- Garosi, E.; Mazloumi, A.; Jafari, A.H.; Keihani, A.; Shamsipour, M.; Kordi, R.; Kazemi, Z. Design and ergonomic assessment of a passive head/neck supporting exoskeleton for overhead work use. Appl. Ergon. 2022, 101, 103699. [Google Scholar] [CrossRef]

- Riccò, M.; Ranzieri, S.; Vezzosi, L.; Balzarini, F.; Bragazzi, N.L. Wearable Exoskeletons on the Workplaces: Knowledge, Attitudes and Perspectives of Health and Safety Managers on the implementation of exoskeleton technology in Northern Italy. Acta Biomedica. 2022, 92, e2021310. [Google Scholar] [CrossRef] [PubMed]

- Bosch, T.; van Eck, J.; Knitel, K.; de Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 54, 212–217. [Google Scholar] [CrossRef] [PubMed]

- Geregei, A.; Shitova, E.; Malakhova, I.; Shuporin, E.; Bondaruk, E.; Efimov, A.; Takh, V. Up-to-date techniques for examining safety and physiological efficiency of industrial exoskeletons. Health Risk Anal. 2020, 2020, 148–159. [Google Scholar] [CrossRef]

- Koopman, A.S.; Kingma, I.; Faber, G.S.; de Looze, M.P.; van Dieën, J.H. Effects of a passive exoskeleton on the mechanical loading of the low back in static holding tasks. J. Biomech. 2019, 83, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Bogue, R. Exoskeletons and robotic prosthetics: A review of recent developments. Ind. Robot. Int. J. Robot. Res. Appl. 2009, 36, 421–427. [Google Scholar] [CrossRef]

- Graham, R.B.; Agnew, M.J.; Stevenson, J.M. Effectiveness of an on-body lifting aid at reducing low back physical demands during an automotive assembly task: Assessment of EMG response and user acceptability. Appl. Ergon. 2009, 40, 936–942. [Google Scholar] [CrossRef]

- Sadler, E.M.; Graham, R.B.; Stevenson, J.M. The personal lift-assist device and lifting technique: A principal component analysis. Ergonomics 2011, 54, 392–402. [Google Scholar] [CrossRef]

- Huysamen, K.; Bosch, T.; de Looze, M.; Stadler, K.S.; Graf, E.; O’Sullivan, L.W. Evaluation of a passive exoskeleton for static upper limb activities. Appl. Ergon. 2018, 70, 148–155. [Google Scholar] [CrossRef]

- de Looze, M.P.; Krause, F.; O’sullivan, L.W. The Potential and Acceptance of Exoskeletons in Industry. In Proceedings of the 2nd International Symposium on Wearable Robotics (WeRob2016), Pisa, Italy, 18–21 October 2017. [Google Scholar] [CrossRef]

- Huysmans, M.A.; De Looze, M.P.; Hoozemans, M.J.M.; Van Der Beek, A.J.; Van Dieën, J.H. The effect of joystick handle size and gain at two levels of required precision on performance and physical load on crane operators. Ergonomics 2006, 49, 1021–1035. [Google Scholar] [CrossRef]

- Visser, B.; De Looze, M.P.; De Graaff, M.P.; Van Dieën, J.H. Effects of precision demands and mental pressure on muscle activation and hand forces in computer mouse tasks. Ergonomics 2004, 47, 202–217. [Google Scholar] [CrossRef]

- Toxiri, S.; Koopman, A.S.; Lazzaroni, M.; Ortiz, J.; Power, V.; De Looze, M.P.; O’Sullivan, L.; Caldwell, D.G. Rationale, Implementation and Evaluation of Assistive Strategies for an Active Back-Support Exoskeleton. Front. Robot. AI 2018, 5, 53. [Google Scholar] [CrossRef] [PubMed]

- Kermavnar, T.; de Vries, A.W.; de Looze, M.P.; O’sullivan, L.W. Effects of industrial back-support exoskeletons on body loading and user experience: An updated systematic review. Ergonomics 2021, 64, 685–711. [Google Scholar] [CrossRef] [PubMed]

- Koopman, A.S.; Näf, M.; Baltrusch, S.J.; Kingma, I.; Rodriguez-Guerrero, C.; Babič, J.; de Looze, M.P.; van Dieën, J.H. Biomechanical evaluation of a new passive back support exoskeleton. J. Biomech. 2020, 105, 109795. [Google Scholar] [CrossRef] [PubMed]

- Abdoli-E, M.; Stevenson, J.M. The effect of on-body lift assistive device on the lumbar 3D dynamic moments and EMG during asymmetric freestyle lifting. Clin. Biomech. 2008, 23, 372–380. [Google Scholar] [CrossRef]

- Whitfield, B.H.; Costigan, P.A.; Stevenson, J.M.; Smallman, C.L. Effect of an on-body ergonomic aid on oxygen consumption during a repetitive lifting task. Int. J. Ind. Ergon. 2014, 44, 39–44. [Google Scholar] [CrossRef]

- Lotz, C.A.; Agnew, M.J.; Godwin, A.A.; Stevenson, J.M. The effect of an on-body personal lift assist device (PLAD) on fatigue during a repetitive lifting task. J. Electromyogr. Kinesiol. 2009, 19, 331–340. [Google Scholar] [CrossRef] [PubMed]

- Frost, D.M.; Abdoli-E, M.; Stevenson, J.M. PLAD (personal lift assistive device) stiffness affects the lumbar flexion/extension moment and the posterior chain EMG during symmetrical lifting tasks. J. Electromyogr. Kinesiol. 2009, 19, e403–e412. [Google Scholar] [CrossRef]

- Godwin, A.A.; Stevenson, J.M.; Agnew, M.J.; Twiddy, A.L.; Abdoli-Eramaki, M.; Lotz, C.A. Testing the efficacy of an ergonomic lifting aid at diminishing muscular fatigue in women over a prolonged period of lifting. Int. J. Ind. Ergon. 2009, 39, 121–126. [Google Scholar] [CrossRef]

- Abdoli-Eramaki, M.; Stevenson, J.M.; Reid, S.A.; Bryant, T.J. Mathematical and empirical proof of principle for an on-body personal lift augmentation device (PLAD). J. Biomech. 2007, 40, 1694–1700. [Google Scholar] [CrossRef]

- Garg, A.; Moore, J.S.; Kapellusch, J.M. The Revised Strain Index: An improved upper extremity exposure assessment model. Ergonomics 2017, 60, 912–922. [Google Scholar] [CrossRef]

- Howard, J.; Murashov, V.; Branche, C.M. Unmanned aerial vehicles in construction and worker safety. Am. J. Ind. Med. 2018, 61, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Murashov, V.; Hearl, F.; Howard, J. Working safely with robot workers: Recommendations for the new workplace. J. Occup. Environ. Hyg. 2016, 13, D61–D71. [Google Scholar] [CrossRef] [PubMed]

- Teizer, J. The role of automation in right-time construction safety. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC 2016), Auburn, AL, USA, 18–21 July 2016. [Google Scholar] [CrossRef]

- Winkler, N.P.; Neumann, P.P.; Säämänen, A.; Schaffernicht, E.; Lilienthal, A.J. High-quality meets low-cost: Approaches for hybrid-mobility sensor networks. In Proceedings of the 36th Danubia Adria Symposium on Advances in Experimental Mechanics (DAS 2019), Pilsen, Czech Republic, 24–27 September 2019. [Google Scholar] [CrossRef]

- Leso, V.; Fontana, L.; Iavicoli, I. The occupational health and safety dimension of Industry 4.0. La Med. Del Lav. 2018, 110, 327–338. [Google Scholar] [CrossRef]

- James, K.L.; Barlow, D.; Bithell, A.; Hiom, S.; Lord, S.; Oakley, P.; Pollard, M.; Roberts, D.; Way, C.; Whittlesea, C. The impact of automation on pharmacy staff experience of workplace stressors. Int. J. Pharm. Pr. 2013, 21, 105–116. [Google Scholar] [CrossRef] [PubMed]

- Brocal, F.; González, C.; Sebastián, M. Technique to identify and characterize new and emerging risks: A new tool for application in manufacturing processes. Saf. Sci. 2018, 109, 144–156. [Google Scholar] [CrossRef]

- Pauliková, A.; Babeľová, Z.G.; Ubárová, M. Analysis of the Impact of Human–Cobot Collaborative Manufacturing Implementation on the Occupational Health and Safety and the Quality Requirements. Int. J. Environ. Res. Public Health 2021, 18, 1927. [Google Scholar] [CrossRef]

- Cho, Y.K.; Kim, K.; Ma, S.; Ueda, J. A robotic wearable exoskeleton for construction worker’s safety and health. In Proceedings of the Construction Research Congress (CRC 2018), New Orleans, LA, USA, 2–4 April 2018. [Google Scholar] [CrossRef]

- Gualtieri, L.; Palomba, I.; Wehrle, E.J.; Vidoni, R. The Opportunities and Challenges of SME Manufacturing Automation: Safety and Ergonomics in Human–Robot Collaboration. In Industry 4.0 for SMEs; Palgrave Macmillan: Cham, Germany, 2020; Chapter 4; pp. 105–144. [Google Scholar] [CrossRef]

- Rempel, D.; Barr, A.; Antonucci, A. A new test bench system for hammer drills: Validation for handle vibration. Int. J. Ind. Ergon. 2017, 62, 17–20. [Google Scholar] [CrossRef]

- Colim, A.; Faria, C.; Braga, A.C.; Sousa, N.; Rocha, L.; Carneiro, P.; Costa, N.; Arezes, P. Towards an Ergonomic Assessment Framework for Industrial Assembly Workstations—A Case Study. Appl. Sci. 2020, 10, 3048. [Google Scholar] [CrossRef]

- Guo, Z.; Yee, R.B.; Mun, K.-R.; Yu, H. Experimental evaluation of a novel robotic hospital bed mover with omni-directional mobility. Appl. Ergon. 2017, 65, 389–397. [Google Scholar] [CrossRef]

- Koppenborg, M.; Nickel, P.; Naber, B.; Lungfiel, A.; Huelke, M. Effects of movement speed and predictability in human-robot collaboration. Hum. Factors Ergon. Manuf. 2017, 27, 197–209. [Google Scholar] [CrossRef]

- Fratczak, P.; Goh, Y.M.; Kinnell, P.; Justham, L.; Soltoggio, A. Robot apology as a post-accident trust-recovery control strategy in industrial human-robot interaction. Int. J. Ind. Ergon. 2021, 82, 103078. [Google Scholar] [CrossRef]

- Pagano, D.; Liu, D.; Waldron, K. A method for optimal design of an inchworm climbing robot. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO 2012), Guangzhou, China, 11–14 December 2012. [Google Scholar] [CrossRef]

- Martinez, C.J.M.; Salguero, R.C.; Palomares, R.; Cornejo, J. Mechatronics Development of Terrestrial Mobile Robot for Exploring and Monitoring Environmental Parameters at Mine Analogue Sites using IoT Platform. In Proceedings of the 27th IEEE International Conference on Electronics, Electrical Engineering and Computing (INTERCON 2020), Online, 3–5 September 2020. [Google Scholar] [CrossRef]

- Inam, R.; Raizer, K.; Hata, A.; Souza, R.; Forsman, E.; Cao, E.; Wang, S. Risk Assessment for Human-Robot Collaboration in an automated warehouse scenario. In Proceedings of the 23rd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA 2018), Turin, Italy, 4–7 September 2018. [Google Scholar] [CrossRef]

- Konstantinidis, F.K.; Balaska, V.; Symeonidis, S.; Mouroutsos, S.G.; Gasteratos, A. AROWA: An autonomous robot framework for Warehouse 4.0 health and safety inspection operations. In Proceedings of the 30th Mediterranean Conference on Control and Automation (MED), Vouliagmeni, Greece, 28 June–1 July 2022. [Google Scholar] [CrossRef]

- YChen, Y.; Yang, C.; Gu, Y.; Hu, B. Influence of Mobile Robots on Human Safety Perception and System Productivity in Wholesale and Retail Trade Environments: A Pilot Study. IEEE Trans. Hum. -Mach. Syst. 2022, 52, 624–635. [Google Scholar] [CrossRef]

- Vasconez, J.P.; Kantor, G.A.; Cheein, F.A.A. Human–robot interaction in agriculture: A survey and current challenges. Biosyst. Eng. 2019, 179, 35–48. [Google Scholar] [CrossRef]

- Benos, L.; Bechar, A.; Bochtis, D. Safety and ergonomics in human-robot interactive agricultural operations. Biosyst. Eng. 2020, 200, 55–72. [Google Scholar] [CrossRef]

- Günther, F.; Mischo, H.; Lösch, R.; Grehl, S.; Güth, F. Increased safety in deep mining with iot and autonomous robots. In Mining Goes Digital; CRC Press: Boca Raton, FL, USA, 2019; pp. 603–611. [Google Scholar] [CrossRef]

- Liang, C.-J.; Lundeen, K.M.; McGee, W.; Menassa, C.C.; Lee, S.; Kamat, V.R. A vision-based marker-less pose estimation system for articulated construction robots. Autom. Constr. 2019, 104, 80–94. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Kamat, V.R. Proximity Prediction of Mobile Objects to Prevent Contact-Driven Accidents in Co-Robotic Construction. J. Comput. Civ. Eng. 2020, 34, 04020022. [Google Scholar] [CrossRef]

- ANSI/RIA R15.08-1-2020; Industrial Mobile Robots—Safety Requirements—Part 1: Requirements for the Industrial Mobile Robot. Robotic Industries Association: Ann Arbor, MI, USA, 2020. Available online: https://webstore.ansi.org/standards/ria/ansiriar15082020 (accessed on 25 March 2023).

- ANSI/RIA R15.06-2012; Industrial Robots And Robot Systems—Safety Requirements. Robotic Industries Association: Ann Arbor, MI, USA, 2012. Available online: https://webstore.ansi.org/standards/ria/ansiriar15062012 (accessed on 25 March 2023).

- ISO 10218-2; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 2: Robot Systems and Integration. ISO: Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/41571.html (accessed on 25 March 2023).

- ISO 10218-1; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 1: Robots. ISO: Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/51330.html (accessed on 25 March 2023).

- ISO/TS 15066; Robots and Robotic Devices—Collaborative Robots. ISO: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/62996.html (accessed on 25 March 2023).

- Pan, M.; Pan, W. Understanding the Determinants of Construction Robot Adoption: Perspective of Building Contractors. J. Constr. Eng. Manag. 2020, 146, 04020040. [Google Scholar] [CrossRef]

- Park, S.; Yu, H.; Menassa, C.C.; Kamat, V.R. A Comprehensive Evaluation of Factors Influencing Acceptance of Robotic Assistants in Field Construction Work. J. Manag. Eng. 2023, 39, 04023010. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.; Murphy, R.; Lee, S.; Ahn, C.R. Delegation or Collaboration: Understanding Different Construction Stakeholders’ Perceptions of Robotization. J. Manag. Eng. 2022, 38, 04021084. [Google Scholar] [CrossRef]

- Rosenfeld, A.; Agmon, N.; Maksimov, O.; Kraus, S. Intelligent agent supporting human–multi-robot team collaboration. Artif. Intell. 2017, 252, 211–231. [Google Scholar] [CrossRef]

- Kim, P.; Park, J.; Cho, Y.K.; Kang, J. UAV-assisted autonomous mobile robot navigation for as-is 3D data collection and registration in cluttered environments. Autom. Constr. 2019, 106, 102918. [Google Scholar] [CrossRef]

- Asadi, K.; Suresh, A.K.; Ender, A.; Gotad, S.; Maniyar, S.; Anand, S.; Noghabaei, M.; Han, K.; Lobaton, E.; Wu, T. An integrated UGV-UAV system for construction site data collection. Autom. Constr. 2020, 112, 103068. [Google Scholar] [CrossRef]

- Ojha, A.; Liu, Y.; Shayesteh, S.; Jebelli, H.; Sitzabee, W.E. Affordable Multiagent Robotic System for Same-Level Fall Hazard Detection in Indoor Construction Environments. J. Comput. Civ. Eng. 2023, 37, 04022042. [Google Scholar] [CrossRef]

- Wang, X.; Liang, C.-J.; Menassa, C.C.; Kamat, V.R. Interactive and Immersive Process-Level Digital Twin for Collaborative Human–Robot Construction Work. J. Comput. Civ. Eng. 2021, 35, 04021023. [Google Scholar] [CrossRef]

- Pérez, L.; Rodríguez-Jiménez, S.; Rodríguez, N.; Usamentiaga, R.; García, D.F. Digital Twin and Virtual Reality Based Methodology for Multi-Robot Manufacturing Cell Commissioning. Appl. Sci. 2020, 10, 3633. [Google Scholar] [CrossRef]

- Wang, L.; Ames, A.; Egerstedt, M. Safety barrier certificates for heterogeneous multi-robot systems. In Proceedings of the American Control Conference (ACC 2016), Boston, MA, USA, 6–8 July 2016. [Google Scholar] [CrossRef]

- Fan, T.; Long, P.; Liu, W.; Pan, J. Fully Distributed Multi-Robot Collision Avoidance via Deep Reinforcement Learning for Safe and Efficient Navigation in Complex Scenarios. arXiv 2018, arXiv:1808.03841. [Google Scholar] [CrossRef]

- Faruq, F.; Parker, D.; Laccrda, B.; Hawes, N. Simultaneous Task Allocation and Planning Under Uncertainty. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2018), Madrid, Spain, 1–5 October 2018. [Google Scholar] [CrossRef]

- Zheng, H.; Liao, Z.; Wang, Y. Human-robot trust integrated task allocation and symbolic motion planning for heterogeneous multi-robot systems. In Proceedings of the Dynamic Systems and Control Conference (DSCC 2018), Atlanta, GA, USA, 30 September–3 October 2018. [Google Scholar] [CrossRef]

| Article | Links | Total Link Strength | Citations |

|---|---|---|---|

| Steinhilber et al. [51] | 19 | 90 | 5 |

| Del Ferraro et al. [52] | 20 | 80 | 15 |

| Howard et al. [53] | 19 | 66 | 24 |

| Steinhilber et al. [54] | 22 | 61 | 7 |

| Park et al. [55] | 17 | 60 | 1 |

| Bär et al. [56] | 17 | 59 | 9 |

| Schwartz et al. [57] | 17 | 53 | 1 |

| Ranavolo et al. [61] | 21 | 51 | 8 |

| Alabdulkarim et al. [42] | 15 | 50 | 18 |

| Baltrusch et al. [58] | 17 | 45 | 46 |

| Kim et al. [41] | 15 | 44 | 75 |

| Schmalz et al. [46] | 15 | 43 | 37 |

| Kim et al. [40] | 12 | 29 | 87 |

| Zelik et al. [59] | 13 | 29 | 2 |

| Schwerha et al. [60] | 16 | 28 | 2 |

| Kopp et al. [62] | 16 | 23 | 9 |

| Benos et al. [63] | 14 | 21 | 1 |

| Tamers et al. [64] | 10 | 19 | 38 |

| Cluster | Keywords | Occurrences | Mean Citations |

|---|---|---|---|

| Industrial robot safety | Occupational safety and health | 40 | 16 |

| Robot | 11 | 7 | |

| Automation | 8 | 5 | |

| Industrial robotics | 7 | 10 | |

| AI | 6 | 10 | |

| Risk assessment | 6 | 13 | |

| Machine learning | 5 | 13 | |

| Manufacturing | 4 | 4 | |

| Workplace | 4 | 33 | |

| Mobile robot | 3 | 4 | |

| Future of work | 2 | 21 | |

| Occupational injury | 2 | 3 | |

| Stress | 2 | 14 | |

| Exoskeleton and WMSDs | Exoskeleton | 16 | 22 |

| WMSDs | 11 | 12 | |

| EMG | 7 | 14 | |

| Assistive device | 6 | 18 | |

| Wearable technology | 6 | 16 | |

| Overhead work | 4 | 44 | |

| Biomechanics | 3 | 15 | |

| Rehabilitation | 3 | 1 | |

| Firefighter | 2 | 1 | |

| Human augmentation | 2 | 13 | |

| Low back pain | 2 | 24 | |

| Oxygen consumption | 2 | 31 | |

| Workload | 2 | 3 | |

| Human–robot collaboration | Human–robot collaboration | 23 | 12 |

| Collaborative robot | 11 | 18 | |

| Ergonomics | 11 | 17 | |

| Industry 4.0 | 8 | 35 | |

| Human factor | 6 | 14 | |

| Virtual reality | 5 | 12 | |

| Anthropomorphism | 4 | 2 | |

| Human–machine interaction | 4 | 3 | |

| Assembly | 2 | 18 | |

| Monitoring | UAV | 5 | 28 |

| Monitoring | 4 | 5 | |

| Indoor air quality | 2 | 3 | |

| Swarm | 2 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, C.-J.; Cheng, M.H. Trends in Robotics Research in Occupational Safety and Health: A Scientometric Analysis and Review. Int. J. Environ. Res. Public Health 2023, 20, 5904. https://doi.org/10.3390/ijerph20105904

Liang C-J, Cheng MH. Trends in Robotics Research in Occupational Safety and Health: A Scientometric Analysis and Review. International Journal of Environmental Research and Public Health. 2023; 20(10):5904. https://doi.org/10.3390/ijerph20105904

Chicago/Turabian StyleLiang, Ci-Jyun, and Marvin H. Cheng. 2023. "Trends in Robotics Research in Occupational Safety and Health: A Scientometric Analysis and Review" International Journal of Environmental Research and Public Health 20, no. 10: 5904. https://doi.org/10.3390/ijerph20105904

APA StyleLiang, C.-J., & Cheng, M. H. (2023). Trends in Robotics Research in Occupational Safety and Health: A Scientometric Analysis and Review. International Journal of Environmental Research and Public Health, 20(10), 5904. https://doi.org/10.3390/ijerph20105904