Carbon Emission Accounting and the Carbon Neutralization Model for a Typical Wastewater Treatment Plant in China

Abstract

1. Introduction

2. Materials and Methods

2.1. The Definition of the Carbon Footprint

2.2. The Current State of Gaobeidian WWTP

2.3. Estimation of Direct GHG Emissions

2.3.1. Direct GHG Emissions from the Wastewater Treatment Process

2.3.2. Direct GHG Emissions from the Sludge Treatment and Disposal Process

2.4. Calculation of Indirect GHG Emissions

2.5. Calculation of the Carbon Emission Reduction

2.5.1. Carbon Emission Reduction Resulting from Water Quality Improvement

2.5.2. Carbon Emission Reduction Resulting from Sludge Treatment and Disposal

2.5.3. Carbon Emission Reduction Resulting from the Recovery of Residual Thermal Energy

3. Results and Discussion

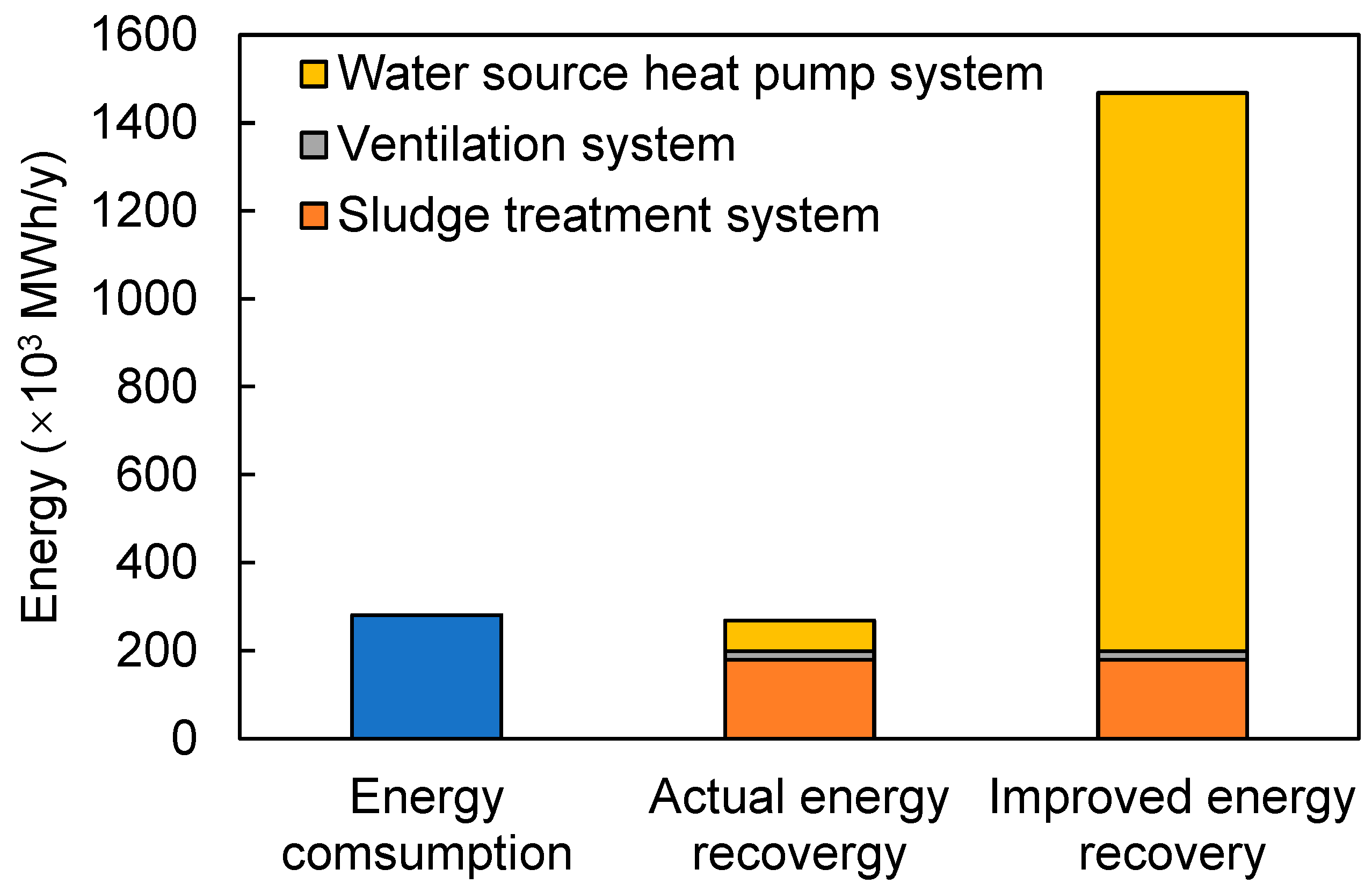

3.1. Analysis of the Energy Balance of Gaobeidian WWTP

3.2. The Carbon Footprint of Gaobeidian WWTP

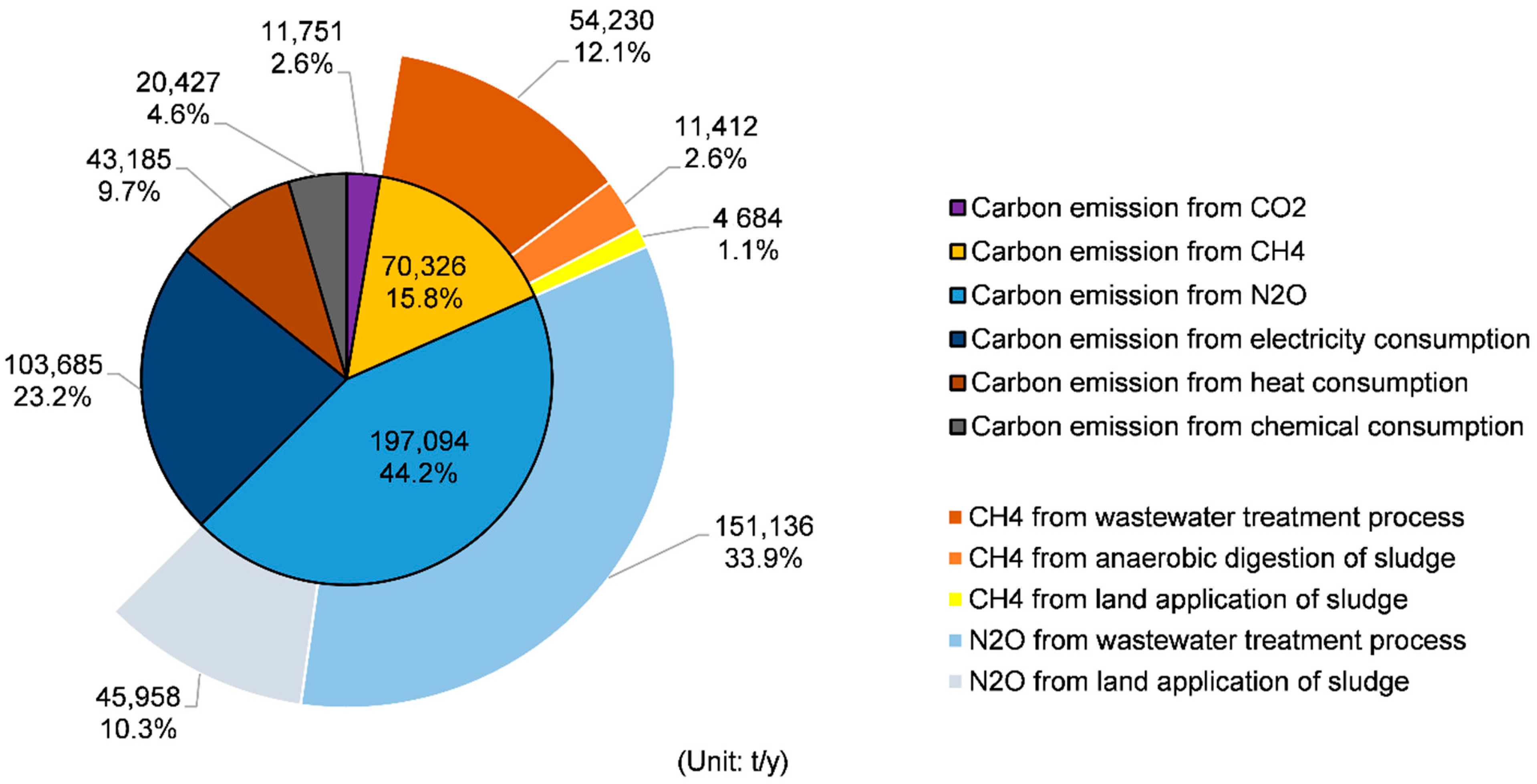

3.2.1. Direct GHG Emissions

3.2.2. Indirect GHG Emissions

3.2.3. Total GHG Emissions

3.3. Carbon Emission Reduction

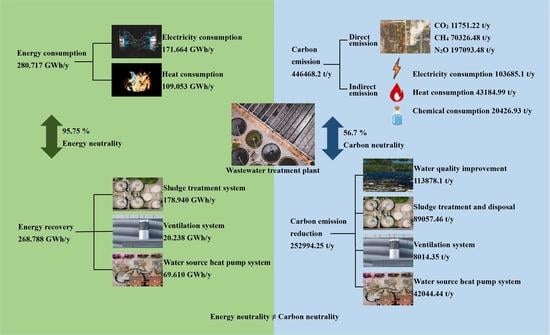

3.4. Carbon Neutralization Evaluation

3.5. Measures to Reduce the Carbon Footprint

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Q.; Wang, Y.; Cao, X.; Liu, X.; Zhang, S. Research Progress of Carbon Neutrality Operation Technology in Sewage Treatment. J. Beijing Univ. Technol. 2022, 48, 292–305. [Google Scholar]

- Zylka, R.; Dabrowski, W.; Malinowski, P.; Karolinczak, B. Modeling of Electric Energy Consumption during Dairy Wastewater Treatment Plant Operation. Energies 2020, 13, 3769. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.; Miao, J.; Abulimiti, A.; Jing, X.; Ren, N. Carbon neutrality of wastewater treatment-A systematic concept beyond the plant boundary. Environ. Sci. Ecotechnology 2022, 11, 100180. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Yuan, Z.; Gu, B.; Tan, X.; Xu, B. The accounting for greenhouse gas emissions of a low-carbon industrial park in China: A case study in Chongqing. Energy Procedia 2017, 142, 3176–3181. [Google Scholar] [CrossRef]

- Wang, H.; Yi, Y.; Keller, A.A.; Xiang, L.; Li, F. Comparative Analysis of Energy Intensity and Carbon Emissions in Wastewater Treatment in USA, Germany, China and South Africa. Applied Energy 2016, 184, 873–881. [Google Scholar] [CrossRef]

- Englehardt, J.; Wu, T.; Bloetscher, F.; Yang, D.; Tchobanoglous, G. Net-zero water management: Achieving energy-positive municipal water supply. Environ. Sci. Water Res. Technol. 2015, 2, 250–260. [Google Scholar] [CrossRef]

- Hao, X.; Liu, R.; Xin, H. Evaluation of the potential for operating carbon neutral WWTPs in China. Water Res. 2015, 87, 424–431. [Google Scholar] [CrossRef]

- Larsen, T.A. CO2-neutral wastewater treatment plants or robust, climate-friendly wastewater management? A systems perspective-ScienceDirect. Water Res. 2015, 87, 513–521. [Google Scholar] [CrossRef]

- Hao, X.; Li, J.; van Loosdrecht, M.C.M.; Jiang, H.; Liu, R. Energy recovery from wastewater: Heat over organics. Water Res. 2019, 161, 74–77. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas In ventories, Chacter 6-Wastewater Treatment and Discharge. In Proceedings of the Intergovernmental Panel on Climate Change, Kyoto, Japan, 12 May 2019. [Google Scholar]

- Tang, J.; Xie, J.; Chen, C.; Yu, C.; Chen, D. Carbon neutral technologies and case studies in urban sewage treatment plants. Chem. Ind. Eng. Prog. 2022, 41, 2662–2671. [Google Scholar]

- Hao, X.; Zhang, Y.; Li, J.; Liu, J. Case Analysis of Energy Neutrality and Carbon Neutrality for Wastewater Treatment. China Water Wastewater 2021, 37, 1–8. [Google Scholar]

- Xi, J.; Gong, H.; Zhang, Y.; Dai, X.; Chen, L. The evaluation of GHG emissions from Shanghai municipal wastewater treatment plants based on IPCC and operational data integrated methods (ODIM). Sci. Total Environ. 2021, 797, 148967. [Google Scholar] [CrossRef] [PubMed]

- Zeng, S.Y.; Chen, X.; Dong, X.; Liu, Y. Efficiency assessment of urban wastewater treatment plants in China: Considering greenhouse gas emissions. Resour. Conserv. Recycl. 2017, 120, 157–165. [Google Scholar] [CrossRef]

- Koutsou, O.P.; Gatidou, G.; Stasinakis, A.S. Domestic wastewater management in Greece: Greenhouse gas emissions estimation at country scale. J. Clean. Prod. 2018, 188, 851–859. [Google Scholar] [CrossRef]

- Liao, X.W.; Tian, Y.J.; Gan, Y.W.; Ji, J.P. Quantifying urban wastewater treatment sector’s greenhouse gas emissions using a hybrid life cycle analysis method-An applica tion on Shenzhen city in China. Sci. Total Environ. 2020, 745, 141176. [Google Scholar] [CrossRef] [PubMed]

- Khiewwijit, R.; Temmink, H.; Rijnaarts, H.; Keesman, K.J. Energy and nutrient recovery for municipal wastewater treatment: How to design a feasible plant layout? Environ. Model. Softw. 2015, 68, 156–165. [Google Scholar] [CrossRef]

- Jin, P.; Li, B.; Mu, D.; Li, X.; Peng, Y. High-efficient nitrogen removal from municipal wastewater via two-stage nitritation/anammox process: Long-term stability assessment and mechanism analysis. Bioresour. Technol. 2019, 271, 150–158. [Google Scholar] [CrossRef]

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A Review of Sludge-to-Energy Recovery Methods. Energies 2019, 12, 60. [Google Scholar] [CrossRef]

- Hao, X.; Zhao, Z.; Li, J.; Li, S.; Jiang, H. Analysis of energy recovery and carbon neutrality for the Kakolanmaki WWTP in Finland. Chin. J. Environ. Eng. 2021, 15, 2849–2857. [Google Scholar]

- Rossi, R.; Hur, A.Y.; Page, M.A.; Thomas, A.O.B.; Butkiewicz, J.J.; Jones, D.W.; Baek, G.; Saikaly, P.E.; Cropek, D.M.; Logan, B.E. Pilot scale microbial fuel cells using air cathodes for producing electricity while treating wastewater. Water Res. 2022, 215, 118208. [Google Scholar] [CrossRef]

- Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Wong, M.S. Carbon footprint analyses of mainstream wastewater treatment technologies under different sludge treatment scenarios in China. MDPI AG 2015, 7, 918–938. [Google Scholar] [CrossRef]

- DB11/890—2012; Discharge Standard of Water Pollutants for Municipal Wastewater Treatment Plants. Beijing Municipal Bureau of Environmental Protection; Beijing Municipal Bureau of Quality and Technical Supervision: Beijing, China, 2012.

- Comparison of Scale, Process, Inlet and Outlet Water Quality of 15 Sewage Treatment Plants in Beijing. Available online: https://max.book118.com/html/2021/0312/5304343002003143.shtm (accessed on 13 March 2021).

- Foley, J.; de Haas, D.; Yuan, Z.; Lant, P. Nitrous oxide generation in full-scale biological nutrient removal wastewater treatment plants. Water Res. 2010, 44, 831–844. [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; Wang, B.; Liu, R.; Jiang, H. Carbon neutrality vs excess methane release from water environments/the methane paradox. Acta Sci. Circumstantiae 2021, 41, 1593–1598. [Google Scholar]

- Lelieveld, J.; Lechtenbohmer, S.; Assonov, S.S.; Brenninkmeijer, C.A.; Dienst, C.; Fischedick, M.; Hanke, T. Greenhouse gases: Low methane leakage from gas pipelines. Nature 2005, 434, 841–842. [Google Scholar] [CrossRef]

- Jing, L.; Wei, A.; Da, T.Q.; Qing, W. Evironmental Impact Report of Beijing Gaobeidian Sewage Treatment Plant Sludge Advanced Digestion Project. Available online: https://jz.docin.com/p-1367485451.html (accessed on 22 November 2015).

- Zhang, Y.; Ge, T.; Sun, Y.; Liu, J.; Gao, C.; Zhang, W. Research on Carbon Emission Model Based on the Whole Process of Urban Sewage Treatment. China Water Wastewater 2021, 37, 65–74. [Google Scholar]

- DB11/T 1785—2020; Requirements for Carbon Dioxide Emission Accounting and Reporting Service Enterprises. Beijing Municipal Administration of Market Supervision: Beijing, China, 2020.

- Niu, D.J.; Huang, H.; Dai, X.H.; Zhao, Y.C. Greenhouse gases emissions accounting for typical sewage sludge digestion with energy utilization and residue land application in China. Waste Manag. 2013, 33, 123–128. [Google Scholar] [CrossRef]

- Hao, X.; Rao, Z.; Li, S.; Li, J.; Jiang, H. Potential Carbon Trading Volume of Thermal Energy Contained in Wastewater. China Water Wastewater 2021, 37, 7–13. [Google Scholar]

- Song, X.; Lin, J.; Liu, J.; Xu, X.; Li, J.; Li, C.; Jiang, H.; Wang, H.; Yin, F. The current situation and engineering practice of sewage treatment technology facing the future. Acta Sci. Circumstantiae 2021, 41, 39–53. [Google Scholar]

- Li, P.; Jiang, Q.; Zhang, Z.; Wang, J. Upgrading reconstruction operation optimizing of Gaobeidian Reclaimed Water Plant. Water Wastewater Eng. 2019, 55, 13–17. [Google Scholar]

| Water Quality Indexes | Influent (mg/L) [24] | Effluent (mg/L) [24] | Removal Efficiency (%) | Effluent Standards (mg/L) [23] |

|---|---|---|---|---|

| COD | 283 | 15 | 95% | 30 |

| BOD5 | 175 | 2.5 | 99% | 6 |

| TP | 6.90 | 0.059 | 99% | 0.3 |

| TN | 50.6 | 10.9 | 78% | 15 |

| SS | 239 | <5 | >98% | 5 |

| Chroma | 50 | 5.4 | 89% | 15 |

| NH4+-N | 44.28 | 0.45 | 99% | 1.5 |

| Projects | Energy Consumption (MWh/y) |

|---|---|

| Electricity consumption of the wastewater treatment process | 94,900 |

| Electricity consumption of the sludge treatment unit | 20,795 |

| Thermal hydrolysis of sludge | 104,920 |

| Electricity consumption of the pump station | 52,080 |

| Heating system for buildings | 4133 |

| Electricity consumption of administrative buildings | 3793 |

| Electricity consumption of fuel transportation | 96 |

| Total | 280,717 |

| Project | COP [32] | Heating/Cooling Capacity (GJ/y) | Equivalent Electricity (MWh/y) | Energy Consumption by Water-Source Heat Pump (MWh/y) | Net Energy Production (MWh/y) |

|---|---|---|---|---|---|

| Heating capacity | 4.24 | 7,417,487 | 2,060,413 | 485,947 | 1,574,467 |

| Cooling capacity | 4.16 | 4,569,615 | 1,269,337 | 305,129 | 964,208 |

| Project | Actual Energy Recovery (MWh/y) | Proportion (%) | Energy Recovery after Residual Thermal Energy Utilization (MWh/y) | Proportion (%) |

|---|---|---|---|---|

| Biogas system | 178,940 | 66.6 | 178,940 | 12.2 |

| Ventilation system | 20,238 | 7.5 | 20,238 | 1.4 |

| Water source heat pump system | 69,610 | 25.9 | 1,269,337 | 86.4 |

| Total | 268,788 | 100 | 1,468,515 | 100 |

| Emission Process | GHG Species | GHG Emission (t/y) | Carbon Emission (t/y) | |

|---|---|---|---|---|

| Wastewater treatment | CO2 | 11,751 | 11,751 | 217,117 |

| CH4 | 2582 | 54,230 | ||

| N2O | 507 | 151,136 | ||

| Sludge treatment and disposal | CH4 (from anaerobic digestion) | 543 | 11,412 | 62,054 |

| CH4 (from land application) | 223 | 4684 | ||

| N2O (from land application) | 154 | 45,958 | ||

| Total | 279,171 | |||

| Chemicals | Annual Consumption (t/y) [28] | Usage | Carbon Emission Factor (kg CO2/kg) | Indirect Carbon Emission (t/y) |

|---|---|---|---|---|

| Sodium acetate | 10,950 | External carbon source | 1.4 | 15,330 |

| Sodium hypochlorite | 4562.5 | Disinfectant | 0.89 | 4061 |

| Polyacrylamide (PAM) | 461.7 | Dewatering flocculant | 1.9 | 877 |

| Fe2O3 | 25.5 | Dry desulfurizer for biogas | 1.3 | 33 |

| FeCl3 (38%) | 601.4 | Desulfurizer in digester | 0.18 | 108 |

| Polyaluminum chloride (PAC) | 32.9 | Chemical phosphors removal | 0.537 | 18 |

| Total | 20,427 | |||

| Total Energy Recovery from Sludge Treatment Process (MWh/y) | Energy Recovery Pathway | Energy (MWh/y) [12] | CO2 Emission Factor of Electricity/Heat | Carbon Emission Reduction (t/y) |

|---|---|---|---|---|

| 178,940 | Electrical energy from heat and power cogeneration | 43,040 | 0.604 t/MWh | 25,996 |

| Heat recovery from flue gases | 19,370 | 0.11 t/GJ | 7671 | |

| Heat recovery from water cylinder jackets | 24,750 | 9801 | ||

| Heat recovery from boiler steams | 91,780 | 36,345 | ||

| Total | 79,813 | |||

| Carbon Emission Project | Present Carbon Emission Reduction (t/y) | Proportion (%) | Carbon Emission Reduction after Residual Thermal Energy Utilization (t/y) | Proportion (%) | |

|---|---|---|---|---|---|

| Water quality improvement | 113,878 | 45.0 | 113,878 | 11.6 | |

| Sludge treatment and disposal processes | Biogas system | 79,813 | 31.5 | 79,813 | 8.2 |

| Sludge land application | 6932 | 2.7 | 6932 | 0.7 | |

| Anammox system | 2313 | 0.9 | 2313 | 0.2 | |

| Ventilation system | 8014 | 3.2 | 8014 | 0.8 | |

| Water source heat pump system | 42,044 | 16.6 | 766,680 | 78.4 | |

| Total | 252,994 | 100 | 977,630 | 100 | |

| Type | Carbon Emission (t/y) | Carbon Emission Reduction (t/y) | Carbon Sink (t/y) | Carbon Neutrality Rate (%) |

|---|---|---|---|---|

| Actual | 446,468 | −252,994 | 193,474 | 56.7% |

| After residual thermal energy utilization | 446,468 | −977,630 | −531,162 | 219.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, C.; Luo, X.; Rong, B.; Nie, X.; Jin, Z.; Xia, X. Carbon Emission Accounting and the Carbon Neutralization Model for a Typical Wastewater Treatment Plant in China. Int. J. Environ. Res. Public Health 2023, 20, 140. https://doi.org/10.3390/ijerph20010140

Pang C, Luo X, Rong B, Nie X, Jin Z, Xia X. Carbon Emission Accounting and the Carbon Neutralization Model for a Typical Wastewater Treatment Plant in China. International Journal of Environmental Research and Public Health. 2023; 20(1):140. https://doi.org/10.3390/ijerph20010140

Chicago/Turabian StylePang, Chenxi, Xi Luo, Bing Rong, Xuebiao Nie, Zhengyu Jin, and Xue Xia. 2023. "Carbon Emission Accounting and the Carbon Neutralization Model for a Typical Wastewater Treatment Plant in China" International Journal of Environmental Research and Public Health 20, no. 1: 140. https://doi.org/10.3390/ijerph20010140

APA StylePang, C., Luo, X., Rong, B., Nie, X., Jin, Z., & Xia, X. (2023). Carbon Emission Accounting and the Carbon Neutralization Model for a Typical Wastewater Treatment Plant in China. International Journal of Environmental Research and Public Health, 20(1), 140. https://doi.org/10.3390/ijerph20010140