Fault Diagnosis and Maintenance Countermeasures of Transverse Drainage Pipe in Subway Tunnel Based on Fault Tree Analysis

Abstract

1. Introduction

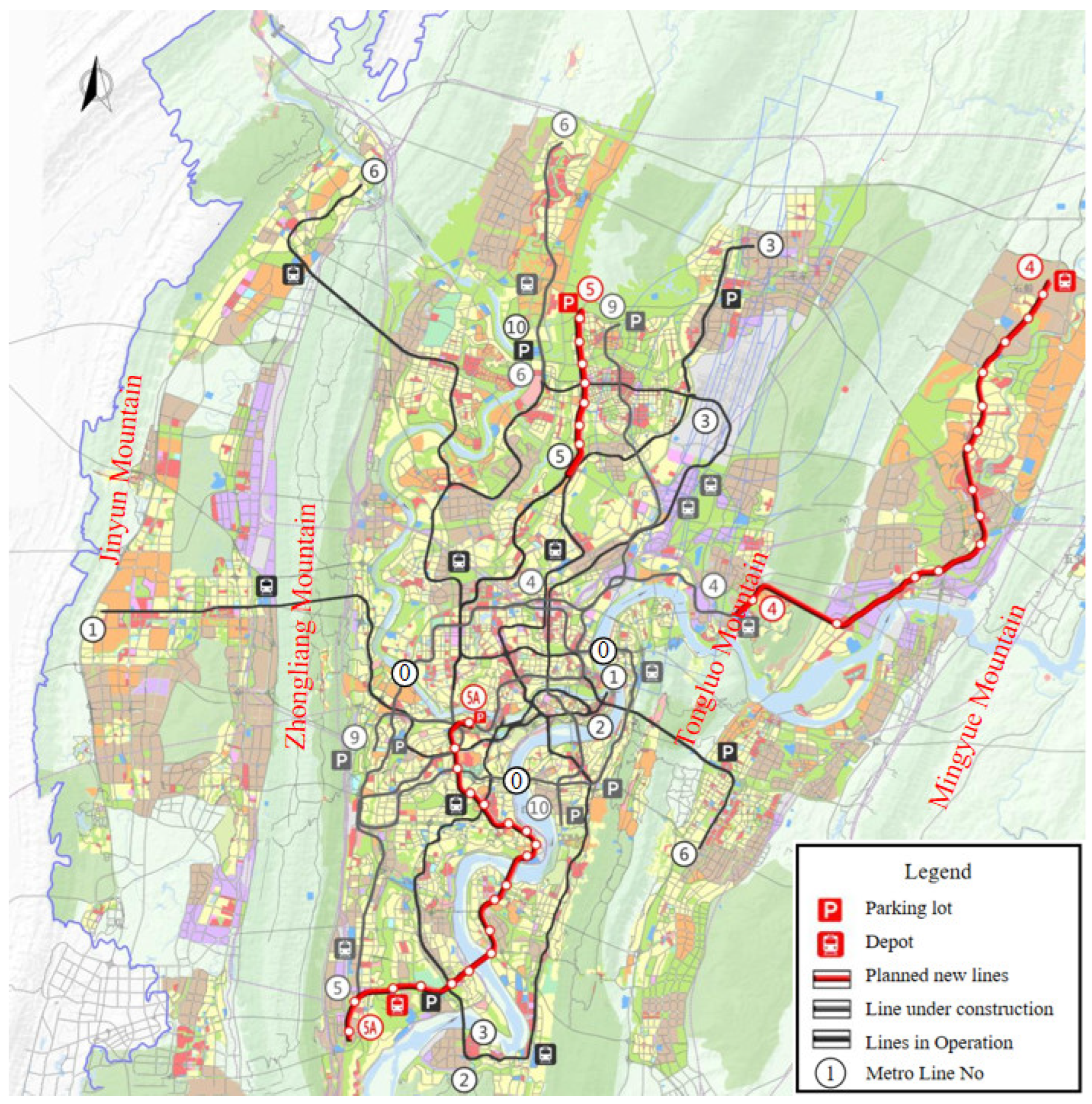

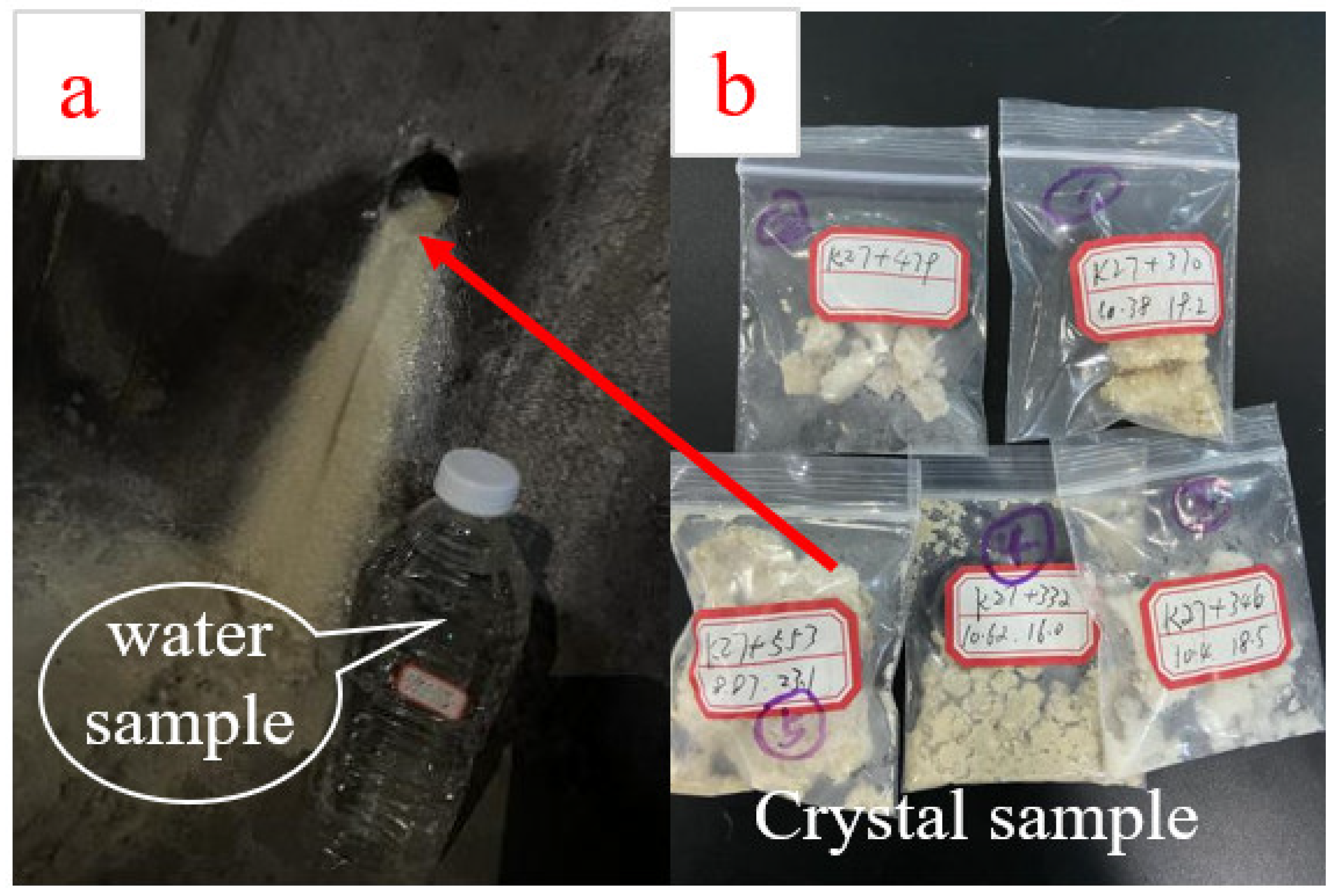

2. Sampling

3. Construction and Analysis of a Fault Tree Model for Blocked Transverse Drainage Pipe in Subway Tunnels

3.1. Selection of Evaluation Methods for Lateral Drain Pipe Blockage

3.2. Analysis of Groundwater Ion Concentration

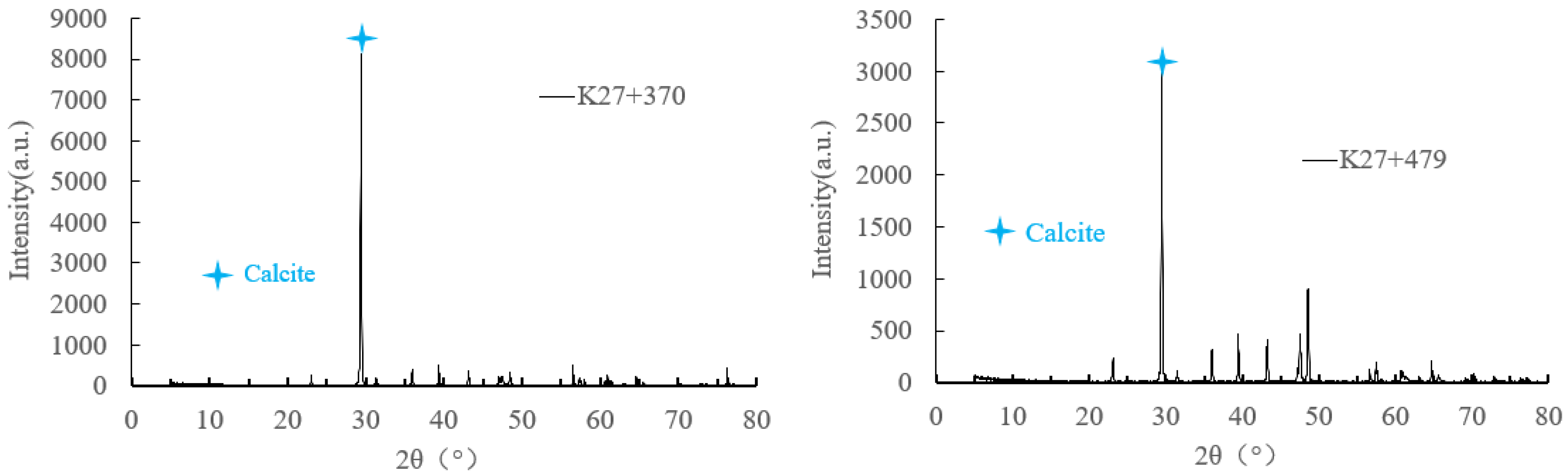

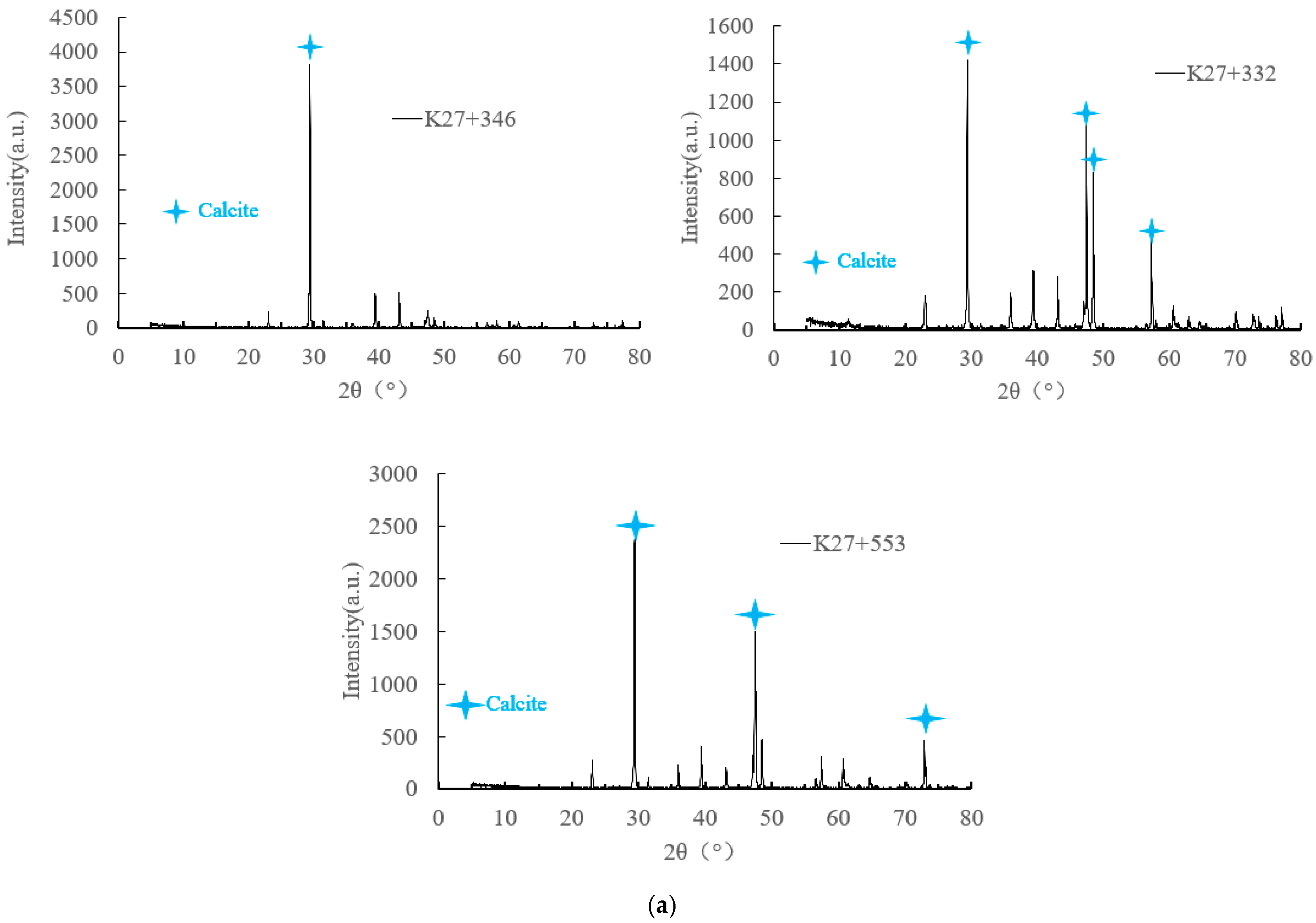

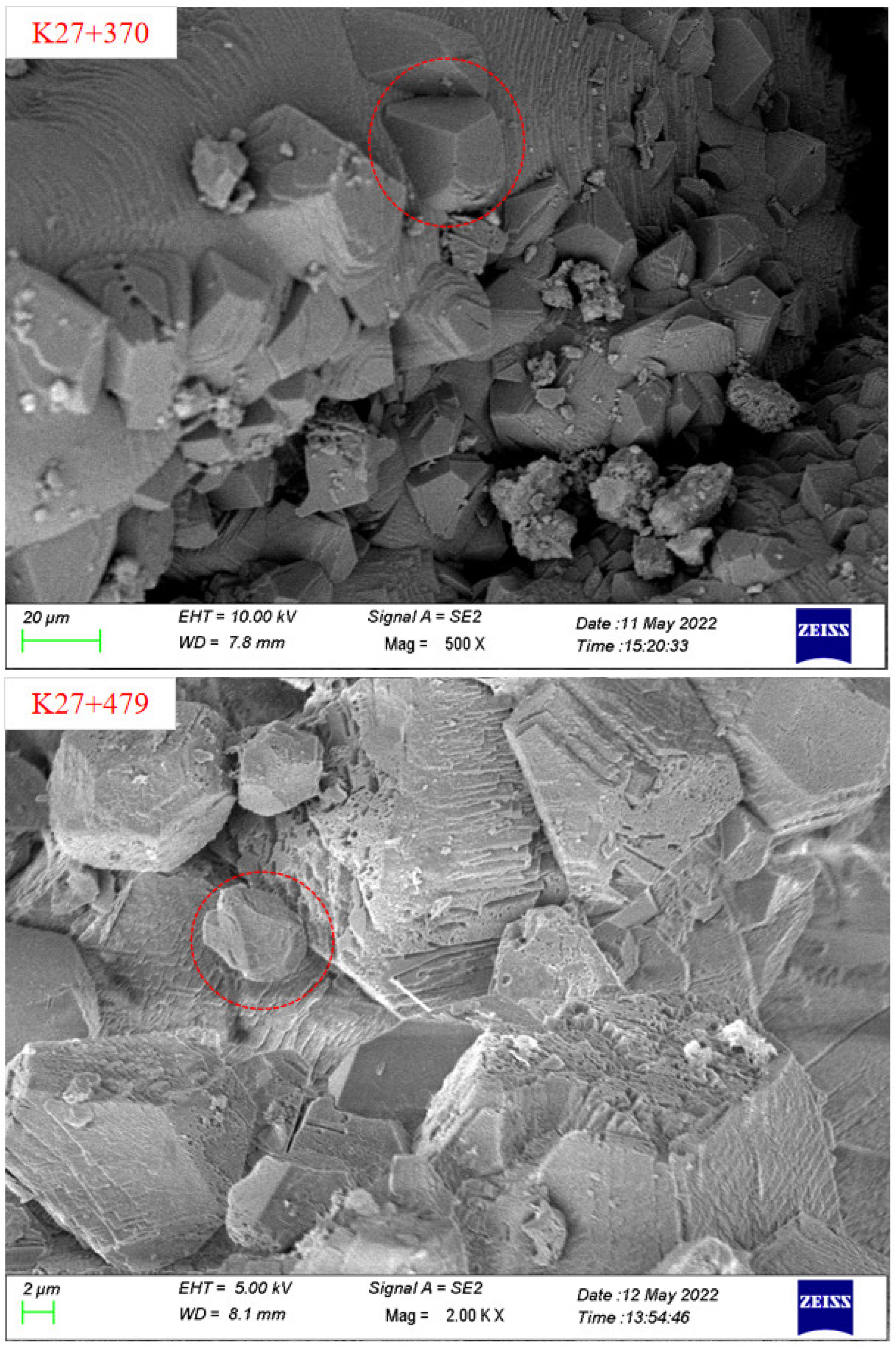

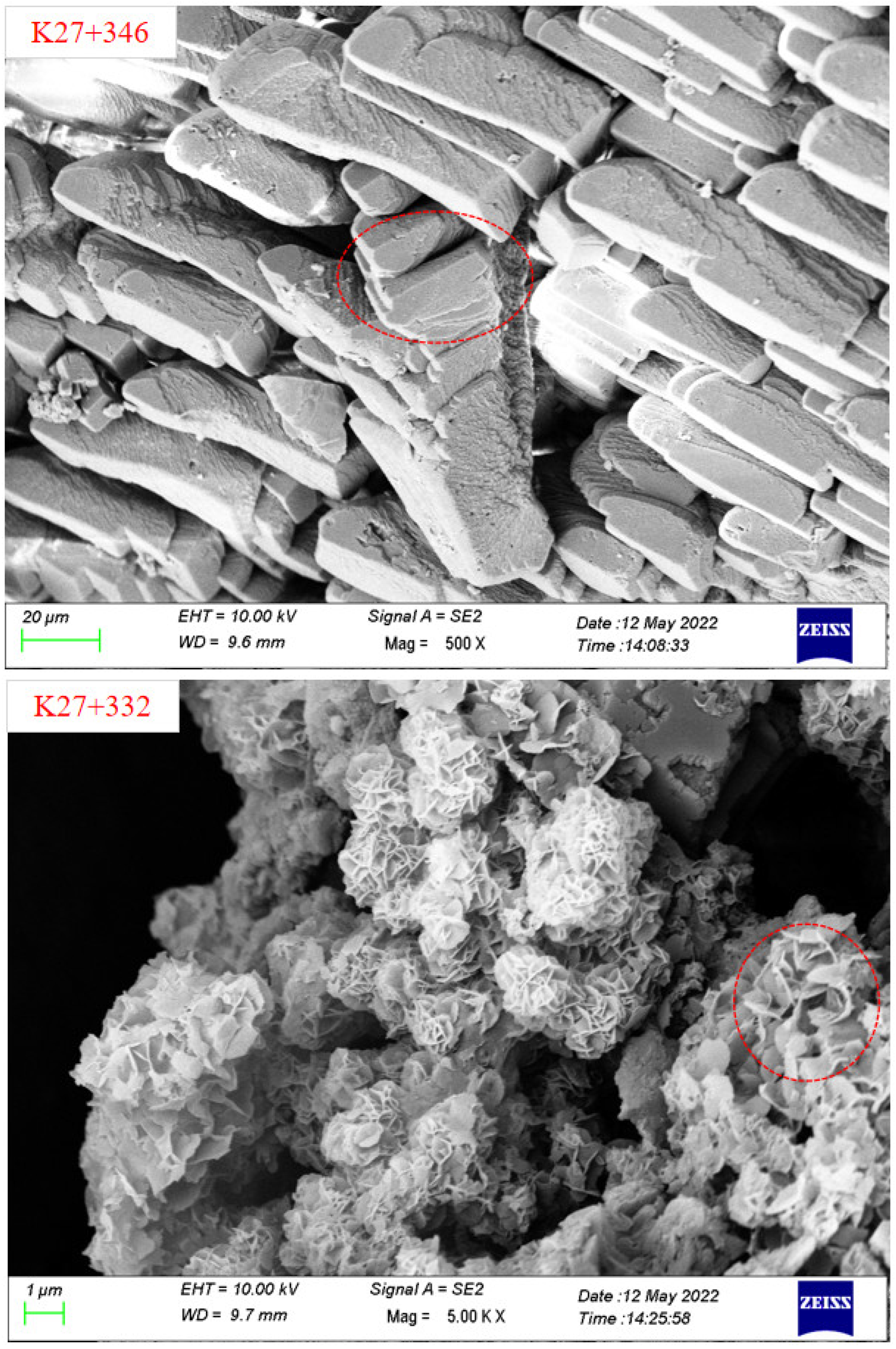

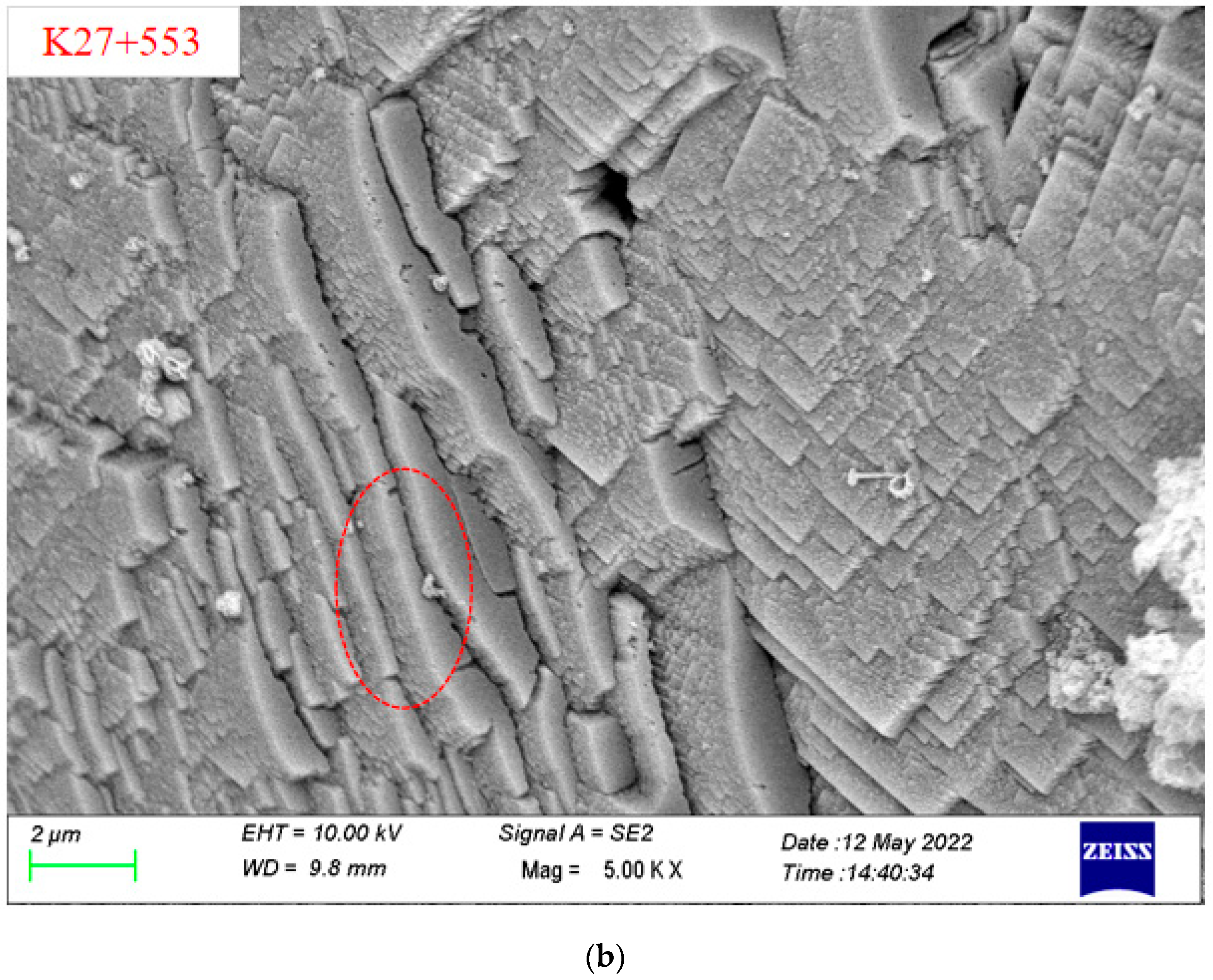

3.3. Test and Analysis of Crystalline Composition

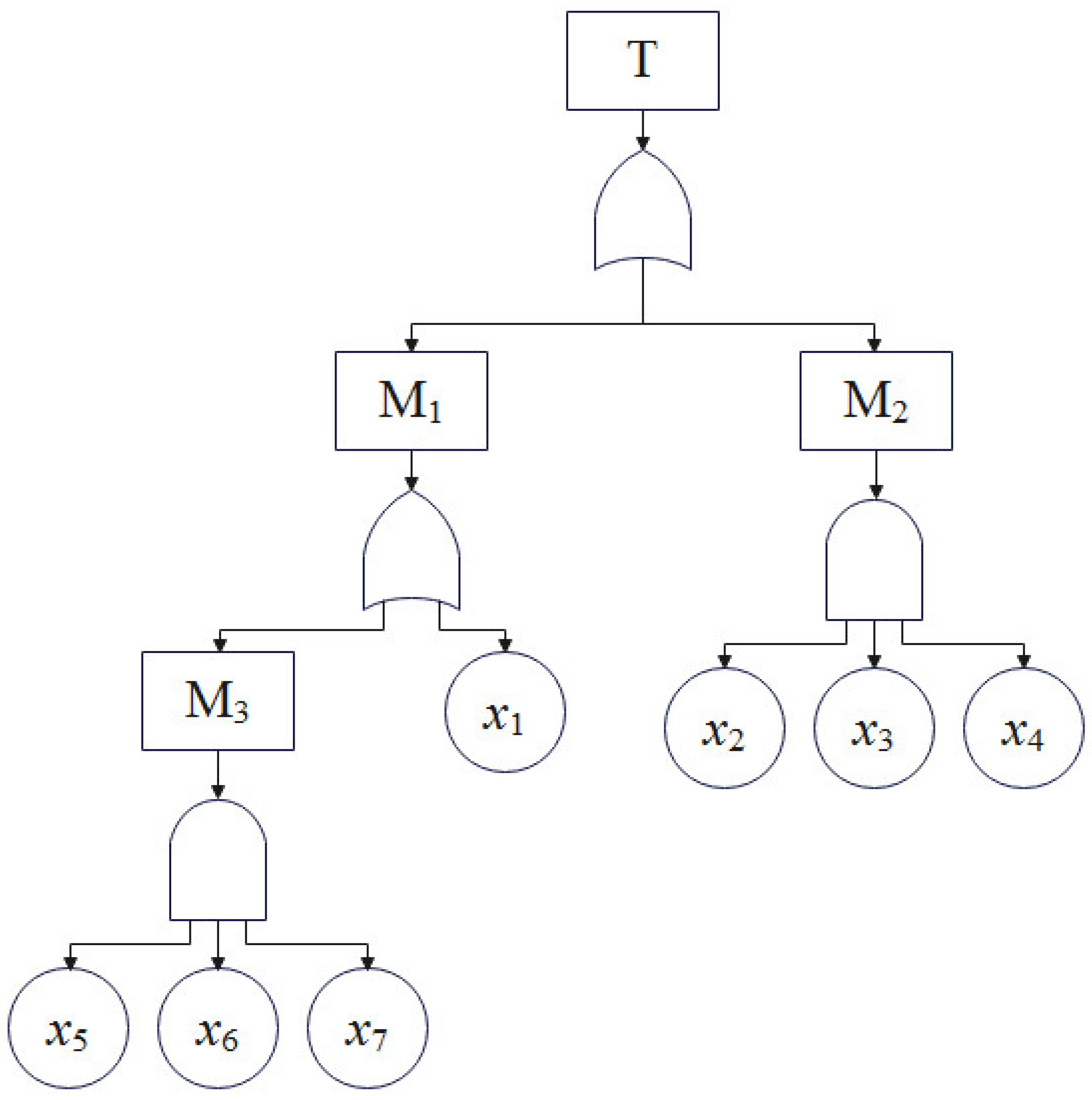

3.4. Fault Tree Model Construction and Analysis for Blocked Transverse Drainage Pipe

3.4.1. Event Determination of Fault Tree Layers

3.4.2. Construction of a Fault Tree

3.4.3. Qualitative Analysis of the Fault Tree

3.4.4. Quantitative Analysis of Fault Tree

- 1.

- Importance Analysis of Basic Event Structure

- 2.

- Probability Importance Analysis of Basic Events

- 3.

- Critical Importance Analysis of Basic Events

- 4.

- Summary and Analysis of the Importance of Basic Events

4. Analysis of Countermeasures for the Maintenance of Transverse Drainage Pipes in Subway Tunnels

4.1. Preventive Maintenance of Transverse Drainage Pipe during Tunnel Construction

- (1)

- Construction Quality Control of Transverse Drainage Pipe in Subway Tunnel

- (2)

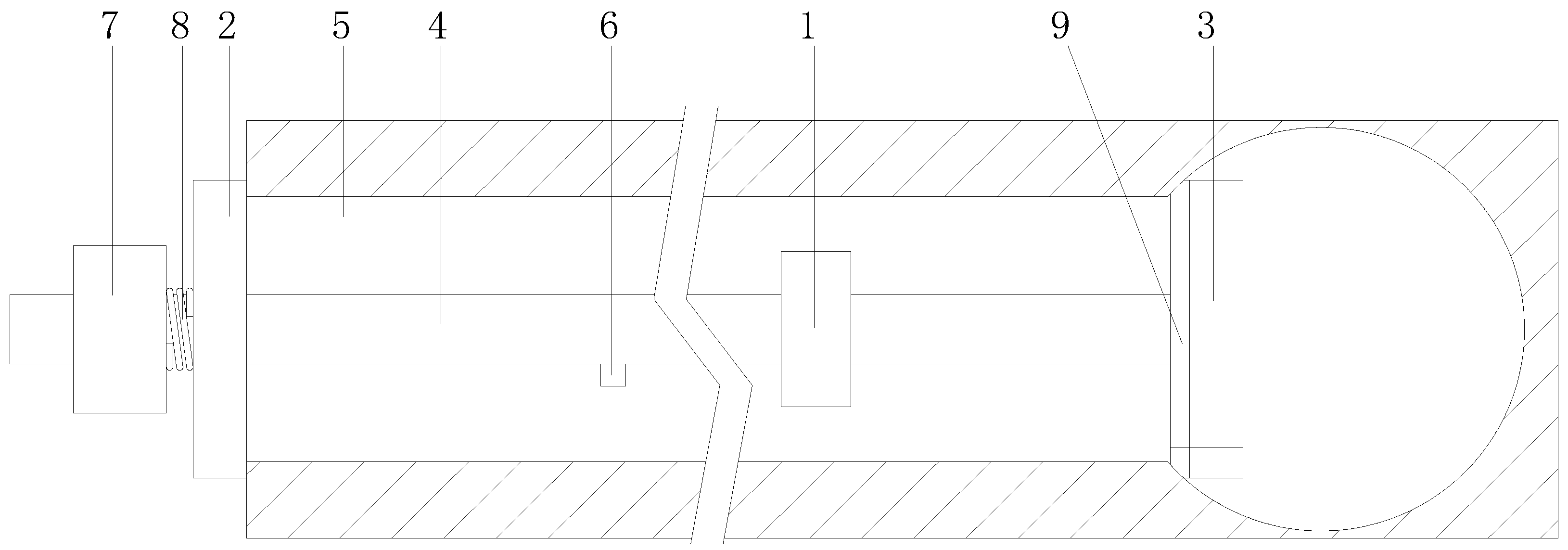

- Anti-Crystallization Blockage Drainage Pipe

4.2. Preventive Maintenance of Transverse Drainage Pipe during Tunnel Operation

- (1)

- Monitoring of Groundwater Ion Concentration

- (2)

- Monitoring of Groundwater pH

- (3)

- Monitoring of Groundwater Temperature

4.3. Maintenance and Treatment of Transverse Drainage Pipe during Tunnel Operation

- (1)

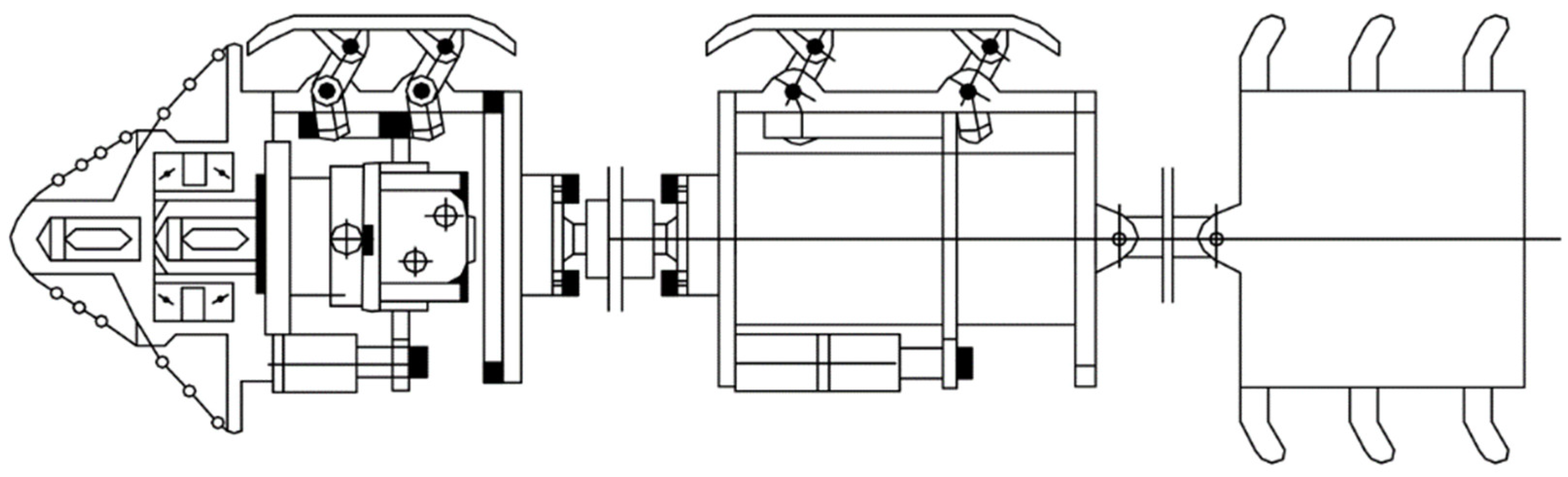

- Physical Treatment Techniques

- (2)

- Chemical Treatment Techniques

5. Conclusions

- The Ca2+ content in groundwater is lower than 100 mg/L, and the HCO3− content is in the range of 100~220 mg/L; most of the groundwater is strongly alkaline with pH greater than 8; the groundwater temperature is in the range of 20 ± 3 °C.

- The basic events of transverse drainage pipe blockage constitute 3 minimal cut sets of the fault tree, and the basic events , , , and are the main causal factors of transverse drainage pipe blockage.

- The preventive maintenance of transverse drainage pipes during tunnel construction includes quality control of the drainage pipes and application of anti-crystallization blockage drainage pipes; the preventive maintenance of transverse drainage pipes during tunnel operation includes the monitoring of groundwater ion concentration, pH, and temperature; the treatment of transverse drainage pipes during tunnel operation includes physical treatment techniques, such as ultrasonic resonance, and chemical treatment techniques, such as acid-base neutralization reactions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Glossary

| Acronyms | Constituent Words |

| FTA | Fault Tree Analysis |

| WBS-RBS | Work Breakdown Structure and Risk Decomposition Structure |

| T-S | Top-Second |

| TBM | Tunnel Boring Machine |

| ATS | Automatic Train Supervision |

| AHP | Analytic Hierarchy Process |

| XRD | X-Ray Diffraction |

| SEM | Scanning Electron Microscope |

References

- Zhou, J.Z. Application of gray correlation fault tree analysis for unprotected open cut excavations. China Civ. Eng. J. 2009, 42, 109–114. [Google Scholar]

- Xu, Z.S.; Wu, A.Y.; Shi, S.L.; Li, X.K.; Li, G.H. Analysis of road tunnel fire risk based on fuzzy fault tree method. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering, Wuhan, China, 15–17 April 2011; Volume 7, pp. 2986–2989. [Google Scholar] [CrossRef]

- Zhu, A.H.; Yang, L.; Li, B. Simulation and application on the reliability of ATS system based on fault tree analysis method. Railw. Stand. Des. 2013, 11, 105–109. [Google Scholar] [CrossRef]

- Ardeshir, A.; Amiri, M.; Ghasemi, Y.; Errington, M. Risk assessment of construction projects for water conveyance tunnels using fuzzy fault tree analysis. Int. J. Civ. Eng. 2014, 12, 396–412. [Google Scholar] [CrossRef]

- Hyun, K.C.; Min, S.; Choi, H.; Park, J.; Lee, I.M. Risk analysis using fault-tree analysis (FTA) and analytic hierarchy process (AHP) applicable to shield TBM tunnels. Tunn. Undergr. Space Technol. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Lin, R.T.; Li, Z.G.; Wu, B. Risk assessment of tunnel engineering based on triangular fuzzy fault tree analysis in Maluan mountain tunnel portal construction. Fujian Archit. Constr. 2017, 1, 72–75. [Google Scholar]

- Zhang, C.Y.; Tao, G.; Zhang, L.J. Fire safety analysis of Nanjing Yangtze River tunnel based on fault tree and triangle fuzzy theory. Procedia Eng. 2018, 211, 979–985. [Google Scholar] [CrossRef]

- Wei, D. Risk assessment for subway construction based on fault tree analysis and analytical hierarchy process: A case study of destabilization of pit supporting structure of tunnel shaft. Saf. Environ. Eng. 2018, 25, 100–104. [Google Scholar] [CrossRef]

- Mottahedi, A.; Ataei, M. Fuzzy fault tree analysis for coal burst occurrence probability in underground coal mining. Tunn. Undergr. Space Technol. 2019, 83, 165–174. [Google Scholar] [CrossRef]

- Chen, W.; Wang, H.; Zhang, G.H.; Wang, C.T.; Zhong, G.Q. Evaluation of tunnel collapse susceptibility based on T-S fuzzy fault tree and bayesian network. J. Shanghai Jiaotong Univ. 2020, 54, 820–830. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, C.; Zong, Z.X. Reliability analysis of urban rail transit operation based on fault tree. Urban Public Transp. 2020, 1, 32–35. [Google Scholar]

- Yang, R.; Deng, Y. Analysis on security risks in tunnel construction based on the fault tree analysis. IOP Conf. Ser. Earth Environ. Sci. 2021, 638, 012089. [Google Scholar] [CrossRef]

- Pan, H.Z.; Huang, T.; Yang, H.J.; Tang, X. Classification and grading assessment method of leakage disasters in running tunnel. Arid Land Geogr. 2009, 32, 145–151. [Google Scholar] [CrossRef]

- Chen, W.W.; Yang, Z.Y. Risk analysis of tunnel leakage based on fault tree analysis. Highw. Automot. Appl. 2012, 6, 211–215. [Google Scholar]

- Liu, J.; Liu, D.; Song, K. Evaluation of the negative effects on groundwater environment resulted by Geleshan tunnel drainage. Mod. Tunn. Technol. 2012, 49, 178–183. [Google Scholar] [CrossRef]

- Wang, G.Y.; Song, X.R.; Zeng, X.Y.; Liu, D.S.; Zhao, D.Y.; Lv, Y.F. Risk evaluation of drainage facilities based on analytic hierarchy process and fuzzy comprehensive evaluation. J. North China Univ. Technol. 2015, 27, 89–94. [Google Scholar]

- Wang, Y.M.; Yang, J.S.; Luo, L.S.; Lin, H. Statistical analysis and fuzzy synthetic evaluation of water pressure load on lining of karst tunnel. J. Zhengzhou Univ. (Eng. Sci.) 2015, 36, 38–42. [Google Scholar]

- Bai, M.Y.; Chen, Y.; Shi, H. Environmental risk assessment of underground water level falling induced by construction in mountain tunnel. J. Railw. Eng. Soc. 2016, 33, 5–10, 15. [Google Scholar]

- Ding, X.; Huang, Q.; Zhu, H.; Hu, H.; Liu, Z.G. Subway tunnel disease associations mining based on fault tree analysis algorithm. Math. Probl. Eng. 2017, 2017, 2621493. [Google Scholar] [CrossRef]

- Luo, J.J.; Lei, G.; Bi, F.C. On the AHP-based design and application of waterproofing and drainage for subway tunnels. Mod. Tunn. Technol. 2017, 54, 24–30. [Google Scholar] [CrossRef]

- Huang, B.M.; Chen, H.B.; Duan, C.L.; Su, T.M. Quality inspection and evaluation method of waterproof and drainage system in highway tunnel. Highw. Transp. Technol. (Appl. Technol. Version) 2018, 14, 276–278. [Google Scholar]

- Huang, C.; Chen, W.J.; Su, D.; Lei, G.P. Analysis of causes of structural diseases in metro tunnels and summary of fault tree models. Mod. Tunn. Technol. 2020, 57 (Suppl. S1), 264–272. [Google Scholar] [CrossRef]

- Ma, Y.; Deng, H.L. Study on the evaluation system of waterproof and drainage system of highway tunnel based on fuzzy comprehensive evaluation method. Constr. Technol. 2020, 49, 98–103. [Google Scholar]

- Nie, C.X.; Rao, Y.J. Study on fuzzy evaluation model of crystallization blockage risk in tunnel drainage system. China Water Transp. 2021, 21, 30–32. [Google Scholar]

- Lee, J.H.; Chu, I.C.; Kim, H.G.; Lee, C.K.; Chun, B.S. Evaluation of technology for preventing drainage pipe blockage in deteriorated tunnel. In Proceedings of the ISOPE-2012 International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012; pp. 606–611. [Google Scholar]

- Higashitani, K.; Kage, A.; Katamura, S.; Imai, K.; Hatade, S. Effect of a magnetic field on the formation of CaCO3 particles. J. Colloid Interf. Sci. 1993, 156, 90–95. [Google Scholar] [CrossRef]

- Nebel, H.; Epple, M. Continuous preparation of calcite, aragonite and vaterite, and of magnesium-substituted amorphous calcium carbonate (Mg-ACC). Z. Anorg. Allg. Chem. 2008, 634, 1439–1443. [Google Scholar] [CrossRef]

- Rinder, T.; Dietzel, M.; Leis, A. Calcium carbonate scaling under alkaline conditions—Case studies and hydrochemical modelling. Appl. Geochem. 2013, 35, 132–141. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhou, Y.F.; Zhang, B.; Zhou, Y.J.; Liu, S.Y. Investigation and Analysis on Crystallization of Tunnel Drainage Pipes in Chongqing. Adv. Mater. Sci. Eng. 2018, 2018, 7042693. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Du, K.; Tao, L.; Zhao, J.M.; Xiao, H.R. Investigation and Discussion on Blocking Mechanism of Drainage System in K arst Tunnels. Railw. Stand. Des. 2019, 63, 131–135. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Li, G.P.; Jia, Q.Q.; Qi, H.Y.; Li, D.W. Study on Characteristics and Sources of Crystal Components of Leakage Water in the Loess Tunnel. Mod. Tunn. Technol. 2020, 57, 154–159. [Google Scholar] [CrossRef]

- Stefanie, E.; Ronny, B.; Albrecht, L.; Guenther, K.; Cyrill, G.; Gunnar, D.; Manfred, N.; Christian, S.; Martin, D. Scale deposits in tunnel drainage systems—A study on fabrics and formation mechanisms. Sci. Total Environ. 2020, 718, 137140. [Google Scholar] [CrossRef]

- Guo, X.X. Crystallization mechanism and countermeasures of drainage system for railway tunnel. China Railw. Sci. 2020, 41, 71–77. [Google Scholar]

- Ye, F.; Tian, C.M.; He, B.; Zhao, M.; Wang, J. Experimental study on scaling and clogging in drainage system of tunnels under construction. China J. Highw. Transp. 2021, 34, 159–170. [Google Scholar] [CrossRef]

- Siegel, F.R.; Reams, M.W. Temperature effect on precipitation of calcium carbonate from calcium bicarbonate solution and its application to cave environments. Sedimentology 2010, 7, 241–248. [Google Scholar] [CrossRef]

- Feng, R.S.; Zhou, J.; Xiao, D.J.; Chen, X.G.; Li, H.M.; Zhang, X.F. Laboratory experimental study on crystal growth of tunnel drainage pipe in high temperature area. Highway 2021, 66, 398–402. [Google Scholar]

- Wang, Y.D.; Liu, Y.; Qi, C.F.; Zhou, T.Y.; Ye, M.; Wang, T. Crystallization law of karst water in tunnel drainage system based on DBL theory. Open Phys. 2021, 19, 241–255. [Google Scholar] [CrossRef]

- Gao, C.; Hao, M.; Chen, J.; Gu, C. Simulation and design of joint distribution of rainfall and tide level in Wuchengxiyu Region, China. Urban Clim. 2021, 40, 101005. [Google Scholar] [CrossRef]

- Li, H.M.; Liu, S.Y.; Xiong, S.; Leng, H.; Chen, H.Q.; Zhang, B.; Liu, Z. Laboratory Experimental Study on Influencing Factors of Drainage Pipe Crystallization in Highway Tunnel in Karst Area. Coatings 2021, 11, 1493. [Google Scholar] [CrossRef]

- Chen, Y.F.; Cui, Y.J.; Barrett, A.G.; Chille, F.; Lassalle, S. Investigation of calcite precipitation in the drainage system of railway tunnels. Tunn. Undergr. Space Technol. 2019, 84, 45–55. [Google Scholar] [CrossRef]

- Ye, F.; He, B.; Tian, C.M.; Zhao, M.; Wang, J.; Han, X.B. Influence of sodium aluminate on calcium leaching of shotcrete in tunnels. Tunn. Undergr. Space Technol. 2021, 117, 104156. [Google Scholar] [CrossRef]

- Yang, T.F.; Cao, H.B.; Wang, Y. Cleaning method of seawater pipeline by using high pressure water jet. Ship Ocean Eng. 2018, 47, 111–114. [Google Scholar]

- Chen, H.; Li, S. Multi-sensor fusion by CWT-PARAFAC-IPSO-SVM for intelligent mechanical fault diagnosis. Sensors 2022, 22, 3647. [Google Scholar] [CrossRef] [PubMed]

- Kordestani, H.; Zhang, C.; Masri, S.F.; Shadabfar, M. An empirical time-domain trend line-based bridge signal decomposing algorithm using Savitzky–Golay filter. Struct. Control Heath 2021, 28, e2750. [Google Scholar] [CrossRef]

- Sun, R.; Wang, J.; Cheng, Q.; Mao, Y.; Ochieng, W.Y. A new IMU-aided multiple GNSS fault detection and exclusion algorithm for integrated navigation in urban environments. GPS Solut. 2021, 25, 147. [Google Scholar] [CrossRef]

- Wang, C.J.; Zhang, Z.B.; Wu, J.; Sun, X.J. Design scheme of multifunctional working robot for sewage pipeline. Constr. Mach. Equip. 2009, 40, 48–51, 92. [Google Scholar]

- Jiang, Y.J.; Du, K.; Liao, J.Y.; Chen, X.; Xiao, H.R. Experimental research on maintainability of drainage facilities in lining construction joints of karst tunnel. Railw. Stand. Des. 2019, 63, 91–96. [Google Scholar] [CrossRef]

- Liu, S.Y.; Zhang, X.F.; Lü, H.Y.; Liu, Q.; Wang, B. The effect of anti-crystallization of tunnel plumage drainpipe under different water filling state. Sci. Technol. Eng. 2018, 18, 156–163. [Google Scholar]

- Liu, S.Y.; Zhang, X.F.; Lü, H.Y.; Liu, Q.; Wang, B. The effect of flocking PVC pipe on the prevention and crystallization of tunnel drains. Sci. Technol. Eng. 2018, 18, 313–319. [Google Scholar]

- Chen, L. Probe into the blockage of drainage pipe in railway tunnel construction. Technol. Mark. 2015, 22, 80. [Google Scholar]

- Zhao, Z.; Xing, F.; Zeng, L.; Guo, Y.C. Concrete durability affected by aggressive carbon dioxide in groundwater. J. Chin. Ceram. Soc. 2013, 41, 224–229. [Google Scholar] [CrossRef]

- Ni, T.; Liu, D.; Xu, Q.; Huang, Z.; Liang, H.; Yan, A. Architecture of cobweb-based redundant TSV for clustered faults. In IEEE Transactions on Very Large Scale Integration (VLSI) Systems; IEEE: London, UK, 2020; Volume 28, pp. 1736–1739. [Google Scholar] [CrossRef]

- Zhan, C.; Dai, Z.; Soltanian, M.R.; de Barros, F.P.J. Data-worth analysis for heterogeneous subsurface structure identification with a stochastic deep learning framework. Water Resour. Res. 2022, 58, e2022WR033241. [Google Scholar] [CrossRef]

- Xiang, K.; Zhou, J.; Zhang, X.F.; Huang, C.; Song, L.; Liu, S.Y. Experimental study on crystallization rule of tunnel drainpipe in alkaline environment. Tunn. Constr. 2019, 39 (Suppl. S2), 207–212. [Google Scholar]

- Liu, Z.; Wang, L.L. Dynamic experimental study on effect of ultrasound on calcium carbonate scaling. Contemp. Chem. Ind. 2014, 43, 935–938. [Google Scholar] [CrossRef]

- Lu, X.X.; Guo, Y.; Lin, X.S.; Gong, T. Study on calcium carbonate scale removal with ultrasonic wave in laboratory. Contemp. Chem. Ind. 2017, 46, 1318–1321. [Google Scholar] [CrossRef]

| Sample Type | Sampling Station | Groundwater pH | Groundwater Temperature | Remarks |

|---|---|---|---|---|

| Groundwater sample | K27 + 338 | 9.51 | 17.80 | 1.5 L |

| K27 + 352 | 9.00 | 19.50 | 1.5 L | |

| K27 + 428 | 10.90 | 22.10 | 1.5 L | |

| K27 + 450 | 7.71 | 21.40 | 1.5 L | |

| K27 + 479 | 7.84 | 20.20 | 1.5 L | |

| K27 + 553 | 8.87 | 23.10 | 1.5 L | |

| K28 + 070 | 8.49 | 19.60 | 1.5 L | |

| Crystal sample | K27 + 370 | 10.38 | 19.20 | / |

| K27 + 479 | 7.84 | 20.20 | / | |

| K27 + 346 | 10.40 | 18.50 | / | |

| K27 + 332 | 10.62 | 16.00 | / | |

| K27 + 553 | 8.87 | 23.10 | / |

| Groundwater Analysis Project | Station Number | |||||||

|---|---|---|---|---|---|---|---|---|

| K27 + 338 | K27 + 352 | K27 + 428 | K27 + 450 | K27 + 479 | K27 + 553 | K28 + 070 | ||

| Groundwater ion concentration (mg/L) | K+ | 8.20 | 7.02 | 12.4 | 6.07 | 6.23 | 9.13 | 10.6 |

| Na+ | 45.8 | 37.6 | 42.7 | 39.9 | 36.0 | 57.9 | 44.3 | |

| Ca2+ | 45.0 | 52.9 | 76.8 | 79.4 | 68.3 | 38.6 | 54.7 | |

| Mg2+ | 9.75 | 9.39 | 0.0 | 15.5 | 15.4 | 11.2 | 16.8 | |

| Cl− | 55.1 | 37.5 | 33.1 | 61.2 | 39.7 | 46.3 | 46.3 | |

| SO42− | 108 | 105 | 81.7 | 82.2 | 89.3 | 82.6 | 89.3 | |

| HCO3− | 100 | 118 | 0.0 | 218 | 187 | 137 | 172 | |

| CO32− | 0 | 0 | 21.5 | 0 | 0 | 0 | 3.07 | |

| OH− | 0 | 0 | 40.9 | 0 | 0 | 0 | 0 | |

| Total hardness (calculated by CaCO3) (mg/L) | 153 | 171 | 192 | 262 | 234 | 143 | 206 | |

| Free CO2 (mg/L) | 9.11 | 4.55 | 0 | 20.5 | 11.4 | 11.4 | 13.7 | |

| pH value | Indoor test | 8.08 | 7.76 | 10.47 | 8.92 | 8.59 | 8.48 | 8.20 |

| Field test | 9.51 | 9.00 | 10.90 | 7.71 | 7.84 | 8.87 | 8.49 | |

| Field test temperature (°C) | 17.80 | 19.50 | 22.10 | 21.40 | 20.20 | 23.10 | 19.60 | |

| Code | Factor | Code | Factor |

|---|---|---|---|

| T | Blocking of cross drainage pipe of subway tunnel | x3 | Groundwater pH value |

| M1 | Impact of drainage pipe construction | x4 | Groundwater temperature |

| M2 | Influence of surrounding geological environment | x5 | Drainage pipe slope is too small |

| M3 | Construction defects of drainage pipe | x6 | The drainage pipe was flattened |

| x1 | Concrete slurry enters the drainage pipe | x7 | Drainage pipe damaged |

| x2 | Concentration of anions and cations in groundwater | / | / |

| Basic Events | Probability of Occurrence | Basic Events | Probability of Occurrence |

|---|---|---|---|

| 0.0417 | 0.0417 | ||

| 0.3333 | 0.0208 | ||

| 0.1250 | 0.0208 | ||

| 0.0833 |

| Basic Events | Structural Importance | Probability Importance | Critical Importance |

|---|---|---|---|

| 1.00 | 1.000 | 0.9227 | |

| 0.25 | 0.010 | 0.0769 | |

| 0.25 | 0.028 | 0.0769 | |

| 0.25 | 0.042 | 0.0769 | |

| 0.25 | 0.000 | 0.0004 | |

| 0.25 | 0.001 | 0.0004 | |

| 0.25 | 0.001 | 0.0004 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhang, X. Fault Diagnosis and Maintenance Countermeasures of Transverse Drainage Pipe in Subway Tunnel Based on Fault Tree Analysis. Int. J. Environ. Res. Public Health 2022, 19, 15471. https://doi.org/10.3390/ijerph192315471

Liu S, Zhang X. Fault Diagnosis and Maintenance Countermeasures of Transverse Drainage Pipe in Subway Tunnel Based on Fault Tree Analysis. International Journal of Environmental Research and Public Health. 2022; 19(23):15471. https://doi.org/10.3390/ijerph192315471

Chicago/Turabian StyleLiu, Shiyang, and Xuefu Zhang. 2022. "Fault Diagnosis and Maintenance Countermeasures of Transverse Drainage Pipe in Subway Tunnel Based on Fault Tree Analysis" International Journal of Environmental Research and Public Health 19, no. 23: 15471. https://doi.org/10.3390/ijerph192315471

APA StyleLiu, S., & Zhang, X. (2022). Fault Diagnosis and Maintenance Countermeasures of Transverse Drainage Pipe in Subway Tunnel Based on Fault Tree Analysis. International Journal of Environmental Research and Public Health, 19(23), 15471. https://doi.org/10.3390/ijerph192315471