A Comprehensive Hydrothermal Co-Liquefaction of Diverse Biowastes for Energy-Dense Biocrude Production: Synergistic and Antagonistic Effects

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

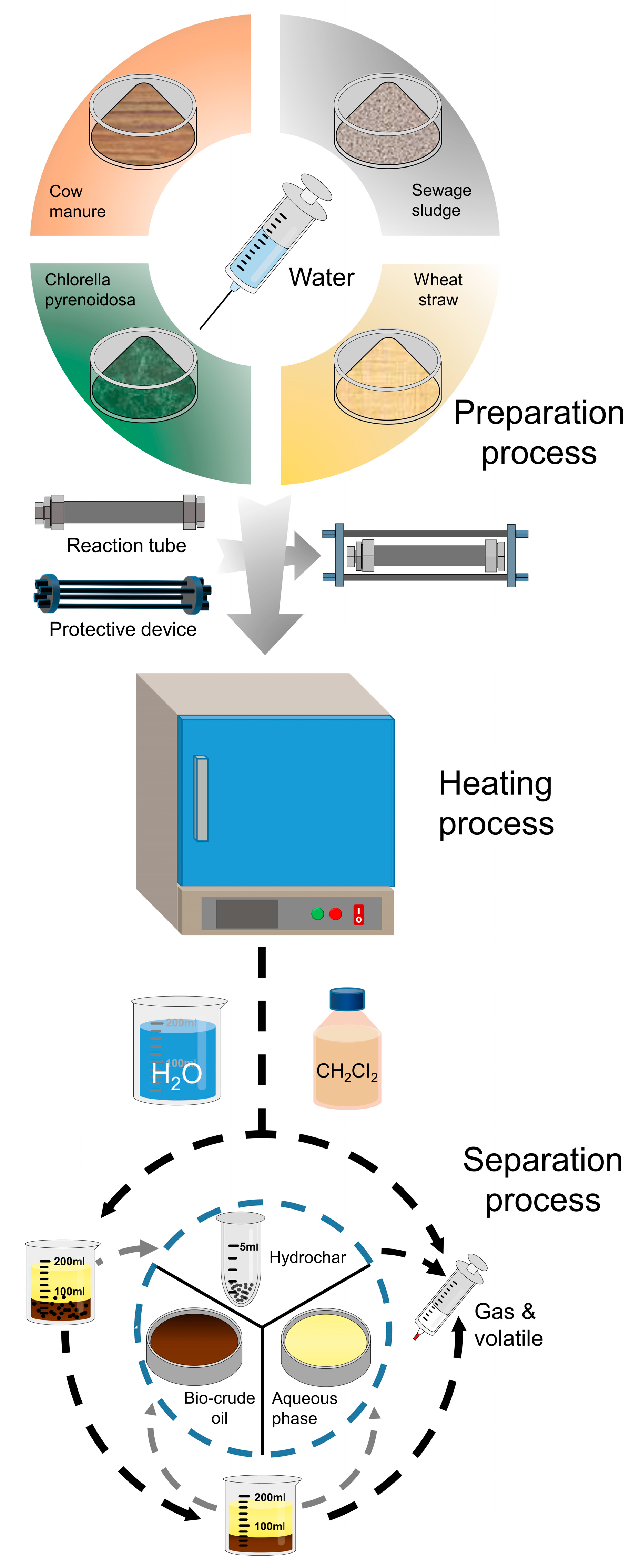

2.2. HTL Experimental Procedures

2.3. Product Recovery

2.4. Analytical Methods

2.5. Data Analysis

3. Results and Discussion

3.1. Feedstock Characterization

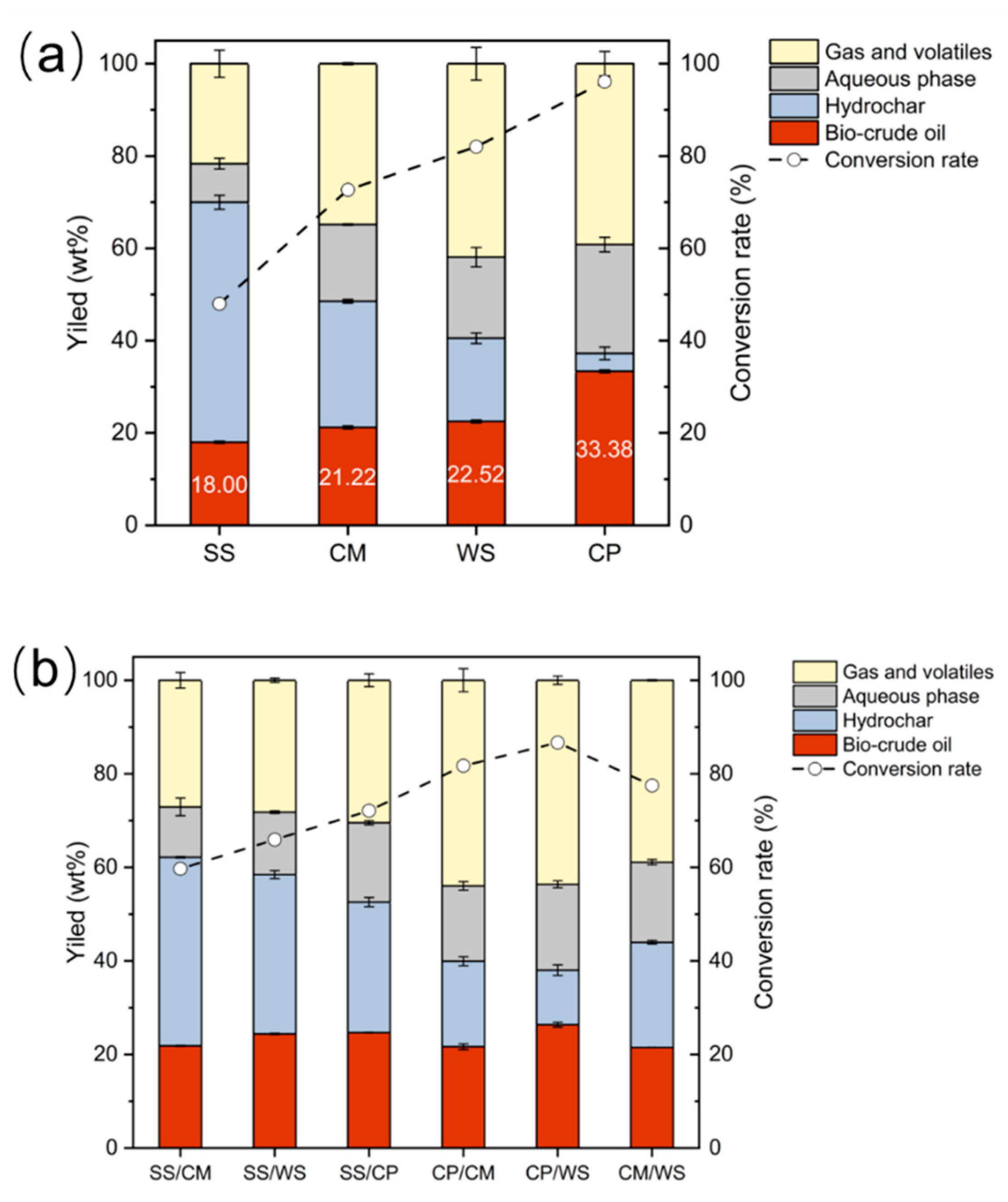

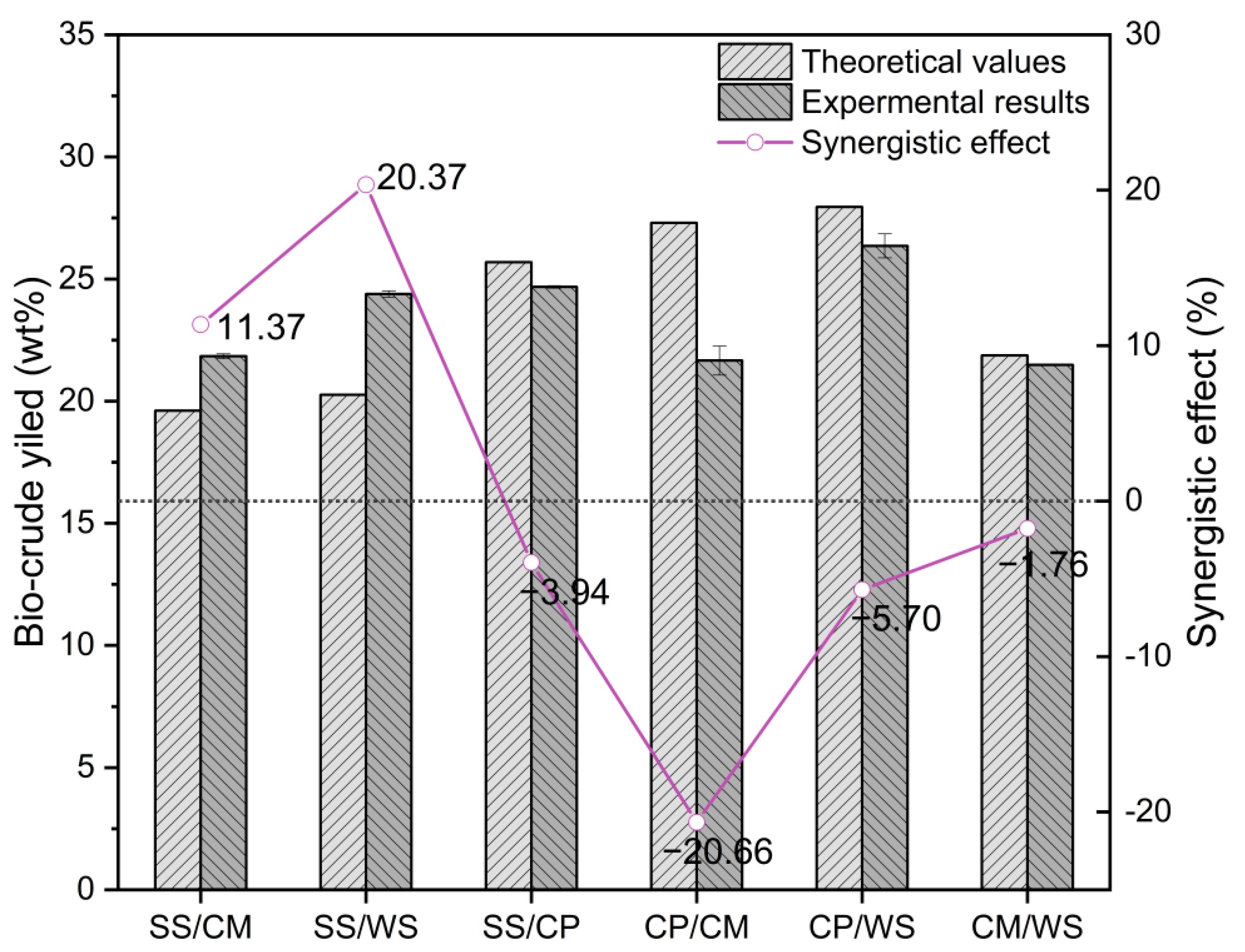

3.2. Hydrothermal Co-Liquefaction of Four Representative Feedstocks: Investigating Synergistic and Antagonistic Effects

3.3. Hydrothermal Co-Liquefaction of Sewage Sludge-Cow Manure: Optimizing Biocrude Yield and Quality

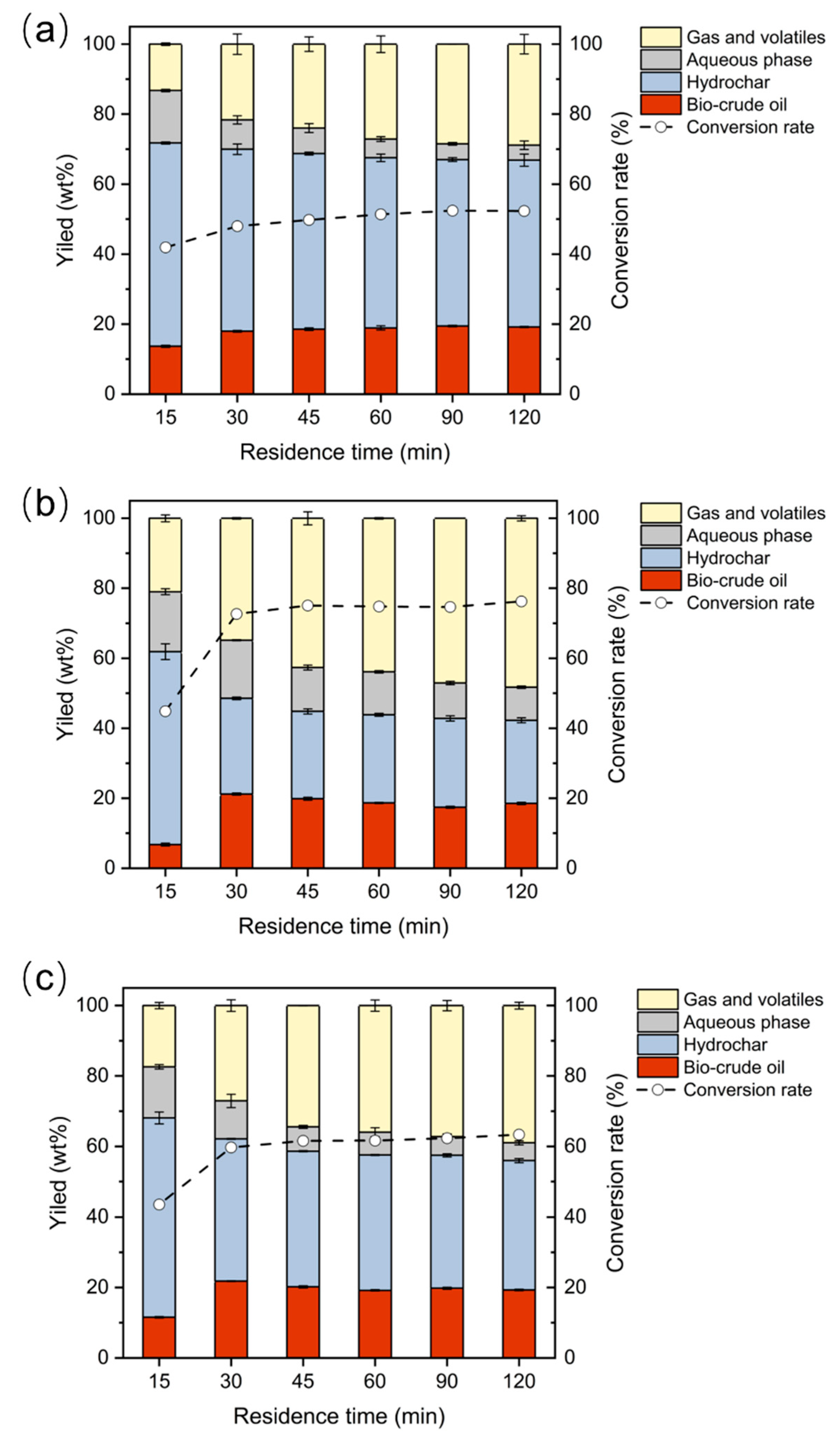

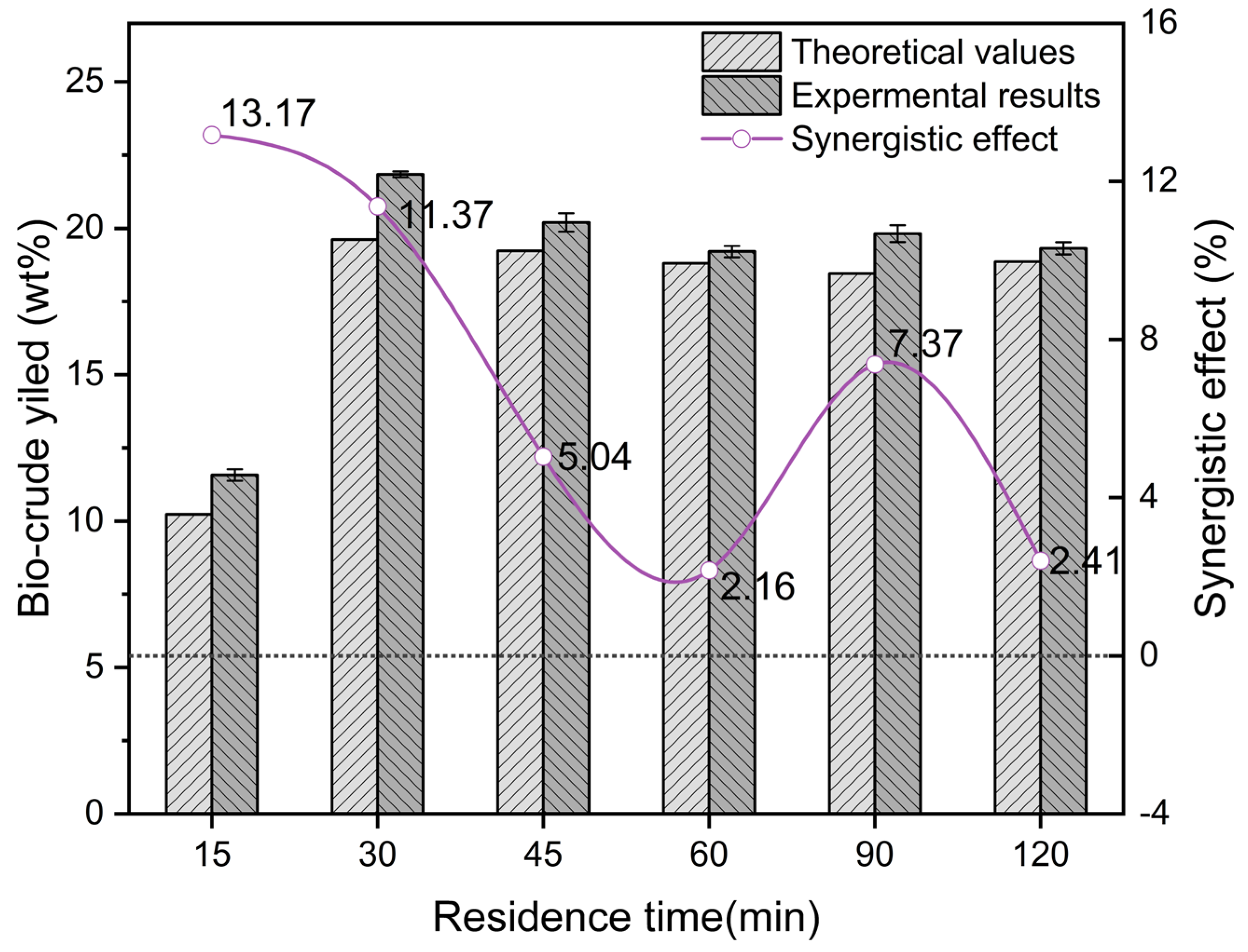

3.3.1. Product Yields of Co-HTL of Binary SS/CM

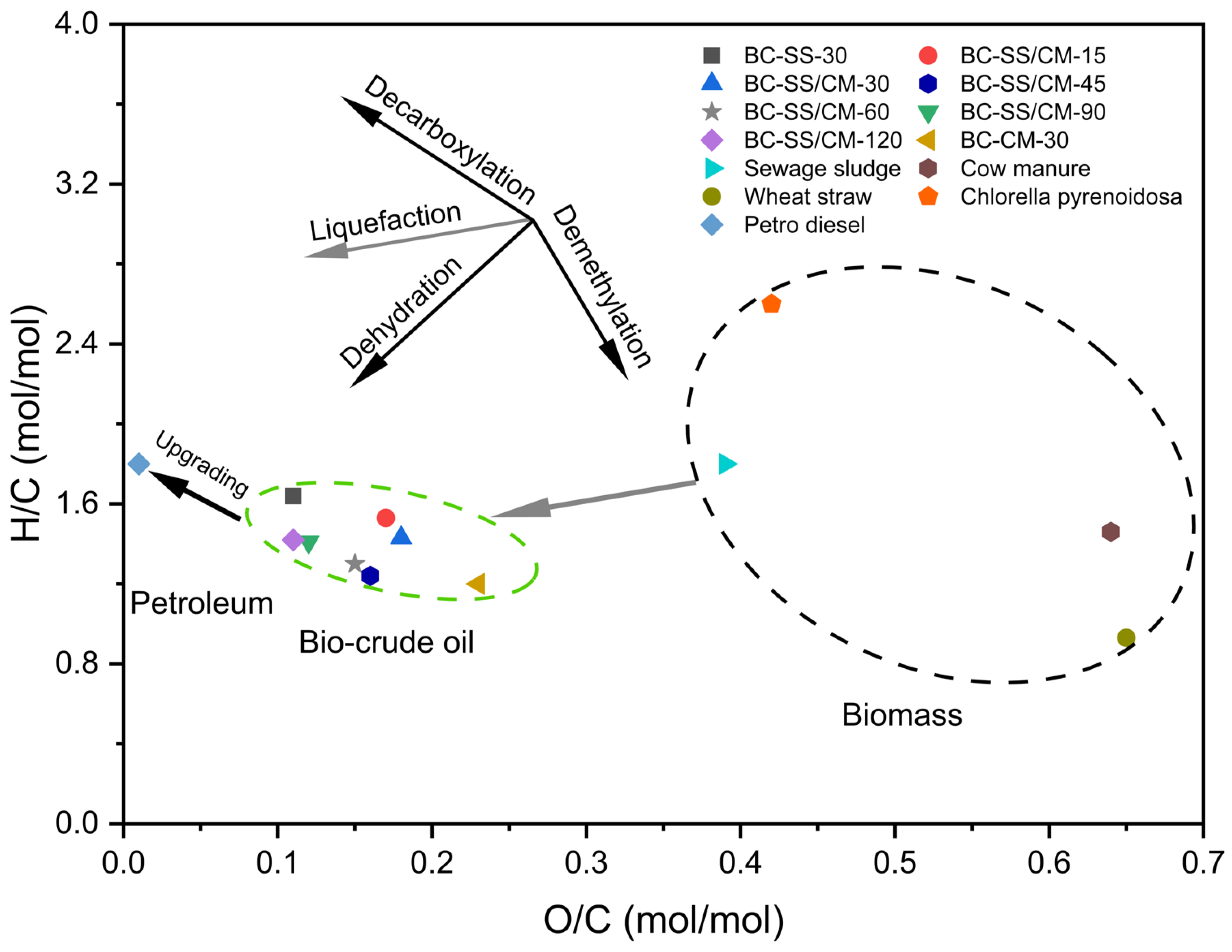

3.3.2. Characteristics of Biocrude Oils

3.3.3. Hydrochar Characterization

3.3.4. Analysis of Gaseous Products

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kabir, S.B.; Khalekuzzaman, M.; Islam, M.B.; Hossain, M.R. Performance optimization of organic solid waste and peat co-liquefaction mechanism for processing sustainable biocrude. Fuel Process. Technol. 2022, 231, 107234. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Chen, S.; Wu, J. Catalytic co-pyrolysis of lignocellulosic biomass with polymers: A critical review. Green Chem. 2016, 18, 4145–4169. [Google Scholar] [CrossRef]

- Islam, M.B.; Khalekuzzaman, M.; Kabir, S.B.; Hossain, M.R.; Alam, M.A. Substituting microalgal biomass with faecal sludge for high-quality biocrude production through co-liquefaction: A sustainable biorefinery approach. Fuel Process. Technol. 2022, 225, 107063. [Google Scholar] [CrossRef]

- Gollakota, A.; Kishore, N.; Gu, S. A review on hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2018, 81, 1378–1392. [Google Scholar] [CrossRef]

- Duan, Y.; He, Z.; Zhang, B.; Wang, B.; Zhang, F. Synergistic effect of hydrothermal co-liquefaction of Camellia oleifera Abel and Spirulina platensis: Parameters optimization and product characteristics. Renew. Energy 2022, 186, 26–34. [Google Scholar] [CrossRef]

- Guo, Y.; Yeh, T.; Song, W.; Xu, D.; Wang, S. A review of bio-oil production from hydrothermal liquefaction of algae. Renew. Sustain. Energy Rev. 2015, 48, 776–790. [Google Scholar] [CrossRef]

- Li, Q.; Liu, D.; Hou, X.; Wu, P.; Song, L.; Yan, Z. Hydro-liquefaction of microcrystalline cellulose, xylan and industrial lignin in different supercritical solvents. Bioresour. Technol. 2016, 219, 281–288. [Google Scholar] [CrossRef]

- Yong, T.L.-K.; Matsumura, Y. Kinetic analysis of lignin hydrothermal conversion in sub-and supercritical water. Ind. Eng. Chem. Res. 2013, 52, 5626–5639. [Google Scholar] [CrossRef]

- Gai, C.; Li, Y.; Peng, N.; Fan, A.; Liu, Z. Co-liquefaction of microalgae and lignocellulosic biomass in subcritical water. Bioresour. Technol. 2015, 185, 240–245. [Google Scholar] [CrossRef]

- Hossain, M.R.; Khalekuzzaman, M.; Kabir, S.B.; Islam, M.B.; Bari, Q.H. Enhancing faecal sludge derived biocrude quality and productivity using peat biomass through co-hydrothermal liquefaction. J. Clean. Prod. 2022, 335, 130371. [Google Scholar] [CrossRef]

- Yang, J.; He, Q.; Yang, L. A review on hydrothermal co-liquefaction of biomass. Appl. Energy 2019, 250, 926–945. [Google Scholar] [CrossRef]

- Chen, X.; Peng, X.; Ma, X.; Wang, J. Investigation of Mannich reaction during co-liquefaction of microalgae and sweet potato waste. Bioresour. Technol. 2019, 284, 286–292. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-J.; Chang, Y.-C.; Lai, F.-Y.; Zhou, C.-F.; Pan, Z.-Q.; Xiao, X.-F.; Wang, J.-X.; Zhou, C.-H. Co-liquefaction of sewage sludge and rice straw/wood sawdust: The effect of process parameters on the yields/properties of bio-oil and biochar products. Energy 2019, 173, 140–150. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, K. Co-HTL of domestic sewage sludge and wastewater treatment derived microalgal biomass—An integrated biorefinery approach for sustainable biocrude production. Energy Convers. Manag. 2020, 204, 112312. [Google Scholar] [CrossRef]

- Leng, L.; Li, J.; Yuan, X.; Li, J.; Han, P.; Hong, Y.; Wei, F.; Zhou, W. Beneficial synergistic effect on bio-oil production from co-liquefaction of sewage sludge and lignocellulosic biomass. Bioresour. Technol. 2018, 251, 49–56. [Google Scholar] [CrossRef]

- Biller, P.; Johannsen, I.; Dos Passos, J.S.; Ottosen, L.D.M. Primary sewage sludge filtration using biomass filter aids and subsequent hydrothermal co-liquefaction. Water Res. 2018, 130, 58–68. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, S.; Cao, B.; Hu, Y.; Abomohra, A.E.-F.; Wang, Q.; Qian, L.; Liu, L.; Liu, X.; He, Z. Optimization of hydrothermal co-liquefaction of seaweeds with lignocellulosic biomass: Merging 2nd and 3rd generation feedstocks for enhanced bio-oil production. Energy 2019, 173, 413–422. [Google Scholar] [CrossRef]

- Souza dos Passos, J.; Glasius, M.; Biller, P. Hydrothermal co-liquefaction of synthetic polymers and Miscanthus giganteus: Synergistic and antagonistic effects. ACS Sustain. Chem. Eng. 2020, 8, 19051–19061. [Google Scholar] [CrossRef]

- Sharma, K.; Shah, A.A.; Toor, S.S.; Seehar, T.H.; Pedersen, T.H.; Rosendahl, L.A. Co-hydrothermal liquefaction of lignocellulosic biomass in supercritical water. Energies 2021, 14, 1708. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, R.; Yan, C.; Han, L.; Lei, H.; Ruan, R.; Zhang, X. Fast hydrothermal co-liquefaction of corn stover and cow manure for biocrude and hydrochar production. Bioresour. Technol. 2021, 340, 125630. [Google Scholar] [CrossRef]

- Saba, A.; Lopez, B.; Lynam, J.G.; Reza, M.T. Hydrothermal liquefaction of loblolly pine: Effects of various wastes on produced biocrude. ACS Omega 2018, 3, 3051–3059. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.A.; Toor, S.S.; Seehar, T.H.; Sadetmahaleh, K.K.; Pedersen, T.H.; Nielsen, A.H.; Rosendahl, L.A. Bio-crude production through co-hydrothermal processing of swine manure with sewage sludge to enhance pumpability. Fuel 2021, 288, 119407. [Google Scholar] [CrossRef]

- Mahesh, D.; Ahmad, S.; Kumar, R.; Chakravarthy, S.; Vinu, R. Hydrothermal liquefaction of municipal solid wastes for high quality bio-crude production using glycerol as co-solvent. Bioresour. Technol. 2021, 339, 125537. [Google Scholar] [CrossRef]

- Xia, J.; Han, L.; Zhang, C.; Guo, H.; Rong, N.; Baloch, H.A.; Wu, P.; Xu, G.; Ma, K. Hydrothermal co-liquefaction of rice straw and Nannochloropsis: The interaction effect on mechanism, product distribution and composition. J. Anal. Appl. Pyrolysis 2022, 161, 105368. [Google Scholar] [CrossRef]

- Cui, Z.; Greene, J.M.; Cheng, F.; Quinn, J.C.; Jena, U.; Brewer, C.E. Co-hydrothermal liquefaction of wastewater-grown algae and crude glycerol: A novel strategy of bio-crude oil-aqueous separation and techno-economic analysis for bio-crude oil recovery and upgrading. Algal Res. 2020, 51, 102077. [Google Scholar] [CrossRef]

- Ellersdorfer, M. Hydrothermal co-liquefaction of Chlorella vulgaris with food processing residues, green waste and sewage sludge. Biomass Bioenergy 2020, 142, 105796. [Google Scholar] [CrossRef]

- Gollakota, A.; Savage, P.E. Fast and Isothermal Hydrothermal Liquefaction of Polysaccharide Feedstocks. ACS Sustain. Chem. Eng. 2020, 8, 3762–3772. [Google Scholar] [CrossRef]

- Kabir, S.B.; Khalekuzzaman, M. Co-liquefaction of organic solid waste with fecal sludge for producing petroleum-like biocrude for an integrated waste to energy approach. J. Clean. Prod. 2022, 354, 131718. [Google Scholar] [CrossRef]

- Dewil, R.; Baeyens, J.; Roels, J.; Steene, B.V.D. Distribution of sulphur compounds in sewage sludge treatment. Environ. Eng. Sci. 2008, 25, 879–886. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Yang, T.; Feng, B.; Kai, X.; Wang, S.; Li, R. Aqueous phase reforming of biocrude derived from lignocellulose hydrothermal liquefaction: Conditions optimization and mechanism study. Renew. Energy 2021, 175, 98–107. [Google Scholar] [CrossRef]

- Leow, S.; Witter, J.R.; Vardon, D.R.; Sharma, B.K.; Guest, J.S.; Strathmann, T.J. Prediction of microalgae hydrothermal liquefaction products from feedstock biochemical composition. Green Chem. 2015, 17, 3584–3599. [Google Scholar] [CrossRef] [Green Version]

- Bhatwadekar, S.; Conti, F.; Sharma, K.; Lozano, E.M.; Toor, S.S.; Pedersen, T.H. Co-liquefaction of sewage sludge with wheat straw in supercritical water–potential for integrating hydrothermal liquefaction with wastewater treatment plants. Sustain. Energy Fuels 2022, 6, 1269–1280. [Google Scholar] [CrossRef]

- Dandamudi, K.P.R.; Mathew, M.; Selvaratnam, T.; Muppaneni, T.; Seger, M.; Lammers, P.; Deng, S. Recycle of nitrogen and phosphorus in hydrothermal liquefaction biochar from Galdieria sulphuraria to cultivate microalgae. Resour. Conserv. Recycl. 2021, 171, 105644. [Google Scholar] [CrossRef]

- Vardon, D.R.; Sharma, B.; Scott, J.; Yu, G.; Wang, Z.; Schideman, L.; Zhang, Y.; Strathmann, T.J. Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresour. Technol. 2011, 102, 8295–8303. [Google Scholar] [CrossRef]

- Obeid, R.; Smith, N.; Lewis, D.M.; Hall, T.; van Eyk, P. A kinetic model for the hydrothermal liquefaction of microalgae, sewage sludge and pine wood with product characterisation of renewable crude. Chem. Eng. J. 2022, 428, 131228. [Google Scholar] [CrossRef]

- Fan, Y.; Fonseca, F.; Gong, M.; Hoffmann, A.; Hornung, U.; Dahmen, N. Energy valorization of integrating lipid extraction and hydrothermal liquefaction of lipid-extracted sewage sludge. J. Clean. Prod. 2021, 285, 124895. [Google Scholar] [CrossRef]

- Taghipour, A.; Hornung, U.; Ramirez, J.A.; Brown, R.J.; Rainey, T.J. Aqueous phase recycling in catalytic hydrothermal liquefaction for algal biomass and the effect on elemental accumulation and energy efficiency. J. Clean. Prod. 2021, 289, 125582. [Google Scholar] [CrossRef]

- Zhang, L.; Champagne, P.; Xu, C.C. Bio-crude production from secondary pulp/paper-mill sludge and waste newspaper via co-liquefaction in hot-compressed water. Energy 2011, 36, 2142–2150. [Google Scholar] [CrossRef]

- Akhtar, J.; Amin, N.A.S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

- Koley, S.; Khadase, M.S.; Mathimani, T.; Raheman, H.; Mallick, N. Catalytic and non-catalytic hydrothermal processing of Scenedesmus obliquus biomass for bio-crude production—A sustainable energy perspective. Energy Convers. Manag. 2018, 163, 111–121. [Google Scholar] [CrossRef]

- Chen, W.-T.; Zhang, Y.; Zhang, J.; Schideman, L.; Yu, G.; Zhang, P.; Minarick, M. Co-liquefaction of swine manure and mixed-culture algal biomass from a wastewater treatment system to produce bio-crude oil. Appl. Energy 2014, 128, 209–216. [Google Scholar] [CrossRef]

- Feng, H.; Zhang, B.; He, Z.; Wang, S.; Salih, O.; Wang, Q. Study on co-liquefaction of Spirulina and Spartina alterniflora in ethanol-water co-solvent for bio-oil. Energy 2018, 155, 1093–1101. [Google Scholar] [CrossRef]

| Characteristics | Sewage Sludge (SS) | Cow Manure (CM) | Wheat Straw (WS) | Chlorella pyrenoidosa (CP) |

|---|---|---|---|---|

| Proximate analysis (wt%) | ||||

| Moisture | 4.44 | 3.90 | 4.81 | 5.24 |

| Volatile matter | 44.26 | 61.37 | 70.02 | 73.90 |

| Fixed carbon a | 6.98 | 17.22 | 14.74 | 16.19 |

| Ash | 44.33 | 17.52 | 10.44 | 4.69 |

| Ultimate analysis (wt%) | ||||

| C | 30.33 | 41.07 | 45.53 | 48.47 |

| H | 4.58 | 5.04 | 3.56 | 10.58 |

| N | 3.60 | 1.10 | 0.88 | 8.58 |

| S | 1.24 | 0.22 | 0.36 | 0.87 |

| O a | 15.93 | 35.05 | 39.23 | 26.81 |

| H/C (mol/mol) | 1.80 | 1.46 | 0.93 | 2.60 |

| O/C (mol/mol) | 0.39 | 0.64 | 0.65 | 0.42 |

| N/C (mol/mol) | 0.10 | 0.02 | 0.02 | 0.15 |

| HHV(MJ/kg) | 14.66 | 16.91 | 15.80 | 27.54 |

| Characteristics | BC-SS/CM | BC-SS/WS | BC-SS/CP | BC-CP/CM | BC-CP/WS | BC-CM/WS |

|---|---|---|---|---|---|---|

| C (wt%) | 71.04 | 70.57 | 72.45 | 72.72 | 72.67 | 71.46 |

| H (wt%) | 8.54 | 8.09 | 8.65 | 7.45 | 7.43 | 6.41 |

| O a (wt%) | 16.64 | 17.95 | 12.89 | 14.59 | 14.67 | 20.75 |

| N (wt%) | 2.60 | 2.44 | 4.70 | 4.78 | 4.92 | 1.24 |

| S (wt%) | 1.18 | 0.95 | 1.31 | 0.46 | 0.31 | 0.14 |

| H/C (mol/mol) | 1.43 | 1.37 | 1.42 | 1.22 | 1.22 | 1.07 |

| O/C (mol/mol) | 0.18 | 0.19 | 0.13 | 0.15 | 0.15 | 0.22 |

| N/C (mol/mol) | 0.03 | 0.03 | 0.06 | 0.06 | 0.06 | 0.01 |

| HHV (MJ/kg) | 34.31 | 33.36 | 35.16 | 33.29 | 33.22 | 31.03 |

| ER (%) | 47.48 | 53.43 | 41.12 | 32.45 | 40.42 | 40.77 |

| Characteristics | BC-SS-30 | BC-SS/CM-15 | BC-SS/CM-30 | BC-SS/CM-45 | BC-SS/CM-60 | BC-SS/CM-90 | BC-SS/CM-120 | BC-CM-30 | Petro-Crude b |

|---|---|---|---|---|---|---|---|---|---|

| C (wt%) | 74.10 | 71.51 | 71.04 | 72.83 | 73.37 | 75.25 | 76.41 | 69.62 | 83–87 |

| H (wt%) | 10.22 | 9.16 | 8.54 | 7.566 | 7.998 | 8.94 | 9.12 | 7.01 | 10–14 |

| O a (wt%) | 10.73 | 16.23 | 16.64 | 15.46 | 14.71 | 11.75 | 10.75 | 21.55 | 0.1–2.0 |

| N (wt%) | 3.04 | 1.94 | 2.60 | 2.93 | 2.89 | 3.07 | 3.00 | 1.54 | 0.05–1.5 |

| S (wt%) | 1.91 | 1.16 | 1.18 | 1.219 | 1.037 | 1.00 | 0.72 | 0.29 | – |

| H/C (mol/mol) | 1.64 | 1.53 | 1.43 | 1.24 | 1.30 | 1.41 | 1.42 | 1.20 | 1.5–2.0 |

| O/C (mol/mol) | 0.11 | 0.17 | 0.18 | 0.16 | 0.15 | 0.12 | 0.11 | 0.23 | <0.02 |

| N/C (mol/mol) | 0.04 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | <0.02 |

| HHV (MJ/kg) | 38.47 | 35.51 | 34.31 | 33.62 | 34.53 | 36.88 | 37.67 | 31.13 | 42–49 |

| ER (%) | 47.24 | 26.04 | 47.48 | 43.04 | 42.02 | 46.31 | 46.10 | 39.07 | – |

| Characteristics | HC-SS-30 | HC-SS/CM-15 | HC-SS/CM-30 | HC-SS/CM-90 | HC-SS/CM-120 | HC-CM-30 |

|---|---|---|---|---|---|---|

| C (wt%) | 11.05 | 32.14 | 21.50 | 20.55 | 17.87 | 40.94 |

| H (wt%) | 1.62 | 4.04 | 2.04 | 1.83 | 1.56 | 3.18 |

| O a (wt%) | 1.73 | 7.32 | 5.91 | 2.49 | 6.35 | – |

| N (wt%) | 1.03 | 1.15 | 1.90 | 1.45 | 1.28 | 2.01 |

| S (wt%) | 0.70 | 0.46 | 0.49 | 0.37 | 0.35 | 0.27 |

| H/C (mol/mol) | 1.75 | 1.5 | 1.13 | 1.06 | 1.04 | 0.92 |

| O/C (mol/mol) | 0.12 | 0.17 | 0.21 | 0.09 | 0.27 | – |

| N/C (mol/mol) | 0.08 | 0.03 | 0.08 | 0.06 | 0.06 | 0.04 |

| HHV (MJ/kg) | 5.89 | 15.88 | 9.44 | 9.29 | 7.53 | 18.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Wang, K.; Liu, Q.; Han, L.; Zhang, X. A Comprehensive Hydrothermal Co-Liquefaction of Diverse Biowastes for Energy-Dense Biocrude Production: Synergistic and Antagonistic Effects. Int. J. Environ. Res. Public Health 2022, 19, 10499. https://doi.org/10.3390/ijerph191710499

Zhang G, Wang K, Liu Q, Han L, Zhang X. A Comprehensive Hydrothermal Co-Liquefaction of Diverse Biowastes for Energy-Dense Biocrude Production: Synergistic and Antagonistic Effects. International Journal of Environmental Research and Public Health. 2022; 19(17):10499. https://doi.org/10.3390/ijerph191710499

Chicago/Turabian StyleZhang, Guanyu, Kejie Wang, Quan Liu, Lujia Han, and Xuesong Zhang. 2022. "A Comprehensive Hydrothermal Co-Liquefaction of Diverse Biowastes for Energy-Dense Biocrude Production: Synergistic and Antagonistic Effects" International Journal of Environmental Research and Public Health 19, no. 17: 10499. https://doi.org/10.3390/ijerph191710499

APA StyleZhang, G., Wang, K., Liu, Q., Han, L., & Zhang, X. (2022). A Comprehensive Hydrothermal Co-Liquefaction of Diverse Biowastes for Energy-Dense Biocrude Production: Synergistic and Antagonistic Effects. International Journal of Environmental Research and Public Health, 19(17), 10499. https://doi.org/10.3390/ijerph191710499