A Method for Modeling the Individual Convenient Zone of a Human

Abstract

:1. Introduction

- For people with unusual needs, particularly seniors, people with disabilities, or others who significantly deviate in their abilities from the average 50th percentile human, it is difficult to obtain reliable and complete anthropometric data in combination with strength data;

- There are cases in which a precise dimensional product adaptation to the, “individual convenient zone” (ICZ) of a specific user is justified. Modern product design and production technology make this possible, provided that the anthropometric and strength characteristics of the user are known.

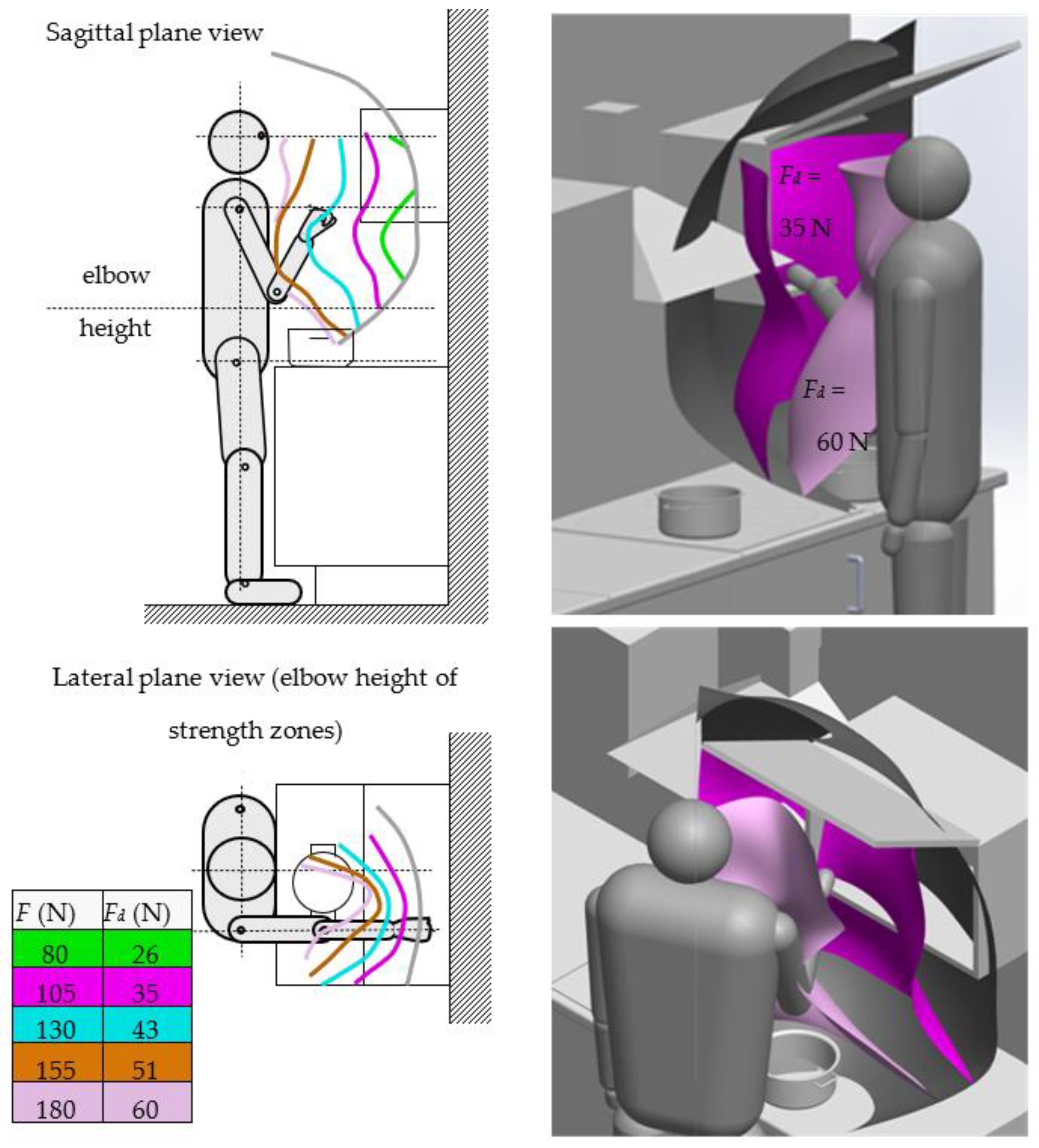

2. Proposed Methodology for Easy Modeling of the “Individual Convenient Zone”

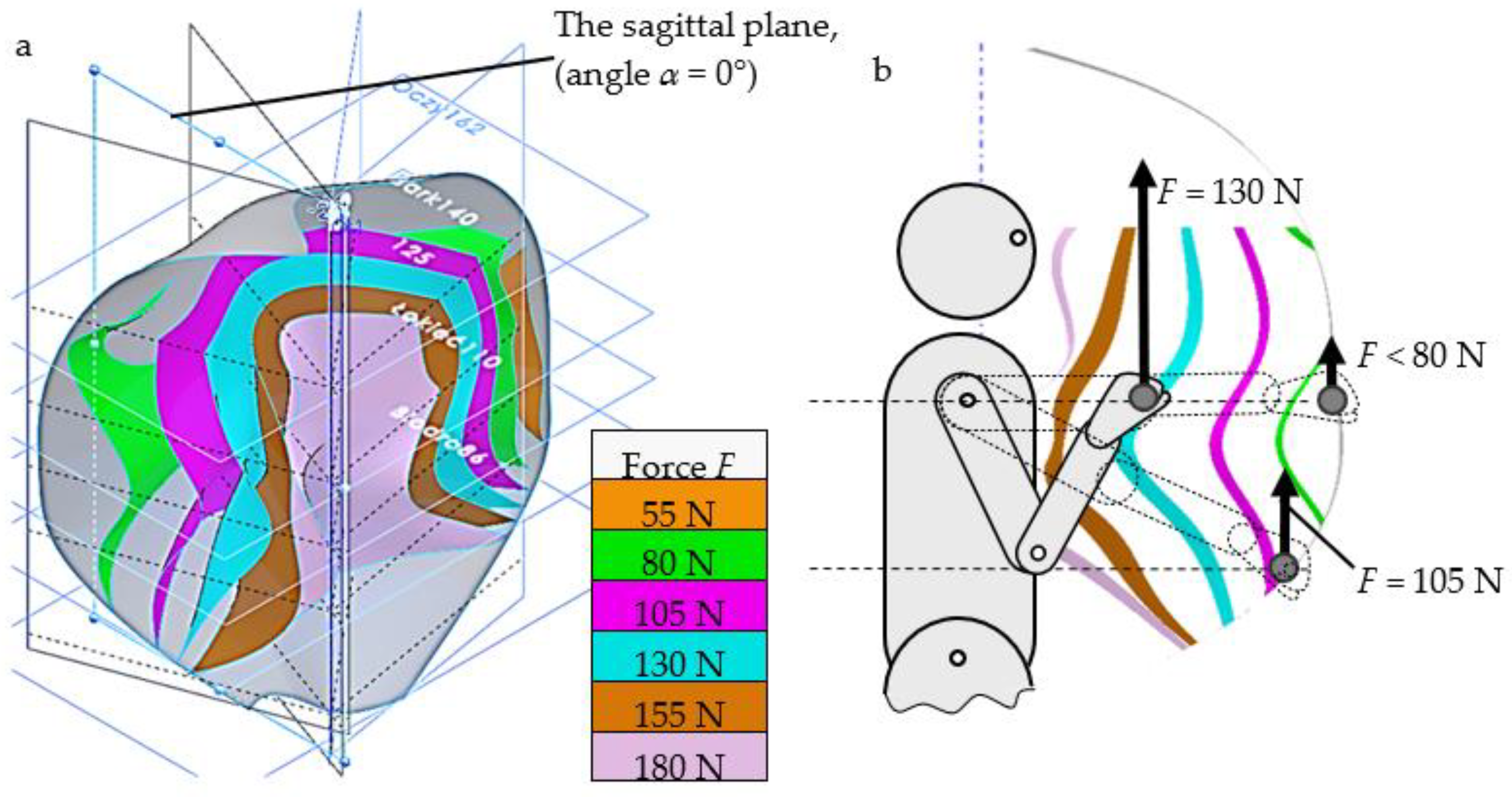

2.1. The Concept of Modeling the Convenient Zone of a Human and Adapting Product Dimensions to This Zone

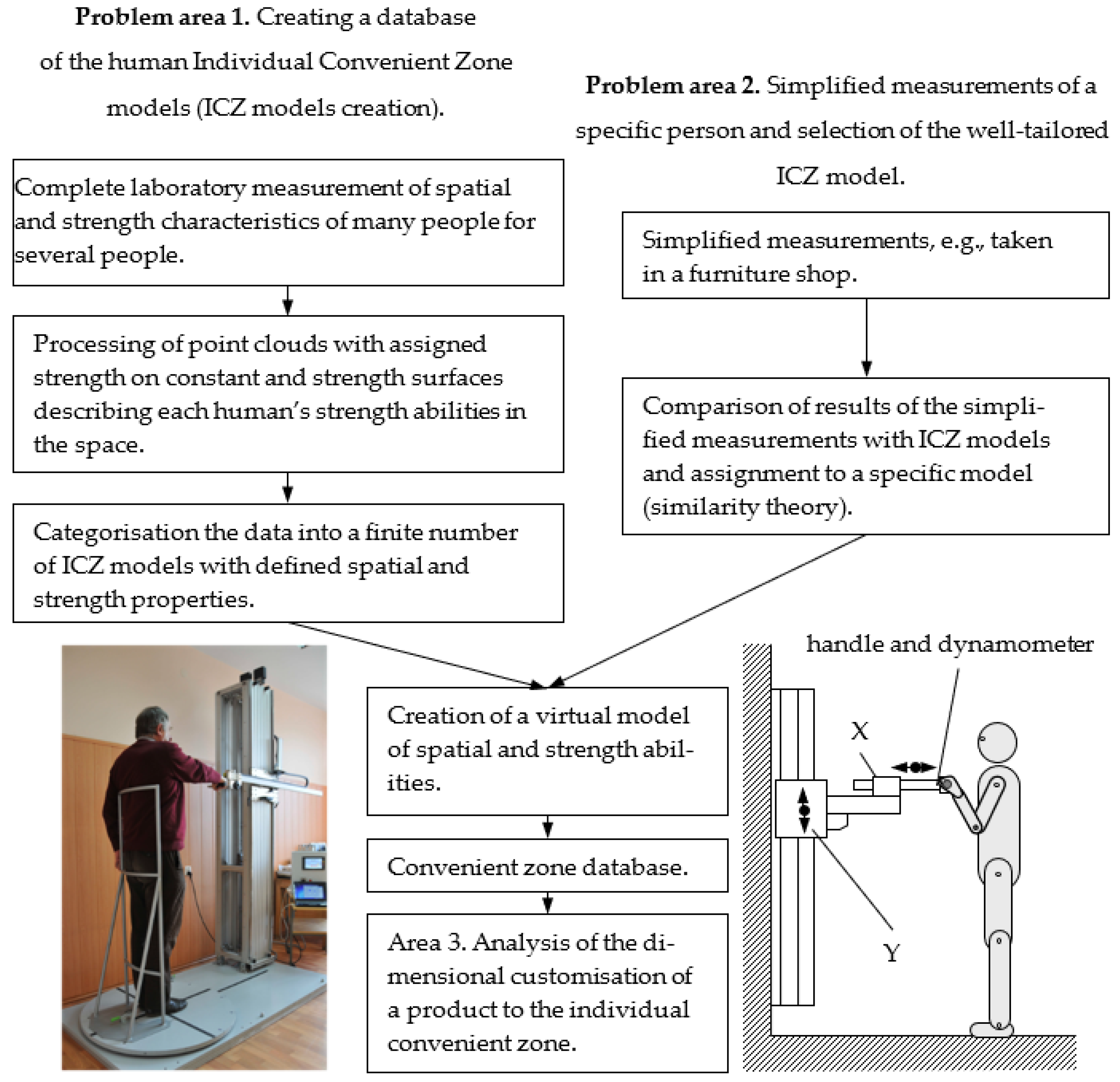

- Problem area 1. Creation of a database of spatial and strength characteristics based on the laboratory measurements of persons with as much variation as possible in body dimensions and strength capabilities (repository of ICZ models);

- Problem area 2. Simplified measurement and categorization of spatial and strength characteristics of a particular individual and the elicitation of the optimal ICZ model for that individual from the database. The measurement of spatial and strength characteristics is carried out in the most simplified way possible, and the categorization and selection of the appropriate ICZ model are carried out automatically, based on an algorithm;

- Problem area 3. Ergonomic analysis of the designed product, i.e., the correctness of the virtual model design of the product, is evaluated using the digital human model (DHM) containing the anthropometric data of a given person supplemented with the ICZ model.

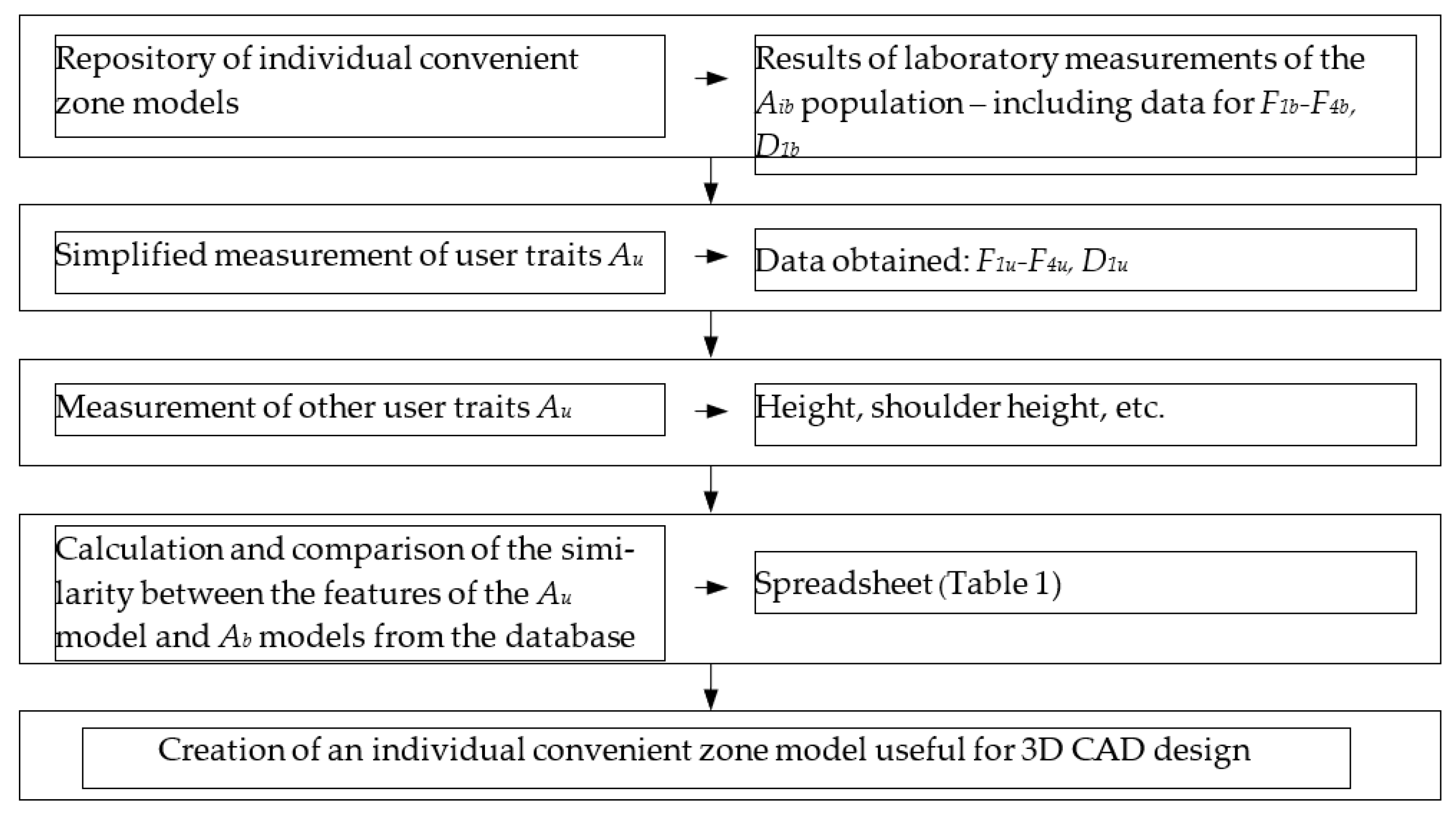

2.2. Determining the Similarity of Spatial and Strength Characteristics of the User of the Designed Technical Object with a Predetermined Person Examined

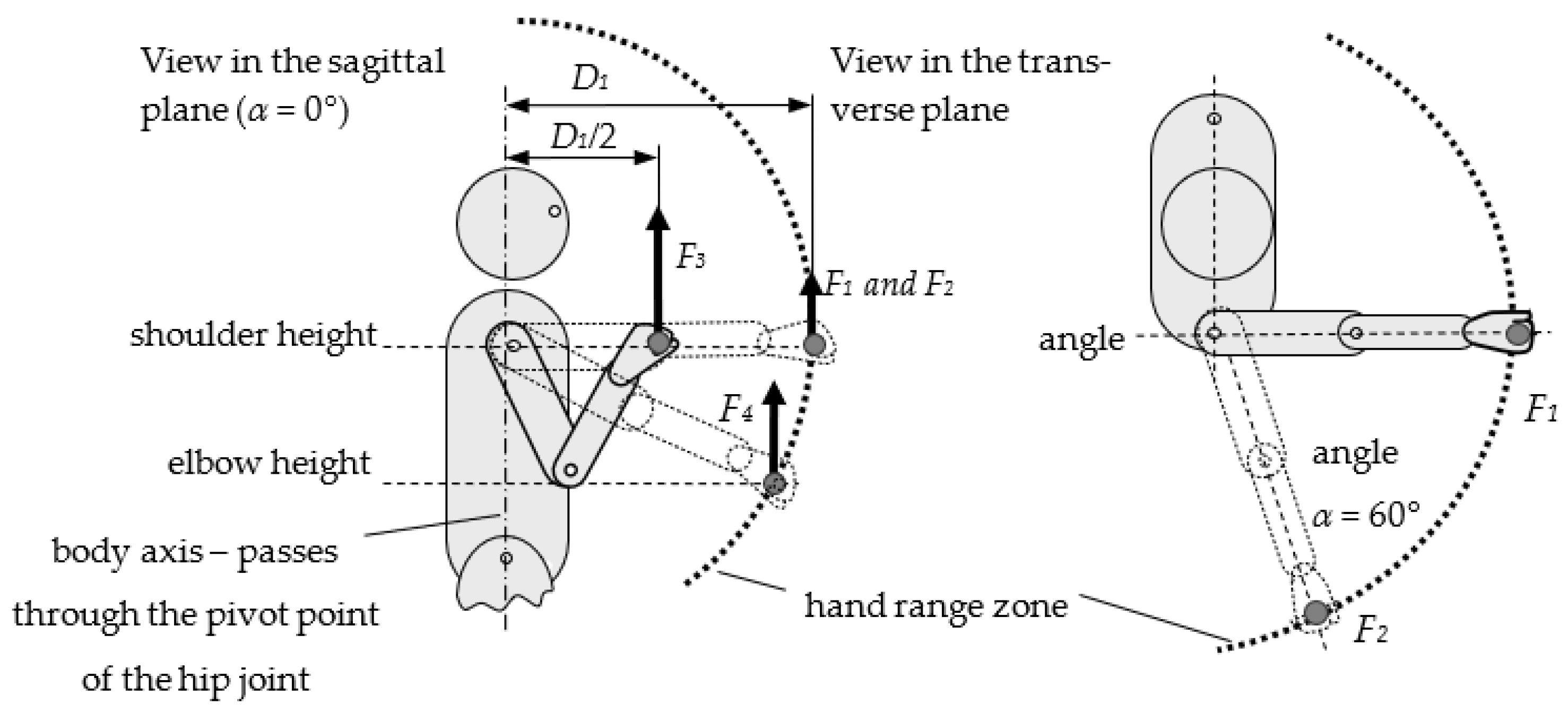

- D1u—dimensions of the upper limb range space in the sagittal plane (α = 0°), at shoulder height;

- F1u—upper limb strength at maximum range within the plane (α = 0°), at shoulder height;

- F2u—upper limb strength at maximum range within the plane (α = 60°), at shoulder height;

- F3u—upper limb strength at midrange (D/2) within the plane α = 0°, at shoulder height;

- F4u—upper limb strength at the maximum range within the plane α = 0°, at elbow height.

3. Verification of Methodology: Case Study

3.1. Problem Area 1: Creating a Database of Spatial and Strength Features. Problem Area 2: Identifying Spatial and Strength Characteristics of a Specific Human Being; Generating an Individual Convenient Zone Model

3.2. Problem Area 3: Ergonomic Analysis of the Product

4. Conclusions

- 1

- Quickly measuring just a few critical spatial and strength characteristics of a person and creating a simplified Au model of their individual convenient zone;

- 2

- Selecting the best-fit and complete convenient zone model Au from the database based on the similarity criterion;

- 3

- The selected model Au describes the “individual convenient zone” (ICZ) of a human subjected to rapid measurement and is helpful in product design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Cott, H.P.; Kinkade, R.G. Human Engineering Guide to Equipment Design; Department of Defense: Washington, DC, USA, 1972; ISBN 0-471-80011-2.

- Kopka, T.; Rubehn, K. Kraftmessungen Im Greifraum Des Menschen. Z. Für Morphol. Anthropol. 1976, 67, 193–214. [Google Scholar] [CrossRef]

- Gallagher, S. Isometric Pushing, Pulling, and Lifting Strengths in Three Postures; SAGE Publications Sage: Los Angeles, CA, USA, 1989; Volume 33, pp. 637–640. [Google Scholar]

- EN 1005-3; Safety of Machinery—Human Physical Performance—Part 3: Recommended Force Limits for Machinery Operation. European Committee for Standardization: Geneva, Switzerland, 2002.

- Rohmert, W.; Berg, K.; Bruder, R.; Schaub, K. Kräfteatlas. 1: Datenauswertung statischer Aktionskräfte. In Schriftenreihe der Bundesanstalt für Arbeitsmedizin Forschung; Wirtschaftsverlag NW, Verlag für Neue Wiss: Bremerhaven, Germany, 1994; ISBN 978-3-89429-524-0. [Google Scholar]

- Wakula, J.; Berg, K.; Schaub, K.; Bruder, R. Der Montagespezifische Kraftatlas. In BGIA-Report; Deutsche Gesetzliche Unfallversicherung (DGUV): Berlin, Germany, 2009; Volume BGIA-Report 3/2009, ISBN 978-3-88383-788-8. [Google Scholar]

- Chaffin, D.B.; Andres, R.O.; Garg, A. Volitional Postures during Maximal Push/Pull Exertions in the Sagittal Plane. Hum. Factors 1983, 25, 541–550. [Google Scholar] [CrossRef] [PubMed]

- Dysart, M.J.; Woldstad, J.C. Posture Prediction for Static Sagittal-Plane Lifting. J. Biomech. 1996, 29, 1393–1397. [Google Scholar] [CrossRef]

- Gedliczka, A.; Pochopień, P. Atlas Miar Człowieka: Dane Do Projektowania i Oceny Ergonomicznej: Antropometria, Biomechanika, Przestrzeń Pracy, Wymiary Bezpieczeństwa/Atlas of Human Measures: Data for Ergonomic Design and Assessment: Anthropometry, Biomechanics, Work Space, Safety Dimensions; Centralny Instytut Ochrony Pracy: Warszawa, Poland, 2001; ISBN 978-83-88703-38-6. [Google Scholar]

- The Measure of Man and Woman: Human Factors in Design, Revised ed.; Tilley, A.R.; Dreyfuss, H. (Eds.) Wiley: New York, NY, USA, 2002; ISBN 978-0-471-09955-0. [Google Scholar]

- Fryar, C.D.; Gu, Q.; Ogden, C.L. Anthropometric Reference Data for Children and Adults: United States, 2007–2010. Vital Health Stat. 11 2012, 1–48. [Google Scholar]

- Seid, A.; Trieb, R.; Rissiek, A. Heiner Bubb Standards in Anthropometry. In Handbook of Standards and Guidelines in Human Factors and Ergonomics; Karwowski, W., Szopa, A., Soares, M., Eds.; Human Factors and Ergonomics; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2021; pp. 229–269. ISBN 978-0-429-16924-3. [Google Scholar]

- Zhu, W.; Fan, X.; Zhang, Y. Applications and Research Trends of Digital Human Models in the Manufacturing Industry. Virtual Real. Intell. Hardw. 2019, 1, 558–579. [Google Scholar] [CrossRef]

- Wolf, A.; Miehling, J.; Wartzack, S. Challenges in Interaction Modelling with Digital Human Models—A Systematic Literature Review of Interaction Modelling Approaches. Ergonomics 2020, 63, 1442–1458. [Google Scholar] [CrossRef] [PubMed]

- Branowski, B.; Pohl, P.; Rychlik, M.; Zablocki, M. Integral Model of the Area of Reaches and Forces of a Disabled Person with Dysfunction of Lower Limbs as a Tool in Virtual Assessment of Manipulation Possibilities in Selected Work Environments. In Universal Access in Human-Computer Interaction: Users Diversity, Pt 2; Stephanidis, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 6766, pp. 12–21. ISBN 978-3-642-21662-6. [Google Scholar]

- Branowski, B.; Pacholski, L.; Rychlik, M.; Zabłocki, M.; Pohl, P. Studies on a New Concept of 3D Data Integration about Reaches and Forces of a Disabled Person on a Wheelchair (CAD Methods in Car and Market Ergonomics): CAD Methods in Car and Market Ergonomics. Hum. Factors Man. 2013, 23, 255–266. [Google Scholar] [CrossRef]

- ISO 20685-2; Ergonomics—3-D Scanning Methodologies for Internationally Compatible Anthropometric Databases—Part 2: Evaluation Protocol of Surface Shape and Repeatability of Relative Landmark Positions. ISO: Geneva, Switzerland, 2015.

- ISO 15537; Principles for Selecting and Using Test Persons for Testing Anthropometric Aspects of Industrial Products and Designs. ISO: Geneva, Switzerland, 2004.

- Branowski, B.; Głowala, S.; Pohl, P.; Rychlik, M.; Zabłocki, M. Urządzenie Do Pomiarów Przestrzeni Manipulacji Zasięgów i Granicznych Sił Zewnętrznych Kończyn Górnych Człowieka/Device for Measuring the Range of Manipulation Space and Limiting External Forces of Human Upper Limbs, Method for Processing the Biomechanical Measurement Data and Method for Presenting the Anthropometric and Biomechanical Data. Patent PL 222500 B1, 2016. [Google Scholar]

- Pohl, P.; Branowski, B.; Gabryelski, J.; Głowala, S.; Sydor, M.; Zabłocki, M. Urządzenie Do Pomiaru Przestrzeni Manipulacji Człowieka w Zakresie Sił Granicznych i Sięgów, Sposób Dokonywania Pomiaru Przestrzeni Manipulacji Człowieka w Zakresie Granicznych Sięgów i Sposób Dokonywania Pomiaru Przestrzeni Manipulacji Człowieka w Zakresie Sił/Device for Measuring the Human Manipulation Space Range in Scope of Forces and Reaching Limits, Method for Making Measurements of The Human Manipulation Space Range in Scope of The Reaching Limits and Method for Making Measurements of the Human Manipulation Space Range in Scope of Forces 2017. Patent PL 226411 B1, 2016. [Google Scholar]

- Finding Groups in Data. In Wiley Series in Probability and Statistics; Kaufman, L.; Rousseeuw, P.J. (Eds.) John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1990; ISBN 978-0-470-31680-1. [Google Scholar]

- Gordon, A.D. Classification. In Monographs on Statistics and Applied Probability, 2nd ed.; Chapman & Hall/CRC: Boca Raton, FL, USA, 1999; ISBN 978-1-58488-013-4. [Google Scholar]

- Cox, M.A.A.; Cox, T.F. Multidimensional Scaling. In Handbook of Data Visualization; Springer: Berlin/Heidelberg, Germany, 2008; pp. 315–347. ISBN 978-3-540-33036-3. [Google Scholar]

- Lewandowska, A.; Branowski, B.; Joachimiak-Lechman, K.; Kurczewski, P.; Selech, J.; Zablocki, M. Sustainable Design: A Case of Environmental and Cost Life Cycle Assessment of a Kitchen Designed for Seniors and Disabled People. Sustainability 2017, 9, 1329. [Google Scholar] [CrossRef] [Green Version]

- Bonenberg, A.; Branowski, B.; Kurczewski, P.; Lewandowska, A.; Sydor, M.; Torzyński, D.; Zabłocki, M. Designing for Human Use: Examples of Kitchen Interiors for Persons with Disability and Elderly People. Hum. Factors Man. 2019, 29, 177–186. [Google Scholar] [CrossRef]

- Katunský, D.; Brausch, C.; Purcz, P.; Katunská, J.; Bullová, I. Requirements and Opinions of Three Groups of People (Aged under 35, between 35 and 50, and over 50 Years) to Create a Living Space Suitable for Different Life Situations. Environ. Impact Assess. Rev. 2020, 83, 106385. [Google Scholar] [CrossRef]

- Schlick, C.; Bruder, R.; Luczak, H.; Mayer, M.; Abendroth, B. Arbeitswissenschaft, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 978-3-540-78332-9. [Google Scholar]

| Features of Examined Persons Ab | The Similarity between au and ab [-] [1,0] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lp | Ab/ ab | F1(N)/ f1 (–) | F2(N)/ f2 (–) | F3 (N)/ f3 (–) | F4 (N)/ f4 (–) | D1 (cm)/ d1 (–) | sim(f1) | sim(f2) | sim(f3) | sim(f4) | sim(d1) | sim(x) |

| 1 | Ab/ | 62/ | 50/ | 125/ | 85/ | 71/ | 0.115 | 0.103 | 0.12 | 0.277 | 0.176 | 0.158 |

| ab | 0.449 | 0.382 | 0.437 | 0.462 | 1 | |||||||

| 2 | Ab/ | 82/ | 62/ | 154/ | 118/ | 54/ | 0.141 | 0.074 | 0.046 | 0 | 0.824 | 0.217 |

| ab | 0.705 | 0.559 | 0.603 | 0.739 | 0 | |||||||

| 3 | Ab/ | 64/ | 52/ | 170/ | 83/ | 66/ | 0.09 | 0.073 | 0.138 | 0.294 | 0.118 | 0.143 |

| ab | 0.474 | 0.412 | 0.695 | 0.445 | 0.706 | |||||||

| 4 | Ab/ | 63/ | 64/ | 90/ | 80/ | 67/ | 0.102 | 0.103 | 0.321 | 0.319 | 0.059 | 0.181 |

| ab | 0.462 | 0.588 | 0.236 | 0.42 | 0.765 | |||||||

| 5 | Ab/ | 66/ | 75/ | 94/ | 77/ | 55/ | 0.064 | 0.265 | 0.298 | 0.344 | 0.765 | 0.347 |

| ab | 0.5 | 0.75 | 0.259 | 0.395 | 0.059 | |||||||

| 6 | Ab/ | 27/ | 24/ | 49/ | 30/ | 70/ | 0.564 | 0.485 | 0.557 | 0.739 | 0.117 | 0.492 |

| ab | 0 | 0 | 0 | 0 | 0.941 | |||||||

| 7 | Ab/ | 88/ | 69/ | 150/ | 117/ | 68/ | 0.218 | 0.177 | 0.023 | 0.008 | 0 | 0.085 |

| ab | 0.782 | 0.662 | 0.58 | 0.731 | 0.824 | |||||||

| 8 | Ab/ | 87/ | 86/ | 115/ | 105/ | 58/ | 0.205 | 0.427 | 0.178 | 0.109 | 0.589 | 0.302 |

| ab | 0.769 | 0.912 | 0.379 | 0.63 | 0.235 | |||||||

| 9 | Ab/ | 87/ | 79/ | 167/ | 99/ | 57/ | 0.205 | 0.324 | 0.121 | 0.159 | 0.648 | 0.291 |

| ab | 0.769 | 0.809 | 0.678 | 0.58 | 0.176 | |||||||

| 10 | Ab/ | 105/ | 92/ | 223/ | 149/ | 65/ | 0.436 | 0.515 | 0.443 | 0.261 | 0.177 | 0.366 |

| ab10 | 1 | 1 | 1 | 1 | 0.647 | |||||||

| 11 | Ab/ | 81/ | 79/ | 102/ | 103/ | 68/ | 0.128 | 0.324 | 0.252 | 0.126 | 0 | 0.166 |

| ab | 0.692 | 0.809 | 0.305 | 0.613 | 0.824 | |||||||

| 12 | Ab/ | 57/ | 45/ | 141/ | 69/ | 67/ | 0.179 | 0.176 | 0.028 | 0.411 | 0.059 | 0.171 |

| ab | 0.385 | 0.309 | 0.529 | 0.328 | 0.765 | |||||||

| Ab min | 27 | 24 | 49 | 30 | 54 | |||||||

| Ab max | 105 | 92 | 223 | 149 | 71 | |||||||

| User features Au | ||||||||||||

| F1 (N)/ f1 (–) | F2 (N)/ f2 (–) | F3 (N)/ f3 (–) | F4 (N)/ f4 (–) | D1 (cm)/ d1 (–) | ||||||||

| Au/ | 71/ | 57/ | 146/ | 110/ | 68/ | |||||||

| au | 0.564 | 0.485 | 0.557 | 0.739 | 0.824 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Branowski, B.; Zabłocki, M.; Kurczewski, P.; Sydor, M. A Method for Modeling the Individual Convenient Zone of a Human. Int. J. Environ. Res. Public Health 2022, 19, 10405. https://doi.org/10.3390/ijerph191610405

Branowski B, Zabłocki M, Kurczewski P, Sydor M. A Method for Modeling the Individual Convenient Zone of a Human. International Journal of Environmental Research and Public Health. 2022; 19(16):10405. https://doi.org/10.3390/ijerph191610405

Chicago/Turabian StyleBranowski, Bogdan, Marek Zabłocki, Przemysław Kurczewski, and Maciej Sydor. 2022. "A Method for Modeling the Individual Convenient Zone of a Human" International Journal of Environmental Research and Public Health 19, no. 16: 10405. https://doi.org/10.3390/ijerph191610405

APA StyleBranowski, B., Zabłocki, M., Kurczewski, P., & Sydor, M. (2022). A Method for Modeling the Individual Convenient Zone of a Human. International Journal of Environmental Research and Public Health, 19(16), 10405. https://doi.org/10.3390/ijerph191610405