Life Cycle Assessment of Construction and Demolition Waste Management in Riyadh, Saudi Arabia

Abstract

:1. Introduction

2. Materials and Methods

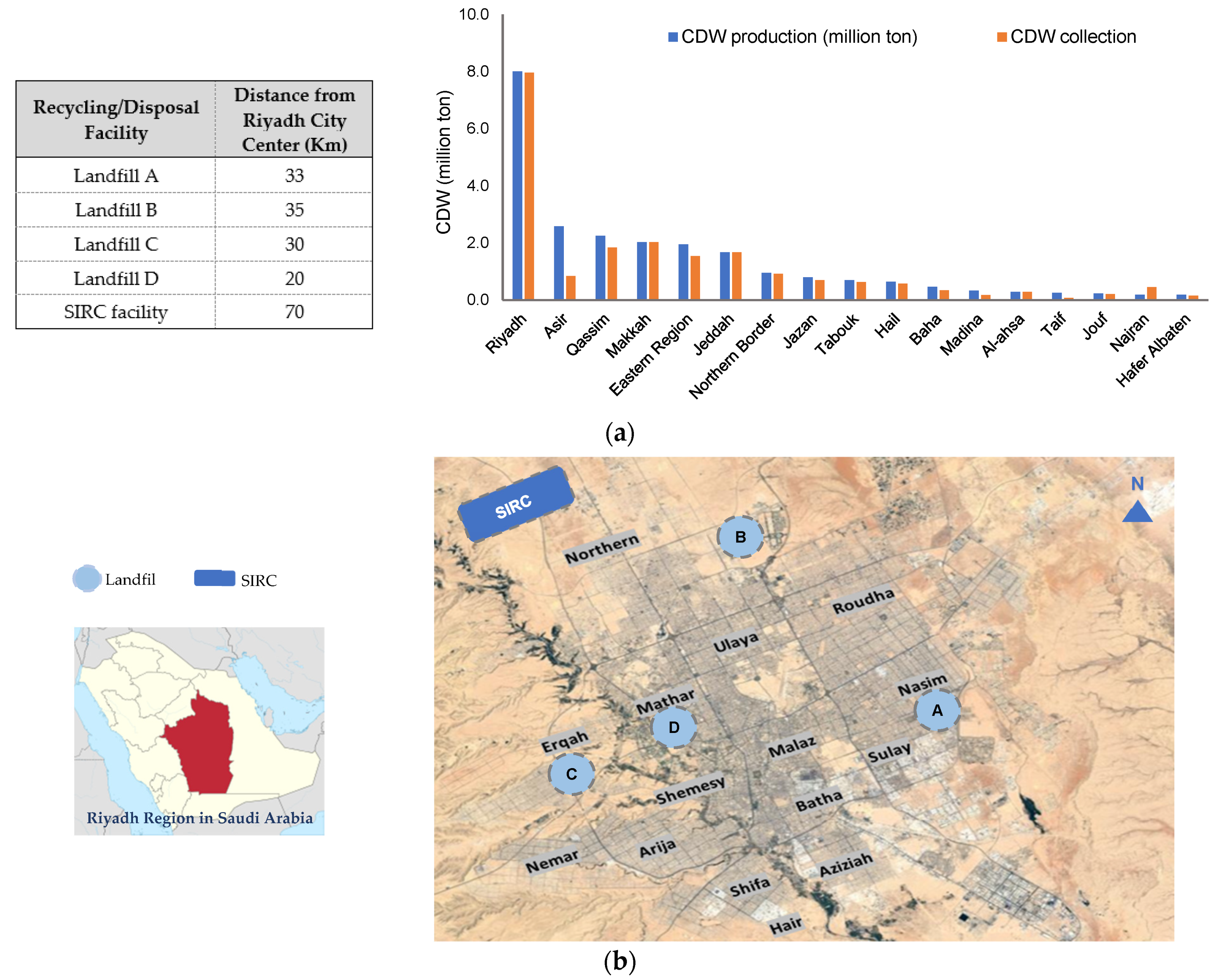

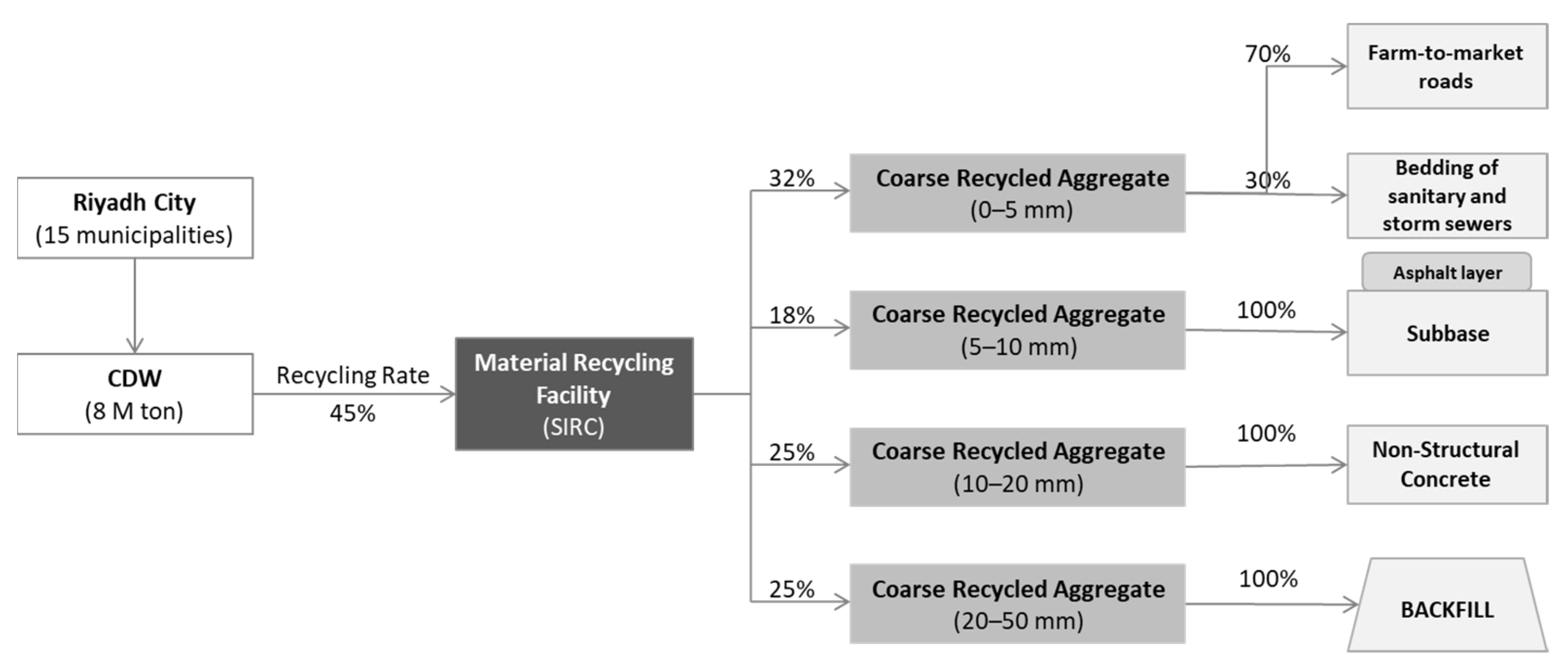

2.1. Study Area and Data Collection

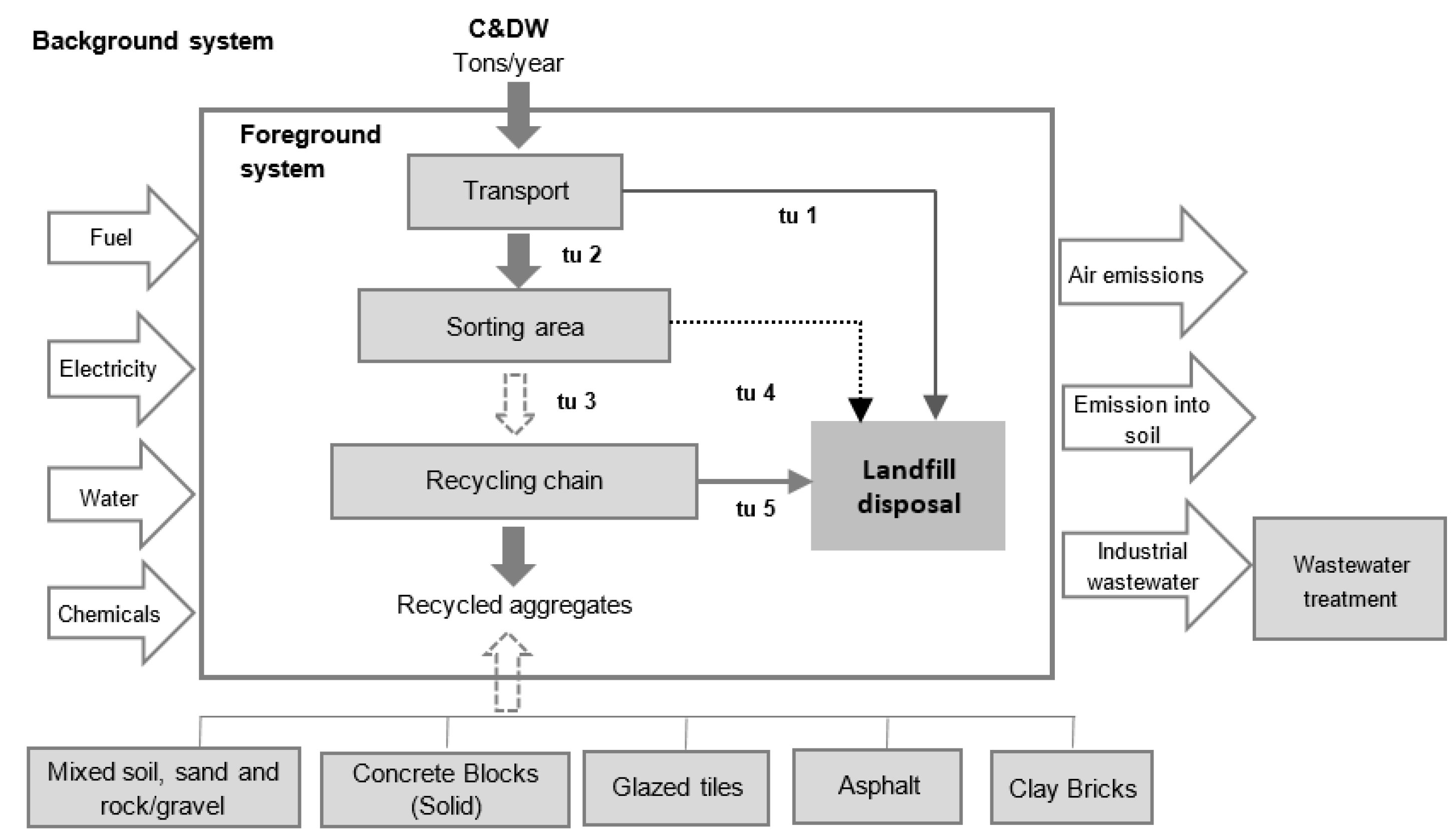

2.2. Life Cycle Assessment

2.2.1. Goal and Scope Definition

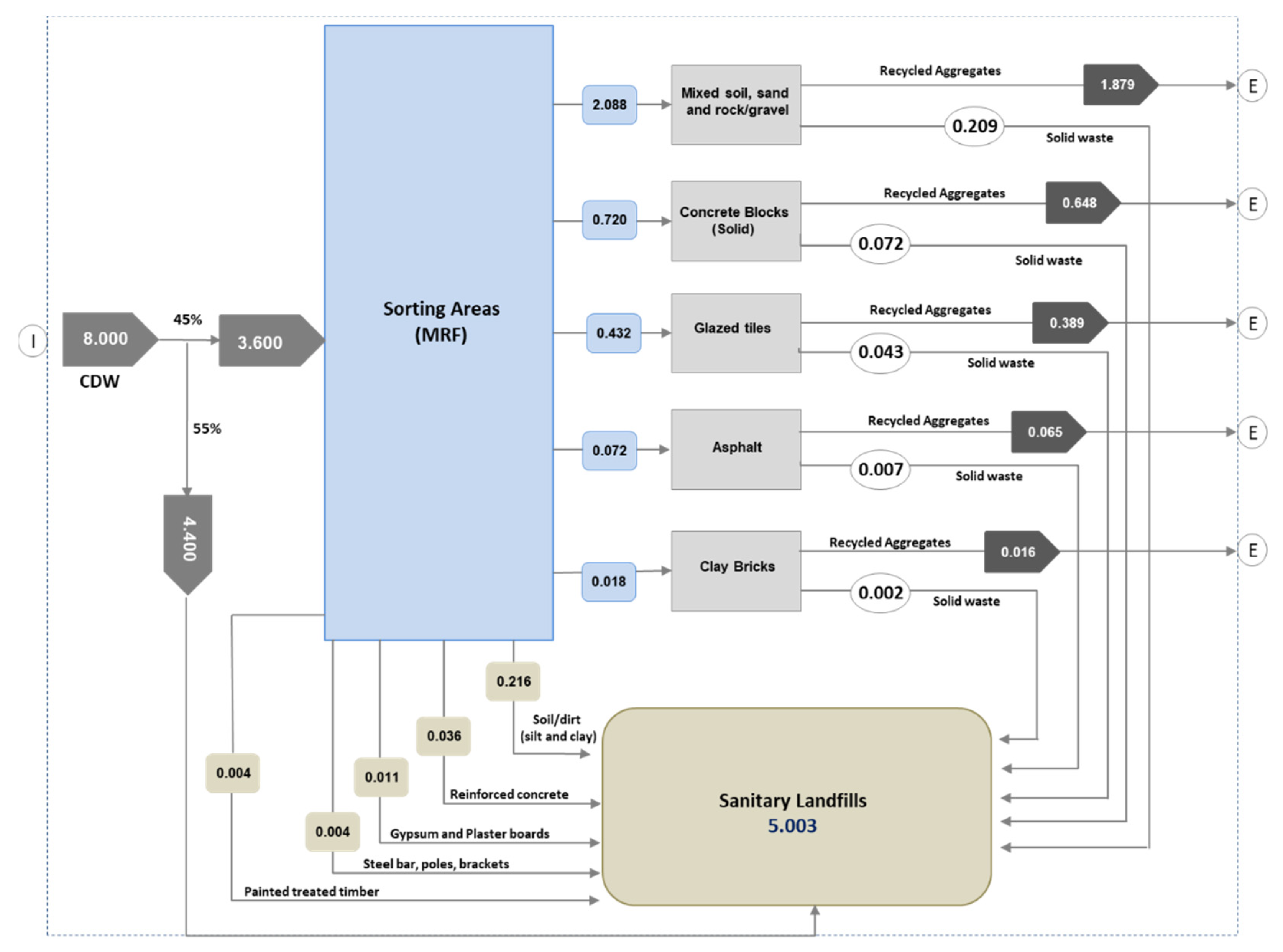

2.2.2. Life Cycle Inventory

2.2.3. Life Cycle Impact Assessment

2.2.4. Interpretation

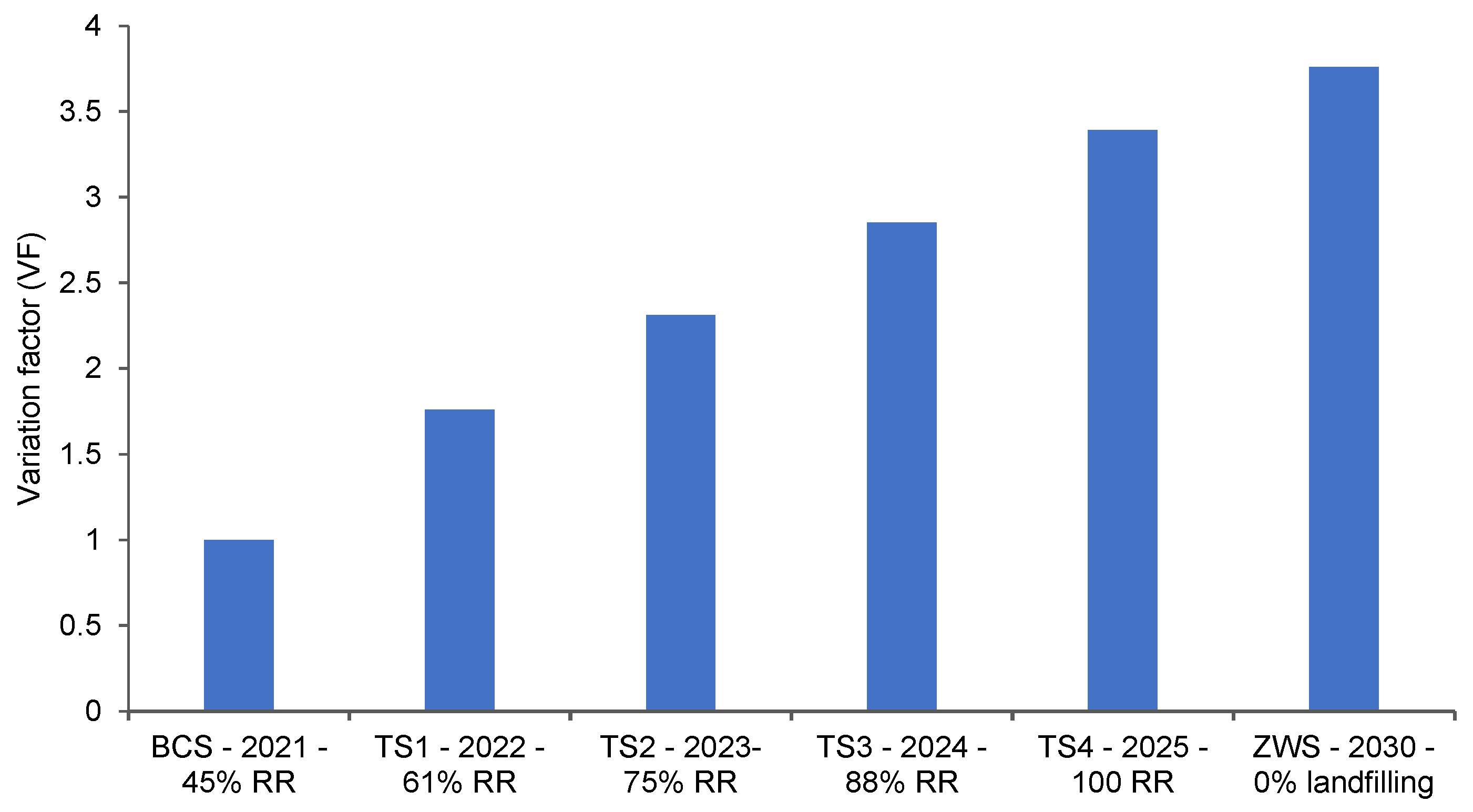

2.3. Development of CDW Management Scenarios

3. Results

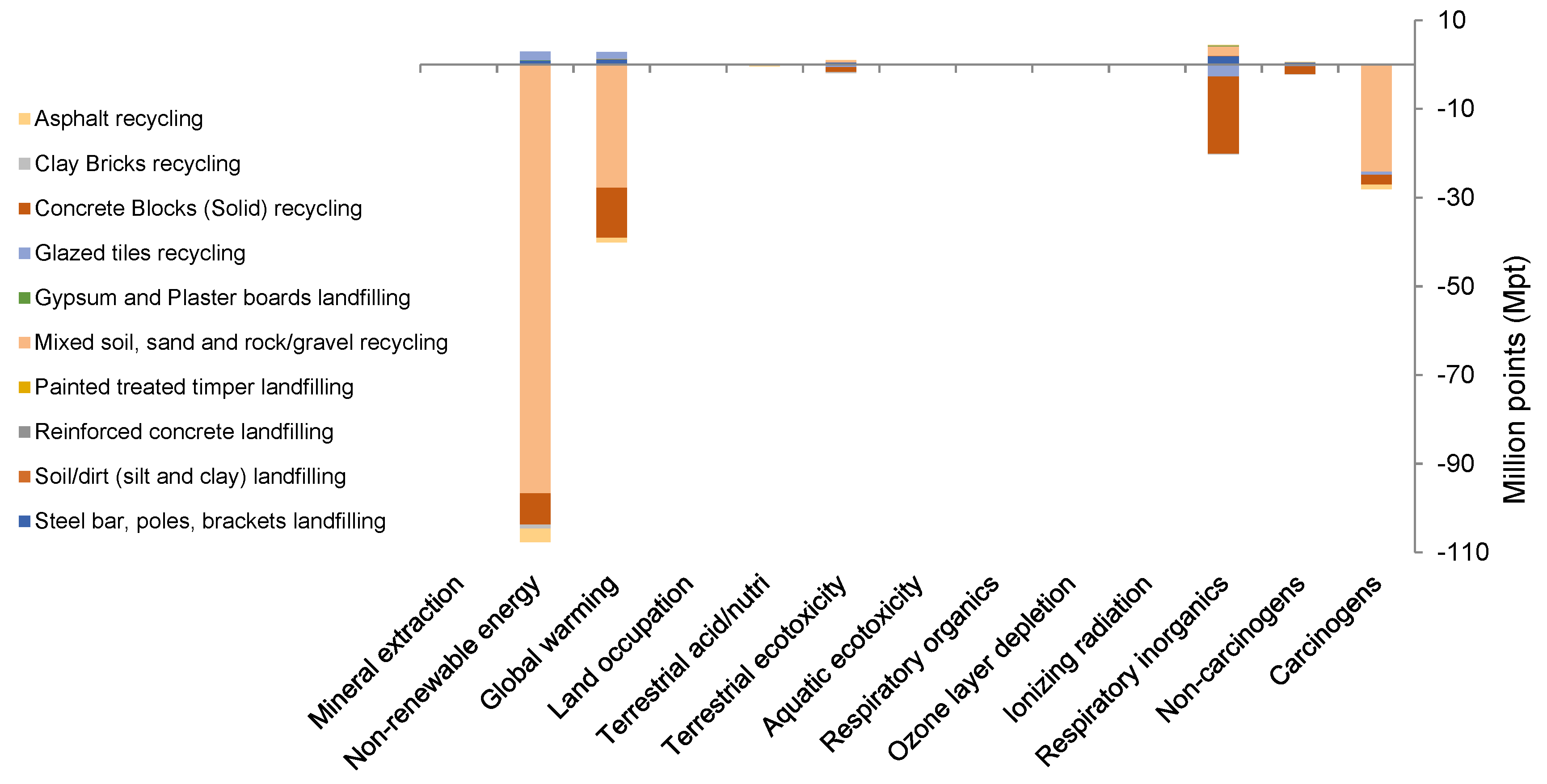

3.1. LCIA of Base Case Scenario

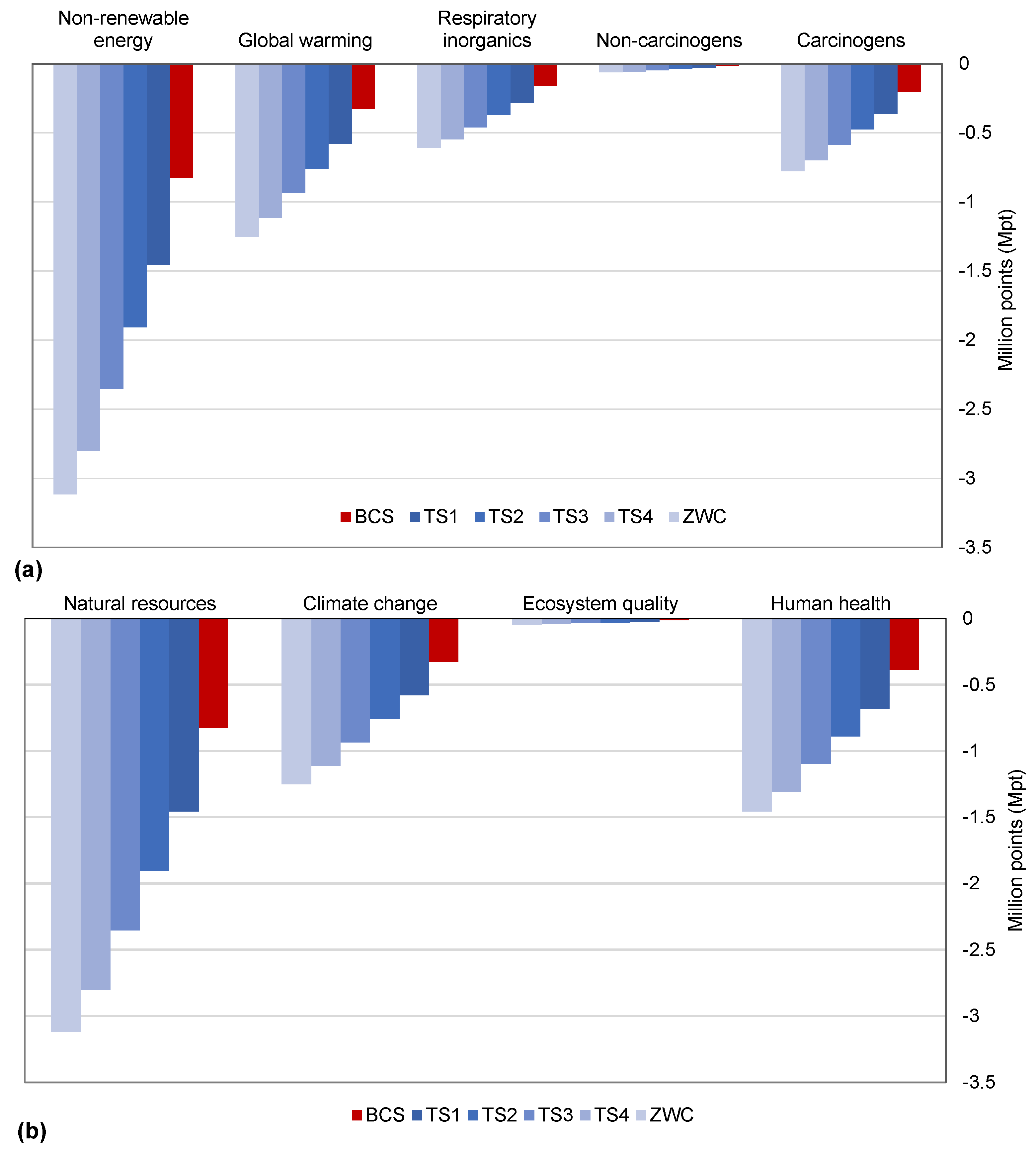

3.2. Life Cycle Impact Assessment of Improvement Scenarios

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BCS | Base case scenario |

| CDW | Construction and demolition waste |

| CML | Centrum voor Milieukunde Leiden |

| DALYs | Disability Adjusted Life Years |

| KSA | Kingdom of Saudi Arabia |

| LCA | Life cycle assessment |

| LCIA | Life cycle impact assessment |

| MRF | Material recovery facility |

| MSSR | Mixed soil, sand, and rock/gravel |

| MTPA | Million tons per annum |

| SIRC | Saudi Investment Recycling Company |

| TS | Treatment Scenario |

| ZWS | Zero waste Scenario |

References

- Kim, J. Construction and demolition waste management in Korea: Recycled aggregate and its application. Clean Technol. Environ. Policy 2021, 23, 2223–2234. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- USEPA. Advancing Sustainable Materials Management: 2018 Fact Sheet; Assessing Trends in Materials Generation and Management in the United States; USEPA: Washington, DC, USA, 2020. [Google Scholar]

- European Statistics-Eurostat. Energy, Transport and Environment Statistics, 2020 ed.; Eurostat: Luxembourg, Germany, 2020. [Google Scholar]

- Hao, J.; Di Maria, F.; Chen, Z.; Yu, S.; Ma, W.; Di Sarno, L. Comparative study of construction and demolition waste management in China and the European Union. Detritus 2020, 14029, 1–8. [Google Scholar]

- CSE. India Manages to Recover and Recycle Only About 1 per cent of its Construction and Demolition (C&D) Waste, Says New CSE Analysis; Centre of Science and Environment: New Delhi, India, 2020. [Google Scholar]

- SCAD Agriculture & Environment. Available online: https://www.scad.ae (accessed on 6 June 2022).

- Alzard, M.H.; El-Hassan, H.; El-Maaddawy, T. Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates. Sustainability 2021, 13, 10348. [Google Scholar] [CrossRef]

- ITA. Waste Management, Saudi Arabia—Country Commercial Guide, International Trade Administration. 2022. Available online: https://www.trade.gov/country-commercial-guides/saudi-arabia-waste-management (accessed on 8 April 2022).

- Al-Ghamdi, O.; Makhdom, B.; Al-Faraj, M.; Al-Akhras, N.; Ahmed, I.M. Management and Recycling of Construction and Demolition Waste in Kingdom of Saudi Arabia. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 3643–3654. [Google Scholar]

- GoConcratctor. How Does Construction Impact the Environment? Available online: https://gocontractor.com/blog/how-does-construction-impact-the-environment/ (accessed on 10 April 2022).

- Kuikka, S.L. LCA of the Demolition of a Building. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweeden, 2012. [Google Scholar]

- Chen, K.; Wang, J.; Yu, B.; Wu, H.; Zhang, J. Critical evaluation of construction and demolition waste and associated environmental impacts: A scientometric analysis. J. Clean Prod. 2021, 287, 125071. [Google Scholar] [CrossRef]

- Spies, S.; 3R in Construction and Demolition Waste (CDW)—Potentials and Constraints. GTZ—German Technical Cooperation, Inaugural Meeting of the Regional 3R Forum in Asia, Tokyo, Japan. 2009. Available online: www.uncrd.or.jp/env/spc/ (accessed on 20 April 2022).

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development, A/RES/70/1, Division for Sustainable Development Goals; UN: New York, NY, USA, 2015. [Google Scholar]

- Saudi Investment Recycling Company, SIRC. Available online: https://sirc.sa (accessed on 20 April 2022).

- Osmani, M. Construction Waste. In Waste: A Handbook for Management; Letcher, T.M., Vallero, D.A., Eds.; Elsevier: Oxford, UK, 2011; pp. 207–218. [Google Scholar]

- Gálvez-Martos, J.L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef] [Green Version]

- MOMRA. 2021. Available online: https://www.momra.gov.sa/GeneralServ/statistic.aspx (accessed on 20 April 2022).

- Blaisi, N.F. Construction and demolition waste management in Saudi Arabia: Current practice and roadmap for sustainable management. J. Clean. Prod. 2019, 221, 167–175. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management—A holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Wenzel, H.; Hauschild, M.Z.; Alting, L. Environmental Assessment of Products. Volume 1: Methodology, Tools, and Case Studies in Product Development; Chapman and Hall: London, UK, 1999; ISBN 0-412-80800-5. [Google Scholar]

- Bovea, M.D.; Powell, J.C. Developments in life cycle assessment applied to evaluate the environmental performance of construction and demolition wastes. Waste Manag. 2016, 50, 151–172. [Google Scholar] [CrossRef]

- Kern, A.P.; Dias, M.F.; Kulakowski, M.P.; Gomes, L.P. Waste generated in high-rise buildings construction: A quantification model based on statistical multiple regression. Waste Manag. 2015, 39, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Bianchini, F.; Hewage, K. How ‘green’ are the green roofs? Life-cycle analysis of green roof materials. Build. Environ. 2012, 48, 57–65. [Google Scholar] [CrossRef]

- Coelho, A.; de Brito, J. Influence of construction and demolition waste management on the environmental impact of buildings. Waste Manag. 2012, 32, 532–541. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Alotaibi, B.A.; Abbas, A.; Ullah, R.; Nayak, R.K.; Azeem, M.I.; Kassem, H.S. Climate Change Concerns of Saudi Arabian Farmers: The Drivers and Their Role in Perceived Capacity Building Needs for Adaptation. Sustainability 2021, 13, 12677. [Google Scholar] [CrossRef]

- Riyadh Municipality. Available online: https://www.alriyadh.gov.sa/ar (accessed on 5 January 2022).

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings. A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management: Life Cycle Assessment, Principles and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- European Commission (EC)–Joint Research Centre–Institute for Environment and Sustainability. Supporting Environmentally Sound Decisions for Waste Management–A technical guide to Life Cycle Thinking (LCT) and Life Cycle Assessment (LCA) for Waste Experts and LCA Practitioners; EUR 24916 EN–2011; Publications Office of the European Union: Luxembourg, Germany, 2011. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef] [Green Version]

- Blengini, G.A.; Garbarino, E. Resource and waste management in Turin (Italy): The role of aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, N.; Di Gregorio, F.; Arena, U. Life cycle assessment of the end-of-life phase of a residential building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef]

- Houssain, M.U.; Wu, Z.; Poon, C.S. Comparative environmental evaluation of construction waste management through different waste sorting systems in Hong Kong. Waste Manag. 2017, 69, 325–335. [Google Scholar] [CrossRef] [PubMed]

- Shan, X.; Zhou, J.; Chang, V.W.-C.; Yang, E.-H. Life cycle assessment of adoption of local recycled aggregates and green concrete in Singapore perspective. J. Clean. Prod. 2017, 164, 918–926. [Google Scholar] [CrossRef]

- Arena, U.; Ardolino, F.; Di Gregorio, F. A life cycle assessment of environmental performances of two combustion- and gasification-based waste-to-energy technologies. Waste Manag. 2015, 41, 60–74. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Comparative analysis of existing prediction models on the creep behavior of recycled aggregate concrete. Eng. Struct. 2015, 100, 31–42. [Google Scholar] [CrossRef]

- Joseph, A.M.; Matthys, S.; De Belie, N. Properties of Concrete with Recycled Aggregates Giving a Second Life to Municipal Solid Waste Incineration Bottom Ash Concrete. Sustainability 2022, 14, 4679. [Google Scholar] [CrossRef]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Effect of curing regime on the performance and microstructure characteristics of alkali-activated slag-fly ash blended concrete. J. Sustain. Cem.-Based Mater. 2021, 10, 289–317. [Google Scholar] [CrossRef]

- Bahrami, N.; Zohrabi, M.; Mahmoudy, S.A.; Akbari, M. Optimum recycled concrete aggregate and micro-silica content in self-compacting concrete: Rheological, mechanical and microstructural properties. J. Build. Eng. 2020, 31, 101361. [Google Scholar] [CrossRef]

| CDW Composition a | Fraction | Amount (Tons per Year) |

|---|---|---|

| Mixed soil, sand, and rock/gravel | 0.58 | 4,640,000 |

| Concrete Blocks (Solid) | 0.2 | 1,600,000 |

| Glazed tiles | 0.12 | 960,000 |

| Soil/dirt (silt and clay) | 0.06 | 480,000 |

| Asphalt | 0.02 | 160,000 |

| Reinforced concrete | 0.01 | 80,000 |

| Gypsum and Plaster boards | 0.003 | 24,000 |

| Clay Bricks | 0.005 | 40,000 |

| Steel bar, poles, brackets | 0.001 | 8000 |

| Painted treated timber | 0.001 | 8000 |

| Total | 1 | 8,000,000 |

| Scenario | Planning Year | Recycling Rate (%) | CDW Disposed to Landfill (%) | ||

|---|---|---|---|---|---|

| Direct Waste to Landfill | Reject from MRF to Landfill | Overall Waste to Landfill | |||

| BCS: Base case scenario | Present | 45 | 55 | 4.5 (10% of RW 1) | 59.5 |

| TS1: Treatment scenario 1 | 2022 | 61 | 39 | 6.1 (10% of RW) | 45.1 |

| TS2: Treatment scenario 2 | 2023 | 76 | 24 | 7.6 (10% of RW) | 31.6 |

| TS3: Treatment scenario 3 | 2024 | 88 | 12 | 8.8 (10% of RW) | 20.8 |

| TS4: Treatment scenario 4 | 2025 | 100 | 0 | 10 (10% of RW) | 10 |

| ZWS: Zero waste scenario | 2030 | 100 | 0 | 0 (Climate neutrality) | 0 |

| Midpoint Category | Endpoint Category | Unit | Environmental Impact Contribution % | |

|---|---|---|---|---|

| Midpoint | Endpoint | |||

| Carcinogens | Human health | kg C2H3Cl eq | 13.3 | 24.9 |

| Non-carcinogens | Human health | kg C2H3Cl eq | 1.1 | |

| Respiratory inorganics | Human health | kg PM2.5 eq | 10.4 | |

| Respiratory organics | Human health | kg C2H4 eq | 0.1 | |

| Terrestrial ecotoxicity | Ecosystem quality | kg TEG soil | 0.5 | 0.8 |

| Terrestrial acid/nutria | Ecosystem quality | kg SO2 eq | 0.2 | |

| Land occupation | Ecosystem quality | m2org.arable | 0.1 | |

| Global warming | Climate change | kg CO2 eq | 21.2 | 21.2 |

| Non-renewable energy | Natural resources | MJ primary | 53.2 | 53.2 |

| Total | 100 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haider, H.; AlMarshod, S.Y.; AlSaleem, S.S.; Ali, A.A.M.; Alinizzi, M.; Alresheedi, M.T.; Shafiquzzaman, M. Life Cycle Assessment of Construction and Demolition Waste Management in Riyadh, Saudi Arabia. Int. J. Environ. Res. Public Health 2022, 19, 7382. https://doi.org/10.3390/ijerph19127382

Haider H, AlMarshod SY, AlSaleem SS, Ali AAM, Alinizzi M, Alresheedi MT, Shafiquzzaman M. Life Cycle Assessment of Construction and Demolition Waste Management in Riyadh, Saudi Arabia. International Journal of Environmental Research and Public Health. 2022; 19(12):7382. https://doi.org/10.3390/ijerph19127382

Chicago/Turabian StyleHaider, Husnain, Sulaiman Yousef AlMarshod, Saleem S. AlSaleem, Ahmed AbdelMonteleb M. Ali, Majed Alinizzi, Mohammad T. Alresheedi, and Md. Shafiquzzaman. 2022. "Life Cycle Assessment of Construction and Demolition Waste Management in Riyadh, Saudi Arabia" International Journal of Environmental Research and Public Health 19, no. 12: 7382. https://doi.org/10.3390/ijerph19127382

APA StyleHaider, H., AlMarshod, S. Y., AlSaleem, S. S., Ali, A. A. M., Alinizzi, M., Alresheedi, M. T., & Shafiquzzaman, M. (2022). Life Cycle Assessment of Construction and Demolition Waste Management in Riyadh, Saudi Arabia. International Journal of Environmental Research and Public Health, 19(12), 7382. https://doi.org/10.3390/ijerph19127382