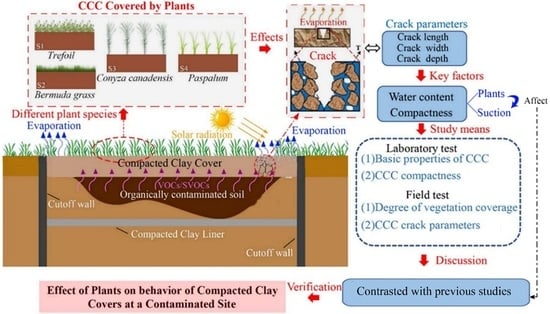

Field Investigation of Effect of Plants on Cracks of Compacted Clay Covers at a Contaminated Site

Abstract

:1. Introduction

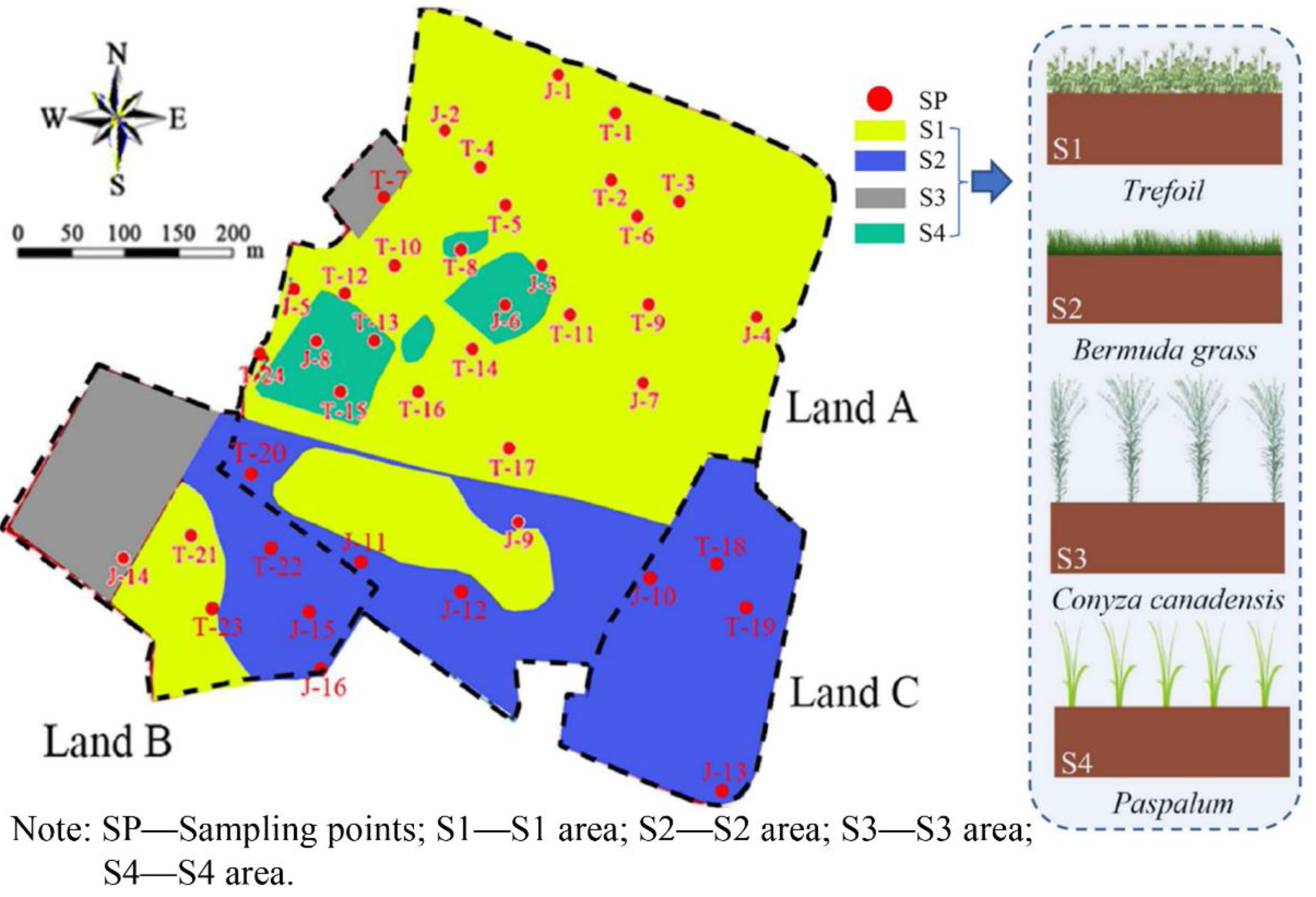

2. Field Tests

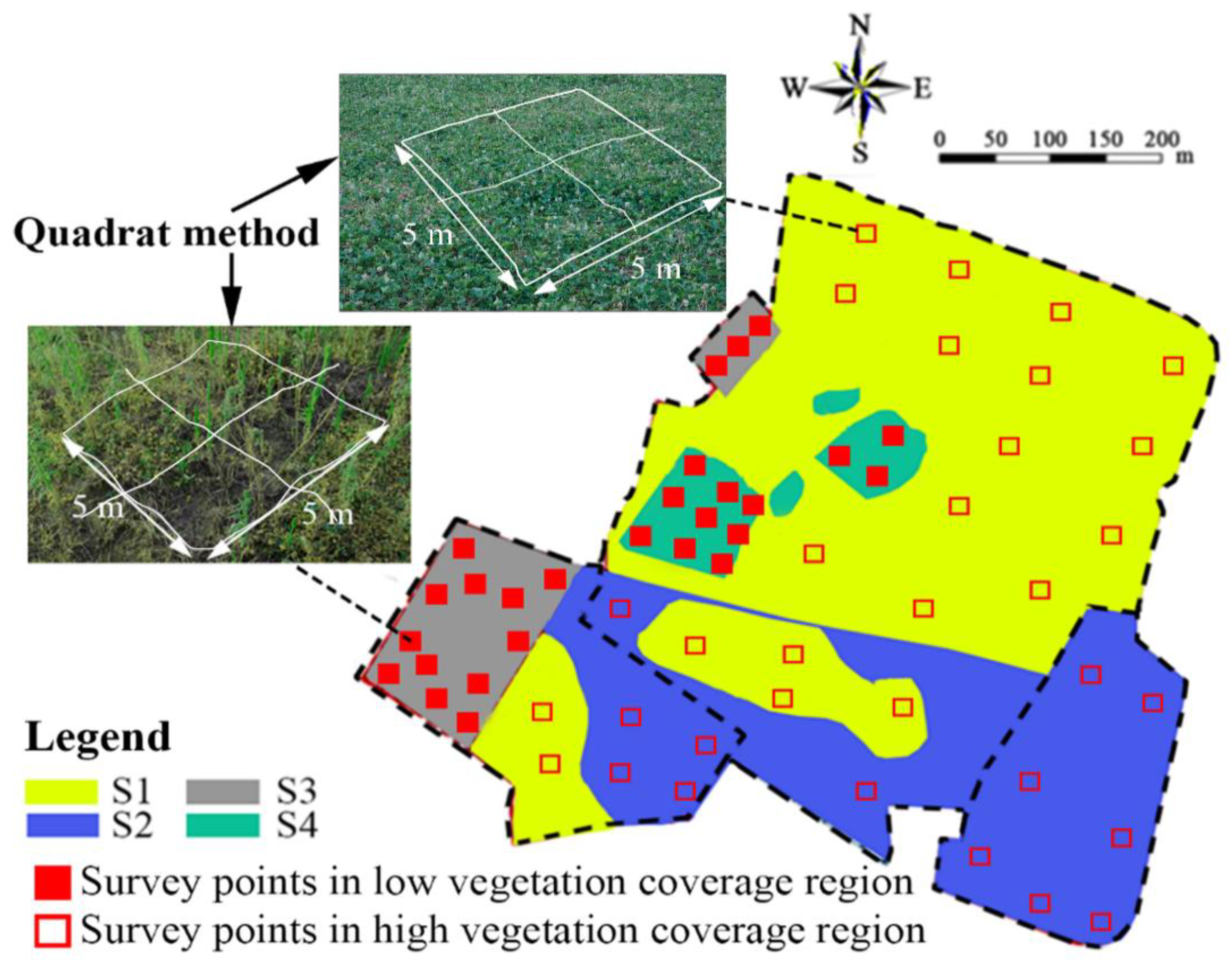

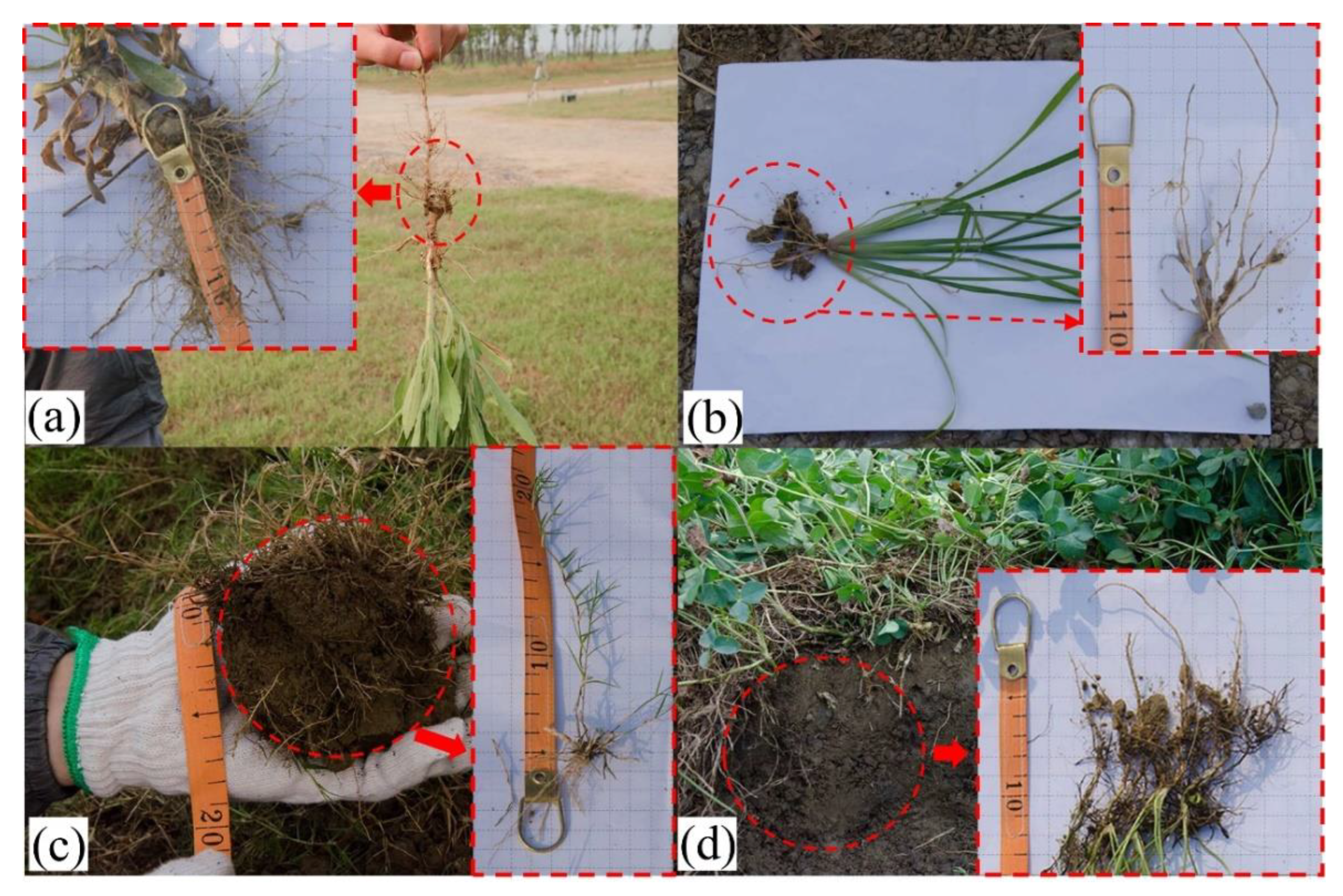

2.1. Vegetation Coverage

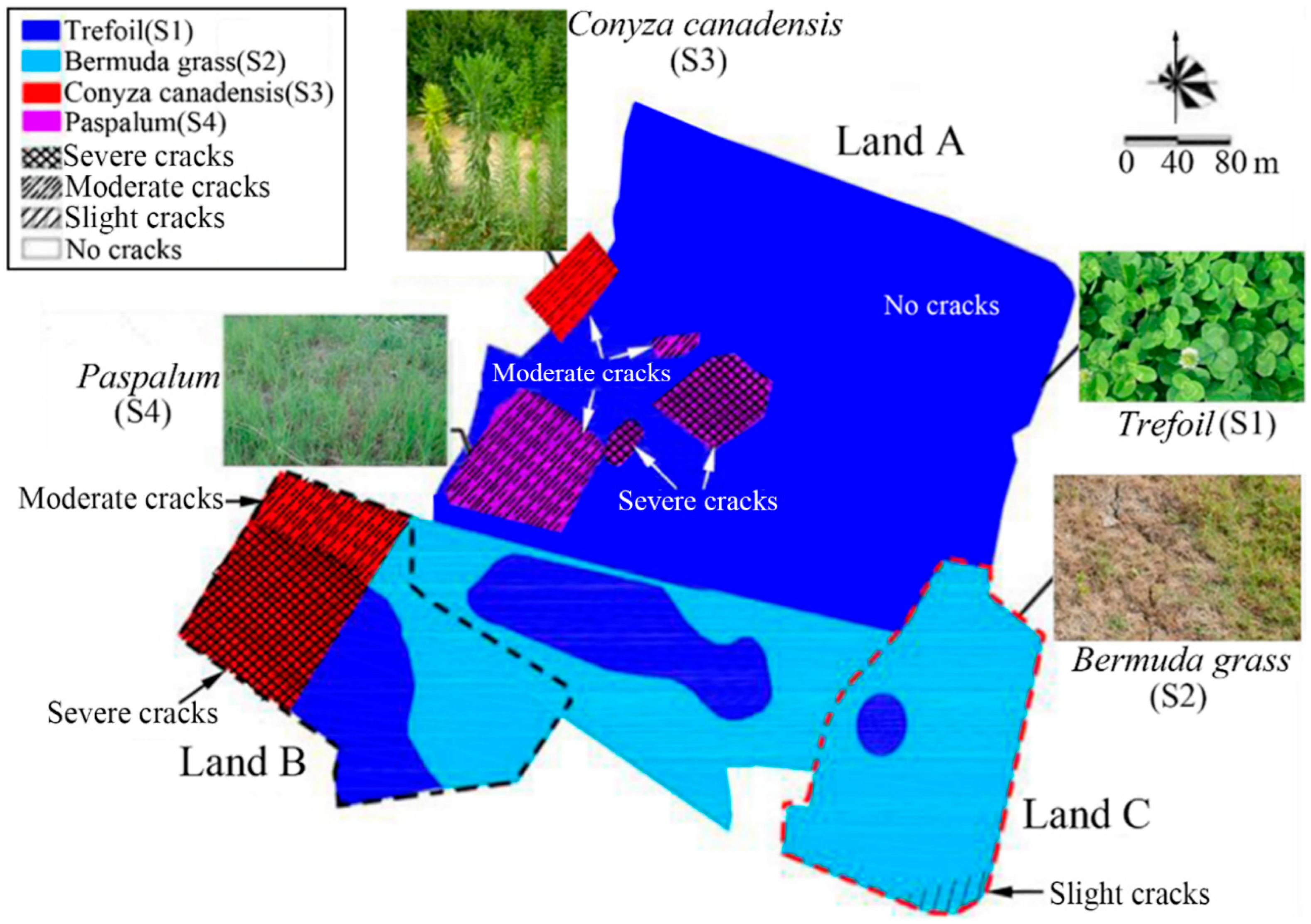

2.2. Site Description

2.3. Properties of CCC

2.3.1. Basic Properties

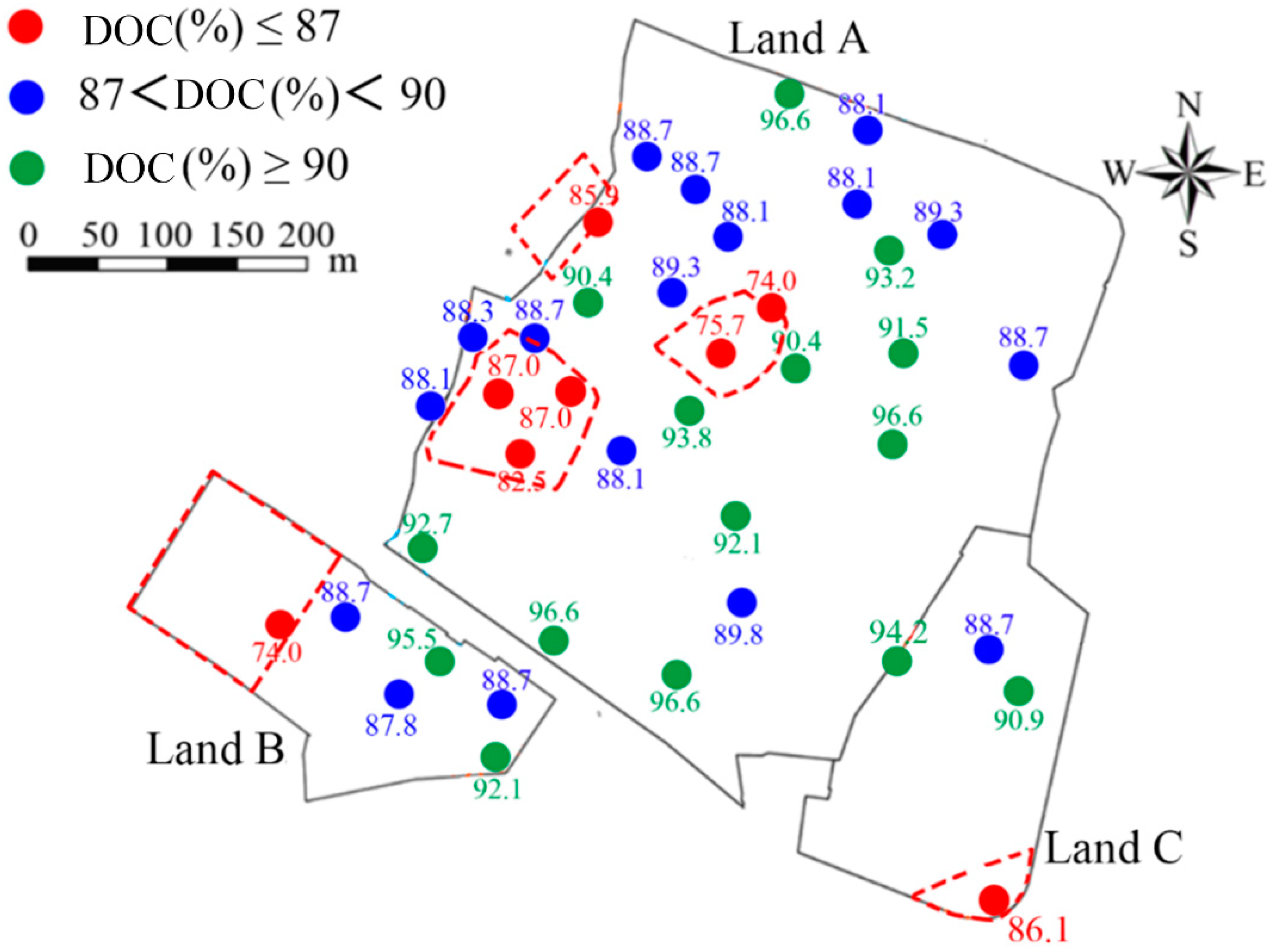

2.3.2. Degree of Compaction of CCCs under Different Vegetation Coverage

2.4. Test Methods

2.4.1. Degree of Vegetation Coverage

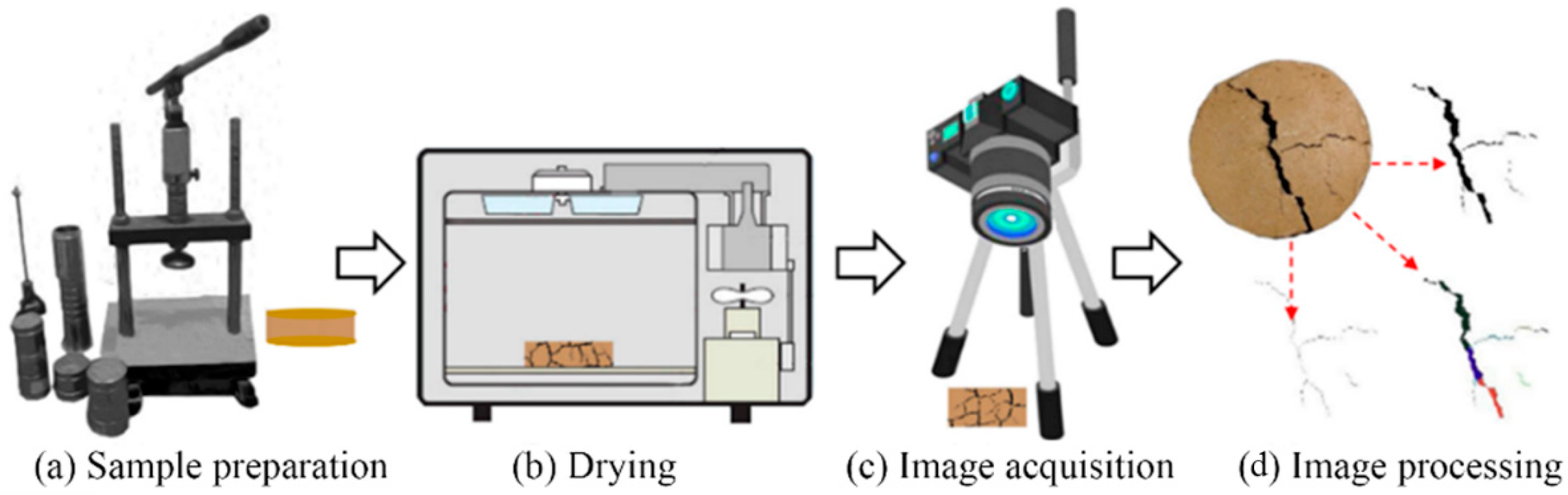

2.4.2. Crack Parameters of CCCs

3. Test Result Analyses

3.1. Effect of Plant Distribution on the Crack Parameters

3.1.1. Crack Length

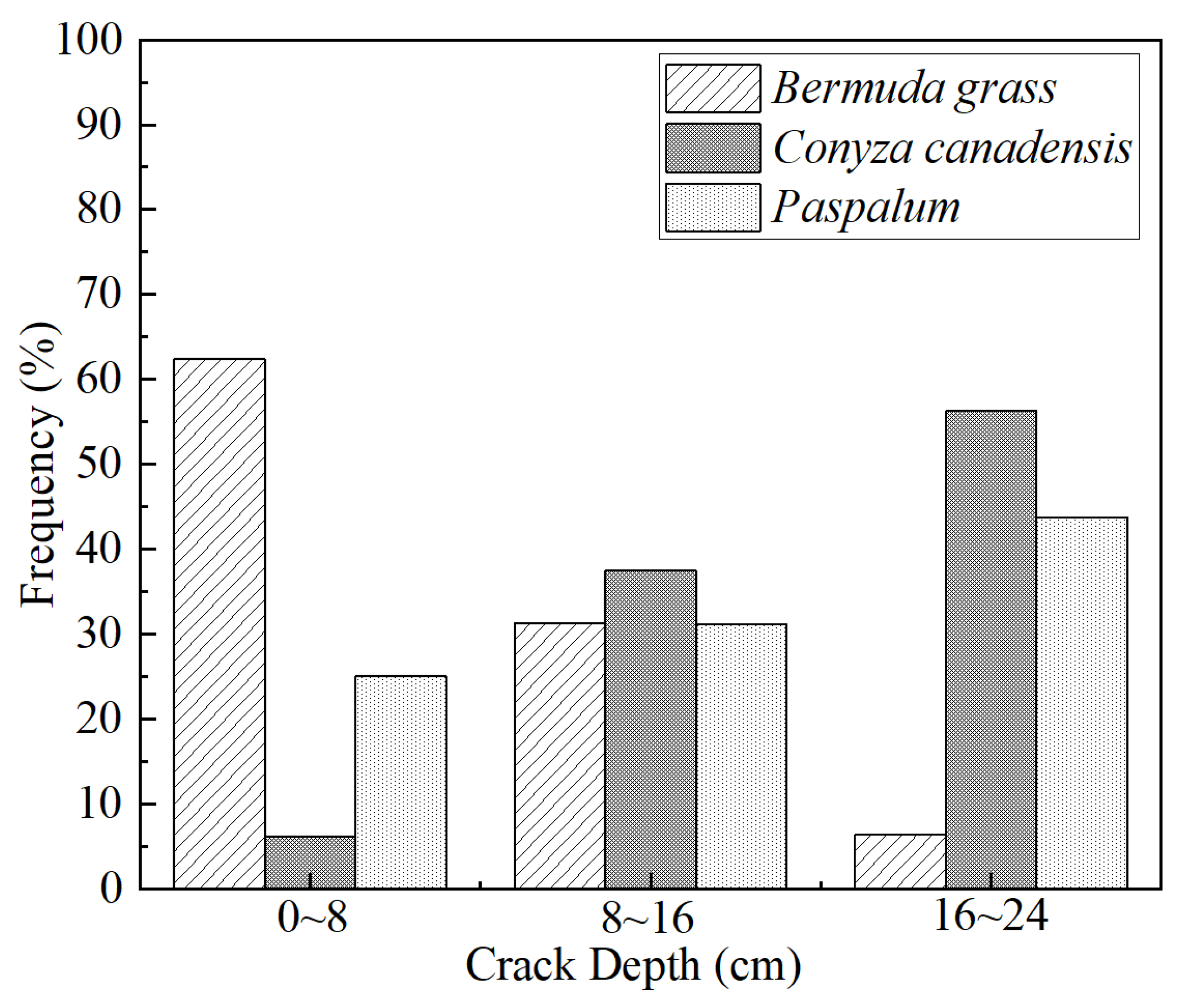

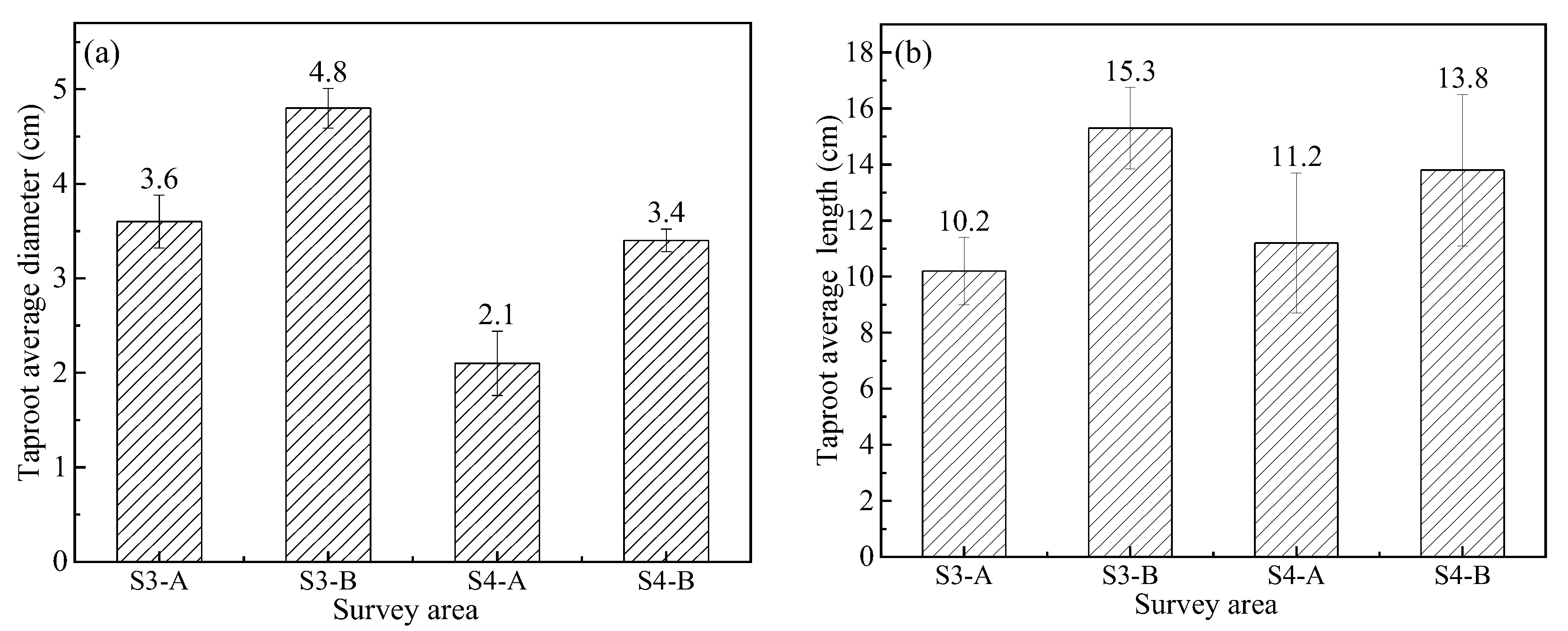

3.1.2. Crack Depth and Width

3.2. Effect of Plant Distribution on Cracking

4. Discussion

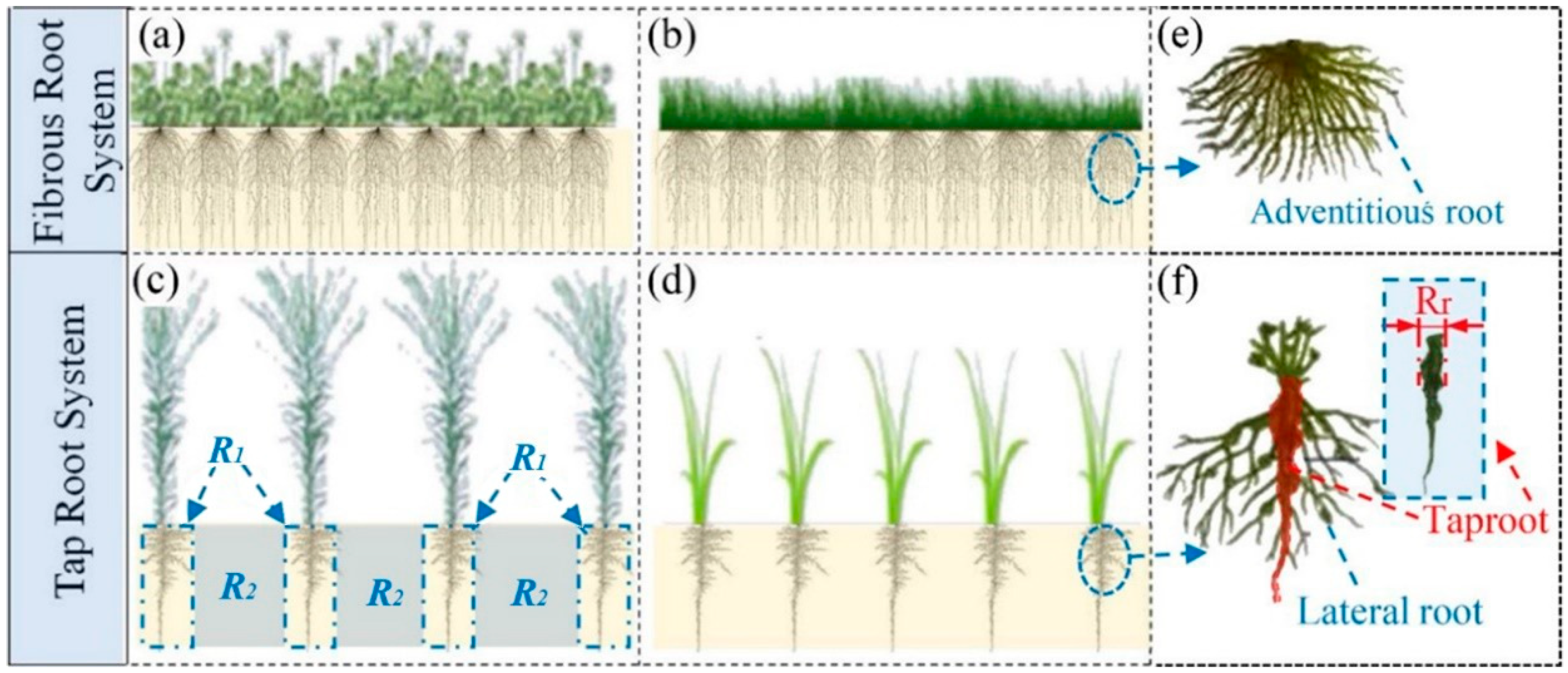

4.1. Influence of Plants on Cracks

- The influence of suction

- 2.

- The influence of root systems

4.2. Influence of DOC on Crack

5. Conclusions

- (1)

- The cracking levels of the CCC were associated with the coverage of plants: the areas at the S3 (Conyza Canadensis) and S4 (Paspalum), the areas at S2 (Bermuda grass), and the area at S1 (Trefoil) had severe, slight, and almost non-exist cracking levels, respectively.

- (2)

- The number of CCC cracks in the areas at S4 was the largest, twice and eight times that of S3 and S2, respectively. The maximum crack length and average crack length of S2 were the minimum, which was approximately 0.92 m, and 0.21 m, respectively. Moreover, the maximum crack length of S2 was 1/7 that of S3 and 1/8 that of S4, respectively, and the average crack length of S2 was 1/9 of S3 and 1/10 of S4, respectively.

- (3)

- The maximum crack depth and maximum crack width of the areas at S2 were the minimum, 1/5 and 1/6 those of S3, and 1/5 and 1/6 those of S4. The average crack depth and average crack width at S2 were 1/5 and 1/6 those of S3, respectively, and 1/5 and 1/7 those of S4, respectively.

- (4)

- The cracking was closely related to the DOC of CCC: when the DOC was less than 87% at the S3 area, severe cracks occurred; when the DOC was greater than 87%, moderate cracks occurred. The areas at S4 also complied with the pattern.

- (5)

- The effect of plants on cracking was considerably exerted by the uneven distribution of the CCC surface suction caused by row planting. Furthermore, plants with fibrous root systems were beneficial for inhabiting CCC cracking.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CCC | Compacted clay cover |

| VOC | Volatile organic compound |

| SVOC | Semi-volatile organic compound |

| DOC | Degree of compaction |

| S2-A | Study area A in S2 |

| S2-B | Study area B in S2 |

| S3-A | Study area A in S3 |

| S3-B | Study area B in S3 |

| S4-A | Study area A in S4 |

| S4-B | Study area B in S4 |

| UAV | Unmanned aerial vehicle |

| NDVI | Normalized difference vegetation index |

| NDVIsoil | NDVI value of bare soil or vegetation-free area |

| NDVIveg | NDVI value of plants at the investigated site |

| NIR | The near-infrared band value |

| RB | The red band value |

| VFC | Vegetation fractional coverage |

| MCL | Maximum crack length |

| MCW | Maximum crack width |

| MCD | Maximum crack depth |

| ACL | Average crack length |

| ACW | Average crack width |

| ACD | Average crack depth |

References

- Morris, P.H.; Graham, J.; Williams, D.J. Cracking in drying soils. Can. Geotech. J. 1992, 29, 263–277. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Liu, C.; Suo, W.; Gao, L. Experimental characterization of shrinkage and desiccation cracking in thin clay layer. Appl. Clay Sci. 2011, 52, 69–77. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.V.S.; Kodikara, J. A study on desiccation cracking behavior of polyester fiber-reinforced expansive clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- Boynton, S.S.; Daniel, D.E. Hydraulic conductivity tests on compacted clay. J. Geotech. Eng. 1985, 111, 465–478. [Google Scholar] [CrossRef]

- Miller, C.J.; Mi, H.; Yesiller, N. Experimental analysis of desiccation crack propagation in clay liners 1. J. Am. Water Resour. Assoc. 1998, 34, 677–686. [Google Scholar] [CrossRef] [Green Version]

- Yesiller, N.; Miller, C.J.; Inci, G.; Yaldo, K. Desiccation and cracking behavior of three compacted landfill liner soils. Eng. Geol. 2000, 57, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Albrecht, B.A.; Benson, C.H. Effect of desiccation on compacted natural clays. J. Geotech. Geoenviron. Eng. 2001, 127, 67–75. [Google Scholar] [CrossRef]

- Jones, G.; Sentenac, P.; Zielinski, M. Desiccation cracking detection using 2-D and 3-D Electrical Resistivity Tomography: Validation on a flood embankment. J. Appl. Geophys. 2014, 106, 196–211. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Ye, W.M.; Chen, B.; Chen, Y.; Ye, B. Desiccation of NaCl-contaminated soil of earthen heritages in the Site of Yar City, northwest China. Appl. Clay Sci. 2016, 124, 1–10. [Google Scholar] [CrossRef]

- Mahmoodlu, M.G.; Hassanizadeh, S.M.; Hartog, N.; Raoof, A. Evaluation of a horizontal permeable reactive barrier for preventing upward diffusion of volatile organic compounds through the unsaturated zone. J. Environ. Manag. 2015, 163, 204–213. [Google Scholar] [CrossRef]

- Xie, H.; Wang, Q.; Bouazza, A.; Feng, S. Analytical model for vapour-phase VOCs transport in four-layered landfill composite cover systems. Comput. Geotech. 2018, 101, 80–94. [Google Scholar] [CrossRef]

- Rivett, M.O.; Wealthall, G.P.; Dearden, R.A.; McAlary, T.A. Review of unsaturated-zone transport and attenuation of volatile organic compound (VOC) plumes leached from shallow source zones. J. Contam. Hydrol. 2011, 123, 130–156. [Google Scholar] [CrossRef]

- You, K.; Zhan, H. Comparisons of diffusive and advective fluxes of gas phase volatile organic compounds (VOCs) in unsaturated zones under natural conditions. Adv. Water Resour. 2013, 52, 221–231. [Google Scholar] [CrossRef]

- Yao, Y.; Shen, R.; Pennell, K.G.; Suuberg, E.M. A review of vapor intrusion models. Environ. Sci. Technol. 2013, 47, 2457–2470. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Pei, J.; Tian, B.; Tang, M. Potential application of biocover soils to landfills for mitigating toluene emission. J. Hazard. Mater. 2015, 299, 18–26. [Google Scholar] [CrossRef]

- Morris, P.H.; Graham, J.; Williams, D.J. Crack depths in drying clays using fracture mechanics. Geotech. Spec. Publ. 1994, 43, 40–53. [Google Scholar]

- Weinberger, R. Initiation and growth of cracks during desiccation of stratified muddy sediments. J. Struct. Geol. 1999, 21, 379–386. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Cui, Y.J.; Liu, C.; Gu, K. Desiccation cracking behavior of polypropylene fiber–reinforced clayey soil. Can. Geotech. J. 2012, 49, 1088–1101. [Google Scholar] [CrossRef]

- Pan, H.; Qing, Y.; Pei, Y.L. Direct and indirect measurement of soil suction in the laboratory. Electron. J. Geotech. Eng. 2010, 15, 1–14. [Google Scholar]

- Cordero, J.A.; Useche, G.; Prat, P.C.; Ledesma, A.; Santamarina, J.C. Soil desiccation cracks as a suction–contraction process. Géotech. Lett. 2017, 7, 279–285. [Google Scholar] [CrossRef]

- Fleureau, J.M.; Wei, X.; Ighil-Ameur, L.; Hattab, M.; Bicalho, K.V. Experimental study of the cracking mechanisms of clay during drying. In Proceedings of the 15th Pan American Conference on Soil Mechanics and Geotechnical Engineering, Buenos Aires, Argentina, 15–18 November 2015; pp. 2101–2108. [Google Scholar]

- Oleszczuk, R.; Bohne, K.; Szatylowicz, J.; Brandyk, T.; Gnatowski, T. Influence of load on shrinkage behavior of peat soils. J. Plant Nutr. Soil Sci. 2003, 166, 220–224. [Google Scholar] [CrossRef]

- Towner, G.D. The mechanics of cracking of drying clay. J. Agric. Eng. Res. 1987, 36, 115–124. [Google Scholar] [CrossRef]

- Konrad, J.M.; Ayad, R. A idealized framework for the analysis of cohesive soils undergoing desiccation. Can. Geotech. J. 1997, 34, 477–488. [Google Scholar] [CrossRef]

- Costa, S.; Kodikara, J.; Shannon, B. Salient factors controlling desiccation cracking of clay in laboratory experiments. Géotechnique 2013, 63, 18. [Google Scholar] [CrossRef]

- Johnston, J.R.; Hill, H.O. A Study of the Shrinking and Swelling Properties of Rendzina Soils. Soil Sci. Soc. Am. J. 1945, 9, 24–29. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.B.; Verma, G.P. Characterization of shrinkage cracks in medium black clay soil of Madhya Pradesh. Plant Soil 1977, 48, 323–333. [Google Scholar] [CrossRef]

- Johnson, W.C. Controlled Soil Cracking as a Possible Means of Moisture Conservation on Wheatlands of the Southwestern Great Plains 1. Agron. J. 1962, 54, 323–325. [Google Scholar] [CrossRef]

- Fox, W.E. Cracking characteristics and field capacity in a swelling soil. Soil Sci. 1964, 98, 413. [Google Scholar]

- Mitchell, A.R.; Van Genuchten, M.T. Shrinkage of bare and cultivated soil. Soil Sci. Soc. Am. J. 1992, 56, 1036–1042. [Google Scholar] [CrossRef]

- Dasog, G.S.; Shashidhara, G.B. Dimension and volume of cracks in a Vertisol under different crop covers. Soil Sci. 1993, 156, 424–428. [Google Scholar] [CrossRef]

- Li, J.H.; Li, L.; Chen, R.; Li, D.Q. Cracking and vertical preferential flow through landfill clay liners. Eng. Geol. 2016, 206, 33–41. [Google Scholar] [CrossRef]

- Bordoloi, S.; Hussain, R.; Gadi, V.K.; Bora, H.; Sahoo, L.; Karangat, R.; Garg, A.; Sreedeep, S. Monitoring soil cracking and plant parameters for a mixed grass species. Géotech. Lett. 2018, 8, 49–55. [Google Scholar] [CrossRef]

- Leung, A.K.; Ng, C.W.W. Analyses of groundwater flow and plant evapotranspiration in a vegetated soil slope. Can. Geotech. J. 2013, 50, 1204–1218. [Google Scholar] [CrossRef]

- Sinnathamby, G.; Phillips, D.H.; Sivakumar, V.; Paksy, A. Landfill cap models under simulated climate change precipitation: Impacts of cracks and root growth. Géotechnique 2014, 64, 95. [Google Scholar] [CrossRef] [Green Version]

- Smethurst, J.; Briggs, K.; Powrie, W.; Ridley, A.; Butcher, D.J.E. Mechanical and hydrological impacts of tree removal on a clay fill railway embankment. Géotechnique 2015, 65, 869–882. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, A.R.; Ellsworth, T.R.; Meek, B.D. Effect of root systems on preferential flow in swelling soil. Commun. Soil Sci. Plant Anal. 1995, 26, 2655–2666. [Google Scholar] [CrossRef]

- Devitt, D.A.; Smith, S.D. Root channel macropores enhance downward movement of water in a Mojave Desert ecosystem. J. Arid Environ. 2002, 50, 99–108. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Ni, J.J.; Leung, A.K.; Zhou, C.; Wang, Z.J. Effects of planting density on tree growth and induced soil suction. Géotechnique 2016, 66, 711–724. [Google Scholar] [CrossRef] [Green Version]

- Jotisankasa, A.; Sirirattanachat, T. Effects of grass roots on soil-water retention curve and permeability function. Can. Geotech. J. 2017, 54, 1612–1622. [Google Scholar] [CrossRef] [Green Version]

- Liang, T.; Bengough, A.G.; Knappett, J.A.; MuirWood, D.; Loades, K.W.; Hallett, P.D.; Boldrin, D.; Leung, A.K.; Meijer, G.J. Scaling of the reinforcement of soil slopes by living plants in a geotechnical centrifuge. Ecol. Eng. 2017, 109, 207–227. [Google Scholar] [CrossRef] [Green Version]

- Song, L.; Li, J.H.; Zhou, T.; Fredlund, D.G. Experimental study on unsaturated hydraulic properties of vegetated soil. Ecol. Eng. 2017, 103, 207–216. [Google Scholar] [CrossRef]

- Huang, Y.; Gao, L.; Yi, Z.; Tai, K.; Kalita, P.; Prapainainar, P.; Garg, A. An application of evolutionary system identification algorithm in modelling of energy production system. Measurement 2018, 114, 122–131. [Google Scholar] [CrossRef]

- Garg, A.; Leung, A.K.; Ng, C.W.W. Transpiration reduction and root distribution functions for a non-crop species Schefflera heptaphylla. Catena 2015, 135, 78–82. [Google Scholar] [CrossRef] [Green Version]

- Loades, K.W.; Bengough, A.G.; Bransby, M.F.; Hallett, P.D. Planting density influence on fibrous root reinforcement of soils. Ecol. Eng. 2010, 36, 276–284. [Google Scholar] [CrossRef]

- Jin, Y.; Jury, W.A. Characterizing the dependence of gas diffusion coefficient on soil properties. Soil Sci. Soc. Am. J. 1996, 60, 66–71. [Google Scholar] [CrossRef]

- ASTM D3441-05; Standard Test Method for Mechanical Cone Penetration Tests of Soil. American Society for Testing and Materials: West Conshohocken, PA, USA, 2005.

- Hunt, R.E. Geotechnical Engineering Investigation Handbook; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Moore, J.E. Field Hydrogeology: A Guide for Site Investigations and Report Preparation; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Hess-Kosa, K. Environmental Site Assessment Phase I: A Basic Guide; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- ASTM. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System) D2487. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Frank, R. Basic principles of Eurocode 7 on Geotechnical design. In Proceedings of the 18th EYGEC, Ancona, Italy, 17–20 June 2007. [Google Scholar]

- ASTM D2216-10; Standard Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM D854; Standard Test Method for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D4253; Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table. ASTM International: West Conshohocken, PA, USA, 2014.

- JTG E40–2007; Test Methods of Soils for Highway Engineering. China Communications Press: Beijing, China, 2007.

- CJJ-2008; Code for Construction and Quality Acceptance of Road Works in City and Town. China Communications Press: Beijing, China, 2008.

- Dunford, R.; Michel, K.; Gagnage, M.; Piégay, H.; Trémelo, M.L. Potential and constraints of Unmanned Aerial Vehicle technology for the characterization of Mediterranean riparian forest. Int. J. Remote Sens. 2009, 30, 4915–4935. [Google Scholar] [CrossRef]

- Salamí, E.; Barrado, C.; Pastor, E. UAV flight experiments applied to the remote sensing of vegetated areas. Remote Sens. 2014, 6, 11051–11081. [Google Scholar] [CrossRef] [Green Version]

- Kaneko, K.; Nohara, S. Review of effective vegetation mapping using the UAV (Unmanned Aerial Vehicle) method. J. Geogr. Inf. Syst. 2014, 6, 733. [Google Scholar] [CrossRef] [Green Version]

- Wong, W.S.D.; Lee, L. Statistical Analysis of Geographic Information with ArcView GIS and ArcGIS; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Rouse, J.W., Jr.; Haas, R.H.; Schell, J.A.; Deering, D.W. Monitoring the Vernal Advancement and Retrogradation (Green Wave Effect) of Natural Vegetation; Goddard Space Flight Center: Greenbelt, MD, USA, 1973. [Google Scholar]

- Matsushita, B.; Yang, W.; Chen, J.; Onda, Y.; Qiu, G. Sensitivity of the enhanced vegetation index (EVI) and normalized difference vegetation index (NDVI) to topographic effects: A case study in high-density cypress forest. Sensors 2007, 7, 2636–2651. [Google Scholar] [CrossRef] [Green Version]

- Townshend, J.R.G.; Justice, C.O. Analysis of the dynamics of African vegetation using the normalized difference vegetation index. Int. J. Remote Sens. 1986, 7, 1435–1445. [Google Scholar] [CrossRef]

- Geerken, R.; Zaitchik, B.; Evans, J.P. Classifying rangeland vegetation type and coverage from NDVI time series using Fourier Filtered Cycle Similarity. Int. J. Remote Sens. 2005, 26, 5535–5554. [Google Scholar] [CrossRef]

- Condit, R. Tropical Forest Census Plots: Methods and Results from Barro Colorado Island, Panama and a Comparison with Other Plots; Springer: Berlin, Germany, 1998. [Google Scholar]

- Wei, L. Wet and Dry Damage of Bentonite Modified Loess and Self-Healing after Soaking in Water. Ph.D. Thesis, Ningxia University, Ningxia, China, 2020. (In Chinese). [Google Scholar]

| Property | Value | Geotechnical Test Methods |

|---|---|---|

| Moisture Content (%) | 22.5 | ASTM D2216 [53] |

| Specific Gravity, Gs | 2.72 | ASTM D854 [54] |

| Liquid Limit, LL (%) | 38.14 | ASTM D4318 [55] |

| Plastic Limit, PL (%) | 14.90 | |

| Optimum Water Content (%) | 25.6 | ASTM D4253 [56] |

| Maximum Dry Density (g/cm3) | 1.78 |

| Temperature (°C) | 40 | 60 | 110 | |

|---|---|---|---|---|

| N | 75% | 2 | 6 | 10 |

| 87% | 0 | 1 | 6 | |

| 95% | 0 | 0 | 3 | |

| N1 | 75% | 4 | 13 | 21 |

| 87% | 0 | 2 | 12 | |

| 95% | 0 | 0 | 4 | |

| L (cm) | 75% | 1.1 | 2.2 | 6.6 |

| 87% | 0 | 0.9 | 3.1 | |

| 95% | 0 | 0 | 1.7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, Y.-Z.; Fu, X.-L.; Zhou, S.-J.; Ni, J.; Du, Y.-J. Field Investigation of Effect of Plants on Cracks of Compacted Clay Covers at a Contaminated Site. Int. J. Environ. Res. Public Health 2022, 19, 7248. https://doi.org/10.3390/ijerph19127248

Bi Y-Z, Fu X-L, Zhou S-J, Ni J, Du Y-J. Field Investigation of Effect of Plants on Cracks of Compacted Clay Covers at a Contaminated Site. International Journal of Environmental Research and Public Health. 2022; 19(12):7248. https://doi.org/10.3390/ijerph19127248

Chicago/Turabian StyleBi, Yu-Zhang, Xian-Lei Fu, Shi-Ji Zhou, Jin Ni, and Yan-Jun Du. 2022. "Field Investigation of Effect of Plants on Cracks of Compacted Clay Covers at a Contaminated Site" International Journal of Environmental Research and Public Health 19, no. 12: 7248. https://doi.org/10.3390/ijerph19127248

APA StyleBi, Y.-Z., Fu, X.-L., Zhou, S.-J., Ni, J., & Du, Y.-J. (2022). Field Investigation of Effect of Plants on Cracks of Compacted Clay Covers at a Contaminated Site. International Journal of Environmental Research and Public Health, 19(12), 7248. https://doi.org/10.3390/ijerph19127248