Preliminary Evaluation of Filtration Efficiency and Differential Pressure ASTM F3502 Testing Methods of Non-Medical Masks Using a Face Filtration Mount

Abstract

1. Introduction

2. Materials and Methods

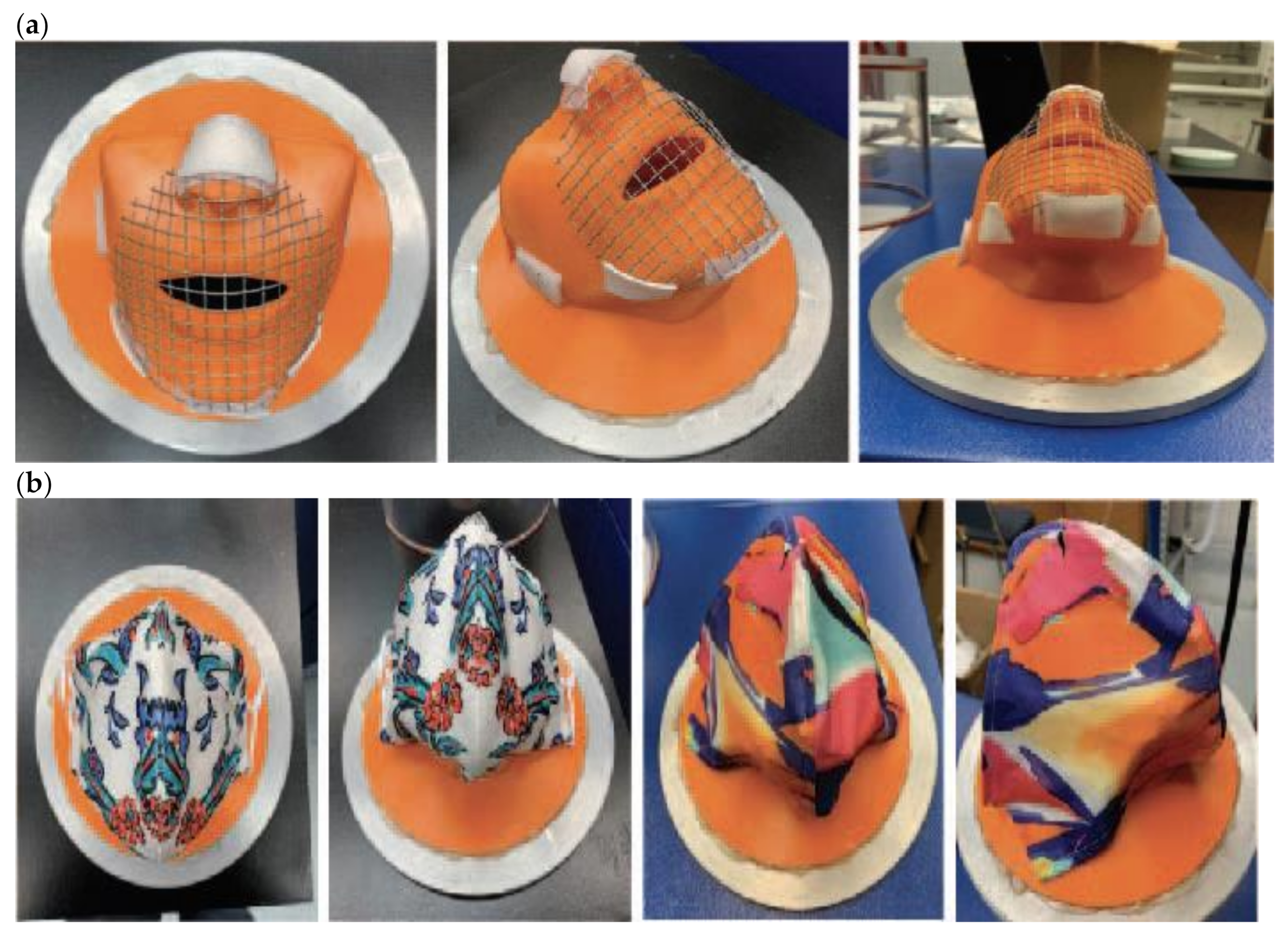

2.1. Testing Procedures Face Filtration Mount

2.2. Testing Procedures Filtration Efficiency

2.3. Products Tested

3. Results

3.1. Filtration Efficiency and Differential Pressure

3.2. Effect of Material Weight and Thickness

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Centers for Disease Control and Prevention (CDC). Businesses and Workplaces; Centers for Disease Control and Prevention: Atlanta, GA, USA, 2021; Available online: https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/businesses-employers.html (accessed on 30 April 2020).

- World Health Organization. Advice on the Use of Masks in the Context of COVID-19: Interim Guidance. Available online: https://www.who.int/publications/i/item/advice-on-the-use-of-masks-in-the-community-during-home-care-and-in-healthcare-settings-in-the-context-of-the-novel-coronavirus-(2019-ncov)-outbreak (accessed on 5 June 2020).

- Drewnick, F.; Pikmann, J.; Fachinger, F.; Moormann, L.; Sprang, F.; Borrmann, S. Aerosol filtration efficiency of household materials for homemade face masks: Influence of material properties, particle size, particle electrical charge, face velocity, and leaks. Aerosol Sci. Technol. 2021, 55, 63–79. [Google Scholar] [CrossRef]

- Klompas, M.; Morris, C.A.; Sinclair, J.; Pearson, M.; Shenoy, E.S. Universal Masking in Hospitals in the Covid-19 Era. N. Engl. J. Med. 2020, 382, e63. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Liao, L.; Xiao, W.; Yu, X.; Wang, H.; Wang, Q.; Lin, Y.L.; Kilinc-Balci, F.S.; Price, A.; Chu, L.; et al. Household Materials Selection for Homemade Cloth Face Coverings and Their Filtration Efficiency Enhancement with Triboelectric Charging. Nano Lett. 2020, 20, 5544–5552. [Google Scholar] [CrossRef] [PubMed]

- Kähler, C.J.; Hain, R. Fundamental protective mechanisms of face masks against droplet infections. J. Aerosol Sci. 2020, 148, 105617. [Google Scholar] [CrossRef] [PubMed]

- Clase, C.M.; Fu, E.L.; Joseph, M.; Beale, R.C.; Dolovich, M.B.; Jardine, M.; Mann, J.F.; Pecoits-Filho, R.; Winkelmayer, W.C.; Carrero, J.J. Cloth Masks May Prevent Transmission of COVID-19: An Evidence-Based, Risk-Based Approach. Ann. Intern. Med. 2020, 173, 489–491. [Google Scholar] [CrossRef] [PubMed]

- Fischer, R.J.; Morris, D.H.; van Doremalen, N.; Sarchette, S.; Matson, M.J.; Bushmaker, T.; Yinda, C.K.; Seifert, S.N.; Gamble, A.; Williamson, B.N.; et al. Assessment of N95 respirator decontamination and re-use for SARS-CoV-2. medRxiv 2020. [Google Scholar] [CrossRef]

- Viola, I.M.; Peterson, B.; Pisetta, G.; Pavar, G.; Akhtar, H.; Menoloascina, F.; Mangano, E.; Dunn, K.E.; Gabl, R.; Nila, A.; et al. Face Coverings, Aerosol Dispersion and Mitigation of Virus Transmission Risk. IEEE Open J. Eng. Med. Biol. 2021, 2, 26–35. [Google Scholar] [CrossRef]

- National Institute for Occupational Safety and Health (NIOSH), National Personal Protective Technology Laboratory. Determination of Particulate Filter Efficiency Level for N95 Series Filters against Solid Particulates for Non-Powered, Air-Purifying Respirators Standard Testing Procedure (STP). Available online: https://www.cdc.gov/niosh/npptl/stps/pdfs/TEB-APR-STP-0059-508.pdf (accessed on 13 December 2019).

- Clapp, P.W.; Sickbert-Bennett, E.E.; Samet, J.M.; Berntsen, J.; Zeman, K.L.; Anderson, D.J.; Weber, D.J.; Bennett, W.D.; US Centers for Disease Control and Prevention Epicenters Program. Evaluation of Cloth Masks and Modified Procedure Masks as Personal Protective Equipment for the Public during the COVID-19 Pandemic. JAMA Intern. Med. 2020, 10. [Google Scholar] [CrossRef]

- ASTM International. Standard Specifications for Barrier Face Coverings; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar] [CrossRef]

- Eninger, R.M.; Honda, T.; Adhikari, A.; Heinonen-Tanski, H.; Reponen, T.; Grinshpun, S.A. Filter Performance of N99 and N95 Facepiece Respirators against Viruses and Ultrafine Particles. Ann. Occup. Hyg. 2008, 52, 385–396. [Google Scholar] [CrossRef] [PubMed]

- Centers for Disease Control and Prevention. Manufacturing Workers and Employers; Centers for Disease Control and Prevention: Atlanta, GA, USA, 2021; Available online: https://www.cdc.gov/coronavirus/2019-ncov/community/guidance-manufacturing-workers-employers.html (accessed on 30 April 2020).

- ASTM International. Specification for Performance of Materials Used in Medical Face Masks; ASTM International: West Conshohocken, PA, USA, 2018; Available online: http://www.astm.org/cgi-bin/resolver.cgi?F2100 (accessed on 6 February 2021).

- ASTM International. Standard Test Method for End (Warp) and Pick (Filling) Count of Woven Fabrics; ASTM International: West Conshohocken, PA, USA, 2018; Available online: http://www.astm.org/cgi-bin/resolver.cgi?D3775 (accessed on 1 February 2021).

- ASTM International. Standard Test Method for Wale and Course Count of Weft Knitted Fabrics; ASTM International: West Conshohocken, PA, USA, 2021; Available online: http://www.astm.org/cgi-bin/resolver.cgi?D8007 (accessed on 15 February 2021).

- ASTM International. Standard Test Methods for Mass Per Unit Area (Weight) of Fabric; ASTM International: West Conshohocken, PA, USA, 2020; Available online: http://www.astm.org/cgi-bin/resolver.cgi?D3776D3776M (accessed on 1 February 2021).

- ASTM International. Standard Test Method for Thickness of Textile Materials; ASTM International: West Conshohocken, PA, USA, 2019; Available online: http://www.astm.org/cgi-bin/resolver.cgi?D1777 (accessed on 5 February 2021).

- Association Française de Normalisation (AFNOR) Group. SPEC S76-001: Masque Barrière. Guide D’exigence Minimales, de Méthode D’essais, de Confection et D’usage; AFNOR: Paris, France, 2020; Available online: https://masquesbarrieres.afnor.org/home/telechargement (accessed on 4 March 2021).

- Konda, A.; Prakash, A.; Moss, G.A.; Schmoldt, M.; Grant, G.D.; Guha, S. Aerosol Filtration Efficiency of Common Fabrics Used in Respiratory Cloth Masks. ACS Nano 2020, 14, 6339–6347. [Google Scholar] [CrossRef] [PubMed]

- Lustig, S.R.; Biswakarma, J.J.H.; Rana, D.; Tilford, S.H.; Hu, W.; Su, M.; Rosenblatt, M.S. Effectiveness of Common Fabrics to Block Aqueous Aerosols of Virus-like Nanoparticles. ACS Nano 2020, 14, 7651–7658. [Google Scholar] [CrossRef] [PubMed]

- Leung, N.H.L.; Chu, D.K.W.; Shiu, E.Y.C.; Chan, K.-H.; McDevitt, J.J.; Hau, B.J.P.; Yen, H.-L.; Li, Y.; Ip, D.K.M.; Peiris, J.S.M.; et al. Respiratory virus shedding in exhaled breath and efficacy of face masks. Nat. Med. 2020, 26, 676–680. [Google Scholar] [CrossRef] [PubMed]

| Mask Layers | Available to Purchase? | Fabric Structure | Fiber Content | Thread/Loop Count (Per 10 cm2) | Mask Total Mass (g/m2) | Mask Total Thickness (mm) |

|---|---|---|---|---|---|---|

| Mask 1 Outer | N | Tricot | 82% nylon 18% spandex | 293 | 296 | 1.05 |

| Mask 1 Lining | - | Single knit | 87% cotton 13% polyester | 153 | - | - |

| Mask 2 Outer | Y | Double knit | 93% polyester 7% spandex | 135 | 431 | 1.50 |

| Mask 2 lining | - | Raschel warp knit | 92% polyester 8% spandex | 217 | - | - |

| Mask 3 Outer | Y | Double weft knit | 100% polyester | 195 | 278 | 0.97 |

| Mask 3 lining | - | Single knit | 50% viscose 50% cotton | 170 | - | - |

| Mask 4 Outer | Y | Raschel warp knit | 100% polyester | 170 | 281 | 1.21 |

| Mask 4 inter-lining | - | Non-woven | 100% polyester | n/a | - | - |

| Mask 4 lining | - | Raschel warp knit | 100% polyester | 209 | - | - |

| Mask 5 Outer | Y | Plain Weave | 100% cotton | 310 | 277 | 0.62 |

| Mask 5 lining | - | Single Knit | 96% polyester 4% spandex | 192 | - | |

| Mask 6 Outer | N | Single Knit | 89% cotton 11% spandex | 229 | 322 | 1.25 |

| Mask 6 lining | - | Single knit | 87% cotton 13% polyester | 153 | - | |

| Mask 7 Outer | Y | Single Knit | 83% polyester 17% spandex | 195 | 192 | 0.46 |

| Mask 8 Outer | Y | Double weft knit | 100% polyester | 212 | 320 | 0.99 |

| Mask 8 lining | - | Double weft knit | 100% polyester | 211 | - | - |

| Mask 9 Outer | Y | Plain Weave | 100% cotton | 245 | 241 | 0.61 |

| Mask 9 lining | - | Plain Weave | 100% cotton | 276 | - | - |

| Mask 10 Outer | Y | Plain Weave | 100% cotton | 324 | 206 | 0.40 |

| Mask 10 lining | - | Plain Weave | 100% cotton | 324 | - | - |

| Mask 11 Outer | Y | Double knit | 100% polyester | 144 | 439 | 2.01 |

| Mask 11 inter-lining | - | open cell foam | 100% polyurethane | n/a | - | - |

| Mask 11 lining | - | Double weft knit | 77% nylon/23% spandex | 234 | - | - |

| Mask | FE Mean PAO % | FE Mean NaCl % | FE SD PAO % | FE SD NaCl % | dP Mean PAO w.c. | dP Mean NaCl w.c. | dP SD PAO w.c. | dP SD NaCl w.c. |

|---|---|---|---|---|---|---|---|---|

| Mask 1 | 3.15 | 8.48 | 0.97 | 0.77 | 0.06 | 0.12 | 0.01 | 0.01 |

| Mask 2 | 2.74 | 6.48 | 0.86 | 1.89 | 0.04 | 0.08 | <0.01 | <0.01 |

| Mask 3 | 3.95 | 10.0 | 1.26 | 1.11 | 0.05 | 0.09 | <0.01 | 0.02 |

| Mask 4 | 3.32 | 5.36 | 0.57 | 0.46 | 0.03 | 0.05 | <0.01 | 0.01 |

| Mask 5 | 2.48 | 5.64 | 0.45 | 1.17 | 0.05 | 0.07 | <0.01 | 0.01 |

| Mask 6 | 5.63 | 6.76 | 1.30 | 0.63 | 0.07 | 0.06 | 0.02 | 0.01 |

| Mask 7 | 3.48 | 5.88 | 0.60 | 2.12 | 0.07 | 0.10 | 0.01 | 0.02 |

| Mask 8 | 6.52 | 8.99 | 1.03 | 0.62 | 0.07 | 0.07 | 0.02 | 0.01 |

| Mask 9 | 0.46 | 2.57 | 0.44 | 0.33 | 0.04 | 0.05 | 0.01 | 0.01 |

| Mask 10 | 1.73 | 3.43 | 0.82 | 0.24 | 0.06 | 0.05 | 0.01 | 0.01 |

| Mask 11 | 4.23 | 11.80 | 1.86 | 2.76 | 0.04 | 0.05 | 0.02 | 0.02 |

| Differential Pressure NaCL (w.c.) | Differential Pressure PAO (w.c.) | Fabric Weight NaCl (g/m2) | Fabric Weight PAO (g/m2) | Fabric Thickness NaCl (mm) | Fabric Thickness PAO (mm) | |

|---|---|---|---|---|---|---|

| Filtration Efficiency (%) | 0.398 * | 0.644 * | 0.557 * | 0.309 * | 0.624 * | 0.368 * |

| Differential Pressure (w.c.) | - | −0.047 | −0.191 | −0.076 | −0.215 | |

| Fabric Weight (g/m2) | - | - | 0.927 * | 0.927 * |

| Key Findings | Applications to Current Research |

|---|---|

| Use of Standard Test Method | Methods of testing outside of standards for N95 and Surgical Masks limit the applicability of the results Following a standardized method provides an accurate assessment of effectiveness of fabric masks Procedure is repeatable and applicable to all types of non-medical fabric masks |

| Substandard Filtration Efficiency | Filtration efficiencies for non-medical fabric masks when tested under similar conditions as N95 and surgical are less than 12% effective General guidance from health organization is 20% minimum Differential pressure is below benchmarks indicating the masks are not hindering breathing |

| Guidance for Public Health Messaging | With lower filtration efficiencies than previous reported, masks alone will not mitigate the spread of COVID-19 Provide verified filtration efficiency information to the health sectors and general public to encourage physical distancing and mask wearing |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freeman, C.; Burch, R.; Strawderman, L.; Black, C.; Saucier, D.; Rickert, J.; Wilson, J.; Bealor, S.A.; Ratledge, M.; Fava, S.; et al. Preliminary Evaluation of Filtration Efficiency and Differential Pressure ASTM F3502 Testing Methods of Non-Medical Masks Using a Face Filtration Mount. Int. J. Environ. Res. Public Health 2021, 18, 4124. https://doi.org/10.3390/ijerph18084124

Freeman C, Burch R, Strawderman L, Black C, Saucier D, Rickert J, Wilson J, Bealor SA, Ratledge M, Fava S, et al. Preliminary Evaluation of Filtration Efficiency and Differential Pressure ASTM F3502 Testing Methods of Non-Medical Masks Using a Face Filtration Mount. International Journal of Environmental Research and Public Health. 2021; 18(8):4124. https://doi.org/10.3390/ijerph18084124

Chicago/Turabian StyleFreeman, Charles, Reuben Burch, Lesley Strawderman, Catherine Black, David Saucier, Jaime Rickert, John Wilson, Sarah Ashley Bealor, Madison Ratledge, Sydney Fava, and et al. 2021. "Preliminary Evaluation of Filtration Efficiency and Differential Pressure ASTM F3502 Testing Methods of Non-Medical Masks Using a Face Filtration Mount" International Journal of Environmental Research and Public Health 18, no. 8: 4124. https://doi.org/10.3390/ijerph18084124

APA StyleFreeman, C., Burch, R., Strawderman, L., Black, C., Saucier, D., Rickert, J., Wilson, J., Bealor, S. A., Ratledge, M., Fava, S., Smith, B., Waggoner, C., Taylor, C., Nichols, A., Skaggs, G., & Callans, T. (2021). Preliminary Evaluation of Filtration Efficiency and Differential Pressure ASTM F3502 Testing Methods of Non-Medical Masks Using a Face Filtration Mount. International Journal of Environmental Research and Public Health, 18(8), 4124. https://doi.org/10.3390/ijerph18084124