The Effects of a Passive Exoskeleton on Human Thermal Responses in Temperate and Cold Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. Participants

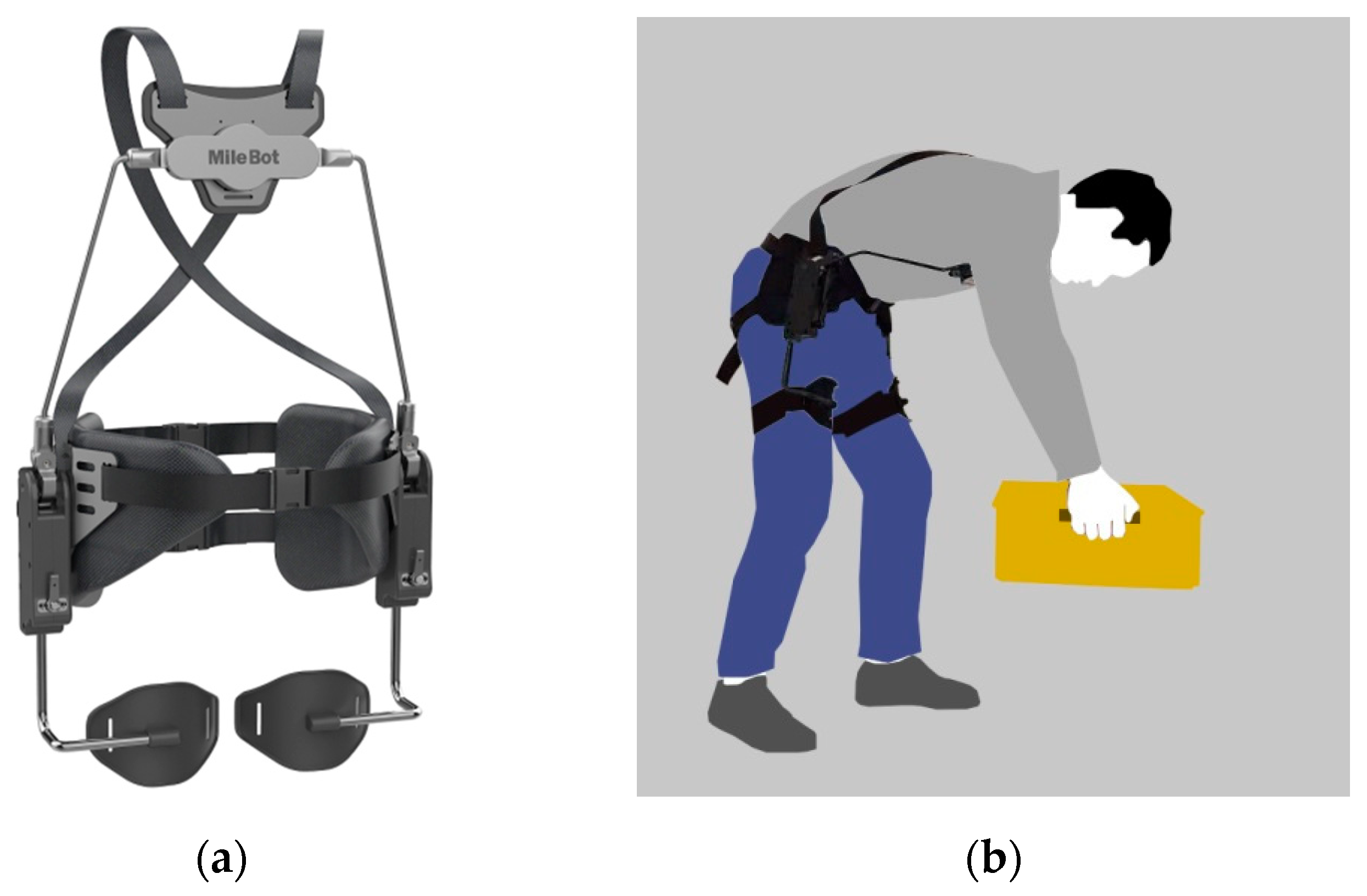

2.2. Passive Exoskeleton

2.3. Experimental Design

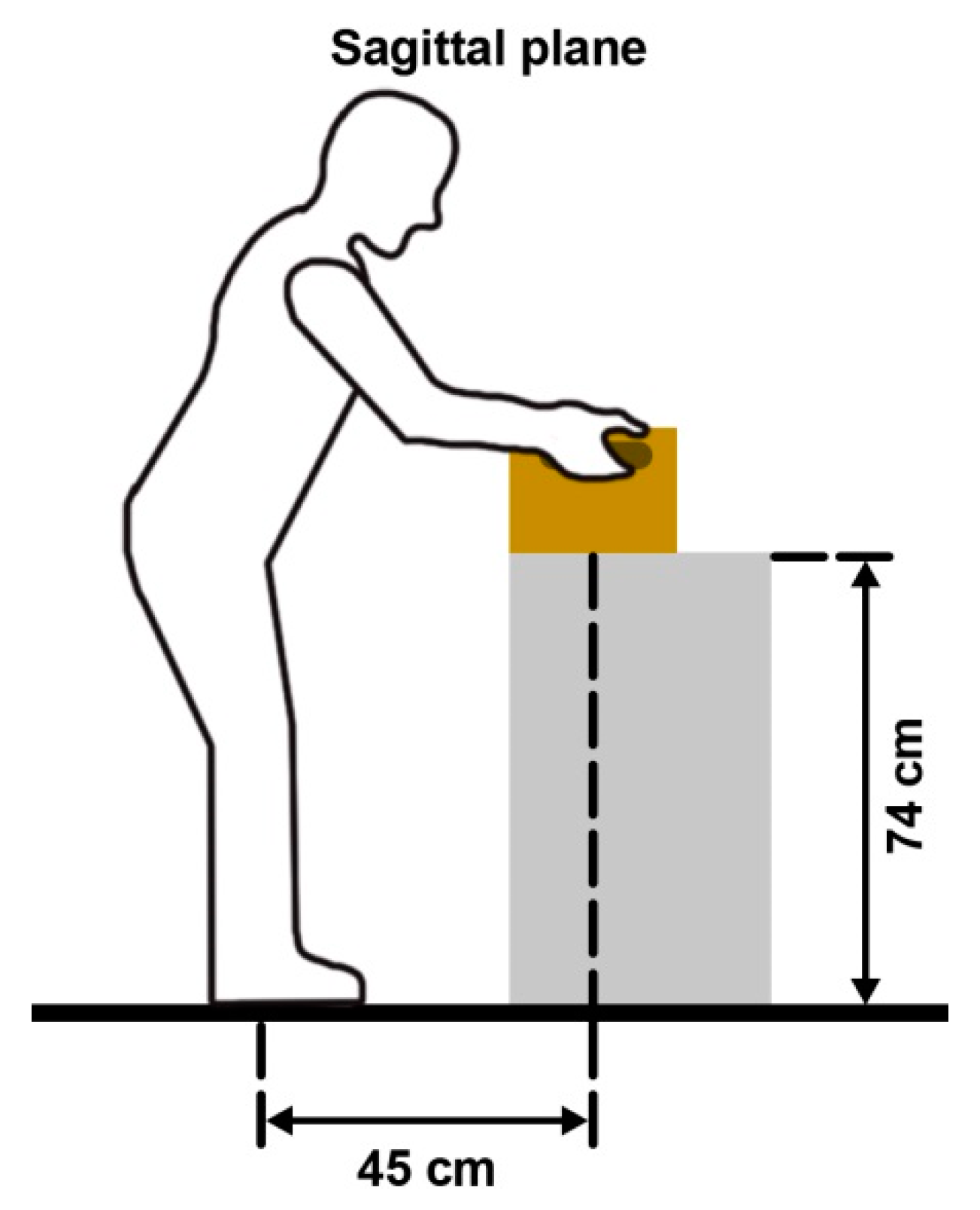

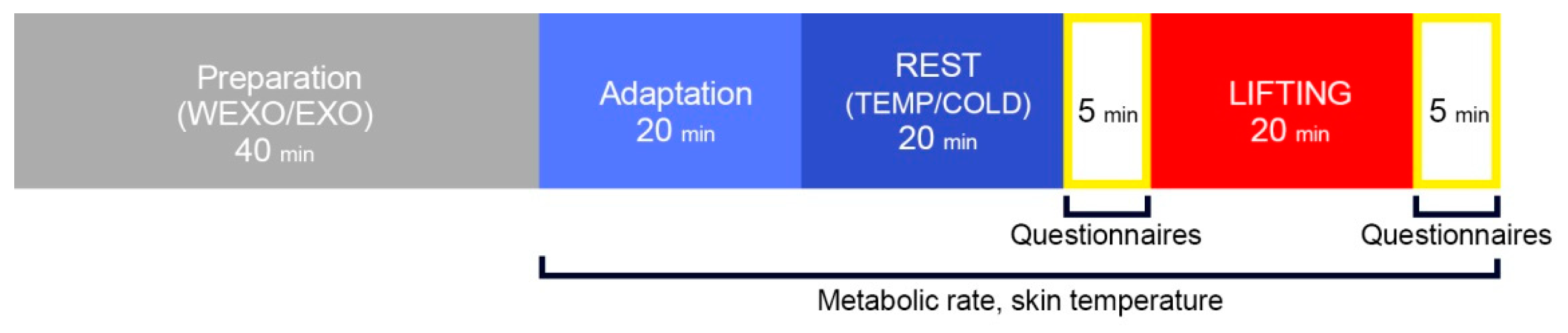

2.4. Procedure

2.5. Physiological and Subjective Measurements

2.5.1. Metabolic Rate

2.5.2. Mean Skin Temperature (MST)

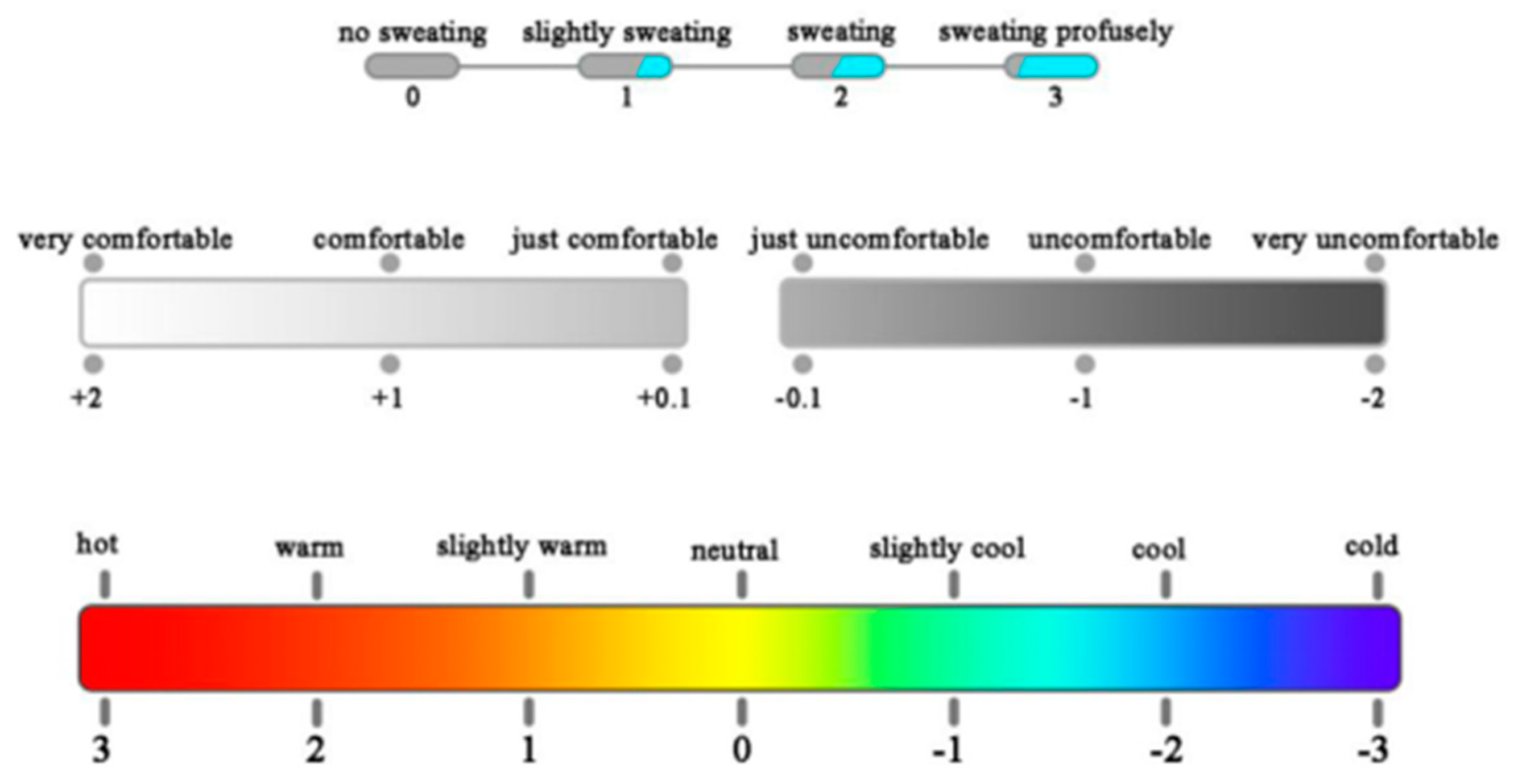

2.5.3. Questionnaires Survey

2.5.4. Statistical Method

3. Results

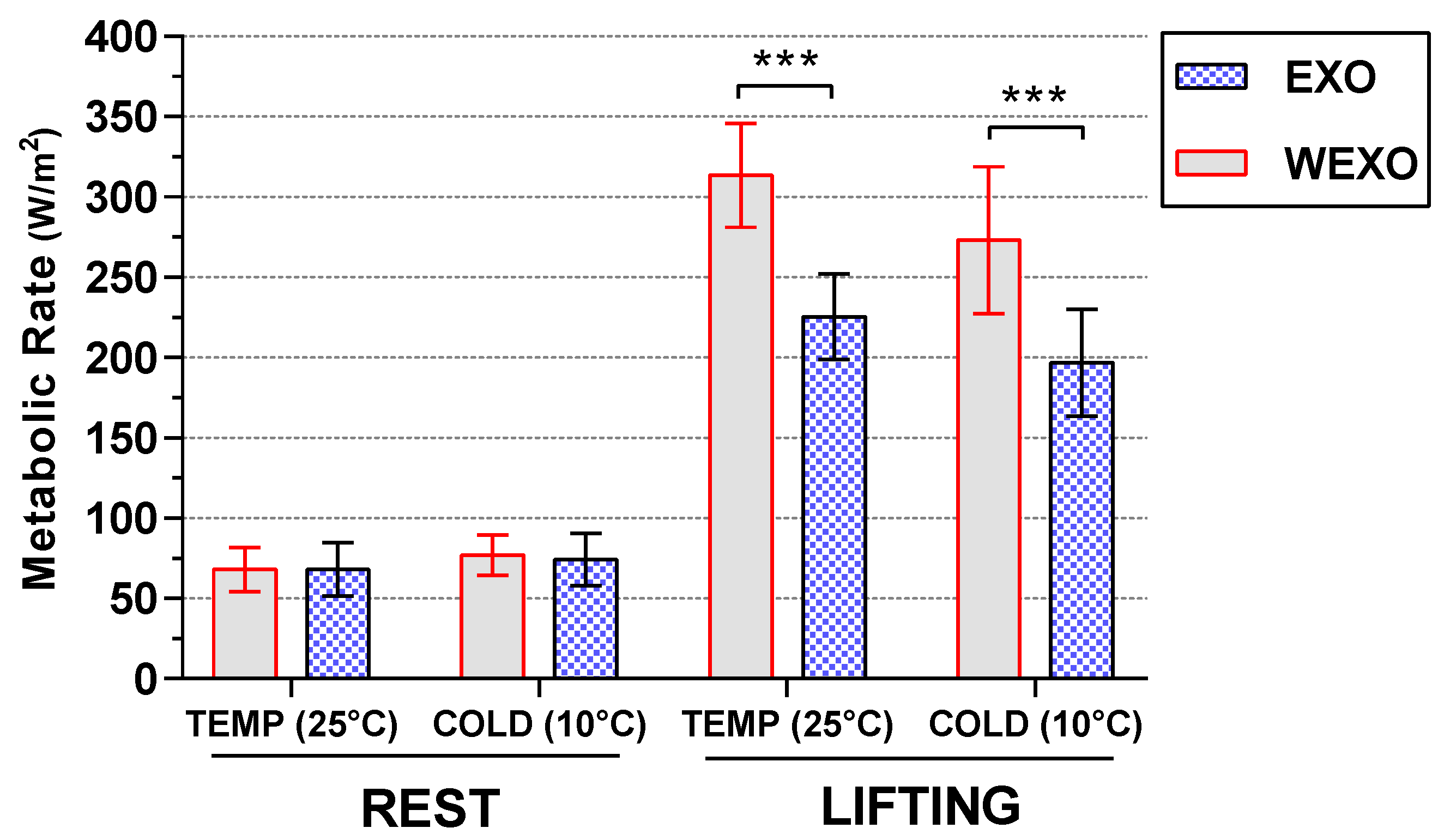

3.1. Results of Metabolic Rate

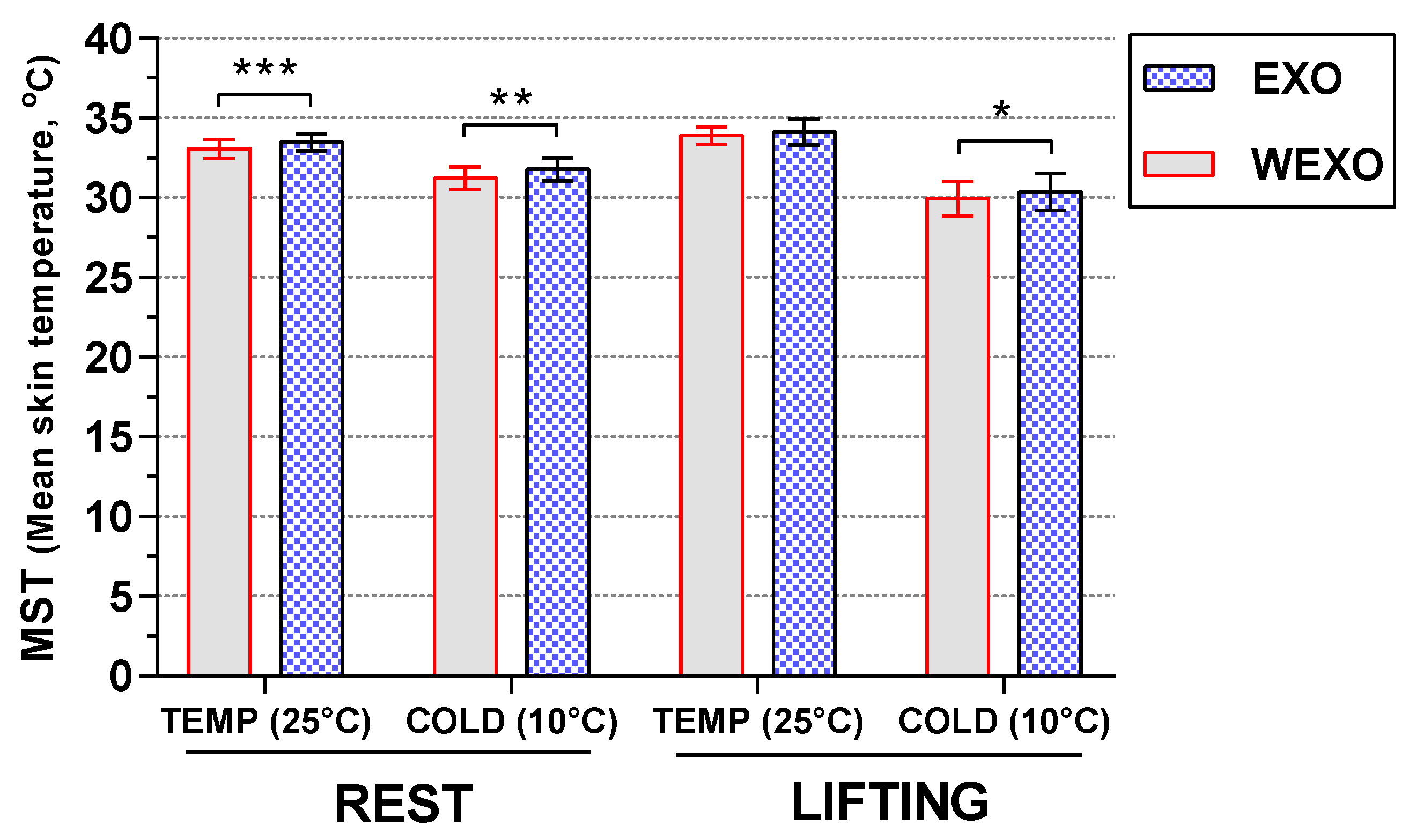

3.2. Results of MST

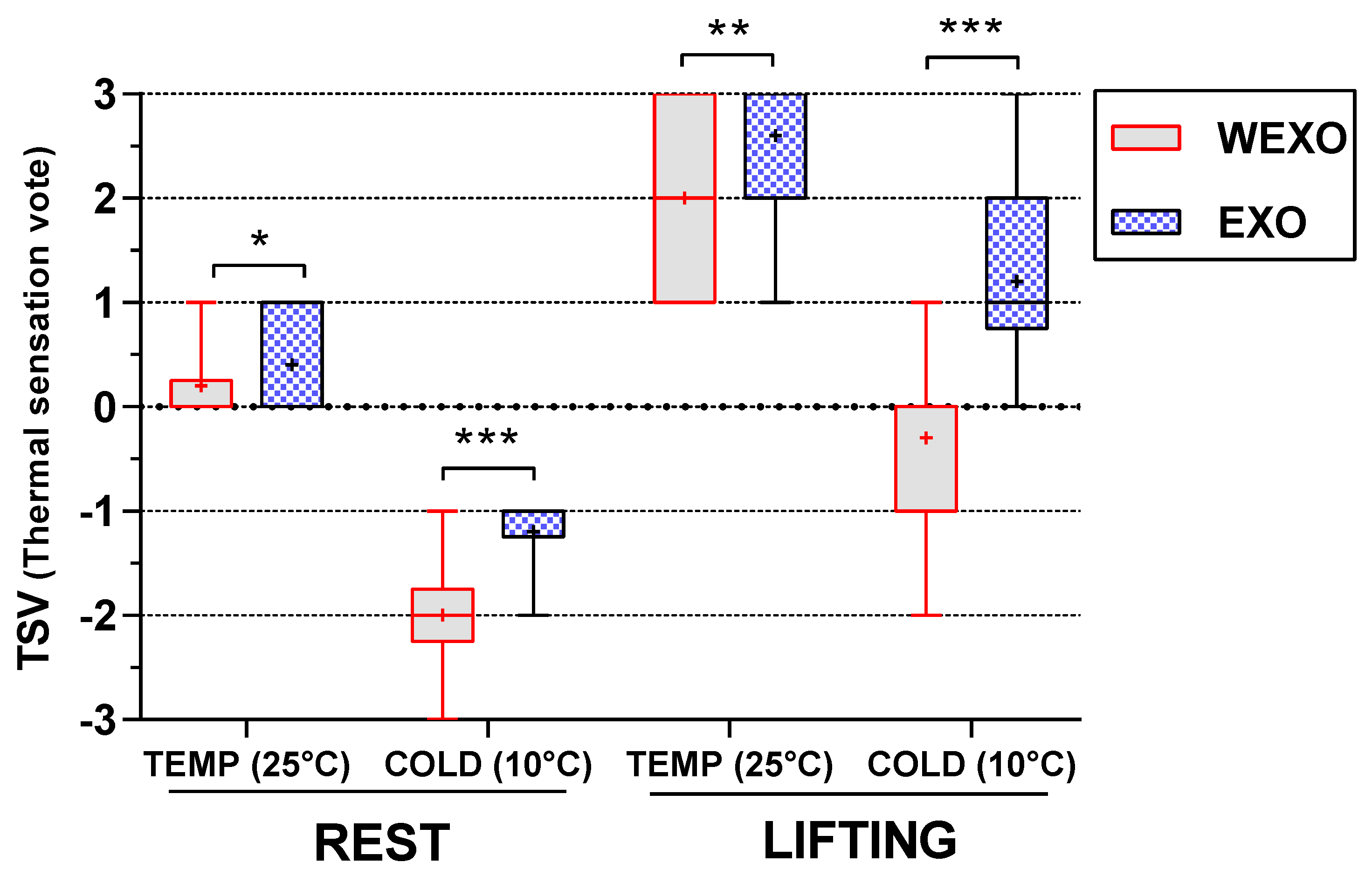

3.3. Results of TSV

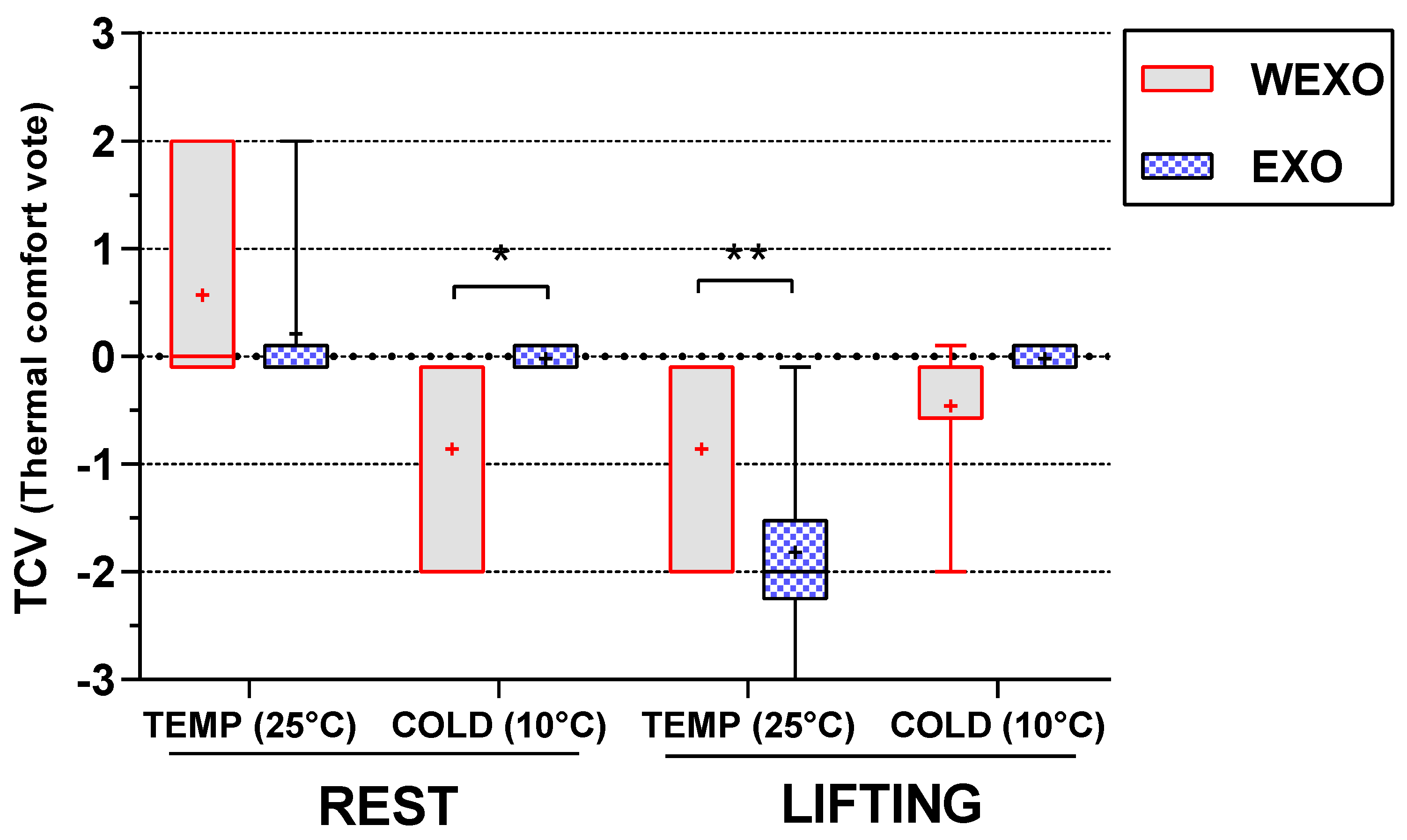

3.4. Results of TCV

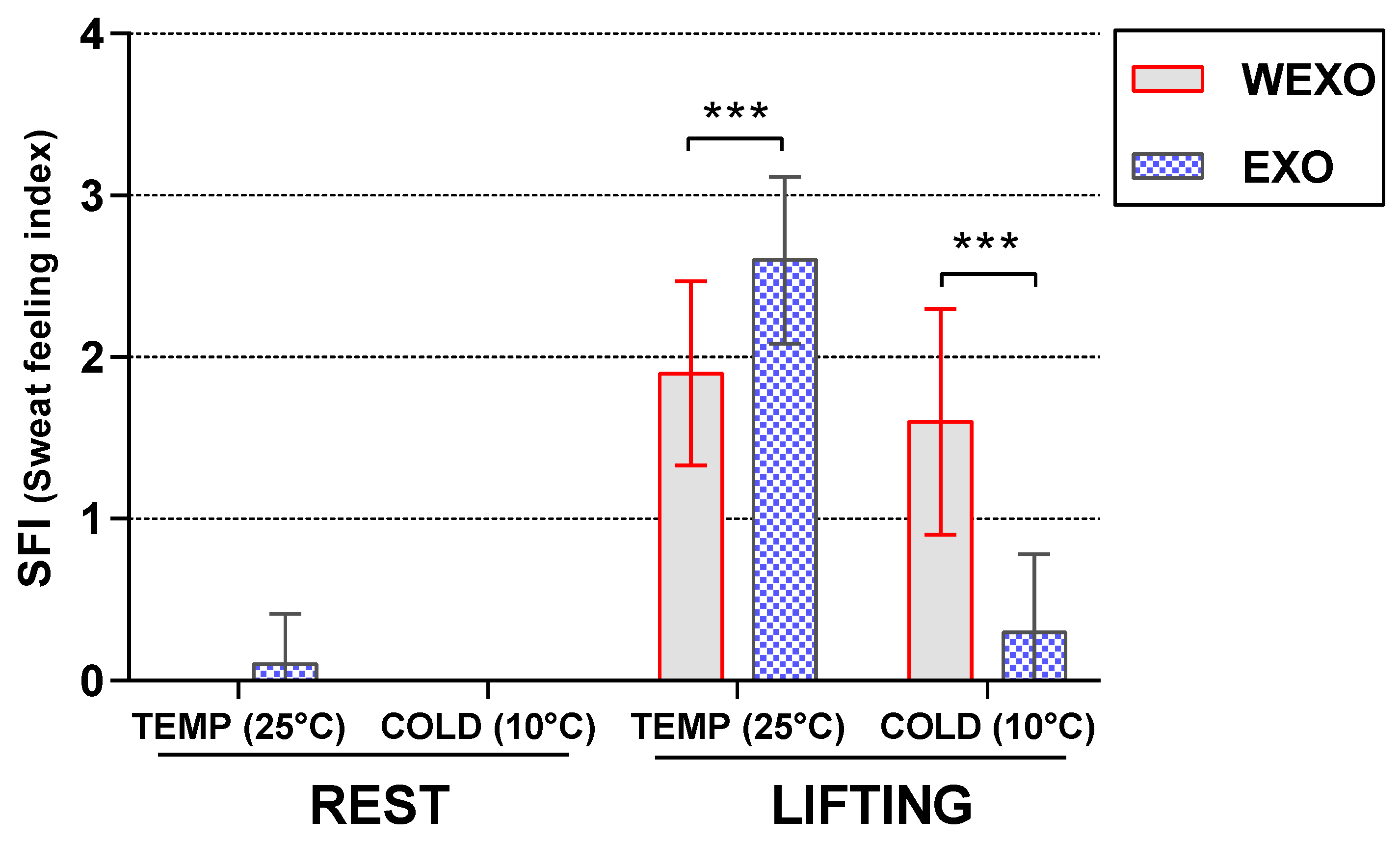

3.5. Results of SFI

4. Discussion

4.1. Effects of Wearing Exoskeleton on Thermal Responses under LIFTING

4.2. Effects of Wearing an Exoskeleton on Thermal Responses under REST

4.3. Limitations and Future Works

5. Conclusions

- Compared to without an exoskeleton, wearing an exoskeleton reduced work metabolic heat production in both hot and cold environments. Metabolic rates slightly increased when wearing the exoskeleton under REST, but the effect was not significant.

- LIFTING in TEMP was observed have a higher metabolic rate than COLD under both WEXO and EXO. Under REST, the metabolic rate in COLD was higher than TEMP, but it was not significant.

- For the LIFTING task, using the exoskeleton in TEMP increased the MST, sweating and thermal sensation, thereby increasing the human thermal discomfort. However, in the COLD environment, the thermal comfort and sweating was significantly improved by wearing the exoskeleton.

- For REST, the MST and thermal sensation in both environments were significantly improved by wearing an exoskeleton, whereas the improving effect of wearing an exoskeleton on thermal comfort was only observed in the cold environment.

- In addition to the support function, the increase in local clothing insulation is one of the key factors affecting thermal responses. Wearing an exoskeleton causes a reduction of the “pumping effect” during work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| WEXO | EXO | |||||||

|---|---|---|---|---|---|---|---|---|

| REST | LIFT | REST | LIFT | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| TEMP | 68.08 | 13.90 | 313.49 | 32.31 | 68.08 | 16.61 | 225.53 | 26.53 |

| COLD | 77.14 | 12.49 | 273.15 | 45.80 | 74.32 | 16.02 | 196.73 | 33.39 |

| WEXO | EXO | |||||||

|---|---|---|---|---|---|---|---|---|

| REST | LIFT | REST | LIFT | |||||

| Mean (°C) | SD | Mean (°C) | SD | Mean (°C) | SD | Mean (°C) | SD | |

| TEMP | 33.07 | 0.59 | 33.87 | 0.53 | 33.48 | 0.53 | 34.13 | 0.80 |

| COLD | 31.22 | 0.70 | 29.95 | 1.06 | 31.78 | 0.73 | 30.37 | 1.15 |

| WEXO | EXO | |||||||

|---|---|---|---|---|---|---|---|---|

| REST | LIFT | REST | LIFT | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| TEMP | 0.20 | 0.42 | 2.00 | 0.82 | 0.70 | 0.48 | 2.60 | 0.70 |

| COLD | −2.00 | 0.67 | −0.30 | 0.82 | −1.20 | 0.42 | 1.20 | 0.92 |

| WEXO | EXO | |||||||

|---|---|---|---|---|---|---|---|---|

| REST | LIFT | REST | LIFT | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| TEMP | 0.57 | 0.99 | −0.86 | 0.98 | 0.21 | 0.64 | −1.82 | 0.99 |

| COLD | −0.86 | 0.98 | −0.46 | 0.81 | −0.02 | 0.10 | −0.02 | 0.10 |

| WEXO | EXO | |||||||

|---|---|---|---|---|---|---|---|---|

| REST | LIFT | REST | LIFT | |||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| TEMP | 0.00 | 0.00 | 1.90 | 0.57 | 0.10 | 0.32 | 2.60 | 0.52 |

| COLD | 0.00 | 0.00 | 1.60 | 0.70 | 0.00 | 0.00 | 0.30 | 0.48 |

References

- Davis, M.A.; Onega, T.; Weeks, W.B.; Lurie, J.D. Where the united states spends its spine dollars expenditures on different ambulatory services for the management of back and neck conditions. Spine 2012, 37, 1693–1701. [Google Scholar] [CrossRef] [PubMed]

- Smets, M. A field evaluation of arm-support exoskeletons for overhead work applications in automotive assembly. Iise Trans. Occup. Ergon. Hum. Factors 2019, 7, 192–198. [Google Scholar] [CrossRef]

- Toxiri, S.; Naf, M.B.; Lazzaroni, M.; Fernandez, J.; Sposito, M.; Poliero, T.; Monica, L.; Anastasi, S.; Caldwell, D.G.; Ortiz, J. Back-support exoskeletons for occupational use: An overview of technological advances and trends. Iise Trans. Occup. Ergon. Hum. Factors 2019, 7, 237–249. [Google Scholar] [CrossRef]

- Schmalz, T.; Schaendlinger, J.; Schuler, M.; Bornmann, J.; Schirrmeister, B.; Kannenberg, A.; Ernst, M. Biomechanical and metabolic effectiveness of an industrial exoskeleton for overhead work. Int. J. Environ. Res. Public Health 2019, 16, 4792. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; van Dieen, J.H.; Koopman, A.S.; Naf, M.B.; Rodriguez-Guerrero, C.; Babic, J.; Houdijk, H. Spexor passive spinal exoskeleton decreases metabolic cost during symmetric repetitive lifting. Eur. J. Appl. Physiol. 2020, 120, 401–412. [Google Scholar] [CrossRef]

- Troster, M.; Wagner, D.; Muller-Graf, F.; Maufroy, C.; Schneider, U.; Bauernhansl, T. Biomechanical model-based development of an active occupational upper-limb exoskeleton to support healthcare workers in the surgery waiting room. Int. J. Environ. Res. Public Health 2020, 17, 5140. [Google Scholar] [CrossRef]

- Cachon, G.; Gallino, S.; Olivares, M. Severe weather and automobile assembly productivity. SSRN Electron. J. 2012. [Google Scholar] [CrossRef]

- Du, C.; Li, B.; Li, Y.; Xu, M.; Yao, R. Modification of the predicted heat strain (phs) model in predicting human thermal responses for chinese workers in hot environments. Build. Environ. 2019, 165, 106349. [Google Scholar] [CrossRef]

- Bortkiewicz, A.; Gadzicka, E.; Szymczak, W.; Szyjkowska, A.; Koszada-Wlodarczyk, W.; Makowiec-Dabrowska, T. Physiological reaction to work in cold microclimate. Int. J. Occup. Med. Environ. Health 2006, 19, 123–131. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE). Standard 55–2013. In Thermal Environmental Conditions for Human Occupancy; ASHRAE Inc.: Atlanta, GA, USA, 2013. [Google Scholar]

- Yang, J.; Weng, W.; Zhang, B. Experimental and numerical study of physiological responses in hot environments. J. Therm. Biol. 2014, 45, 54–61. [Google Scholar] [CrossRef]

- Flouris, A.D.; Schlader, Z.J. Human behavioral thermoregulation during exercise in the heat. Scand. J. Med. Sci. Sports 2015, 25, 52–64. [Google Scholar] [CrossRef] [PubMed]

- Johnson, J.M. Exercise in a hot environment: The skin circulation. Scand. J. Med. Sci. Sports 2010, 20, 29–39. [Google Scholar] [CrossRef] [PubMed]

- Gagge, A.P.; Stolwijk, J.A.; Saltin, B. Comfort and thermal sensations and associated physiological responses during exercise at various ambient temperatures. Environ. Res. 1969, 2, 209–229. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, R.; Li, Y.; Miao, Y.; Zhao, J. Human thermal sensation and comfort in a non-uniform environment with personalized heating. Sci. Total Environ. 2017, 578, 242–248. [Google Scholar] [CrossRef]

- Yang, L.; Gao, S.; Zhao, S.; Zhang, H.; Arens, E.; Zhai, Y. Thermal comfort and physiological responses with standing and treadmill workstations in summer. Build. Environ. 2020, 185, 107238. [Google Scholar] [CrossRef]

- Schlader, Z.J.; Simmons, S.E.; Stannard, S.R.; Muendel, T. Skin temperature as a thermal controller of exercise intensity. Eur. J. Appl. Physiol. 2011, 111, 1631–1639. [Google Scholar] [CrossRef] [PubMed]

- Anderson, G.S. Human morphology and temperature regulation. Int. J. Biometeorol. 1999, 43, 99–109. [Google Scholar] [CrossRef]

- Castellani, J.W.; Young, A.J. Human physiological responses to cold exposure: Acute responses and acclimatization to prolonged exposure. Auton. Neurosci. Basic Clin. 2016, 196, 63–74. [Google Scholar] [CrossRef]

- Ugursal, A.; Culp, C. Gender differences of thermal comfort perception undertransient environmental and metabolic conditions. Ashrae Trans. 2013, 119, 52–62. [Google Scholar]

- Al-Bouwarthan, M.; Quinn, M.M.; Kriebel, D.; Wegman, D.H. Risk of kidney injury among construction workers exposed to heat stress: A longitudinal study from saudi arabia. Int. J. Environ. Res. Public Health 2020, 17, 3775. [Google Scholar] [CrossRef]

- Wagoner, R.S.; López-Gálvez, N.I.; de Zapien, J.G.; Griffin, S.C.; Canales, R.A.; Beamer, P.I. An occupational heat stress and hydration assessment of agricultural workers in north mexico. Int. J. Environ. Res. Public Health 2020, 17, 2102. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, P.S.; Gite, L.P. Evaluation of work-rest schedules during operation of a rotary power tiller. Int. J. Ind. Ergon. 2006, 36, 203–210. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, N.; Lv, S. Human response and productivity in hot environments with directed thermal radiation. Build. Environ. 2021, 187, 107408. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, X.; Zheng, Z.; Oladokun, M.O.; Fang, Z. Experimental investigation into the effects of different metabolic rates of body movement on thermal comfort. Build. Environ. 2020, 168, 106489. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A.P.C. Optimizing work-rest schedule for construction rebar workers in hot and humid environment. Build. Environ. 2013, 61, 104–113. [Google Scholar] [CrossRef]

- Ji, X.; Wang, D.; Li, P.; Zheng, L.; Sun, J.; Wu, X. Siat-wexv2: A wearable exoskeleton for reducing lumbar load during lifting tasks. Complexity 2020, 2020, 8849427. [Google Scholar] [CrossRef]

- Wei, W.; Zha, S.J.; Xia, Y.X.; Gu, J.H.; Lin, X.C. A hip active assisted exoskeleton that assists the semi-squat lifting. Appl. Sci. Basel 2020, 10, 2424. [Google Scholar] [CrossRef]

- Koopman, A.S.; Kingma, I.; Faber, G.S.; de Looze, M.P.; van Dieen, J.H. Effects of a passive exoskeleton on the mechanical loading of the low back in static holding tasks. J. Biomech. 2019, 83, 97–103. [Google Scholar] [CrossRef]

- Qu, X.; Qu, C.; Ma, T.; Yin, P.; Zhao, N.; Xia, Y.; Qu, S. Effects of an industrial passive assistive exoskeleton on muscle activity, oxygen consumption and subjective responses during lifting tasks. PLoS ONE 2021, 16, e0245629. [Google Scholar] [CrossRef]

- Huysamen, K.; Bosch, T.; de Looze, M.; Stadler, K.S.; Graf, E.; O’Sullivan, L.W. Evaluation of a passive exoskeleton for static upper limb activities. Appl. Ergon. 2018, 70, 148–155. [Google Scholar] [CrossRef]

- Makinen, T.M.; Palinkas, L.A.; Reeves, D.L.; Paakkonen, T.; Rintamaki, H.; Leppaluoto, J.; Hassi, J. Effect of repeated exposures to cold on cognitive performance in humans. Physiol. Behav. 2006, 87, 166–176. [Google Scholar] [CrossRef] [PubMed]

- Tirloni, A.S.; dos Reis, D.C.; Dias, N.F.; Moro, A.R.P. The use of personal protective equipment: Finger temperatures and thermal sensation of workers’ exposure to cold environment. Int. J. Environ. Res. Public Health 2018, 15, 2583. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Li, N.; Zhou, L.; Wang, K.; Zhang, W. Thermal comfort and energy consumption in cold environment with retrofitted huotong (warm-barrel). Build. Environ. 2017, 112, 285–295. [Google Scholar] [CrossRef]

- Wang, H.; Xu, M.; Bian, C. Experimental comparison of local direct heating to improve thermal comfort of workers. Build. Environ. 2020, 177, 106884. [Google Scholar] [CrossRef]

- AENOR. Ergonomics of the Thermal Environment-Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria (UNE-EN ISO 7730:2005); AENOR: Madrid, Spain, 2006. [Google Scholar]

- Young, A.J.; O’Brien, C.; Sawka, M.N.; Gonzalez, R.R. Physiological problems associated with wearing nbc protective clothing during cold weather. Aviat. Space Environ. Med. 2000, 71, 184–189. [Google Scholar] [PubMed]

- Triolo, E.R.; Stella, M.H.; BuSha, B.F. A force augmenting exoskeleton for the human hand designed for pinching and grasping. In Proceedings of the 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 17–22 July 2018; Volume 2018, pp. 1875–1878. [Google Scholar]

- Pan, C.-T.; Chang, C.-C.; Sun, P.-Y.; Lee, C.-L.; Lin, T.-C.; Yen, C.-K.; Yang, Y.-S. Development of multi-axis motor control systems for lower limb robotic exoskeleton. J. Med. Biol. Eng. 2019, 39, 752–763. [Google Scholar] [CrossRef]

- Bougrinat, Y.; Achiche, S.; Raison, M. Design and development of a lightweight ankle exoskeleton for human walking augmentation. Mechatronics 2019, 64, 102297. [Google Scholar] [CrossRef]

- Liu, Z.-h.; Qiu, Y.-x.; Zhu, Z.-h.; Zhou, Y.-w.; Tang, Z. Effects of memory foam on optimizing shoulder fatigue of wearable exoskeleton. J. Donghua Univ. 2016, 33, 536–539. [Google Scholar]

- Peng, L.; Su, B.; Yu, A.; Jiang, X. Review of clothing for thermal management with advanced materials. Cellulose 2019, 26, 6415–6448. [Google Scholar] [CrossRef]

- Zhang, Y.; Cong, H. Development and performance of coffee carbon fiber weft knitted fabric. J. Text. Res. 2013, 34, 39–43. [Google Scholar]

- Morrissey, M.P.; Rossi, R.M. Recent developments in reflective cold protective clothing. Int. J. Cloth. Sci. Technol. 2015, 27, 17–22. [Google Scholar] [CrossRef]

- Huang, Z.; Cheng, B.; Gou, Z.; Zhang, F. Outdoor thermal comfort and adaptive behaviors in a university campus in china’s hot summer-cold winter climate region. Build. Environ. 2019, 165, 106414. [Google Scholar] [CrossRef]

- Waters, T.R.; Putzanderson, V.; Garg, A.; Fine, L.J. Revised niosh equation for the design and evaluation of manual lifting tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef] [PubMed]

- Miyachi, M.; Yamamoto, K.; Ohkawara, K.; Tanaka, S. Mets in adults while playing active video games: A metabolic chamber study. Med. Sci. Sports Exerc. 2010, 42, 1149–1153. [Google Scholar] [CrossRef] [PubMed]

- Goto, T.; Toftum, J.; de Dear, R.; Fanger, P.O. Thermal sensation and thermophysiological responses to metabolic step-changes. Int. J. Biometeorol. 2006, 50, 323–332. [Google Scholar] [CrossRef] [PubMed]

- Nishi, Y. Measurement of thermal balance of man. Stud. Environ. Sci. 1981, 10, 29–39. [Google Scholar]

- Luo, M.H.; Zhou, X.; Zhu, Y.X.; Sundell, J. Revisiting an overlooked parameter in thermal comfort studies, the metabolic rate. Energy Build. 2016, 118, 152–159. [Google Scholar] [CrossRef]

- Nishi, Y.; Gagge, A.P. Direct evaluation of convective heat transfer coefficient by naphthalene sublimation. J. Appl. Physiol. 1970, 29, 830–838. [Google Scholar] [CrossRef]

- Gallagher, S.; Marras, W.S. Tolerance of the lumbar spine to shear: A review and recommended exposure limits. Clin. Biomech. 2012, 27, 973–978. [Google Scholar] [CrossRef]

- Schlader, Z.J.; Stannard, S.R.; Muendel, T. Evidence for thermoregulatory behavior during self-paced exercise in the heat. J. Therm. Biol. 2011, 36, 390–396. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhao, S.; Yang, L.; Wei, N.; Xu, Q.; Zhang, H.; Arens, E. Transient human thermophysiological and comfort responses indoors after simulated summer commutes. Build. Environ. 2019, 157, 257–267. [Google Scholar] [CrossRef]

- Havenith, G.; Heus, R.; Lotens, W.A. Resultant clothing insulation—A function of body movement, posture, wind, clothing fit and ensemble thickness. Ergonomics 1990, 33, 67–84. [Google Scholar] [CrossRef]

- Byrne, J.; Ludington-Hoe, S.M.; Voss, J.G. Occupational heat stress, thermal comfort, and cognitive performance in the or: An integrative review. Aorn J. 2020, 111, 536–545. [Google Scholar] [CrossRef]

- Bakkevig, M.K.; Nielsen, R. Impact of wet underwear on thermoregulatory responses and thermal comfort in the cold. Ergonomics 1994, 37, 1375–1389. [Google Scholar] [CrossRef] [PubMed]

- Bakkevig, M.K.; Nielsen, R. The impact of activity level on sweat accumulation and thermal comfort using different underwear. Ergonomics 1995, 38, 926–939. [Google Scholar] [CrossRef] [PubMed]

- Pascoe, D.D.; Shanley, L.A.; Smith, E.W. Clothing and exercise.1. Biophysics of heat-transfer between the individual, clothing and environment. Sports Med. 1994, 18, 38–54. [Google Scholar] [CrossRef]

- Schmidt, D.; Schlee, G.; Milani, T.L.; Germano, A.M.C. Thermal sensitivity mapping—Warmth and cold detection thresholds of the human torso. J. Therm. Biol. 2020, 93, 102718. [Google Scholar] [CrossRef]

- Gerrett, N.; Ouzzahra, Y.; Coleby, S.; Hobbs, S.; Redortier, B.; Voelcker, T.; Havenith, G. Thermal sensitivity to warmth during rest and exercise: A sex comparison. Eur. J. Appl. Physiol. 2014, 114, 1451–1462. [Google Scholar] [CrossRef]

- Tanaka, M.; Tochihara, Y.; Yamazaki, S.; Ohnaka, T.; Yoshida, K. Thermal-reaction and manual performance during cold-exposure while wearing cold-protective clothing. Ergonomics 1983, 26, 141–149. [Google Scholar] [CrossRef]

- Arens, E.; Zhang, H.; Huizenga, C. Partial- and whole-body thermal sensation and comfort—Part ii: Non-uniform environmental conditions. J. Therm. Biol. 2006, 31, 60–66. [Google Scholar] [CrossRef]

- Rida, M.; Ghaddar, N.; Ghali, K.; Hoballah, J. Elderly bioheat modeling: Changes in physiology, thermoregulation, and blood flow circulation. Int. J. Biometeorol. 2014, 58, 1825–1843. [Google Scholar] [CrossRef] [PubMed]

| Tested Environmental Parameters | TEMP | COLD | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| Indoor air temperature (°C) | 25 | 0.2 | 10.1 | 0.4 |

| Mean radiant temperature (°C) | 25.2 | 0.2 | 10.3 | 0.2 |

| Air velocity (m/s) | <0.1 | <0.1 | ||

| Relative humidity (%) | 50 | 2.7 | 50 | 3.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Li, X.; Lai, J.; Zhu, A.; Zhang, X.; Zheng, Z.; Zhu, H.; Shi, Y.; Wang, L.; Chen, Z. The Effects of a Passive Exoskeleton on Human Thermal Responses in Temperate and Cold Environments. Int. J. Environ. Res. Public Health 2021, 18, 3889. https://doi.org/10.3390/ijerph18083889

Liu Y, Li X, Lai J, Zhu A, Zhang X, Zheng Z, Zhu H, Shi Y, Wang L, Chen Z. The Effects of a Passive Exoskeleton on Human Thermal Responses in Temperate and Cold Environments. International Journal of Environmental Research and Public Health. 2021; 18(8):3889. https://doi.org/10.3390/ijerph18083889

Chicago/Turabian StyleLiu, Yang, Xiaoling Li, Jiarui Lai, Aibin Zhu, Xiaodong Zhang, Ziming Zheng, Huijin Zhu, Yueyang Shi, Long Wang, and Zhangyi Chen. 2021. "The Effects of a Passive Exoskeleton on Human Thermal Responses in Temperate and Cold Environments" International Journal of Environmental Research and Public Health 18, no. 8: 3889. https://doi.org/10.3390/ijerph18083889

APA StyleLiu, Y., Li, X., Lai, J., Zhu, A., Zhang, X., Zheng, Z., Zhu, H., Shi, Y., Wang, L., & Chen, Z. (2021). The Effects of a Passive Exoskeleton on Human Thermal Responses in Temperate and Cold Environments. International Journal of Environmental Research and Public Health, 18(8), 3889. https://doi.org/10.3390/ijerph18083889