Rapid Degradation of Carbon Tetrachloride by Microscale Ag/Fe Bimetallic Particles

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Preparation of Bimetallic Particles

2.3. Batch Reactor Experiments

2.4. Analysis Procedure

3. Results and Discussion

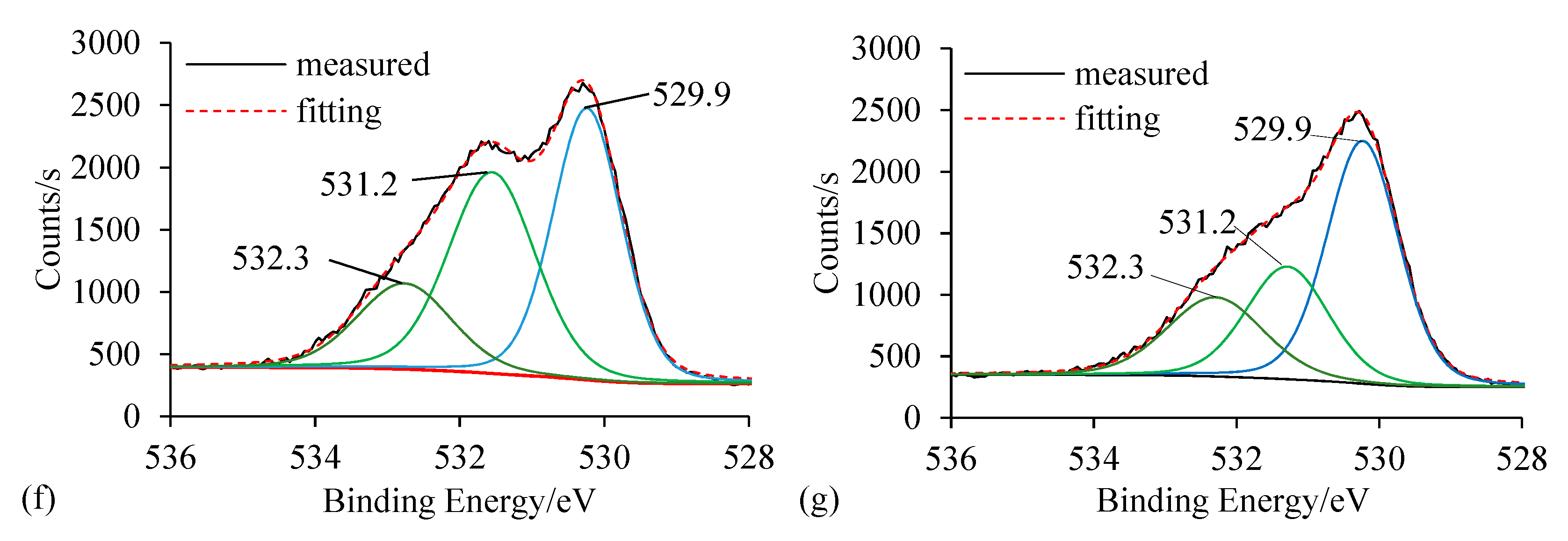

3.1. Characterization of Ag/Fe Particles

3.2. Kinetics of CCl4 Degradation

- (a)

- Direct reduction by ZVI:

- (b)

- Reduction by catalytic hydrogenation:

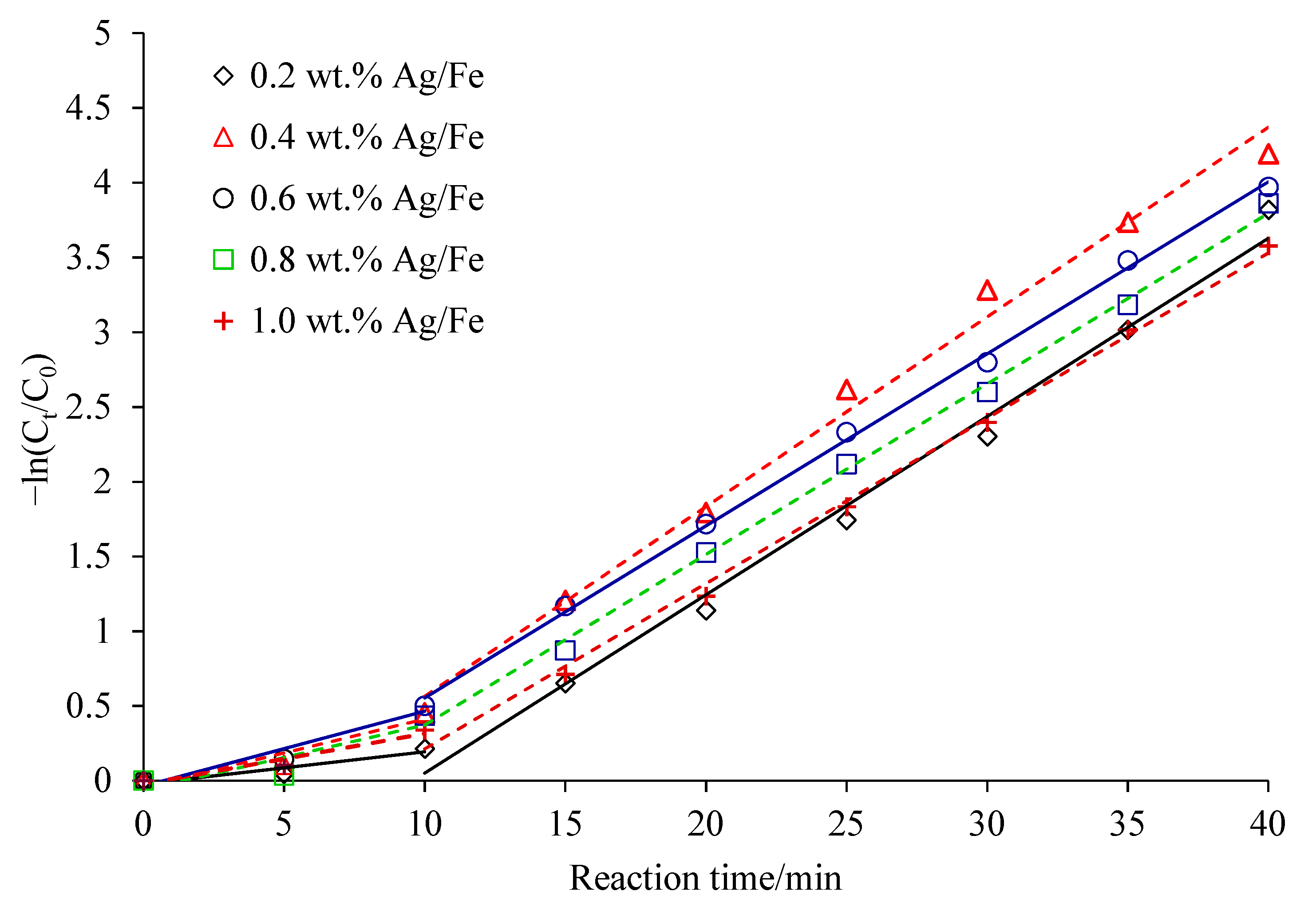

3.3. Factors Affecting CCl4 Degradation with Ag/Fe Bimetallic Particles

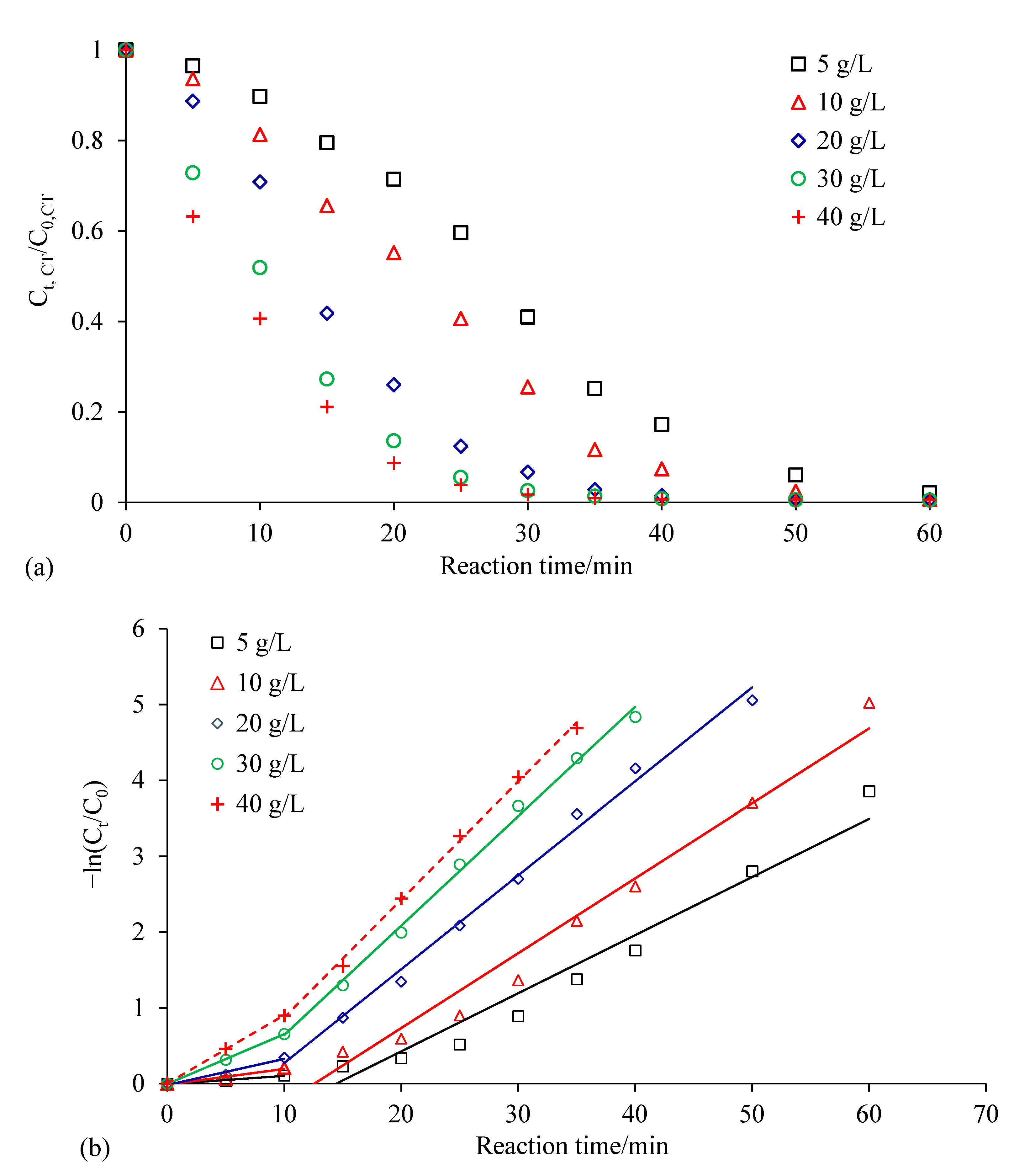

3.3.1. Effect of Ag/Fe Dosage on the CCl4 Degradation

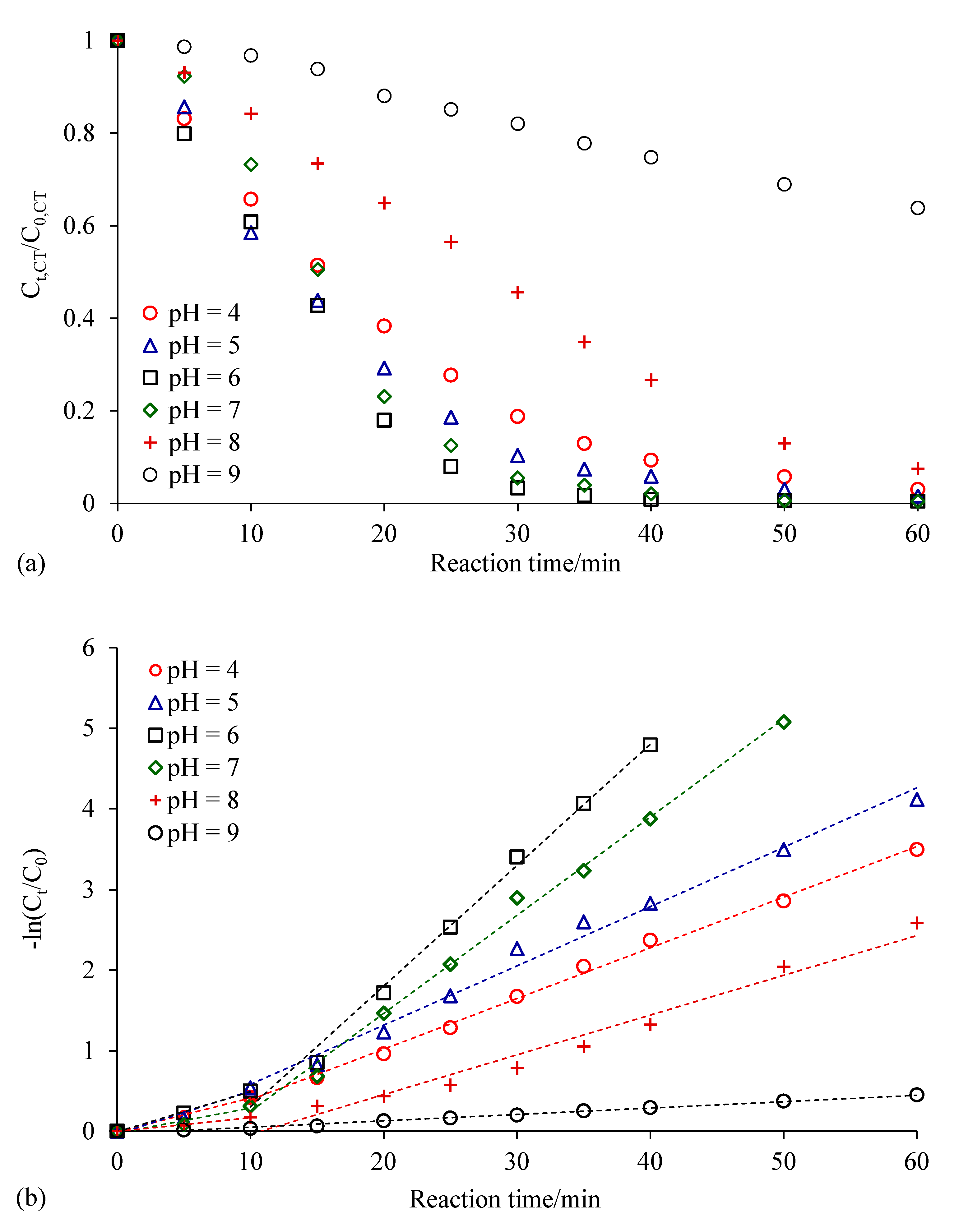

3.3.2. Effect of pH on CCl4 Degradation

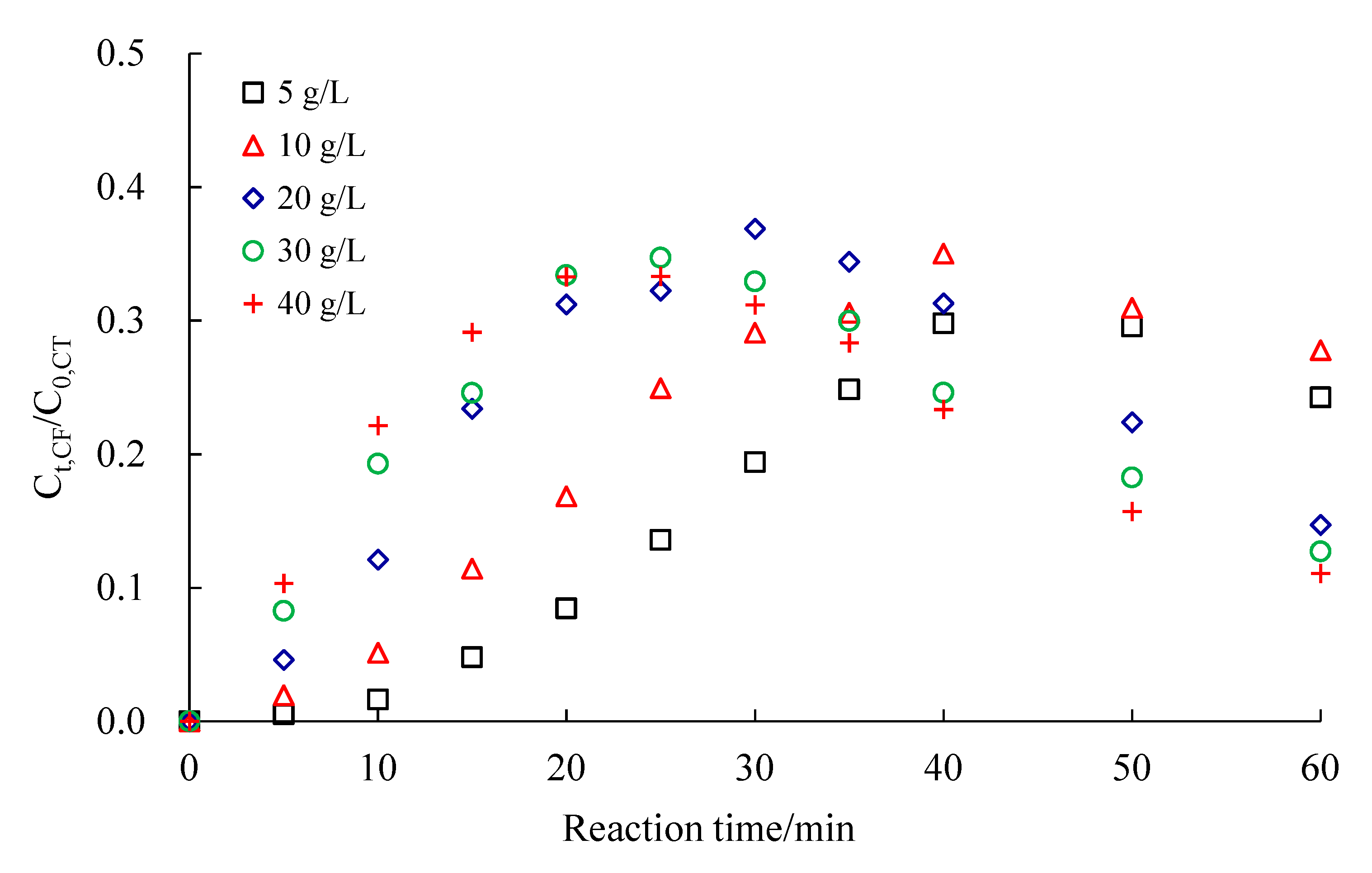

3.3.3. Effect of Humic Acid on CCl4 Degradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Zhao, H.; Zhu, L. Remediation of soil contaminated with organic compounds by nanoscale zero-valent iron: A review. Sci. Total Environ. 2021, 760, 143413. [Google Scholar] [CrossRef]

- Galdames, A.; Ruiz-Rubio, L.; Orueta, M.; Sánchez-Arzalluz, M.; Vilas-Vilela, J.L. Zero-Valent Iron Nanoparticles for Soil and Groundwater Remediation. Int. J. Environ. Res. Public Health 2020, 16, 5817. [Google Scholar] [CrossRef]

- Fang, Y.; Wen, J.; Zeng, G.; Shen, M.; Cao, W.; Gong, J.; Zhang, Y. From nZVI to SNCs: Development of a better material for pollutant removal in water. Environ. Sci. Pollut. Res. 2018, 7, 6175–6195. [Google Scholar] [CrossRef] [PubMed]

- Chaithawiwat, K.; Vangnai, A.; Mcevoy, J.M.; Pruess, B.; Krajangpan, S.; Khan, E. Role of oxidative stress in inactivation of Escherichia coli BW25113 by nanoscale zero-valent iron. Sci. Total Environ. 2016, 565, 857–862. [Google Scholar] [CrossRef]

- Li, G.; Qi, J.; Lv, N.; Qiu, X.; Gu, Y.; Zhao, J.; He, F. Mechanistic role of nitrate anion in TCE dechlorination by ball milled ZVI and sulfidated ZVI: Experimental investigation and theoretical analysis. J. Hazard. Mater. 2021, 403, 123844. [Google Scholar]

- Velimirovic, M.; Larsson, P.O.; Simons, Q.; Bastiaens, L. Reactivity screening of microscale zerovalent irons and iron sulfides towards different CAHs under standardized experimental conditions. J. Hazard. Mater. 2013, 252, 204–212. [Google Scholar] [CrossRef]

- Velimirovic, M.; Carniato, L.; Simons, Q.; Schoups, G.; Seuntjens, P.; Bastiaens, L. Corrosion rate estimations of microscale zerovalent iron particles via direct hydrogen production measurements. J. Hazard. Mater. 2014, 270, 18–26. [Google Scholar] [CrossRef]

- Gastone, F.; Tosco, T.; Sethi, R. Green stabilization of microscale iron particles using guar gum: Bulk rheology, sedimentation rate and enzymatic degradation. J. Colloid Interface Sci. 2014, 421, 33–43. [Google Scholar] [CrossRef]

- Mondino, F.; Piscitello, A.; Bianco, C.; Gallo, A.; de Folly D’Auris, A.; Tosco, T.; Tagliabue, M.; Sethi, R. Injection of zerovalent iron gels for aquifer nanoremediation: Lab experiments and modeling. Water 2020, 3, 826. [Google Scholar] [CrossRef]

- Yamaguchi, R.; Kurosu, S.; Suzuki, M.; Kawase, Y. Hydroxyl radical generation by zero-valent iron/Cu (ZVI/Cu) bimetallic catalyst in wastewater treatment: Heterogeneous Fenton/Fenton-like reactions by Fenton reagents formed in-situ under oxic conditions. Chem. Eng. J. 2018, 334, 1537–1549. [Google Scholar] [CrossRef]

- Huo, X.; Zhou, P.; Liu, Y.; Cheng, F.; Liu, Y.; Cheng, X.; Zhang, Y.; Wang, Q. Removal of contaminants by activating peroxymonosulfate (PMS) using zero valent iron (ZVI)-based bimetallic particles (ZVI/Cu, ZVI/Co, ZVI/Ni, and ZVI/Ag). RSC Adv. 2020, 47, 28232–28242. [Google Scholar] [CrossRef]

- Wang, R.; Tang, T.; Lu, G.; Huang, K.; Yin, H.; Lin, Z.; Wu, F.; Dang, Z. Rapid debromination of polybrominated diphenyl ethers (PBDEs) by zero valent metal and bimetals: Mechanisms and pathways assisted by density function theory calculation. Environ. Pollut. 2018, 240, 745–753. [Google Scholar] [CrossRef]

- Sun, Y.; Li, J.; Huang, T.; Guan, X. The influences of iron characteristics, operating conditions and solution chemistry on contaminants removal by zero-valent iron: A review. Water Res. 2016, 100, 277–295. [Google Scholar] [CrossRef]

- O’Carroll, D.; Sleep, B.; Krol, M.; Boparai, H.; Kocur, C. Nanoscale zero valent iron and bimetallic particles for contaminated site remediation. Adv. Water Resour. 2013, 51, 104–122. [Google Scholar] [CrossRef]

- Zhuang, Y.; Ahn, S.; Seyfferth, A.L.; Masue-Slowey, Y.; Fendorf, S.; Luthy, R.G. Dehalogenation of polybrominated diphenyl ethers and polychlorinated biphenyl by bimetallic, impregnated, and nanoscale zerovalent iron. Environ. Sci. Technol. 2011, 11, 4896–4903. [Google Scholar] [CrossRef]

- Wang, R.; Lu, G.; Lin, H.; Huang, K.; Tang, T.; Xue, X.; Yang, X.; Yin, H.; Dang, Z. Relative roles of H-atom transfer and electron transfer in the debromination of polybrominated diphenyl ethers by palladized nanoscale zerovalent iron. Environ. Pollut. 2017, 222, 331–337. [Google Scholar] [CrossRef]

- Yan, W.; Herzing, A.A.; Li, X.; Kiely, C.J.; Zhang, W.X. Structural evolution of Pd-doped nanoscale zero-valent iron (nZVI) in aqueous media and implications for particle aging and reactivity. Environ. Sci. Technol. 2010, 11, 4288–4294. [Google Scholar] [CrossRef] [PubMed]

- Prieto, P.; Nistor, V.; Nouneh, K.; Oyama, M.; Abd-Lefil, M.; Díaz, R. XPS study of silver, nickel and bimetallic silver–nickel nanoparticles prepared by seed-mediated growth. Appl. Surf. Sci. 2012, 22, 8807–8813. [Google Scholar] [CrossRef]

- Li, X.; Elliott, D.W.; Zhang, W. Zero-valent iron nanoparticles for abatement of environmental pollutants: Materials and engineering aspects. Crit. Rev. Solid State Mater. Sci. 2006, 4, 111–122. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W. Sequestration of metal cations with zerovalent iron nanoparticles a study with high resolution X-ray photoelectron spectroscopy (HR-XPS). J. Phys. Chem. C 2007, 19, 6939–6946. [Google Scholar] [CrossRef]

- Zhu, X.; Han, B.; Feng, Q. Common anions affected removal of carbon tetrachloride in groundwater using granular sponge zerovalent Iron. Water Air Soil Pollut. 2020, 4, 1–13. [Google Scholar] [CrossRef]

- Kim, Y.H.; Carraway, E.R. Dechlorination of chlorinated ethenes and acetylenes by palladized iron. Environ. Technol. 2003, 7, 809–819. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Chen, C.; Chang, Y.; Liu, H. Dechlorination of chlorinated methanes by Pd/Fe bimetallic nanoparticles. J. Hazard. Mater. 2009, 2, 815–823. [Google Scholar] [CrossRef]

- Ju, Y.; Yu, Y.; Wang, X.; Zhang, S.; Liu, R.; Fu, J.; Han, J.; Fang, J.; Dionysiou, D.D. Environmental application of millimetre-scale sponge iron (s-Fe0) particles (III): The effect of surface silver. J. Hazard. Mater. 2015, 299, 618–629. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.; Yang, S.; Wang, X.; Sun, C. Reductive degradation of tetrabromobisphenol A over iron-silver bimetallic nanoparticles under ultrasound radiation. Chemosphere 2010, 79, 672–678. [Google Scholar] [CrossRef] [PubMed]

- Ritter, K.; Odziemkowski, M.S.; Gillham, R.W. An in situ study of the role of surface films on granular iron in the permeable iron wall technology. J. Contam. Hydrol. 2002, 1, 87–111. [Google Scholar] [CrossRef]

- Liu, C.C.; Tseng, D.H.; Wang, C.Y. Effects of ferrous ions on the reductive dechlorination of trichloroethylene by zero-valent iron. J. Hazard. Mater. 2006, 3, 706–713. [Google Scholar] [CrossRef] [PubMed]

- Chaplin, B.P.; Reinhard, M.; Schneider, W.F.; Schüth, C.; Shapley, J.R.; Strathmann, T.J.; Werth, C.J. Critical review of Pd-based catalytic treatment of priority contaminants in water. Environ. Sci. Technol. 2012, 7, 3655–3670. [Google Scholar] [CrossRef]

- Islam, S.; Han, Y.; Yan, W. Reactions of chlorinated ethenes with surface-sulfidated iron materials: Reactivity enhancement and inhibition effects. Environ. Sci. Proc. Imp. 2020, 3, 759–770. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, W.; Peng, P.; Huang, W. Reductive dechlorination of tetrachlorobisphenol A by Pd/Fe bimetallic catalysts. J. Hazard. Mater. 2013, 262, 634–641. [Google Scholar] [CrossRef]

- Tian, H.; Li, J.; Mu, Z.; Hao, Z. Effect of pH on DDT degradation in aqueous solution using bimetallic Ni/Fe nanoparticles. Sep. Purif. Technol. 2009, 66, 84–89. [Google Scholar] [CrossRef]

- Dong, H.; Zhang, C.; Hou, K.; Cheng, Y.; Deng, J.; Jiang, Z.; Tang, L.; Zeng, G. Removal of trichloroethylene by biochar supported nanoscale zero-valent iron in aqueous solution. Sep. Purif. Technol. 2017, 188, 188–196. [Google Scholar] [CrossRef]

- Dong, T.; Luo, H.; Wang, Y.; Hu, B.; Chen, H. Stabilization of Fe-Pd bimetallic nanoparticles with sodium carboxymethyl cellulose for catalytic reduction of para-nitrochlorobenzene in water. Desalination 2011, 271, 11–19. [Google Scholar] [CrossRef]

- Fu, R.; Yang, Y.; Xu, Z.; Zhang, X.; Guo, X.; Bi, D. The removal of chromium (VI) and lead (II) from groundwater using sepiolite-supported nanoscale zero-valent iron (S-NZVI). Chemosphere 2005, 138, 726–734. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Ruan, W.; Huang, H.; Shen, C.; Yuan, B.; Huang, C. Fabrication and characterization of Fe/Ni nanoparticles supported by polystyrene resin for trichloroethylene degradation. Chem. Eng. J. 2016, 283, 730–739. [Google Scholar] [CrossRef]

- Pradhan, G.K.; Parida, K.M. Fabrication, growth mechanism, and characterization of α-Fe2O3 nanorods. ACS Appl. Mater. Interfaces 2011, 2, 317–323. [Google Scholar] [CrossRef]

- Artinger, R.; Buckau, G.; Geyer, S.; Fritz, P.; Wolf, M.; Kim, J.I. Characterization of groundwater humic substances: Influence of sedimentary organic carbon. Appl. Geochem. 2000, 1, 97–116. [Google Scholar] [CrossRef]

- Tratnyek, P.G.; Scherer, M.M.; Deng, B.; Hu, S. Effects of natural organic matter, anthropogenic surfactants, and model quinones on the reduction of contaminants by zero-valent iron. Water Res. 2001, 18, 4435–4443. [Google Scholar] [CrossRef]

- Doong, R.A.; Lai, Y.J. Dechlorination of tetrachloroethylene by palladized iron in the presence of humic acid. Water Res. 2005, 11, 2309–2318. [Google Scholar] [CrossRef]

- Yi, Y.; Wu, J.; Tu, G.; Zhao, D.; Fang, Z.; Tsang, P.E. The humic acid influenced the behavior and reactivity of Ni/Fe nanoparticles in the removal of deca-brominated diphenyl ether from aqueous solution. Environ. Sci. Pollut. Res. 2019, 10, 10136–10147. [Google Scholar] [CrossRef] [PubMed]

| Experiment Set | pH | CCl4 Concentration (µg/L) | Ag/Fe Dosage (g/L) | Ag Loading on Ag/Fe (wt.%) | Humic Acid Concentration (mg/L) |

|---|---|---|---|---|---|

| #1 | 7.0 | 2.0 × 104 | 20 | 0.2, 0.4, 0.6, 0.8, 1.0 | 0 |

| #2 | 7.0 | 2.0 × 104 | 5, 10, 20, 30, 40 | 0.4 | 0 |

| #3 | 4.0, 5.0, 6.0, 7.0, 8.0 | 2.0 × 104 | 20 | 0.4 | 0 |

| #4 | 7.0 | 2.0 × 104 | 20 | 0.4 | 0, 5, 10, 20 |

| Ag Loading | 0.2 wt.% | 0.4 wt.% | 0.6 wt.% | 0.8 wt.% | 1.0 wt.% | |

|---|---|---|---|---|---|---|

| Stage I | Equation | −ln(Ct/C0) = 0.0214t − 0.0204 | −ln(Ct/C0) = 0.0454t − 0.0404 | −ln(Ct/C0) = 0.0501t − 0.0356 | −ln(Ct/C0) = 0.0435t − 0.0612 | −ln(Ct/C0) = 0.0338t − 0.0224 |

| kobs (min−1) | 0.0214 | 0.0454 | 0.0501 | 0.0435 | 0.0338 | |

| R2 | 0.902 | 0.924 | 0.943 | 0.929 | 0.950 | |

| Stage II | Equation | −ln(Ct/C0) = 0.1193t − 1.1412 | −ln(Ct/C0) = 0.1269t − 0.7044 | −ln(Ct/C0) = 0.1151t − 0.5962 | −ln(Ct/C0) = 0.1141t − 0.7679 | −ln(Ct/C0) = 0.1106t − 0.8928 |

| kobs (min−1) | 0.1193 | 0.1269 | 0.1151 | 0.1141 | 0.1106 | |

| R2 | 0.990 | 0.991 | 0.998 | 0.998 | 0.996 | |

| Dosage (g/L) | 5 | 10 | 20 | 30 | 40 | |

|---|---|---|---|---|---|---|

| Stage I | Equation | −ln(Ct/C0) = 0.0109t − 0.0062 | −ln(Ct/C0) = 0.0207t − 0.0126 | −ln(Ct/C0) = 0.0345t − 0.0174 | −ln(Ct/C0) = 0.0656t − 0.0037 | −ln(Ct/C0) = 0.0900t − 0.0092 |

| kobs (min−1) | 0.0109 | 0.0207 | 0.0345 | 0.0656 | 0.0900 | |

| R2 | 0.962 | 0.957 | 0.970 | 0.999 | 0.999 | |

| Stage II | Equation | −ln(Ct/C0) = 0.0767t − 1.1079 | −ln(Ct/C0) = 0.0988t − 1.2418 | −ln(Ct/C0) = 0.1238t − 0.9669 | −ln(Ct/C0) = 0.1443t − 0.8014 | −ln(Ct/C0) = 0.1556t − 0.6848 |

| kobs (min−1) | 0.0767 | 0.0988 | 0.1238 | 0.1443 | 0.1556 | |

| R2 | 0.9521 | 0.971 | 0.993 | 0.996 | 0.998 | |

| Ag/Fe Dosage (g/L) | Ag Dosage (g/L) | kobs (min−1) | kSA1 (L/(minm2)) | kAg2 (L/(minm2)) | R2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Stage I | Stage II | Stage I | Stage II | Stage I | Stage II | Stage I | Stage II | ||

| 5 | 0.02 | 0.0109 | 0.0767 | 0.0234 | 0.1649 | 0.5450 | 3.8350 | 0.9624 | 0.9521 |

| 10 | 0.04 | 0.0207 | 0.0988 | 0.0223 | 0.1062 | 0.5175 | 2.4700 | 0.9575 | 0.971 |

| 20 | 0.08 | 0.0345 | 0.1238 | 0.0185 | 0.0666 | 0.4313 | 1.5475 | 0.9702 | 0.9933 |

| 30 | 0.12 | 0.0656 | 0.1433 | 0.0235 | 0.0514 | 0.5467 | 1.1942 | 0.9996 | 0.996 |

| 40 | 0.16 | 0.0900 | 0.1556 | 0.0242 | 0.0418 | 0.5625 | 0.9725 | 0.9999 | 0.9978 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Zhou, L.; Li, Y.; Han, B.; Feng, Q. Rapid Degradation of Carbon Tetrachloride by Microscale Ag/Fe Bimetallic Particles. Int. J. Environ. Res. Public Health 2021, 18, 2124. https://doi.org/10.3390/ijerph18042124

Zhu X, Zhou L, Li Y, Han B, Feng Q. Rapid Degradation of Carbon Tetrachloride by Microscale Ag/Fe Bimetallic Particles. International Journal of Environmental Research and Public Health. 2021; 18(4):2124. https://doi.org/10.3390/ijerph18042124

Chicago/Turabian StyleZhu, Xueqiang, Lai Zhou, Yuncong Li, Baoping Han, and Qiyan Feng. 2021. "Rapid Degradation of Carbon Tetrachloride by Microscale Ag/Fe Bimetallic Particles" International Journal of Environmental Research and Public Health 18, no. 4: 2124. https://doi.org/10.3390/ijerph18042124

APA StyleZhu, X., Zhou, L., Li, Y., Han, B., & Feng, Q. (2021). Rapid Degradation of Carbon Tetrachloride by Microscale Ag/Fe Bimetallic Particles. International Journal of Environmental Research and Public Health, 18(4), 2124. https://doi.org/10.3390/ijerph18042124