Analysis of the Hardness of Soft Relining Materials for Removable Dentures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Laboratory Materials and Methods

- Sofreliner Tough M (Tokuyama, Taitou-ku Tokyo, Japan) is a soft material based on additional silicone. Binds AT room temperature. It is used in the indirect and direct method.

- Sofreliner Tough S (Tokuyama, Taitou-ku Tokyo, Japan) is an A-silicone material. The product is qualified as a super soft material. The Sofreliner set includes pastes applied using an automix cartridge system and a primer used to bond with acrylic surfaces. The material binds at room temperature both in the direct and indirect method.

- Mollosil Plus (Detax, Ettlingen, Germany) is a Type A silicone material that polymerizes at low temperature. It is available in automatic mixing containers when applied on a denture by direct and indirect methods.

- Ufi Gel SC (VOCO, Cuxhaven, Germany) is a soft A-silicone material. The material is cured at room temperature, which makes Ufi Gel SC simple and quick to use. Relining can be done directly in the patient’s mouth and in the laboratory. The kit includes an automix cartridge system.

- GC Reline Soft (GC, Tokyo, Japan) is a soft A-silicone-based relining material for long-term indirect and direct relining at room temperature. The material is available in automatic mixing cartridges.

- Elite Soft Relining (Zhermack, Badia Polesine, Italy) is an additional silicone material for use in the dental office using the direct method and in the technical laboratory using the indirect method. Cross-linking of the material occurs at room temperature [26].

- Molloplast B (Detax, Ettlingen, Germany) is a one-component silicone used in the indirect method. The material polymerizes at high temperature in a water bath or in the microwave.

- Vertex Soft (Vertex Dental, Soesterberg, The Netherlands) is a denture polymer that polymerizes under the influence of heat. Polymerization takes place by heating the material for 3 h at 70 °C, and then for 30 min at 100 °C.

- Villacryl Soft (Zhermack, Badia Polesine, Italy) is an acrylic material that polymerizes at a high temperature—at 65 degrees under a pressure of 2.2 Bar for 30 min.

- Flexacryl Soft (Lang Dental, Wheeling, IL, USA) is a flexible acrylic material used in the indirect method for relining denture plates.

2.2. Statistical Analysis

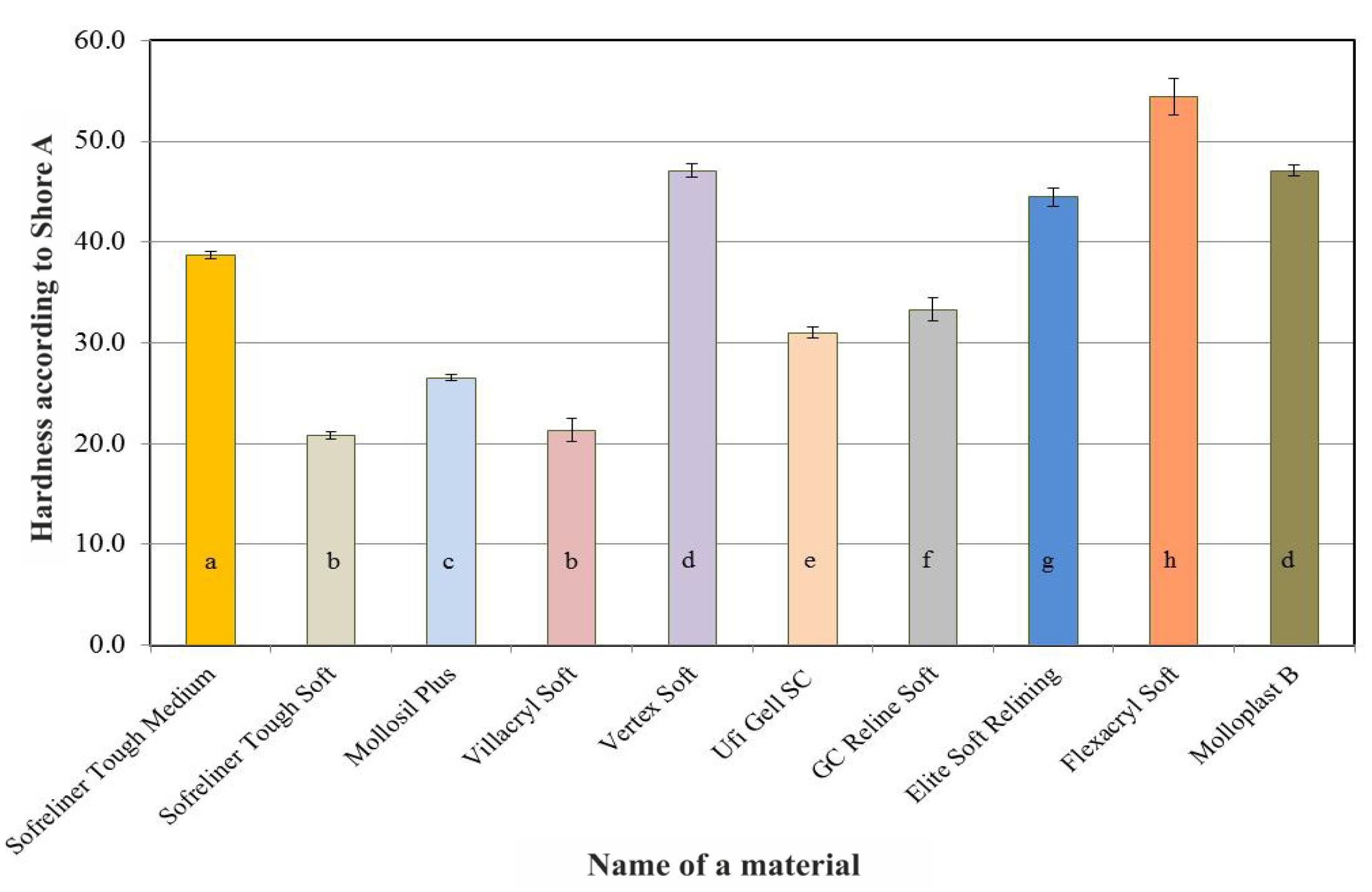

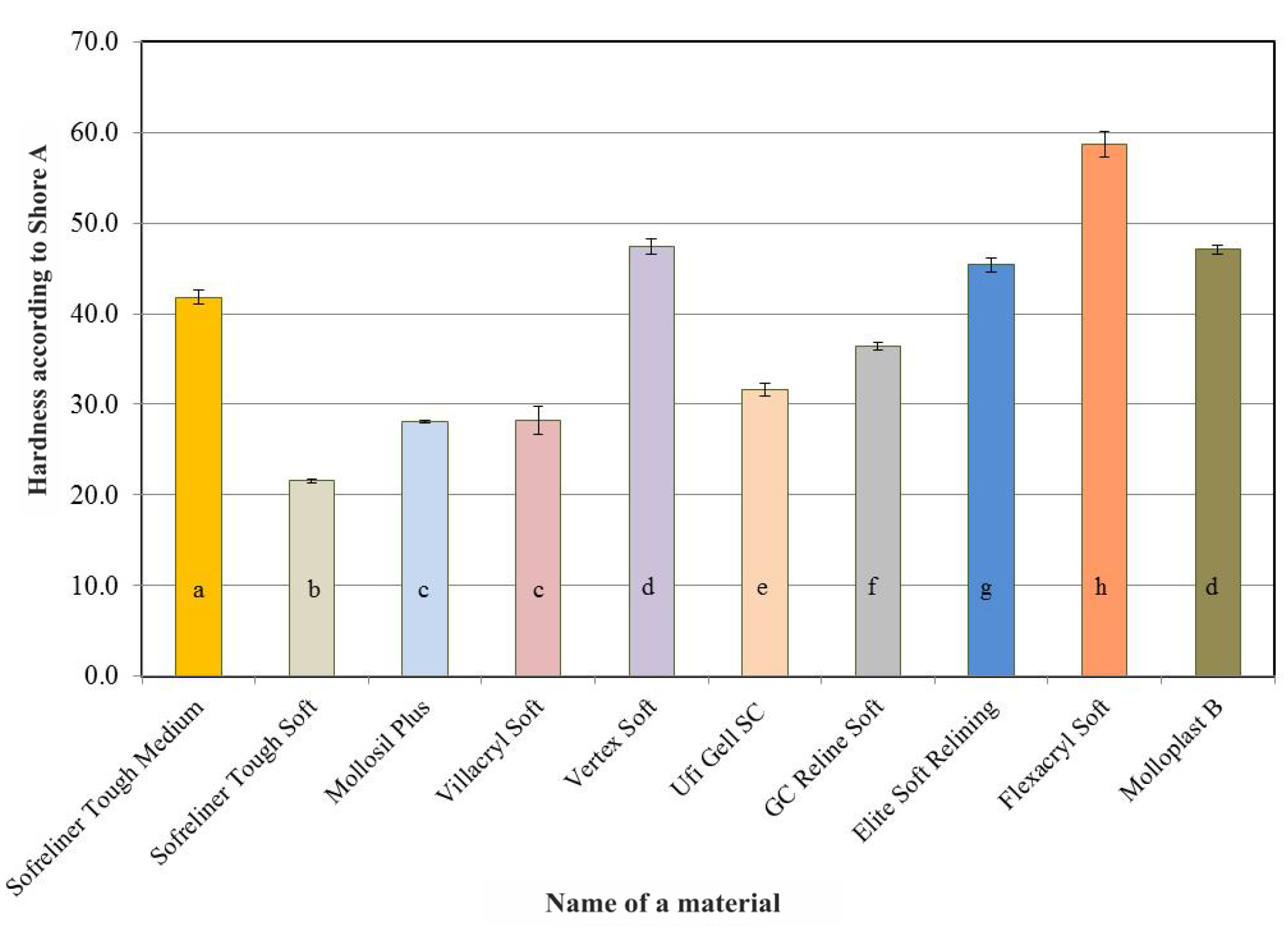

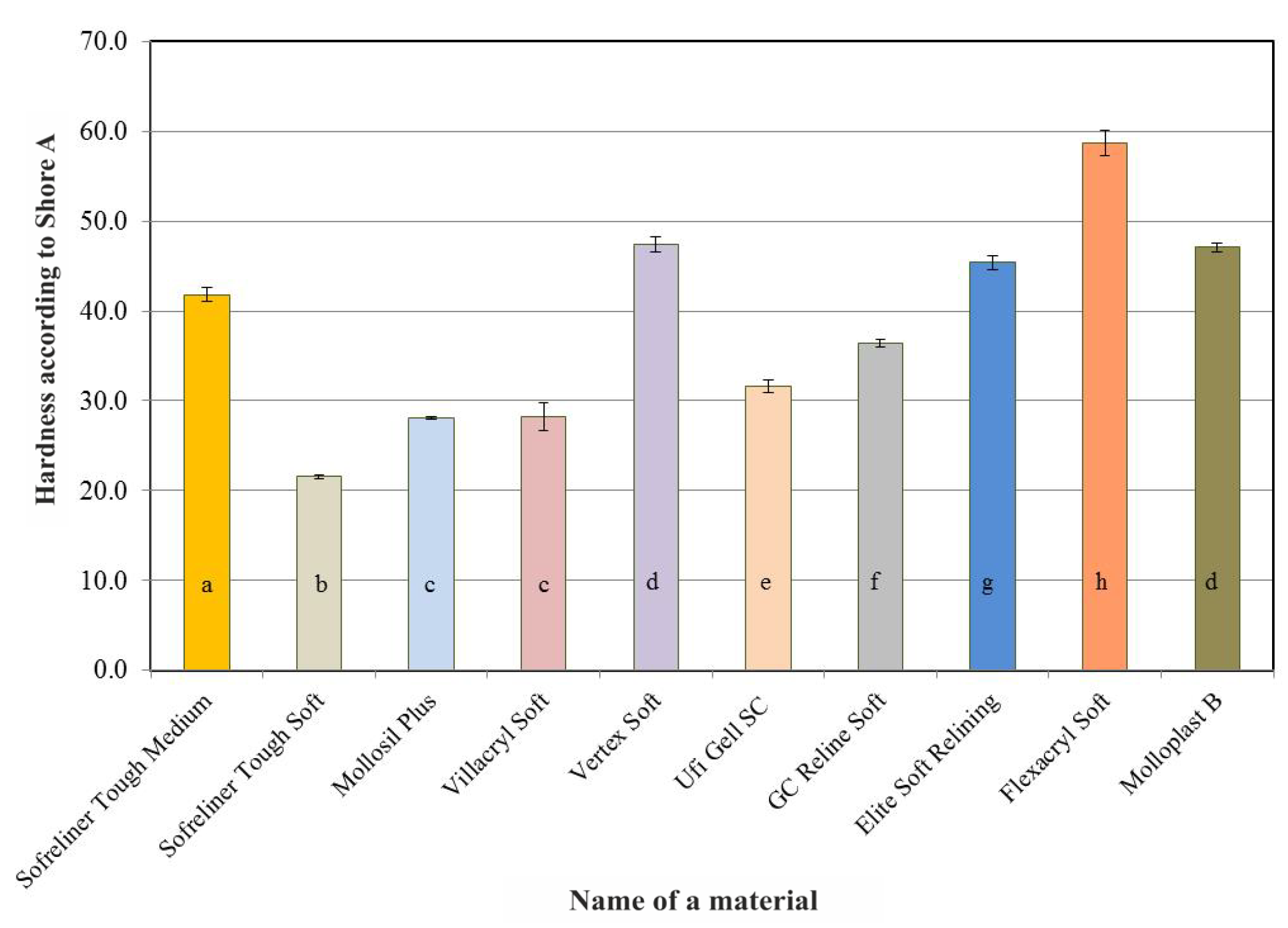

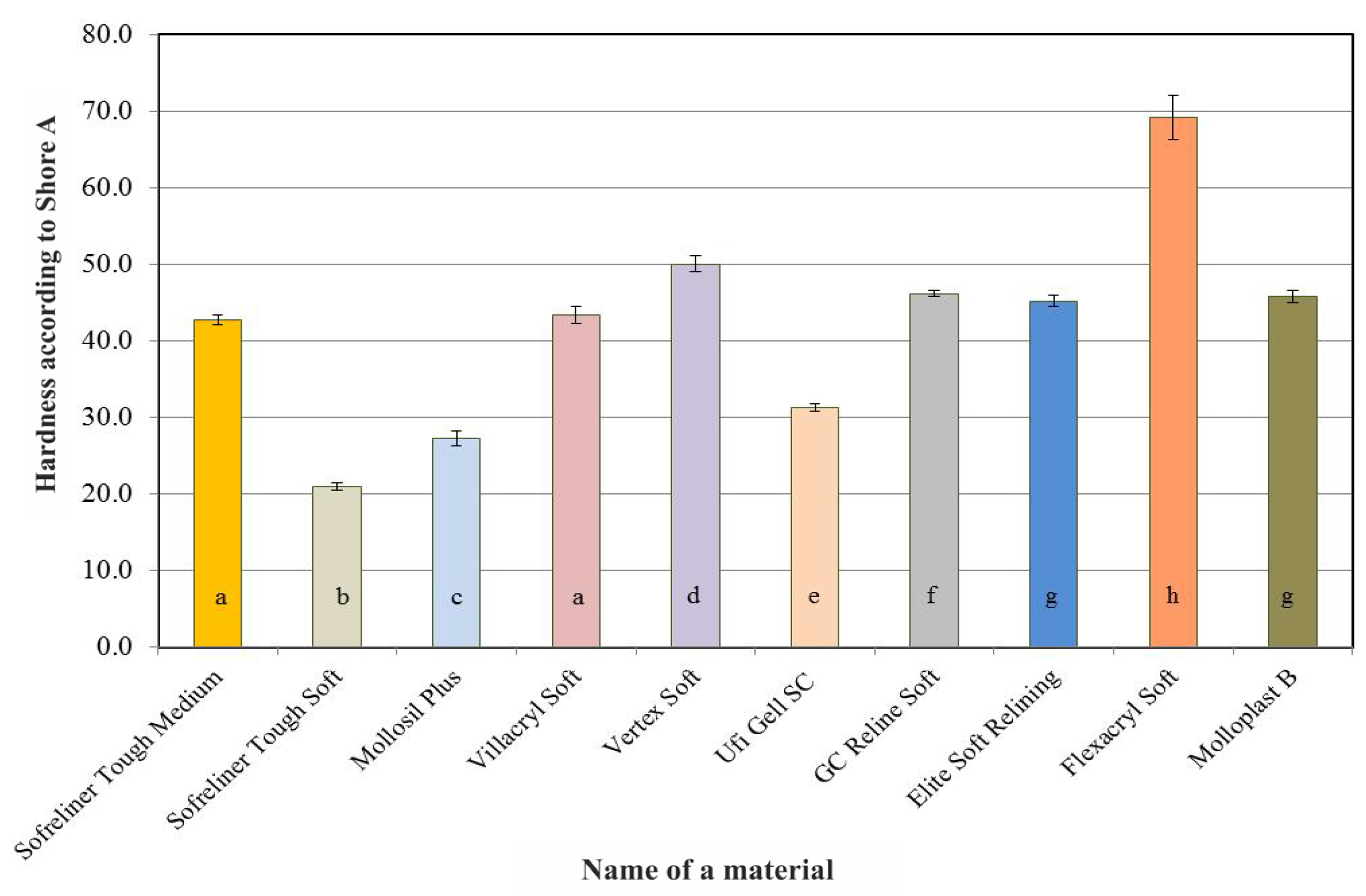

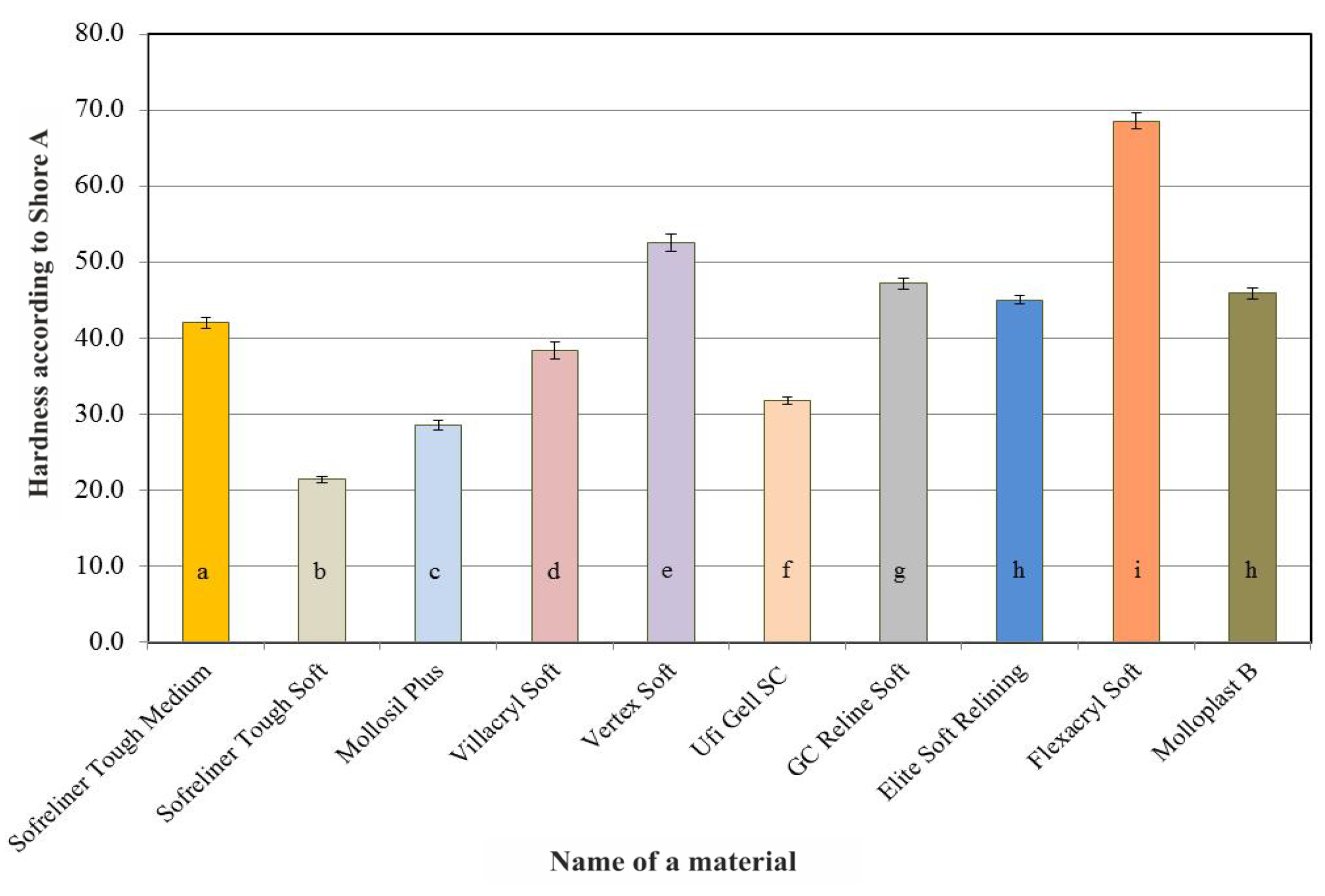

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kasperski, J.; Rój, R.; Białożyt, E.; Gruca, O.; Czelakowska, A.; Rosak, P. Changes in articulation in edentate patients during replacement and adaptation to complete dentures. Preliminary reports. Pol. J. Environ. Stud. 2015, 24, 151–154. [Google Scholar]

- Rój, R.; Białożyt, E.; Kasperski, J.; Morawiec, T.; Kownacki, P.; Wrzoł, M.; Ruci, O.; Skrzypczek-Wielgus, E.; Gładysz, E.; Molęcki, D.; et al. Quality of life in patients using complete dentures in terms of food selection and consumption. Pol. J. Environ. Stud. 2016, 25, 58–61. [Google Scholar]

- Locker, D.; Matear, D.; Stephens, M.; Lawrence, H.; Payne, B. Comparison of the GOHAI and OHIP-14 as measures of the oral health-related quality of life of the elderly. Commun. Dent. Oral Epidemiol. 2001, 29, 373–381. [Google Scholar] [CrossRef] [PubMed]

- Listl, S. Chewing abilities of elderly populations in Europe. Int. Dent. J. 2011, 61, 175–178. [Google Scholar] [CrossRef]

- Osterberg, T.; Carlsson, G.E. Dental state, prosthodontic treatment and chewing ability—A study of five cohorts of 70-year-old subjects. J. Oral Rehabil. 2007, 34, 553–559. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, G.; Omar, R. The future of complete dentures in oral rehabilitation. A critical review. J. Oral Rehabil. 2010, 37, 143–156. [Google Scholar] [CrossRef]

- Białożyt, E.; Rój, R.; Tysiąc-Miśta, M.; Cieślik, M. Stomatopatie protetyczne. Med. Trib. Stomatol. 2015, 9, 24–28. [Google Scholar]

- Tysiąc-Miśta, M.; Białożyt, E.; Nitsze, M.; Cieślik, M. Zalecenia dotyczące użytkowania protez całkowitych. Med. Trib. Stomatol. 2016, 5, 6–8. [Google Scholar]

- Tysiąc-Miśta, M.; Białożyt, E.; Nitsze, M.; Cięslik, M. Świadomość pacjentów bezzębnych użytkujących protezy całkowite w zakresie higieny jamy ustnej i uzupełnień protetycznych. Period. Nauk. Akad. Polon. 2016, 17, 55–67. [Google Scholar]

- Gabrowska, E.; Mikołaj, M. Zasady żywienia osób w starszym wieku. Gerontol. Polska 2006, 14, 57–62. [Google Scholar]

- Żmudzki, J.; Chladek, G.; Malara, P. Use of finite element analysis for the assessment of biomechanical factors related to pain sensation beneath complete dentures during mastication. J. Prosthet. Dent. 2018, 100, 934–941. [Google Scholar] [CrossRef]

- Żmudzki, J.; Chladek, W. Modelowa ocena skuteczności miękkich podścieleń do eliminacji urazów błony śluzowej podłoża protetycznego. Protet. Stomatol. 2009, LIX, 394–400. [Google Scholar]

- Kreve, S.; Dos Reis, A.C. Denture liners: A systematic review relative to adhesion and mechanical properties. Sci. World J. 2019. [Google Scholar] [CrossRef] [Green Version]

- Yankova, M.; Yordanov, B.; Dimova-Gabrovska, M.; Apostolov, N. Resilient lining materials forremovable dentures: Types, composition and technology. J. IMAB 2019, 25, 2632–2639. [Google Scholar] [CrossRef]

- Ibraheem, E.M.; ElGabry, H.S. Effect of mandibular complete dentures relining on occlusal force distribution using T-scan system. Bull. Natl. Res. Cent. 2021, 45, 93. [Google Scholar] [CrossRef]

- Pisani, M.X.; Malheiros-Segundo, A.D.; Balbino, K.L.; Souza, R.D.F.; Paranhos, H.D.F.O.; Lovato da Silva, C.H. Oral health related quality of life of edentulous patients after denture relining with a siliconebased soft liner. Gerodontology 2012, 29, 474–480. [Google Scholar] [CrossRef]

- Kucharski, Z.; Kostrzewa-Janicka, J. Materiały elastyczne w protetycznym leczeniu bezzębia. Protet. Stomatol. 2014, 64, 246–251. [Google Scholar] [CrossRef]

- Kucharski, Z. Analiza porównawcza elastycznych materiałów przeznaczonych do podścieleń ruchomych uzupełnień protetycznych. Protet. Stomatol. 1998, 2, 110–115. [Google Scholar]

- Kimoto, S.; Kimoto, K.; Gunji, A.; Kawai, Y.; Murakami, H.; Tanaka, K.; Syu, K.; Aoki, H.; Toyoda, M.; Kobayashi, K. Clinical effects of acrylic resilient denture liners applied to mandibular complete dentures on the alveolar ridge. J. Oral Rehabil. 2007, 34, 862–869. [Google Scholar] [CrossRef] [PubMed]

- Szalewski, L.; Bożyk, A.; Michalczewski, G.; Borowicz, J. Rehabilitacja protetyczna po zabiegach resekcyjnych. Mag. Stomatol. 2013, 23, 30–33. [Google Scholar]

- Kucharski, Z.; Dominiak, K. Zastosowanie materiałów elastycznych w leczeniu protetycznym bezzębia u pacjenta po zabiegu osteosyntezy trzonu żuchwy—Opis przypadku. Protet. Stomatol. 2013, 63, 134–139. [Google Scholar] [CrossRef]

- Gajowiak, I.M. Etiologia i zasady leczenia zmian rozrostowych zapalno-włóknistych w zakresie podłoża protetycznego na podstawie opisu przypadku. Porad. Stomatol. 2010, 10, 200–205. [Google Scholar]

- Duda, M. Różne zastosowania mas podścielających w protetyce stomatologicznej. Twój Przeg. Stomatol. 2003, 3, 40–42. [Google Scholar]

- Majewski, S.; Pryliński, M. Materiały I Technologie Współczesnej Protetyki Stomatologicznej; Wydawnictwo Czelej: Lublin, Poland, 2013. [Google Scholar]

- Sohail Zafar, M. Prosthodontic applications of polymethyl methacrylate (PMMA): An update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef]

- Kenneth, J.A.; Chiayi, S.; Rawls, R.H. Phillips’s Sciences of Dental Materials; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- International Organization for Standardization. ISO 10139-2:2009 Dentistry—Soft Lining Materials for Removable Dentures—Part. 2: Materials for Long-Term Use; ISO International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Kim, B.J.; Yang, H.S.; Chun, M.G.; Park, Y.J. Shore hardness and tensile bond strength of long-term soft denture lining materials. J. Prosthet. Dent. 2014, 112, 1289–1297. [Google Scholar] [CrossRef] [PubMed]

- Iwaki, M.; Akiba, N.; Minakuchi, S.; Takahashi, H. Influence of methyl mercaptan at early setting stages on the properties of self curing addition silicone resilient denture lining materials. J. Prosthodont. Res. 2009, 53, 161–165. [Google Scholar] [CrossRef] [PubMed]

- Mese, A.; Guzel, K.G. Effect of storage duration on the hardness and tensile bond strength of silicone- and acrylic resin-based resilient denture liners to a processed denture base acrylic resin. J. Prosthet. Dent. 2008, 99, 153–159. [Google Scholar] [CrossRef]

- Canay, S.; Hersek, N.; Tulunolu, I.; Uzun, G. Evaluation of colour and hardness changes of soft lining materials in food colorant solutions. J. Oral Rehabil. 1999, 26, 821–829. [Google Scholar] [CrossRef] [PubMed]

- Polyzois, G.L.; Frangou, M.J. Influence of curing method, sealer, and water storage on the hardness of a soft lining material over time. J. Prosthodont. 2001, 10, 42–45. [Google Scholar] [CrossRef]

- Mancuso, D.N.; Goiato, M.C.; Zuccolotti, B.C.; Moreno, A.; dos Santos, D.M.; Pesqueira, A.A. Effect of thermocycling on hardness, absorption, solubility and colour change of soft lines. Gerodontology 2012, 29, 215–219. [Google Scholar] [CrossRef]

- Niarchou, A.; Ntala, P.; Pantopoulos, A.; Polyzois, G.; Frangou, M. Effect of immersion cleansing in color stability and hardness of soft denture reliners. J. Craniofac. Surg. 2012, 23, 426–429. [Google Scholar] [CrossRef] [PubMed]

- Brożek, R.; Koczorowski, R.; Rogalewicz, R.; Voelkel, A.; Czarnecka, B.; Nicholson, J.W. Effect of denture cleansers on chemical and mechanical behavior of selected soft lining materials. Dent. Mater. 2011, 27, 281–290. [Google Scholar] [CrossRef] [PubMed]

| Trade Name of the Material | Conditioning Time in Distilled Water | |||

|---|---|---|---|---|

| 24 h | 28 Days | |||

| Shore’a A ≤ 25 | 25 < Shore’a A ≤ 50 | Shore’a A ≤ 35 | Shore’a A ≤ 55 | |

| Sofreliner Tough Medium | N | Y | N | Y |

| Sofreliner Tough Soft | Y | Y | Y | Y |

| Mollosil Plus | N | Y | N | Y |

| Villacryl Soft | Y | Y | Y | Y |

| Vertex Soft | N | Y | N | Y |

| Ufi Gel SC | N | Y | N | Y |

| GC RELINE Soft | N | Y | N | Y |

| Elite Soft Relining | N | Y | N | Y |

| Flexacryl Soft | N | N | N | N |

| Molloplast B | N | Y | N | Y |

| Conditioning Time | Sum of Squares | Degrees of Freedom | Root Mean Square | Value of the Fisher Statistic | p |

|---|---|---|---|---|---|

| 24 h | 18,439,724 | 9 | 2,048,858 | 2,302,482 | <0.0001 |

| 7 days | 17,608,458 | 9 | 1,956,495 | 2,605,055 | <0.0001 |

| 28 days | 24,360,182 | 9 | 2,706,687 | 1,256,763 | <0.0001 |

| 60 days | 24,319,921 | 9 | 2,702,213 | 1,790,562 | <0.0001 |

| 90 days | 23,911,916 | 9 | 2,656,880 | 3,930,129 | <0.0001 |

| Material | Sum of Squares | Degrees of Freedom | Root Mean Square | Value of the Fisher Statistic | p |

|---|---|---|---|---|---|

| Sofreliner Tough Medium | 157,845 | 4 | 39,461 | 74,141 | <0.0001 |

| Sofreliner Tough Soft | 6693 | 4 | 1673 | 10,642 | <0.0001 |

| Mollosil Plus | 37,971 | 4 | 9493 | 24,435 | <0.0001 |

| Villacryl Soft | 4,469,218 | 4 | 1,117,304 | 767,379 | <0.0001 |

| Vertex Soft | 306,887 | 4 | 76,722 | 75,161 | <0.0001 |

| Ufi Gel SC | 5024 | 4 | 1256 | 3386 | 0.0137 |

| GC Reline Soft | 2,547,227 | 4 | 636,807 | 991,966 | <0.0001 |

| Elite Soft Relining | 7194 | 4 | 1799 | 2583 | 0.0445 |

| Flexacryl Soft | 2,953,463 | 4 | 738,366 | 120,034 | <0.0001 |

| Molloplast B | 2,547,227 | 4 | 636,807 | 13590 | <0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Białożyt-Bujak, E.; Wyszyńska, M.; Chladek, G.; Czelakowska, A.; Gala, A.; Orczykowska, M.; Białożyt, A.; Kasperski, J.; Skucha-Nowak, M. Analysis of the Hardness of Soft Relining Materials for Removable Dentures. Int. J. Environ. Res. Public Health 2021, 18, 9491. https://doi.org/10.3390/ijerph18189491

Białożyt-Bujak E, Wyszyńska M, Chladek G, Czelakowska A, Gala A, Orczykowska M, Białożyt A, Kasperski J, Skucha-Nowak M. Analysis of the Hardness of Soft Relining Materials for Removable Dentures. International Journal of Environmental Research and Public Health. 2021; 18(18):9491. https://doi.org/10.3390/ijerph18189491

Chicago/Turabian StyleBiałożyt-Bujak, Ewa, Magdalena Wyszyńska, Grzegorz Chladek, Aleksandra Czelakowska, Andrzej Gala, Magdalena Orczykowska, Agata Białożyt, Jacek Kasperski, and Małgorzata Skucha-Nowak. 2021. "Analysis of the Hardness of Soft Relining Materials for Removable Dentures" International Journal of Environmental Research and Public Health 18, no. 18: 9491. https://doi.org/10.3390/ijerph18189491

APA StyleBiałożyt-Bujak, E., Wyszyńska, M., Chladek, G., Czelakowska, A., Gala, A., Orczykowska, M., Białożyt, A., Kasperski, J., & Skucha-Nowak, M. (2021). Analysis of the Hardness of Soft Relining Materials for Removable Dentures. International Journal of Environmental Research and Public Health, 18(18), 9491. https://doi.org/10.3390/ijerph18189491