Preliminary Research: Validation of the Method of Evaluating Resistance to Surface Wetting with Liquid of Protective Materials Intended for Polymer Protective Gloves

Abstract

1. Introduction

2. Materials and Methods

2.1. Tested Materials

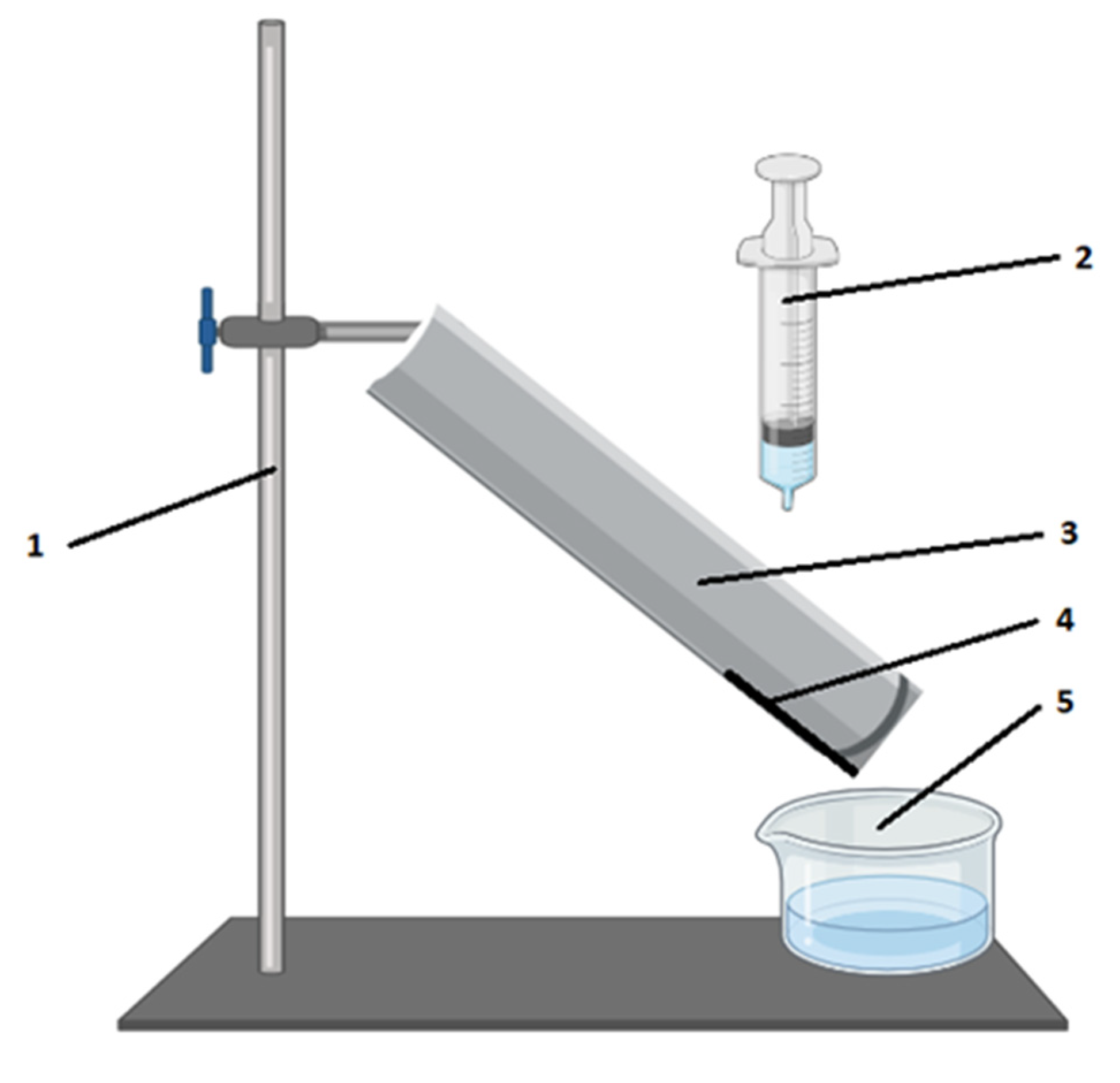

2.2. Surface Wettability Measurements Experimental Protocol

3. Results

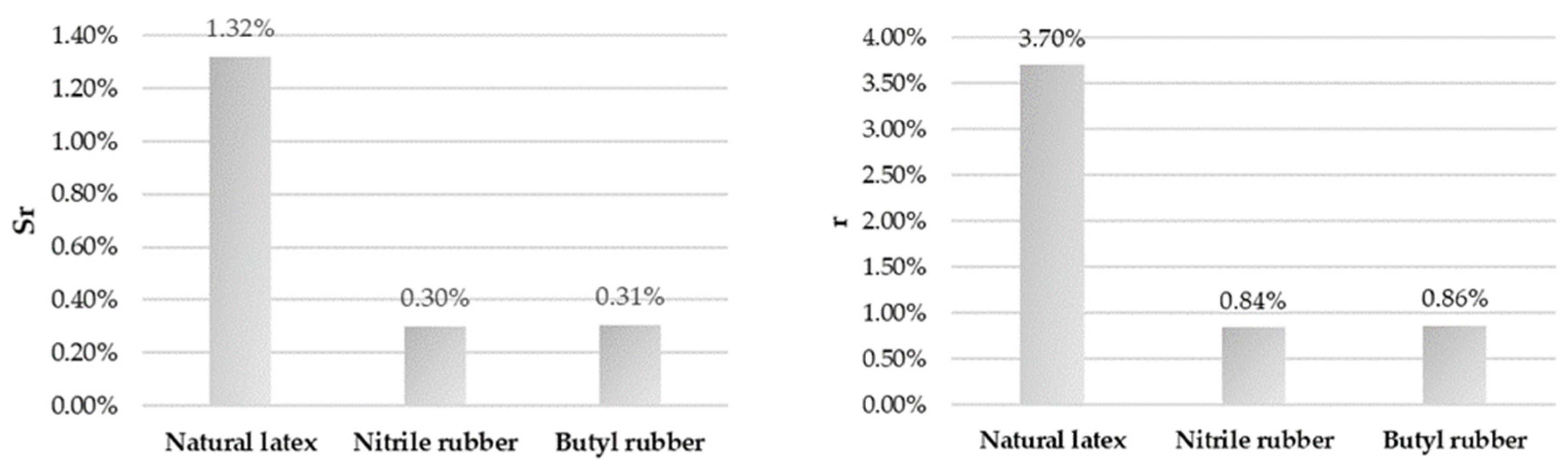

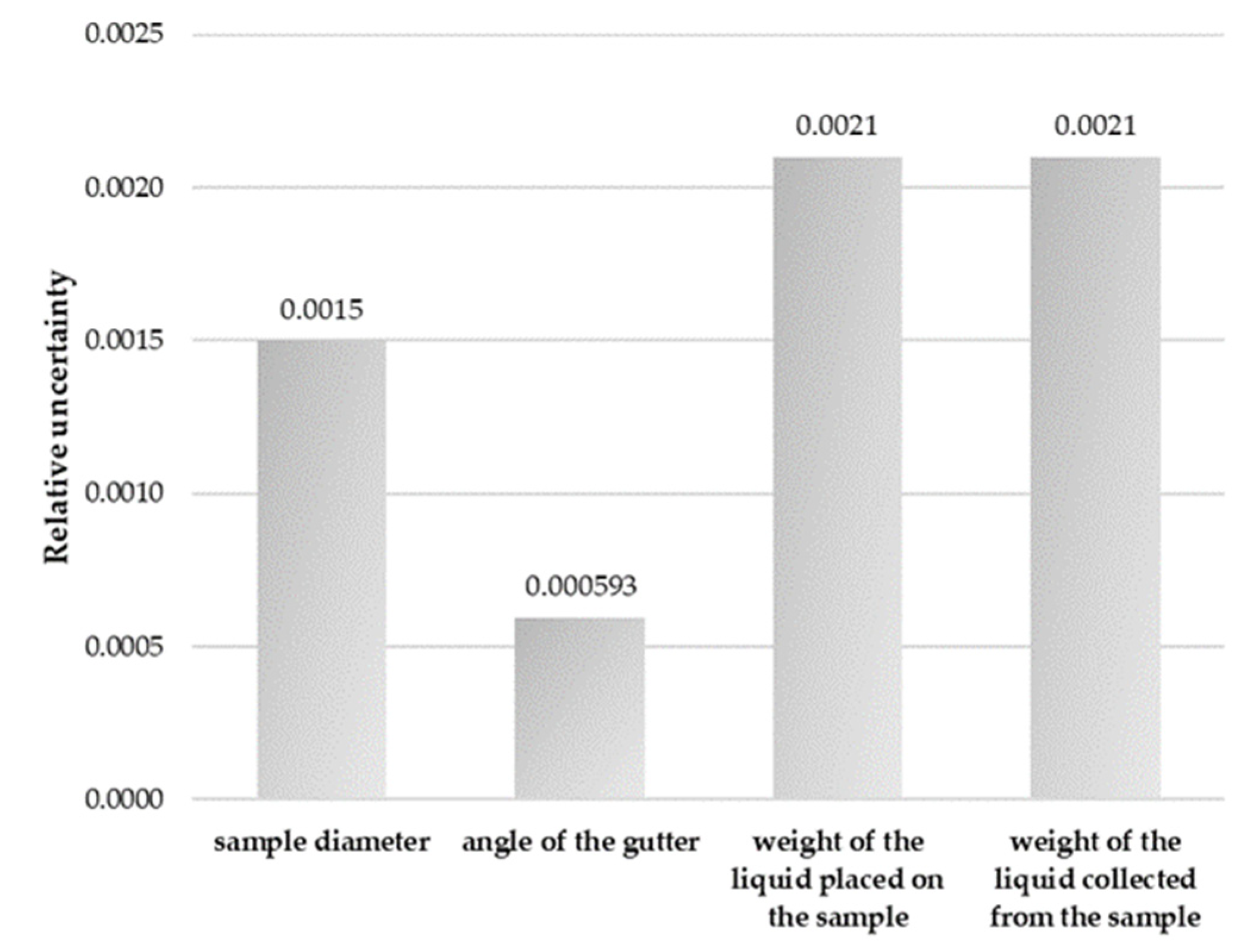

3.1. Validation and Statistical Analysis

3.2. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, T.D.; Dejoy, D.M.; Dyal, M.A. Safety specific transformational leadership, safety motivation and personal protective equipment use among firefighters. Saf. Sci. 2020, 131, 104930. [Google Scholar] [CrossRef]

- Linde, S.J.L.; Franken, A.; du Plessis, J.L. Effectiveness of Personal Protective Equipment in Reducing Skin Exposure to Soluble Platinum. Ann. Work Expo. Health 2021, 65, 485–491. [Google Scholar] [CrossRef]

- McQuerry, M.; Easter, E.; Cao, A. Disposable versus reusable medical gowns: A performance comparison. Am. J. Infect. Control 2021, 49, 563–570. [Google Scholar] [CrossRef]

- Roda-Sales, A.; Sancho-Bru, J.L.; Vergara, M.; Gracia-Ibáñez, V.; Jarque-Bou, N.J. Effect on manual skills of wearing instrumented gloves during manipulation. J. Biomech. 2020, 98, 109512. [Google Scholar] [CrossRef]

- Wei, X.; Zhao, B.; Li, X.-M.; Wang, Z.; He, B.-Q.; He, T.; Jiang, B. CF4 plasma surface modification of asymmetric hydrophilic polyethersulfone membranes for direct contact membrane distillation. J. Membr. Sci. 2012, 407-408, 164–175. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, W.; Su, B.L. Superhydrophobic surfaces: From natural to biomimetic to functional. J. Colloid Interface Sci. 2011, 353, 335–355. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Zhou, M.; Li, J.; Ye, X.; Li, G.; Cai, L. Superhydrophobic surfaces fabricated by microstructuring of stainless steel using a femtosecond laser. Appl. Surf. Sci. 2009, 256, 61–66. [Google Scholar] [CrossRef]

- Naik, R.R.; Singamaneni, S. Introduction: Bioinspired and Biomimetic Materials. Chem. Rev. 2017, 117, 12581–12583. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Shao, R.; Wang, G.; Sun, S. Hierarchical hydrophobic surfaces with controlled dual transition between rose petal effect and lotus effect via structure tailoring or chemical modification. Colloids Surf. A Physicochem. Eng. Asp. 2021, 622, 126661. [Google Scholar] [CrossRef]

- Arzt, E.; Quan, H.; McMeeking, R.M.; Hensel, R. Functional surface microstructures inspired by nature—From adhesion and wetting principles to sustainable new devices. Prog. Mater. Sci. 2021, 120, 100823. [Google Scholar] [CrossRef]

- Wimalasiri, V.K.; Weerathunga, H.U.; Kottegoda, N.; Karunaratne, V. Silica Based Superhydrophobic Nanocoatings for Natural Rubber Surfaces. J. Nanomater. 2017, 2017, 2102467. [Google Scholar]

- Xu, S.; Wang, Q.; Wang, N. Chemical Fabrication Strategies for Achieving Bioinspired Superhydrophobic Surfaces with Micro and Nanostructures: A Review. Adv. Eng. Mater. 2021, 23, 2001083. [Google Scholar] [CrossRef]

- Li, S.; Huang, J.; Chen, Z.; Chen, G.; Lai, Y. A review on special wettability textiles: Theoretical models, fabrication technologies and multifunctional applications. J. Mater. Chem. 2017, 5, 31–55. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Sun, Z.; Liao, T.; Liu, K.; Jiang, L.; Kim, J.H.; Dou, S.X. Fly-Eye Inspired Superhydrophobic Anti-Fogging Inorganic Nanostructures. Small 2014, 10, 3001–3006. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Z.; Yu, J.; Wu, Y.; Shao, W.; Jianga, T.; Xu, X. Preparation of lotus-like hierarchical microstructures on zinc substrate and study of its wettability. Rsc Adv. 2014, 4, 33730–33738. [Google Scholar] [CrossRef]

- Wu, J.; Li, J.; Deng, B.; Jiang, H.; Wang, Z.; Yu, M.; Li, L.; Xing, C.; Li, Y. Self-healing of the superhydrophobicity by ironing for the abrasion durable superhydrophobic cotton fabrics. Sci. Rep. 2013, 3, 2951. [Google Scholar] [CrossRef] [PubMed]

- Solga, A.; Cerman, Z.; Striffler, B.F.; Spaeth, M.; Barthlott, W. The dream of staying clean: Lotus and biomimetic surfaces. Bioinspir. Biomim. 2007, 2, S126. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.; Tuteja, A.; Chhatre, S.; Mabry, J.M.; Cohen, R.E.; McKinley, G.H. Fabrics with tunable oleophobicity. Adv. Mater. 2009, 21, 2190–2195. [Google Scholar] [CrossRef]

- Fürstner, R.; Barthlott, W.; Neinhuis, C.; Walzel, P. Wetting and Self-Cleaning Properties of Artificial Superhydrophobic Surfaces. Langmuir 2005, 21, 956–961. [Google Scholar] [CrossRef]

- Do Nascimento, R.M.; Ramos, S.M.M.; Bechtold, I.H.; Hernandes, A.C. Wettability Study on Natural Rubber Surfaces for Applications as Biomembranes. ACS Biomater. Sci. Eng. 2018, 4, 2784–2793. [Google Scholar] [CrossRef]

- Kwon, J.; Jung, H.; Jung, J.; Lee, J. Micro/nanostructured coating for cotton textiles that repel oil, water, and chemical warfare agents. Polymers 2020, 12, 1826. [Google Scholar] [CrossRef] [PubMed]

- Hildayani, G.M.; Fahrunisa, N.; Rachmadhani; Rachmawati, S.A.; Nugroho, A.; Saepudin, E.; Sufiandi, S. Hydrophobic Coating on Woven Material for Personal Protective Equipment. J. Phys. Conf. Ser. 2021, 1893, 12012. [Google Scholar]

- Zhou, W.; Gong, X.; Li, Y.; Si, Y.; Zhang, S.; Yu, J.; Ding, B. Waterborne electrospinning of fluorine-free stretchable nanofiber membranes with waterproof and breathable capabilities for protective textiles. J. Colloid Interface Sci. 2021, 602, 105–114. [Google Scholar] [CrossRef]

- Zimmermann, J.; Seeger, S.; Reifler, F.A. Water Shedding Angle: A New Technique to Evaluate the Water-Repellent Properties of Superhydrophobic Surfaces. Text. Res. J. 2009, 79, 1565–1570. [Google Scholar] [CrossRef]

- Barkay, Z. Wettability study using transmitted electrons in environmental scanning electron microscope. Appl. Phys. Lett. 2010, 96, 183109. [Google Scholar] [CrossRef]

- Stelmashenko, N.A.; Craven, J.P.; Donald, A.M.; Terentjev, E.M.; Thiel, B.L. Topographic contrast of partially wetting water droplets in environmental scanning electron microscopy. J. Microsc. 2001, 204, 172–183. [Google Scholar] [CrossRef] [PubMed]

- Bogner, A.; Thollet, G.; Basset, D.; Jouneau, P.-H.; Gauthier, C. Wet STEM: A new development in environmental SEM for imaging nano-objects included in a liquid phase. Ultramicroscopy 2005, 104, 290–301. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.; Kota, A.K.; Mabry, J.M.; Tuteja, A. Superomniphobic surfaces for effective chemical shielding. J. Am. Chem. Soc. 2013, 135, 578–581. [Google Scholar] [CrossRef]

- Chi, H.; Xu, Z.; Zhang, T.; Li, X.; Wu, Z.; Zhao, Y. Randomly heterogeneous oleophobic/pH-responsive polymer coatings with reversible wettability transition for multifunctional fabrics and controllable oil–water separation. J. Colloid Interface Sci. 2021, 594, 122–130. [Google Scholar] [CrossRef]

- EN ISO 6530:2005—Protective Clothing—Protection against Liquid Chemicals—Test Method for Resistance of Materials to Penetration by Liquids. Available online: https://www.iso.org/standard/38303.html (accessed on 6 July 2021).

- PN-ISO 5725-1:1994—Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 1: General Principles and Definitions. Available online: https://www.iso.org/obp/ui/#iso:std:iso:5725:-1:ed-1:v1:en (accessed on 12 July 2021).

- PN-ISO 5725-2:1994—Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 2: Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method. Available online: https://www.iso.org/standard/11834.html (accessed on 12 July 2021).

- Koradecka, D. Use of Personal Protective Equipment in the Workplace. In Handbook of Human Factors and Ergonomics; John Wiley & Sons Press: Hudson County, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Zedalis, M.S.; Kessler, K. Frequently Asked Questions: Ergonomics and Hand Protection. Occup. Health Saf. 2007, 76, 64–66. [Google Scholar]

- Irzmańska, E.; Dyńska-Kukulska, K. Permeation of mineral oils through protective glove materials in view of literature data and authors’ own studies. Rev. Anal. Chem. 2012, 31, 113–122. [Google Scholar] [CrossRef]

- Krzemińska, S.; Irzmańska, E. Preliminary Evaluation of the Ergonomic Properties of Gloves for Protection Against Mineral Oils Based on Manual Dexterity Test. J. Test. Eval. 2013, 41, 875–882. [Google Scholar] [CrossRef]

- Xu, W.; QueHee, S.S. Permeation of a straight oil metalworking fluid through a disposable nitrile, chloroprene, vinyl, and latex gloves. J. Hazard. Mater. 2007, 147, 923–929. [Google Scholar] [CrossRef]

- Rios, P.F.; Dodiuk, H.; Kenig, S.; McCarthy, S.; Dotan, A. The effects of nanostructure and composition on the hydrophobic properties of solid surfaces. J. Adhes. Sci. Technol. 2006, 20, 563–587. [Google Scholar] [CrossRef]

- Bhushan, B.; Koch, K.; Yung, Y.C. Nanostructures for superhydrophobicity and low adhesion. Soft Matter 2008, 4, 1799–1804. [Google Scholar] [CrossRef]

- Harrabi, L.; Dolez, P.; Vu-Khanh, T.; Lara, J.; Tremblay, G.; Nadeau, S.; Larivière, C. Characterization of protective gloves stiffness: Development of a multidirectional deformation test method. Saf. Sci. 2008, 46, 1025–1036. [Google Scholar] [CrossRef]

- Gauvin, C.; Tellier, C.; Daigle, R.; Petitjean-Roget, T. Evaluation of dexterity tests for gloves. In Proceedings of the 3rd European Conference on Protective Clothing and Nokobetef 8, Gdynia, Poland, 10–12 May 2006. [Google Scholar]

- PN-EN ISO 4920:2012 Textile Fabrics–Determination of Resistance to Surface Wetting (Spray Test). Available online: https://www.iso.org/standard/50706.html (accessed on 12 July 2021).

- Mostafa, A.; Abouel-Kasem, A.; Bayoumi, M.; El-Sebaie, M. Rubber-Filler Interactions and Its Effect in Rheological and Mechanical Properties of Filled Compounds. J. Test. Eval. 2010, 38, 101942. [Google Scholar]

- Krzemińska, S.; Rzymski, W.M. Barrierity of hydrogenated butadiene-acrylonitrile rubber and butyl rubber after exposure to organic solvents. Int. J. Occup. Saf. Ergon. 2011, 17, 41–47. [Google Scholar] [CrossRef][Green Version]

- Krzemińska, S.; Rzymski, W.M. Effect of layered silicate on the barrier properties of cured butyl rubber. Int. J. Phys. Conf. Ser. 2009, 146, 012007. [Google Scholar] [CrossRef]

| Type of Material | Sample Designation | Photographs | Thickness [mm] | Contact Angle for Water [°] | Work of Adhesion [mJ/m2] | ||

|---|---|---|---|---|---|---|---|

| Palmar Surface | Dorsal Surface | Palmar | Dorsal | ||||

| Natural Latex | G1 |  |  | 0.92 ± 0.01 | 64.97 ± 8.61 | 67.47 ± 5.19 | 118.57 |

| Nitrile Rubber | G2 |  |  | 0.20 ± 0.01 | 32.48 ± 0.98 | 25.46 ± 12.14 | 152.32 |

| Butyl Rubber | G3 |  |  | 0.67 ± 0.02 | 79.21 ± 9.68 | 76.49 ± 3.77 | 153.36 |

| Component | Validated Method | EN ISO 6530:2008 |

|---|---|---|

| Gutter | rigid PCV gutter, of semi-cylindrical shape, with an internal diameter (70 ± 5) mm, length (190 ± 2) mm and inclination 45° | rigid transparent gutter, of semi-cylindrical shape, with an internal diameter (125 ± 5) mm, length (300 ± 2) mm and inclination 45° |

| Needle | needle (0.8 ± 0.02) mm | hypodermic needle, bore (0.8 ± 0.02) mm |

| Syringe | syringe with volume (10 ± 0.5) mL | syringe or other leak-free attachment to the needle, capable of delivering (10 ± 0.5) cm3 of test liquid |

| Beaker | small beaker | |

| Foil | foil resistant to the test liquid | transparent film resistant to the test liquid |

| Paper | absorbent paper, 0.15 mm to 0.3 mm thick | |

| Stopwatch | stopwatch, accurate to 0.1 s | |

| Balance | balance, accurate to 0.01 g | |

| Test specimens | three specimens from palmar surface of protective gloves with diameter 100 mm | six specimens of (360 ± 2) mm by (235 ± 5) mm from the clothing or sample of material |

| Sample | Part | Measurement Series j | Results [%] | Average | Standard Deviation Sd | Variance S2rj | ||

|---|---|---|---|---|---|---|---|---|

| n = 1 | n = 2 | n = 3 | ||||||

| Latex rubber | Palmar | Series 1 | 98.75 | 98.46 | 96.75 | 97.99 | 1.081 | 1.169 |

| Series 2 (after 1 month) | 99.50 | 97.00 | 96.83 | 97.78 | 1.495 | 2.235 | ||

| Series 3 (after 3 months) | 97.32 | 99.00 | 97.25 | 97.86 | 0.991 | 0.982 | ||

| Dorsal | Series 1 | 96.34 | 99.50 | 98.75 | 98.20 | 1.651 | 2.756 | |

| Series 2 (after 1 month) | 97.32 | 99.75 | 99.25 | 98.77 | 1.283 | 1.646 | ||

| Series 3 (after 3 months) | 96.83 | 99.25 | 98.78 | 98.29 | 1.283 | 1.646 | ||

| St.dev. of the within-laboratory reproducibility of the SRn series [%] | 1.203 | 0.999 | 1.114 | |||||

| Intra-laboratory reproducibility variance S2Rn [%2] | 1.447 | 0.998 | 1.241 | |||||

| Nitrile rubber | Palmar | Series 1 | 98.50 | 99.25 | 99.50 | 99.08 | 0.520 | 0.271 |

| Series 2 (after 1 month) | 99.00 | 99.00 | 99.50 | 99.17 | 0.289 | 0.083 | ||

| Series 3 (after 3 months) | 99.25 | 99.00 | 99.25 | 99.17 | 0.144 | 0.021 | ||

| Dorsal | Series 1 | 99.50 | 99.75 | 99.75 | 99.67 | 0.144 | 0.021 | |

| Series 2 (after 1 month) | 97.56 * | 99.75 | 99.75 | 99.75 | 0 | 0 | ||

| Series 3 (after 3 months) | 99.25 | 100.00 | 99.50 | 99.58 | 0.382 | 0.146 | ||

| St.dev. of the within-laboratory reproducibility of the SRn series [%] | 0.379 | 0.431 | 0.188 | |||||

| Intra-laboratory reproducibility variance S2Rn [%2] | 0.144 | 0.185 | 0.035 | |||||

| Butyl rubber | Palmar | Series 1 | 98.75 | 99.50 | 98.75 | 99.00 | 0.433 | 0.188 |

| Series 2 (after 1 month) | 98.75 | 99.00 | 99.25 | 99.00 | 0.250 | 0.063 | ||

| Series 3 (after 3 months) | 99.00 | 99.00 | 99.00 | 99.00 | 0 | 0 | ||

| Dorsal | Series 1 | 98.75 | 99.50 | 99.00 | 99.08 | 0.382 | 0.142 | |

| Series 2 (after 1 month) | 99.25 | 99.49 | 99.50 | 99.41 | 0.141 | 0.020 | ||

| Series 3 (after 3 months) | 98.75 | 99.25 | 99.50 | 99.17 | 0.382 | 0.146 | ||

| St.dev. of the within-laboratory reproducibility of the SRn series [%] | 0.210 | 0.244 | 0.354 | |||||

| Intra-laboratory reproducibility variance S2Rn [%2] | 0.044 | 0.060 | 0.125 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irzmańska, E.; Jastrzębska, A.; Makowicz, M. Preliminary Research: Validation of the Method of Evaluating Resistance to Surface Wetting with Liquid of Protective Materials Intended for Polymer Protective Gloves. Int. J. Environ. Res. Public Health 2021, 18, 9202. https://doi.org/10.3390/ijerph18179202

Irzmańska E, Jastrzębska A, Makowicz M. Preliminary Research: Validation of the Method of Evaluating Resistance to Surface Wetting with Liquid of Protective Materials Intended for Polymer Protective Gloves. International Journal of Environmental Research and Public Health. 2021; 18(17):9202. https://doi.org/10.3390/ijerph18179202

Chicago/Turabian StyleIrzmańska, Emilia, Aleksandra Jastrzębska, and Magdalena Makowicz. 2021. "Preliminary Research: Validation of the Method of Evaluating Resistance to Surface Wetting with Liquid of Protective Materials Intended for Polymer Protective Gloves" International Journal of Environmental Research and Public Health 18, no. 17: 9202. https://doi.org/10.3390/ijerph18179202

APA StyleIrzmańska, E., Jastrzębska, A., & Makowicz, M. (2021). Preliminary Research: Validation of the Method of Evaluating Resistance to Surface Wetting with Liquid of Protective Materials Intended for Polymer Protective Gloves. International Journal of Environmental Research and Public Health, 18(17), 9202. https://doi.org/10.3390/ijerph18179202