1. Introduction

Recently, resource shortages and environmental pollution have become serious problems facing all countries in the world. Faced with the urgent requirements of resource conservation and environmental friendliness, modern enterprise production management needs to focus on how to balance economic benefits and environmental sustainable development [

1]. In the early 1980s, the concept of supply chain management (SCM) emerged in the literature, which refers to the management of materials, information flow and logistics activities within and between companies [

2]. Over time, SCM has developed in terms of information flow, internal and external relationship networks, and governance of supply networks [

3]. At the end of the 20th century, Green Supply Chain Management (GSCM) emerged as a new management model and gradually gained people’s attention, and pursues both economic benefits and environmentally sustainable development [

4]. Now it has been favored by research in various fields. Green product design, green supplier evaluation, green production, green packaging and transportation, green marketing and resource recycling are all key links involved in GSCM [

1]. In the whole supply chain, the green supplier is located in the upstream, which plays a great role in cost-saving and environmental protection, and can run through all links of the downstream supply chain [

1]. The selection of green suppliers can effectively improve the compatibility and environmental performance of the supply chain, which is the core part of GSCM [

5].

Some environmental standards need to be emphasized when choosing green suppliers [

6]. In the existing studies, some scholars selected suppliers for standards related to environmental practices [

7] or standards related to hazardous substances management [

8]. Some scholars used social, economic and environmental practices as criteria when selecting suppliers [

9]. In addition, there are some studies that use the company’s GSCM reputation as the standard for selecting suppliers [

6]. However, according to the author’s review of the existing literature, it is not found that the relevant research criteria include after-sales service. In the decision-making process of selecting green suppliers, it is necessary to focus on uncertain language and incomplete information environment issues. Sun et al. [

10] proposed a weights-determining method in MCDM based on negation of probability distribution. This method combines probability distribution negation with evidence theory to reduce the uncertainty caused by human subjective factors through quantitative evaluation of criterion ambiguity. Instead of being provided in advance by the decision maker, Fei and Deng [

11] proposed a new criterion weight determination method based on similarity measures and aggregation operators of PFNs and IVPFNs, which effectively reduces people’s subjective initiative. Therefore, some measures should be taken to improve the reliability of decision results in uncertain environments.

At the same time, scholars used different research methods for green supplier selection in green supply chain management practices. For example, the extended AHP (FAHP, FEAHP), the analytic network process (ANP), applying chi-square tests to explore operational green supplier performance (Vachon and Klassen (2005)), fuzzy TOPSIS and other individual methodology approaches. There are some integrated methodology approaches such as the aggregated ANP and DEA, the aggregated AHP and DEA and the aggregated ANN, MADA, DEA and ANP. In this article, the fuzzy TOPSIS method is used to study supplier selection in green supply chains. For the study of supplier selection, AHP has a large scale and requires experts to evaluate the attributes in pairs, which is too subjective. In addition, its eigenvalue and eigenvector exact method is quite complex. ANN is too complex, the technical requirements are high, it needs a lot of experience and data support, and is not convenient. DEA is objective, but the number of evaluation indexes is required to be less than the number of suppliers, which is obviously not applicable. The traditional TOPSIS approach is easy to understand and fast, but it does not reflect the preferences of decision makers well. However, the fuzzy TOPSIS method quoted in this paper is convenient and efficient, it will not simply use the traditional fuzzy algorithm and will not lead to a degree of distortion or range too large.

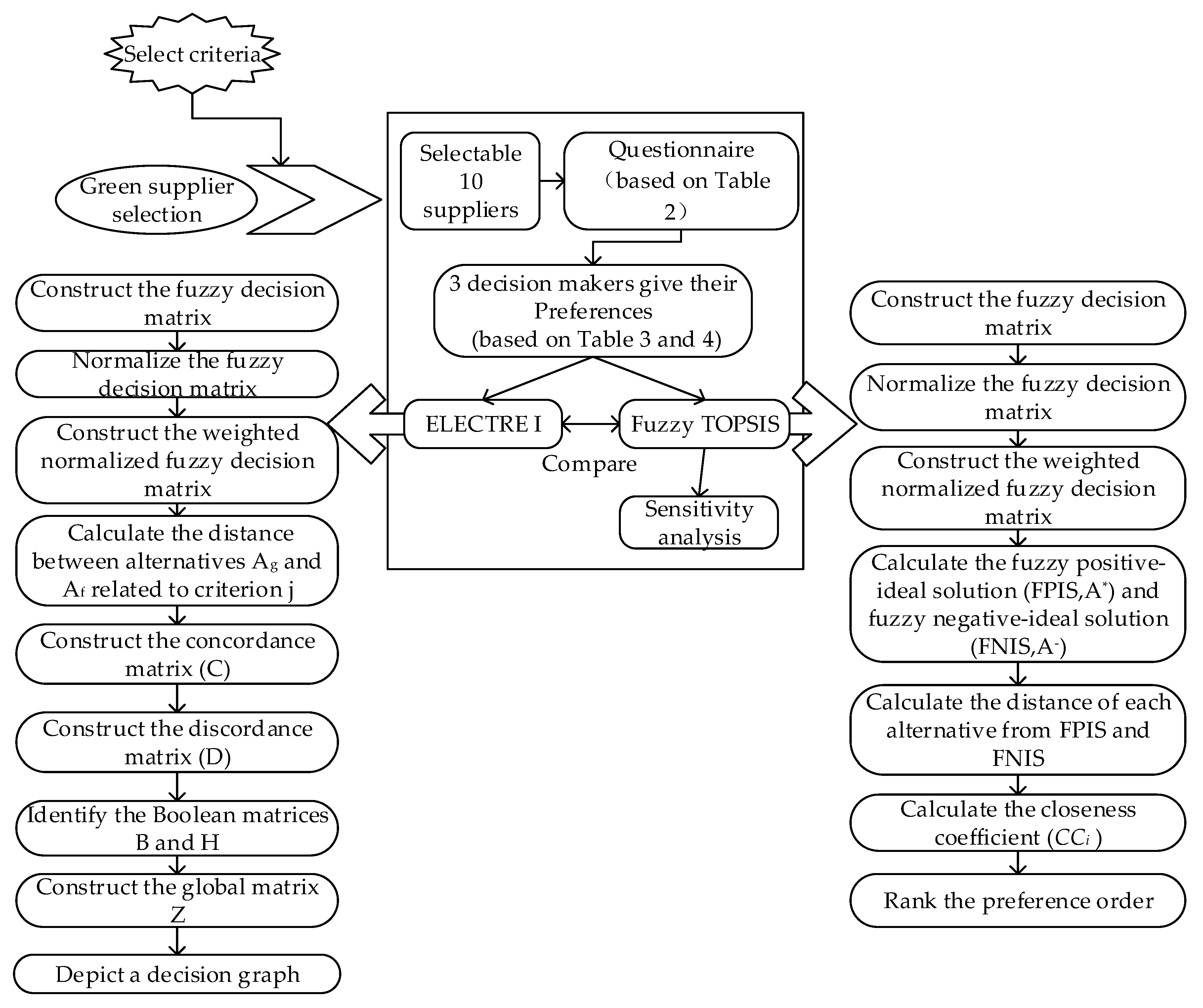

Based on the above analysis, this paper throws away the redundant and similar criteria and proposes 12 criteria that are suitable for the current selection of green suppliers. In addition, a framework of selecting the best green suppliers based on the fuzzy TOPSIS method and the ELECTRE method is proposed, which provides a more reliable practical method for enterprises to choose green suppliers.

The remainder of this paper is arranged as follows.

Section 2 sets up some basic background related to green supply chain management, fuzzy TOPSIS and the ELECTRE method. Then, we introduce some theoretical knowledge about fuzzy TOPSIS and fuzzy ELECTRE I in

Section 3, which lays a foundation for this paper to study the selection of green suppliers. In

Section 4, the method is applied to the supplier selection of a China electronics factory. In addition, a comprehensive sensitivity analysis is performed on the results, calculated using the TOPSIS method to further study the impact of the threshold on the final assessment. In addition, in order to verify the accuracy of the application results of fuzzy TOPSIS method, this paper uses ELECTRE I method to analyze the case, and the final results are similar to the fuzzy TOPSIS technology. Finally, the paper summarizes and analyzes the limitations of this paper and future research direction in

Section 5.

4. Application of the Proposed Green Supplier Selection Framework

An enterprise’s environmental social responsibility is the responsibility consciousness that every enterprise should have. With the enhancement of people’s awareness of ecological protection, the concept of sustainable development is deeply rooted in people’s hearts. Various domestic policies encourage enterprises to develop in a green way, and green environmental protection is gradually incorporated into the corporate culture of each enterprise. We will demonstrate our application of this method in the selection of green suppliers for a Chinese electronics company. In order to achieve sustainable development, the case company is responsible for the products it sells and the environmental impact it causes. The case company realizes that providing greener electronic products not only better meets the needs of customers but also reflects the social value of the company. Finding good green suppliers is the key to improve its supply chain management. The case company’s sustainability manager seeks a way to identify and select suppliers that support the case company’s adoption of GSCM practices.

In this case, ten major suppliers have been identified as candidates for the company (supplier A1, A2, A3, A4, A5, A6, A7, A8, A9 and A10). According to the principles of scientificity, feasibility, systematicness, independence, hierarchy, comparability, dynamics, flexibility and completeness, this paper designs 12 green supplier evaluation criteria. From the previous procurement and green procurement strategy assessment, and by referring to the supplier selection decision criteria in previous studies, we included 11 of the 17 criteria confirmed by Zhu (2008), deleted redundant criteria and combined similar criteria. During the process of selecting criteria, in addition to the traditional decision criteria for supplier selection, in the process of understanding the company’s actual operating conditions and requirements on its suppliers, we learned that the raw materials or parts provided by previous suppliers did not have good after-sales service, and the company often had to deal with defective products by itself. Through interviews with some other electronic companies, we found a similar situation. In order to realize the sustainable development of the company, a criterion of after-sales service was added after the discussion of experts. The final list contains 12 criteria. These criteria are management support for supply chain management (C1), follow legal environmental requirements and policies (C2), passed ISO 14001 certification (C3), use environmentally friendly technologies and equipment (C4), developing ecological products (C5), use environmentally friendly materials (C6), reduce the use of harmful substances (C7), lean management (C8), sustainable recycling design (C9), reasonable inventory management (C10), conduct internal environmental management evaluation of suppliers (C11), and quality after-sales service (C12).

Table 2 presents the details of these criteria.

According to the purpose of the company, we prepared questionnaires to evaluate 10 suppliers, sent the questionnaire to the academic expert group for content analysis and improvement and chose three experienced senior management personnel of the panel (the selected decision makers not only have a deep understanding of the company’s business strategy and operation strategy, but also are familiar with the company’s procurement strategy, supplier selection process and procurement performance results). In this paper, we use 0-10 scale and 0-1 scale to score the alternatives and criteria, as shown in

Table 3 and

Table 4, respectively. To obtain the weight preference of the criteria, three decision makers (D1, D2, D3) were asked to score the selected criteria according to the language terms in

Table 4.

Table 5 shows the fuzzy weight of each decision maker on each criterion. According to the language terms in

Table 3, each decision maker scores 10 alternatives according to the 12 decision criteria developed.

Table 6,

Table 7 and

Table 8 are the fuzzy decision matrices of three decision makers.

4.1. Application of Fuzzy TOPSIS

In the following, we will take the criterion 1 and the alternative 1 as an example to demonstrate the application of the fuzzy TOPSIS method in the proposed framework:

Firstly, we use Equation (9) to calculate the fuzzy aggregated weights (

w) of each criterion as follows:

Likewise, the remaining criteria can be computed and the result is presented in

Table 9.

Secondly, we also use Equation (9) to calculate the fuzzy aggregated weights (

w) of each alternatives. The rating for A1 for C1 can be computed as:

Similarly, the remaining alternatives can be computed and the fuzzy aggregated decision matrix is presented in

Table 10.

Thirdly, we use Equations (11) and (12) to normalize the fuzzy aggregated decision matrix. The normalized rating for A1 for C1 can be calculated as

We only calculate

because all the selected criteria as shown in

Table 11 are benefit criteria. The normalized fuzzy aggregated decision matrix is presented in

Table 12.

Next, we use Equation (13) to compute the fuzzy weighted decision matrix. For A1, the fuzzy weight of C1 is given by

Similarly, the remaining can be computed and the result is presented in

Table 13. Next, the fuzzy positive-ideal solution (

A*) and the fuzzy negative-ideal solution (

A−) of the 10 alternatives can be calculated using Equations (14) and (15) respectively.

Next, we compute the distance of each alternative from the positive-ideal solution

and the distance of each alternative from the negative-ideal solution

using Equation (8). Therefore, for A1 and C1, the distance

and

can be given by

Similarly, we get the distances of the remaining criteria for the 10 alternatives. The results are presented in

Table 14 and

Table 15.

Next, we use Equations (16) and (17) to calculate the distance

and

. For A1 and C1, the distances are given by

Similarly, the distances of remaining alternatives from

A* to

A- can be computed. Then, we calculate the closeness coefficient (

CCi) of each alternative. Therefore, the

CCi of A1 is given by

Similarly, the

CCi of other alternatives can be computed. The results are shown in

Table 16.

Finally, we compare the CCi of each alternatives and rank them.

4.2. Results

The final results of fuzzy TOPSIS analysis are shown in

Table 17. According to the calculation of the closeness coefficient, the ranking of 10 suppliers is:

A9 > A2 > A3 > A5 > A1 > A8 > A7 > A6 > A4 > A10

Based on the ranking, we can say that the supplier 9 is the best selection.

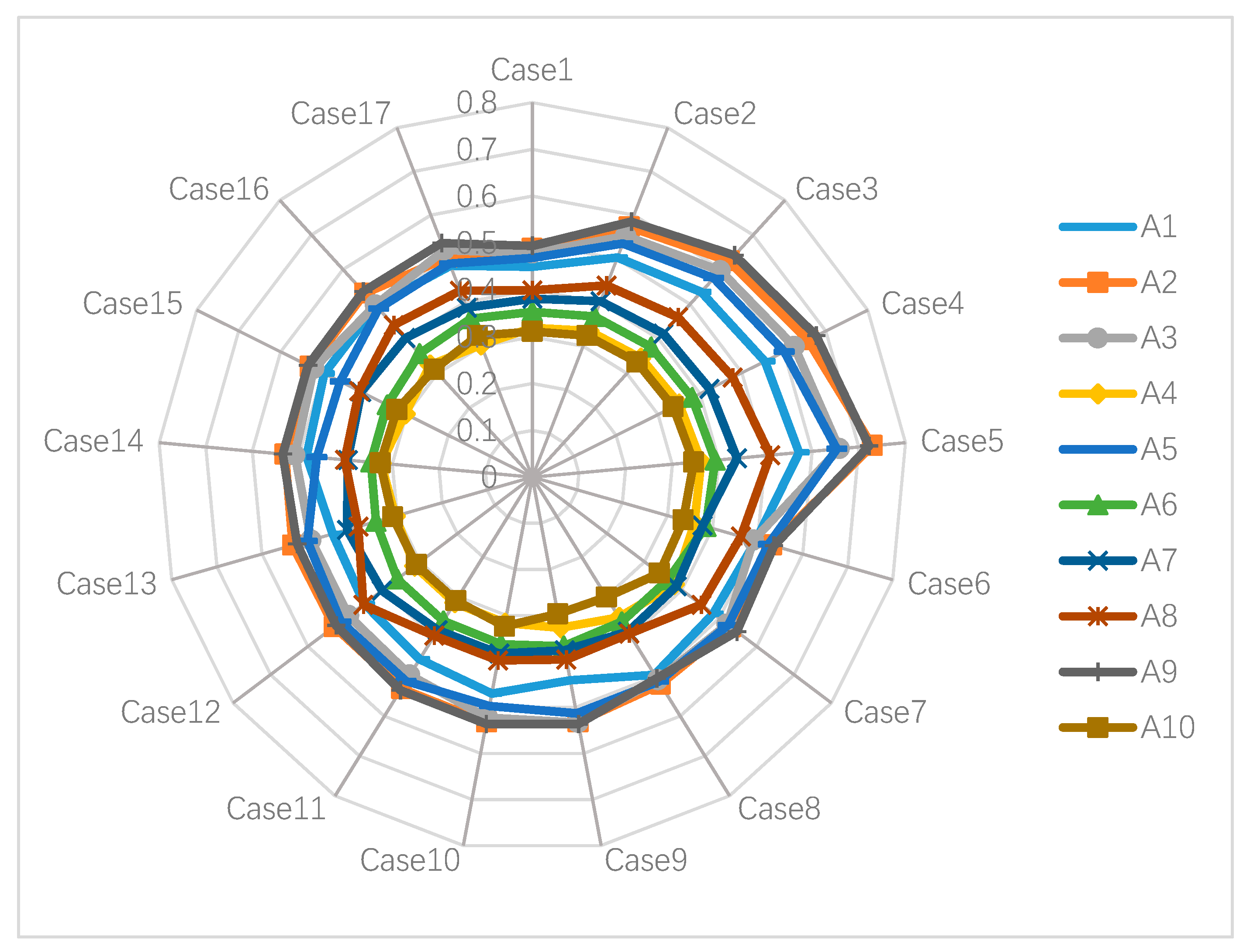

4.3. Sensitivity Analysis

The purpose of sensitivity analysis is to examine the influence of choosing different weights for criteria on the selection of green supplier. To perform the sensitivity analysis, we ranked the 12 criteria affecting GSCM by their importance according to the weights given above, as shown in

Table 18. In this sensitivity analysis, we conducted 17 cases and their details are presented in

Table 19. In the first five cases of sensitivity analysis, we let all criteria’s weights vary from very low (VL) to very high (VH) which are (0,0.2,0.4), (0.2,0.4,0.6), (0.4,0.6,0.8), (0.6,0.8,1), and (0.8,0.9,1). In the 6th case, we set the weight of the first criterion to very high (0.8,0.9,1) and the rest to very low (0,0.2,0.4). In the 7th cases, we set the weight of the 2nd criterion to very high (0.8,0.9,1) and the rest to very low (0,0.2,0.4), and the rest of the cases are done in the same way. We calculate the closeness coefficient of each alternative in different cases, and the alternatives were ranked under 17 different cases. The results of the sensitivity analysis are presented in

Table 20 and

Figure 3.

According to the sensitivity analysis results in

Table 20 and

Figure 4, we can see that even if the rank of the green supplier changed slightly with the weight changed, generally, supplier 9 is the best. Supplier 9 has the highest closeness coefficient in 13 cases (case numbers 1–4, 6–7, 9–11, 14–17). Supplier 2 is the best in the remaining four cases. Therefore, it is clear that our decision-making process is relatively insensitive to changes in the weights of the criteria.

4.4. Application of Fuzzy ELECTRE I

In this section, we illustrate the application of the fuzzy ELECTRE I method in the framework of this paper:

Firstly, we use Equation (10) to calculate the distance between Ag and Af related to the j criterion, and the results are shown in

Table 21. The steps before this step are the same as those before the fuzzy TOPSIS method to calculate the distance. Secondly, in order to obtain the concordance matrix, we use Equation (19) to calculate the preference value between two given alternatives on each criterion, and the results are shown in

Table 22. Thirdly, we use Equation (20) to get the discordance matrix as shown in

Table 23. Fourthly, we obtain the Boolean matrices B and H based on the minimum concordance level and minimum discordance level by using Equations (21) and (22), respectively. The Boolean matrices B and H are shown in

Table 24 and

Table 25 respectively. Fifthly, we use Equation (23) to obtain the global matrix Z as shown in

Table 26. Finally, we get the results of the fuzzy ELECTRE I, as shown in

Table 27.

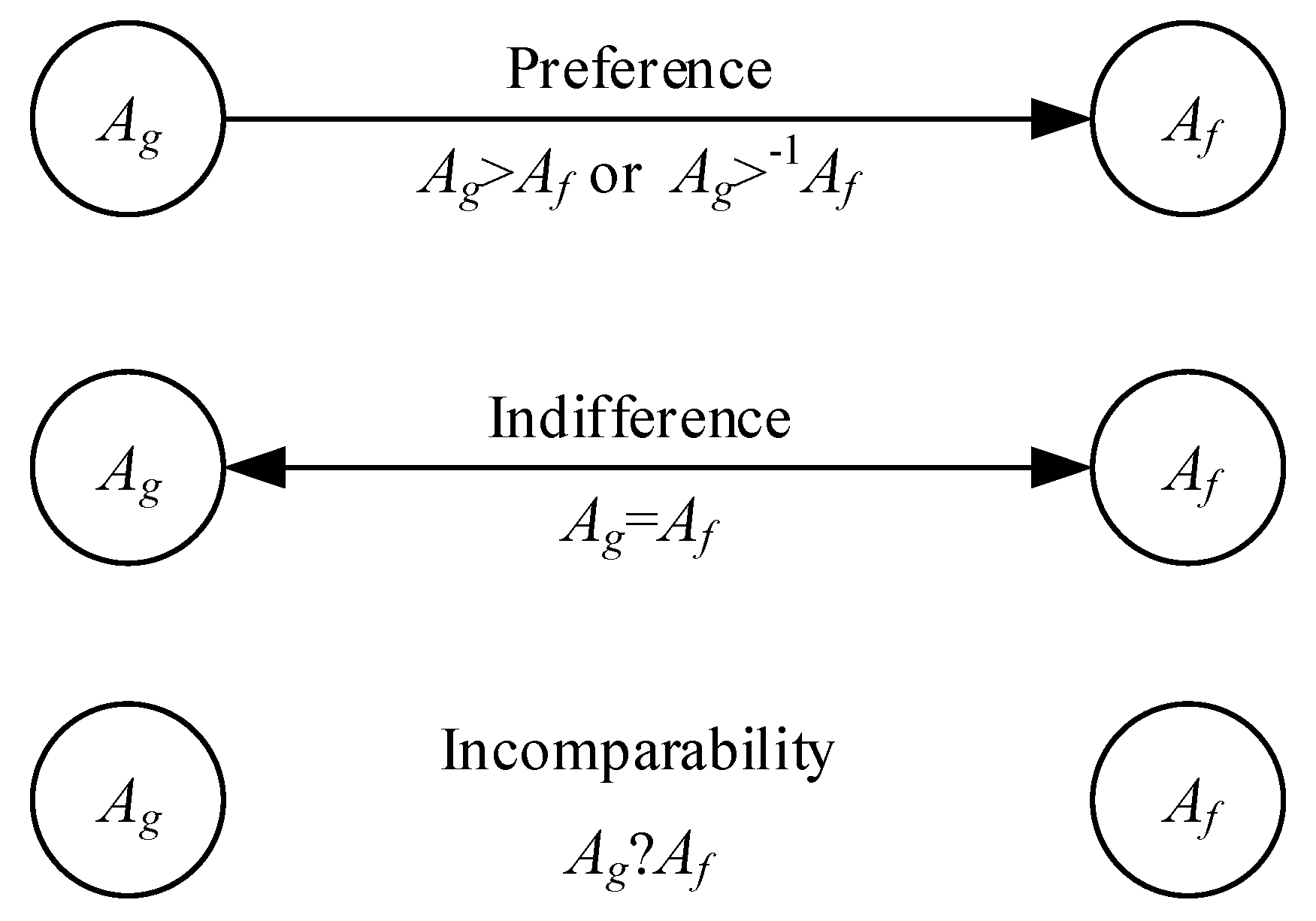

It can be concluded from the global matrix Z that A2, A5 and A9 are the three alternatives with the most advantages over other alternatives. Moreover, we can conclude from the outranking relations among all the alternatives that A2, A5 and A9 are incomparable. Therefore, A2, A5 and A9 constitute a set of best alternatives.

4.5. Discussion

In this section, we compare the results of the application of the fuzzy TOPSIS method and the ELECTRE I method to the green supplier selection of a Chinese Internet company, as shown in

Table 28.

We also use a line chart to compare the ranking of the green suppliers of the internet company under the two methods, as shown in

Figure 5. The figure more vividly shows the similarity of the evaluation of ten suppliers under the two methods.

By considering the rankings of each alternative of the two methods in

Table 28, it is found that the rankings of the ten alternatives are almost the same; in this case, A9 is the first and A10 is the tenth in the decision-making problem of green supplier selection. Generally, enterprises can choose more than one supplier in order to reduce the risk brought by suppliers. Therefore, A2 can be included in the supplier range selected by the company as the second of all alternatives. Comparing the TOPSIS method and the ELECTRE I method, there are the following similarities and differences:

(1) Both are based on different criteria and the relative importance of the criteria in the linguistic variables, and the scheme is intuitively fuzzy scored, then, the true value membership and non-truth value membership function.

(2) Both are based on the concept of distance measurement in an intuitionistic fuzzy environment.

(3) The TOPSIS method provides full compensation in the group decision-making process; however, the ELECTRE method provides partial compensation from the perspective of criterion information processing [

58].

(4) The TOPSIS method is a derivation of a preference rank order based on approaching ideal solution technology; but, the ELECTRE method is a derivation of recommendations based on outranking relations.

(5) The goal of the TOPSIS method is ranking problematic; the goal of the ELECTRE method is choice problematic [

57]. The TOPSIS method can provide a selection sequence of alternatives; the ELECTRE method will provide a set of good alternatives.

In our research process, at least three advantages of the TOPSIS method are fully reflected and applied [

41,

42]:

(1) A reasonable logical fit with the basic principles of human selection;

(2) A scalar value that accounts for both the best and worst alternatives simultaneously;

(3) A simple calculation process that is easy to program into a spreadsheet.

Therefore, the results of our study are highly credible.

5. Conclusions

From the review of the current literature, it can be seen that GSCM has become a topic that enterprises must pay attention to. GSCM practice will help companies improve their business performance while responding to the background of green development. An important part of the company’s GSCM practice—how to evaluate suppliers and select the best green suppliers is critical.

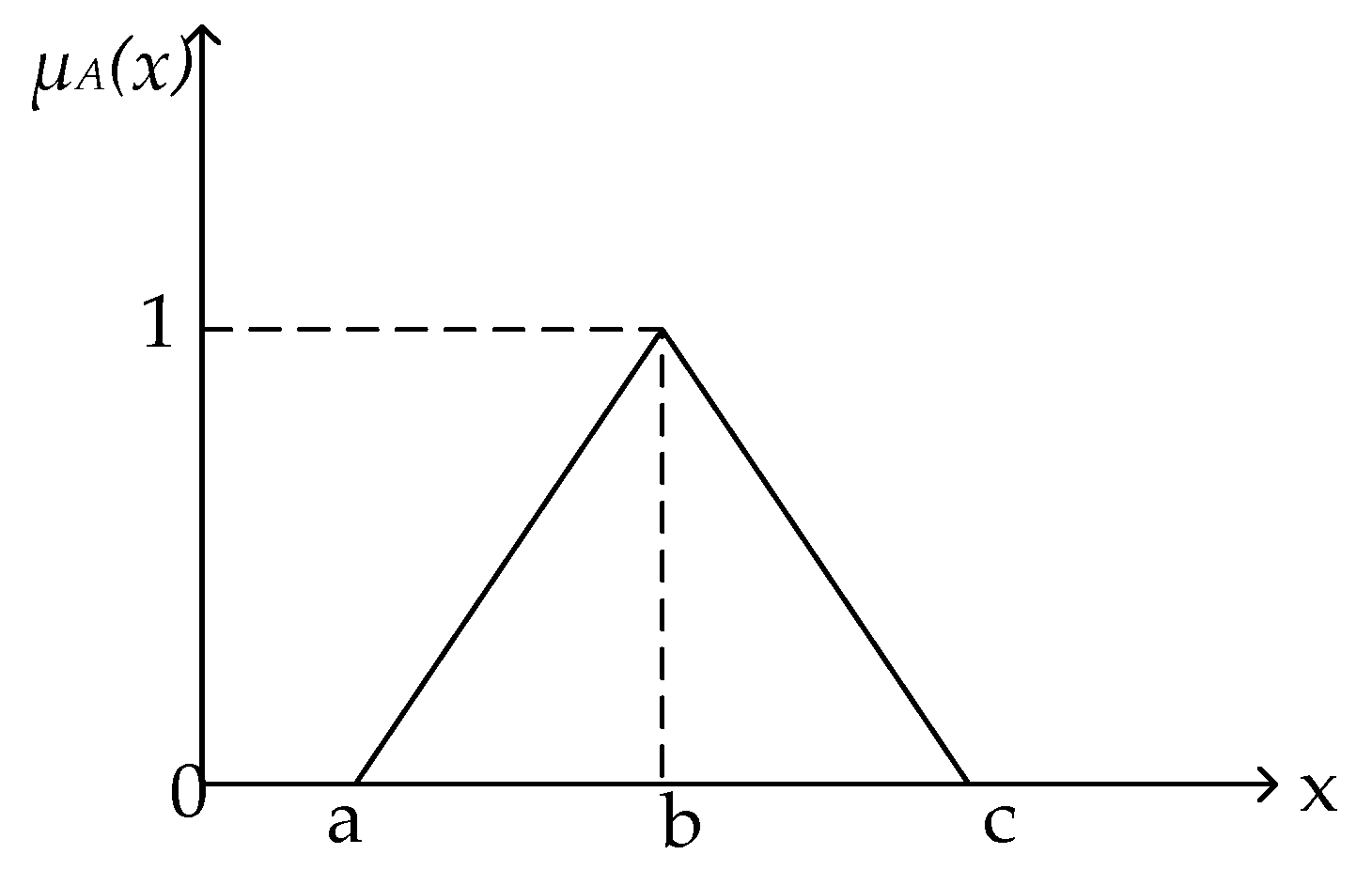

This paper studies the selection of green suppliers in the language environment of triangular fuzzy numbers based on GSCM practice. The framework of a green supplier selection method for enterprises is presented. In order to make a reasonable and reliable evaluation of alternative suppliers, this paper selects 12 criteria that affect supplier GSCM practices based on the literature review and expert’s opinions. Using the fuzzy TOPSIS method and the ELECTRE method, the results of the two methods are compared to obtain the best green suppliers. Applying the framework to the green supplier selection of a Chinese internet company, the results show that the main influential criteria for CSCM practices are management support for green supply chain management, use of environmentally friendly materials, following legal environmental requirements and policies, reducing the use of harmful substances, developing ecological products and sustainable recycling design. The fundamental requirement for achieving really green development is the support of management for GSCM. In addition, our new criterion 12 (quality after-sales service) also affects the selection of green suppliers. In China, companies have gradually realized the importance of supply chain management and the importance of after-sales service. Yet, few companies combine supplier selection with their after-sales services for governance. After-sales service is not only a service strategy formulated by manufacturers to distributors and retail enterprises, or a service strategy of sellers to consumers, but also a service of suppliers to manufacturers. The complexity of supply chain management is obvious. By reducing problems at the source, the entire supply chain can run more smoothly. The criteria are divided into benefit and cost, and 10 suppliers are evaluated by 12 criteria. The alternative which is close to the positive-ideal solution but far away from the negative-ideal solution was selected as the best alternative. Finally, we analyzed and found that alternative 9 is the best selection and that alternative 2 can also be included in the company’s selection of green suppliers

The superposition of the two methods improves the reliability of the results. However, this paper does have some limitations. This paper proposes an evaluation framework for selecting green suppliers and applies it to practical cases, but it is not widely used for the time being. In addition, this paper also has shortcomings in methods. For the two methods of fuzzy TOPSIS and ELECTRE, the application of this paper will result in the difficulty of data processing in the case of many alternative suppliers and many evaluation criteria. We will make innovations in the application of the two methods in future research, making them more convenient, intuitive and effective, and the results more precise, so as to improve the application of the framework. Our future research methods may include the use of Intuitionistic fuzzy sets and Pythagorean sets, and then, compare the results obtained by these methods with the results obtained in this work. The improvement of the solution method of the supplier selection problem and the development of a more efficient and high-quality group decision support system under the fuzzy environment are the directions of future research topics.