Short- and Long-Term Structural Characterization of Cured-in-Place Pipe Liner with Reinforced Glass Fiber Material

Abstract

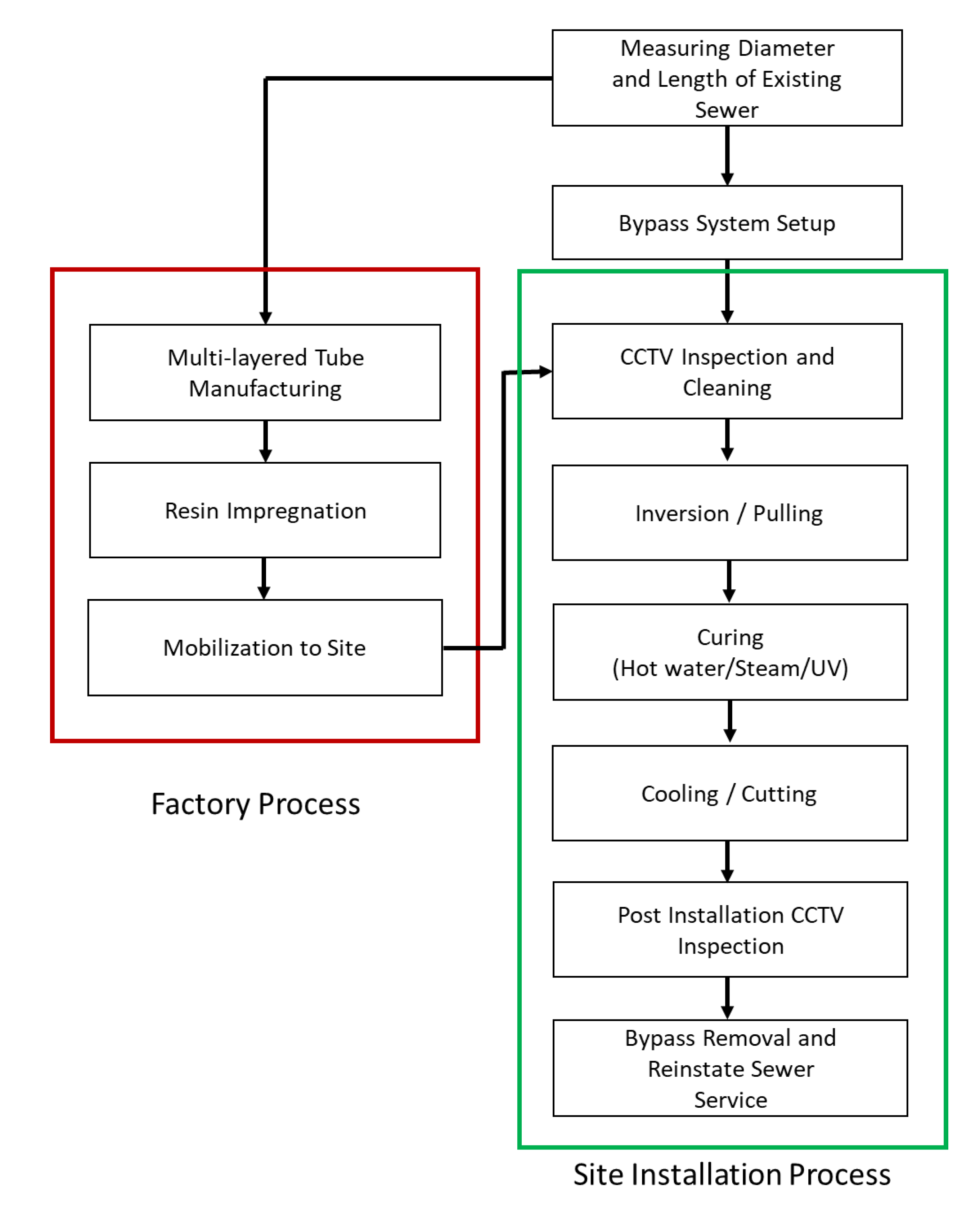

1. Introduction

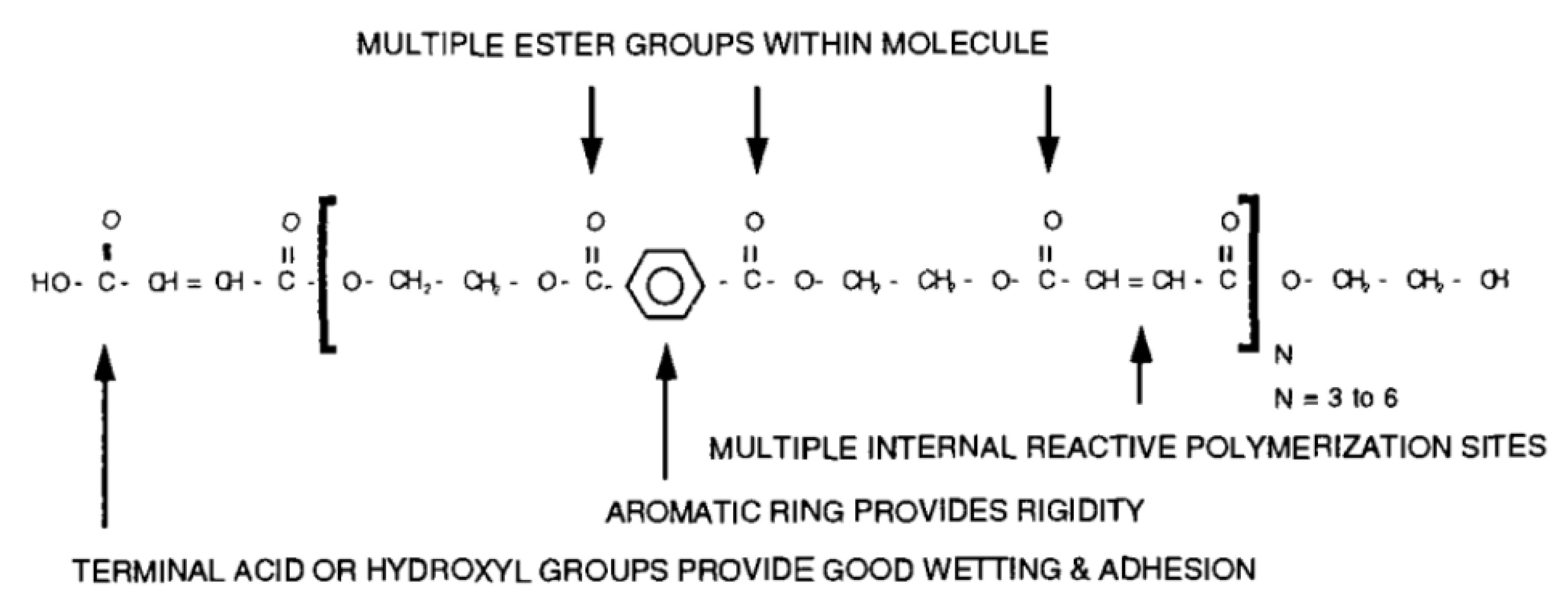

2. Experimental Materials and Methods

2.1. Short-Term Test

2.2. Long-Term Test

3. Results and Discussion

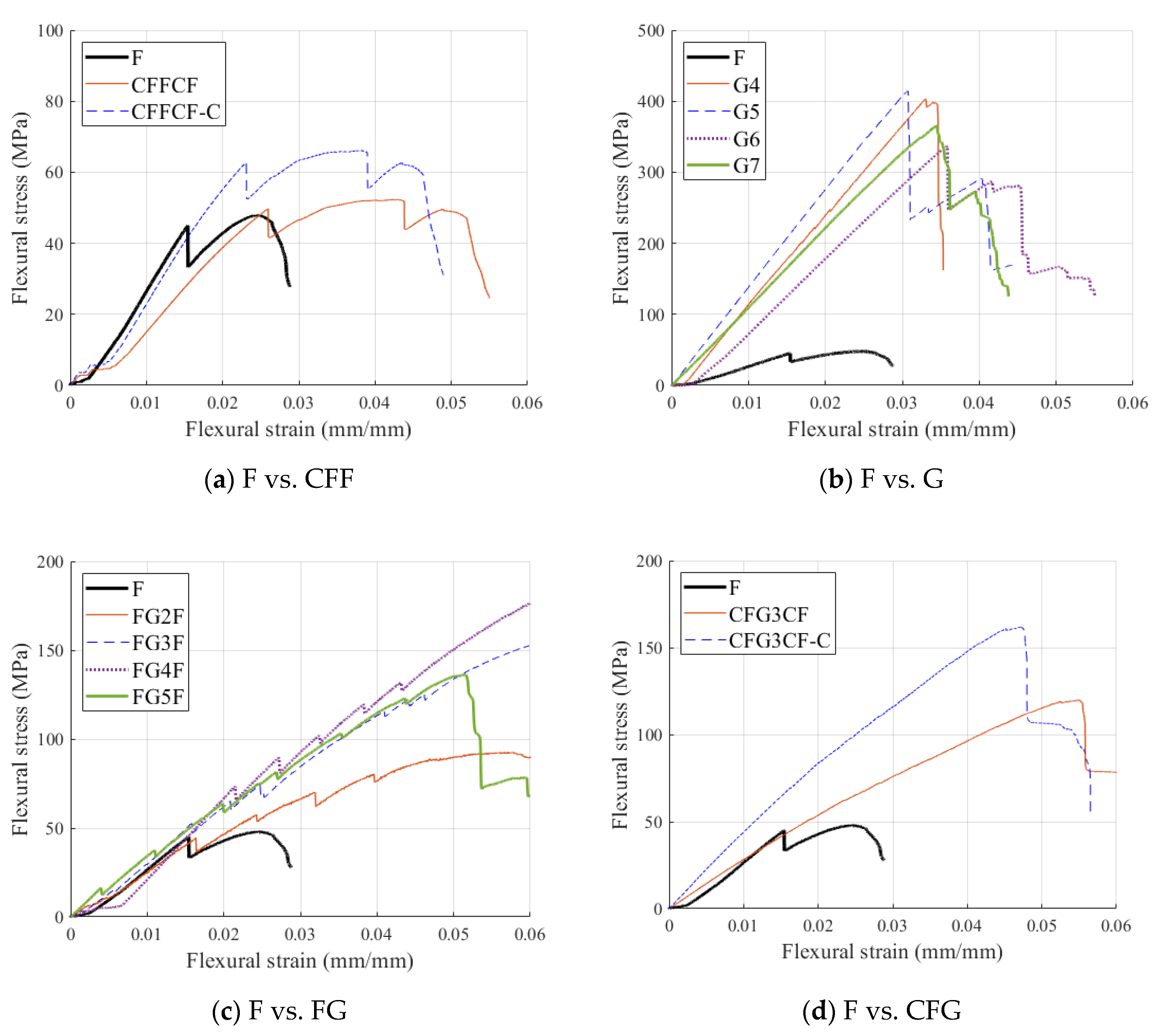

3.1. Short-Term Structural Characterization

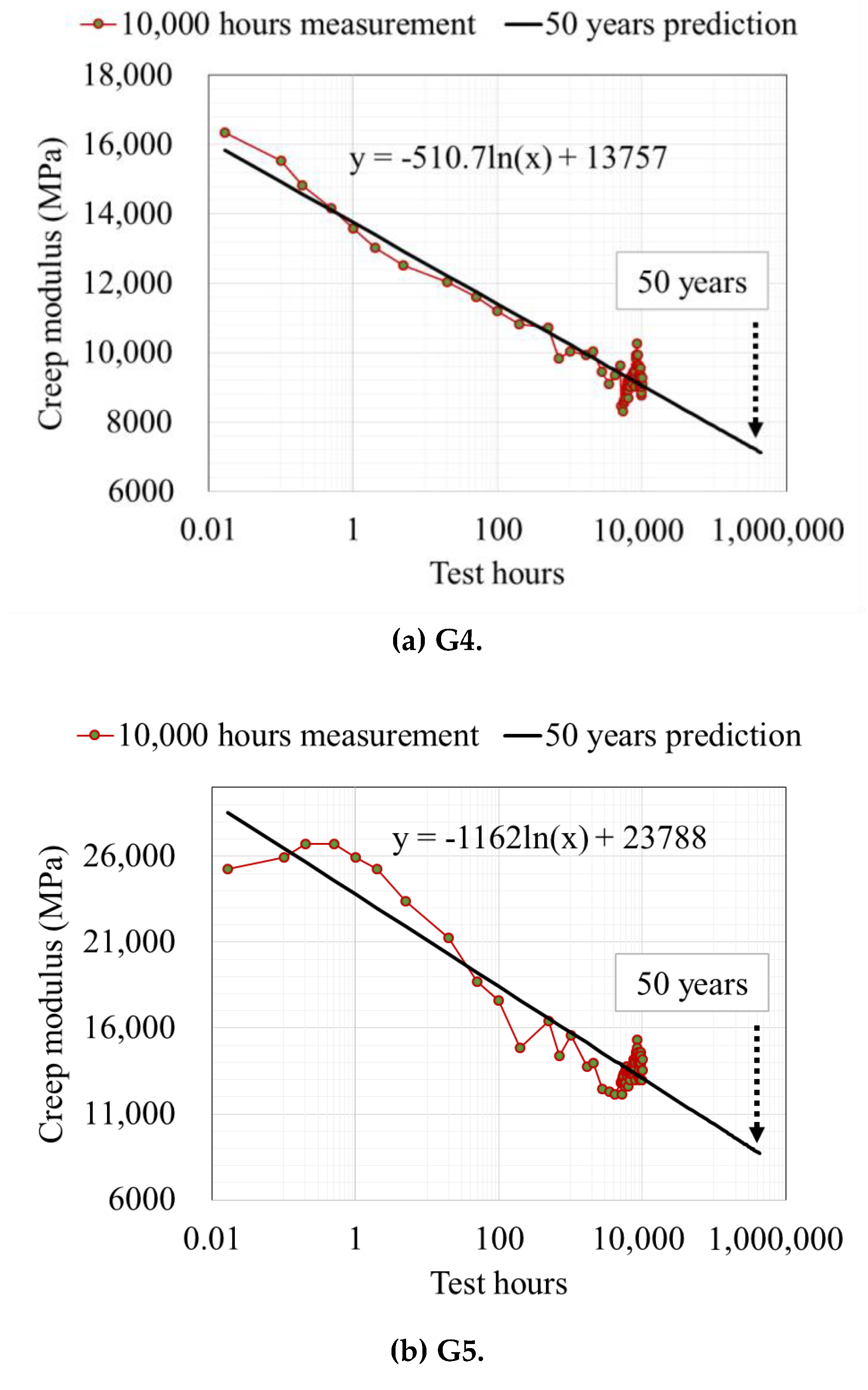

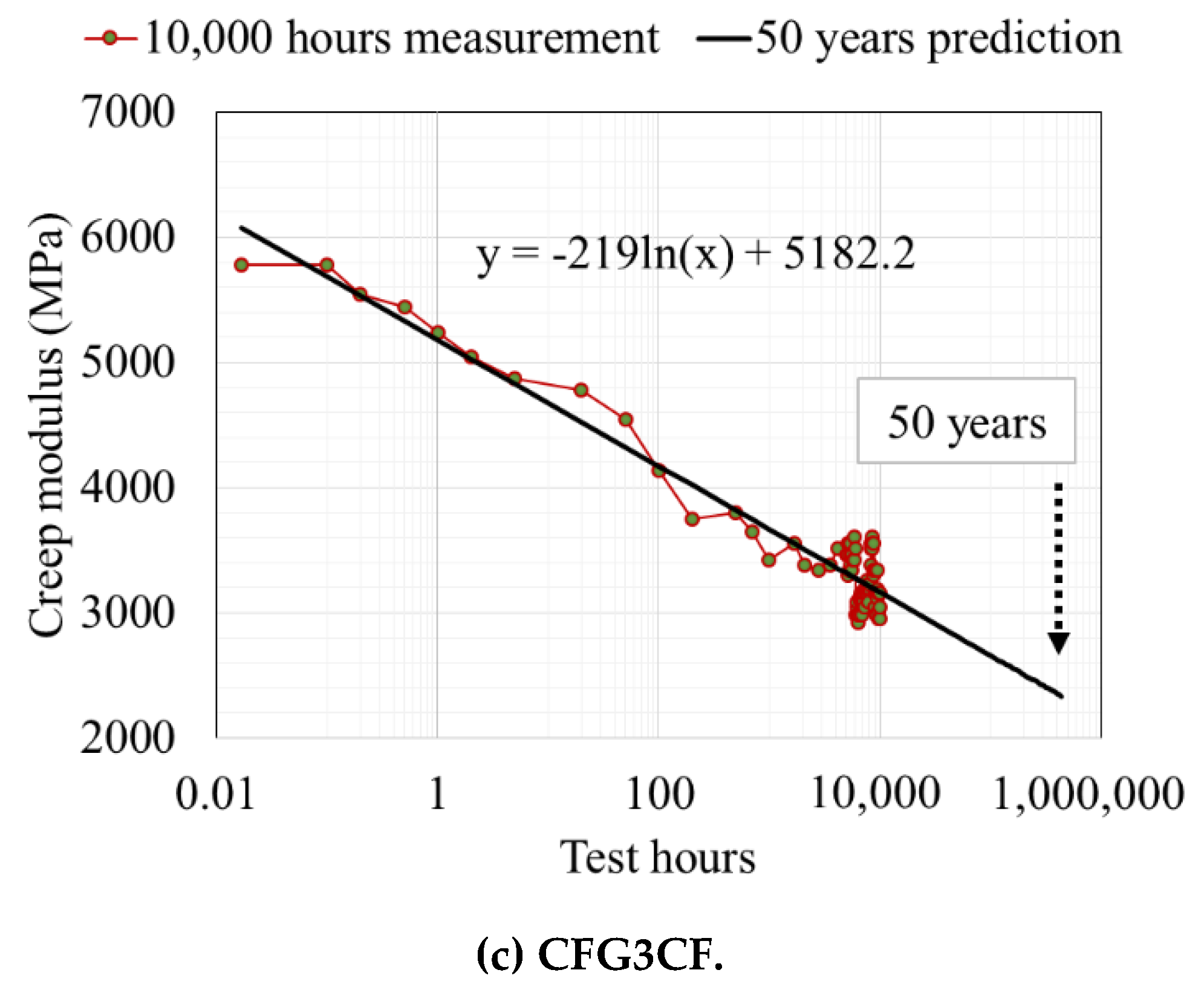

3.2. Long-Term Structural Characterization

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buttrick, D.; Van Schalkwyk, A. Hazard and risk assessment for sinkhole formation on dolomite land in South Africa. Environ. Geol. 1998, 36, 170–178. [Google Scholar] [CrossRef]

- Gangavarapu, B.S.; Najafi, M.; Salem, O. Quantitative analysis and comparison of traffic disruption using open-cut and trenchless methods of pipe installation. In New Pipeline Technologies, Security, and Safety; American Society of Civil Engineers: Reston, VA, USA, 2003; pp. 1714–1724. [Google Scholar]

- Cohen, A. Applications of Maxi Rig horizontal directional drilling for municipal sewer/water markets. In ICPTT 2013: Trenchless Technology; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 535–544. [Google Scholar]

- Kamat, S.M. Comparison of Dust Generation from Open Cut and Trenchless Technology Methods for Utility Construction. Master’s Thesis, University of Texas at Arlington, Arlington, TX, USA, May 2001. [Google Scholar]

- Jung, Y.J.; Sinha, S.K. Evaluation of trenchless technology methods for municipal infrastructure system. J. Infrastruct. Syst. 2007, 13, 144–156. [Google Scholar] [CrossRef]

- Najafi, M.; Kim, K.O. Life-cycle-cost comparison of trenchless and conventional open-cut pipeline construction projects. In Pipeline Engineering and Construction: What’s on the Horizon; American Society of Civil Engineers: Reston, VA, USA, 2004; pp. 1–6. [Google Scholar]

- McKim, R.A. Selection method for trenchless technologies. J. Infrastruct. Syst. 1997, 3, 119–125. [Google Scholar] [CrossRef]

- Kampbell, N.E. Waterline Rehabilitation: The Objectives and the technologies. In Proceedings of the North American Society for Trenchless Technology (NASTT) No Dig 2007 Conference, San Diego, CA, USA, 16–19 April 2007. [Google Scholar]

- Syachrani, S.; Jeong, H.S.D.; Rai, V.; Chae, M.J.; Iseley, T. A risk management approach to the safety assessment of trenchless technologies for culvert rehabilitation. Tunn. Undergr. Space Technol. 2010, 25, 681–688. [Google Scholar] [CrossRef]

- Hollaway, L. Polymeric materials. In Polymer Composites for Civil and Structural Engineering; Blackie Academic & Professional: Bishopbriggs, UK, 1993; pp. 24–27. [Google Scholar]

- ASTM International. Standard practice for rehabilitation of existing pipelines and conduits by the inversion and curing of a resin-impregnated tube. In Annual Book of ASTM Standards; ASTM F1216; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Sedgeman, A.; Schmidt, M.; Ehsani, M.; Murphy, M. Water flows uphill in Colorado: Rehabilitation of 54-inch irrigation siphon. In Proceedings of the North American Society for Trenchless Technology (NASTT) No Dig 2019 Conference, Chicago, IL, USA, 17–20 March 2019. [Google Scholar]

- NASTT. CIPP mechanical properties and testing. In Nastt’s Cured-in-Place (Cipp) Good Practices Guidelines; North American Society for Trenchless Technology: Cleveland, OH, USA, 2015; pp. 2–17. [Google Scholar]

- Lancaster, I.; Zarghamee, M. The evolution of carbon fiber CIPP (CFCIPP) for small diameter potable water & fire suppression systems. In Proceedings of the North American Society for Trenchless Technology (NASTT) No Dig 2019 Conference, Chicago, IL, USA, 17–20 March 2019. [Google Scholar]

- Riahi, A.M. Short-Term and Long-Term Mechanical Properties of Cipp Liners. Master’s Thesis, University of Waterloo, Waterloo, ON, USA, 2015. [Google Scholar]

- Donaldson, B.M. Environmental implications of cured-in-place pipe rehabilitation technology. Transp. Res. Rec. 2009, 2123, 172–179. [Google Scholar] [CrossRef]

- Ra, K.; Sendesi, S.M.T.; Nuruddin, M.; Zyaykina, N.N.; Conkling, E.N.; Boor, B.E.; Whelton, A.J. Considerations for emission monitoring and liner analysis of thermally manufactured sewer cured-in-place-pipes (CIPP). J. Hazard. Mater. 2019, 371, 540–549. [Google Scholar] [CrossRef] [PubMed]

- Alam, S.; Matthews, J.; Sterling, R.; Allouche, E.; Selvakumar, A.; Condit, W.; Downey, D. Evaluation of testing methods for tracking CIPP liners’ life-cycle performance. Cogent Eng. 2018, 5, 1463594. [Google Scholar] [CrossRef]

- Nuruddin, M.; Mendis, G.P.; Ra, K.; Sendesi, S.M.T.; Futch, T.; Goodsell, J.; Howarter, J.A. Evaluation of the physical, chemical, mechanical, and thermal properties of steam-cured PET/polyester cured-in-place pipe. J. Compos. Mater. 2019, 53, 2687–2699. [Google Scholar] [CrossRef]

- Kleweno, D.G. Physical Properties and Chemical Resistance of Selected Resins for Cured-in-Place Pipe Rehabilitation. In Buried Plastic Pipe Technology, 2nd ed.; Eckstein, D., Ed.; ASTM Publication: Philadelphia, PA, USA, 1994. [Google Scholar]

- ASTM International. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. In Annual Book of ASTM Standards; ASTM D790; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Korean Standards Association. Cured-in-place thermosetting resin tube for renovation of sewer piping system. KS M 3550-9 2016. (In Korean) [Google Scholar]

- ASTM International. Standard test methods for tensile, compressive, and flexural creep and creep-rupture of plastics. In Annual Book of ASTM Standards; ASTM D2990; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Water Industry Specification. Specification for renovation of gravity sewers by lining with cured-in-place pipe. WIS 4-34-04 1995. [Google Scholar]

- Guice, L.K.; Straughan, W.T.; Norris, C.R.; Bennett, R.D. Long-Term Structural Behavior of Pipeline Rehabilitation Systems; Technical Report #302; Trenchless Technology Center, Louisiana Tech University: Ruston, LA, USA, 1994. [Google Scholar]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Ji, H.W.; Yoo, S.S.; Kim, J.; Koo, D.D. The mechanical properties of high strength reinforced Cured-in-place pipe (CIPP) liner composites for urban water infrastructure rehabilitation. Water 2018, 10, 983. [Google Scholar] [CrossRef]

- Sudheer, M.; Pradyoth, K.R.; Somayaji, S. Analytical and numerical validation of epoxy/glass structural composites for elastic models. Am. J. Mater. Sci. 2015, 3, 162–168. [Google Scholar]

- Alam, S.; Sterling, R.L.; Allouche, E.; Condit, W.; Matthews, J.; Selvakumar, A.; Simicevic, J. A retrospective evaluation of the performance of linear systems used to rehabilitate municipal gravity sewers. Tunn. Undergr. Space Technol. 2015, 50, 451–464. [Google Scholar] [CrossRef]

| Chemical Solution | Concentration (%) |

|---|---|

| Tap water (pH 6–9) | 100 |

| Nitric acid | 5 |

| Phosphoric acid | 10 |

| Sulfuric acid | 10 |

| Gasoline | 100 |

| Vegetable oil | 100 |

| Detergent | 0.1 |

| Soap | 0.1 |

| Material Name | Abbreviation | Thickness | Type |

|---|---|---|---|

| Unsaturated polyester resin | - | n/a (Liquid state) | Iso-type |

| Polyester nonwoven felt | F | 2 mm | Polyester |

| Polyester nonwoven felt with coating film | CF | 1.5 mm | Polyester |

| Roving cross glass fiber and chopped strand mat | G | 1 mm | E-glass |

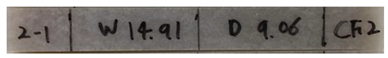

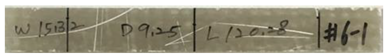

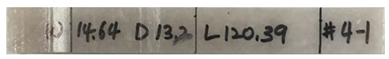

| Group | Samples Designations | Standard Images of Samples |

|---|---|---|

| F | F |  |

| CFF | CFFCF |  |

| G | G4/G5/G6/G7 |  |

| FG | FG2F/FG3F/FG4F/FG5F |  |

| CFG | CFG3CF |  |

| Samples | Thickness (d, mm) | Flexural Properties | ||

|---|---|---|---|---|

| Strain (r, %) | Strength (σf, MPa) | Modulus (EB, MPa) | ||

| F | 8.47 | 2.4 | 48 | 3488 |

| CFFCF | 9.06 | 4.3 | 52 | 2309 |

| CFFCF excluding C | 8.06 | 3.8 | 66 | 3279 |

| G4 | 5.55 | 3.3 | 403 | 13,800 |

| G5 | 5.85 | 3.1 | 414 | 13,700 |

| G6 | 8.86 | 3.6 | 337 | 10,490 |

| G7 | 9.03 | 3.4 | 365 | 10,820 |

| FG2F | 6.61 | 5 | 90 | 3474 |

| FG3F | 7.64 | 5 | 132 | 4718 |

| FG4F | 9.44 | 5 | 150 | 4830 |

| FG5F | 13.16 | 5 | 135 | 4200 |

| CFG3CF | 7.14 | 5 | 115 | 2917 |

| CFG3CF excluding C | 6.14 | 4.7 | 161 | 4586 |

| Samples | d (mm) | EB (MPa) | M (kg) | EL50 (MPa) | CL (CRF) |

|---|---|---|---|---|---|

| G4 | 5.14 | 12,800 | 10 | 7121 | 0.56 |

| G5 | 5.94 | 13,600 | 15 | 8688 | 0.64 |

| CFG3CF excluding C | 5.96 | 4590 | 4.5 | 2336 | 0.51 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, H.W.; Koo, D.D.; Kang, J.-H. Short- and Long-Term Structural Characterization of Cured-in-Place Pipe Liner with Reinforced Glass Fiber Material. Int. J. Environ. Res. Public Health 2020, 17, 2073. https://doi.org/10.3390/ijerph17062073

Ji HW, Koo DD, Kang J-H. Short- and Long-Term Structural Characterization of Cured-in-Place Pipe Liner with Reinforced Glass Fiber Material. International Journal of Environmental Research and Public Health. 2020; 17(6):2073. https://doi.org/10.3390/ijerph17062073

Chicago/Turabian StyleJi, Hyon Wook, Dan Daehyun Koo, and Jeong-Hee Kang. 2020. "Short- and Long-Term Structural Characterization of Cured-in-Place Pipe Liner with Reinforced Glass Fiber Material" International Journal of Environmental Research and Public Health 17, no. 6: 2073. https://doi.org/10.3390/ijerph17062073

APA StyleJi, H. W., Koo, D. D., & Kang, J.-H. (2020). Short- and Long-Term Structural Characterization of Cured-in-Place Pipe Liner with Reinforced Glass Fiber Material. International Journal of Environmental Research and Public Health, 17(6), 2073. https://doi.org/10.3390/ijerph17062073