Mn-Fe Layered Double Hydroxide Intercalated with Ethylene-Diaminetetraacetate Anion: Synthesis and Removal of As(III) from Aqueous Solution around pH 2–11

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Intercalated Mn-Fe LDHs

2.2.1. Preparation of EDTA@MF-LDHs

2.2.2. Preparation of CO3@MF-LDHs

2.3. Characterization

2.4. Batch Experiment

3. Results

3.1. Characterization of Intercalated Mn-Fe-LDHs

3.1.1. XRD

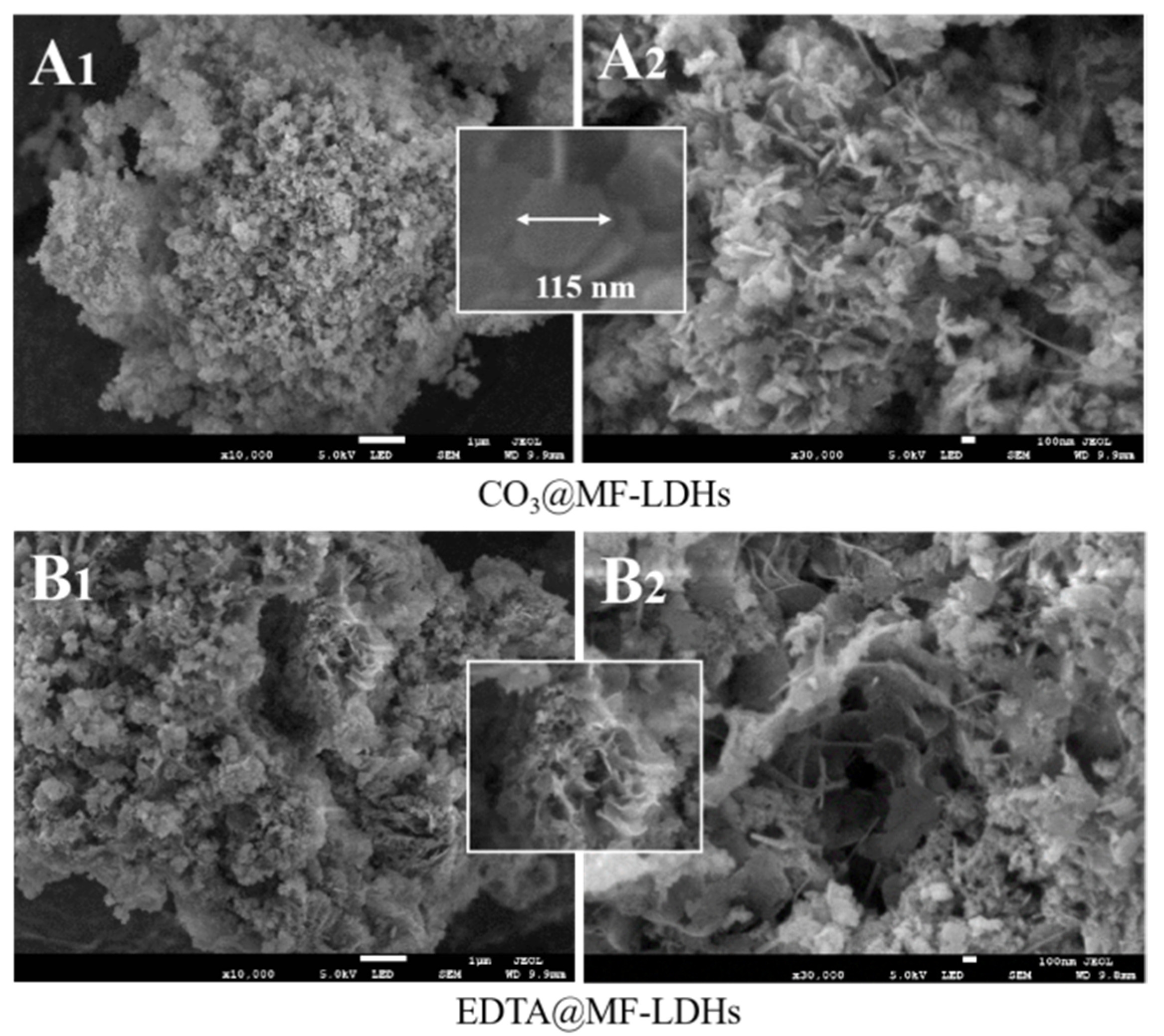

3.1.2. SEM and EDS

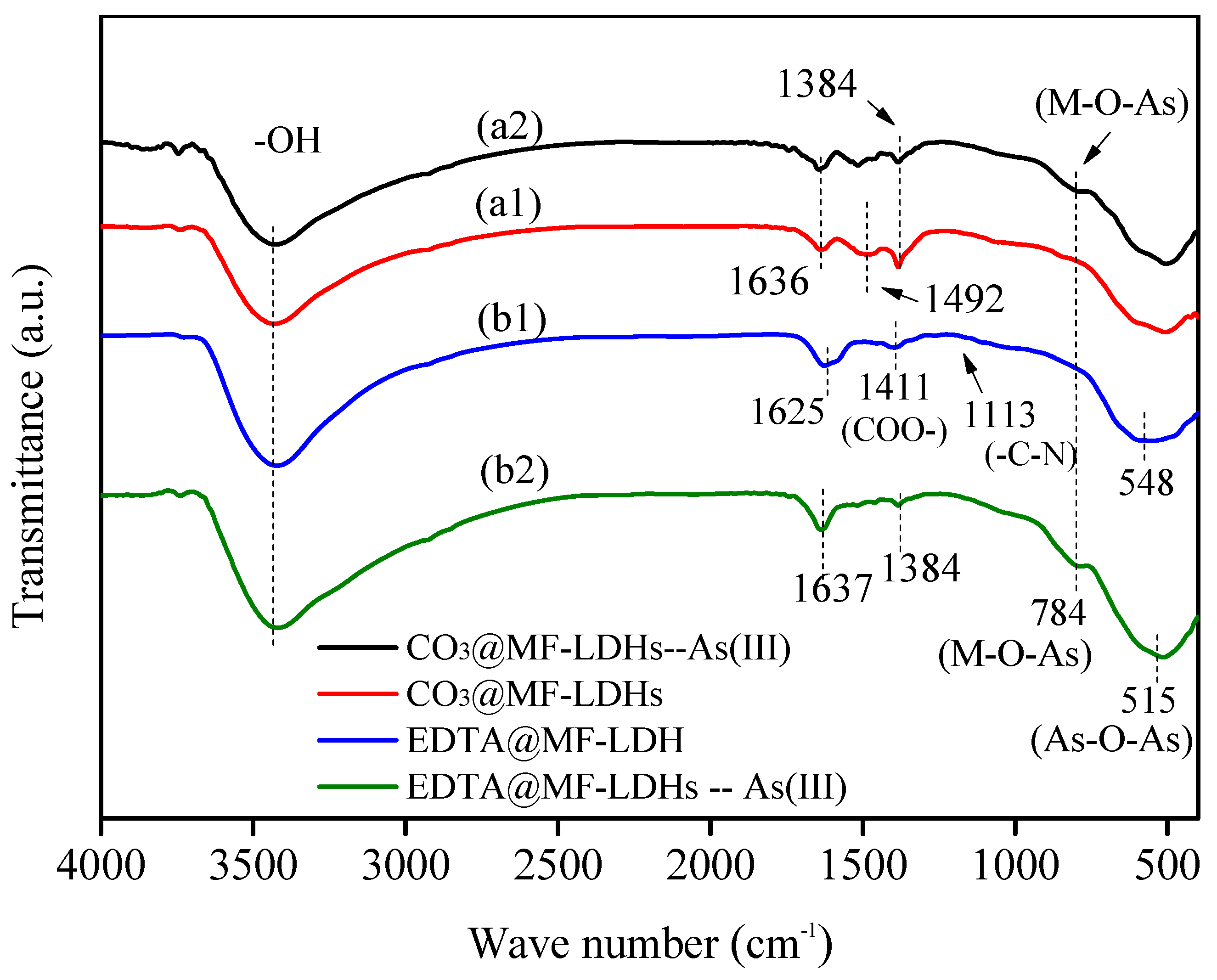

3.1.3. FT-IR

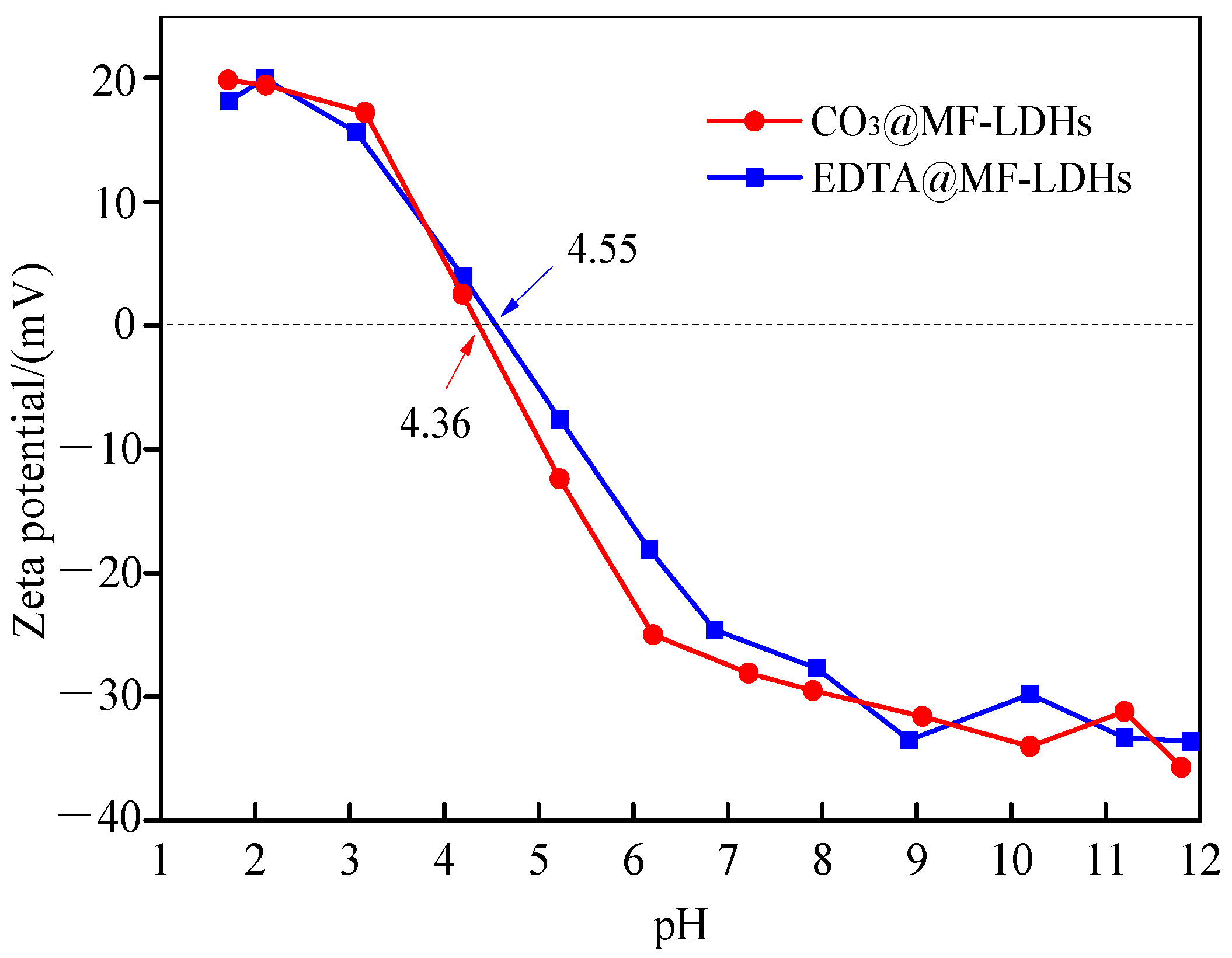

3.1.4. Point of Zero Charge

3.2. Sorption Performance

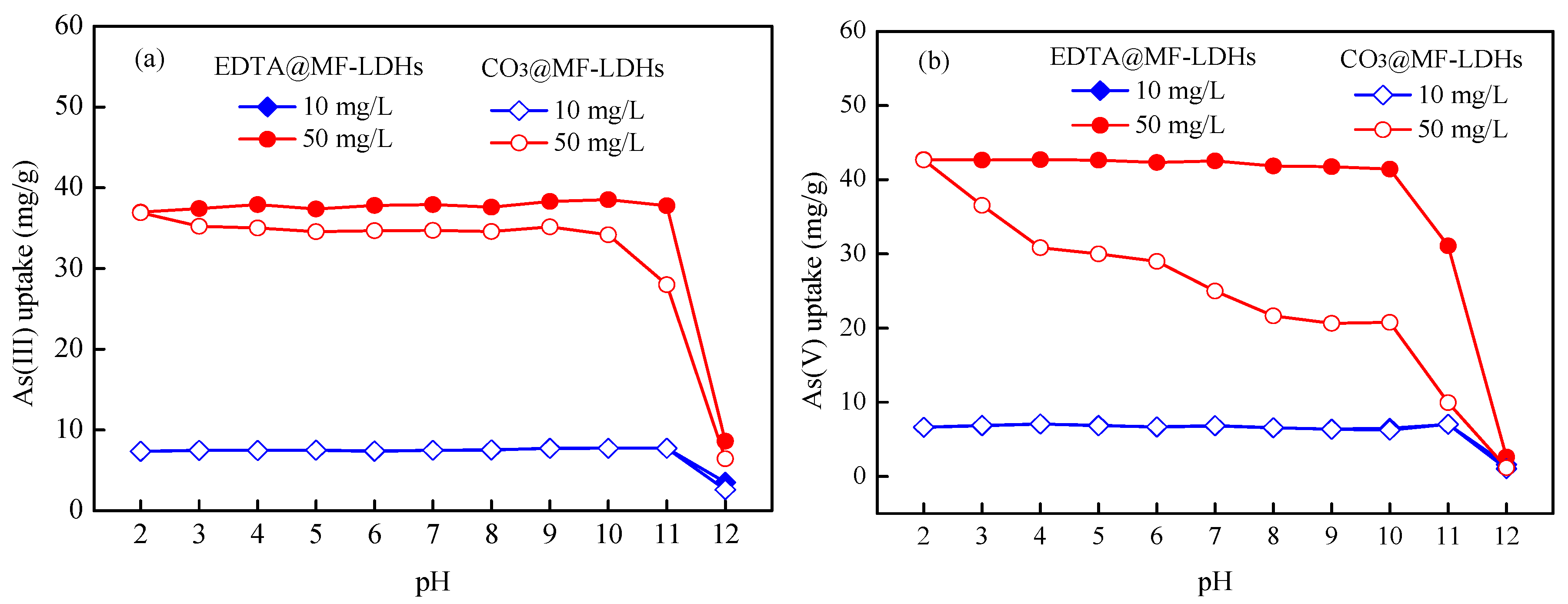

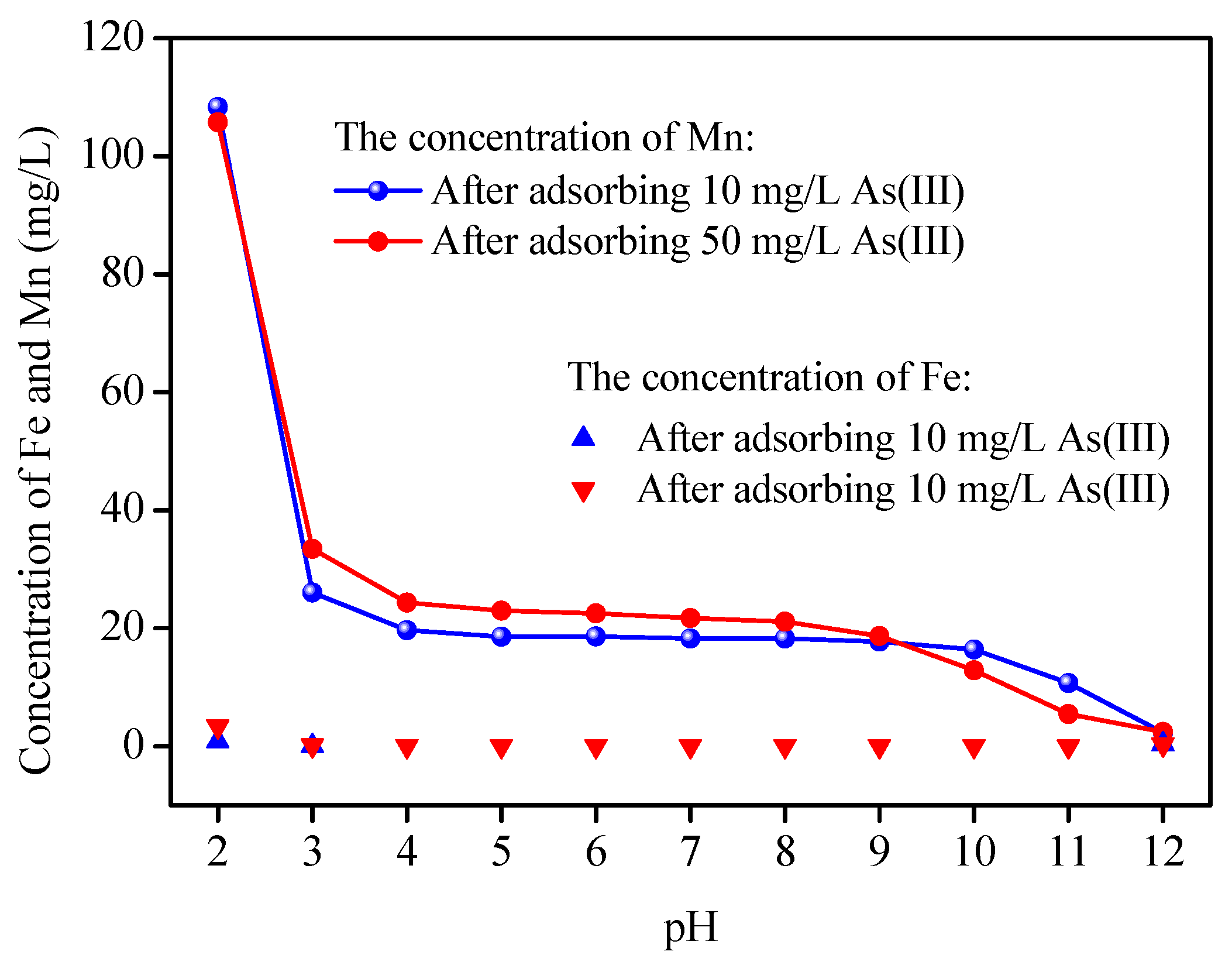

3.2.1. Effect of pH

- Step one: H3AsO4→H2AsO4− + H+ , pKa1 = 2.1;

- Step two: H2AsO4−→HASO42− + H+ , pKa2 = 6.7;

- Step three: HAsO42−→ AsO43− + H+ , pKa3 = 11.2;

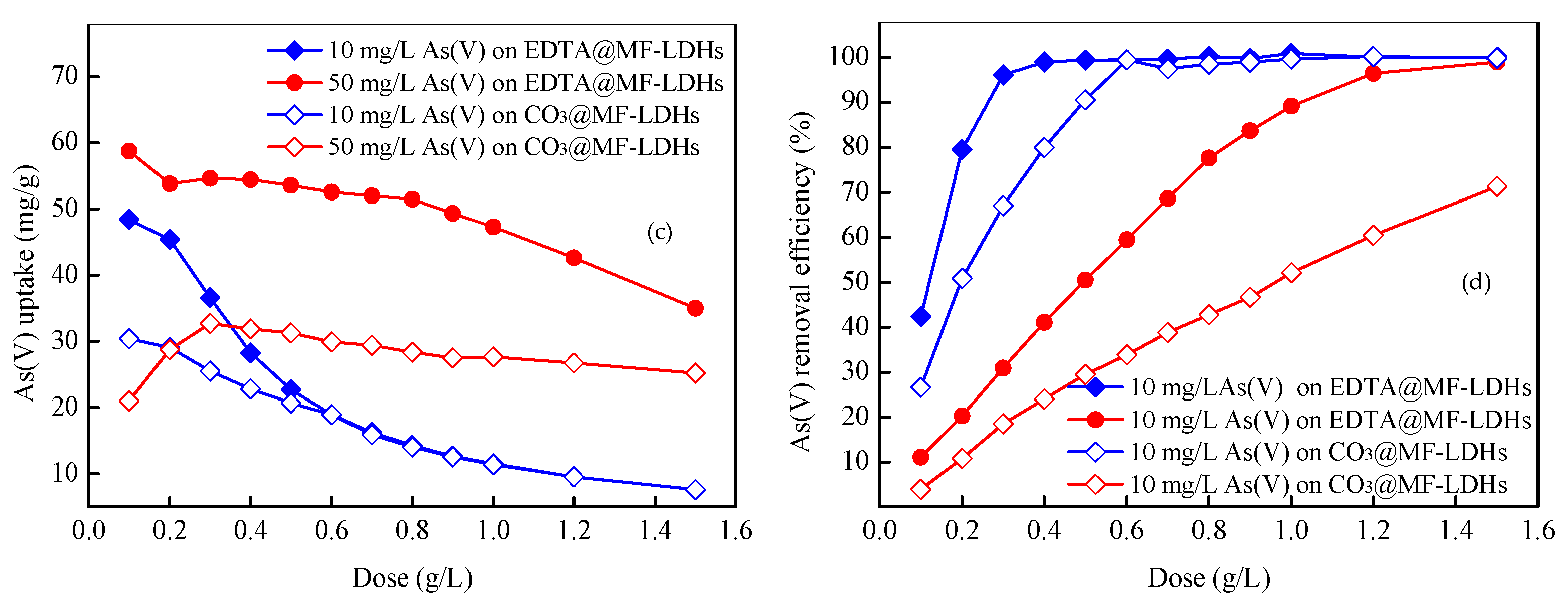

3.2.2. Effect of Dose

3.2.3. Sorption Kinetics

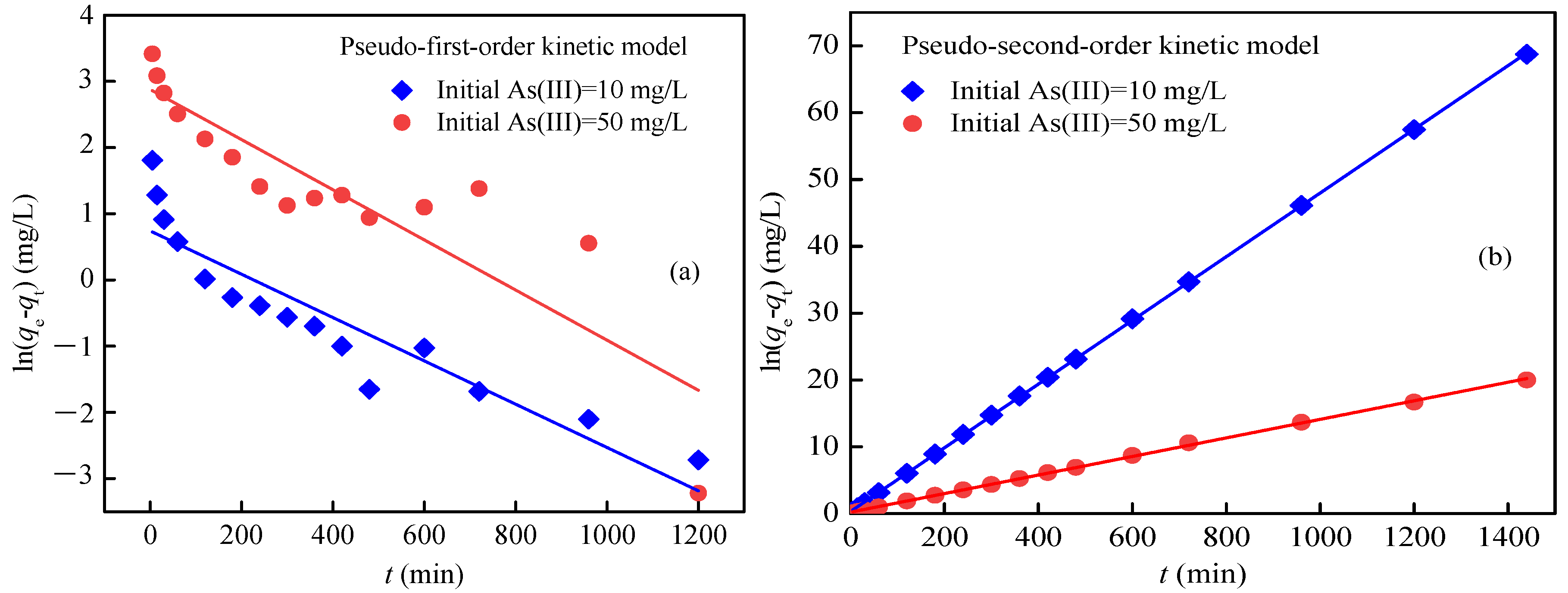

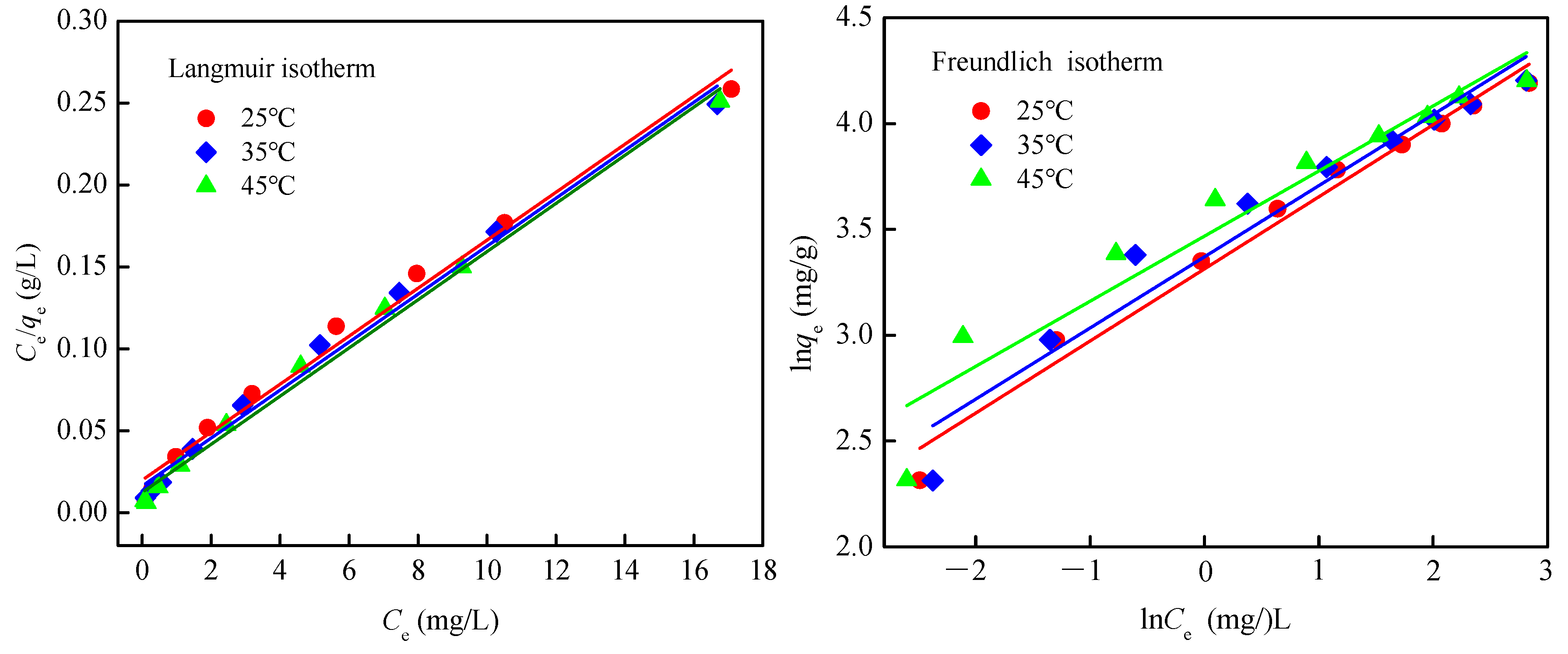

3.2.4. Sorption Isotherms

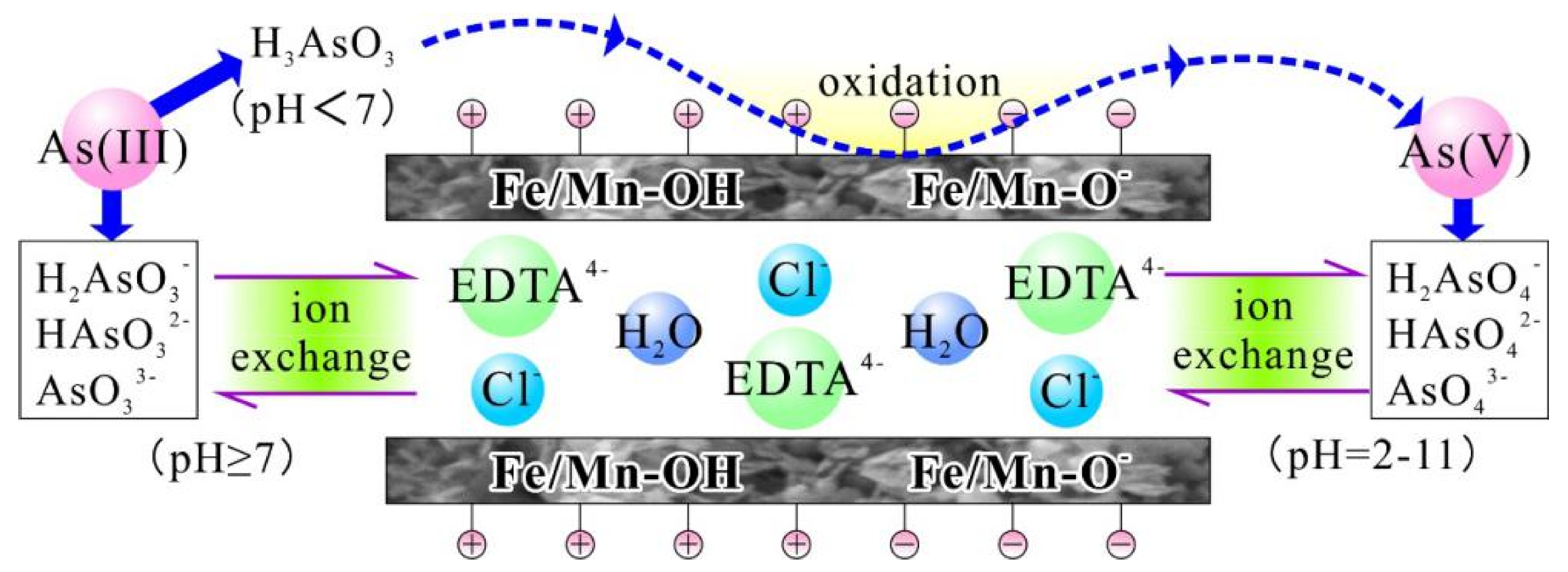

3.2.5. Removal Mechanisms

3.2.6. Material Stability Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Wen, Z.P.; Zhang, Y.L.; Zhou, X.F.; Chen, R. Effective As (III) and As (V) immobilization from aqueous solution by nascent ferrous hydroxide colloids (FHC). Sep. Purif. Technol. 2017, 176, 395–401. [Google Scholar] [CrossRef]

- Bai, Y.H.; Yang, T.T.; Liang, J.S.; Qu, J.H. The role of biogenic Fe-Mn oxides formed in situ for arsenic oxidation and adsorption in aquatic ecosystems. Water Res. 2016, 98, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Bamidele, E.A.; Makhatha, M.E.; Nheta, W. A Review of Lanthanum Nanoparticles Impregnated Compound Arsenic Fixation kinetics in Copper Aqueous Solution. In Paper 170 at Technologies & Materials for Renewable Energy, Environment & Sustainability; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Sheng, T.T.; Baig, S.A.; Hu, Y.J.; Xue, X.Q.; Xu, X.H. Development, characterization and evaluation of iron-coated honeycomb briquette cinders for the removal of As (V) from aqueous solutions. Arab. J. Chem. 2014, 7, 27–36. [Google Scholar] [CrossRef]

- Zhou, Y.Z.; Zeng, Y.Y.; Zhou, J.L.; Guo, H.M.; Li, Q.; Jia, R.L.; Chen, Y.F.; Zhao, J.T. Distribution of groundwater arsenic in Xinjiang, PR China. Appl. Geochem. 2017, 77, 116–125. [Google Scholar] [CrossRef]

- Asere, T.G.; Stevens, C.V.; Laing, G.D. Use of (modified) natural adsorbents for arsenic remediation: A review. Sci. Total Environ. 2019, 676, 706–720. [Google Scholar] [CrossRef]

- Baþkan, M.B.; Pala, A.; Türkman, A. Türkman, Arsenate removal by coagulation using iron salts and organic polymers. Ekoloji 2010, 19, 69–76. [Google Scholar]

- Sankpal, U.T.; Pius, H.; Khan, M.; Shukoor, M.I.; Maliakal, P.; Lee, C.M.; Abdelrahim, M.; Connelly, S.F.; Basha, R. Environmental factors in causing human cancers: Emphasis on tumorigenesis. Tumor. Biol. 2012, 33, 1265–1274. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Q.; Gao, S.; Shang, J.K. As (III) removal by hydrous titanium dioxide prepared from one-step hydrolysis of aqueous TiCl4 solution. Water Res. 2010, 44, 5713–5721. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U., Jr. Arsenic removal from water/wastewater using adsorbents—A critical review. J. Hazard. Mater. 2007, 142, 1–53. [Google Scholar] [CrossRef]

- Borho, M.; Wilderer, P. Optimized removal of arsenate (III) by adaptation of oxidation and precipitation processes to the filtration step. Water Sci. Technol. 1996, 34, 25–31. [Google Scholar] [CrossRef]

- Lee, H.; Choi, W. Photocatalytic oxidation of arsenite in TiO2 suspension: Kinetics and mechanisms. Environ. Sci. Technol. 2002, 36, 3872–3878. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Kim, C.; Choi, I.; Rengaraj, S.; Yi, J. Arsenic removal using mesoporous alumina prepared via a templating method. Environ. Sci. Technol. 2004, 38, 924–931. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Fu, F.; Dionysiou, D.D.; Tang, B. Adsorption, oxidation, and reduction behavior of arsenic in the removal of aqueous As (III) by mesoporous Fe/Al bimetallic particles. Water Res. 2016, 96, 22–31. [Google Scholar] [CrossRef] [PubMed]

- Du, Q.; Zhang, S.; Pan, B.; Lv, L.; Zhang, W.; Zhang, Q. Bifunctional resin-ZVI composites for effective removal of arsenite through simultaneous adsorption and oxidation. Water Res. 2013, 47, 6064–6074. [Google Scholar] [CrossRef] [PubMed]

- Bissen, M.; Frimmel, F.H. Arsenic—A review. Part I: Occurrence, toxicity, speciation, mobility. Acta Hydroch. Hydrob. 2003, 31, 9–18. [Google Scholar] [CrossRef]

- Abdul, K.S.M.; Jayasinghe, S.S.; Chandana, E.P.; Jayasumana, C.; De Silva, P.M.C. Arsenic and human health effects: A review. Environ. Toxicol. Pharmacol. 2015, 40, 828–846. [Google Scholar] [CrossRef]

- Goh, K.H.; Lim, T.T.; Dong, Z.L. Enhanced Arsenic Removal by Hydrothermally Treated Nanocrystalline Mg/Al Layered Double Hydroxide with Nitrate Intercalation. Environ. Sci. Technol. 2009, 43, 2537–2543. [Google Scholar] [CrossRef]

- Wang, S.; Gao, B.; Li, Y. Enhanced arsenic removal by biochar modified with nickel (Ni) and manganese (Mn) oxyhydroxides. J. Ind. Eng. Chem. 2016, 37, 361–365. [Google Scholar] [CrossRef]

- Wang, S.; Gao, B.; Li, Y.; Zimmerman, A.R.; Cao, X. Sorption of arsenic onto Ni/Fe layered double hydroxide (LDH)-biochar composites. RSC Adv. 2016, 6, 17792–17799. [Google Scholar] [CrossRef]

- Yue, X.; Liu, W.; Chen, Z.; Lin, Z. Simultaneous removal of Cu (II) and Cr (VI) by Mg–Al–Cl layered double hydroxide and mechanism insight. J. Environ. Sci. 2017, 53, 16–26. [Google Scholar] [CrossRef]

- Kameda, T.; Saito, S.; Umetsu, Y. Mg-Al layered double hydroxide intercalated with ethylene-diaminetetraacetate anion: Synthesis and application to the uptake of heavy metal ions from an aqueous solution. Sep. Purif. Technol. 2005, 47, 20–26. [Google Scholar] [CrossRef]

- Liu, P.; Liu, H.; Li, Y.; Dong, C. Remediation of arsenic contaminated soils and treatment of washing effluent using calcined Mn-Fe Layered double hydroxide. Adv. Mater. 2014, 955–959, 2014–2021. [Google Scholar] [CrossRef]

- Wu, X.L.; Tan, X.L.; Yang, S.T.; Wen, T.; Guo, H.L.; Wang, X.K.; Xu, A.W. Coexistence of adsorption and coagulation processes of both arsenate and NOM from contaminated groundwater by nanocrystallined Mg/Al layered double hydroxides. Water Res. 2013, 47, 4159–4168. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.L.; Guo, L.; Huang, H.; Jiang, Y.H.; Li, M.; Leng, Y.J. Removal of phosphorus by the core-shell bio-ceramic/Zn-layered double hydroxides (LDHs) composites for municipal wastewater treatment in constructed rapid infiltration system. Water Res. 2016, 96, 280–291. [Google Scholar] [CrossRef]

- Jiang, J.Q.; Ashekuzzaman, S.M.; Hargreaves, J.S.J.; McFarlane, A.R.; Badruzzamanc, A.B.M.; Tarekc, M.H. Removal of Arsenic (III) from groundwater applying a reusable Mg-Fe-Cl layered double hydroxide. J. Chem. Technol. Biotechnol 2015, 90, 1160–1166. [Google Scholar] [CrossRef]

- Evans, D.G.; Slade, R.C. Structural aspects of layered double hydroxides. In Layered Double Hydroxides; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1–87. [Google Scholar]

- Williams, G.R.; Khan, A.I.; O’Hare, D. Mechanistic and kinetic studies of guest ion intercalation into layered double hydroxides using time-resolved, in-situ X-ray powder diffraction. In Layered Double Hydroxides; Springer: Berlin/Heidelberg, Germany, 2006; pp. 161–192. [Google Scholar]

- Taylor, H. Segregation and cation-ordering in sjögrenite and pyroaurite. Mineral. Mag. 1969, 37, 338–342. [Google Scholar] [CrossRef]

- Allmann, R. The crystal structure of pyroaurite. Acta Crystallogr. B 1968, 24, 972–977. [Google Scholar] [CrossRef]

- Nakayama, H.; Hirami, S.; Tsuhako, M. Selective adsorption of mercury ion by mercaptocarboxylic acid intercalated Mg–Al layered double hydroxide. J. Colloid Interface Sci. 2017, 315, 177–183. [Google Scholar] [CrossRef]

- Pavlovic, I.; Pérez, M.; Barriga, C.; Ulibarri, M. Adsorption of Cu2+, Cd2+ and Pb2+ ions by layered double hydroxides intercalated with the chelating agents diethylenetriaminepentaacetate and meso-2, 3-dimercaptosuccinate. Appl. Clay Sci. 2009, 43, 125–129. [Google Scholar] [CrossRef]

- Liang, X.; Hou, W.; Xu, Y.; Sun, G.; Wang, L.; Sun, Y.; Qin, X. Sorption of lead ion by layered double hydroxide intercalated with diethylenetriaminepentaacetic acid. Colloid Surf. A 2010, 366, 50–57. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, H.; Qu, J.; Jefferson, W. Arsenate uptake and arsenite simultaneous sorption and oxidation by Fe–Mn binary oxides: Influence of Mn/Fe ratio, pH, Ca2+, and humic acid. J. Colloid Interface Sci. 2012, 366, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Deschamps, E.; Ciminelli, V.S.; Höll, W.H. Removal of As (III) and As (V) from water using a natural Fe and Mn enriched sample. Water Res. 2005, 39, 5212–5220. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.; Zhou, J.; Wang, X.; Dai, Y.; Dang, Z.; Zhu, N.; Li, P.; Wu, J. Adsorption of Cu–EDTA complexes from aqueous solutions by polymeric Fe/Zr pillared montmorillonite: Behaviors and mechanisms. Desalination 2011, 277, 288–295. [Google Scholar] [CrossRef]

- Rojas, R.; Perez, M.R.; Erro, E.M.; Ortiz, P.I.; Ulibarri, M.A.; Giacomelli, C.E. EDTA modified LDHs as Cu2+ scavengers: Removal kinetics and sorbent stability. J. Colloid Interface Sci. 2009, 331, 425–431. [Google Scholar] [CrossRef]

- Deng, L.; Shi, Z.; Wang, L.; Zhou, S. Fabrication of a novel NiFe2O4/Zn-Al layered double hydroxide intercalated with EDTA composite and its adsorption behavior for Cr (VI) from aqueous solution. J. Phys. Chem. Solids 2017, 104, 79–90. [Google Scholar] [CrossRef]

- Kameda, T.; Hoshi, K.; Yoshioka, T. Preparation of Cu-Al layered double hydroxide intercalated with ethylenediaminetetraacetate by coprecipitation and its uptake of rare earth ions from aqueous solution. Solid State Sci. 2013, 17, 28–34. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Y.; Ruan, X.; Yu, Y.; Zhu, M.; Zhang, J.; Zhou, J.; Xu, Y.; Liu, J.; Qian, G. Advanced treatment of stabilized landfill leachate after biochemical process with hydrocalumite chloride (Ca/Al–Cl LDH). Bioresour. Technol. 2016, 210, 131–137. [Google Scholar] [CrossRef]

- Gao, H.; Song, Z.; Zhang, W.; Yang, X.; Wang, X.; Wang, D. Synthesis of highly effective absorbents with waste quenching blast furnace slag to remove Methyl Orange from aqueous solution. J. Environ. Sci. 2017, 53, 68–77. [Google Scholar] [CrossRef]

- Abderrazek, K.; Frini Srasra, N.; Srasra, E. Synthesis and Characterization of [Zn-Al] Layered Double Hydroxides: Effect of the Operating Parameters. J. Chin. Chem. Soc. 2017, 64, 346–353. [Google Scholar] [CrossRef]

- Das, J.; Patra, B.S.; Baliarsingh, N.; Parida, K. Calcined Mg-Fe-CO3 LDH as an adsorbent for the removal of selenite. J. Colloid Interface Sci. 2007, 316, 216–223. [Google Scholar] [CrossRef]

- Yan, D.; Lu, J.; Wei, M.; Ma, J.; Evans, D.G.; Duan, X. A combined study based on experiment and molecular dynamics: Perylene tetracarboxylate intercalated in a layered double hydroxide matrix. Phys. Chem. Chem. Phys. 2009, 11, 9200–9209. [Google Scholar] [CrossRef] [PubMed]

- Bontchev, R.P.; Liu, S.; Krumhansl, J.L.; Voigt, J.; Nenoff, T.M. Synthesis, characterization, and ion exchange properties of hydrotalcite Mg6Al2(OH)16(A)x(A′) 2-x·4H2O (A, A′ = Cl−, Br−, I−, and NO3−, 2 ≥ x ≥ 0) derivatives. Chem. Mater. 2003, 15, 3669–3675. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Q.; Liu, J.; Chen, R.; Zhang, H.; Li, R.; Wang, J. Ni–Mn LDH-decorated 3D Fe-inserted and N-doped carbon framework composites for efficient uranium (VI) removal. Environ. Sci. Nano 2018, 5, 467–475. [Google Scholar] [CrossRef]

- Su, Q.; Gu, L.; Yao, Y.; Zhao, J.; Ji, W.; Ding, W.; Au, C.T. Layered double hydroxides derived Nix(MgyAlzOn) catalysts: Enhanced ammonia decomposition by hydrogen spillover effect. Appl. Catal. B-Environ. 2017, 201, 451–460. [Google Scholar] [CrossRef]

- Aisawa, S.; Hirahara, H.; Uchiyama, H.; Takahashi, S.; Narita, E. Synthesis and thermal decomposition of Mn–Al layered double hydroxides. J. Solid State Chem. 2002, 167, 152–159. [Google Scholar] [CrossRef]

- Pena, M.E.; Korfiatis, G.P.; Patel, M.; Lippincott, L.; Meng, X. Adsorption of As (V) and As (III) by nanocrystalline titanium dioxide. Water Res. 2005, 39, 2327–2337. [Google Scholar] [CrossRef]

- Wang, T.; Li, C.; Wang, C.; Wang, H. Biochar/MnAl-LDH composites for Cu (ΙΙ) removal from aqueous solution. Colloid Surf. A 2018, 538, 443–450. [Google Scholar] [CrossRef]

- Chen, H.; Lin, J.; Zhang, N.; Chen, L.; Zhong, S.; Wang, Y.; Zhang, W.; Ling, Q. Preparation of MgAl-EDTA-LDH based electrospun nanofiber membrane and its adsorption properties of copper (II) from wasteWater. J. Hazard. Mater. 2018, 345, 1–9. [Google Scholar] [CrossRef]

- Huang, Y.; Keller, A.A. EDTA functionalized magnetic nanoparticle sorbents for cadmium and lead contaminated water treatment. Water Res. 2015, 80, 159–168. [Google Scholar] [CrossRef]

- Guo, X.; Liu, X.; Hao, X.; Zhu, S.; Dong, F.; Wen, Z.; Zhang, X. Nickel-manganese layered double hydroxide nanosheets supported on nickel foam for high-performance supercapacitor electrode materials. Electrochim. Acta 2016, 194, 179–186. [Google Scholar] [CrossRef]

- Hao, H.; Liu, G.; Wang, Y.; Shi, B.; Han, K.; Zhuang, Y.; Kong, Y. Simultaneous cationic Cu (II)-anionic Sb (III) removal by NH2-Fe3O4-NTA core-shell magnetic nanoparticle sorbents synthesized via a facile one-pot approach. J. Hazard. Mater. 2019, 362, 246–257. [Google Scholar] [CrossRef] [PubMed]

- Adeleke, J.; Theivasanthi, T.; Thiruppathi, M.; Swaminathan, M.; Akomolafe, T.; Alabi, A. Photocatalytic degradation of methylene blue by ZnO/NiFe2O4 nanoparticles. Appl. Surf. Sci. 2018, 455, 195–200. [Google Scholar] [CrossRef]

- Chandra, V.; Park, J.; Chun, Y.; Lee, J.W.; Hwang, I.C.; Kim, K.S. Water-dispersible magnetite-reduced graphene oxide composites for arsenic removal. ACS Nano 2010, 4, 3979–3986. [Google Scholar] [CrossRef] [PubMed]

- Shan, C.; Ma, Z.; Tong, M. Efficient removal of trace antimony (III) through adsorption by hematite modified magnetic nanoparticles. J. Hazard. Mater. 2014, 268, 229–236. [Google Scholar] [CrossRef]

- Hong, J.; Zhu, Z.; Lu, H.; Qiu, Y. Synthesis and arsenic adsorption performances of ferric-based layered double hydroxide with α-alanine intercalation. Chem. Eng. J. 2014, 252, 267–274. [Google Scholar] [CrossRef]

- Otgonjargal, E.; Kim, Y.S.; Park, S.-M.; Baek, K.; Yang, J.S. Mn-Fe layered double hydroxides for adsorption of As (III) and As (V). Sep. Purif. Technol. 2012, 47, 2192–2198. [Google Scholar]

- Foo, K.; Hameed, B. Preparation, characterization and evaluation of adsorptive properties of orange peel based activated carbon via microwave induced K2CO3 activation. Bioresour. Technol. 2012, 104, 679–686. [Google Scholar] [CrossRef]

- Crini, G. Kinetic and equilibrium studies on the removal of cationic dyes from aqueous solution by adsorption onto a cyclodextrin polymer. Dyes Pigment. 2008, 77, 415–426. [Google Scholar] [CrossRef]

- Wang, T.; Yang, W.; Song, T.; Li, C.; Zhang, L.; Wang, H.; Chai, L. Cu doped Fe₃O₄ magnetic adsorbent for arsenic: Synthesis, property, and sorption application. RSC Adv. 2015, 5, 50011–50018. [Google Scholar] [CrossRef]

- Lu, H.; Lu, T.; Zhang, H.; Qiu, Y.; Yin, D.; Zhu, Z. Enhanced adsorption performance of aspartic acid intercalated Mg-Zn-Fe-LDH materials for arsenite. Dalton Trans. 2018, 47, 4994–5004. [Google Scholar] [CrossRef]

- Wu, K.; Jing, C.; Zhang, J.; Liu, T.; Wang, W. Magnetic Fe3O4@CuO nanocomposite assembled on graphene oxide sheets for the enhanced removal of arsenic(III/V) from Water. Appl. Surf. Sci. 2019, 466, 746–756. [Google Scholar] [CrossRef]

- Raven, K.P.; Jain, A.; Loeppert, R.H. Arsenite and Arsenate Adsorption on Ferrihydrite: Kinetics, Equilibrium, and Adsorption Envelopes. Environ. Sci. Technol. 1998, 32, 344–349. [Google Scholar] [CrossRef]

- Ren, Y.; Wei, X.; Zhang, M. Adsorption character for removal Cu (II) by magnetic Cu (II) ion imprinted composite adsorbent. J. Hazard. Mater. 2008, 158, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Matusik, J.; Hyla, J.; Maziarz, P.; Rybka, K.; Leiviskä, T. Performance of Halloysite-Mg/Al LDH Materials for Aqueous As(V) and Cr(VI) Removal. Materials 2019, 12, 3569. [Google Scholar] [CrossRef]

- Zhu, Z.Z.; Zhang, j.; Zhu, Y.N.; Liu, J.; Tang, S.; Zhang, L.H.; Wang, Y.R. Dissolution, Stability and Solubility of Tooeleite[Fe6(AsO3)4(SO4)(OH)4·4H2O] at 25–45 °C and pH 2–12. Materials 2020, 10, 921. [Google Scholar] [CrossRef]

| Diffraction Index | d(003) | d(006) | d(012) | d(110) | a = 2d(110) | c = 3d(003) |

|---|---|---|---|---|---|---|

| CO3@MF-LDHs | 0.762 | 0.381 | 0.271 | 0.161 | 0.322 | 2.286 |

| EDTA@MF-LDHs | 0.804 | 0.400 | 0.276 | 0.162 | 0.324 | 2.412 |

| Initial As(III) Concentration (mg/L) | Pseudo-First-Order Constant | Pseudo-Second-Order Constant | |||||

|---|---|---|---|---|---|---|---|

| K1 (/min) | qe (mg/g) | R2 | k2 (g/(mg·min)) | h (g/(mg·min)) | qe (mg/g) | R2 | |

| 10 | 0.003 | 2.010 | 0.843 | 0.008 | 3.279 | 20.960 | 1.000 |

| 50 | 0.004 | 17.780 | 0.765 | 0.001 | 4.684 | 71.940 | 0.999 |

| Temperature (°C) | Langmuir Constant | Freundlich Constant | |||||

|---|---|---|---|---|---|---|---|

| qm (mg/g) | KL (L/mg) | RL | R2 | KF (mg1−1/n·L1/n/g) | 1/n | R2 | |

| 25 | 68.49 | 0.734 | 0.027–0.214 | 0.986 | 27.481 | 0.341 | 0.979 |

| 35 | 68.49 | 0.896 | 0.022–0.183 | 0.989 | 29.093 | 0.336 | 0.942 |

| 45 | 68.03 | 1.186 | 0.017–0.144 | 0.992 | 28.413 | 0.308 | 0.917 |

| Adsorbents | Temperature (°C) | Concentration of As(III) (mg/L) | Qmax (mg/g) | KL (L/mg) | Source |

|---|---|---|---|---|---|

| Ferryhydrite | - | 2000 | 778 | - | [65] |

| Ferryhydrite | 25 | 100 | 122.63 | 0.302 | [1] |

| Mn–Fe-LDH | 45 | 100 | 113.12 | - | [59] |

| Fe3O4/Cu(OH)2 | 25 | 85 | 37.97 | - | [62] |

| Mg7Zn7Fe4-Asp-LDH | 25 | 100 | 94.81 | 0.2664 | [63] |

| Mg7Zn1Fe4-Phe-LDH | 25 | 100 | 58.09 | 0.0988 | |

| Fe3O4@CuO | 25 | 75 | 50.58 | 0.058 | [64] |

| Fe@Cu&GO | 25 | 70.36 | 0.182 | ||

| MgAl-MoS4-LDH | 25 | 400 | 99 | - | [66] |

| EDTA@MF-LDHs | 25 | 50 | 68.49 | 0.734 | This study |

| 35 | 68.49 | 0.896 | |||

| 45 | 68.03 | 1.186 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Zhu, Z.; Zhao, N.; Fang, Y.; Gao, Y.; Zhu, Y.; Zhang, L. Mn-Fe Layered Double Hydroxide Intercalated with Ethylene-Diaminetetraacetate Anion: Synthesis and Removal of As(III) from Aqueous Solution around pH 2–11. Int. J. Environ. Res. Public Health 2020, 17, 9341. https://doi.org/10.3390/ijerph17249341

Liu G, Zhu Z, Zhao N, Fang Y, Gao Y, Zhu Y, Zhang L. Mn-Fe Layered Double Hydroxide Intercalated with Ethylene-Diaminetetraacetate Anion: Synthesis and Removal of As(III) from Aqueous Solution around pH 2–11. International Journal of Environmental Research and Public Health. 2020; 17(24):9341. https://doi.org/10.3390/ijerph17249341

Chicago/Turabian StyleLiu, Guifeng, Zongqiang Zhu, Ningning Zhao, Yali Fang, Yingying Gao, Yinian Zhu, and Lihao Zhang. 2020. "Mn-Fe Layered Double Hydroxide Intercalated with Ethylene-Diaminetetraacetate Anion: Synthesis and Removal of As(III) from Aqueous Solution around pH 2–11" International Journal of Environmental Research and Public Health 17, no. 24: 9341. https://doi.org/10.3390/ijerph17249341

APA StyleLiu, G., Zhu, Z., Zhao, N., Fang, Y., Gao, Y., Zhu, Y., & Zhang, L. (2020). Mn-Fe Layered Double Hydroxide Intercalated with Ethylene-Diaminetetraacetate Anion: Synthesis and Removal of As(III) from Aqueous Solution around pH 2–11. International Journal of Environmental Research and Public Health, 17(24), 9341. https://doi.org/10.3390/ijerph17249341