Reusable Face Masks as Alternative for Disposable Medical Masks: Factors that Affect their Wear-Comfort

Abstract

1. Introduction

2. Materials and Methods

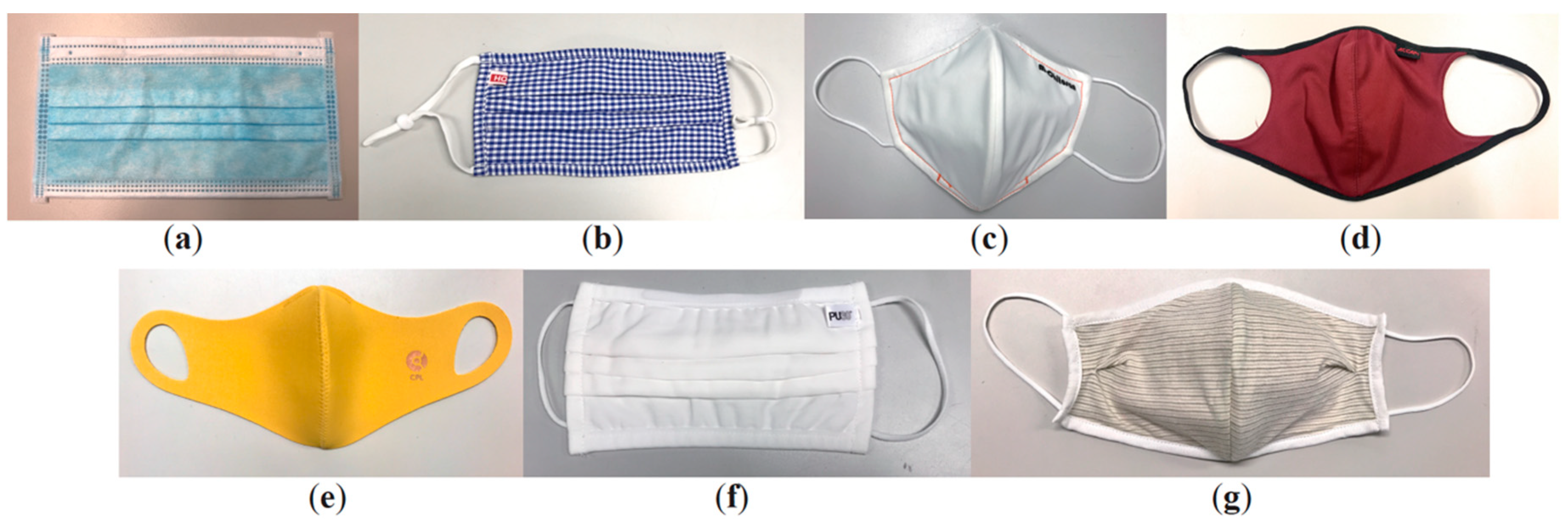

2.1. Materials

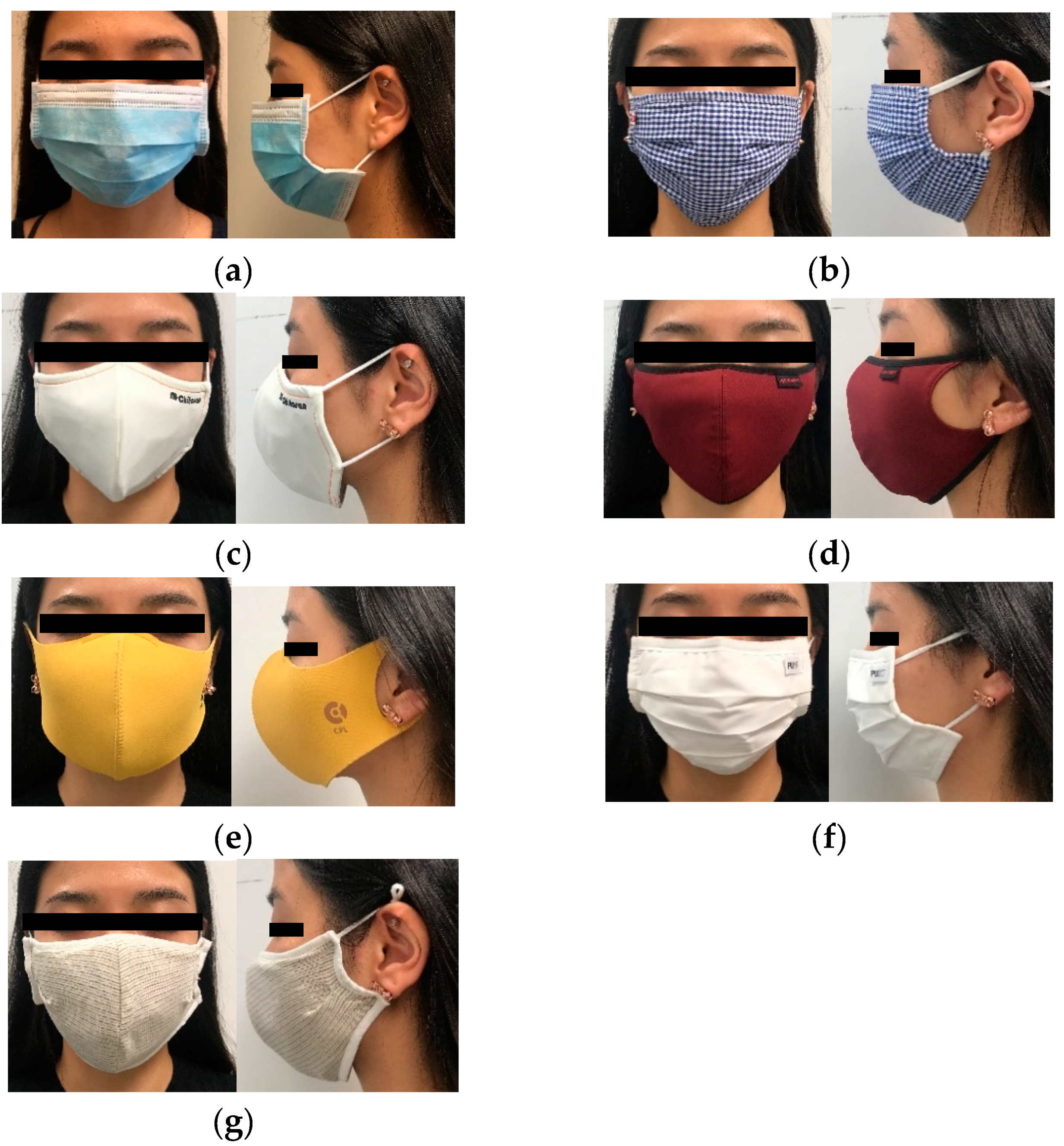

2.1.1. Sample A—Disposable Surgical Mask

2.1.2. Sample B—HODO Mask

2.1.3. Sample C—M-Chitosan Mask

2.1.4. Sample D—Accapi Far-Infrared Energy Mask

2.1.5. Sample E—Copper Line Mask

2.1.6. Sample F—PU30 Mask

2.1.7. Sample G—CU Mask

2.2. Methods

3. Results

3.1. Fabric Specifications

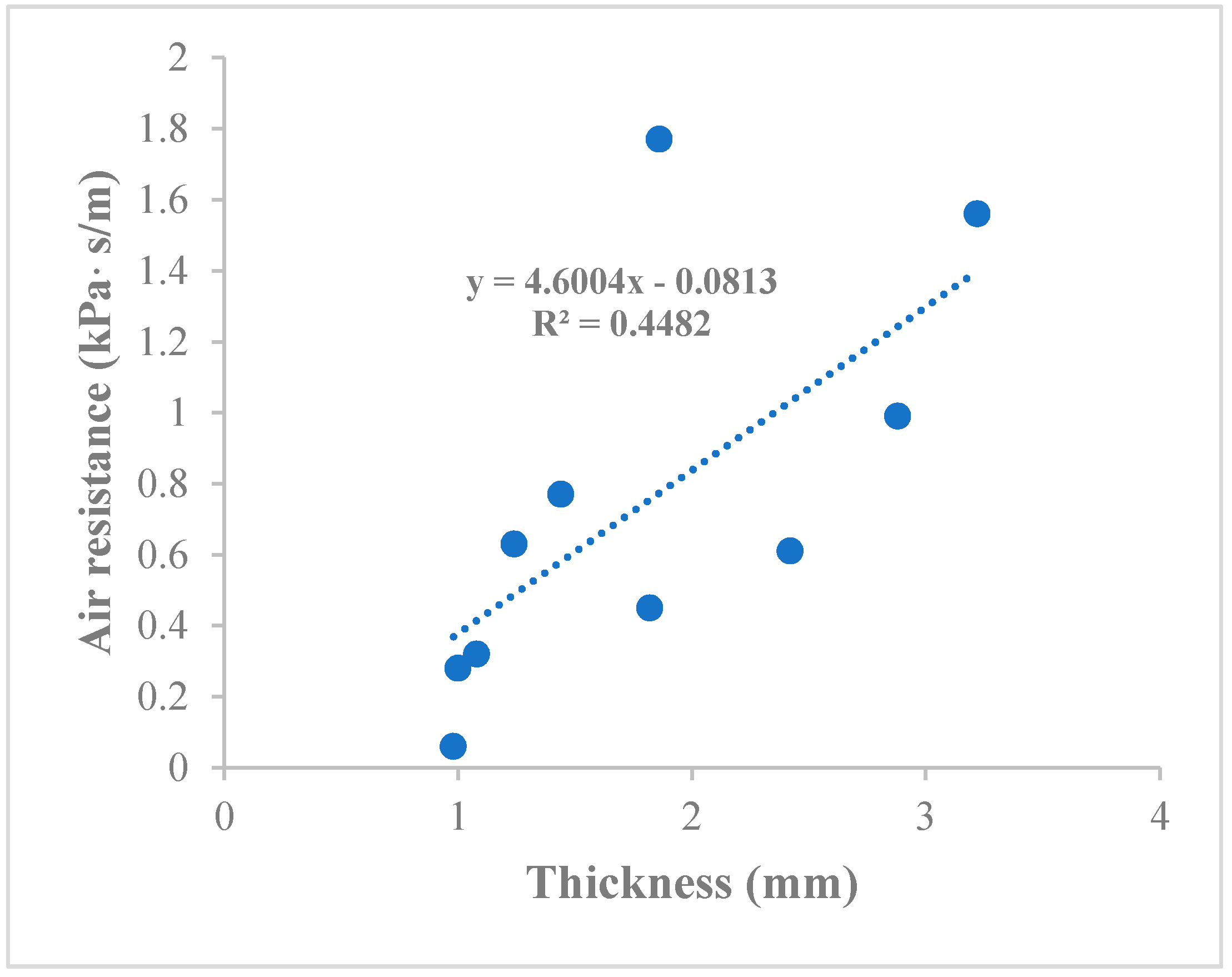

3.2. Fabric Thickness and Air Permeability

3.3. Water Vapor Permeability

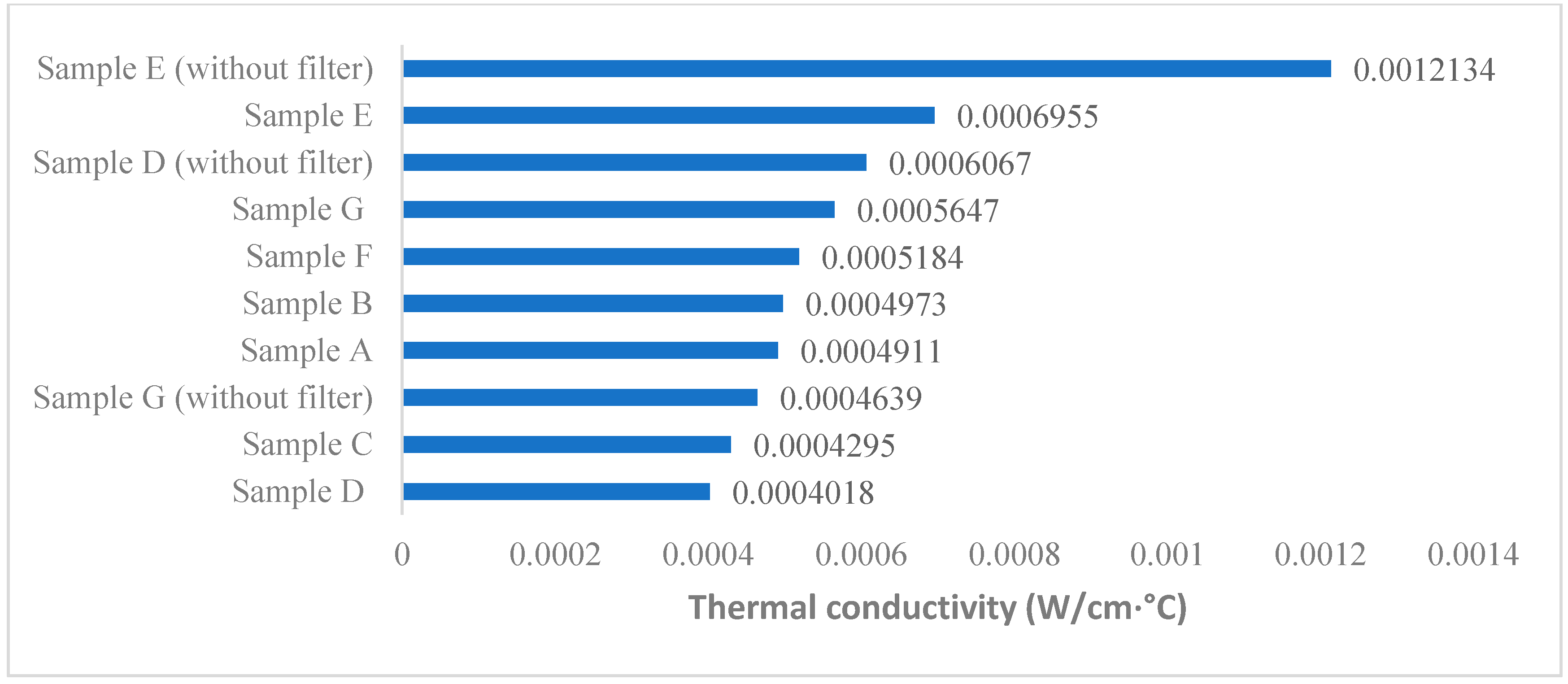

3.4. Thermal Conductivity

3.5. Correlation Between Different Test Results

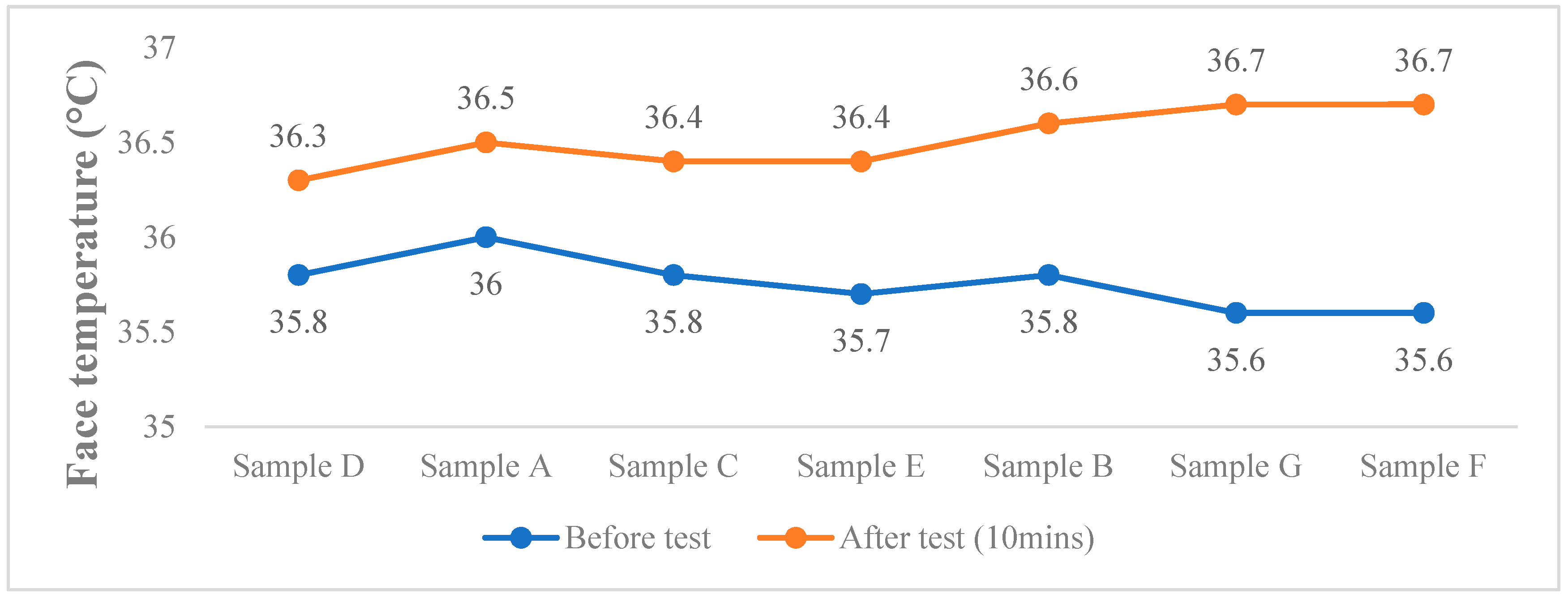

3.6. Wear Trial

4. Discussion

4.1. Possible Factors that Affect Breathability

4.1.1. Thickness

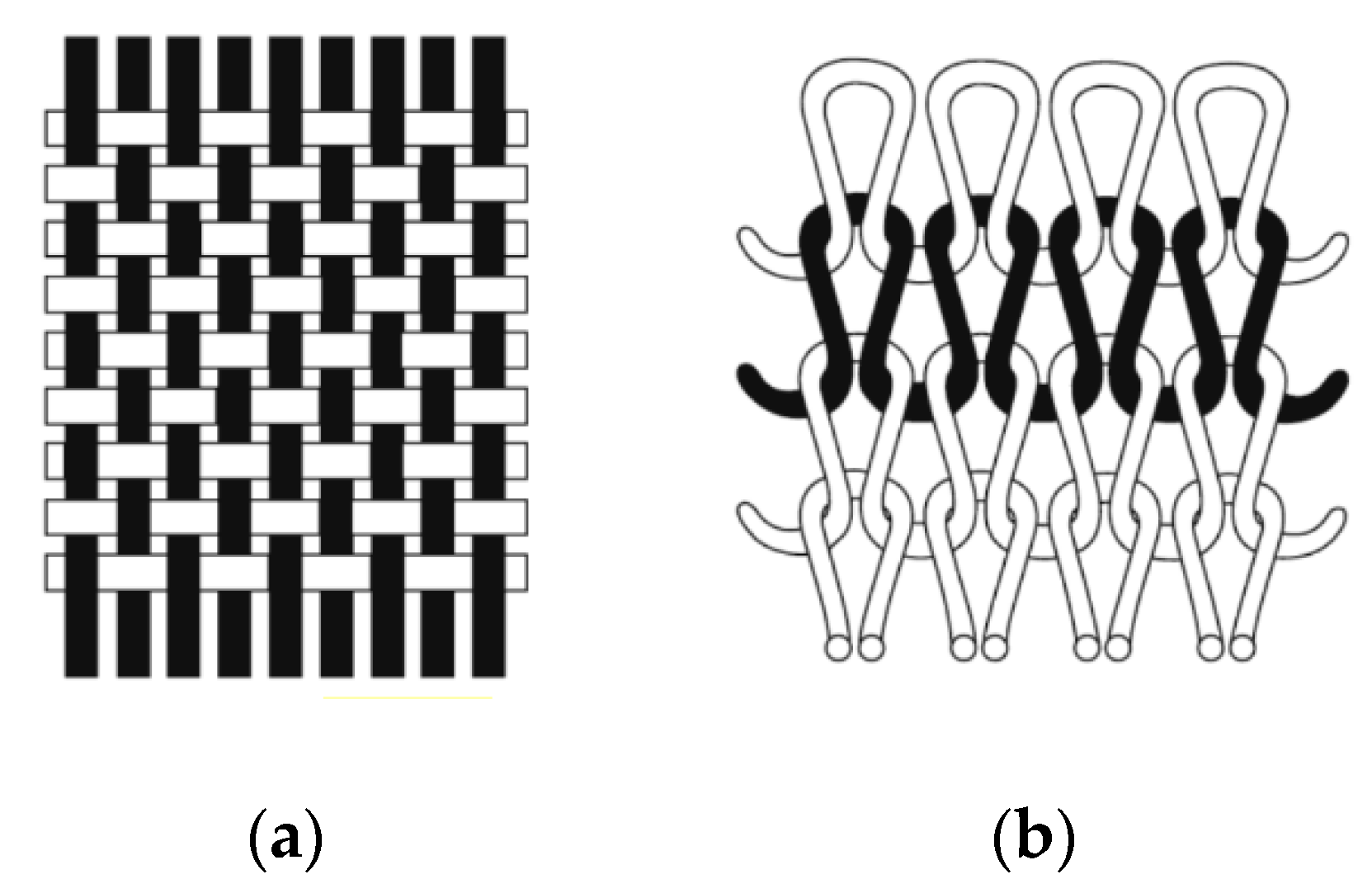

4.1.2. Fabric Structure: Woven vs. Knitted

4.1.3. Permeability of Filter

4.1.4. Goodness of Fit and Climate

4.2. Possible Factors that Affect Thermal Regulation

4.2.1. Thermal Conductivity of Materials Used

4.2.2. Permeability of Filters

4.2.3. Water Vapor Permeability

4.3. Recommendations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- De Man, P.; Van Straten, B.; Dobbelsteen, J.V.D.; Van Der Eijk, A.; Horeman, T.; Koeleman, H. Sterilization of disposable face masks by means of standardized dry and steam sterilization processes an alternative in the fight against mask shortages due to COVID−19. J. Hosp. Infect. 2020, 105, 356–357. [Google Scholar] [CrossRef] [PubMed]

- Missoni, E.; Armocida, B.; Formenti, B. Face Masks for All and All for Face Masks in the COVID−19 Pandemic: Community Level Production to Face the Global Shortage and Shorten the Epidemic. Disaster Med. Public Health Prep. 2020, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Burki, T. Global shortage of personal protective equipment. Lancet Infect. Dis. 2020, 20, 785–786. [Google Scholar] [CrossRef]

- Chua, M.H.; Cheng, W.; Goh, S.S.; Kong, J.; Li, B.; Lim, J.Y.C.; Mao, L.; Wang, S.; Xue, K.; Yang, L.; et al. Face Masks in the New COVID−19 Normal: Materials, Testing, and Perspectives. Research 2020, 2020, 1–40. [Google Scholar] [CrossRef]

- Ng, J.; Lai, C.K. Coronavirus Mask Shortage: What did Hong Kong do to Deserve This Government? South China Morning Post: Hong Kong, China, 2020. [Google Scholar]

- Secon, H. People Are Racing to Buy Face Masks Amid the Coronavirus Outbreak, but They Probably won’t Protect you from Illness. Business Insider. Available online: https://www.businessinsider.com/wuhan-coronavirus-face-masks-not-entirely-effective−2020−1 (accessed on 27 August 2020).

- NIOSH. NIOSH Recommended Guidelines for Personal Respiratory Protection of Workers in Health-Care Facilities Potentially Exposed to Tuberculosis; United State Department of Health and Human Services, National Institute for Occupational Saftety and Health: Cincinnati, OH, USA, 1992. [Google Scholar]

- Huang, J.; Huang, V. Evaluation of the Efficiency of Medical Masks and the Creation of New Medical Masks. J. Int. Med. Res. 2007, 35, 213–223. [Google Scholar] [CrossRef]

- Hu, J.Y.; Li, Y.I.; Yeung, K.W. 15—Air permeability. In Clothing Biosensory Engineering; Li, Y., Wong, A.S.W., Eds.; Woodhead Publishing: Cambridge, UK, 2006; pp. 252–260. [Google Scholar]

- Kulichenko, A.V. Theoretical Analysis, Calculation, and Prediction of the Air Permeability of Textiles. Fibre Chem. 2005, 37, 371–380. [Google Scholar] [CrossRef]

- Hu, J.; Li, Y.; Yeung, K.-W.; Wong, A.S.W.; Xu, W. Moisture Management Tester: A Method to Characterize Fabric Liquid Moisture Management Properties. Text. Res. J. 2005, 75, 57–62. [Google Scholar] [CrossRef]

- Erdumlu, N.; Saricam, C. Investigating the effect of some fabric parameters on the thermal comfort properties of flat knitted acrylic fabrics for winter wear. Text. Res. J. 2016, 87, 1349–1359. [Google Scholar] [CrossRef]

- Palen, T.E.; Felix, K.G. Surgical Masks vs N95 Respirators for Preventing Influenza. JAMA 2010, 303, 937–939. [Google Scholar] [CrossRef]

- Suen, L.K.P.; Yang, L.; Ho, S.S.; Fung, K.H.; Boost, M.V.; Wu, C.S.; Au-Yeung, C.H.; O’Donoghue, M.M. Reliability of N95 respirators for respiratory protection before, during, and after nursing procedures. Am. J. Infect. Control. 2017, 45, 974–978. [Google Scholar] [CrossRef]

- Rosenstock, L. 42 CFR Part 84: Respiratory protective devices implications for tuberculosis protection. Infect. Control. Hosp. Epidemiol. 1995, 16, 529–531. [Google Scholar] [CrossRef] [PubMed]

- HODO Sport. Hyproof Cycle Use Face Medical (Adult). Available online: http://www.hodosports.com/hyproof-cycle-use-face-adult−15856397257690577.html (accessed on 30 June 2020).

- HODO International. Disposable Masks. Available online: https://www.hodointernational.com/products/detail/disposable-masks.html (accessed on 26 August 2020).

- M-Chitosan. Available online: https://m-chitosan.com/en/home/ (accessed on 30 June 2020).

- 3M Care. 3M Infection Prevention N95 Particulate Respirators, 1860/1860S and 1870—Frequently asked questions. Available online: https://multimedia.3m.com/mws/media/323208O/n95-particulate-respirators−1860−1860s−1870-faqs.pdf (accessed on 30 June 2020).

- Copper Mask. Copper Line Mask. Available online: https://www.coppermask.com/ (accessed on 30 June 2020).

- Coppper Line HK. Copper Line Mask. Available online: https://www.facebook.com/copperlineHK/ (accessed on 30 June 2020).

- LMNTAL. ANTI-MICROBIAL COPPER LINE MASKS. Available online: https://lmntal.com/products/antibacterial-copper-line-masks (accessed on 26 August 2020).

- PolyU. PolyU Develops PU30TM—Antiviral, Washable & Reusable Face Mask. Available online: https://www.polyu.edu.hk/fast/research/PU30/ (accessed on 26 August 2020).

- PU30. PU30 Mask. Available online: https://www.facebook.com/PU30ITCstore/ (accessed on 26 August 2020).

- Qmask. CU Mask. Available online: https://www.qmask.gov.hk/about (accessed on 30 June 2020).

- ASTM F2100−19e1, Standard Specification for Performance of Materials Used in Medical Face Masks; ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 30 June 2020).

- Behera, B.K.; Hari, P.K. Textile Institute. In Woven Textile Structure: Theory and Applications; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar]

- Behera, B.K.; Hari, P.K. (Eds.) 1—He basics of woven fabric structure. In Woven Textile Structure; Woodhead Publishing: Cambridge, UK, 2010; pp. 3–8. [Google Scholar]

- Behera, B.K.; Hari, P.K. (Eds.) 19—Assessing the comfort of woven fabrics: Thermal properties. In Woven Textile Structure; Woodhead Publishing: Cambridge, UK, 2010; pp. 330–342. [Google Scholar]

- Morishima, M.; Mitsuno, T. Analysis of hygienic face mask patterns for young people. Text. Res. J. 2019, 89, 4670–4680. [Google Scholar] [CrossRef]

- Sun, Z.; Pan, N. 7—Thermal conduction and moisture diffusion in fibrous materials. In Thermal and Moisture Transport in Fibrous Materials; Pan, N., Gibson, P., Eds.; Woodhead Publishing: Cambridge, UK, 2006; pp. 225–270. [Google Scholar]

- Dileo, T.; Roberge, R.J.; Kim, J.-H. Effect of wearing an N95 filtering facepiece respirator on superomedial orbital infrared indirect brain temperature measurements. J. Clin. Monit. 2016, 31, 67–73. [Google Scholar] [CrossRef][Green Version]

- Roberge, R.; Benson, S.; Kim, J.-H. Thermal burden of N95 filtering facepiece respirators. Ann. Occup. Hyg. 2012, 56, 808–814. [Google Scholar] [CrossRef]

- Good Fellow. Copper Information. Available online: http://www.goodfellow.com/E/Copper.html (accessed on 30 June 2020).

- Good Fellow. Aluminium Information. Available online: http://www.goodfellow.com/E/Aluminium.html (accessed on 30 June 2020).

- Good Fellow. Platinum Information. Available online: http://www.goodfellow.com/E/Platinum.html (accessed on 30 June 2020).

- Good Fellow. Titanium Information. Available online: http://www.goodfellow.com/E/Titanium.html (accessed on 30 June 2020).

- Engineering ToolBox. Thermal Conductivity of Selected Materials and Gases. Available online: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html (accessed on 30 June 2020).

- Huang, J.; Qian, X. Comparison of Test Methods for Measuring Water Vapor Permeability of Fabrics. Text. Res. J. 2008, 78, 342–352. [Google Scholar] [CrossRef]

- Bakkevig, M.K.; Nielsen, R. The impact of activity level on sweat accumulation and thermal comfort using different underwear. Ergonomics 1995, 38, 926–939. [Google Scholar] [CrossRef]

- Suen, L.K.P.; Guo, Y.P.; Ho, S.S.; Au-Yeung, C.H.; Lam, S. Comparing mask fit and usability of traditional and nanofibre N95 filtering facepiece respirators before and after nursing procedures. J. Hosp. Infect. 2020, 104, 336–343. [Google Scholar] [CrossRef]

- Li, J.; Gao, F.; Liu, L.; Zhang, Z. Needleless electro-spun nanofibers used for filtration of small particles. Express Polym. Lett. 2013, 7, 683–689. [Google Scholar] [CrossRef]

- Yang, A.; Cai, L.; Zhang, R.; Wang, J.; Hsu, P.-C.; Wang, H.; Zhou, G.; Xu, J.; Cui, Y. Thermal Management in Nanofiber-Based Face Mask. Nano Lett. 2017, 17, 3506–3510. [Google Scholar] [CrossRef]

- Baig, A.S.; Knapp, C.; Eagan, A.E.; Radonovich, L.J., Jr. Health care workers’ views about respirator use and features that should be included in the next generation of respirators. Am. J. Infect. Control. 2010, 38, 18–25. [Google Scholar] [CrossRef]

- Gralton, J.; McLaws, M.-L. Protecting healthcare workers from pandemic influenza: N95 or surgical masks? Crit. Care Med. 2010, 38, 657–667. [Google Scholar] [CrossRef] [PubMed]

- Roberge, R.J.; Coca, A.; Williams, W.J.; Palmiero, A.J.; Powell, J.B. Surgical mask placement over N95 filtering facepiece respirators: Physiological effects on healthcare workers. Respirology 2010, 15, 516–521. [Google Scholar] [CrossRef] [PubMed]

- Krah, J.; Novak, D.; Stradtman, L. Preparedness through Daily Practice: The Myths of Respiratory Protection in Healthcare; United State Department of Health and Human Services, National Institute for Occupational Saftety and Health: Washington, WA, USA, 2016. [Google Scholar]

- Bowen, L.E. Does That Face Mask Really Protect You? Appl. Biosaf. 2010, 15, 67–71. [Google Scholar] [CrossRef]

- Oberg, T.; Brosseau, L.M. Surgical mask filter and fit performance. Am. J. Infect. Control 2008, 36, 276–282. [Google Scholar] [CrossRef]

| Images Under Microscope 1 | Material Used (Excluding Filter) | Fabric Structure | Density/Inch | |

|---|---|---|---|---|

| Sample A |  | Polypropylene | Non-woven | / |

| Sample B |  | Cotton | Woven | 80 × 80 |

| Sample C |  | Natural fiber, Chitosan | Knitted Interlining Woven | 70 × 140 |

| Sample D |  | Conventional fiber, Aluminium, Platinum, Titanium | Knitted Woven | 50 × 60 |

| Sample E |  | Polyester, Copper, Polyurethane | Knitted | 50 × 70 |

| Sample F |  | Cotton | Woven Non-woven Knitted | 140 × 80 |

| Sample G |  | Natural fiber, Copper | Knitted Non-woven Woven | 80 × 80 |

| Thickness (mm) | Air resistance (kPa.s/m) | |

|---|---|---|

| Sample A | 1.24 | 0.63 |

| Sample B | 1.00 | 0.28 |

| Sample C | 1.82 | 0.45 |

| Sample D (without filter) | 1.44 | 0.77 |

| Sample D (with filter) | 1.86 | 1.77 |

| Sample E (without filter) | 2.88 | 0.99 |

| Sample E (with filter) | 3.22 | 1.56 |

| Sample F | 1.08 | 0.32 |

| Sample G (without filter) | 0.98 | 0.06 |

| Sample G (with filter) | 2.42 | 0.61 |

| Correlation between | R2 Value | |

|---|---|---|

| Breathability | Thickness and air resistance | 0.45 |

| Water vapor permeability and air resistance 1 | 0.12 | |

| Thermal conductivity and air resistance | 0.05 | |

| Thermal regulation | Thickness and thermal conductivity | 0.39 |

| Water vapor permeability and thermal conductivity 1 | 0.03 |

| Length (cm) | Width (cm) | Type | Features | |

|---|---|---|---|---|

| Sample A | 9.5 | 17.5 | Pleated | Bendable wire |

| Sample B | 8.5 | 17.5 | Pleated | Bendable wire Adjustable ear strings |

| Sample C | 17 | 19 | 3D | / |

| Sample D | 14.5 | 17.5 | 3D | Changeable filter |

| Sample E | 14 | 23.5 | 3D | Changeable filter, Nose pad |

| Sample F | 9 | 17.5 | Pleated | 2 Bendable wires |

| Sample G | 14 | 20.5 | 3D | Changeable filter |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.-P.; Yip, J.; Kan, C.-W.; Chiou, J.-C.; Yung, K.-F. Reusable Face Masks as Alternative for Disposable Medical Masks: Factors that Affect their Wear-Comfort. Int. J. Environ. Res. Public Health 2020, 17, 6623. https://doi.org/10.3390/ijerph17186623

Lee K-P, Yip J, Kan C-W, Chiou J-C, Yung K-F. Reusable Face Masks as Alternative for Disposable Medical Masks: Factors that Affect their Wear-Comfort. International Journal of Environmental Research and Public Health. 2020; 17(18):6623. https://doi.org/10.3390/ijerph17186623

Chicago/Turabian StyleLee, Ka-Po, Joanne Yip, Chi-Wai Kan, Jia-Chi Chiou, and Ka-Fu Yung. 2020. "Reusable Face Masks as Alternative for Disposable Medical Masks: Factors that Affect their Wear-Comfort" International Journal of Environmental Research and Public Health 17, no. 18: 6623. https://doi.org/10.3390/ijerph17186623

APA StyleLee, K.-P., Yip, J., Kan, C.-W., Chiou, J.-C., & Yung, K.-F. (2020). Reusable Face Masks as Alternative for Disposable Medical Masks: Factors that Affect their Wear-Comfort. International Journal of Environmental Research and Public Health, 17(18), 6623. https://doi.org/10.3390/ijerph17186623