Analysis of Human Factors Relationship in Hazardous Chemical Storage Accidents

Abstract

:1. Introduction

2. Accident Analysis Method

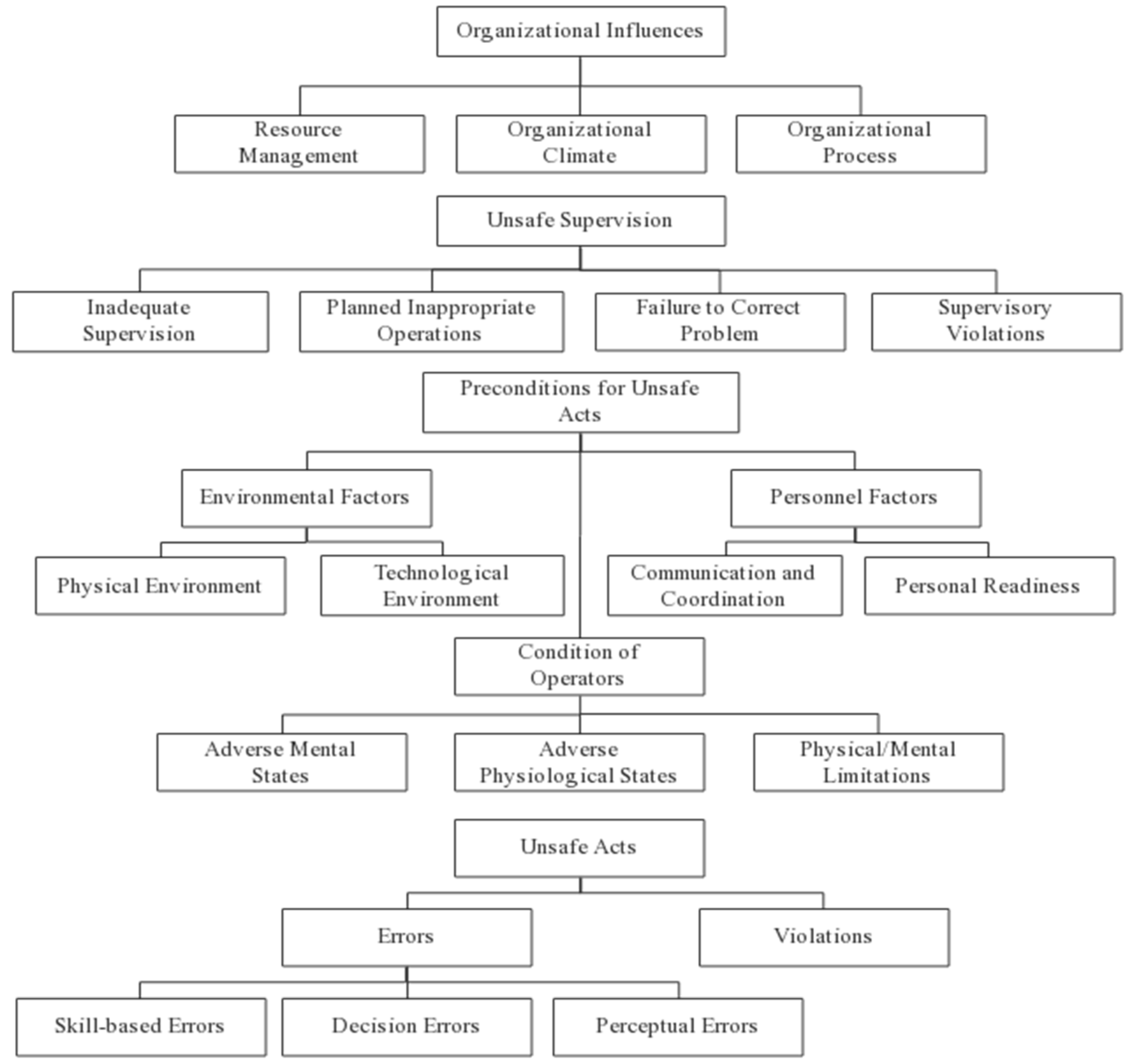

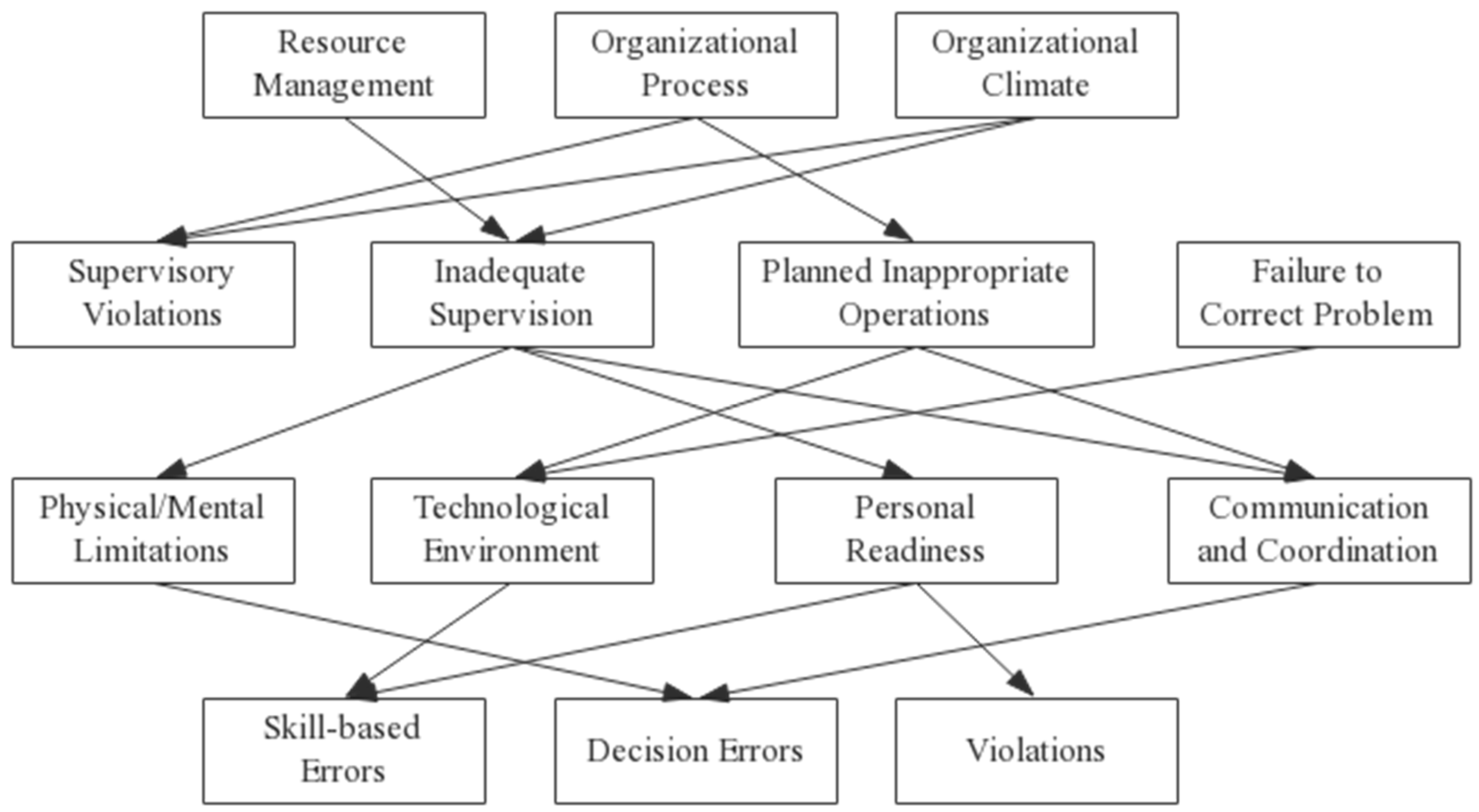

2.1. Improving the HFACS Model

2.2. Chi-Square Test and Odds Ratio Analysis

2.2.1. Chi-Square Test

2.2.2. Odds Ratio Analysis

3. Analysis of Hazardous Chemical Storage Accidents

4. Using χ2/OR to Analyze the Relevance of Human Factors in Hazardous Chemical Storage Accidents

5. Results Analysis

5.1. Defect of Organizational Influences

5.2. Unsafe Supervision

5.3. Preconditions for Unsafe Acts

5.4. Unsafe Acts

6. Conclusions

- A modified HFACS model was established for human factors analysis of hazardous chemical storage accidents. Some items of the original HFACS model were not fully applicable to the analysis of hazardous chemical storage accidents. Therefore, according to the actual situation and characteristics of the collected hazardous chemical storage accidents, an HFACS model suitable for the analysis of hazardous chemical storage accidents was established.

- The high-frequency human factors in hazardous chemical storage accidents were obtained. According to the results, the high-frequency accident causes under the HFACS framework were Resource Management (88.095%), Violations (85.714%), Inadequate Supervision (76.190%), Organizational Process (73.810%), Technological Environment (69.048%) and Personal Readiness (64.286%).

- In total, 16 groups of significant causal relationships were determined among the four levels of factors in the improved HFACS model. The chi-square test and odds ratio analysis verified 16 groups of significant causal relationships among the four levels of factors, including Resource Management and Inadequate Supervision, Organizational Process and Planned Inappropriate Operations, Planned Inappropriate Operations and Technological Environment, Inadequate Supervision and Physical/Mental Limitations, Technological Environment and Skill-Based Errors, Personal Readiness and Violations, among others.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, L.; Qian, Y.; Hu, Q.M. An Analysis of Hazardous Chemical Accidents in China between 2006 and 2017. Sustainability 2018, 10, 2935. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.D.; Zheng, X.P. Characteristics of hazardous chemical accidents in China: A statistical investigation. J. Loss Prev. Process Ind. 2012, 25, 686–693. [Google Scholar] [CrossRef]

- Jiang, W.; Han, W. Analysis of “2·28” KEEPER Chemical Industries Hazardous Chemical Explosion Accident Based on FTA and HFACS. Int. J. Environ. Res. Public Health 2018, 15, 2151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Edwards, E. Man and machine: Systems for safety. In Proceedings of the British Airline Pilots Association Technical Symposium; British Airline Pilots Association: London, UK, 1972; pp. 21–36. [Google Scholar]

- Reason, J. Human error: Models and management. West. J. Med. 2000, 172, 393. [Google Scholar] [CrossRef] [Green Version]

- Wiegmann, D.A.; Shappell, S.A. A Human Error Approach to Aviation Accident Analysis: The Human Factors Analysis and Classification System; Routledge: London, UK, 2003. [Google Scholar]

- Dekker, S.W. Reconstructing human contributions to accidents: The new view on error and performance. J. Saf. Res. 2002, 33, 371–385. [Google Scholar] [CrossRef]

- Shappell, S.; Detwiler, C.; Holcomb, K. Human error and commercial aviation accidents: An analysis using the human factors analysis and classification system. Hum. Factors 2007, 49, 227–242. [Google Scholar] [CrossRef] [PubMed]

- Daramola, A.Y. An investigation of air accidents in Nigeria using the Human Factors Analysis and Classification System (HFACS) framework. J. Air Transp. Manag. 2014, 35, 39–50. [Google Scholar] [CrossRef]

- Michał, L.; Magott, J.; Skorupski, J. A System-Theoretic Accident Model and Process with Human Factors Analysis and Classification System taxonomy. Saf. Sci. 2018, 110, 393–410. [Google Scholar]

- Rashid, H.S.J.; Place, C.S.; Braithwaite, G.R. Helicopter maintenance error analysis: Beyond the third order of the HFACS-ME. Int. J. Ind. Ergon. 2010, 40, 636–647. [Google Scholar] [CrossRef]

- Patterson, J.M.; Shappell, S.A. Operator error and system defificiencies: Analysis of 508 mining incidents and accidents from Queensland, Australia using HFACS. Accid. Anal. Prev. 2010, 42, 1379–1385. [Google Scholar] [CrossRef]

- Chauvin, C.; Lardjane, S.; Morel, G. Human and organisational factors in maritime accidents: Analysis of collisions at sea using the HFACS. Accid. Anal. Prev. 2013, 59, 26–37. [Google Scholar] [CrossRef]

- Baysari, M.T.; Caponecchia, C.; Mcintosh, A.S. Classification of errors contributing to rail incidents and accidents: A comparison of two human error identification techniques. Saf. Sci. 2009, 47, 948–957. [Google Scholar] [CrossRef]

- Cohen, T.N.; Francis, S.E.; Wiegmann, D.A. Using HFACS-Healthcare to Identify Systemic Vulnerabilities During Surgery. Am. J. Med. Qual. 2018, 33, 614–622. [Google Scholar] [CrossRef] [PubMed]

- Hale, A.; Walker, D.; Walters, N. Developing the understanding of underlying causes of construction fatal accidents. Saf. Sci. 2012, 50, 2020–2027. [Google Scholar] [CrossRef]

- Gong, Y.; Fan, Y. Applying HFACS approach to accident analysis in petro-chemical industry in China: Case study of explosion at Bi-benzene Plant in Jilin. In Proceedings of the AHFE 2016 International Conference on Safety Management and Human Factors, Walt Disney World, FL, USA, 17–22 July 2016; Pedro, A., Ed.; Springer: Cham, Switzerland, 2016; pp. 399–406. [Google Scholar]

- Zhou, L.; Fu, G.; Xue, Y.J.Y. Human and organizational factors in Chinese hazardous chemical accidents: A case study of ‘8.12’ Tianjin Port fire and explosion using the HFACS-HC. Int. J. Occup. Saf. Ergon. 2018, 24, 329–340. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.H.; Yang, X.C. Analysis of Road Transportation Accidents of Hazardous Chemicals in China. J. Polil Sci. Law 2020, 37, 122–128. (In Chinese) [Google Scholar]

- Duan, W.; Chen, G.; Ye, Q. The situation of hazardous chemical accidents in China between 2000 and 2006. J. Hazard Mater. 2011, 186, 1489–1494. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.Y.; Ren, J.W.; Cheng, H.W. Research on Coal Mine Safety System Deficiencies and Unsafe Acts. China Saf. Sci. J. 2011, 11, 130–137. (In Chinese) [Google Scholar]

| Author | Industry/Field of Application | Method | Principal Results | Reference |

|---|---|---|---|---|

| Dekker | - | - | The HFACS model is the most powerful tool for human factors analysis of various accidents | [7] |

| Shappell | Aviation | HFACS analysis method | The majority of accidents were caused by the air crew and environment | [8] |

| Daramola | Aviation | HFACS analysis method | Supervision violation to crew resource management to decision errors was considered the most likely path to accidents | [9] |

| Michal et al. | Aviation | HFACS and STAMP analysis method | Confirmed the feasibility of the STAMP-HFACS analysis method | [10] |

| Rashid et al. | Helicopter maintenance | HFACS-ME analysis method | Proposed the HFACS-ME model for helicopter maintenance accidents and studied the survival rate of helicopter maintenance accidents and the distribution of accident severity | [11] |

| Patterson and Shappell | Coal mine | HFACS-MI analysis method | Skill-based errors are the most common unsafe behavior, with no significant difference between different types of mines | [12] |

| Chauvin et al. | Maritime transportation | The improved HFACS analysis method | Most collision accidents were caused by decision errors | [13] |

| Baysari et al. | Railway transportation | HFACS and TRACEr methods | Suggested the effectiveness of the HFACS and TRACEr methods, but each tool seems to ignore certain important factors related to the occurrence of errors | [14] |

| Cohen et al. | Medical science | HFACS-Healthcare methods | HFACS and Healthcare can be used to identify system weaknesses during surgery | [15] |

| Hale et al. | Architecture | HFACS analysis method | Deficiencies in planning and risk assessment, hardware design, purchase and installation, and contracting strategies during building construction were found | [16] |

| Gong and Fan | Chemical industry | HFACS analysis method | Classified the human factors that led to the accident, confirming the usefulness and feasibility of the HFACS for accident analysis in the chemical industry | [17] |

| Zhou et al. | Chemical industry | HFACS analysis method | The interaction between different levels of human factors in the Ruihai company led to the accident, and the accident investigation report displayed limitations in the identification of human factors and guidance for similar accident prevention | [18] |

| Low-Level Factors | High-Level Factors | Row Sum | |

|---|---|---|---|

| Exist | None | ||

| Exist | n11(f11) | n12(f12) | nr1 |

| None | n21(f21) | n22(f22) | nr2 |

| Column Sum | nc1 | nc2 | n |

| No. | Date of Accident | Enterprises | Type of Accident | Number of Deaths | Economic Damage (RMB) |

|---|---|---|---|---|---|

| 1 | 7 January 2010 | PETROCHINA Lanzhou Petrochemical Company | Explosion | 6 | 9 million |

| 2 | 29 June 2010 | PETROCHINA Liaoyang Petrochemical Company | Explosion | 3 | 1.5 million |

| 3 | 24 October 2010 | Dalian CNPC International Storage and Transportation Co., Ltd. | Fire disaster | - | - |

| 4 | 18 January 2011 | Inner Mongolia Wuhai Chemical Industry Co., Ltd. | Explosion | 3 | 3 million |

| 5 | 5 August 2011 | Harbin Kaile Chemical Products Factory | Explosion | 3 | - |

| 6 | 28 February 2012 | Hebei KEEPER Chemical Industries Co., Ltd. | Explosion | 25 | 44.59 million |

| 7 | 1 March 2013 | Jianping Hongshen Trading Co., Ltd. | Explosion | 7 | 12.1 million |

| 8 | 2 June 2013 | PETROCHINA Dalian Petrochemical Company | Explosion | 4 | 6.97 million |

| 9 | 3 June 2013 | Jilin Baoyuanfeng Poultry Co., Ltd. | Fire disaster | 121 | 182 million |

| 10 | 31 August 2013 | Shanghai Wengpai Refrigeration Industry Co., Ltd. | Poisoning | 15 | 25.1 million |

| 11 | 14 September 2013 | Fushun Shunte Chemical Co., Ltd. | Explosion | 5 | 1.2 million |

| 12 | 20 November 2013 | Pucheng Xingzhen Xinglong Village Paper Tube Product Factory | Explosion | 5 | 2 million |

| 13 | 1 January 2014 | Shandong Bin Yang gasification Co., Ltd. | Poisoning | 4 | 5.36 million |

| 14 | 21 March 2014 | Inner Mongolia Baotou Steel Hefa Rare Erath Co., Ltd. | Explosion | 1 | - |

| 15 | 6 April 2015 | Tenglong Aromatics (Zhangzhou) Co., Ltd. | Explosion | - | 94.57 million |

| 16 | 16 July 2015 | Shtar Science & Technology Group Petrochemical Co., Ltd. | Explosion | - | 28.12 million |

| 17 | 12 August 2015 | Tianjin Port Ruihai International Logistics Co., Ltd. | Explosion | 165 | 6.866 billion |

| 18 | 28 November 2015 | Handan Longgang Chemical Co., Ltd. | Poisoning | 3 | 3.9 million |

| 19 | 22 April 2016 | Jiangsu Tak Bridge Company Limited Storage | Fire disaster | 1 | 25.32 million |

| 20 | 5 June 2016 | Shandong Weifang Huahao Agrochemical Co., Ltd. | Poisoning | 3 | 2.4 million |

| 21 | 18 August 2016 | Yangquan Coal Industry Group Taiyuan Chemical New Material Co., Ltd. | Explosion | - | 1.75 million |

| 22 | 8 September 2016 | Shijiazhuang Jinzhou (illegal dye manufacturer) | Explosion | 7 | 6.1 million |

| 23 | 20 September 2016 | Wanhua Chemical Group Co., Ltd. | Explosion | 4 | 5.73 million |

| 24 | 24 January 2017 | Jiangxi Sanmei Chemical Co., Ltd. | Poisoning | 2 | 7.4 million |

| 25 | 27 February 2017 | Jilin Songyuan Petrochemical Co., Ltd. | Explosion | 3 | 5.9 million |

| 26 | 2 April 2017 | Anqing Wanhua Oil products Co., Ltd. | Explosion | 5 | 7.866 million |

| 27 | 13 May 2017 | Hebei Lixing Special Rubber Co., Ltd. | Poisoning | 2 | 3.2 million |

| 28 | 5 June 2017 | Linyi Jinyu Petrochemical Co., Ltd. | Explosion | 10 | 44.68 million |

| 29 | 28 September 2017 | Guangdong Tenglong Chemical Technology Co., Ltd. | Fire disaster | - | 247.6 thousand |

| 30 | 19 December 2017 | Shandong Rike Chemical Co., Ltd. | Fire disaster | 7 | 14.79 million |

| 31 | 10 February 2018 | Jiujiang Zhongwei Technology Chemical Co., Ltd. | Explosion | 2 | 1.7 million |

| 32 | 1 March 2018 | Tangshan Huayi IndustryHoldings Co., Ltd. | Fire disaster | 4 | 5.37 million |

| 33 | 27 March 2018 | Zaozhuang Showers Industrial Co., Ltd. | Explosion | 9 | 9 million |

| 34 | 12 May 2018 | Shanghai SECCO Petrochemical Co., Ltd. | Explosion | 6 | 5.36 million |

| 35 | 12 July 2018 | Yibin Hengda Technology Co., Ltd. | Explosion | 19 | 41.42 million |

| 36 | 13 July 2018 | Sichuan Jiangyou Changte No. 1 Factory Comprehensive Service Company | Explosion | 1 | 1.4 million |

| 37 | 12 November 2018 | Jinan Huifeng Carbon Co., Ltd. | Explosion | 6 | 11.45 million |

| 38 | 28 November 2018 | Hebei Shenghua Chemical Industry Co., Ltd. | Explosion | 24 | 41.48 million |

| 39 | 21 March 2019 | Jiangsu Xiangshui Tianjiayi Chemical Co., Ltd. | Explosion | 78 | 1986.35 million |

| 40 | 15 April 2019 | Qilu Tianhe Pharmaceutical Co., Ltd. | Poisoning | 10 | 18.67 million |

| 41 | 6 August 2019 | Guangdong Guangkang Biochemical Technology Co., Ltd. | Fire disaster | - | 9.5 million |

| 42 | 16 September 2019 | Guangzhou Human Engineering Materials Co., Ltd. | Explosion | 2 | 2.26 million |

| HFACS Framework Items | Frequency | Proportion (%) | |

|---|---|---|---|

| Organizational Influences | Resource Management | 37 | 88.095 |

| Organizational Climate | 24 | 57.143 | |

| Organizational Process | 31 | 73.810 | |

| Unsafe Supervision | Inadequate Supervision | 32 | 76.190 |

| Planned Inappropriate Operations | 20 | 47.619 | |

| Failure to Correct Problem | 23 | 54.762 | |

| Supervisory Violations | 23 | 54.762 | |

| Preconditions for Unsafe Acts | Physical Environment | 8 | 19.048 |

| Technological Environment | 29 | 69.048 | |

| Adverse Mental States | 9 | 21.429 | |

| Adverse Physiological States | 1 | 2.381 | |

| Physical/Mental Limitations | 20 | 47.619 | |

| Communication and Coordination | 24 | 57.143 | |

| Personal Readiness | 27 | 64.286 | |

| Unsafe Acts | Skill-based Errors | 20 | 47.619 |

| Decision Errors | 22 | 52.381 | |

| Perceptual Errors | 3 | 7.143 | |

| Violations | 36 | 85.714 | |

| Decision Errors | Communication and Coordination | Row Sum | |

|---|---|---|---|

| Exist | None | ||

| Exist | 16 | 6 | 22 |

| None | 8 | 12 | 20 |

| Column Sum | 24 | 18 | 42 |

| HFACS Level | χ2 Test | OR | 95% Confidence Interval | ||

|---|---|---|---|---|---|

| χ2 | p | Upper Limit | Lower Limit | ||

| Causal Relationship Between Organizational Influence Level and Unsafe Supervision Level | |||||

| Resource Management × Inadequate Supervision | 6.675 | 0.010 | 20.667 | 218.712 | 1.953 |

| Organizational Climate × Inadequate Supervision | 3.948 | 0.047 | 4.455 | 20.710 | 0.958 |

| Organizational Climate × Supervisory Violations | 9.259 | 0.002 | 7.800 | 31.151 | 1.953 |

| Organizational Process × Planned Inappropriate Operations | 5.177 | 0.023 | 6.231 | 33.771 | 1.150 |

| Organizational Process × Supervisory Violations | 4.546 | 0.033 | 4.848 | 22.107 | 1.063 |

| Causal Relationship Between Unsafe Supervision Level and Preconditions for Unsafe Acts Level | |||||

| Inadequate Supervision × Physical/Mental Limitations | 4.014 | 0.045 | 5.143 | 28.141 | 0.940 |

| Inadequate Supervision × Communication and Coordination | 7.394 | 0.007 | 8.800 | 49.162 | 1.575 |

| Inadequate Supervision × Personal Readiness | 11.212 | 0.001 | 14.286 | 83.171 | 2.454 |

| Planned Inappropriate Operations × Technological Environment | 4.546 | 0.033 | 4.722 | 20.887 | 1.068 |

| Planned Inappropriate Operations × Communication and Coordination | 4.972 | 0.026 | 4.333 | 16.248 | 1.156 |

| Failure to Correct Problem × Technological Environment | 4.375 | 0.036 | 4.275 | 17.420 | 1.049 |

| Causal Relationship Between Preconditions for Unsafe Acts Level and Unsafe Acts Level | |||||

| Technological Environment × Skill-based Errors | 7.843 | 0.005 | 9.000 | 48.437 | 1.672 |

| Physical/Mental Limitations × Decision Errors | 4.752 | 0.029 | 4.083 | 14.863 | 1.122 |

| Communication and Coordination × Decision Errors | 4.582 | 0.032 | 4.000 | 14.624 | 1.094 |

| Personal Readiness × Skill-based Errors | 4.107 | 0.043 | 4.000 | 15.868 | 1.008 |

| Personal Readiness × Violations | 4.706 | 0.030 | 13.000 | 125.520 | 1.346 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, W.; Han, W.; Zhou, J.; Huang, Z. Analysis of Human Factors Relationship in Hazardous Chemical Storage Accidents. Int. J. Environ. Res. Public Health 2020, 17, 6217. https://doi.org/10.3390/ijerph17176217

Jiang W, Han W, Zhou J, Huang Z. Analysis of Human Factors Relationship in Hazardous Chemical Storage Accidents. International Journal of Environmental Research and Public Health. 2020; 17(17):6217. https://doi.org/10.3390/ijerph17176217

Chicago/Turabian StyleJiang, Wei, Wei Han, Jiankai Zhou, and Zhishun Huang. 2020. "Analysis of Human Factors Relationship in Hazardous Chemical Storage Accidents" International Journal of Environmental Research and Public Health 17, no. 17: 6217. https://doi.org/10.3390/ijerph17176217

APA StyleJiang, W., Han, W., Zhou, J., & Huang, Z. (2020). Analysis of Human Factors Relationship in Hazardous Chemical Storage Accidents. International Journal of Environmental Research and Public Health, 17(17), 6217. https://doi.org/10.3390/ijerph17176217