A Numerical Analysis of the Cooling Performance of a Hybrid Personal Cooling System (HPCS): Effects of Ambient Temperature and Relative Humidity

Abstract

1. Introduction

2. Methodology

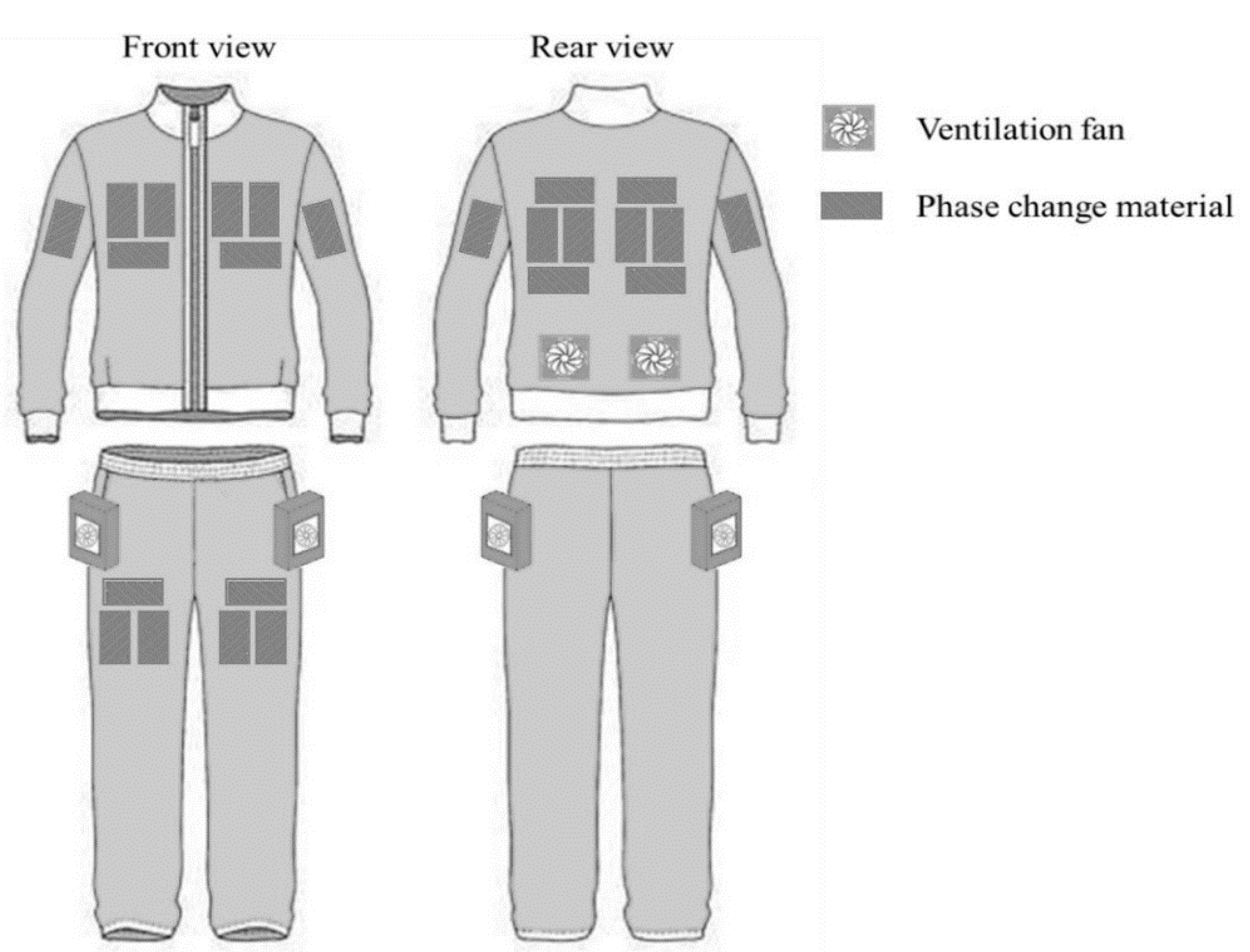

2.1. Description of the HPCS

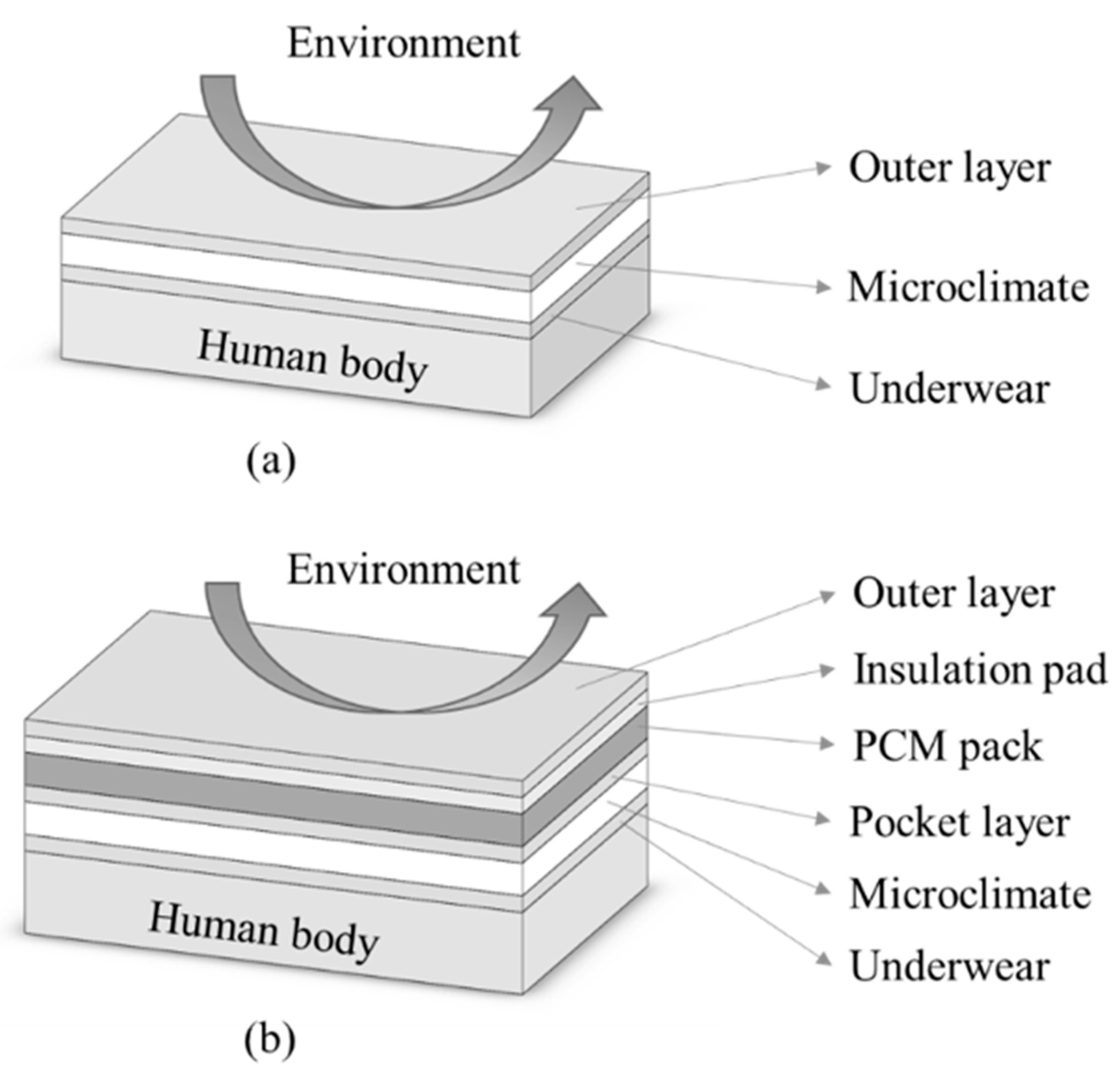

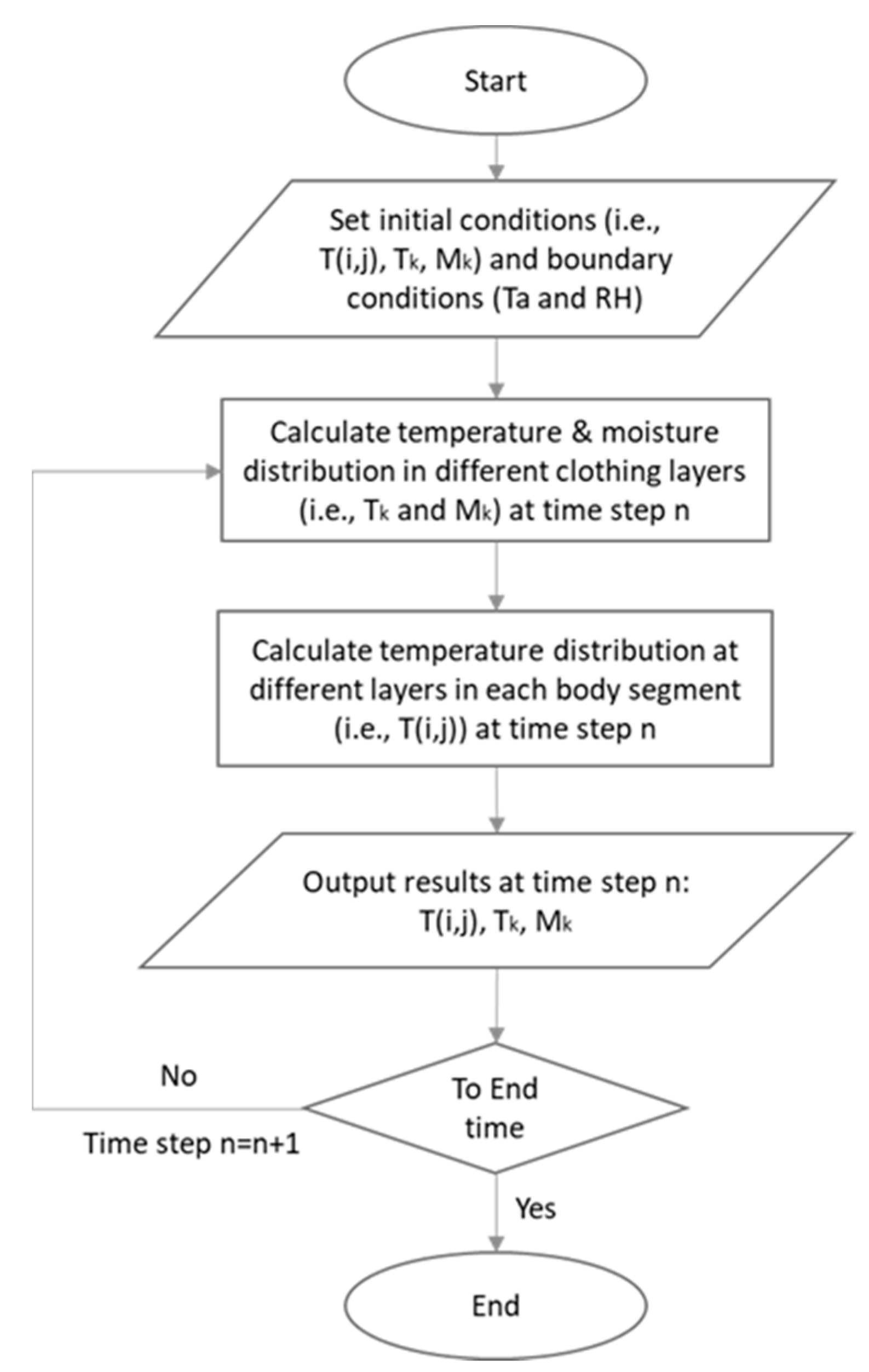

2.2. Numerical Model of the HPCS

- (1)

- Local thermal and moisture transports both reach equilibrium instantly in each clothing layer;

- (2)

- The mobile liquid water purely exiting in the underwear layer dispersed into the whole fabric layer throughout the whole segment instantaneously;

- (3)

- The air ventilation by fans is considered as the independent air exchange between the clothing microclimate and the ambient environment for each segment, i.e., no air transport between any adjacent segments. Besides, the HPCS was considered air-tight and air could only go out from the openings at the sleeves (to avoid possible air leakage, an elastic waistband was used at the bottom of the air ventilation jacket and the waist area of air ventilation trousers, the neck area of the jacket was also tightened using zippers).

- (4)

- PCM packs are regarded as a uniform material with a constant thickness, and they closely adhere to the pocket textiles.

2.3. Simulation Parameters

3. Results and Discussion

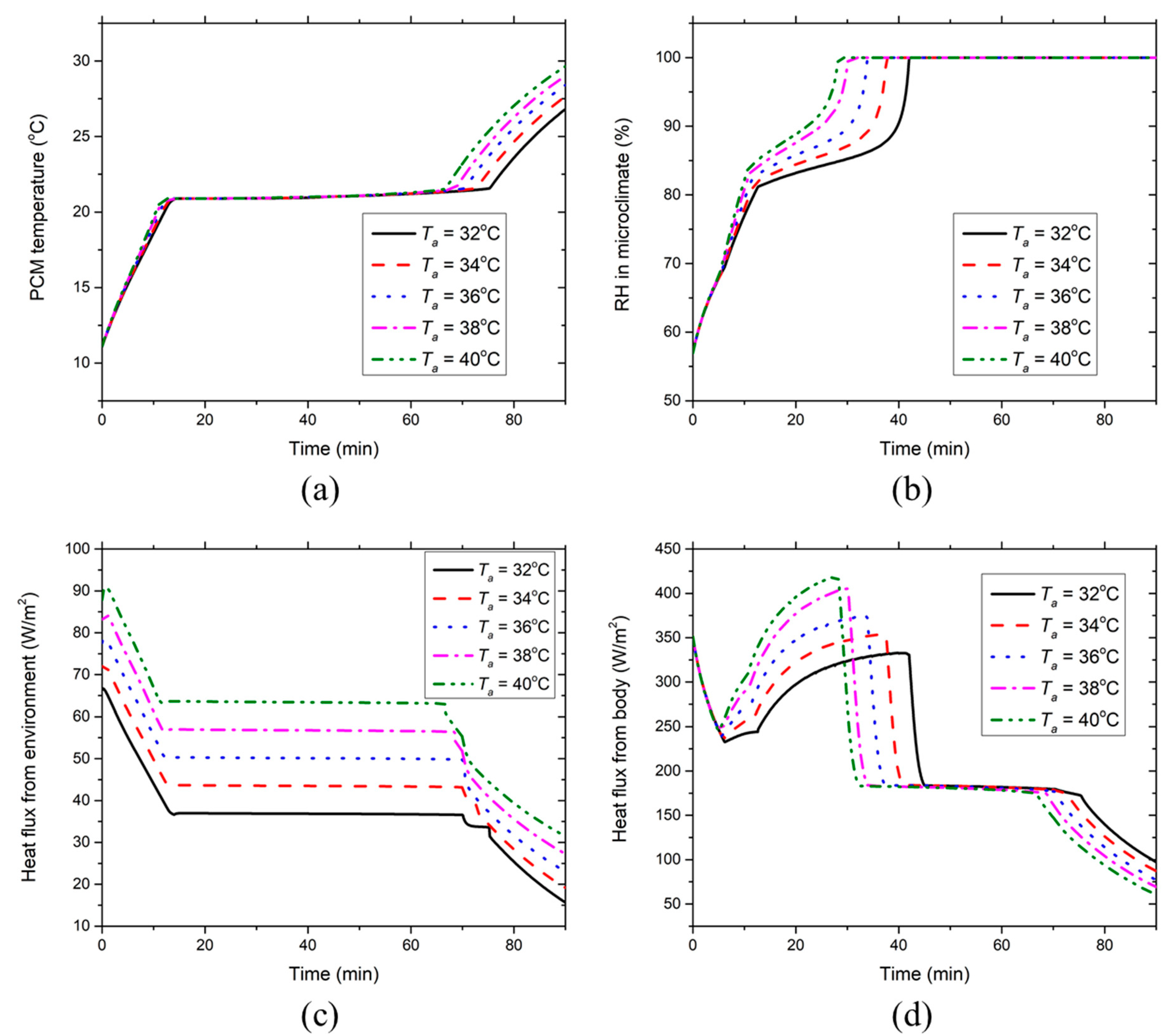

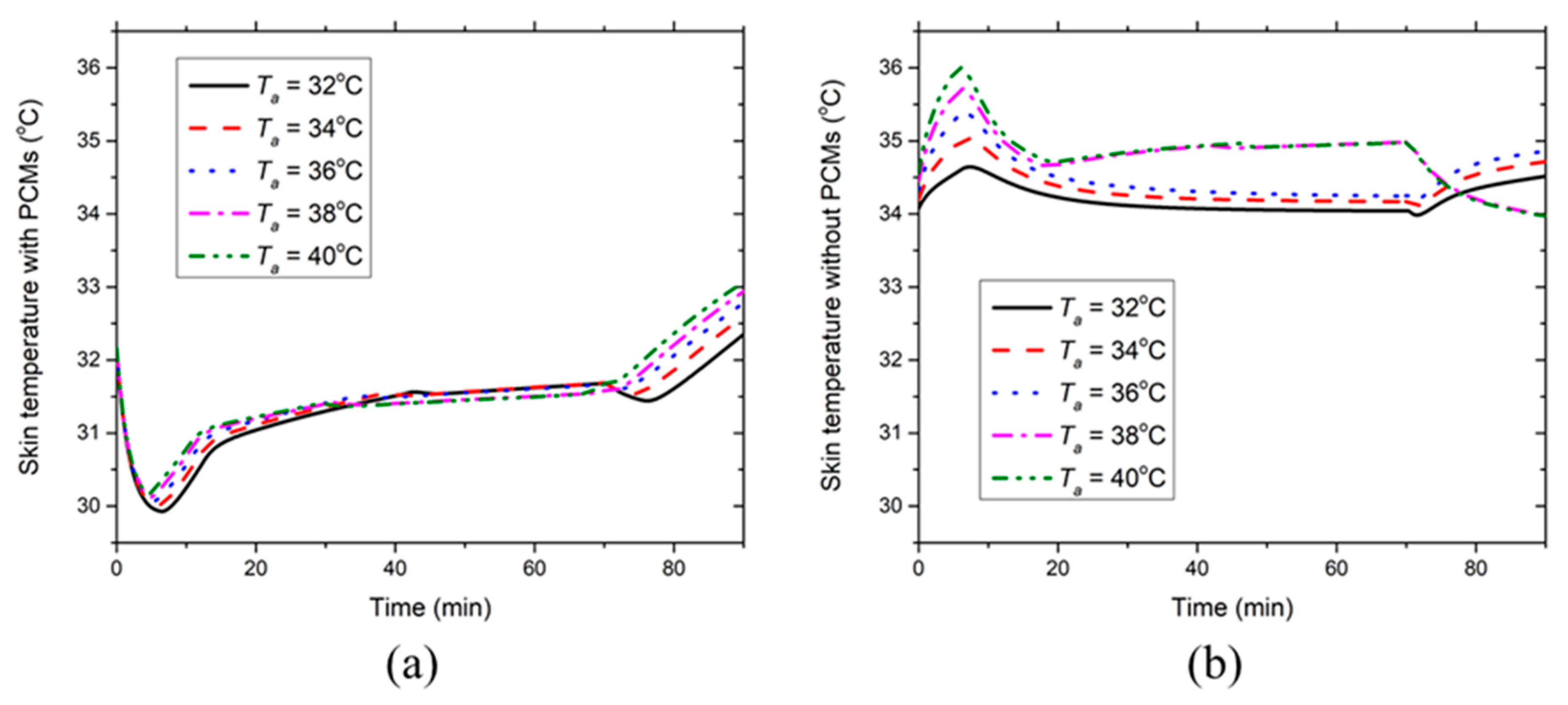

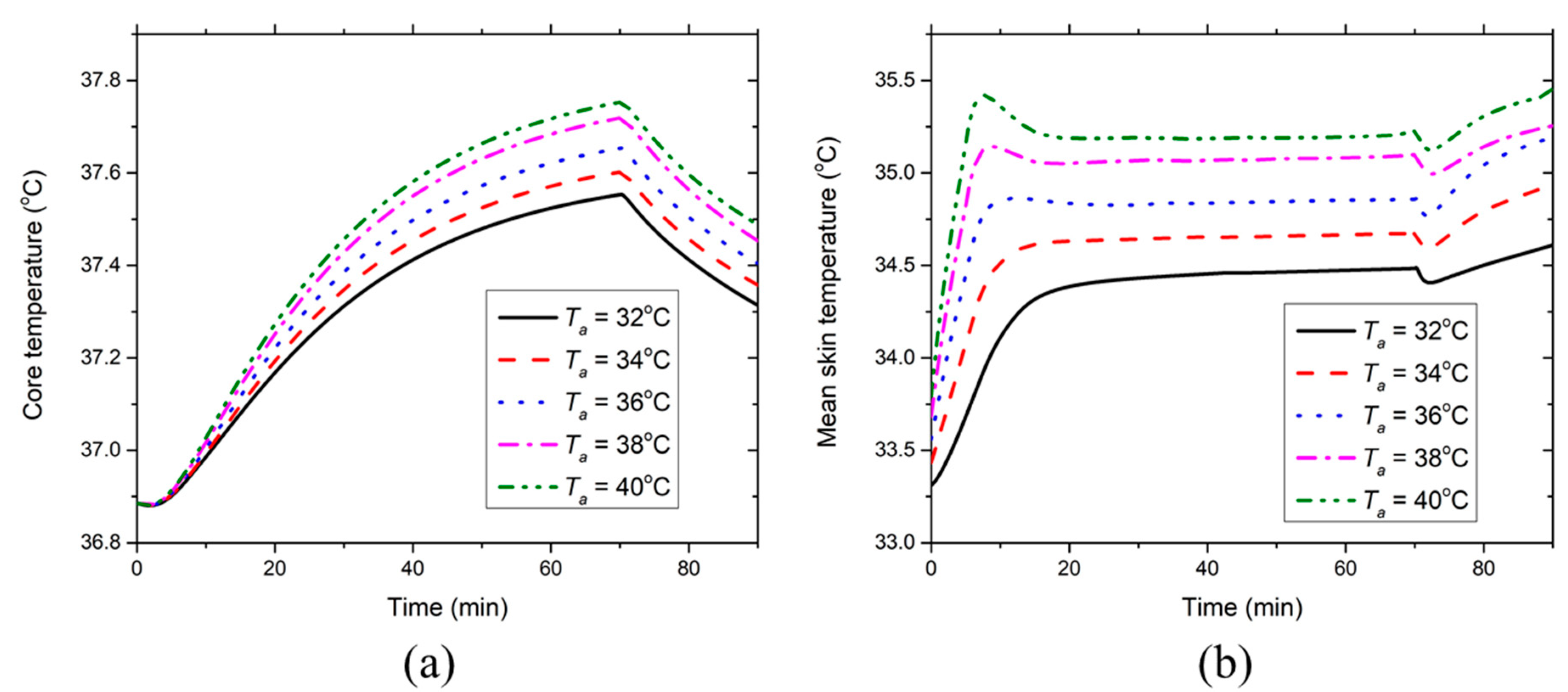

3.1. Effect of Environmental Temperatures

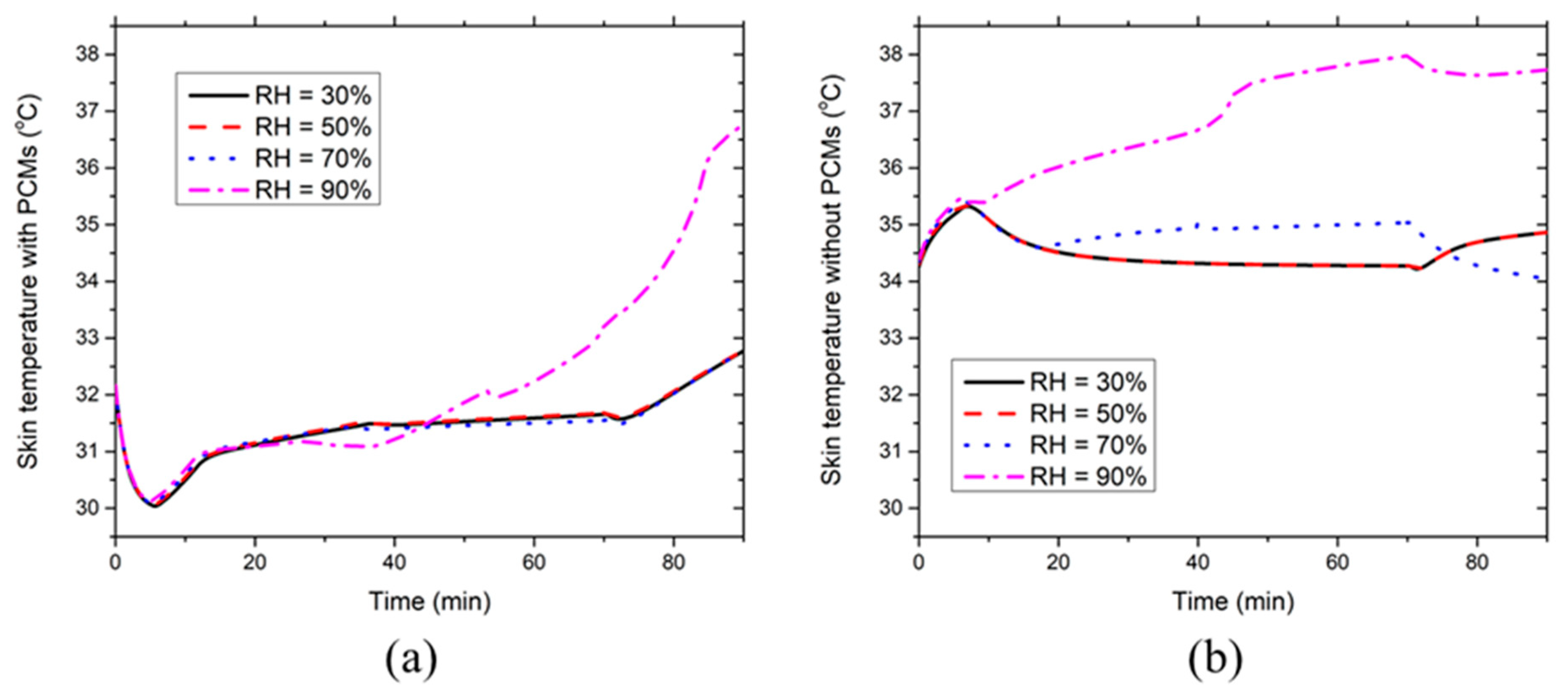

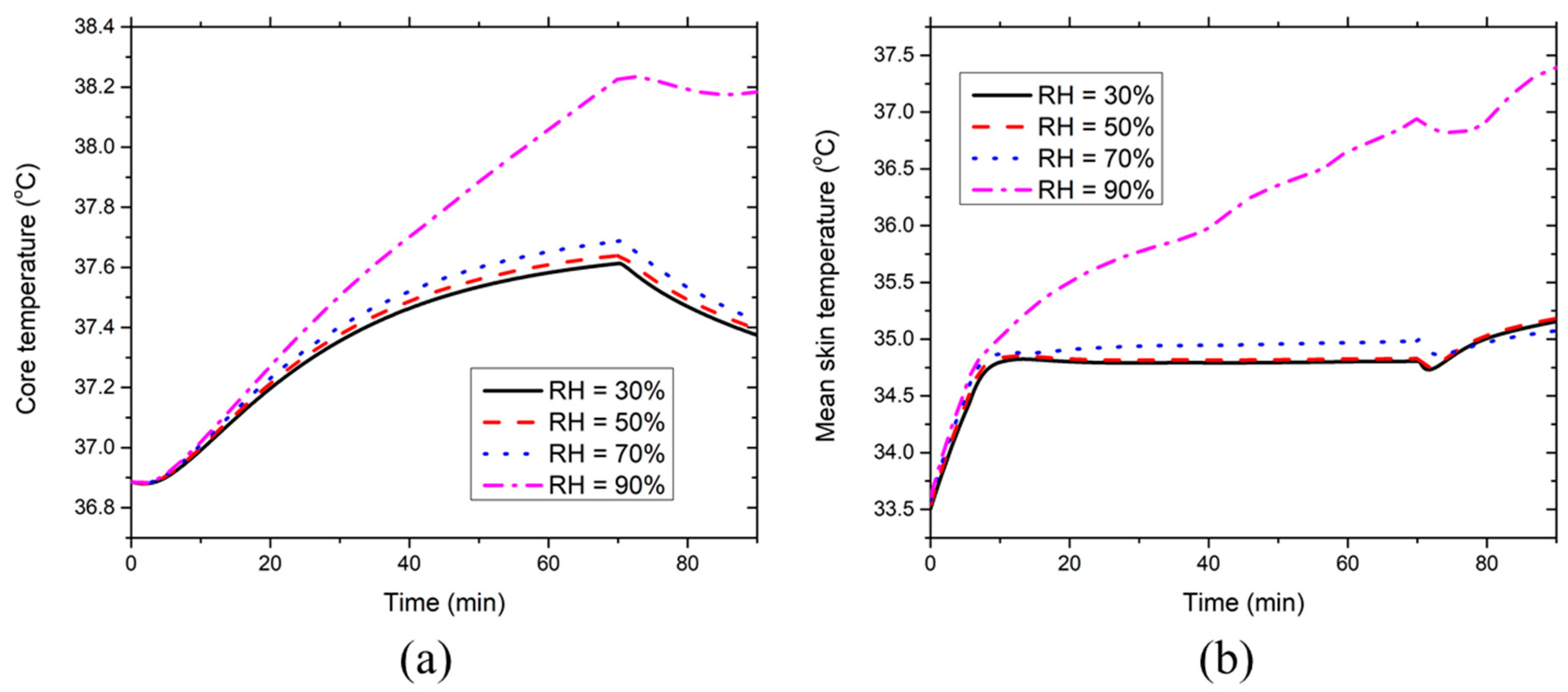

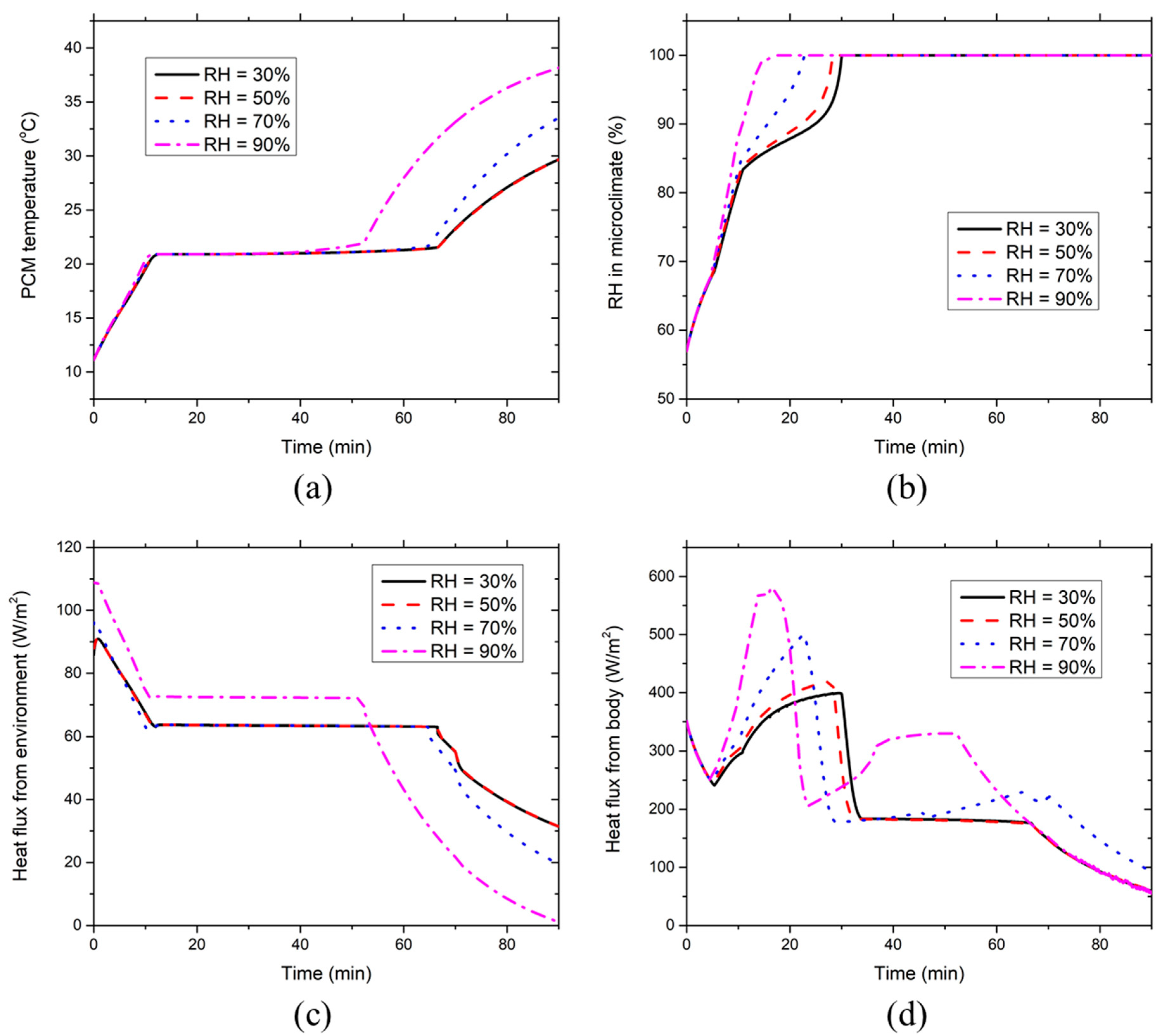

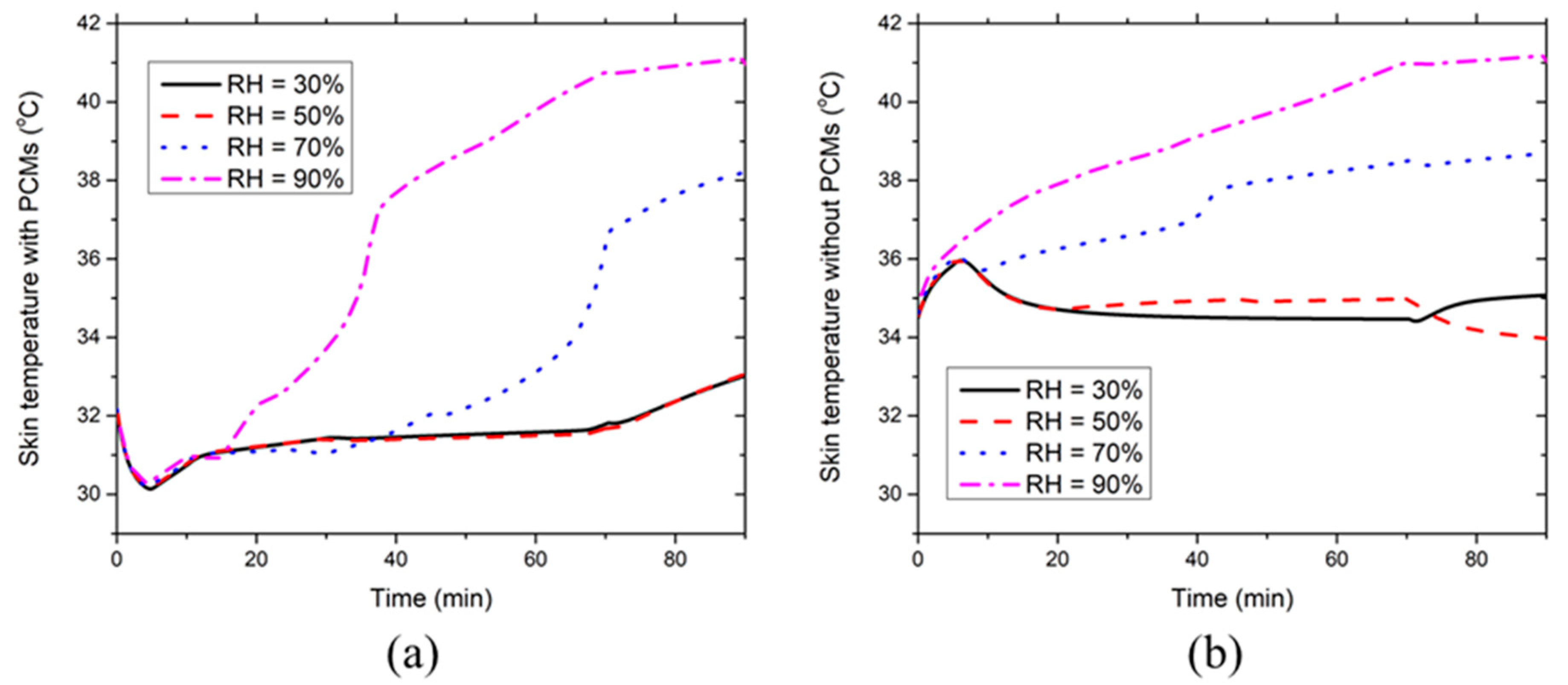

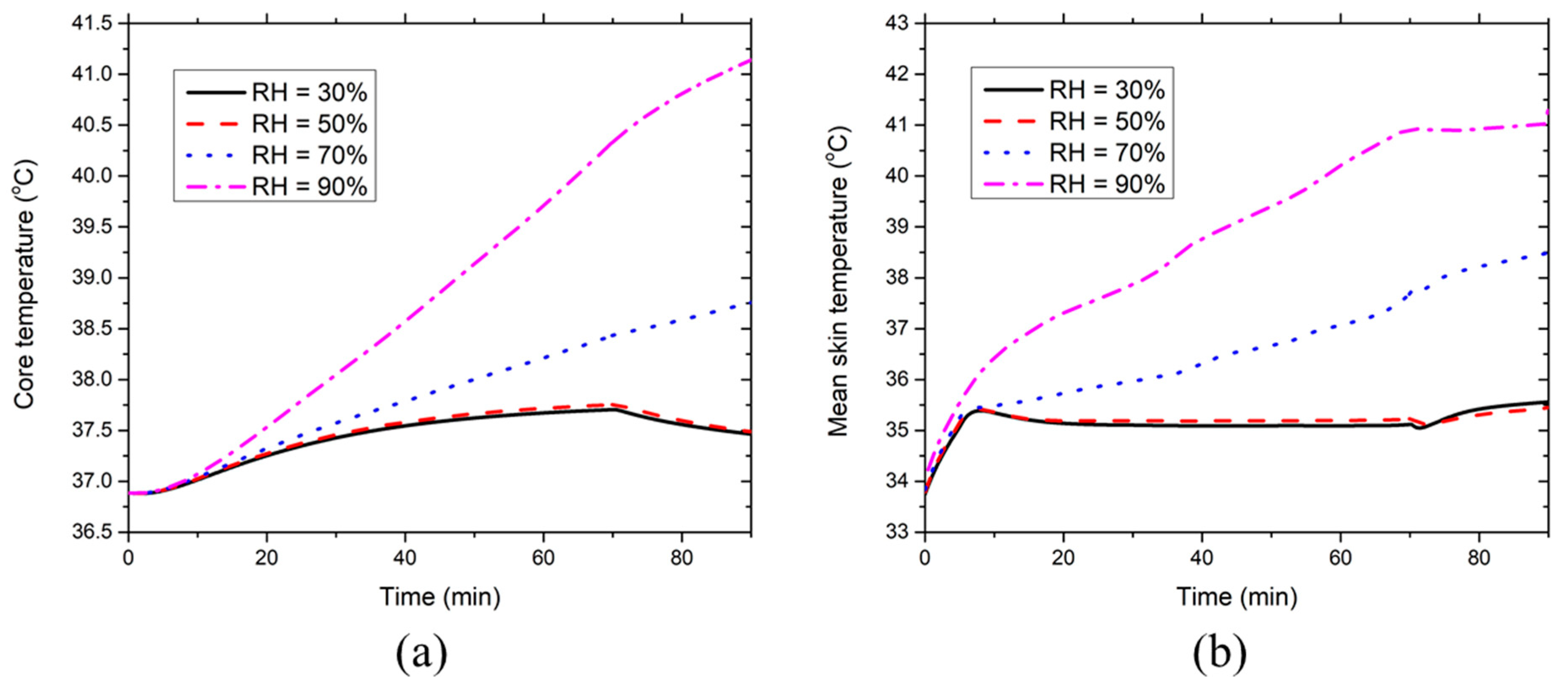

3.2. Effect of Relative Humidity in Moderately Hot Environments (36 °C)

3.3. Effect of Relative Humidity in Extremely Hot Environments (40 °C)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ratnam, J.V.; Behera, S.K.; Ratna, S.B.; Rajeevan, M.; Yamagata, T. Anatomy of Indian heatwaves. Sci. Rep. 2016, 6, 24395. [Google Scholar] [CrossRef] [PubMed]

- Klinenberg, E. Heat Wave: A Social Autopsy of Disaster in Chicago; University of Chicago Press: Chicago, IL, USA, 2015. [Google Scholar]

- Guo, Y.; Gasparrini, A.; Armstrong, B.G.; Tawatsupa, B.; Tobias, A.; Lavigne, E.; Coelho, M.; Pan, X.; Kim, H.; Hashizume, M.; et al. Heat wave and mortality: A multicountry, multicommunity study. Environ. Health Perspect. 2017, 125, 087006. [Google Scholar] [CrossRef] [PubMed]

- Hansen, A.; Bi, P.; Nitschke, M.; Ryan, P.; Pisaniello, D.; Tucker, G. The effect of heat waves on mental health in a temperate Australian city. Environ. Health Perspect. 2008, 116, 1369–1375. [Google Scholar] [CrossRef]

- Deng, Q.; Zhao, J.; Liu, W.; Li, Y. Heatstroke at home: Prediction by thermoregulation modeling. Build. Environ. 2018, 137, 147–156. [Google Scholar] [CrossRef]

- Kjellstrom, T.; Holmer, I.; Lemke, B. Workplace heat stress, health and productivity—An increasing challenge for low and middle–income countries during climate change. Glob. Health Action 2009, 2, 2047. [Google Scholar] [CrossRef]

- Ranney, M.L.; Griffeth, V.; Jha, A.K. Critical supply shortage—The need for ventilators and personal protective equipment during the Covid-19 pandemic. N. Engl. J. Med. 2020, 382, e41. [Google Scholar] [CrossRef]

- Adams, J.G.; Walls, R.M. Supporting the health care workforce during the Covid-19 global epidemic. JAMA 2020, 323, 1439–1440. [Google Scholar] [CrossRef]

- Li, W.; Zhang, J.; Xiao, S.; Sun, L. Characteristics of deaths amongst health workers in China during the outbreak of COVID-19 infection. J Infect. 2020, 81, 147–178. [Google Scholar] [CrossRef]

- Zhao, M.; Gao, C.; Wang, F.; Kuklane, K.; Holmer, I.; Li, J. A study on local cooling of garments with ventilation fans and openings placed at different torso sites. Int. J. Ind. Ergon. 2013, 43, 232–237. [Google Scholar] [CrossRef]

- Guo, T.; Shang, B.; Duan, B.; Luo, X. Design and testing of a liquid cooled garment for hot environments. J. Therm. Biol. 2015, 49–50, 47–54. [Google Scholar] [CrossRef]

- Bartkowiak, G.; Dabrowska, A.; Marszalek, A. Assessment of an active liquid cooling garment intended for use in a hot environment. Appl. Ergon. 2017, 58, 182–189. [Google Scholar] [CrossRef]

- Itani, M.; Ghaddar, N.; Ghali, K.; Ouahrani, D.; Chakroun, W. Cooling vest with optimized PCM arrangement targeting torso sensitive areas that trigger comfort when cooled for improving human comfort in hot conditions. Energy Build. 2017, 139, 417–425. [Google Scholar] [CrossRef]

- Rothmaier, M.; Weder, M.; Meyer –Heim, A.; Kesselring, J. Design and performance of personal cooling garments based on three-layer laminates. Med. Biol. Eng. Comput. 2008, 46, 825–832. [Google Scholar] [CrossRef]

- Zhao, D.; Lu, X.; Fan, T.; Wu, Y.S.; Lou, L.; Wang, Q.; Fan, J.; Yang, R. Personal thermal management using portable thermoelectrics for potential building energy saving. Appl. Energy 2018, 218, 282–291. [Google Scholar] [CrossRef]

- Yang, Y.; Stapleton, J.; Diagne, B.T.; Kenny, G.P.; Lan, C.Q. Man-portable personal cooling garment based on vacuum desiccant cooling. Appl. Therm. Eng. 2012, 47, 18–24. [Google Scholar] [CrossRef]

- Boriskina, S.V. Nanoporous fabrics could keep you cool. Science 2016, 353, 986–987. [Google Scholar] [CrossRef] [PubMed]

- Yazdi, M.M.; Sheikhzadeh, M. Personal cooling garments: A review. J. Text. Inst. 2014, 105, 1231–1250. [Google Scholar] [CrossRef]

- Al Sayed, C.; Vinches, L.; Hallé, S. Towards Optimizing a Personal Cooling Garment for Hot and Humid Deep Mining Conditions. Open J. Optim. 2016, 5, 35–43. [Google Scholar] [CrossRef]

- Yazdi, M.M.; Sheikhzadeh, M.; Chavoshi, S.E. Modeling the performance of a PCM cooling vest considering its side effects. Int. J. Cloth. Sci. Technol. 2015, 27, 573–586. [Google Scholar] [CrossRef]

- Xu, X.; Gonzalez, J. Determination of the cooling capacity for body ventilation system. Eur. J. Appl. Physiol. 2011, 111, 3155–3160. [Google Scholar] [CrossRef]

- Webbon, B.; Montgomery, L.; Miller, L.; Williams, B. A comparison of three liquid-ventilation cooling garments during treadmill exercise. Aviat. Space Environ. Med. 1981, 52, 408–415. [Google Scholar] [PubMed]

- Wang, T.; Wang, L.; Bai, L.; Lin, G.; Bu, X.; Liu, X.; Xie, G. Experimental study on the performance of a liquid cooling garment with the application of MEPCMS. Energy Conv. Manag. 2015, 103, 943–957. [Google Scholar] [CrossRef]

- Song, W.; Wang, F. The hybrid personal cooling system (PCS) could effectively reduce the heat strain while exercising in a hot and moderate humid environment. Ergonomics 2016, 59, 1009–1018. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Wang, F.; Wei, F. Hybrid cooling clothing to improve thermal comfort of office workers in a hot indoor environment. Build. Environ. 2016, 100, 92–101. [Google Scholar] [CrossRef]

- Guo, Y.; Chan, A.P.C.; Wong, F.K.W.; Li, Y.; Sun, S.; Han, X. Developing a hybrid cooling vest for combating heat stress in the construction industry. Text. Res. J. 2017, 89, 004051751774368. [Google Scholar] [CrossRef]

- Yi, W.; Zhao, Y.; Chan, A.P.C. Evaluating the Effectiveness of Cooling Vest in a Hot and Humid Environment. Ann. Work. Expos. Health 2017, 61, 481–494. [Google Scholar] [CrossRef]

- Wan, X.; Wang, F.; Udayraj. Numerical analysis of cooling effect of hybrid cooling clothing incorporated with phase change material (PCM) packs and air ventilation fans. Int. J. Heat Mass Transf. 2018, 126, 636–648. [Google Scholar] [CrossRef]

- Kang, Z.; Udayraj; Wan, X.; Wang, F. A new hybrid personal cooling system (HPCS) incorporating insulation pads for thermal comfort management: Experimental validation and parametric study. Build. Environ. 2018, 145, 276–289. [Google Scholar] [CrossRef]

- Zhao, M.; Gao, C.; Wang, F.; Kuklane, K.; Holmér, I.; Li, J. The torso cooling of vests incorporated with phase change materials: A sweat evaporation perspective. Text. Res. J. 2012, 83, 418–425. [Google Scholar] [CrossRef]

- Chinevere, T.D.; Cadarette, B.S.; Goodman, D.A.; Ely, B.R.; Cheuvront, S.N.; Sawka, M.N. Efficacy of body ventilation system for reducing strain in warm and hot climates. Eur. J. Appl. Physiol. 2008, 103, 307–314. [Google Scholar] [CrossRef]

- Du, Y.; Wang, S.; Jin, L.Z.; Wang, S.; Gai, W.M. Experimental investigation and theoretical analysis of the human comfort prediction model in a confined living space. Appl. Therm. Eng. 2018, 141, 61–69. [Google Scholar] [CrossRef]

- Choudhary, B.; Udayraj; Wang, F.; Ke, Y.; Yang, J. Development and experimental validation of a 3D numerical model based on CFD of the human torso wearing air ventilation clothing. Int. J. Heat Mass Transf. 2020, 147, 118973. [Google Scholar] [CrossRef]

- Wan, X.; Fan, J. A transient thermal model of the human body–clothing–environment system. J. Therm. Biol. 2008, 33, 87–97. [Google Scholar] [CrossRef]

- Gao, C.; Kuklane, K.; Wang, F.; Holmer, I. Personal cooling with phase change materials to improve thermal comfort from a heat wave perspective. Indoor Air 2012, 22, 523–530. [Google Scholar] [CrossRef]

- Tanabe, S.; Kobayashi, K.; Nakano, J.; Ozeki, Y.; Konishi, M. Evaluation of thermal comfort using combined multi-node thermoregulation (65MN) and radiation models and computational fluid dynamics (CFD). Energy Build. 2002, 34, 637–646. [Google Scholar] [CrossRef]

- Antony Aroul Raj, V.; Velraj, R. Heat transfer and pressure drop studies on a PCM-heat exchanger module for free cooling applications. Int. J. Therm. Sci. 2011, 50, 1573–1582. [Google Scholar] [CrossRef]

- del Barrio, E.P.; Dauvergne, J.L. A non-parametric method for estimating enthalpy-temperature functions of shape-stabilized phase change materials. Int. J. Heat Mass Transf. 2011, 54, 1268–1277. [Google Scholar] [CrossRef]

- W.H.O. Health Factors Involved in Working under Conditions of Heat Stress: Report of a WHO Scientific Group. Available online: https://apps.who.int/iris/bitstream/handle/10665/40716/WHO_TRS_412.pdf?sequence=1&isAllowed=y (accessed on 11 June 2020).

- A.C.G.I.H. TLV for Heat Stress and Strain in Threshold Limit Values for Chemical Substances and Physical Agents & Biological Exposure Indices; American Conference of Governmental Industrial Hygienists (ACGIH): Cincinnati, OH, USA, 2016; Available online: https://www.nsc.org/Portals/0/Documents/facultyportal/Documents/fih-6e-appendix-b.pdf (accessed on 11 June 2020).

| Variables | Values |

|---|---|

| Environmental temperature (°C) | 32, 34, 36, 38, 40 |

| Environmental RH at 36 °C (%) | 30, 50, 70, 90 |

| Environmental RH at 40 °C (%) | 30, 50, 70, 90 |

| Simulated Temperature (°C) | Maximal Core Temperature (°C) | Maximal Mean Skin Temperature (°C) | ||||||

|---|---|---|---|---|---|---|---|---|

| RH = 30% | RH = 50% | RH = 70% | RH = 90% | RH = 30% | RH = 50% | RH = 70% | RH = 90% | |

| 32 | - | - | 37.57 | - | - | 34.64 | - | - |

| 34 | - | - | 37.62 | - | - | 34.92 | - | - |

| 36 | 37.58 | 37.62 | 37.70 | 38.28 | 35.24 | 35.24 | 35.21 | 37.48 |

| 38 | - | - | 37.75 | - | - | 35.31 | - | - |

| 40 | 37.73 | 37.74 | 37.77 | 41.20 | 35.75 | 35.48 | 38.58 | 41.22 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, P.; Kang, Z.; Wang, F.; Udayraj. A Numerical Analysis of the Cooling Performance of a Hybrid Personal Cooling System (HPCS): Effects of Ambient Temperature and Relative Humidity. Int. J. Environ. Res. Public Health 2020, 17, 4995. https://doi.org/10.3390/ijerph17144995

Xu P, Kang Z, Wang F, Udayraj. A Numerical Analysis of the Cooling Performance of a Hybrid Personal Cooling System (HPCS): Effects of Ambient Temperature and Relative Humidity. International Journal of Environmental Research and Public Health. 2020; 17(14):4995. https://doi.org/10.3390/ijerph17144995

Chicago/Turabian StyleXu, Pengjun, Zhanxiao Kang, Faming Wang, and Udayraj. 2020. "A Numerical Analysis of the Cooling Performance of a Hybrid Personal Cooling System (HPCS): Effects of Ambient Temperature and Relative Humidity" International Journal of Environmental Research and Public Health 17, no. 14: 4995. https://doi.org/10.3390/ijerph17144995

APA StyleXu, P., Kang, Z., Wang, F., & Udayraj. (2020). A Numerical Analysis of the Cooling Performance of a Hybrid Personal Cooling System (HPCS): Effects of Ambient Temperature and Relative Humidity. International Journal of Environmental Research and Public Health, 17(14), 4995. https://doi.org/10.3390/ijerph17144995