1. Introduction

Forestry is regarded as a dangerous industry [

1]. Ozden et al. (2011) [

2] state that all countries that provide incidence rate statistics by industry report the highest rates in forestry. Regardless of the use of modern techniques and machinery, occupational accidents are frequent and, in many cases, fatal, especially in forest harvesting [

3,

4]. These accidents are often followed by material and environmental damage, as well as financial compensations to the victims or their families [

5], thus having additional effects on the financial stability of businesses in forestry.

The most demanding occupations in forestry connect to motor–manual forest harvesting (chainsaw felling and tree processing, skidding with a skidder). It is a hard work and requires holding awkward positions [

6]. In addition, workers are exposed to a combination of factors stemming from the work environment or the processed materials [

7]. The main risk factors connected to the work environment include rugged terrain, climatic conditions, biological agents, and exposure to noise, vibrations, and exhaust fumes. Other risks connected to forest harvesting include using sharp, powered tools, heavy loads, and heavy machinery [

8,

9,

10]. Due to this, workers also often suffer from various occupational diseases of the muscular, skeletal, nervous, vascular, and auditory systems [

11,

12,

13].

As [

14] state, felling and extraction of timber are operations where most fatal accidents occur. Each of these operations has its specifics, depending on the natural and technological conditions and share of manual labor in the timber production process. Timber logging, namely motor–manual, is connected with a high risk of an occupational accident (OA) occurring [

15]. On the other hand, mechanized logging is considered relatively safe, though with the deployment of cut-to-length technologies, new risks emerge, connected with their increased complexity and mental strain of the operators [

16,

17,

18].

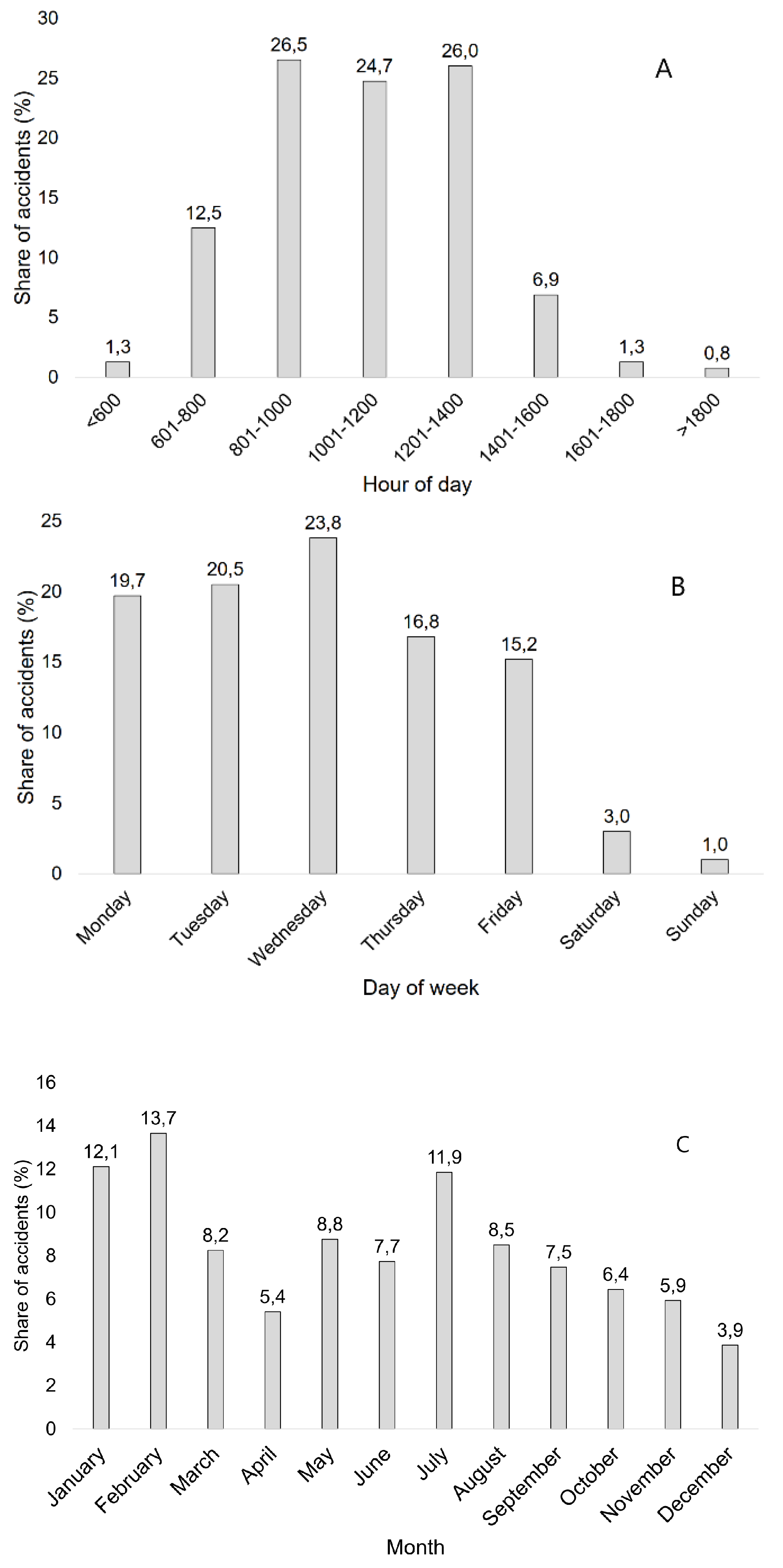

From a temporal point of view, accidents in forest harvesting occur mostly in the first half of the workweek. According to [

15,

19,

20], most OAs occur on Mondays and Tuesdays, though [

15] reported a rather uniform distribution, with the exception of Friday, when the frequency of OAs is approximately half of the frequency in other workweek days. Within the work shifts, the likelihood of a worker to suffer an accident peaks before the lunch break, followed by a smaller increase before the end of the shift [

15,

19,

21,

22]. There are several potential causes for such a distribution of accidents throughout the shifts: (i) worker effort increases in the times when most accidents occur; (ii) the dose of work environment factors (e.g., noise, vibration, heat/cold exposure) exceeds the capacity of the workers to cope with them; (iii) fatigue sets in; (iv) workers deplete their energy and fluid reserves from meals, thus increasing the fatigue level, etc. [

15,

23,

24,

25,

26,

27].

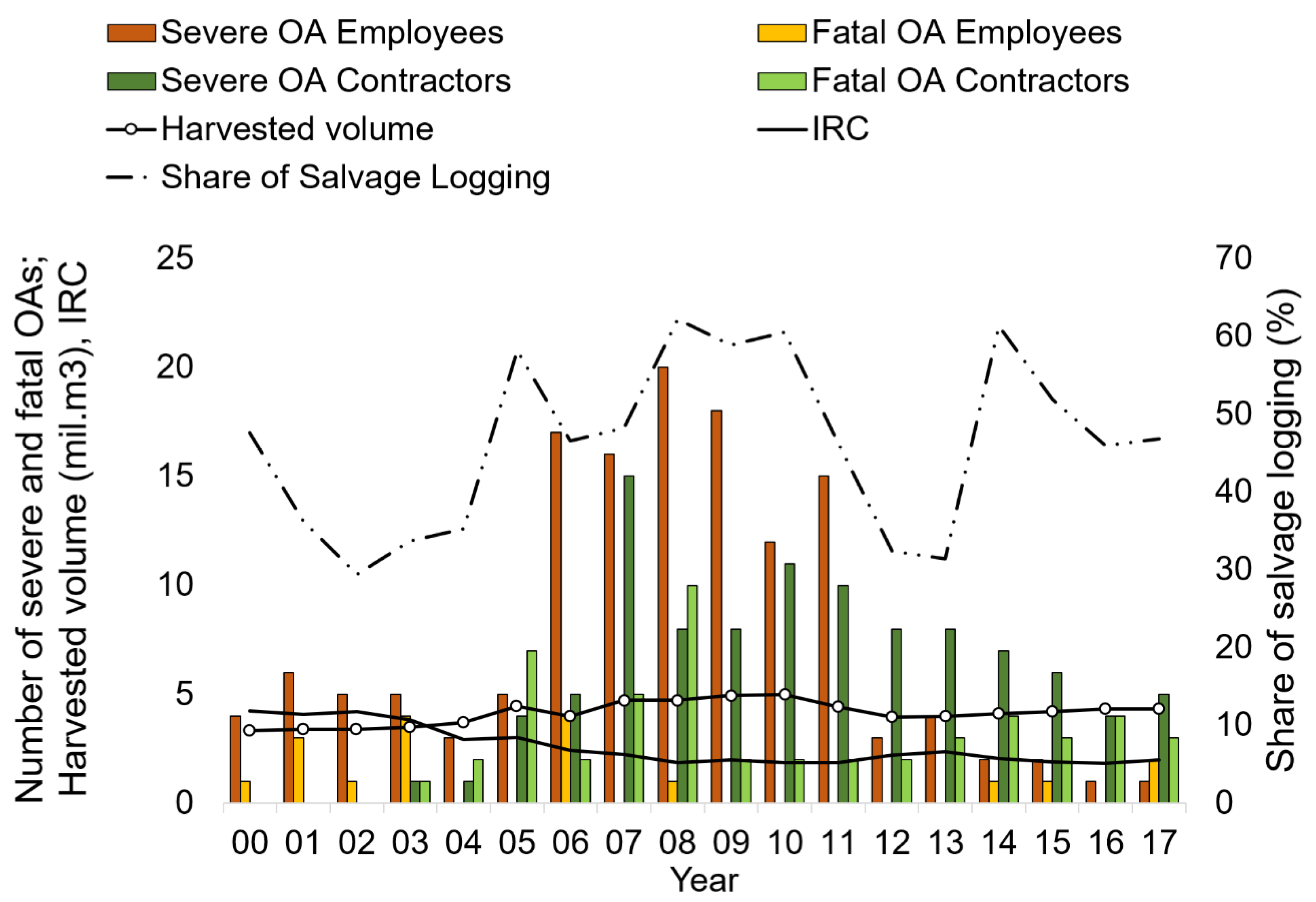

Slovak forestry faces the problem of a large share of salvage logging, ranging from 31% in the year 2000 to 57% in the year 2015 [

28]. This was caused by windstorms in the early 2000s and a subsequent bark beetle outbreak in the country [

28,

29]. These problems are the most visible when we look at the largest raw timber producer in the country—Forests of the Slovak Republic, GOE (government-owned enterprise; FSR). The company manages about 46% of all Slovak forests (886,252 ha) and harvests about half of all timber (4.7 million m

3 in the year 2015) [

28]. The large share of salvage logging can further increase the number of occupational accidents, including, but not limited to, forest harvesting [

15,

30,

31].

This paper focuses on assessing the occupational accidents suffered by the employees and contractors of the FSR during the 2000–2017 period, from a temporal and operational point of view. We analyze the records of the FSR and test the effects of several factors on the number of accidents or the severity. We set the following hypotheses for testing: (H1) contractors of the FSR suffer significantly more severe and fatal OAs than employees; (H2) the total annual volume of harvests and the share of salvage logging significantly affect the number of OAs occurring at the FSR within a given year; (H3) inexperienced workers suffer significantly more OAs than experienced workers; (H4) worker age significantly affects the number of OAs; (H5) significantly more OAs occur during the first half of the workweek; (H6) significantly more OAs occur during the first half of the work shift; (H7) significantly more OAs occur in forest harvesting than in any other occupation; (H8) the distribution of types of injuries vary significantly throughout the year (e.g., more fractures occur in a given season); and (H9) the distribution of body parts injured vary significantly throughout the year (e.g., more lower-limb injuries in a given season).

2. Materials and Methods

2.1. Data Sources

During our analyses, we used databases of the FSR OSH (Occupational Safety and Health) department. According to the OSH management system of the FSR, all OAs suffered by the company employees and contractors were stored in a generic human resources database. From the year 2006 on, FSR kept a comprehensive database of all severe and fatal OAs according to the Slovak regulation no. 500/2006 Coll. [

32]. Until that year, record-keeping was managed by individual branches. The regulation mandates that every OA must be registered by the company and for OAs that cause the injured employee to lose working days, a record must be kept in accordance with the template specified by the regulation. The template specified in [

32] transposed the regulation of the European Parliament and Council no. 89/391/EEC [

33] to Slovak legislation. Therefore, the Slovak OA record template contained (among other information) a narrative mode of injury, description of the material agent, and cause of accident. These characteristics were then coded by FSR safety officers according to the European Statistics on Accidents at Work (ESAW) [

34]. In cases when the narrative parts of the record conflicted with the information encoded through [

34], we resolved the conflict by recoding the ESAW variables according to the information provided in the narratives. This database only contained information on the OAs that occurred to workers with a direct relationship with the FSR —employees (E), contractors (C), and their employees, and people who harvest timber allotments from the FSR forests (F) (FSR sells them the right to harvest a small amount of low-grade timber for firewood). It did not contain any information on the OAs that occurred to subcontractors.

2.2. Variables Analyzed

From the generic database on human resources for the years 2000–2017, we gathered information on the number of employees and the occupational structure, as well as general information on the number and structure of OAs, based on the relationship of the worker with the FSR. In case of FSR employees, we recorded: (i) number of employees (v1) divided by sex—male or female and according to type of work—technical/office staff or manual worker; (ii) number of OAs (v2) classified by severity —minor (no days lost), registered (up to three days lost), severe (more than three days lost), and fatal; (iii) number of days lost due to an OA or an occupational illness (OI) (v3); (iv) reported near-misses (v4); (v) number of OIs (v5)—vasoneurosis, borreliosis, hearing loss, and other. Workers who were not employees of the FSR, i.e., contractors and people who harvest their timber allotments were obliged to report to the FSR only severe and fatal OAs. In these cases, we gathered the same information as for employees.

The more-detailed database created from OA records was effectively a subset of the generic human-resource database. The OA record database contained data on 401 cases which occurred during the years 2006–2017. We gathered the following information from the OA records: sex (v6), age (v7), occupation (v8), and experience (v9) of the injured worker, as well as the date (v10), hour (v11), day of week (v12), month (v13), severity (v14), operation (v15) during which the incident occurred, type of injury (v16), and injured body part (v17).

2.3. Data Analyses

We included all OA records in the database of the FSR OSH department. To achieve a more robust dataset, we merged similar occupations (e.g., all employees of the directorate and branches who worked inside offices were labeled “office”, workers in the garage were labelled “mechanic”, etc.). We analyzed the following occupations: (i) animal handler; (ii) office; (iii) feller; (iv) forester; (v) mechanic; (vi) haulage truck driver; (vii) wood processing line operator; (viii) wood processing line supervisor; (ix) forest worker (various manual tasks); (x) other (unspecified); (xi) skidder operator; (xii) machine operator (unspecified); (xiii) silviculture worker (various manual tasks in nurseries, forest establishment, tending, etc.); (xiv) harvester and forwarder operator; (xv) helicopter pilot; and (xvi) loader operator.

The workers in all mentioned occupations carried out operations during which they suffered an injury. Due to the variability of the operations, we merged similar operations, as well: (i) felling (including delimbing and bucking); (ii) repairs and maintenance; (iii) timber haulage; (iv) forest management; (v) skidding; (vi) wood processing (automated at a conversion depot); (vii) walking; (viii) other (unspecified); (ix) operating other machines; (x) sideline operations; (xi) silviculture; (xii) game; (xiii) animal care; and (xiv) forest road construction and maintenance. As for severity of an accident, we distinguished between minor injuries that did not cause the loss of working days, registered injuries that caused a loss of between one and three working days, severe injuries that caused a loss of more than three working days, and fatal accidents that caused death. This way, we were able to work with a more manageable dataset.

First, we calculated the Incidence Rate Coefficient (IRC) according to [

1]:

where OA

TOT is the total number of occupational accidents and illnesses in the company, 200,000 is the constant for calculating the incidence rate per 100 employees who work standard eight-hour shifts, and H

TOT is the total number of hours worked by all employees of the company.

We analyzed the relationships between v2 (number of OAs) categorized according to v14 (severity of the OA) and the relationship of the worker with the FSR, the share of incidental fellings, and annual harvested volume. We used generalized linear models (GLMs) to analyze the potential difference between v2 (number of OAs) suffered by employees and contractors of the FSR categorized according to v14 (severity of the OA). We used logistic regression of the GLMs to analyze the effects of v7 (age), v8 (occupation), v9 (experience), and v15 (operation) on v2 (number of OAs) categorized according to v14 (severity of the OA) and their relationship with the FSR (employees and contractors).

We used contingency tables for basic analyses and an χ2 test to analyze the distribution of the variable v2 (number of OAs) in individual categories. We also used this approach when analyzing v7 (age), v9 (experience), v11 (hour), v12 (day of week), v13 (month), v16 (type of injury), and v17 (injured body part), as well as for analysis of the distribution of the fatal accidents for v2 (number of OAs) and v6 (sex). We used an χ 2 test, along with Cramér’s V coefficient, to test v2 (number of OAs) and v7 (age), v11 (hour), v12 (day), and v13 (month). Microsoft Word, Excel, Statistica 12, and R software served to process and analyze the gathered material.

4. Discussion

The problem of occupational safety and health was studied by numerous authors. Tsioras et al. (2011) report that the accident rate declined from 155 accidents per million hours worked (years 1980–1989) to 77 accidents (years 2000–2009) in the Austrian federal forest enterprise. Bentley et al. (2005) state that the accident rate decreased in New Zealand, as well, from 20 accidents per million hours worked in 1999 to 14 accidents in 2001. The decreasing accident rate could relate to improvements to the safety management systems in forestry enterprises and promoting safety programs in the industry [

35,

36,

37]. We observed a similar trend considering the employees of FSR, when both the absolute numbers of OAs and IRC decreased, from 505 OAs in the year 2000 to 62 in the year 2017 and 3.88 IRC in the year 2000 to 1.80 IRC in the year 2017.

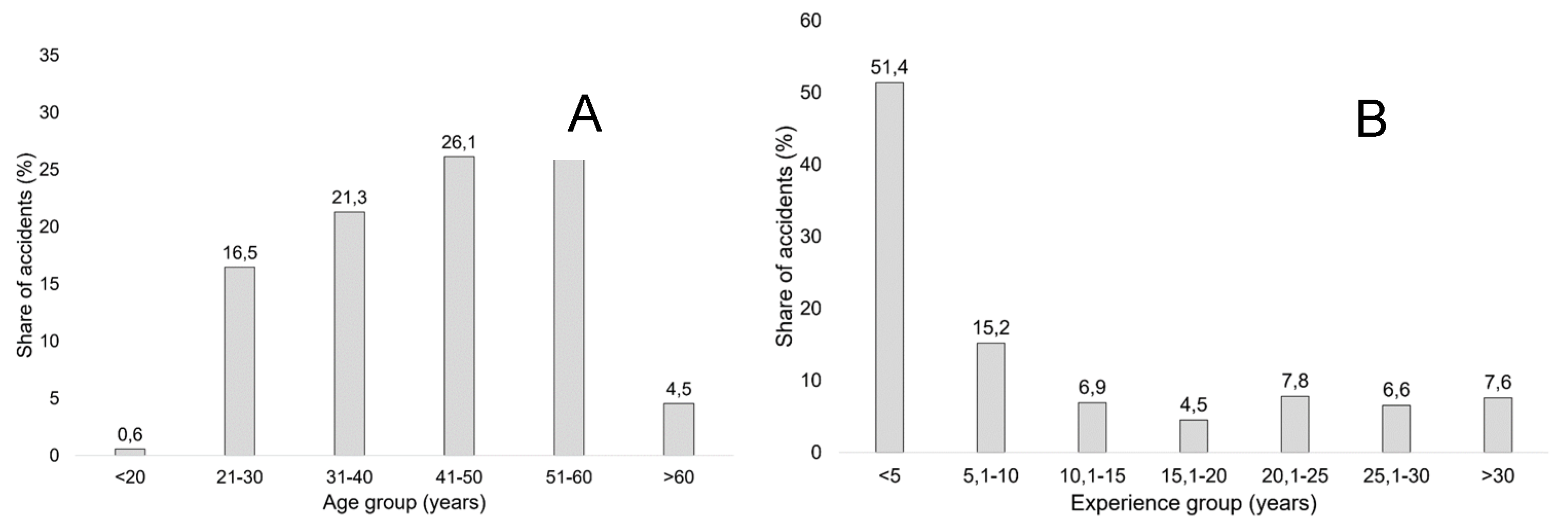

Two thirds of the OAs reported occurred to workers between the ages of 25 and 54 years, with the mean age reaching 43 years. Wilhelmson et al. (2005) [

38] report similar results: that older workers in forestry, between the age of 50 and 59, suffer the most OAs. In addition, Tsioras et al. (2014) [

15] report the mean age of the workers who suffered an OA was 40 years. Lagerstrom et al. (2017) [

39] and Laschi et al. (2016) [

8] report that the workers in the age group of 31–50 years suffer the most OAs; furthermore, they report that the duration of the sick leave increases with age. This could be due to the fact that older workers tend to lose vigilance during the shifts, especially when the shifts are prolonged and nonstandard [

40]. Another group suffering many accidents was composed of young, inexperienced workers. Inexperienced workers frequently lack the skills and habits necessary to work safely, so they tend to get injured more frequently [

41]. The high share of accidents occurring to young workers points to the industry’s underperformance in safety training, because, as Boini et al. (2017) [

41] state, the frequency of OAs halves if the students undertake occupational health and safety training.

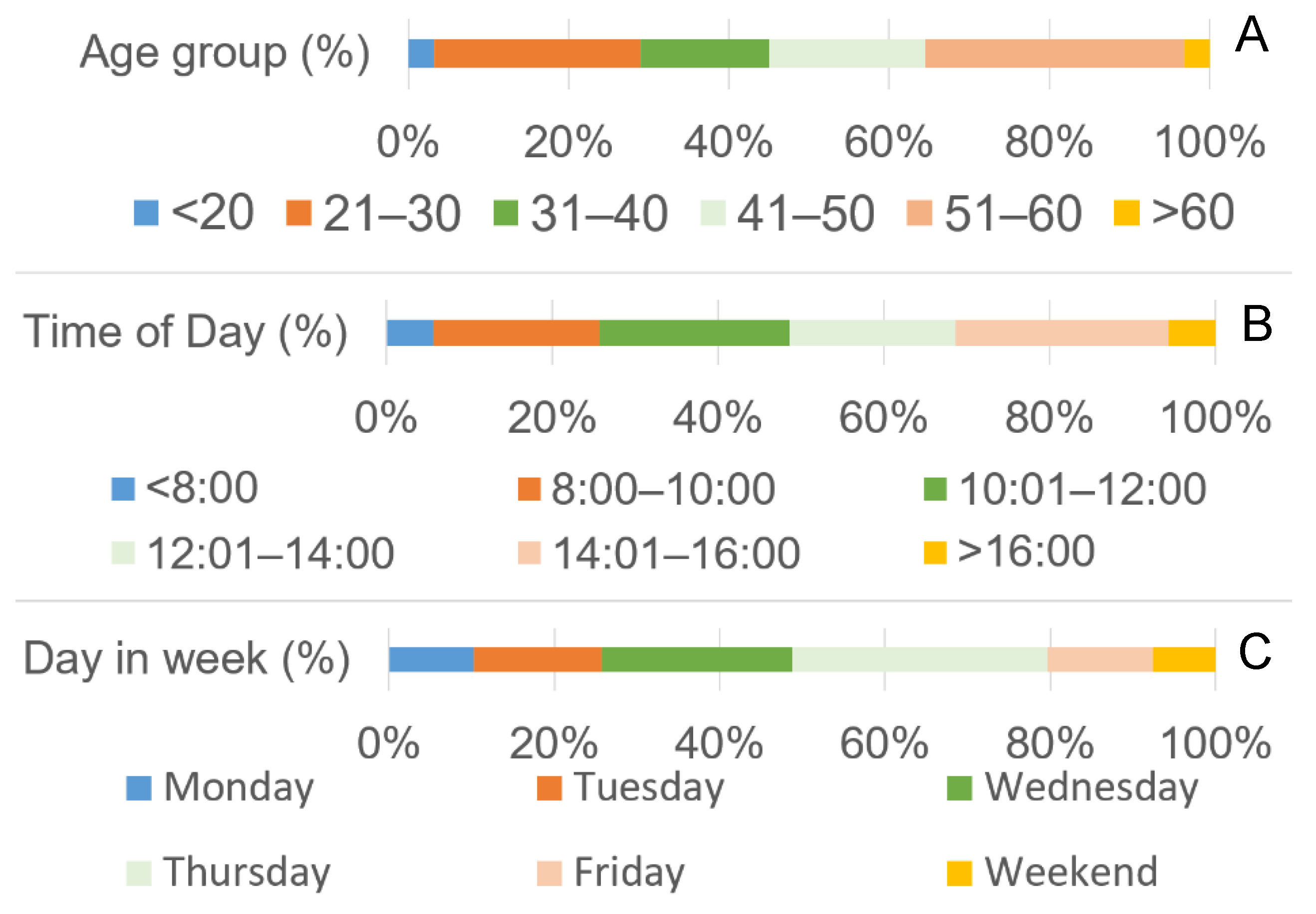

The number of OAs at the FSR increased during the first half of the week, from Monday until Wednesday, when almost two-thirds of all accidents occurred. From Wednesday until the end of the week, the accident frequency gradually decreased. This goes against many similar studies in forestry. For example, Lagerstrom et al. (2017) [

39], Laschi et al. (2016) [

8], Tsioras et al. (2014) [

15], and Wigglesworth (2006) [

42] all state that accidents occur on Monday most frequently, reporting that more than one-fifth of all accidents occur on this day. The differences between accident frequency during particular workweek days proved to be insignificant in our case, as approximately one-fifth of all accidents occurred on Monday and Tuesday. However, as Wigglesworth (2006) [

42] states, the increasing number of accidents could be due to fatigue of workers, which accumulates throughout the week and is likely to increase in nonstandard shifts.

Many seasonal factors affect the number of accidents occurring in forestry throughout the year. Forest harvesting is most intensive during the drier summer months. This connected to the increased accident frequency during the summer season. Lagerstrom et al. (2017) [

39] reported similar results, with a uniform distribution of accidents throughout the summer season. Similarly, Ghaffariyan (2016) [

43] reported the largest share of accidents in Australia occurred in January and February (more than 10% each month) and lowest in December and September. On the other hand, even though harvesting is not as intensive during the winter season, the working environment is more dangerous. Tsioras et al. (2014) [

15] reported the highest accident frequency in March and February. We observed that most accidents occurred during the winter months of January and February. The lowest frequency of OAs occurred in December (4%), which could be attributed to the upcoming winter holidays and the connected lowered productivity [

43].

Almost two-thirds of all accidents at the FSR occurred before noon, and the frequency peaked between 8:01 and 10:00 a.m. The second period in which most accidents occurred was just after noon, between 12:01 and 2:00 p.m. According to Folkard and Tucker (2003) [

44] and Folkard and Lombardi (2006) [

45], the distribution of accidents throughout the day is connected to the duration and type of shift, as well as the frequency of breaks. This could explain the gradual increase of accidents occurring around noon. The decrease in accident frequency after 2:00 p.m. could be linked to gradual decrease in productivity throughout the day [

46] that reaches a minimum with the approaching end of the shift (only exceptionally the shifts lasted longer than after 3:30 p.m.).

Naturally, workers exposed to diverse and demanding work environment and material agents during harvesting operations suffered the most injuries [

1,

26,

47,

48]. Felling and stem processing were the most dangerous operations; more than one-fifth of all accidents occurred during these operations. These were followed by repairs and maintenance and timber haulage. On the other hand, only about every tenth accident occurred during timber extraction. The relatively high share of injuries sustained during timber haulage compared to extraction could be due to the fact that FSR outsources a considerably smaller portion of haulage than other harvesting operations, which can affect the number of reported accidents [

49]. Similar overall results were reported by Ghaffariyan (2016) [

43] and Potočnik et al. (2009) [

49], who also observed that majority of injuries were sustained during forest harvesting operations.

Contrary to what we expected, season had little effect on both the type of injury sustained by the victims or the body parts they injured. We expected that injuries associated with slips, trips, and falls, i.e., fractures, sprains, strains, and dislocations, would be more abundant in seasons when the working environment provided optimal conditions for such accidents (i.e., slippery surfaces, snow and ice formations, etc.). Slip, trip, and fall OAs can be partially prevented by using properly designed footwear [

50], although this will solve only part of the problem. Another part of the solution is in improving situation awareness. This means identifying the unevenness or other faults of the level terrain (frequently hidden at a glance), following the proper procedures of machine ingress and egress [

49], and using other preventive measures.

The diverse and dangerous material agents affecting forestry workers showed in the high frequency of fatal accidents. Similar results were reported by [

1,

51,

52,

53]. Limiting direct interaction between the worker and forest exterior and dangerous hand tools, such as the chain saw, proved to be a good way of decreasing the number of severe and fatal accidents in forest harvesting [

53,

54,

55,

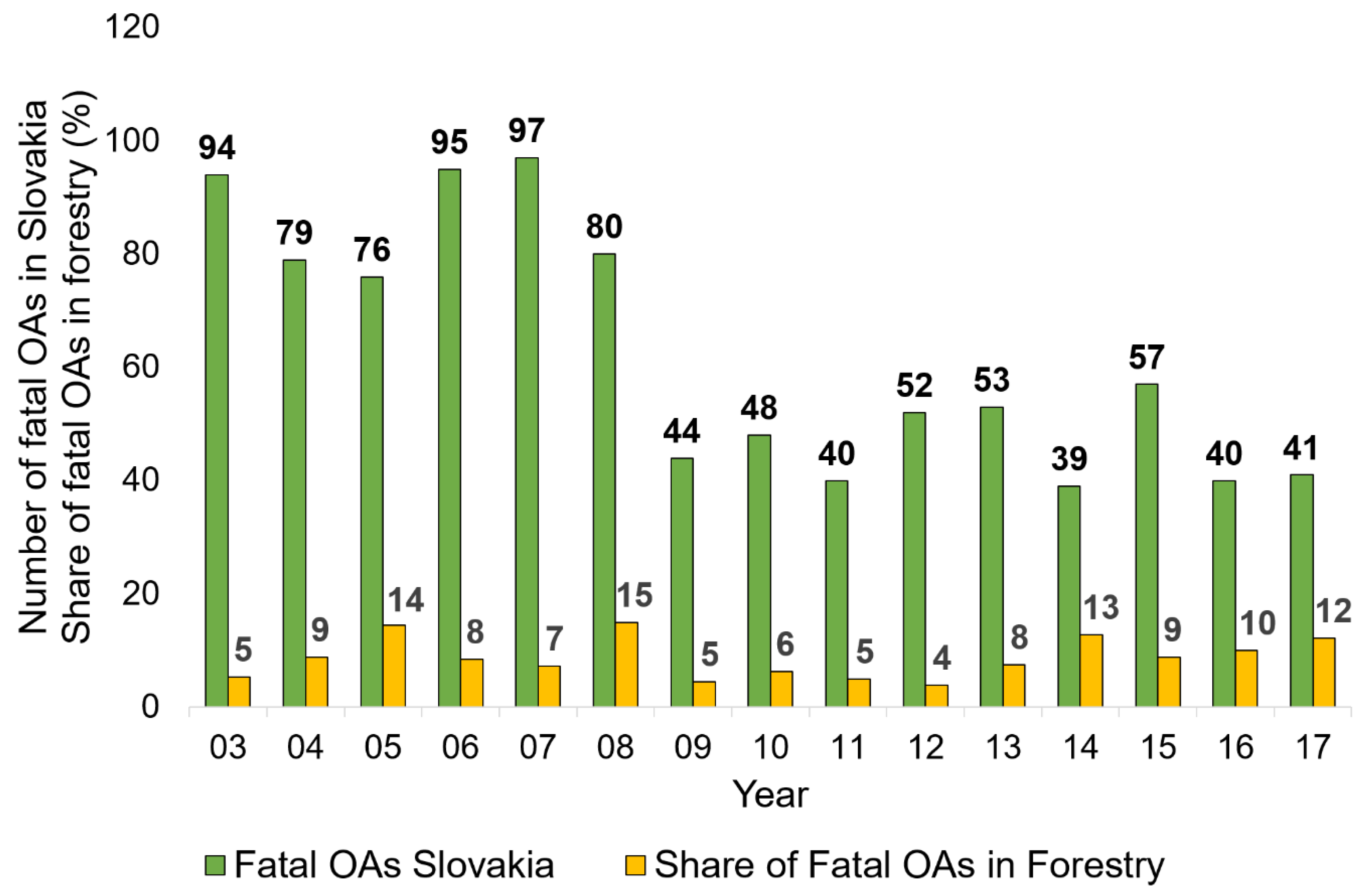

56]. The mean share of forestry on the total number of fatalities in Slovakia was 9% (

Figure 5). Considering that only about 1% of the Slovak workforce is employed in the sector, this share is high. Young workers with limited experience, who are prone to suffer fatal OAs, would likely benefit from safety seminars and courses that would help them develop suitable skills for safe logging [

42]. Aside from insufficient experience in safe logging practices, Newman et al. (2018) [

24] identify low situation awareness as the cause of many fatalities. In their study, they identified factors such as pressure to be highly productive at all costs, sleep deprivation, and physical fatigue, as well as the inadequate safety training, as causes of low situation awareness.

The results of the GLM analysis (

Table 2) proved that the differences between the number of OAs suffered by FSR employees and contractors were statistically significant for all severity categories. The total number of reported accidents could suggest that the occupational safety of contractors was better than that of employees. However, we must keep in mind that contractors were not obliged to report minor and registered OAs. In fact, Thelin (2002) [

56] states that contractors and small-scale foresters are hesitant to report safety incidents. A sign of this behavior could be found in the fact that contractors recorded fewer nonfatal accidents, but more fatal accidents, which are virtually unconcealable and must be reported to the authorities. In case of severe and fatal accidents, we attribute the significance of the difference between the number of OAs to the fact that FSR outsources the most dangerous occupations, mainly those connected to forest operations (e.g., forest harvesting, road constructions and maintenance, processing timber at conversion depots, etc.) where the likelihood of a severe OA occurring is higher than for office staff. This assumption is partially reinforced by the results of the logistic regression (

Table 7), where, aside from employee age and experience, operations and occupations that occur in the field correlate significantly with the number of OAs in all severity categories. These include foresters, haulage truck drivers, and other machine operators (e.g., those used in road construction and maintenance). The data shown in

Table 7 relate only to FSR employees; we were unable to conduct these analyses for contractors, as there was very little variance in the occupations (they were almost exclusively contracted to perform tasks in forest harvesting) and operations (most OAs suffered by contractors occurred during felling) they performed. On the other hand, data from other analyses (

Table 1) show that contractors were indeed more likely to suffer a severe or fatal OA during their work.

This brings us to common weaknesses of studies, such the reliability of statistical data. Even though large companies like the FSR implement strong mechanisms that secure relatively reliable accident reporting, their contractors omit implementing such measures, either deliberately or because they lack the knowledge of the legislation and the skills required [

39,

57,

58]. Furthermore, the coding of ESAW variables requires considerable skills. As Jacinto et al. (2016) [

58] state there is a great interrater variability of variable coding. On the other hand, we based our analyses on a robust dataset, which contained long-term data, and coped with the problem of statistical data reliability by double-checking all OA records. The fact that the Slovak OA record contains legacy sections containing narrative descriptions of the OA helped us greatly.