Seaweed Polysaccharides: A Rational Approach for Food Safety Studies

Abstract

1. Introduction

2. Seaweed Polysaccharides: Structural and Functional Overview

2.1. Chemical Diversity

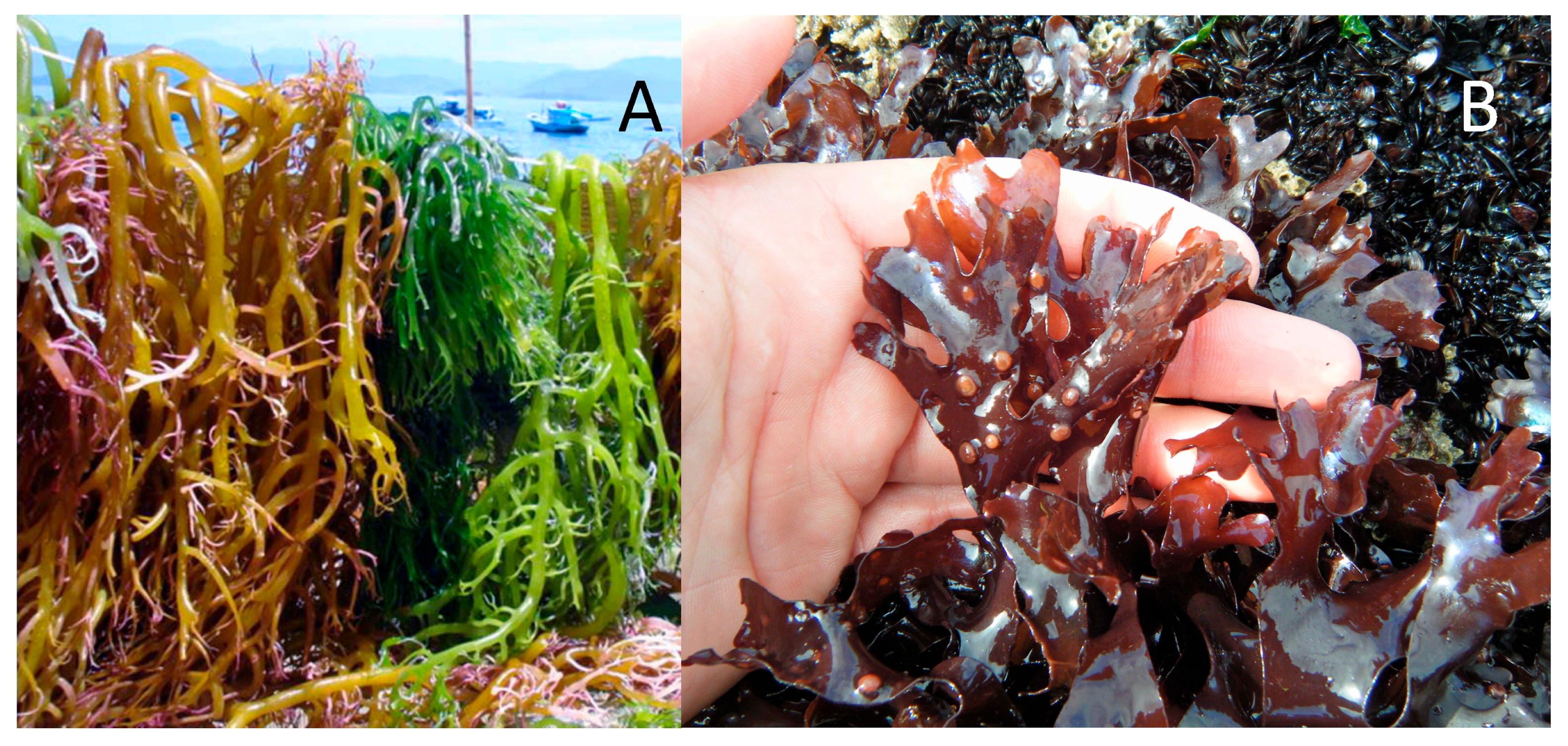

2.1.1. Alginate

2.1.2. Agar

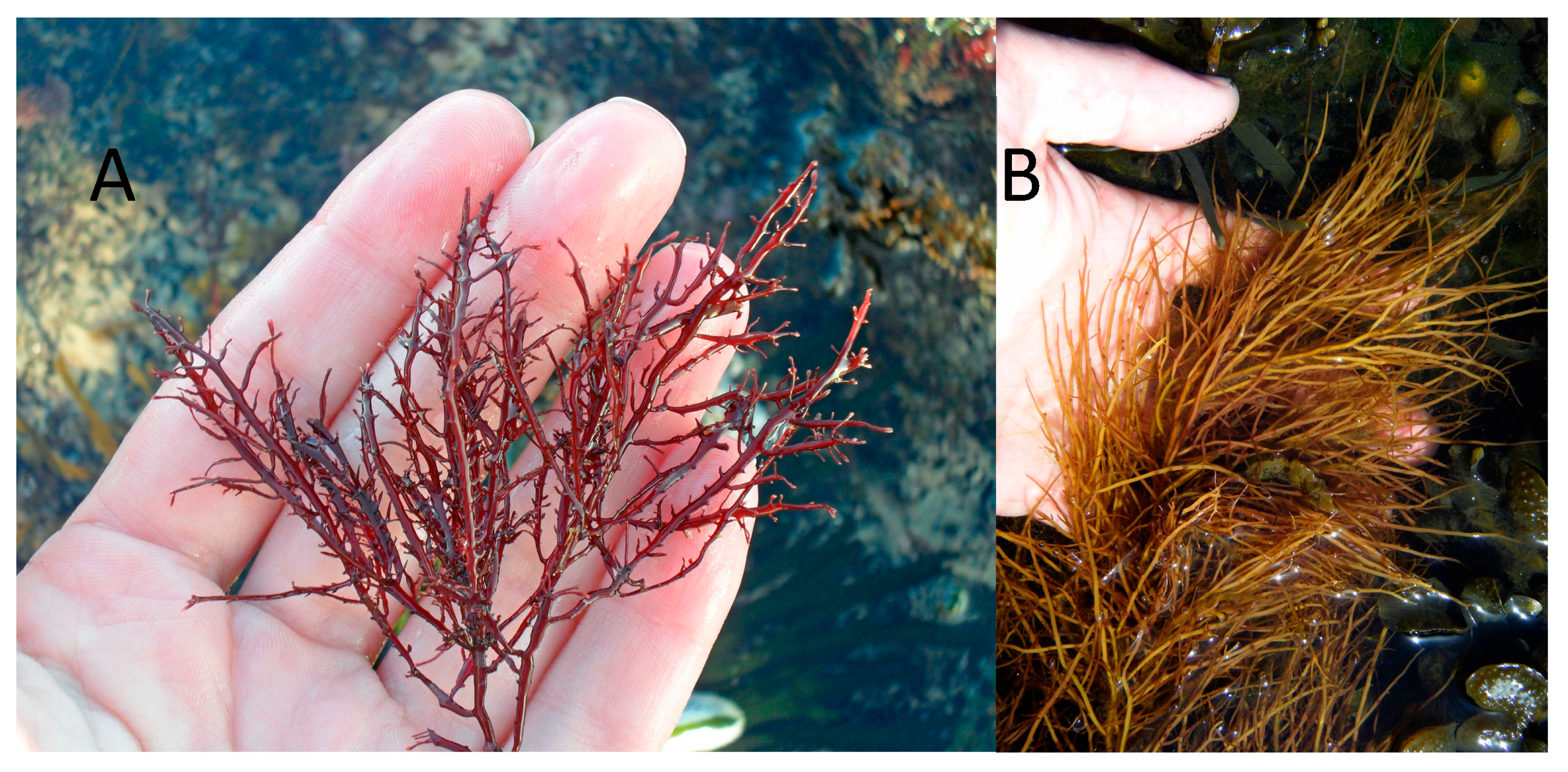

2.1.3. Carrageenan

| Parameter | Specification |

|---|---|

| Description | Yellowish to tan powder; odourless; tasteless; dissolves in hot water to form viscous solutions; gels in presence of certain cations |

| Identification | Positive for sulphate esters (~15–40% w/w as SO42−) and galactose units; IR spectrum matches carrageenan reference; positive gelation with potassium chloride |

| Loss on Drying | ≤12% (105 °C, 4 h) |

| Ash Content (as sodium/potassium/calcium salts) | 15–40% |

| pH (1% solution) | 8.0–11.0 |

| Viscosity | Defined by grade, typically ≥ 5 mPa·s |

| Sulphate Content | 15–40% (w/w, as SO42−) |

| Acid-insoluble Matter | ≤2% |

| Lead (Pb) | ≤2 mg/kg |

| Arsenic (As) | ≤3 mg/kg |

| Cadmium (Cd) | ≤1 mg/kg |

| Mercury (Hg) | ≤1 mg/kg |

| Formaldehyde (if used in processing) | ≤50 mg/kg |

| Microbiological Quality | Absence of Salmonella in 25 g; absence of E. coli in 1 g; total aerobic plate count within GMP limits |

| Poligeenan Content (low-MW degraded carrageenan) | Not detectable at >5% of total mass; MW distribution profile consistent with undegraded carrageenan (>100 kDa majority) |

| Functionality | Thickener, stabilizer, gelling agent, water binder, suspension aid |

3. Carrageenan in the Human Health

4. Seaweed Polysaccharides and Gastrointestinal Interaction

4.1. Stability and Hydrolysis in the Digestive Tract

4.2. Gaps in Current Digestive Assays

4.3. Digestion and Hydrolysis: Understanding Molecular Stability

5. A Rational Framework for Future Studies

5.1. Models of Simulated Digestion

5.2. Limitations of Current In Vitro Digestion Models

5.3. Need for Standardized Digestion Assays

5.4. Simulating Physical and Chemical Reactions

5.5. Molecular Integrity and Degradation Tracking

5.5.1. FTIR-ATR

5.5.2. NMR and Advanced Analytical Techniques

5.5.3. Electrochemical Analysis

5.5.4. Final Remarks

5.6. Microbiome Interaction and Metabolite Profiling

6. Recommendation

7. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Salido, M.; Soto, M.; Seoane, S. Seaweed: Nutritional and Gastronomic Perspective. A Review. Algal Res. 2024, 77, 103357. [Google Scholar] [CrossRef]

- Xie, C.; Lee, Z.J.; Ye, S.; Barrow, C.J.; Dunshea, F.R.; Suleria, H.A.R. A Review on Seaweeds and Seaweed-Derived Polysaccharides: Nutrition, Chemistry, Bioactivities, and Applications. Food Rev. Int. 2024, 40, 1312–1347. [Google Scholar] [CrossRef]

- Cotas, J.; Pacheco, D.; Araujo, G.S.; Valado, A.; Critchley, A.T.; Pereira, L. On the Health Benefits vs. Risks of Seaweeds and Their Constituents: The Curious Case of the Polymer Paradigm. Mar. Drugs 2021, 19, 164. [Google Scholar] [CrossRef] [PubMed]

- Leandro, A.; Pacheco, D.; Cotas, J.; Marques, J.C.; Pereira, L.; Gonçalves, A.M.M. Seaweed’s Bioactive Candidate Compounds to Food Industry and Global Food Security. Life 2020, 10, 140. [Google Scholar] [CrossRef]

- Wu, X.; Guo, Y.; Dai, C.; Zhao, C. The Pharmacological Potential of Algal Polysaccharides in Food Applications and Chronic Disease Management. Future Pharmacol. 2025, 5, 29. [Google Scholar] [CrossRef]

- Mendes, M.; Cotas, J.; Gutiérrez, I.B.; Gonçalves, A.M.M.; Critchley, A.T.; Hinaloc, L.A.R.; Roleda, M.Y.; Pereira, L. Advanced Extraction Techniques and Physicochemical Properties of Carrageenan from a Novel Kappaphycus alvarezii Cultivar. Mar. Drugs 2024, 22, 491. [Google Scholar] [CrossRef]

- Cotas, J.; Tavares, J.O.; Silva, R.; Pereira, L. Seaweed as a Safe Nutraceutical Food: How to Increase Human Welfare? Nutraceuticals 2024, 4, 323–362. [Google Scholar] [CrossRef]

- Mendes, M.; Cotas, J.; Pacheco, D.; Ihle, K.; Hillinger, A.; Cascais, M.; Marques, J.C.; Pereira, L.; Gonçalves, A.M.M. Red Seaweed (Rhodophyta) Phycocolloids: A Road from the Species to the Industry Application. Mar. Drugs 2024, 22, 432. [Google Scholar] [CrossRef]

- Liu, F.; Hou, P.; Zhang, H.; Tang, Q.; Xue, C.; Li, R.W. Food-grade Carrageenans and Their Implications in Health and Disease. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3918–3936. [Google Scholar] [CrossRef]

- McKim, J.M. Food Additive Carrageenan: Part I: A Critical Review of Carrageenan in Vitro Studies, Potential Pitfalls, and Implications for Human Health and Safety. Crit. Rev. Toxicol. 2014, 44, 211–243. [Google Scholar] [CrossRef]

- Tobacman, J.K. Review of Harmful Gastrointestinal Effects of Carrageenan in Animal Experiments. Environ. Health Perspect. 2001, 109, 983–994. [Google Scholar] [CrossRef]

- McKim, J.M.; Willoughby, J.A.; Blakemore, W.R.; Weiner, M.L. Clarifying the Confusion between Poligeenan, Degraded Carrageenan, and Carrageenan: A Review of the Chemistry, Nomenclature, and in Vivo Toxicology by the Oral Route. Crit. Rev. Food Sci. Nutr. 2019, 59, 3054–3073. [Google Scholar] [CrossRef] [PubMed]

- Yao, W.; Kong, Q.; You, L.; Zhong, S.; Hileuskaya, K. Polysaccharides from Brown Seaweed: Physicochemical Properties, Absorption in the Intestine, and Beneficial Effects on Intestinal Barrier. Food Front. 2023, 4, 1547–1560. [Google Scholar] [CrossRef]

- Shannon, E.; Conlon, M.; Hayes, M. Seaweed Components as Potential Modulators of the Gut Microbiota. Mar. Drugs 2021, 19, 358. [Google Scholar] [CrossRef] [PubMed]

- McKim, J.M.; Baas, H.; Rice, G.P.; Willoughby, J.A.; Weiner, M.L.; Blakemore, W. Effects of Carrageenan on Cell Permeability, Cytotoxicity, and Cytokine Gene Expression in Human Intestinal and Hepatic Cell Lines. Food Chem. Toxicol. 2016, 96, 1–10. [Google Scholar] [CrossRef]

- Feferman, L.; Bhattacharyya, S.; Oates, E.; Haggerty, N.; Wang, T.; Varady, K.; Tobacman, J.K. Carrageenan-Free Diet Shows Improved Glucose Tolerance and Insulin Signaling in Prediabetes: A Randomized, Pilot Clinical Trial. J. Diabetes Res. 2020, 2020, 8267980. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Liu, H.; Zhang, Z.; Jam, M.; Dudeja, P.K.; Michel, G.; Linhardt, R.J.; Tobacman, J.K. Carrageenan-Induced Innate Immune Response Is Modified by Enzymes That Hydrolyze Distinct Galactosidic Bonds. J. Nutr. Biochem. 2010, 21, 906–913. [Google Scholar] [CrossRef]

- Khandwal, D.; Patel, S.; Pandey, A.K.; Mishra, A. A Comprehensive, Analytical Narrative Review of Polysaccharides from the Red Seaweed Gracilaria: Pharmaceutical Applications and Mechanistic Insights for Human Health. Nutrients 2025, 17, 744. [Google Scholar] [CrossRef]

- Michel, G.; Nyval-Collen, P.; Barbeyron, T.; Czjzek, M.; Helbert, W. Bioconversion of Red Seaweed Galactans: A Focus on Bacterial Agarases and Carrageenases. Appl. Microbiol. Biotechnol. 2006, 71, 23–33. [Google Scholar] [CrossRef]

- Rioux, L.-E.; Turgeon, S.L.; Beaulieu, M. Structural Characterization of Laminaran and Galactofucan Extracted from the Brown Seaweed Saccharina Longicruris. Phytochemistry 2010, 71, 1586–1595. [Google Scholar] [CrossRef]

- Rodrigues, D.; Freitas, A.C.; Pereira, L.; Rocha-Santos, T.A.P.; Vasconcelos, M.W.; Roriz, M.; Rodríguez-Alcalá, L.M.; Gomes, A.M.P.; Duarte, A.C. Chemical Composition of Red, Brown and Green Macroalgae from Buarcos Bay in Central West Coast of Portugal. Food Chem. 2015, 183, 197–207. [Google Scholar] [CrossRef]

- Zvyagintseva, T.N.; Shevchenko, N.M.; Chizhov, A.O.; Krupnova, T.N.; Sundukova, E.V.; Isakov, V.V. Water-Soluble Polysaccharides of Some Far-Eastern Brown Seaweeds. Distribution, Structure, and Their Dependence on the Developmental Conditions. J. Exp. Mar. Biol. Ecol. 2003, 294, 1–13. [Google Scholar] [CrossRef]

- Haug, A.; Larsen, B.; Smidsrød, O. Uronic Acid Sequence in Alginate from Different Sources. Carbohydr. Res. 1974, 32, 217–225. [Google Scholar] [CrossRef]

- Younes, M.; Aggett, P.; Aguilar, F.; Crebelli, R.; Filipič, M.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Kuhnle, G.G.; et al. Re-evaluation of Alginic Acid and Its Sodium, Potassium, Ammonium and Calcium Salts (E 400–E 404) as Food Additives. EFSA J. 2017, 15, 5049. [Google Scholar] [CrossRef]

- Hernández-Carmona, G.; Freile-Pelegrín, Y.; Hernández-Garibay, E. Conventional and Alternative Technologies for the Extraction of Algal Polysaccharides. In Functional Ingredients from Algae for Foods and Nutraceuticals; Elsevier: Amsterdam, The Netherlands, 2013; pp. 475–516. [Google Scholar]

- Abdul Khalil, H.P.S.; Lai, T.K.; Tye, Y.Y.; Rizal, S.; Chong, E.W.N.; Yap, S.W.; Hamzah, A.A.; Nurul Fazita, M.R.; Paridah, M.T. A Review of Extractions of Seaweed Hydrocolloids: Properties and Applications. Express Polym. Lett. 2018, 12, 296–317. [Google Scholar] [CrossRef]

- Brownlee, I.A.; Seal, C.J.; Wilcox, M.; Dettmar, P.W.; Pearson, J.P. Applications of Alginates in Food. In Alginates: Biology and Applications; Springer: Berlin/Heidelberg, Germany, 2009; pp. 211–228. [Google Scholar]

- Draget, K.I.; Smidsrød, O.; Skjåk-Bræk, G. Alginates from Algae. In Biopolymers Online; Vandamme, E.J., De Baets, S., Steinbüchel, A., Eds.; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar]

- Cardozo, K.H.M.; Guaratini, T.; Barros, M.P.; Falcão, V.R.; Tonon, A.P.; Lopes, N.P.; Campos, S.; Torres, M.A.; Souza, A.O.; Colepicolo, P.; et al. Metabolites from Algae with Economical Impact. Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 2007, 146, 60–78. [Google Scholar] [CrossRef]

- Qin, Y.; Jiang, J.; Zhao, L.; Zhang, J.; Wang, F. Applications of Alginate as a Functional Food Ingredient. In Biopolymers for Food Design; Elsevier: Amsterdam, The Netherlands, 2018; pp. 409–429. [Google Scholar]

- Hemmingson, J.A.; Furneaux, R.H.; Murray-Brown, V.H. Biosynthesis of Agar Polysaccharides in Gracilaria chilensis Bird, McLachlan et Oliveira. Carbohydr. Res. 1996, 287, 101–115. [Google Scholar] [CrossRef]

- Mortensen, A.; Aguilar, F.; Crebelli, R.; Di Domenico, A.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Lambré, C.; Leblanc, J.; et al. Re-evaluation of Agar (E 406) as a Food Additive. EFSA J. 2016, 14, 4645. [Google Scholar] [CrossRef]

- McHugh, D.J. A Guide to the Seaweed Industry; FAO: Rome, Italy, 2003; ISBN 9251049580. [Google Scholar]

- Vinagre, F.; Alegria, M.J.; Ferreira, A.S.; Nunes, C.; Nunes, M.C.; Raymundo, A. Characterization and Gelling Potential of Macroalgae Extracts Obtained Through Eco-Friendly Technologies for Food-Grade Gelled Matrices. Gels 2025, 11, 290. [Google Scholar] [CrossRef]

- Kohl, M.; Capellmann, R.F.; Laurati, M.; Egelhaaf, S.U.; Schmiedeberg, M. Directed Percolation Identified as Equilibrium Pre-Transition towards Non-Equilibrium Arrested Gel States. Nat. Commun. 2016, 7, 11817. [Google Scholar] [CrossRef]

- Gero, D.; Chosidow, D.; Marmuse, J.-P. An Unusual Cause of Solid Food Intolerance and Gastric Pouch Dilation 5 Years after Roux-En-Y Gastric Bypass: Agar-Agar Bezoar. Surg. Obes. Relat. Dis. 2015, 11, 1184–1185. [Google Scholar] [CrossRef] [PubMed]

- Melnick, R.L.; Huff, J.; Haseman, J.K.; Dieter, M.P.; Grieshaber, C.K.; Wyand, D.S.; Russfield, A.B.; Murthy, A.S.K.; Fleischman, R.W.; Lilja, H.S. Chronic Effects of Agar, Guar Gum, Gum Arabic, Locust-Bean Gum, or Tara Gum in F344 Rats and B6C3F1 Mice. Food Chem. Toxicol. 1983, 21, 305–311. [Google Scholar] [CrossRef] [PubMed]

- van de Velde, F.; Ruiter, G.A. De Carrageenan. In Biopolymers; Steinbüchel, A., De Baets, S., VanDamme, E.J., Eds.; Wiley-VCH: Weinheim, Germany, 2002; Volume 6, pp. 245–274. ISBN 3527302271. [Google Scholar]

- Cohen, S.M.; Ito, N. A Critical Review of the Toxicological Effects of Carrageenan and Processed Eucheuma Seaweed on the Gastrointestinal Tract. Crit. Rev. Toxicol. 2002, 32, 413–444. [Google Scholar] [CrossRef] [PubMed]

- Younes, M.; Aggett, P.; Aguilar, F.; Crebelli, R.; Filipič, M.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Kuhnle, G.G.; et al. Re-evaluation of Carrageenan (E 407) and Processed Eucheuma Seaweed (E 407a) as Food Additives. EFSA J. 2018, 16, 5238. [Google Scholar] [CrossRef]

- Joint FAO/Who Expert Committee on Food Additives. Summary Report of the Seventy-Ninth Meeting of JECFA; JECFA: Geneva, Switzerland, 2014. [Google Scholar]

- Bixler, H.J. The Carrageenan Controversy. J. Appl. Phycol. 2017, 29, 2201–2207. [Google Scholar] [CrossRef]

- FDA. Title 21 CFR—Code of Federal Regulations; FDA: Silver Spring, MD, USA, 2014. [Google Scholar]

- David, S.; Shani Levi, C.; Fahoum, L.; Ungar, Y.; Meyron-Holtz, E.G.; Shpigelman, A.; Lesmes, U. Revisiting the Carrageenan Controversy: Do We Really Understand the Digestive Fate and Safety of Carrageenan in Our Foods? Food Funct. 2018, 9, 1344–1352. [Google Scholar] [CrossRef]

- Houghton, D.; Wilcox, M.D.; Chater, P.I.; Brownlee, I.A.; Seal, C.J.; Pearson, J.P. Biological Activity of Alginate and Its Effect on Pancreatic Lipase Inhibition as a Potential Treatment for Obesity. Food Hydrocoll. 2015, 49, 18–24. [Google Scholar] [CrossRef]

- Kozu, H.; Nakata, Y.; Nakajima, M.; Neves, M.A.; Uemura, K.; Sato, S.; Kobayashi, I.; Ichikawa, S. Analysis of Disintegration of Agar Gel Particles with Different Textures Using Gastric Digestion Simulator. Jpn. J. Food Eng. 2015, 16, 161–166. [Google Scholar] [CrossRef]

- Mackie, A.; Mulet-Cabero, A.-I.; Torcello-Gómez, A. Simulating Human Digestion: Developing Our Knowledge to Create Healthier and More Sustainable Foods. Food Funct. 2020, 11, 9397–9431. [Google Scholar] [CrossRef]

- Martino, J.V.; Van Limbergen, J.; Cahill, L.E. The Role of Carrageenan and Carboxymethylcellulose in the Development of Intestinal Inflammation. Front. Pediatr. 2017, 5, 96. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Borthakur, A.; K. Dudeja, P.; K. Tobacman, J. Carrageenan Reduces Bone Morphogenetic Protein-4 (BMP4) and Activates the Wnt/β-Catenin Pathway in Normal Human Colonocytes. Dig. Dis. Sci. 2007, 52, 2766–2774. [Google Scholar] [CrossRef]

- Blakemore, W.R.; Davis, S.R.; Hroncich, M.M.; Vurma, M. Carrageenan Analysis. Part 1: Characterisation of the Carrageenan Test Material and Stability in Swine-Adapted Infant Formula. Food Addit. Contam. Part A 2014, 31, 1661–1669. [Google Scholar] [CrossRef] [PubMed]

- Blakemore, W.R.; Brant, A.F.; Bissland, J.G.; Bissland, N.D. Carrageenan Analysis. Part 3: Quantification in Swine Plasma. Food Addit. Contam. Part A 2014, 31, 1673–1677. [Google Scholar] [CrossRef] [PubMed]

- Tobacman, J.K. Filament Disassembly and Loss of Mammary Myoepithelial Cells after Exposure to Lambda-Carrageenan. Cancer Res. 1997, 57, 2823–2826. [Google Scholar] [PubMed]

- Weiner, M.L.; McKim, J.M.; Blakemore, W.R. Parameters and Pitfalls to Consider in the Conduct of Food Additive Research, Carrageenan as a Case Study. Food Chem. Toxicol. 2016, 87, 31–44, Addendum in Food Chem. Toxicol. 2017, 107, 208–214. [Google Scholar] [CrossRef]

- Sokolova, E.V.; Bogdanovich, L.N.; Ivanova, T.B.; Byankina, A.O.; Kryzhanovskiy, S.P.; Yermak, I.M. Effect of Carrageenan Food Supplement on Patients with Cardiovascular Disease Results in Normalization of Lipid Profile and Moderate Modulation of Immunity System Markers. PharmaNutrition 2014, 2, 33–37. [Google Scholar] [CrossRef]

- Zammel, N.; Saeed, M.; Bouali, N.; Elkahoui, S.; Alam, J.M.; Rebai, T.; Kausar, M.A.; Adnan, M.; Siddiqui, A.J.; Badraoui, R. Antioxidant and Anti-Inflammatory Effects of Zingiber Officinale Roscoe and Allium Subhirsutum: In Silico, Biochemical and Histological Study. Foods 2021, 10, 1383. [Google Scholar] [CrossRef]

- Borthakur, A.; Bhattacharyya, S.; Anbazhagan, A.N.; Kumar, A.; Dudeja, P.K.; Tobacman, J.K. Prolongation of Carrageenan-Induced Inflammation in Human Colonic Epithelial Cells by Activation of an NFκB-BCL10 Loop. Biochim. Biophys. Acta (BBA) Mol. Basis Dis. 2012, 1822, 1300–1307. [Google Scholar] [CrossRef]

- Sensoy, I. A Review on the Food Digestion in the Digestive Tract and the Used in Vitro Models. Curr. Res. Food Sci. 2021, 4, 308–319. [Google Scholar] [CrossRef]

- Brown, E.M.; Allsopp, P.J.; Magee, P.J.; Gill, C.I.; Nitecki, S.; Strain, C.R.; McSorley, E.M. Seaweed and Human Health. Nutr. Rev. 2014, 72, 205–216. [Google Scholar] [CrossRef]

- Rastall, R.A.; Gibson, G.R.; Gill, H.S.; Guarner, F.; Klaenhammer, T.R.; Pot, B.; Reid, G.; Rowland, I.R.; Sanders, M.E. Modulation of the Microbial Ecology of the Human Colon by Probiotics, Prebiotics and Synbiotics to Enhance Human Health: An Overview of Enabling Science and Potential Applications. FEMS Microbiol. Ecol. 2005, 52, 145–152. [Google Scholar] [CrossRef]

- Rowland, I. Optimal Nutrition: Fibre and Phytochemicals. Proc. Nutr. Soc. 1999, 58, 415–419. [Google Scholar] [CrossRef]

- Bellanco, A.; Félix, J.; Díaz Del Cerro, E.; Martínez Cuesta, M.C.; De la Fuente, M.; Requena, T. Influence of Consumption of the Food Additive Carrageenan on the Gut Microbiota and the Intestinal Homeostasis of Mice. Food Funct. 2024, 15, 6759–6767. [Google Scholar] [CrossRef]

- Komisarska, P.; Pinyosinwat, A.; Saleem, M.; Szczuko, M. Carrageenan as a Potential Factor of Inflammatory Bowel Diseases. Nutrients 2024, 16, 1367. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Zhou, J.; Xuan, R.; Chen, J.; Han, H.; Liu, J.; Niu, T.; Chen, H.; Wang, F. Dietary κ-Carrageenan Facilitates Gut Microbiota-Mediated Intestinal Inflammation. Carbohydr. Polym. 2022, 277, 118830. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Zhong, L.; Zeng, M.; Kraithong, S.; Xia, X.; Kuang, W.; Wang, Q.; Huang, R. Seaweed Polysaccharides as Potential Prebiotics: Rationale, Factors, Prebiotic Activity Manifestations, Gut Health Mechanisms and Extraintestinal Impacts. Trends Food Sci. Technol. 2025, 163, 105202. [Google Scholar] [CrossRef]

- Cherry, P.; O’Hara, C.; Magee, P.J.; McSorley, E.M.; Allsopp, P.J. Risks and Benefits of Consuming Edible Seaweeds. Nutr. Rev. 2019, 77, 307–329. [Google Scholar] [CrossRef]

- Cherry, P.; Yadav, S.; Strain, C.R.; Allsopp, P.J.; McSorley, E.M.; Ross, R.P.; Stanton, C. Prebiotics from Seaweeds: An Ocean of Opportunity? Mar. Drugs 2019, 17, 327. [Google Scholar] [CrossRef]

- Clark, M.J.; Slavin, J.L. The Effect of Fiber on Satiety and Food Intake: A Systematic Review. J. Am. Coll. Nutr. 2013, 32, 200–211. [Google Scholar] [CrossRef]

- Bouzerzour, K.; Morgan, F.; Cuinet, I.; Bonhomme, C.; Jardin, J.; Le Huërou-Luron, I.; Dupont, D. In Vivo Digestion of Infant Formula in Piglets: Protein Digestion Kinetics and Release of Bioactive Peptides. Br. J. Nutr. 2012, 108, 2105–2114. [Google Scholar] [CrossRef]

- Guerra, A.; Etienne-Mesmin, L.; Livrelli, V.; Denis, S.; Blanquet-Diot, S.; Alric, M. Relevance and Challenges in Modeling Human Gastric and Small Intestinal Digestion. Trends Biotechnol. 2012, 30, 591–600. [Google Scholar] [CrossRef] [PubMed]

- Amigo, L.; Hernández-Ledesma, B. Current Evidence on the Bioavailability of Food Bioactive Peptides. Molecules 2020, 25, 4479. [Google Scholar] [CrossRef] [PubMed]

- Kraan, S. Algal Polysaccharides, Novel Applications and Outlook. In Carbohydrates—Comprehensive Studies on Glycobiology and Glycotechnology; InTech: London, UK, 2012. [Google Scholar]

- Scientific Opinion on the Substantiation of Health Claims Related to Dietary Fibre (ID 744, 745, 746, 748, 749, 753, 803, 810, 855, 1415, 1416, 4308, 4330) Pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J. 2010, 8, 1735. [CrossRef]

- Scientific Opinion on the Substantiation of Health Claims Related to the Replacement of Mixtures of Saturated Fatty Acids (SFAs) as Present in Foods or Diets with Mixtures of Monounsaturated Fatty Acids (MUFAs) and/or Mixtures of Polyunsaturated Fatty Aci. EFSA J. 2011, 9, 2069. [CrossRef]

- Ramnani, P.; Chitarrari, R.; Tuohy, K.; Grant, J.; Hotchkiss, S.; Philp, K.; Campbell, R.; Gill, C.; Rowland, I. In Vitro Fermentation and Prebiotic Potential of Novel Low Molecular Weight Polysaccharides Derived from Agar and Alginate Seaweeds. Anaerobe 2012, 18, 1–6. [Google Scholar] [CrossRef]

- Li, J.; Lv, Y.; Shao, M.; Lv, D.; Fu, Z.; Guo, P.; Li, Q.; Shang, Q. Fermentation of Alginate and Its Oligosaccharides by the Human Gut Microbiota: Structure–Property Relationships and New Findings Focusing on Bacteroides Xylanisolvens. Nutrients 2025, 17, 1424. [Google Scholar] [CrossRef]

- Pirsa, S.; Hafezi, K. Hydrocolloids: Structure, Preparation Method, and Application in Food Industry. Food Chem. 2023, 399, 133967. [Google Scholar] [CrossRef]

- Gotteland, M.; Riveros, K.; Gasaly, N.; Carcamo, C.; Magne, F.; Liabeuf, G.; Beattie, A.; Rosenfeld, S. The Pros and Cons of Using Algal Polysaccharides as Prebiotics. Front. Nutr. 2020, 7, 163. [Google Scholar] [CrossRef]

- Bannon, C.D.; Eckenberger, J.; Snelling, W.J.; Huseyin, C.E.; Allsopp, P.; Strain, C.; Ramnani, P.; Chitarrari, R.; Grant, J.; Hotchkiss, S.; et al. Low-Molecular-Weight Seaweed-Derived Polysaccharides Lead to Increased Faecal Bulk but Do Not Alter Human Gut Health Markers. Foods 2021, 10, 2988. [Google Scholar] [CrossRef]

- Freitas, D.; Lazaridou, A.; Duijsens, D.; Kotsiou, K.; Corbin, K.R.; Alongi, M.; Perez-Moral, N.; Simsek, S.; El, S.N.; Gwala, S.; et al. Starch Digestion: A Comprehensive Update on the Underlying Modulation Mechanisms and Its in Vitro Assessment Methodologies. Trends Food Sci. Technol. 2025, 159, 104969. [Google Scholar] [CrossRef]

- Lovegrove, A.; Edwards, C.H.; De Noni, I.; Patel, H.; El, S.N.; Grassby, T.; Zielke, C.; Ulmius, M.; Nilsson, L.; Butterworth, P.J.; et al. Role of Polysaccharides in Food, Digestion, and Health. Crit. Rev. Food Sci. Nutr. 2017, 57, 237–253. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Mercado, A.I.; Plaza-Diaz, J. Dietary Polysaccharides as Modulators of the Gut Microbiota Ecosystem: An Update on Their Impact on Health. Nutrients 2022, 14, 4116. [Google Scholar] [CrossRef] [PubMed]

- Swackhamer, C.; Jang, S.; Park, B.-R.; Hamaker, B.R.; Jung, S.K. Structure-Based Standardization of Prebiotic Soluble Dietary Fibers Based on Monosaccharide Composition, Degree of Polymerization, and Linkage Composition. Carbohydr. Polym. 2025, 367, 123949. [Google Scholar] [CrossRef] [PubMed]

- Vinke, P.C.; El Aidy, S.; van Dijk, G. The Role of Supplemental Complex Dietary Carbohydrates and Gut Microbiota in Promoting Cardiometabolic and Immunological Health in Obesity: Lessons from Healthy Non-Obese Individuals. Front. Nutr. 2017, 4, 34. [Google Scholar] [CrossRef]

- Karim, A.; Mohammadi, L.; Osse, E.F.; Aider, M.; Saqui-Salces, M.; Khalloufi, S. Effect of Polysaccharide-Induced Viscosity on the Digestion of Proteins, Fats, and Carbohydrates in Food: A Comprehensive Review and Future Perspectives. Trends Food Sci. Technol. 2024, 153, 104757. [Google Scholar] [CrossRef]

- Kong, F.; Singh, R.P. Disintegration of Solid Foods in Human Stomach. J. Food Sci. 2008, 73, R67–R80. [Google Scholar] [CrossRef]

- Singh, H.; Ye, A.; Ferrua, M.J. Aspects of Food Structures in the Digestive Tract. Curr. Opin. Food Sci. 2015, 3, 85–93. [Google Scholar] [CrossRef]

- Calbet, J.A.L.; Holst, J.J. Gastric Emptying, Gastric Secretion and Enterogastrone Response after Administration of Milk Proteins or Their Peptide Hydrolysates in Humans. Eur. J. Nutr. 2004, 43, 127–139. [Google Scholar] [CrossRef]

- Nguyen, T.T.P.; Bhandari, B.; Cichero, J.; Prakash, S. Gastrointestinal Digestion of Dairy and Soy Proteins in Infant Formulas: An in Vitro Study. Food Res. Int. 2015, 76, 348–358. [Google Scholar] [CrossRef]

- Bornhorst, G.M.; Singh, R.P. Kinetics of in Vitro Bread Bolus Digestion with Varying Oral and Gastric Digestion Parameters. Food Biophys. 2013, 8, 50–59. [Google Scholar] [CrossRef]

- Hur, S.J.; Lim, B.O.; Decker, E.A.; McClements, D.J. In Vitro Human Digestion Models for Food Applications. Food Chem. 2011, 125, 1–12. [Google Scholar] [CrossRef]

- Ménard, O.; Cattenoz, T.; Guillemin, H.; Souchon, I.; Deglaire, A.; Dupont, D.; Picque, D. Validation of a New in Vitro Dynamic System to Simulate Infant Digestion. Food Chem. 2014, 145, 1039–1045. [Google Scholar] [CrossRef] [PubMed]

- Dupont, D.; Alric, M.; Blanquet-Diot, S.; Bornhorst, G.; Cueva, C.; Deglaire, A.; Denis, S.; Ferrua, M.; Havenaar, R.; Lelieveld, J.; et al. Can Dynamic in Vitro Digestion Systems Mimic the Physiological Reality? Crit. Rev. Food Sci. Nutr. 2019, 59, 1546–1562. [Google Scholar] [CrossRef] [PubMed]

- Vital, N.; Gramacho, A.C.; Silva, M.; Cardoso, M.; Alvito, P.; Kranendonk, M.; Silva, M.J.; Louro, H. Challenges of the Application of In Vitro Digestion for Nanomaterials Safety Assessment. Foods 2024, 13, 1690. [Google Scholar] [CrossRef]

- Wang, R.; Mohammadi, M.; Mahboubi, A.; Taherzadeh, M.J. In-Vitro Digestion Models: A Critical Review for Human and Fish and a Protocol for in-Vitro Digestion in Fish. Bioengineered 2021, 12, 3040–3064. [Google Scholar] [CrossRef] [PubMed]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F.; et al. INFOGEST Static in Vitro Simulation of Gastrointestinal Food Digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar] [CrossRef]

- Ośko, J.; Nasierowska, K.; Grembecka, M. Application of In Vitro Digestion Models in the Evaluation of Dietary Supplements. Foods 2024, 13, 2135. [Google Scholar] [CrossRef]

- Dávila León, R.; González-Vázquez, M.; Lima-Villegas, K.E.; Mora-Escobedo, R.; Calderón-Domínguez, G. In Vitro Gastrointestinal Digestion Methods of Carbohydrate-rich Foods. Food Sci. Nutr. 2024, 12, 722–733. [Google Scholar] [CrossRef]

- Grundy, M.M.-L.; Edwards, C.H.; Mackie, A.R.; Gidley, M.J.; Butterworth, P.J.; Ellis, P.R. Re-Evaluation of the Mechanisms of Dietary Fibre and Implications for Macronutrient Bioaccessibility, Digestion and Postprandial Metabolism. Br. J. Nutr. 2016, 116, 816–833. [Google Scholar] [CrossRef]

- Cebrián-Lloret, V.; Martínez-Abad, A.; Recio, I.; López-Rubio, A.; Martínez-Sanz, M. In Vitro Digestibility of Proteins from Red Seaweeds: Impact of Cell Wall Structure and Processing Methods. Food Res. Int. 2024, 178, 113990. [Google Scholar] [CrossRef]

- Lopez-Santamarina, A.; Sinisterra-Loaiza, L.; Mondragón-Portocarrero, A.; Ortiz-Viedma, J.; Cardelle-Cobas, A.; Abuín, C.M.F.; Cepeda, A. Potential Prebiotic Effect of Two Atlantic Whole Brown Seaweeds, Saccharina Japonica and Undaria Pinnatifida, Using in Vitro Simulation of Distal Colonic Fermentation. Front. Nutr. 2023, 10, 1170392. [Google Scholar] [CrossRef]

- Akter, A.; Sobuj, M.K.A.; Islam, M.S.; Chakroborty, K.; Tasnim, N.; Ayon, M.H.; Hossain, M.F.; Rafiquzzaman, S.M. Seaweed Polysaccharides: Sources, Structure and Biomedical Applications with Special Emphasis on Antiviral Potentials. Future Foods 2024, 10, 100440. [Google Scholar] [CrossRef]

- Gong, T.; Liu, X.; Wang, X.; Lu, Y.; Wang, X. Applications of Polysaccharides in Enzyme-Triggered Oral Colon-Specific Drug Delivery Systems: A Review. Int. J. Biol. Macromol. 2024, 275, 133623. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Food Hydrocolloids: Application as Functional Ingredients to Control Lipid Digestion and Bioavailability. Food Hydrocoll. 2021, 111, 106404. [Google Scholar] [CrossRef]

- Cruz-Casas, D.E.; Aguilar, C.N.; Ascacio-Valdés, J.A.; Rodríguez-Herrera, R.; Chávez-González, M.L.; Flores-Gallegos, A.C. Enzymatic Hydrolysis and Microbial Fermentation: The Most Favorable Biotechnological Methods for the Release of Bioactive Peptides. Food Chem. Mol. Sci. 2021, 3, 100047. [Google Scholar] [CrossRef]

- Triantis, V.; Bode, L.; van Neerven, R.J.J. Immunological Effects of Human Milk Oligosaccharides. Front. Pediatr. 2018, 6, 190. [Google Scholar] [CrossRef]

- Yang, X.; Zeng, D.; Li, C.; Yu, W.; Xie, G.; Zhang, Y.; Lu, W. Therapeutic Potential and Mechanism of Functional Oligosaccharides in Inflammatory Bowel Disease: A Review. Food Sci. Hum. Wellness 2023, 12, 2135–2150. [Google Scholar] [CrossRef]

- Ninonuevo, M.R.; Bode, L. Infant Formula Oligosaccharides Opening the Gates (for Speculation): Commentary on the Article by Barrat et al. on Page 34. Pediatr. Res. 2008, 64, 8–10. [Google Scholar] [CrossRef]

- Han, H.; Liu, Z.; Yin, J.; Gao, J.; He, L.; Wang, C.; Hou, R.; He, X.; Wang, G.; Li, T.; et al. D-Galactose Induces Chronic Oxidative Stress and Alters Gut Microbiota in Weaned Piglets. Front. Physiol. 2021, 12, 634283. [Google Scholar] [CrossRef]

- Chávez-Murillo, C.E.; Veyna-Torres, J.I.; Cavazos-Tamez, L.M.; de la Rosa-Millán, J.; Serna-Saldívar, S.O. Physicochemical Characteristics, ATR-FTIR Molecular Interactions and in Vitro Starch and Protein Digestion of Thermally-Treated Whole Pulse Flours. Food Res. Int. 2018, 105, 371–383. [Google Scholar] [CrossRef]

- Yao, H.-Y.-Y.; Wang, J.-Q.; Yin, J.-Y.; Nie, S.-P.; Xie, M.-Y. A Review of NMR Analysis in Polysaccharide Structure and Conformation: Progress, Challenge and Perspective. Food Res. Int. 2021, 143, 110290. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Gao, L.; Yu, Z. Revealing the Complexity of Polysaccharides: Advances in NMR Spectroscopy for Structural Elucidation and Functional Characterization. Appl. Sci. 2025, 15, 5246. [Google Scholar] [CrossRef]

- Bhinderwala, F.; Wase, N.; DiRusso, C.; Powers, R. Combining Mass Spectrometry and NMR Improves Metabolite Detection and Annotation. J. Proteome Res. 2018, 17, 4017–4022. [Google Scholar] [CrossRef]

- Gathungu, R.M.; Bird, S.S.; Sheldon, D.P.; Kautz, R.; Vouros, P.; Matson, W.R.; Kristal, B.S. Identification of Metabolites from Liquid Chromatography–Coulometric Array Detection Profiling: Gas Chromatography–Mass Spectrometry and Refractionation Provide Essential Information Orthogonal to LC–MS/MicroNMR. Anal. Biochem. 2014, 454, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Bao, Z.-X.; Zhao, P.-J.; Li, G.-H. Advances in the Study of Metabolomics and Metabolites in Some Species Interactions. Molecules 2021, 26, 3311. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, D.; Gu, S.; Wu, N.; Wang, K.; Zhang, Y. Size Exclusion Chromatography and Asymmetrical Flow Field-Flow Fractionation for Structural Characterization of Polysaccharides: A Comparative Review. Int. J. Biol. Macromol. 2024, 277, 134236. [Google Scholar] [CrossRef]

- Ji, C.; Ma, Y.; Xie, Y.; Guo, J.; Ba, H.; Zhou, Z.; Zhao, K.; Yang, M.; He, X.; Zheng, W. Isolation and Purification of Carbohydrate Components in Functional Food: A Review. RSC Adv. 2024, 14, 23204–23214. [Google Scholar] [CrossRef]

- Deguara, S.; Jauncey, K.; Agius, C. Enzyme Activities and PH Variations in the Digestive Tract of Gilthead Sea Bream. J. Fish. Biol. 2003, 62, 1033–1043. [Google Scholar] [CrossRef]

- Tse, G.; Lai, E.T.H.; Yeo, J.M.; Tse, V.; Wong, S.H. Mechanisms of Electrical Activation and Conduction in the Gastrointestinal System: Lessons from Cardiac Electrophysiology. Front. Physiol. 2016, 7, 182. [Google Scholar] [CrossRef]

- Pais, A.C.S.; Coscueta, E.R.; Pintado, M.M.; Silvestre, A.J.D.; Santos, S.A.O. Exploring the Bioaccessibility and Intestinal Absorption of Major Classes of Pure Phenolic Compounds Using in Vitro Simulated Gastrointestinal Digestion. Heliyon 2024, 10, e28894. [Google Scholar] [CrossRef]

- De Jesus Raposo, M.; De Morais, A.; De Morais, R. Emergent Sources of Prebiotics: Seaweeds and Microalgae. Mar. Drugs 2016, 14, 27. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Y.; Jiang, P.; Xu, Y.; Zheng, W.; Song, S.; Ai, C. Effect of Sulfate Group on Sulfated Polysaccharides-Induced Improvement of Metabolic Syndrome and Gut Microbiota Dysbiosis in High Fat Diet-Fed Mice. Int. J. Biol. Macromol. 2020, 164, 2062–2072. [Google Scholar] [CrossRef]

- Yang, Q.; Chang, S.; Zhang, X.; Luo, F.; Li, W.; Ren, J. The Fate of Dietary Polysaccharides in the Digestive Tract. Trends Food Sci. Technol. 2024, 150, 104606. [Google Scholar] [CrossRef]

- Hettle, A.G.; Vickers, C.J.; Boraston, A.B. Sulfatases: Critical Enzymes for Algal Polysaccharide Processing. Front. Plant Sci. 2022, 13, 837636. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Description | White to yellowish-brown powder; odourless; tasteless; soluble in water forming viscous colloidal solution |

| Identification | Positive for uronic acids (mannuronic & guluronic) via chemical test or IR spectrum matching standard alginate |

| Loss on Drying | ≤15% (105 °C, 4 h) |

| Ash Content (as sodium salt) | 18–27% |

| pH (1% aqueous solution) | 3.5–10.0 |

| Insoluble Matter | ≤2% |

| Lead (Pb) | ≤2 mg/kg |

| Arsenic (As) | ≤3 mg/kg |

| Cadmium (Cd) | ≤1 mg/kg |

| Mercury (Hg) | ≤1 mg/kg |

| Formaldehyde (if used in extraction) | ≤50 mg/kg |

| Microbiological Quality | Absence of Salmonella spp. in 25 g; absence of E. coli in 1 g; total aerobic count within GMP limits |

| Heavy Metals (as Pb) | ≤0.001% |

| Functionality | Thickener, gelling agent, stabilizer, emulsifier |

| Parameter | Typical/Recommended Specification |

|---|---|

| Description | White to pale-yellow translucent flakes or powder; odourless; forms a firm, clear gel in hot water |

| Identification | Positive for 3,6-anhydro-L-galactose and D-galactose by specific chemical tests or FTIR; melting/setting point profile consistent with agar |

| Loss on Drying | ≤12% (105 °C, 4 h) |

| Ash Content | Typical: 1–8% (depends on purification; lower for agarose) |

| pH (1% solution) | ~5.0–7.0 |

| Insoluble Matter | ≤2% |

| Gel Strength (Bloom or g/cm2 equivalent) | Typical: 400–1200 g/cm2 (many food grades ≥ 600 g/cm2) |

| Viscosity (1–2% solution, specified temp) | Specified by grade (e.g., medium/high gel) |

| Lead (Pb) | ≤2 mg/kg (typical limit) |

| Arsenic (As) | ≤3 mg/kg (typical limit) |

| Cadmium (Cd) | ≤1 mg/kg (typical limit) |

| Mercury (Hg) | ≤1 mg/kg (typical limit) |

| Microbiological Quality | Salmonella absent in 25 g; E. coli absent in 1 g; total plate count within GMP limits |

| Residual Solvents/Chemicals | Not detected or below method LOQ (e.g., if solvents were used in processing) |

| Adulterants/Substitutes | No starch, cellulose, or cheaper gelling agents detectable |

| Functionality | Gelling agent, stabilizer, thickener, clarifier (microbiology/media uses are separate) |

| Detection System | Advantages | Insights Provided | Limitations |

|---|---|---|---|

| FTIR-ATR | Fast, non-destructive, minimal prep | Detects sulfation, uronic acids, bond breakage, new groups | Limited structural detail |

| NMR | Detailed structural info, no derivatization | Identifies sugar composition, linkages, substitutions | Expensive, low sensitivity, needs large pure samples |

| MS | Highly sensitive, detects small/rare metabolites | Identifies oligosaccharides, sulfation states, degradation products | Complex prep, matrix effects, hard to resolve isomers |

| Chromatography | Separates by size/charge, quantitative | Tracks degradation rate, MW distribution, supports MS/NMR | Limited structural resolution, best as complementary |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cotas, J.; Lourenço, M.; Figueirinha, A.; Valado, A.; Pereira, L. Seaweed Polysaccharides: A Rational Approach for Food Safety Studies. Mar. Drugs 2025, 23, 412. https://doi.org/10.3390/md23110412

Cotas J, Lourenço M, Figueirinha A, Valado A, Pereira L. Seaweed Polysaccharides: A Rational Approach for Food Safety Studies. Marine Drugs. 2025; 23(11):412. https://doi.org/10.3390/md23110412

Chicago/Turabian StyleCotas, João, Mariana Lourenço, Artur Figueirinha, Ana Valado, and Leonel Pereira. 2025. "Seaweed Polysaccharides: A Rational Approach for Food Safety Studies" Marine Drugs 23, no. 11: 412. https://doi.org/10.3390/md23110412

APA StyleCotas, J., Lourenço, M., Figueirinha, A., Valado, A., & Pereira, L. (2025). Seaweed Polysaccharides: A Rational Approach for Food Safety Studies. Marine Drugs, 23(11), 412. https://doi.org/10.3390/md23110412