Development and Validation of a Liquid Chromatography–Tandem Mass Spectrometry Method for Screening Potential Citrate Lyase Inhibitors from a Library of Marine Compounds

Abstract

1. Introduction

2. Results

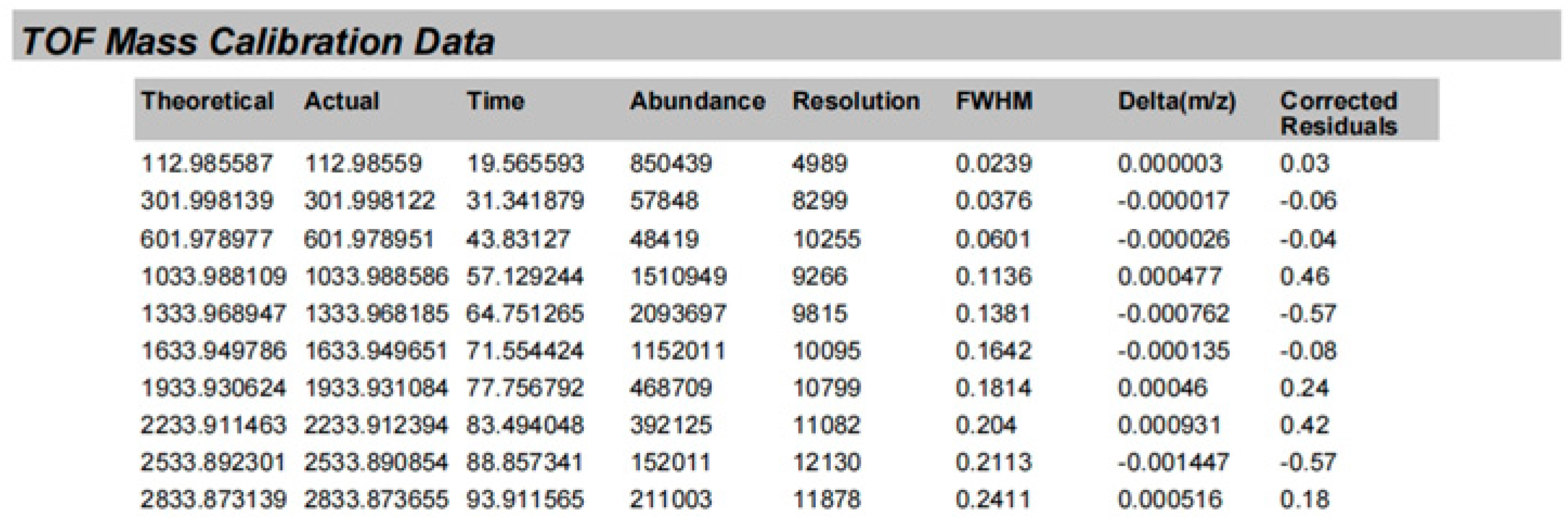

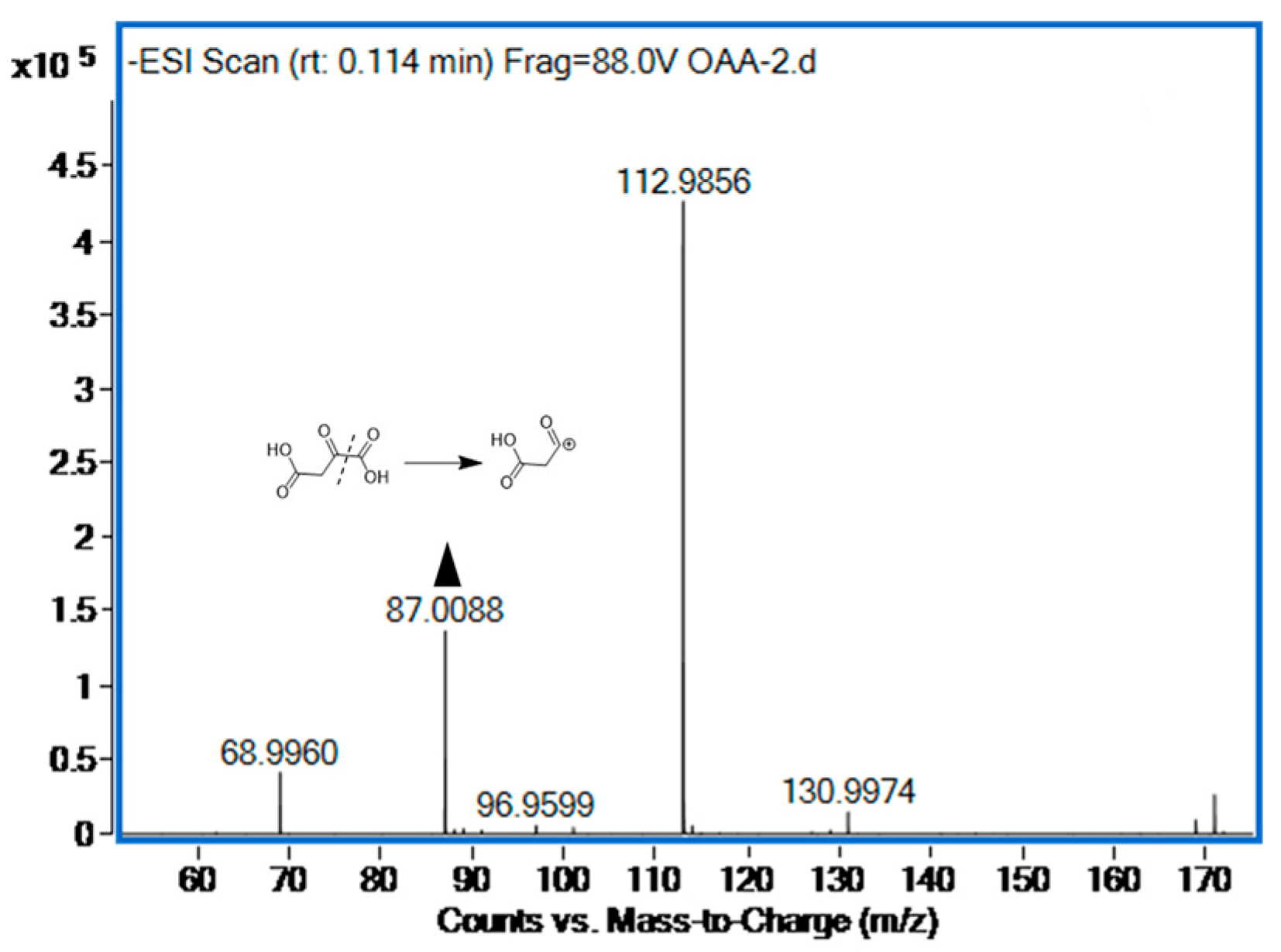

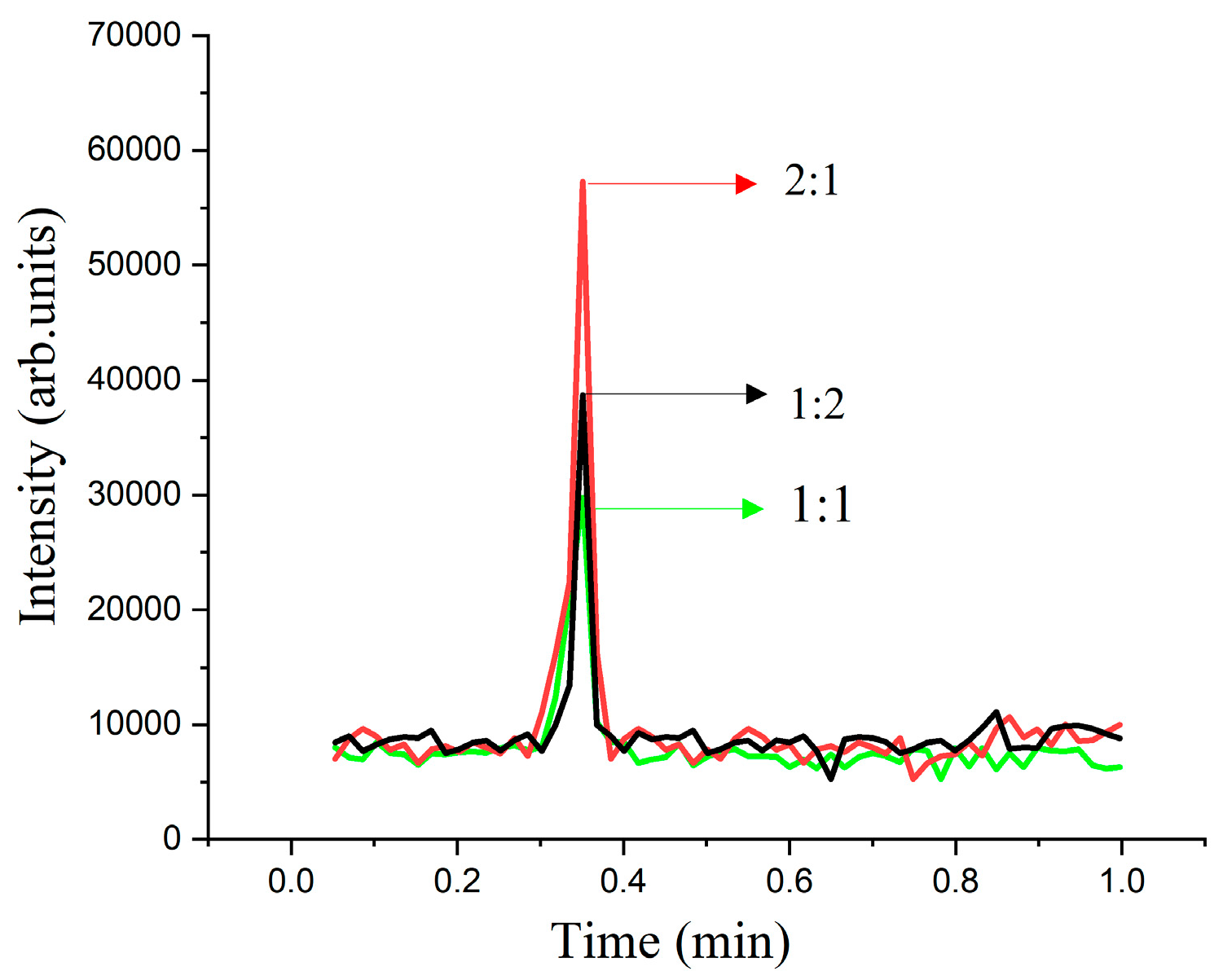

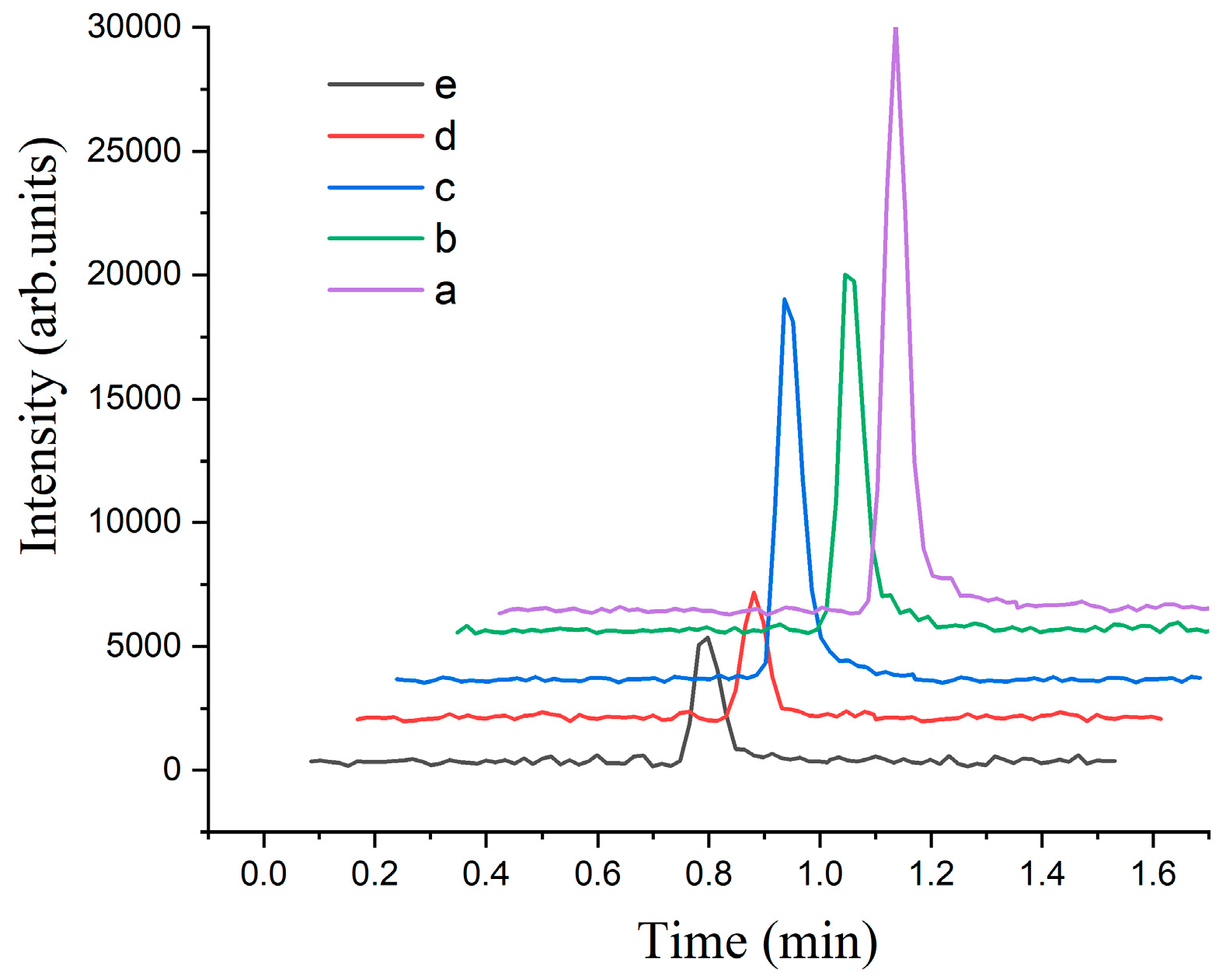

2.1. Optimization of UHPLC-QTOF MS Conditions

2.2. Methodological Validation

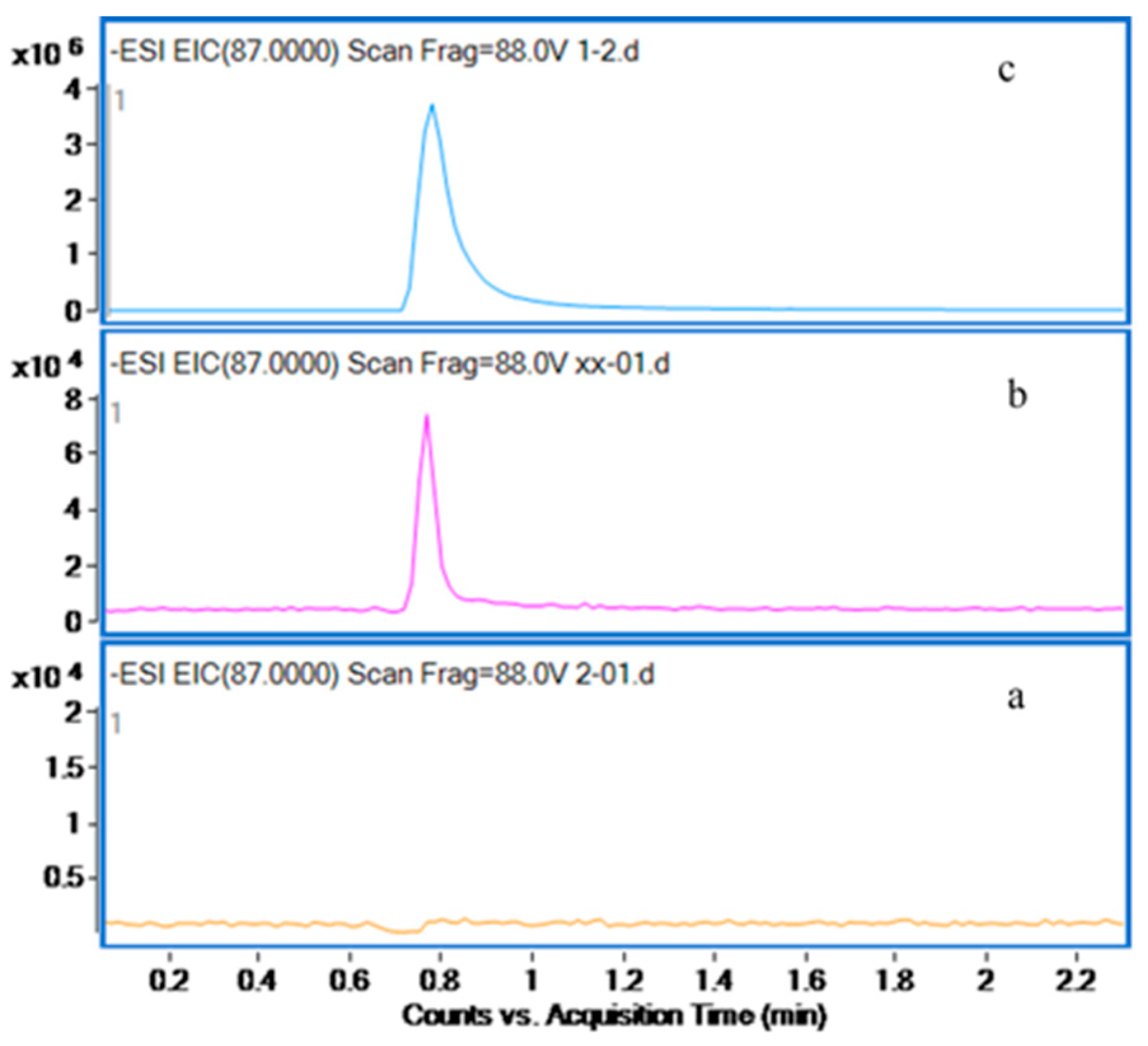

2.2.1. Selectivity

2.2.2. Linearity and the Limit of Detection

2.2.3. Accuracy and Precision

2.2.4. Stability

2.2.5. Matrix Effects

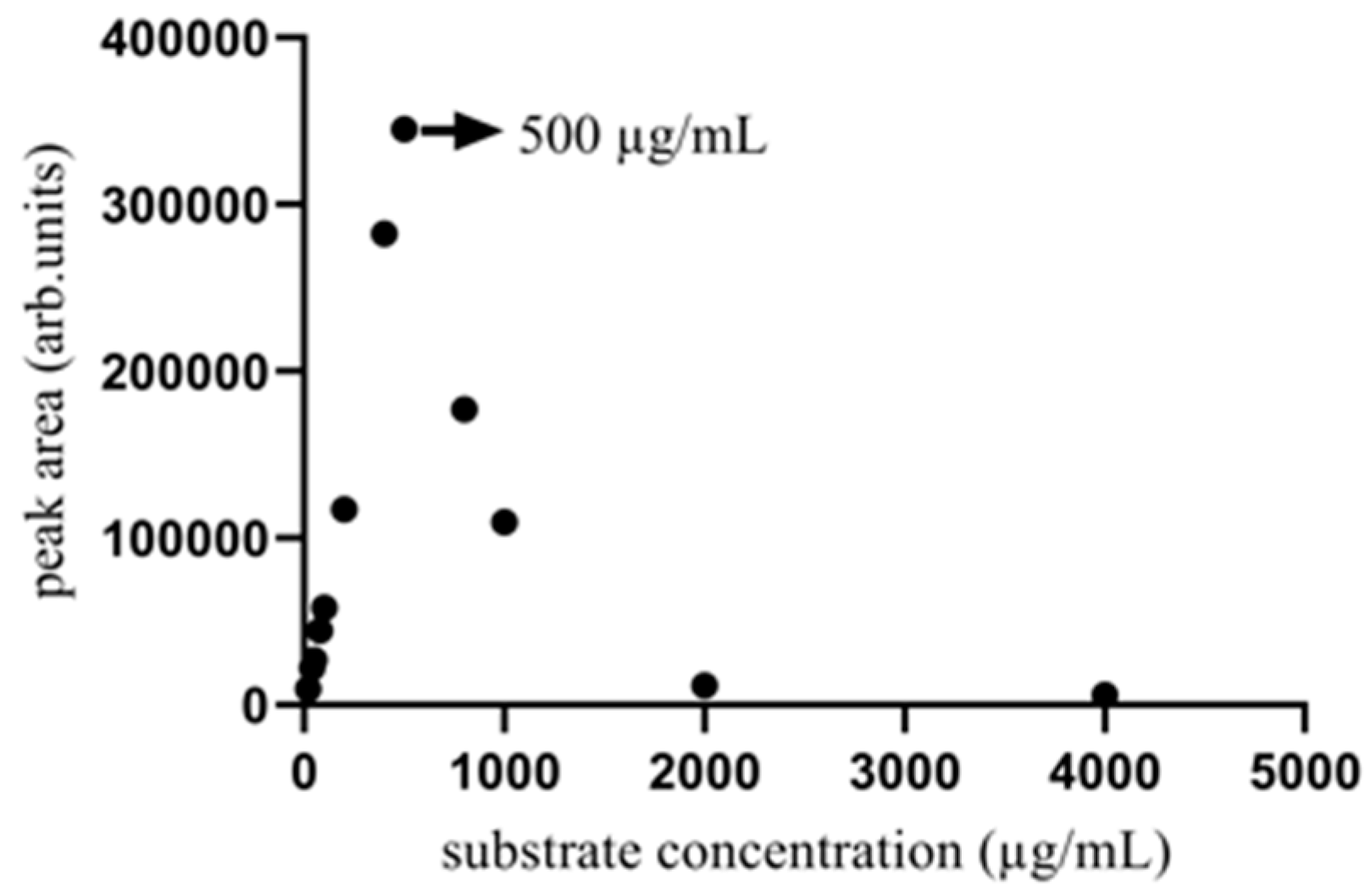

2.3. Enzyme Reaction

2.4. Determination of Enzyme Inhibitory Components in Herbs

2.4.1. Natural Inhibitors of Citrate Lyase

2.4.2. Identification of Inhibitory Components of Rhubarb and Salvia miltiorrhiza

- (1)

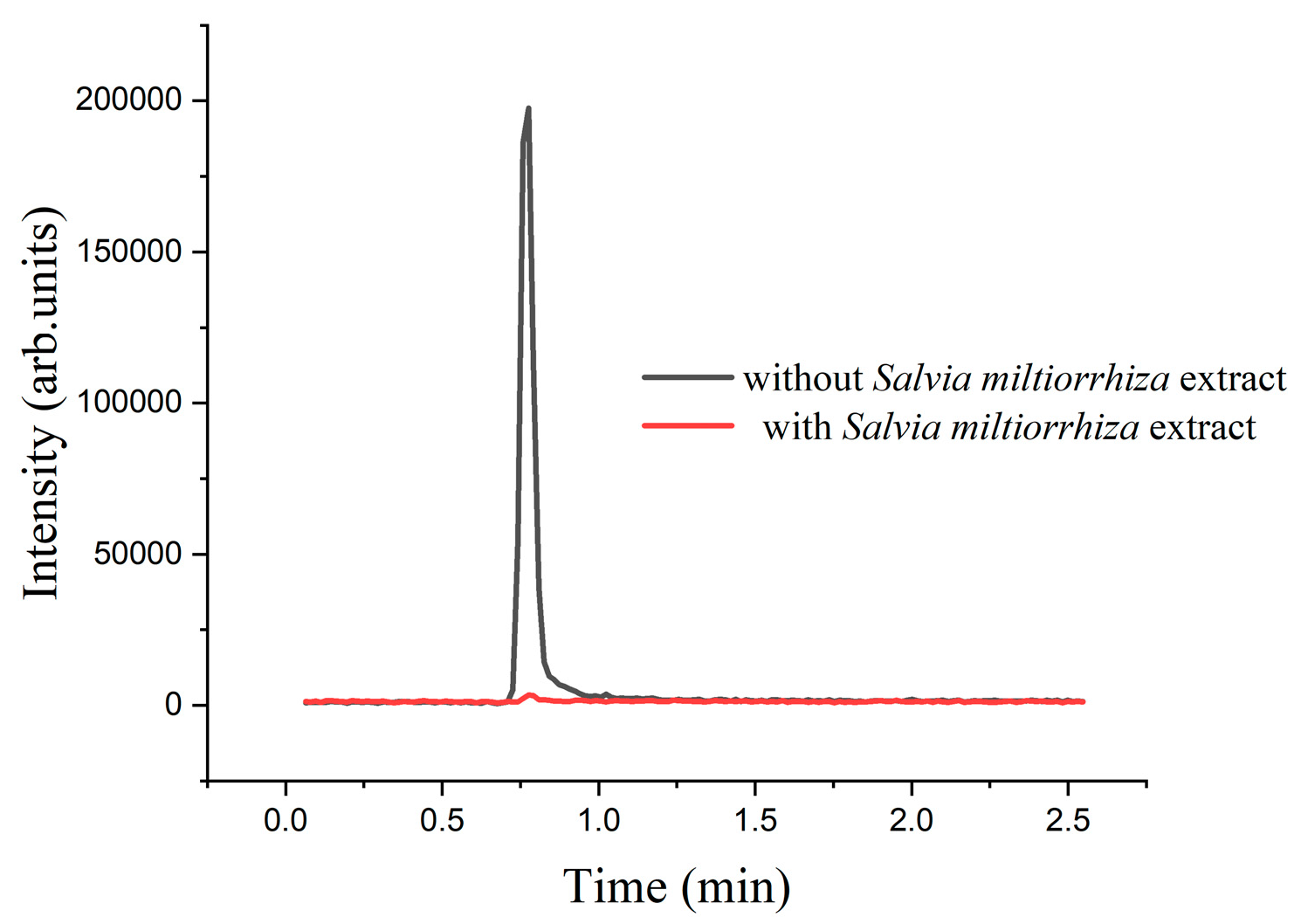

- Identification of inhibitory components of Salvia miltiorrhiza

- (2)

- Identification of inhibitory components of Rhubarb

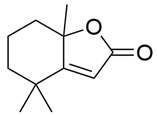

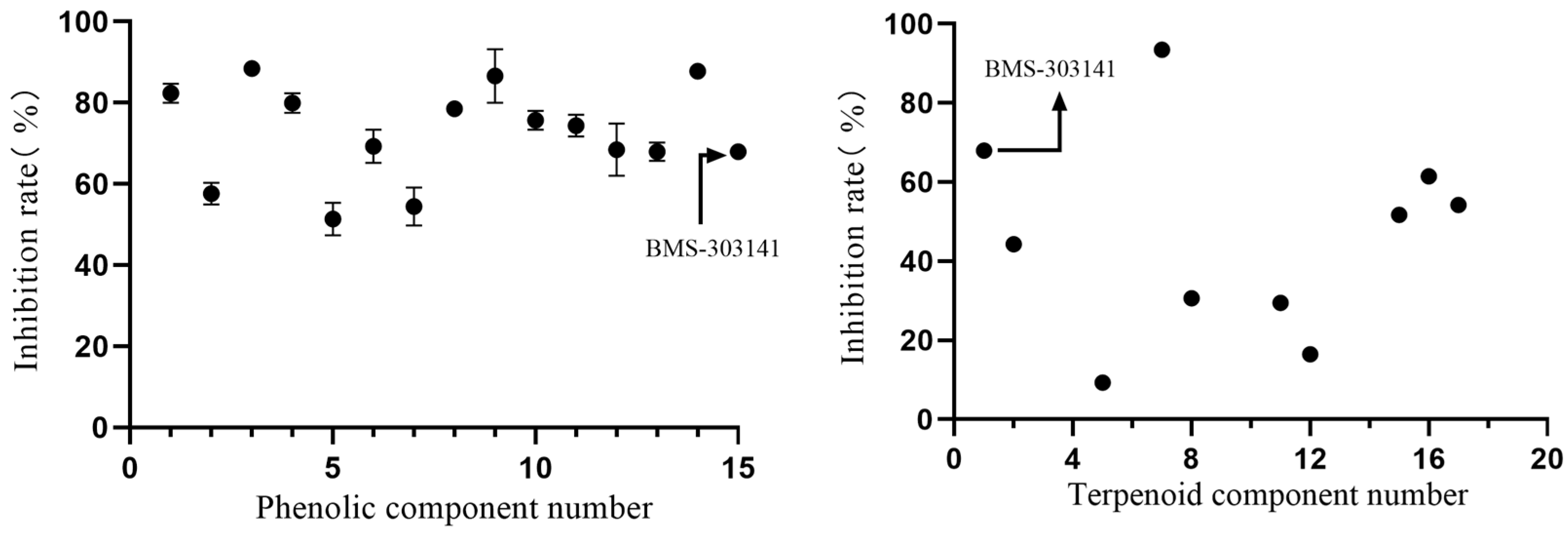

2.5. Screening Marine Libraries for Potential Enzyme Inhibitors

2.6. Kinetic Studies of Enzyme Reactions

3. Discussion

4. Materials and Methods

4.1. Chemicals and Reagents

4.2. UHPLC-QTOF MS Conditions

4.3. Sample Preparation

4.4. Extraction Procedure

4.5. Establishment of Enzyme Reaction System

4.6. Enzyme Assay and Kinetic Measurements

4.7. Inhibition Study

4.8. Identification of Herbs with Inhibitory Effects

4.9. Analysis of the Inhibiting Components of Rhubarb and Salvia miltiorrhiza

- (1)

- Analysis of the inhibiting components of Salvia miltiorrhiza

- (2)

- Analysis of the inhibiting components of Rhubarb

4.10. Screening Inhibitors from Marine Compound Libraries

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Methodological Validation

| Compound | Linear Range (μg/mL) | Linear | Slope (±SD) | Intercept (±SD) | R2 |

|---|---|---|---|---|---|

| Oxaloacetic acid | 10–200 | y = 8306.58x − 11111.56 | 8206.57668 ± 38.65798 | −11,111.56465 ± 4137.8749 | 0.9999 |

| Batch | Slope (±SD) | Intercept (±SD) | R2 |

|---|---|---|---|

| 1 | 8198.66972 ± 15.16927 | −12,681.96387 ± 1640.80757 | 0.9998 |

| 2 | 9699.73101 ± 142.90583 | −7440.10026 ± 15,296.36055 | 0.9989 |

| 3 | 8880.74623 ± 160.50934 | 33,829.95929 ± 17,180.60581 | 0.9984 |

| QC Concentration (mg/L) | Intraday | Interday | ||

|---|---|---|---|---|

| Accuracy (RE, %) | Precision (RSD, %) | Accuracy (RE, %) | Precision (RSD, %) | |

| 10 | 99.44 | 1.75 | 103.44 | 8.45 |

| 20 | 96.27 | 2.65 | 98.38 | 7.85 |

| 50 | 92.72 | 0.96 | 90.63 | 11.23 |

| 160 | 97.41 | 1.03 | 95.67 | 6.52 |

| QC Concentration (mg/L) | Bench-Top Stability | Autosampler Stability | Freeze–Thaw Stability | Long-Term Stability | ||||

|---|---|---|---|---|---|---|---|---|

| Accuracy (RE, %) | Precision (RSD, %) | Accuracy (RE, %) | Precision (RSD, %) | Accuracy (RE, %) | Precision (RSD, %) | Accuracy (RE, %) | Precision (RSD, %) | |

| 10 | 90.71 | 5.78 | 104.79 | 1.67 | 100.07 | 2.83 | 88.41 | 3.41 |

| 20 | 99.87 | 4.92 | 88.79 | 14.23 | 98.37 | 9.95 | 91.81 | 2.07 |

| 50 | 100.47 | 2.45 | 86.10 | 1.97 | 85.36 | 2.55 | 89.28 | 6.35 |

| 160 | 106.95 | 3.04 | 94.35 | 8.47 | 87.25 | 3.87 | 101.73 | 8.96 |

| Compound | QC Concentration (mg/L) | Recovery Rate (%) | RSD (%) |

|---|---|---|---|

| Oxaloacetic acid | 20 | 105.5 | 5.8 |

| 50 | 103.6 | 7.1 | |

| 160 | 97.0 | 1.2 |

Appendix B

| Phenolic Compound | CAS | Inhibition Rate | Inhibition Rate | Inhibition Rate | Mean | SD |

| 1 | 118-79-6 | 84.18% | 83.19% | 79.77% | 82.38% | 2.31% |

| 2 | 585-76-2 | 57.43% | 60.33% | 54.99% | 57.58% | 2.67% |

| 3 | 120-32-1 | 88.82% | 87.44% | 89.11% | 88.46% | 0.89% |

| 4 | 608-33-3 | 80.80% | 77.20% | 81.85% | 79.95% | 2.44% |

| 5 | 41833-13-0 | 46.77% | 53.22% | 54.09% | 51.36% | 4.00% |

| 6 | 76045-71-1 | 70.90% | 64.63% | 72.33% | 69.29% | 4.10% |

| 7 | 1200-93-7 | 50.74% | 52.96% | 59.71% | 54.47% | 4.67% |

| 8 | 4526-56-1 | 80.06% | 77.60% | 78.04% | 78.57% | 1.31% |

| 9 | 3354-82-3 | 90.79% | 90.04% | 78.95% | 86.59% | 6.63% |

| 10 | 84743-75-9 | 74.74% | 74.02% | 78.37% | 75.71% | 2.33% |

| 11 | 18000-24-3 | 72.88% | 72.81% | 77.45% | 74.38% | 2.66% |

| 12 | 84743-76-0 | 67.71% | 62.45% | 75.26% | 68.47% | 6.44% |

| 13 | 116569-08-5 | 69.62% | 65.36% | 68.84% | 67.94% | 2.27% |

| 14 | 9005-32-7 | 88.65% | 87.59% | 87.25% | 87.83% | 0.73% |

| 15 | 943962-47-8 | 67.68% | 68.14% | 68.08% | 67.97% | 0.25% |

| Terpenoid Compound | CAS | Inhibition Rate | Inhibition Rate | Inhibition Rate | Mean | SD |

| 1 | 943962-47-8 | 67.68% | 68.14% | 68.08% | 67.97% | 0.25% |

| 2 | 1117-52-8 | 40.13% | 41.63% | 51.08% | 44.28% | 5.94% |

| 3 | 472-61-7 | -- | -- | -- | -- | -- |

| 4 | 7235-40-7 | -- | -- | -- | -- | -- |

| 5 | 559-74-0 | 0.90% | 3.61% | 23.44% | 9.32% | 12.31% |

| 6 | 7683-64-9 | -- | -- | -- | -- | -- |

| 7 | 15905-32-5 | 96.95% | 86.25% | 97.05% | 93.42% | 6.21% |

| 8 | 57-88-5 | 16.31% | 40.64% | 34.82% | 30.59% | 12.70% |

| 9 | 434-16-2 | -- | -- | -- | -- | -- |

| 10 | 67-97-0 | -- | -- | -- | -- | -- |

| 11 | 11103-57-4 | 14.79% | 42.88% | 30.62% | 29.43% | 14.08% |

| 12 | 59-02-9 | 2.40% | 30.57% | -- | 16.49% | 19.92% |

| 13 | 11032-49-8 | -- | -- | -- | -- | -- |

| 14 | 84-80-0 | -- | -- | -- | -- | -- |

| 15 | 1406-65-1 | 54.71% | 78.18% | 22.20% | 51.70% | 28.11% |

| 16 | 68-26-8 | 90.66% | 66.19% | 27.58% | 61.48% | 31.80% |

| 17 | 77-06-5 | 71.06% | 71.87% | 19.78% | 54.24% | 29.84% |

| 18 | 150-86-7 | -- | -- | -- | -- | -- |

| 19 | 17092-92-1 | -- | -- | -- | -- | -- |

| 20 | 15356-74-8 | -- | -- | -- | -- | -- |

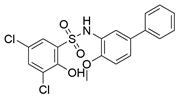

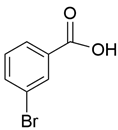

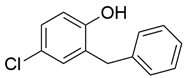

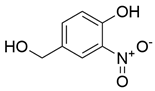

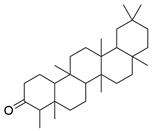

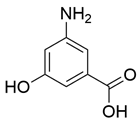

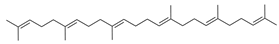

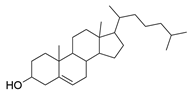

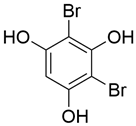

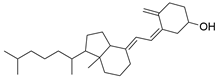

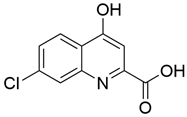

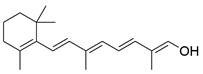

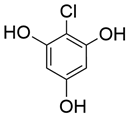

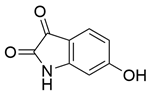

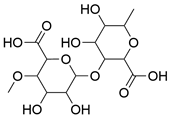

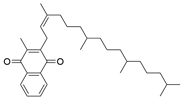

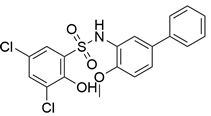

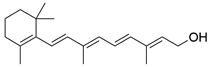

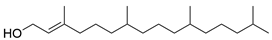

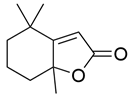

| Phenols CAS | Structural Formulae | Terpenoids CAS | Structural Formulae |

|---|---|---|---|

| 118-79-6 |  | 943962-47-8 |  |

| 585-76-2 |  | 1117-52-8 |  |

| 120-32-1 |  | 472-61-7 |  |

| 608-33-3 |  | 7235-40-7 |  |

| 41833-13-0 |  | 559-74-0 |  |

| 76045-71-1 |  | 7683-64-9 |  |

| 1200-93-7 |  | 15905-32-5 |  |

| 4526-56-1 |  | 57-88-5 |  |

| 3354-82-3 |  | 434-16-2 |  |

| 84743-75-9 |  | 67-97-0 |  |

| 18000-24-3 |  | 11103-57-4 |  |

| 84743-76-0 |  | 59-02-9 |  |

| 116569-08-5 |  | 11032-49-8 |  |

| 9005-32-7 |  | 84-80-0 |  |

| 943962-47-8 |  | 1406-65-1 |  |

| 68-26-8 |  | ||

| 77-06-5 |  | ||

| 150-86-7 |  | ||

| 17092-92-1 |  | ||

| 15356-74-8 |  |

Appendix C

| Company | CAS | Purity (%) | CAS | Purity (%) | CAS | Purity (%) | CAS | Purity (%) |

| Bide Pharmatech Ltd. (Shanghai, China) | 118-79-6 | 98 | 15356-74-8 | 97 | 7683-64-9 | 98 | 76045-71-1 | 97 |

| 585-76-2 | 99.34 | 1117-52-8 | 95 | 57-88-5 | 98 | 150-86-7 | 95 | |

| 120-32-1 | 98 | 472-61-7 | 95 | 434-16-2 | 95 | 17092-92-1 | 98 | |

| 608-33-3 | 99.86 | 3354-82-3 | 95 | 67-97-0 | 98 | 18000-24-3 | 99 | |

| 41833-13-0 | 99.94 | 84743-75-9 | 97 | 11103-57-4 | 350,000 IU/g | 84743-76-0 | 97 | |

| 943962-47-8 | 99.15 | 68-26-8 | 98 | 9005-32-7 | 24.75 | |||

| Company | CAS | Purity (%) | Company | CAS | Purity (%) | |||

| Aladdin Global Corporation Limited | 7235-40-7 | 96 | Mclin Medical Equipment Products Co., Ltd (Shanghai, China) | 15905-32-5 | 90 | |||

| Aladdin Global Corporation Limited | 559-74-0 | F579523 (SKU) | 59-02-9 | 99 | ||||

| Shanghai Topscience Co., Ltd. (Shanghai, China) | 1200-93-7 | TN7156 (SKU) | 11032-49-8 | 98 | ||||

| Shanghai Topscience Co., Ltd. (Shanghai, China) | 4526-56-1 | TN7197 (SKU) | 84-80-0 | 98 | ||||

| Shanghai Topscience Co., Ltd. (Shanghai, China) | 116569-08-5 | TN7147 (SKU) | 1406-65-1 | C832317 (SKU) | ||||

| 77-06-5 | 90 | |||||||

Appendix D

References

- Gordon, S.V.; Bottai, D.; Simeone, R.; Stinear, T.P.; Brosch, R. Pathogenicity in the tubercle bacillus: Molecular and evolutionary determinants. Bioessays 2009, 31, 378–388. [Google Scholar] [CrossRef]

- Hu, J.; Jin, K.; He, Z.G.; Zhang, H. Citrate lyase CitE in Mycobacterium tuberculosis contributes to mycobacterial survival under hypoxic conditions. PLoS ONE 2020, 15, e0230786. [Google Scholar] [CrossRef]

- Srinivasan, V.; Morowitz, H.J. Ancient genes in contemporary persistent microbial pathogens. Biol. Bull. 2006, 210, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Arora, G.; Chaudhary, D.; Kidwai, S.; Sharma, D.; Singh, R. CitE Enzymes Are Essential for Mycobacterium tuberculosis to Establish Infection in Macrophages and Guinea Pigs. Front. Cell Infect. Microbiol. 2018, 8, 385. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, A.C.; Singh, M.; Srere, P.A.; Glusker, J.P. Reactivity and inhibitor potential of hydroxycitrate isomers with citrate synthase, citrate lyase, and ATP citrate lyase. J. Biol. Chem. 1977, 252, 7583–7590. [Google Scholar] [CrossRef]

- Robinson, J.B.; Singh, M., Jr.; Srere, P.A. Structure of the prosthetic group of Klebsiella aerogenes citrate (pro-3S)-lyase. Proc. Natl. Acad. Sci. USA 1976, 73, 1872–1876. [Google Scholar] [CrossRef]

- Schneider, K.; Dimroth, P.; Bott, M. Biosynthesis of the prosthetic group of citrate lyase. Biochemistry 2000, 39, 9438–9450. [Google Scholar] [CrossRef] [PubMed]

- Devi Khwairakpam, A.; Singh Shyamananda, M.; Lalduhsaki Sailo, B.; Raju Rathnakaram, S.; Padmavathi, G.; Kotoky, J.; B Kunnumakkara, A. ATP citrate lyase (ACLY): A promising target for cancer prevention and treatment. Curr. Drug Targets 2015, 16, 156–163. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, S.; Sivaraman, C. Bacterial citrate lyase. J. Biosci. 1984, 6, 379–401. [Google Scholar] [CrossRef]

- Rokita, S.E.; Srere, P.A.; Walsh, C.T. 3-Fluoro-3-deoxycitrate: A probe for mechanistic study of citrate-utilizing enzymes. Biochemistry 1982, 21, 3765–3774. [Google Scholar] [CrossRef]

- Alyar, S.; Şen, T.; Özmen, Ü.Ö.; Alyar, H.; Adem, Ş.; Şen, C. Synthesis, spectroscopic characterizations, enzyme inhibition, molecular docking study and DFT calculations of new Schiff bases of sulfa drugs. J. Mol. Struct. 2019, 1185, 416–424. [Google Scholar] [CrossRef]

- Akkad, R.; Schwack, W. Multi-enzyme inhibition assay for the detection of insecticidal organophosphates and carbamates by high-performance thin-layer chromatography applied to determine enzyme inhibition factors and residues in juice and water samples. J. Chromatogr. B 2010, 878, 1337–1345. [Google Scholar] [CrossRef] [PubMed]

- Pei, J.; Li, Q.; Kennedy, R.T. Rapid and label-free screening of enzyme inhibitors using segmented flow electrospray ionization mass spectrometry. J. Am. Soc. Mass Spectrom. 2010, 21, 1107–1113. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Xing, J.; Zheng, Z.; Song, F.; Liu, Z.; Liu, S. Ultrahigh performance liquid chromatography–triple quadrupole mass spectrometry inhibitors fishing assay: A novel method for simultaneously screening of xanthine oxidase inhibitor and superoxide anion scavenger in a single analysis. Anal. Chim. Acta 2012, 715, 64–70. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Wu, Y.; Liu, Y.; Tang, Y.; Che, Z.; Wu, T. Chemical profiles and screening of potential α-glucosidase inhibitors from Sichuan pepper using ultra-filtration combined with UHPLC-Q-TOF. Ind. Crops Prod. 2020, 143, 111874. [Google Scholar] [CrossRef]

- Mocan, A.; Moldovan, C.; Zengin, G.; Bender, O.; Locatelli, M.; Simirgiotis, M.; Crișan, G. UHPLC-QTOF-MS analysis of bioactive constituents from two Romanian Goji (Lycium barbarum L.) berries cultivars and their antioxidant, enzyme inhibitory, and real-time cytotoxicological evaluation. Food Chem. Toxicol. 2018, 115, 414–424. [Google Scholar] [CrossRef] [PubMed]

- Rathore, R.; Corr, J.J.; Lebre, D.T.; Seibel, W.L.; Greis, K.D. Extending matrix-assisted laser desorption/ionisation triple quadrupole mass spectrometry enzyme screening assays to targets with small molecule substrates. Rapid Commun. Mass. Sp. 2009, 23, 3293–3300. [Google Scholar] [CrossRef] [PubMed]

- Kantar, S.A.; Biswal, R.P.; Kumar, P.; Dharanikota, M.; Agraharam, A. Antioxidant and Antidiabetic Activities, and UHPLC-ESI-QTOF-MS-Based Metabolite Profiling of an Endophytic Fungus Nigrospora sphaerica BRN 01 Isolated from Bauhinia purpurea L. Appl. Biochem. Biotechnol. 2023, 195, 7465–7482. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, Z.; Zhang, H.; Yin, S.; Xia, F.; Zhang, Q.; Wan, J.; Gao, J.; Yang, F. LC–MS-based multivariate statistical analysis for the screening of potential thrombin/factor Xa inhibitors from Radix Salvia Miltiorrhiza. Chin. Med.-UK 2020, 15, 38. [Google Scholar] [CrossRef]

- Kong, W.J.; Zhang, S.S.; Zhao, Y.L.; Wu, M.Q.; Chen, P.; Wu, X.R.; Ma, X.P.; Guo, W.Y.; Yang, M.H. Combination of chemical fingerprint and bioactivity evaluation to explore the antibacterial components of Salvia miltiorrhizae. Sci. Rep. 2017, 7, 8112. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z. Chemical composition, antimicrobial and antioxidant activities of the essential oil in leaves of Salvia miltiorrhiza Bunge. J. Essent. Oil Res. 2009, 21, 476–480. [Google Scholar] [CrossRef]

- Piret, R. Polyphenolic Composition of Rhubarb (Rheum rhaponticum L.) and Blackcurrant (Ribes nigrum L.), Antibacterial and Free Radical Scavenging Properties of These Plants in Comparison with Some Other Food Plants. Ph.D. Thesis, Estonian University of Life Sciences, Tartu, Estonia, 2021. [Google Scholar]

- Bhattacharjee, M.K.; Bommareddy, P.K.; DePass, A.L. A Water-Soluble Antibiotic in Rhubarb Stalk Shows an Unusual Pattern of Multiple Zones of Inhibition and Preferentially Kills Slow-Growing Bacteria. Antibiotics 2021, 10, 951. [Google Scholar] [CrossRef]

- Lee, D.G.; Jung, H.J.; Woo, E.R. Antimicrobial property of (+)-lyoniresinol 3alpha O beta D glucopyranoside isolated from the root bark of Lycium chinense Miller against human pathogenic microorganisms. Arch. Pharm. Res. 2005, 28, 1031–1036. [Google Scholar] [CrossRef] [PubMed]

- Ilić, T.; Dodevska, M.; Marčetić, M.; Božić, D.; Kodranov, I.; Vidović, B. Chemical Characterization, Antioxidant and Antimicrobial Properties of Goji Berries Cultivated in Serbia. Foods 2020, 9, 1614. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.J.; Bang, W.S.; Hong, J.Y.; Kwon, O.J.; Shin, S.R.; Yoon, K.Y. Antioxidant and antimicrobial activities of black Doraji (Platycodon grandiflorum). Korean J. Food Preserv. 2013, 20, 510–517. [Google Scholar] [CrossRef]

- Yuan, J.Q.; Yang, X.Z.; Miao, J.H.; Tang, C.P.; Ke, C.Q.; Zhang, J.B.; Ma, X.J.; Ye, Y. New triterpene glucosides from the roots of Rosa laevigata Michx. Molecules 2008, 13, 2229–2237. [Google Scholar] [CrossRef]

- Tian, Y.N.; Li, B.L.; Hu, J.J.; Xie, J.D.; Xiao, W.J.; Nie, L.H.; Wu, J.W. Rosanortriterpenes A-B, two new nortriterpenes from the fruits of Rosa laevigata var. leiocapus. Nat. Prod. Res. 2021, 35, 1172–1179. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Li, J.; Zhu, T.; Gu, Q.; Li, D. Advanced tools in marine natural drug discovery. Curr. Opin. Biotechnol. 2016, 42, 13–23. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.; Li, C.; Lai, T.; Luo, L. In Silico Analysis of USP7 Inhibitors Based on Building QSAR Models and Fragment Design for Screening Marine Compound Libraries. Mar. Drugs 2024, 22, 1. [Google Scholar] [CrossRef]

- Kiuru, P.; D’Auria, M.V.; Muller, C.D.; Tammela, P.; Vuorela, H.; Yli-Kauhaluoma, J. Exploring marine resources for bioactive compounds. Planta Medica 2014, 80, 1234–1246. [Google Scholar] [CrossRef]

- Sigwart, J.D.; Blasiak, R.; Jaspars, M.; Jouffray, J.B.; Tasdemir, D. Unlocking the potential of marine biodiscovery. Nat. Prod. Rep. 2021, 38, 1235–1242. [Google Scholar] [CrossRef] [PubMed]

- US Food and Drug Administration, Bioanalytical Method Validation Guidance for Industry. 2018. Available online: https://www.fda.gov/downloads/drugs/guidances/ucm070107.pdf (accessed on 18 November 2021).

- Ma, P.; Liu, J.; Zhang, C.; Liang, Z. Regulation of water-soluble phenolic acid biosynthesis in Salvia miltiorrhiza Bunge. Appl. Biochem. Biotechnol. 2013, 170, 1253–1262. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiong, X.; Feng, B. Cardiovascular effects of salvianolic Acid B. Evid Based Complement Altern. Med. 2013, 2013, 247948. [Google Scholar] [CrossRef]

- Koerner, S.K.; Hanai, J.I.; Bai, S.; Jernigan, F.E.; Oki, M.; Komaba, C.; Shuto, E.; Sukhatme, V.P.; Sun, L. Design and synthesis of emodin derivatives as novel inhibitors of ATP-citrate lyase. Eur. J. Med. Chem. 2017, 126, 920–928. [Google Scholar] [CrossRef]

- Li, J.S.; Liu, Y.N.; Li, J.Y.; Lei, C.; Hou, A.J. Acylphloroglucinol-monoterpene meroterpenoids from Eucalyptus tereticornis and their inhibitory activity against ATP citrate lyase. Phytochemistry 2023, 207, 113565. [Google Scholar] [CrossRef]

- Giffhorn, F.; Zimmermann, T.; Kuhn, A. Substrate specificity of citrate lyase deacetylase of Rhodopseudomonas gelatinosa and Rhodopseudomonas palustris. J. Bacteriol. 1981, 147, 463–470. [Google Scholar] [CrossRef]

- Zhan, Z.; Li, A.; Zhang, W.; Wu, X.; He, J.; Li, Z.; Li, Y.; Sun, J.; Zhang, H. ATP-citrate lyase inhibitor improves ectopic lipid accumulation in the kidney in a db/db mouse model. Front. Endocrinol. 2022, 13, 914865. [Google Scholar] [CrossRef] [PubMed]

- Inoue, H.; Suzuki, F.; Tanioka, H.; Takeda, Y. Role of ATP in the ATP citrate lyase reaction. Biochem. Biophys. Res. Commun. 1967, 26, 602–608. [Google Scholar] [CrossRef]

- Carbone, D.; De Franco, M.; Pecoraro, C.; Bassani, D.; Pavan, M.; Cascioferro, S.; Parrino, B.; Cirrincione, G.; Dall’Acqua, S.; Sut, S. Structural Manipulations of Marine Natural Products Inspire a New Library of 3-Amino-1,2,4-Triazine PDK Inhibitors Endowed with Antitumor Activity in Pancreatic Ductal Adenocarcinoma. Mar. Drugs 2023, 21, 288. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Zou, X.; Luan, P.; Liu, X.; Wang, N.; Wang, Q.; Guan, H.; Xu, Z. Direct Determination of Enzymes in Dried Blood Spots by High-Performance Liquid Chromatography–Mass Spectrometry (HPLC-MS) for the Screening of Antithrombotic Agents. Anal. Lett. 2022, 55, 2308–2324. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Guan, H.; Xu, Z. Development and Validation of a Liquid Chromatography–Tandem Mass Spectrometry Method for Screening Potential Citrate Lyase Inhibitors from a Library of Marine Compounds. Mar. Drugs 2024, 22, 245. https://doi.org/10.3390/md22060245

Wang J, Guan H, Xu Z. Development and Validation of a Liquid Chromatography–Tandem Mass Spectrometry Method for Screening Potential Citrate Lyase Inhibitors from a Library of Marine Compounds. Marine Drugs. 2024; 22(6):245. https://doi.org/10.3390/md22060245

Chicago/Turabian StyleWang, Jiahong, Huashi Guan, and Zhe Xu. 2024. "Development and Validation of a Liquid Chromatography–Tandem Mass Spectrometry Method for Screening Potential Citrate Lyase Inhibitors from a Library of Marine Compounds" Marine Drugs 22, no. 6: 245. https://doi.org/10.3390/md22060245

APA StyleWang, J., Guan, H., & Xu, Z. (2024). Development and Validation of a Liquid Chromatography–Tandem Mass Spectrometry Method for Screening Potential Citrate Lyase Inhibitors from a Library of Marine Compounds. Marine Drugs, 22(6), 245. https://doi.org/10.3390/md22060245