Abstract

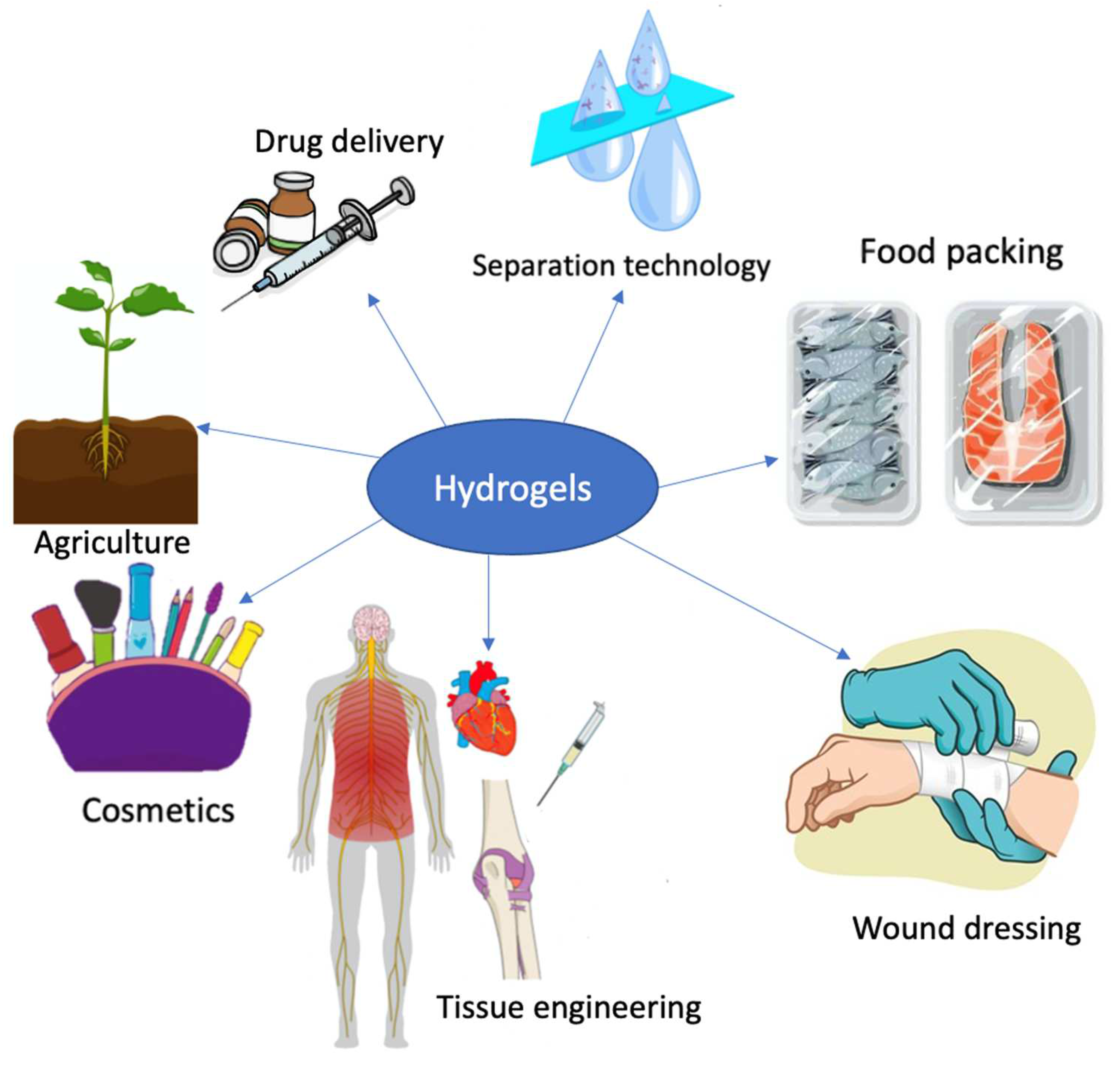

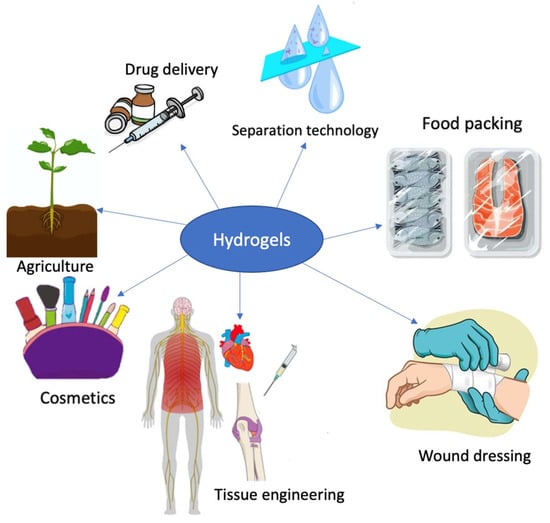

Hydrogels are three-dimensional crosslinked hydrophilic polymer networks with great potential in drug delivery, tissue engineering, wound dressing, agrochemicals application, food packaging, and cosmetics. However, conventional synthetic polymer hydrogels may be hazardous and have poor biocompatibility and biodegradability. Algal polysaccharides are abundant natural products with biocompatible and biodegradable properties. Polysaccharides and their derivatives also possess unique features such as physicochemical properties, hydrophilicity, mechanical strength, and tunable functionality. As such, algal polysaccharides have been widely exploited as building blocks in the fabrication of polysaccharide-based hydrogels through physical and/or chemical crosslinking. In this review, we discuss the extraction and characterization of polysaccharides derived from algae. This review focuses on recent advances in synthesis and applications of algal polysaccharides-based hydrogels. Additionally, we discuss the techno-economic analyses of chitosan and acrylic acid-based hydrogels, drawing attention to the importance of such analyses for hydrogels. Finally, the future prospects of algal polysaccharides-based hydrogels are outlined.

1. Introduction

Hydrogels are three-dimensional, crosslinked, hydrophilic polymeric networks capable of swelling in water and absorbing a considerable amount of water [1]. Chemical or physical crosslinks between the polymer chains prevent the polymeric networks from dissolving [2]. The concept of hydrogels was first put forward in 1894 when the term was used to describe a colloidal gel of inorganic salts [3]. In 1960, Wichterle and Lim published a landmark article in the scientific journal, Nature, in which synthetic poly(2-hydroxyethyl methacrylate) gels were designed as soft contact lenses [4]. These promising materials have been widely applied in the fields of biotechnology, including drug delivery [1,2], tissue engineering [5,6], wound dressing [7,8], agrochemicals application [9,10], separation [11,12], food packaging [13,14], and cosmetics and personal care products [15,16]. The hydrophilic polymer structures can be designed using physical and/or chemical crosslinking methods. Generally, hydrogels can be chemically crosslinked via crosslinker addition [17,18,19], photo- or radiation-initiated free radical polymerization [20,21,22], or enzyme-assisted reaction [23,24]. They can also be produced based on noncovalent interactions, such as electrostatic interaction, hydrogen bonding, van der Waals force, host-guest interaction, and hydrophobic interaction [25,26,27,28].

According to the source of materials, hydrogels can be divided into natural and synthetic hydrogels. Up to now, a variety of hydrogels with unique functions have been obtained from renewable natural polymers, among which, hydrogels derived from algal polysaccharides have attracted tremendous interest due to their outstanding biocompatibility and biodegradability. In recent decades, several polysaccharides—alginate, agarose, carrageenan, fucoidan, ulvan, laminarin, porphyrin, starch, and cellulose—have been extracted from marine seaweeds, including red algae [29,30,31,32], brown algae [33,34,35,36], and green algae [37,38]. As the research further develops, algal polysaccharides have been identified as important bioactive natural compounds with various well-documented benefits: anti-wrinkle, UV protection, antioxidant, immunomodulatory, anti-inflammatory, antibacterial and antiviral, and antiallergic qualities [39,40].

Algae are regarded as the most abundant and promising natural resources for the next generation of biorefineries. With the increasing growth of the algae industry and the development of algae biorefinery, the need for high-value applications of algae-extracted biopolymers is increasing. In this review, we present commonly used methods for the extraction and characterization of algal polysaccharides and further discuss the gelation mechanism and hydrogel preparation methods, as well as hydrogel characterization methods. This review also extends to discussing recent advances in promising application potentials of algal polysaccharides-based hydrogels. Additionally, techno-economic analyses of polysaccharides-based hydrogels (e.g., chitosan hydrogels) and a hydrogel based on acrylic acid, as well as their limitations, are discussed. Finally, we outline the prospect of algal polysaccharides-based hydrogels with respect to extraction, synthesis, and applications perspectives.

2. Algae-Based Polysaccharides Extraction

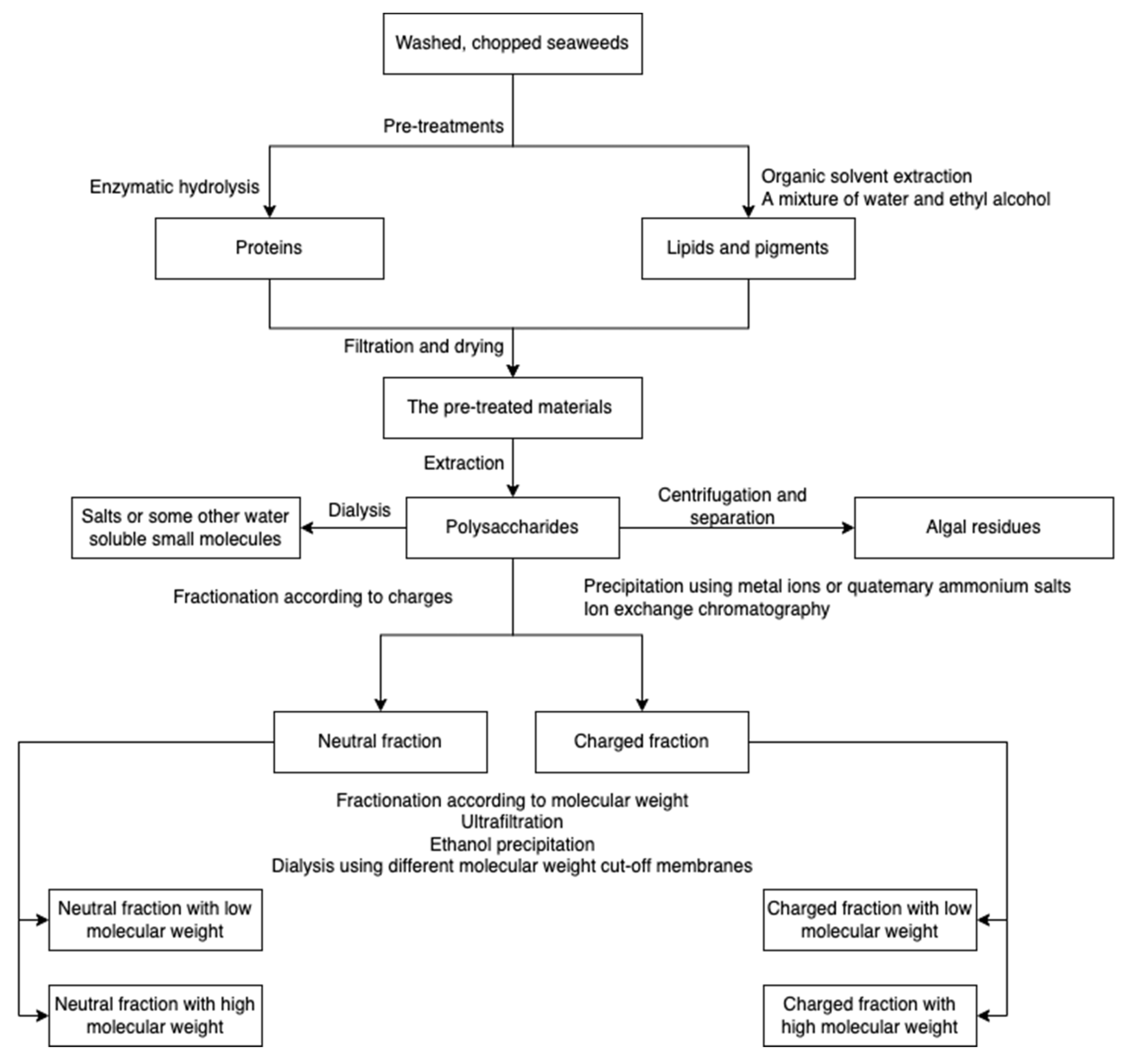

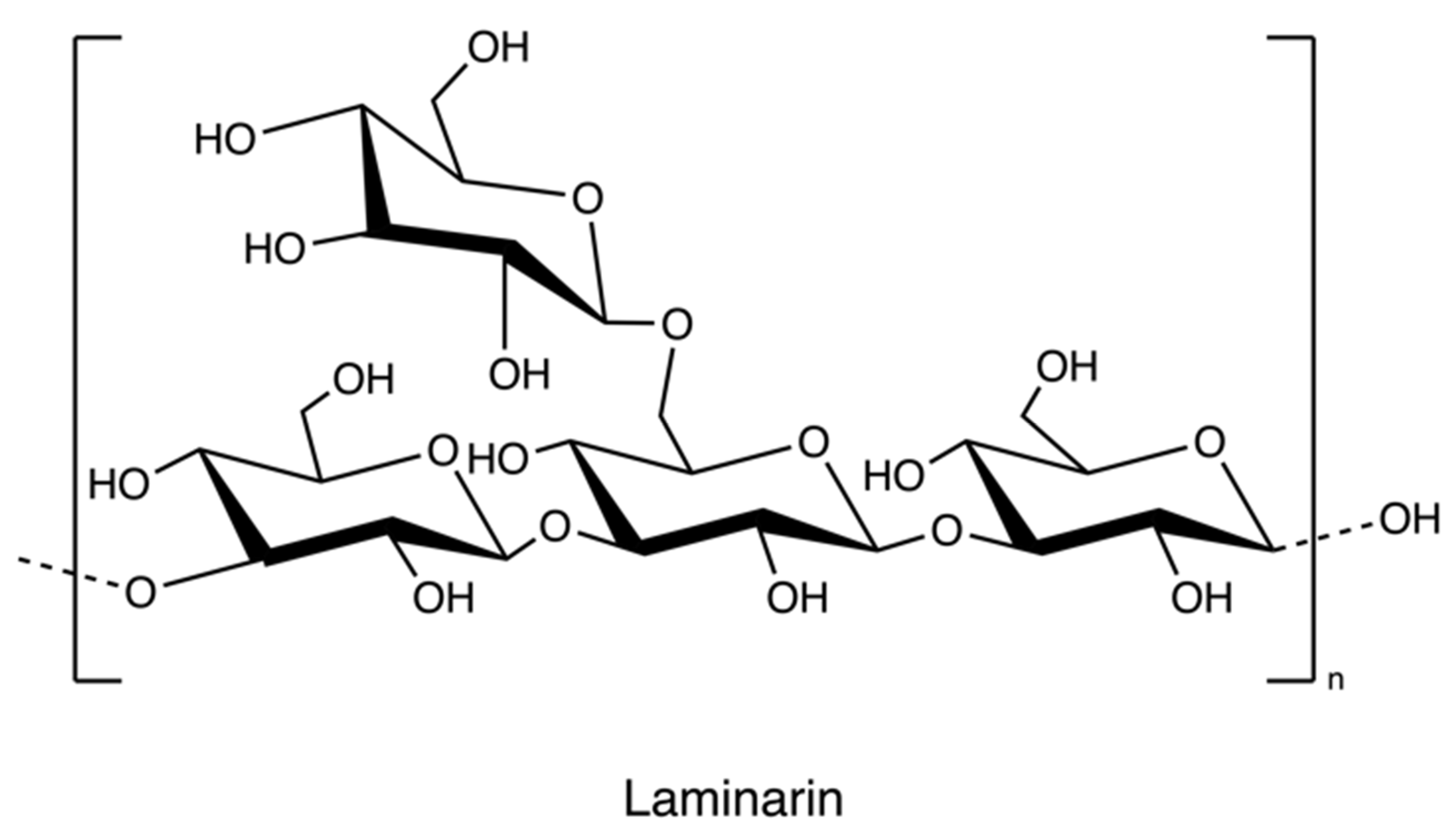

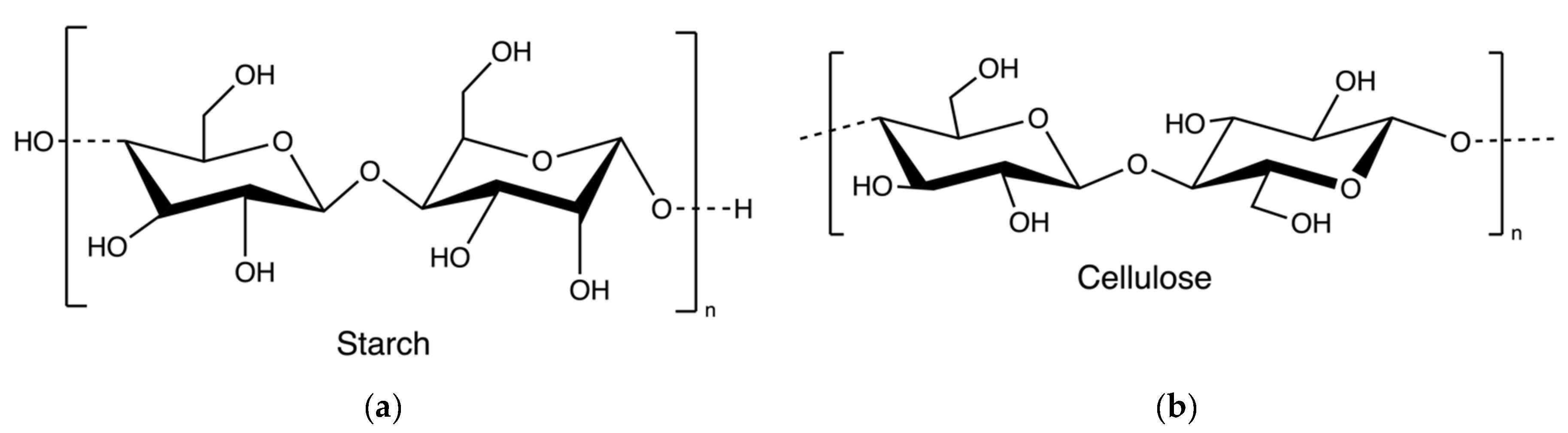

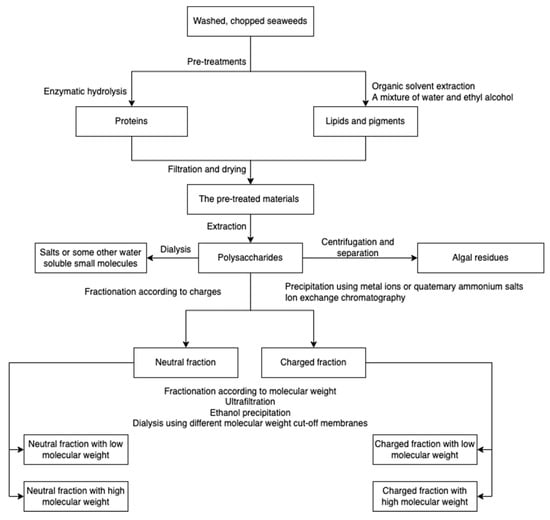

Major algal polysaccharides produced at the industrial scale include agar, alginate, carrageenan, starch, and cellulose, among which, alginate, carrageenan, and agarose have been commercially exploited from seaweeds [41]. However, the production processes vary depending on the polysaccharide type. For example, highly branched laminarin can be extracted in both cold and hot acidic conditions, while ulvan and fucoidan can be extracted in only hot aqueous environments [42,43,44,45]. The composition and structure of polysaccharides vary depending on the species, collection sites, harvesting season, and water quality [46,47,48,49,50]. The conditions of extraction and purification processes influence the polysaccharide properties [51,52] and the resulting polysaccharide-derived hydrogels. However, the effect of polysaccharide structure and composition on hydrogel properties has not been widely studied due to the fact that for the synthesis of hydrogel, purchased algal polysaccharides are often used rather than obtaining the polysaccharides from extraction and purification [7,53,54]. A schematic overview for algal polysaccharide extraction is presented in Figure 1. Prior to polysaccharides extraction, seaweeds are usually pre-treated using organic solvents and enzymatic hydrolysis to remove non-targets/impurities. The resulting raw polysaccharides are further purified with dialysis, bleaching, etc. [34,55].

Figure 1.

A schematic overview of algal polysaccharide extraction, purification, and fractionation.

2.1. Alginate

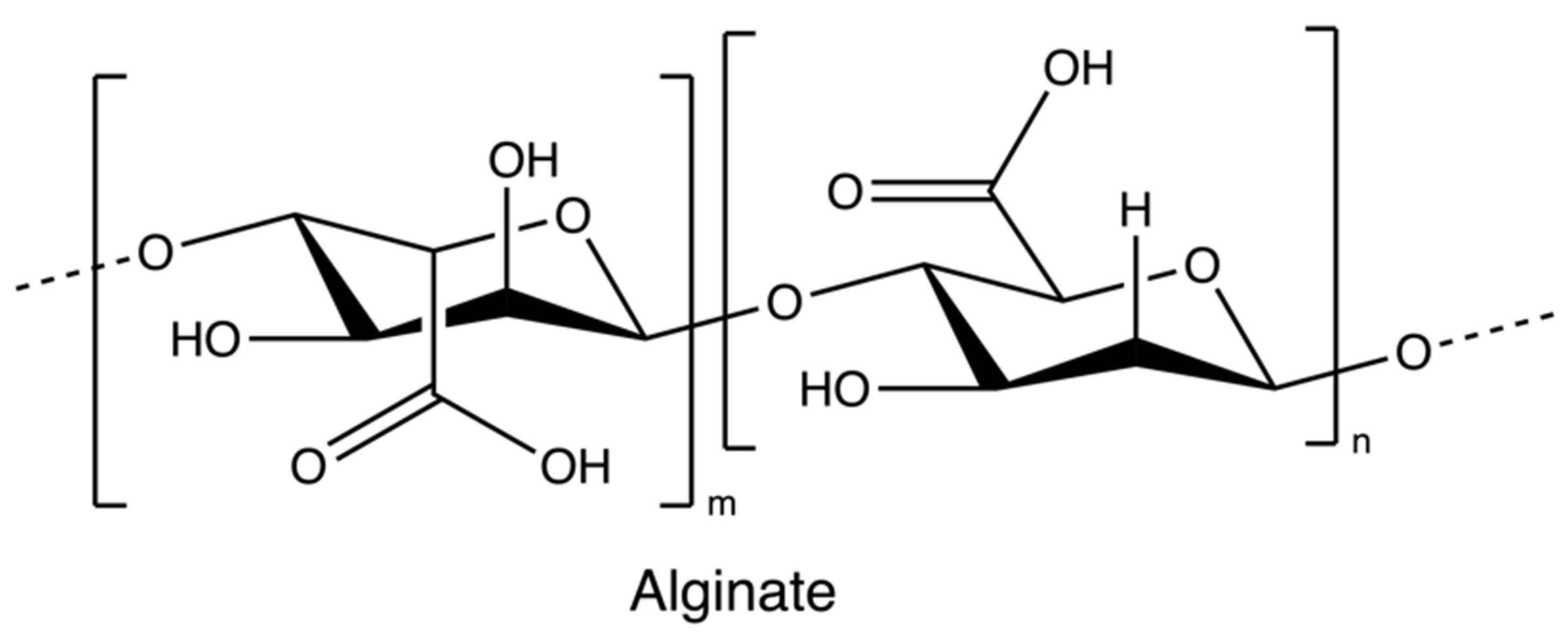

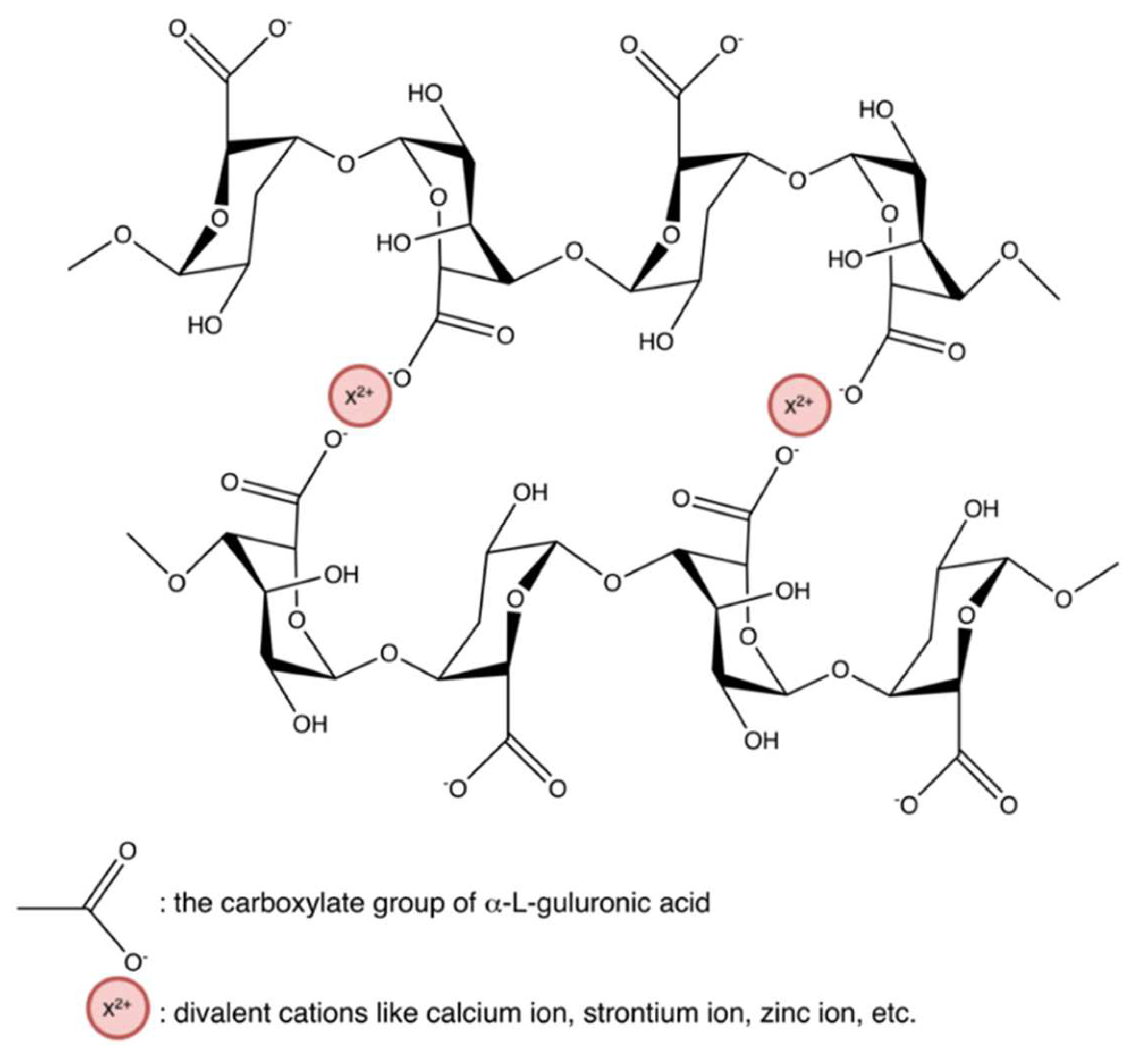

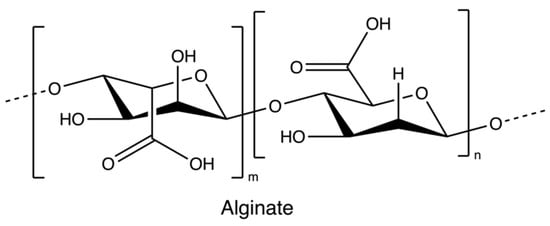

Alginate (Figure 2) is an anionic polymer, first discovered in the 1880s, and industrial production started in 1929 [56]. It is mainly isolated from brown seaweed species, such as Ascophyllum nodosum, Laminaria japonica, Laminaria hyperborean, Ecklonia maxima, Laminaria digitata, and Macrocystis pyrifera. Its molecular structure comprises the copolymeric blocks of β-d-mannuronic acid and α-L-guluronic acid. Alginates usually present in a salt or acid form; the salt form plays a major role in the cell wall formation process of brown seaweed species. The acid form is known as alginic acid, which is present in the intercellular matrix material of brown algae as raw gels. The gels of alginate comprise salts of alginate with metal cations found in seawater, such as sodium ions [56,57].

Figure 2.

The chemical structure of Alginate.

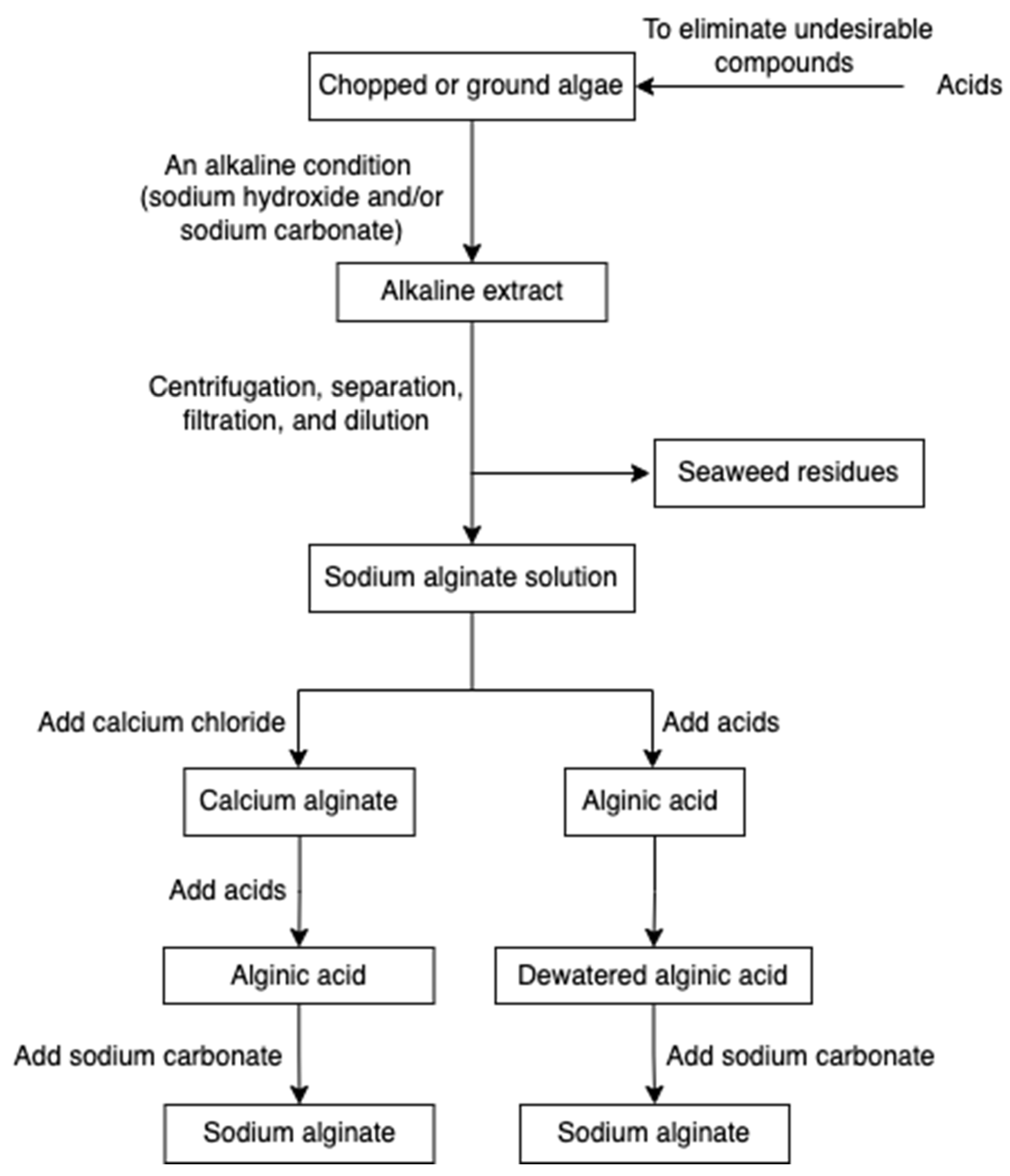

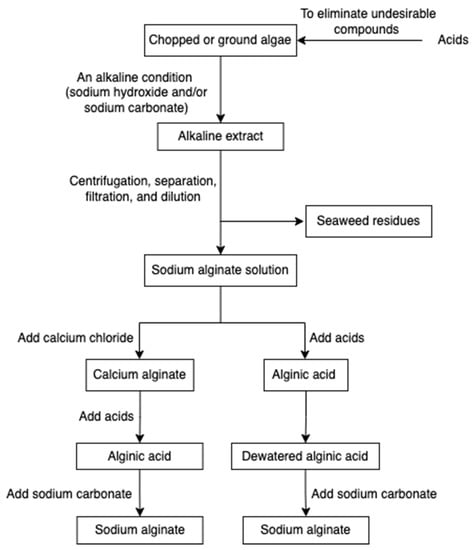

The alginate extraction process involves several steps (Figure 3) [36,57,58,59]. Chopped or ground algae materials are treated with acids to eliminate undesirable compounds through the proton exchanging reaction. Subsequently, an alkaline condition (sodium hydroxide and/or sodium carbonate) is applied to neutralize the alginic acid, and hence insoluble alginic acids are converted into a sodium alginate solution. To remove seaweed residues, centrifugation followed by separation, filtration, and dilution are employed. The filtrated extract is then directly acidified to form alginic acid or undergoes an intermediate step of gelling as calcium alginate before conversion. The alginic acid and calcium alginate can also be further converted into sodium alginate.

Figure 3.

The scheme of alginate extraction.

Some innovative methods are also employed to extract alginate from brown seaweeds, such as the subcritical water hydrolysis extraction [33,60,61] and the microwave-assisted extraction [62,63], but those methods still remain in the lab stage.

2.2. Carrageenan

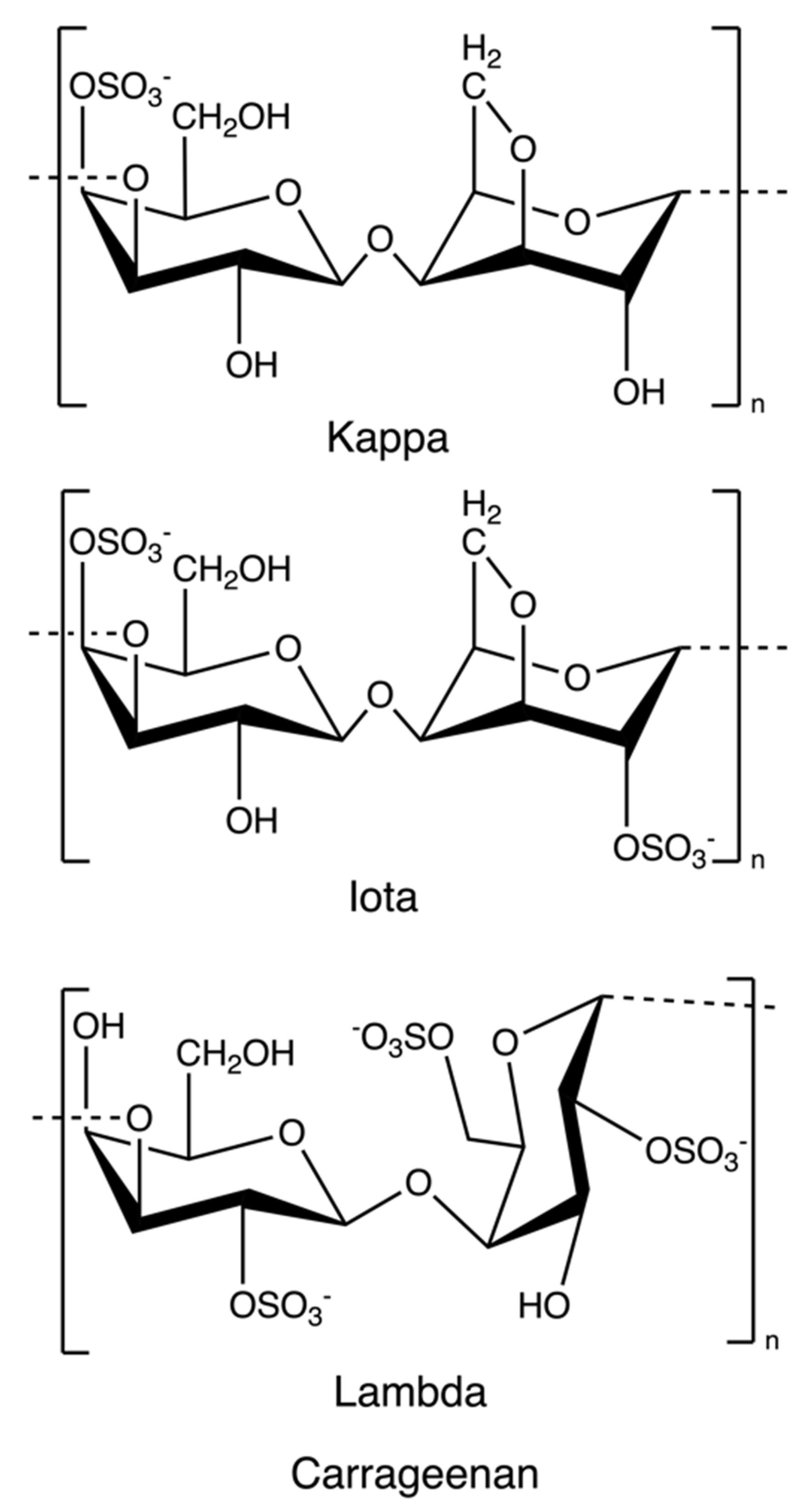

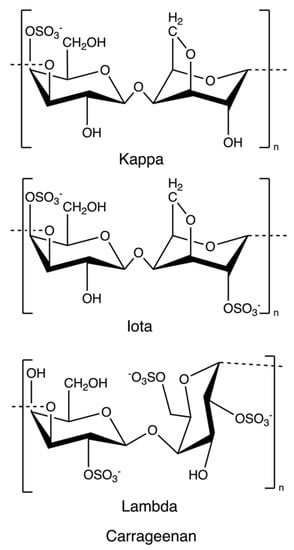

Carrageenan is an anionic, sulphated polysaccharide consisting of alternating long linear chains of (1 → 3)-β-d-galactose and (1 → 4)-3, 6-anhydro-α-d-galactose (3, 6-AG) or (1 → 4)-α-d-galactose with ester sulphates (15–40%) [41]. These novel renewable natural polymers originate from the marine red algae family. They can be sorted into six basic forms depending on their source, solubility, and sulphate content: kappa, iota, lambda, mu, nu, and theta; among which, kappa, iota, and lambda (Figure 4) are commonly used as materials for hydrogel preparation due to their viscoelastic and gelling properties [64]. Currently, most carrageenans are extracted from Kappaphycus alvarezii and Eucheuma denticulatum [41], but some of them are still isolated from Chondrus crispus [65]. Original carrageenan, also known as refined carrageenan and filtered carrageenan, is used as a material for hydrogel production.

Figure 4.

The chemical structure of kappa-, iota, and lambda-carrageenan.

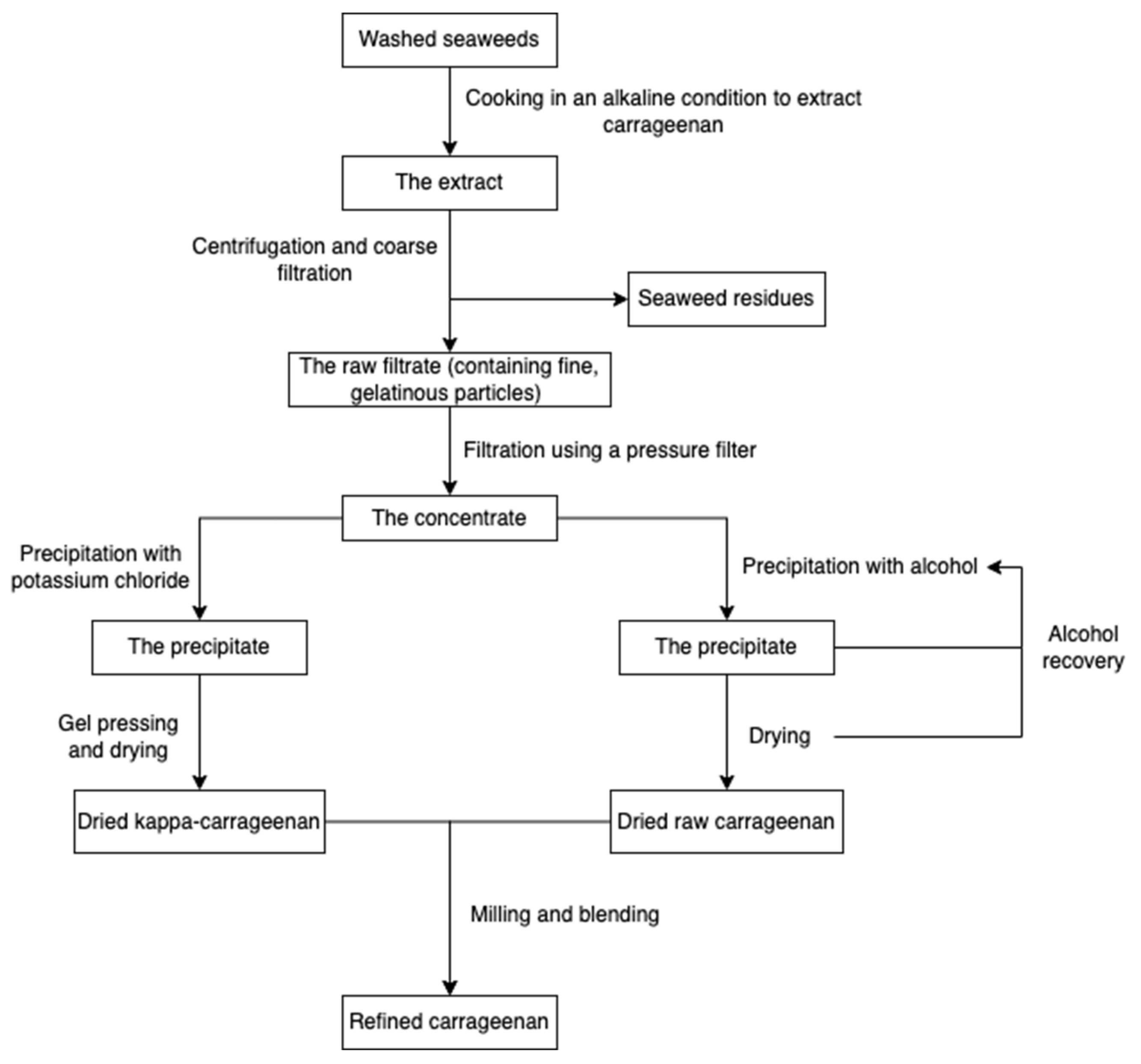

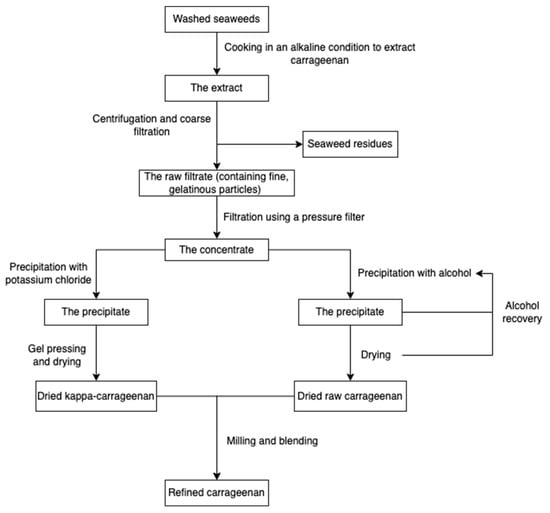

The production procedure (Figure 5) started with cooking raw red seaweeds in alkaline conditions (e.g., sodium hydroxide) to increase the 3, 6-AG content and then extract carrageenans. After extraction, seaweed residues are filtered to obtain a concentrated polysaccharide solution. The polysaccharide solution is precipitated with isopropanol until acquiring fibrous coagulum, followed by separation, pressing, washing, drying, and milling. The alcohol-precipitation method is suitable for all carrageenans, while the gel method involving potassium chloride is usually used for the kappa-carrageenan extraction [55,65]. Carrageenans can also be extracted using eco-friendly technologies, such as microwave-assisted extraction [66,67] and the deep eutectic solvents method [68].

Figure 5.

The scheme of carrageenan extraction.

2.3. Agarose

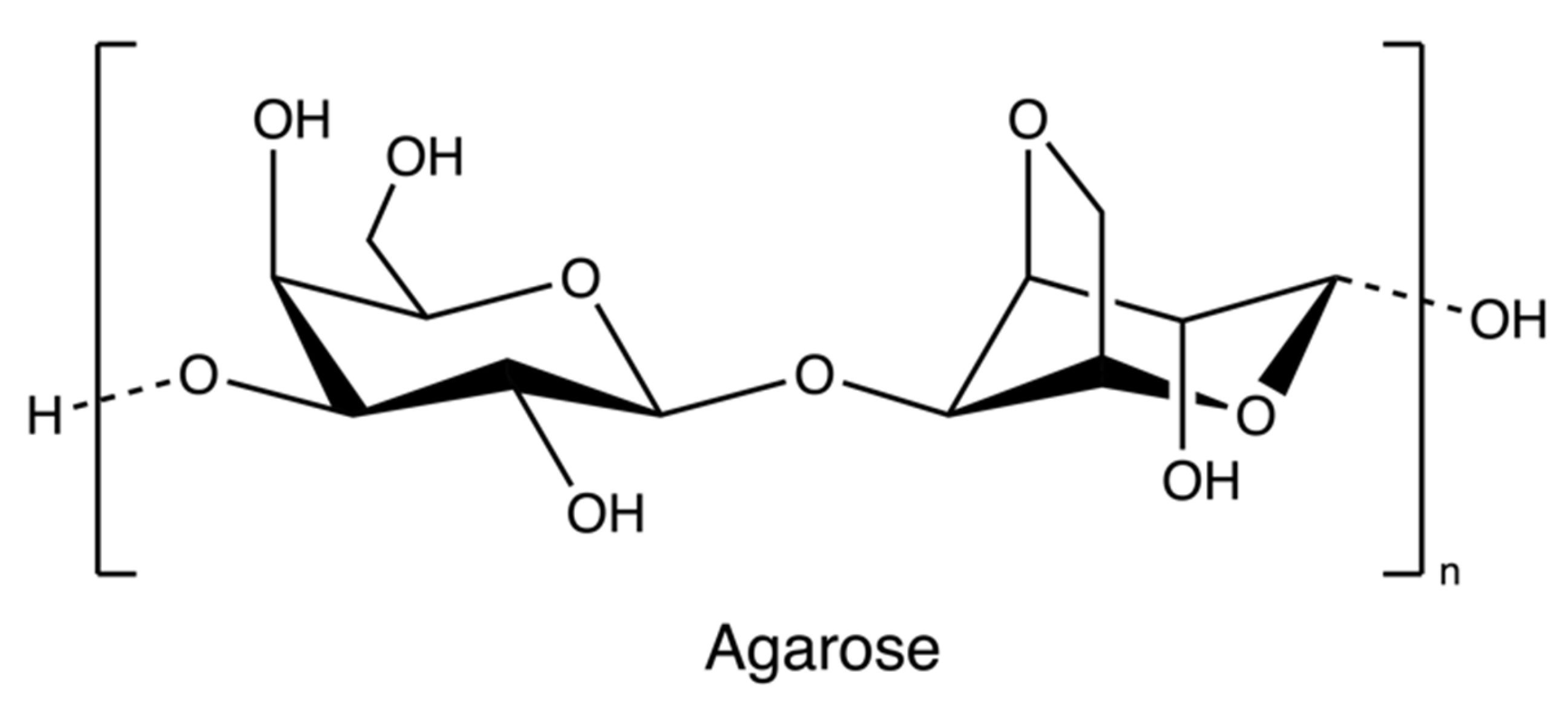

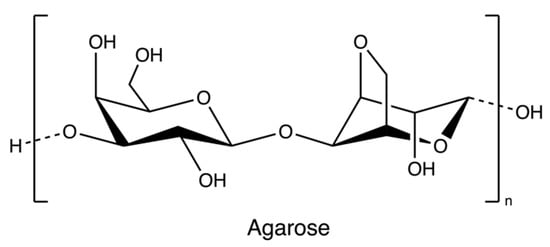

Agarose (Figure 6), a marine-based linear polysaccharide, is naturally derived from red algae, such as species of Gelidium and Gracilaria. Its gelling component, agarose, is an alternating copolymer of (1 → 3)-β-d-galactose and (1 → 4)-3,6-anhydro-α-L-galactose residues [69].

Figure 6.

The chemical structure of agarose.

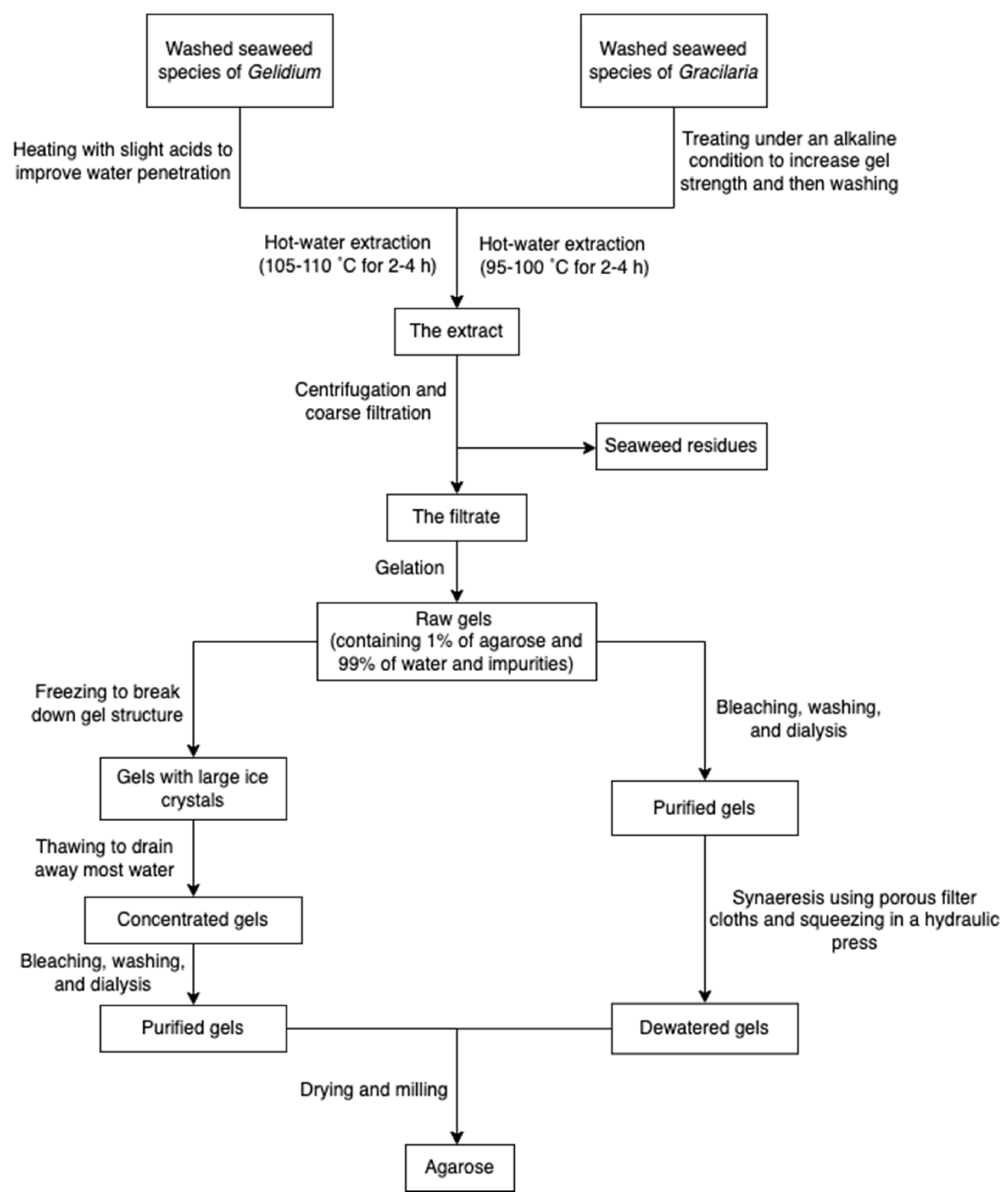

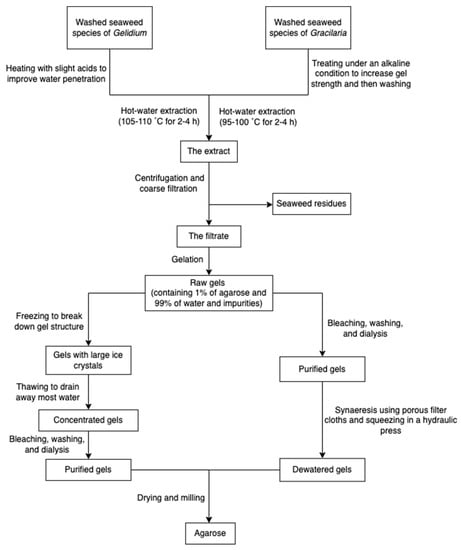

The process of production of agarose varies from species. Species of Gelidium are usually pre-treated under heat with slight acids to improve water penetration, while species of Gracilaria are treated with alkali to increase the 3,6-AG content. The extraction processes (Figure 7) all rely on hot water extraction. After hot water extraction, the extract is filtered to remove seaweed residues. The agar filtrate is sequentially cooled to form a gel. The resulting gel may be treated with bleach to discolor it, washed to remove the bleach, and soaked in water to remove salts through osmosis. Because the gel primarily consists of water and impurities (about 99%), it is usually dried through the freezing/thawing process and pressing. However, compared with synaeresis using a porous filter and a hydraulic press, the freeze-thaw process is relatively expensive due to capital cost and energy consumption. Dewatered agar gel is further dried and milled [55]. Furthermore, to obtain pure agar, agaropectin can be removed through precipitation with poly(ethylene glycol) [70]. Researchers also used ionic liquids (solvents that contain only ions and have a melting point below 100 °C, such as choline acetate) as a medium to extract agarose from red algae [29].

Figure 7.

The scheme of agarose extraction.

2.4. Fucoidan

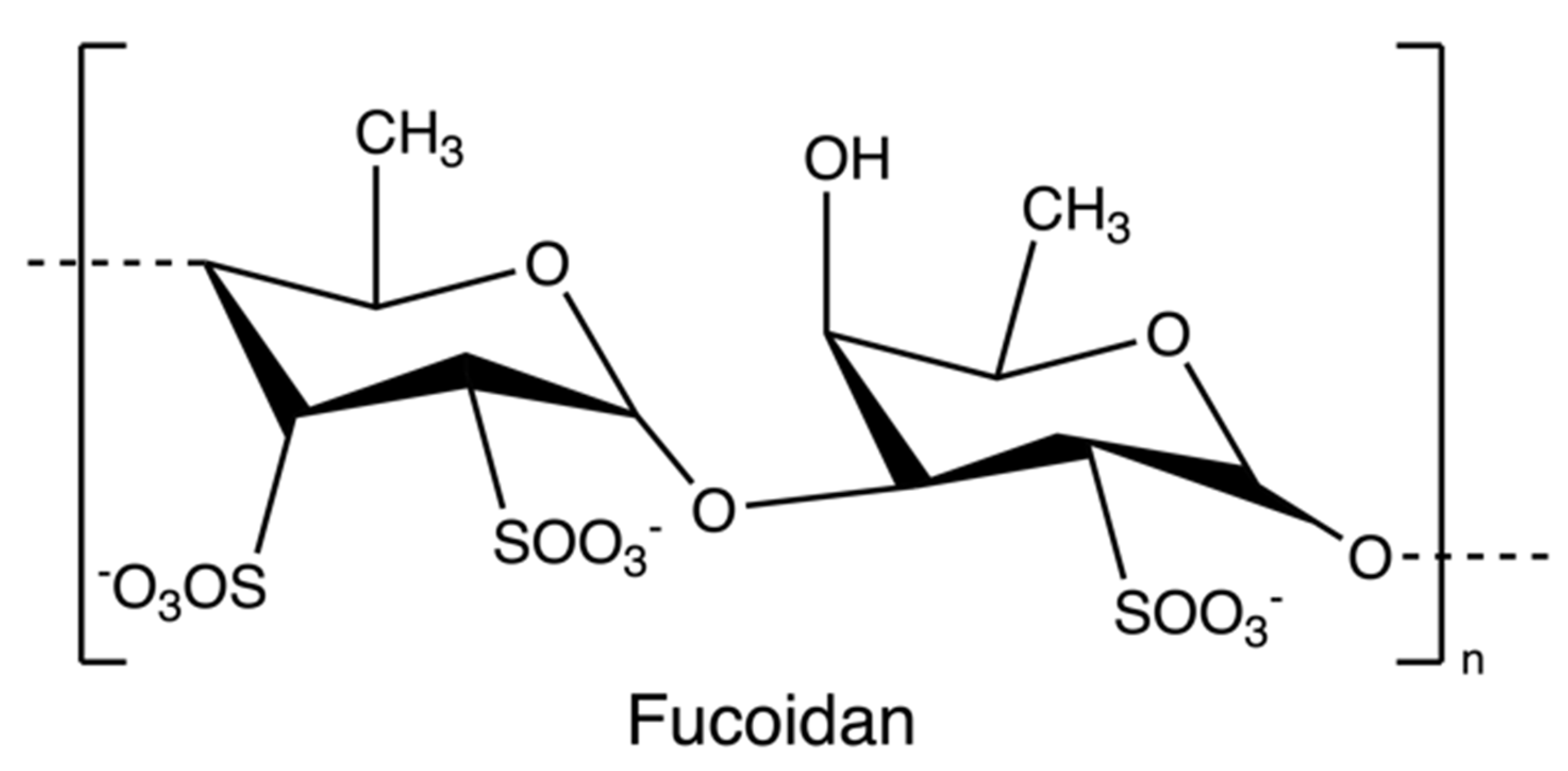

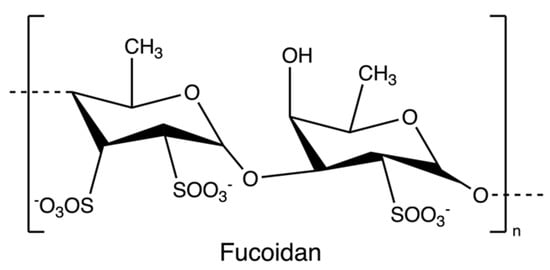

Fucoidans (Figure 8) are sulphated polysaccharides from the cell wall matrix of brown algae, which are comprised of α-1,3 and α-1,4 linked units of fucose with sulphate esters at positions 2, 3, and/or 4. However, the structure and sulfation pattern of the sugar backbone of these polysaccharides are species-specific [71].

Figure 8.

The chemical structure of fucoidan.

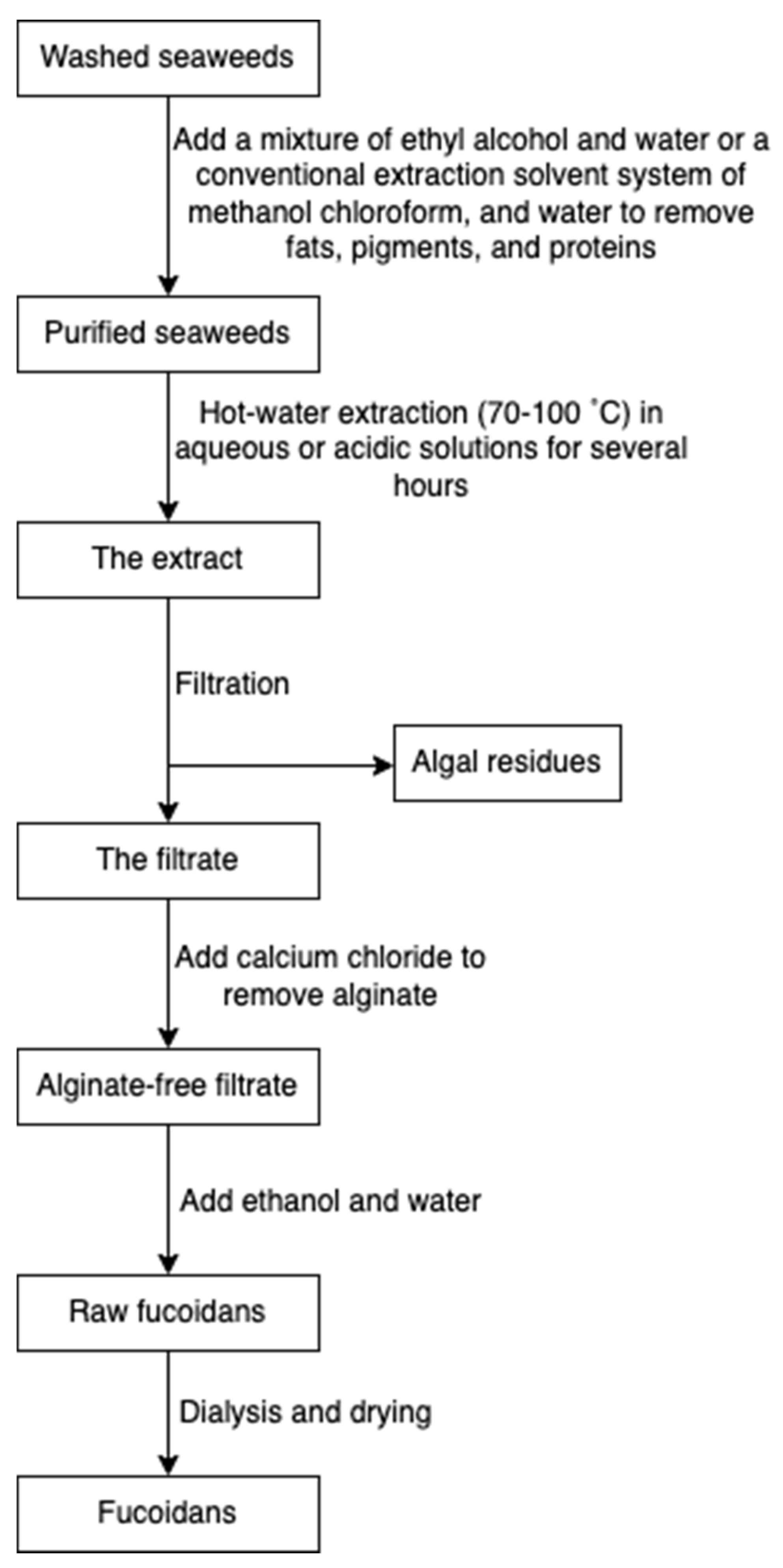

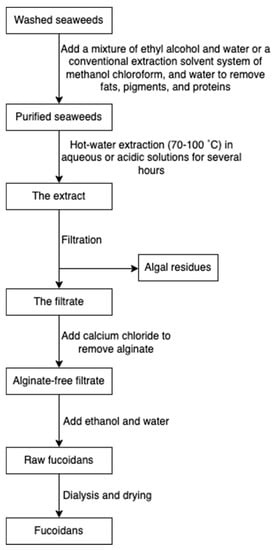

Fucoidan is commonly extracted by cooking algal raw materials in hot aqueous or acidic solutions for several hours at 70 to 100 °C [45]. Prior to hot water extraction, fats, pigments, and proteins are firstly extracted with a mixture of ethyl alcohol and water or a conventional extraction solvent system of methanol, chloroform, and water. The pre-treatment step prevents the coextraction of other algal compounds [71]. Following hot water extraction, algae residues are filtered, and subsequently, calcium chloride is added to remove alginate. The mixture is re-extracted with ethanol and water to obtain fucoidans, followed by dialysis and drying (Figure 9) [34]. Some novel extraction procedures, such as microwave-assisted extraction [72] and enzyme-assisted extraction [73], have also been reported for fucoidan extraction.

Figure 9.

The scheme of fucoidan extraction.

2.5. Ulvan

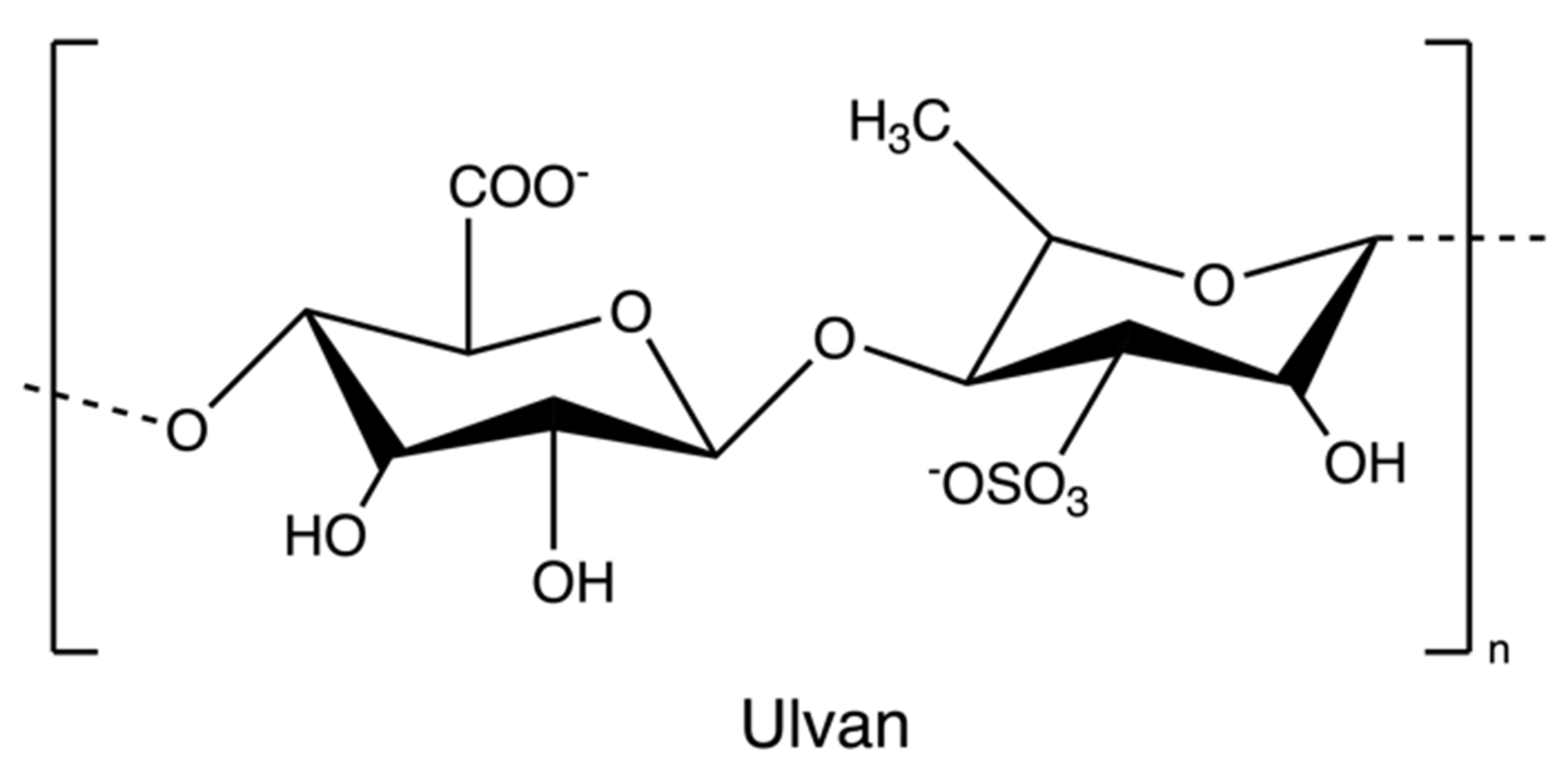

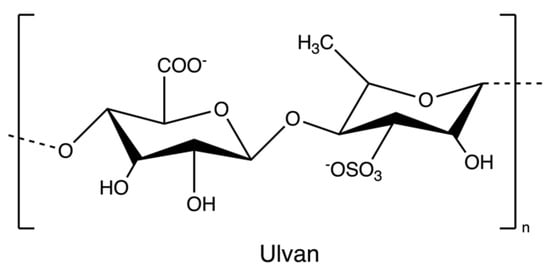

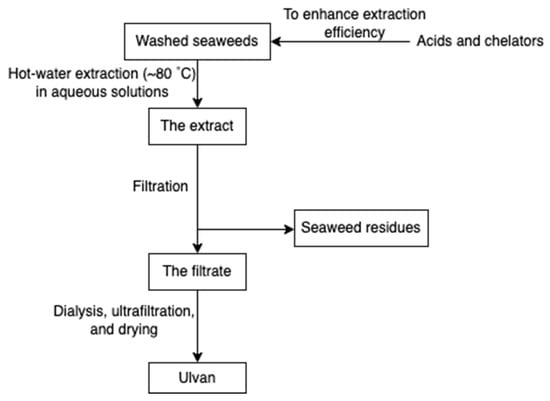

Ulvan (Figure 10) is a gelling sulphated polysaccharide from the species of green algae Ulva. It comprises sulphated rhamnose, uronic acids (glucuronic acid and iduronic acid), and xylose. The extraction yields and product quality are highly associated with the extraction and purification processes, pre-treatment, biomass sources, and storage [44]. Similarly, the solubility of ulvan in aqueous solutions can be improved by extraction at high temperatures over 80 °C but lower than the boiling point of the water (avoiding degradation) [43,44]. However, hot water extraction may result in low extraction yields due to the interaction between ulvan and algal cell wall components [37]. Therefore, chelators and acids are employed to overcome the structural integrity of the plant cell wall, hence increasing the extraction efficiency of ulvan. After extraction, dialysis and ultrafiltration are used to remove excess salts and small molecules in the ulvan extracts (Figure 11) [44]. Microwave-assisted extraction is an alternative to the conventional extraction of ulvan [43].

Figure 10.

The chemical structure of ulvan.

Figure 11.

The scheme of ulvan extraction.

2.6. Laminarin

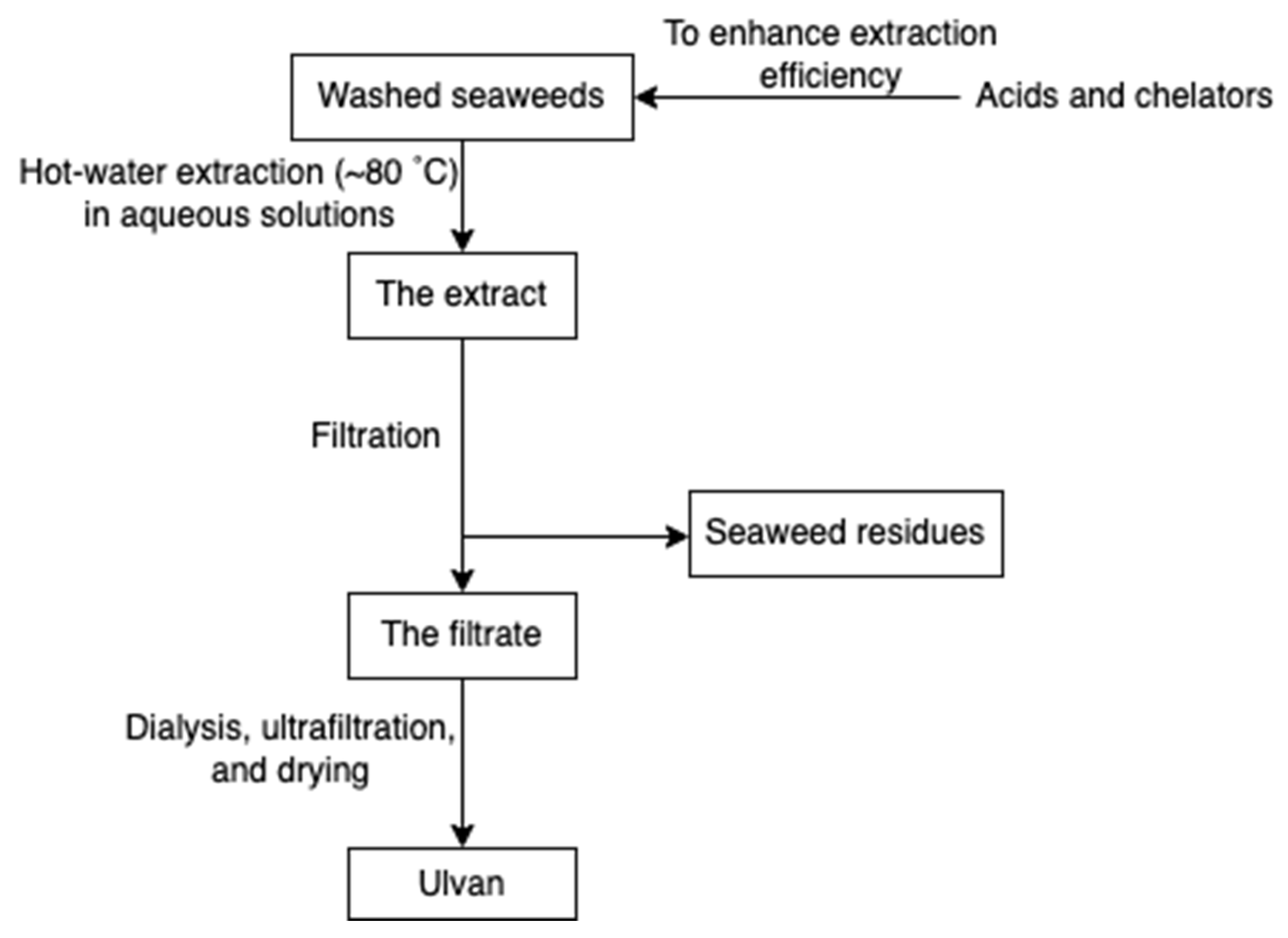

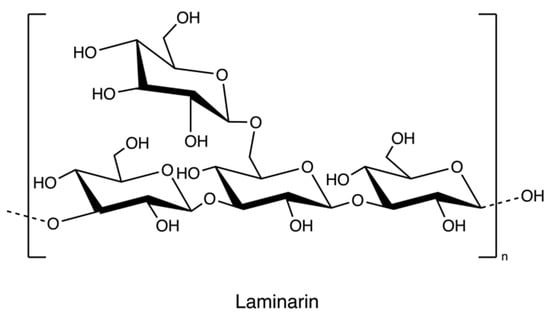

Laminarin (Figure 12), a storage polysaccharide, is isolated from brown algae Laminaria and Saccharina species. It is a class of low molecular weight β-glucans. The structure includes (1,3)-β-d-glucopyranose residues with some 6-O-branching in the main chain and some β-(1,6)-intrachain links. Notably, it has been reported that laminarin content is up to 35% of brown algae on a dry weight basis [74].

Figure 12.

The chemical structure of laminarin.

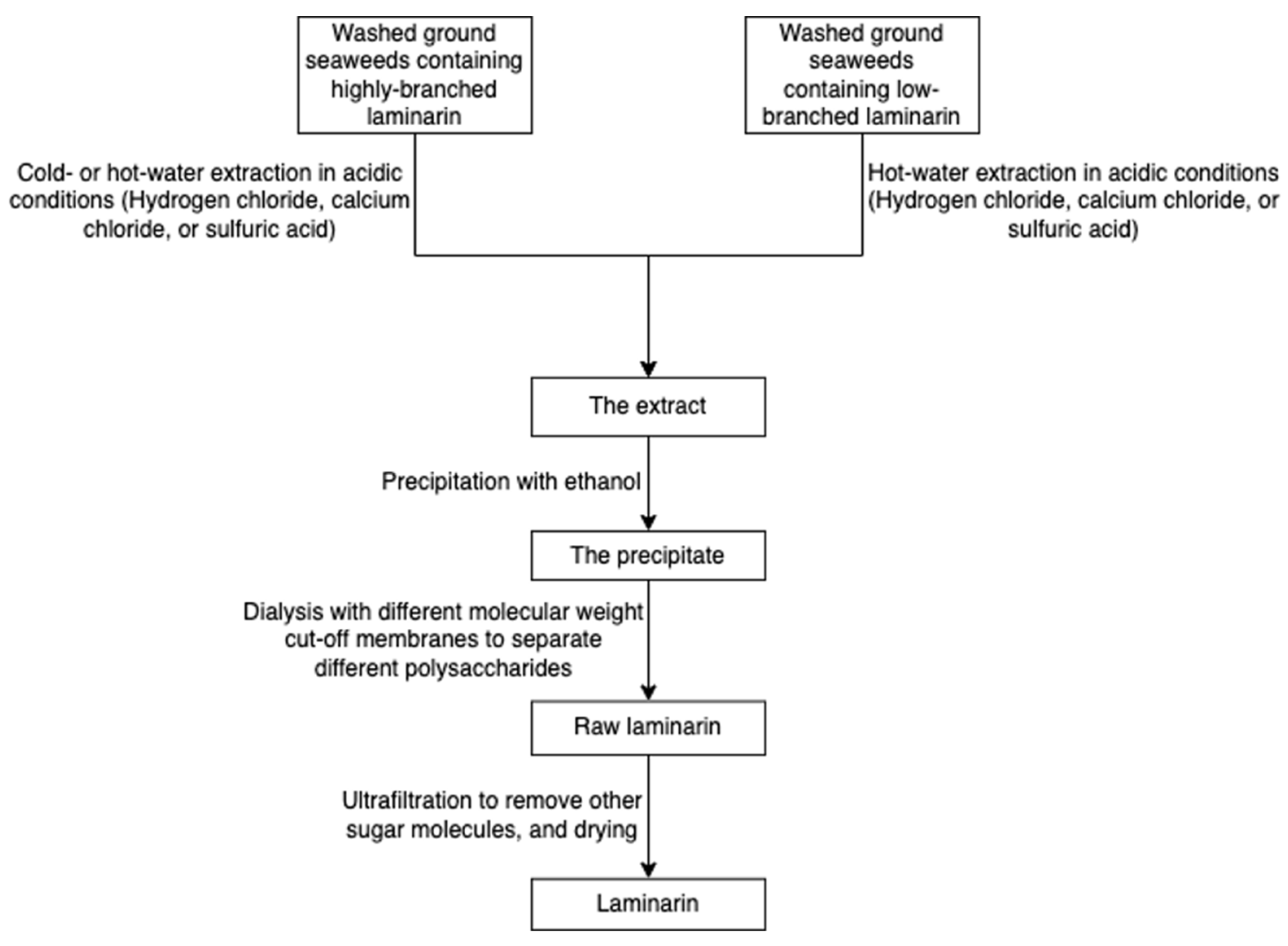

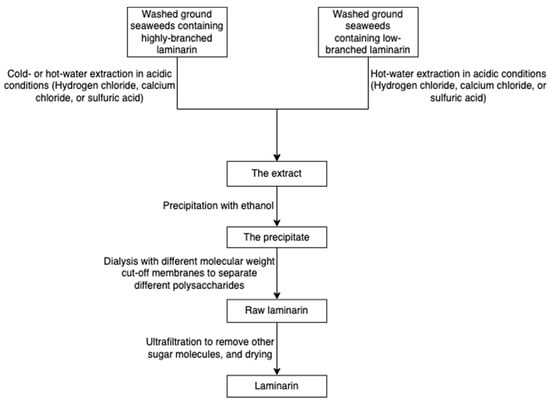

The solubility of laminarin depends on the level of branching. Highly branched laminarin is soluble in both cold water and hot water, while laminarin with a low branching level is soluble only in hot water [42]. In contrast to other gelling polysaccharides such as alginate and agarose, laminarin does not have thickening and gelling properties [75]. The general process of laminarin extraction at the lab level incorporates grinding, precipitation in an acid or basic medium, ultrafiltration, and dialysis (Figure 13) [76]. Because the molecular weight of laminarin is relatively lower than other polysaccharides in seaweeds, researchers employed dialysis coupled with molecular weight selection membranes to separate different polysaccharides [77]. A greener technique, ultrasound-assisted extraction, has been used to recover laminarin from Irish brown seaweeds [35].

Figure 13.

The scheme of laminarin extraction.

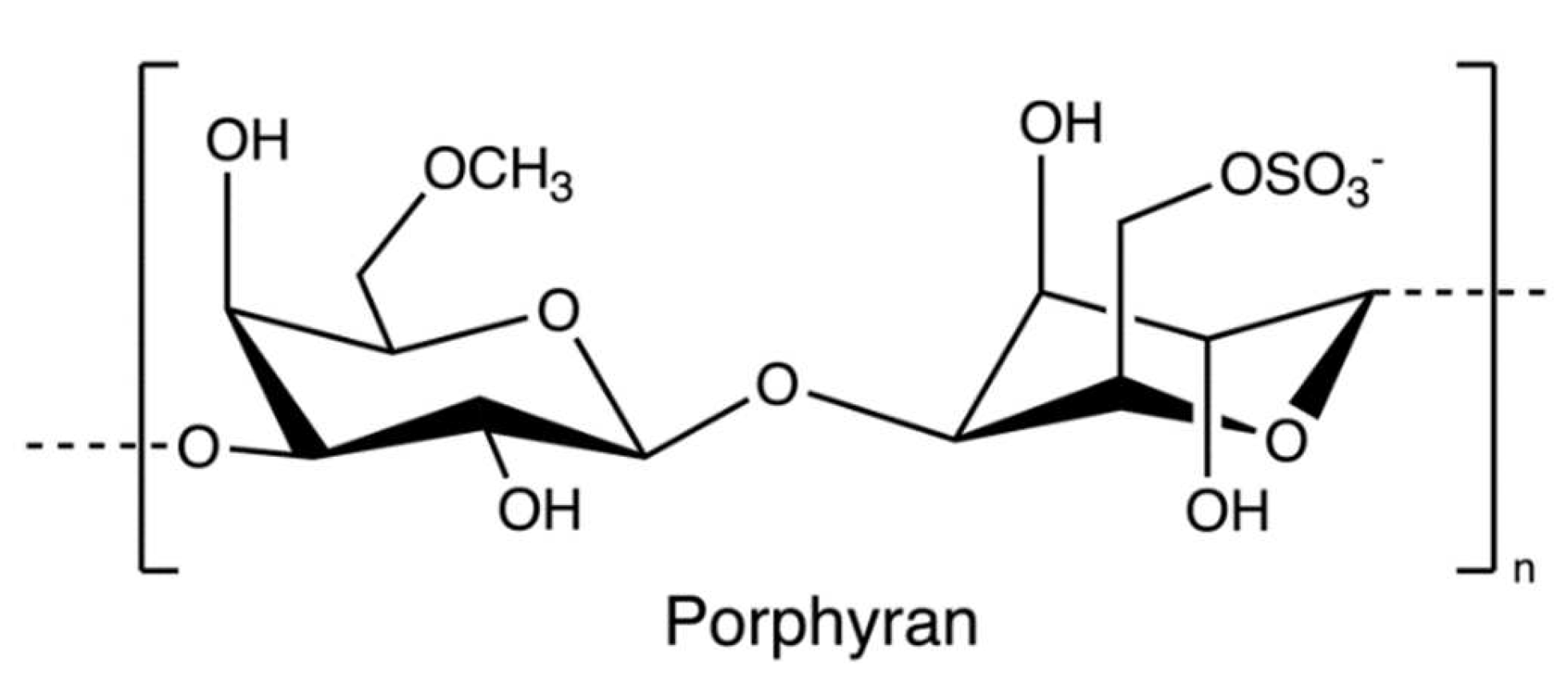

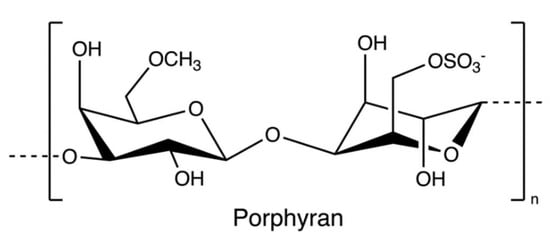

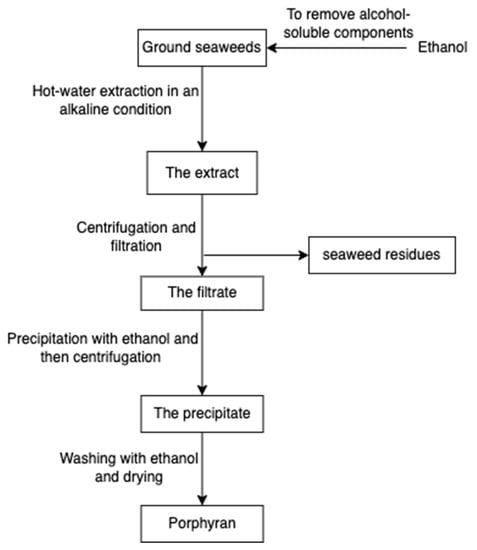

2.7. Porphyran

Porphyran (Figure 14), a sulphated polysaccharide from the red algae of Porphyra yezoensis, contains residues of d-galactose, L-galactose, 3, 6-anhydro-l-galactose, 6-O-methyl-d-galactose, and ester sulphate. The structure of porphyrin is similar to that of carrageenan and agarose, so the extraction process is comparable (Figure 15); for example, pre-treatment with alkali (e.g., sodium hydroxide) can increase 3, 6-AG content enhancing the gelation property [78]. Furthermore, ethanol is added to remove alcohol-soluble components in the pre-treatment [79].

Figure 14.

The chemical structure of porphyran.

Figure 15.

The scheme of porphyran extraction.

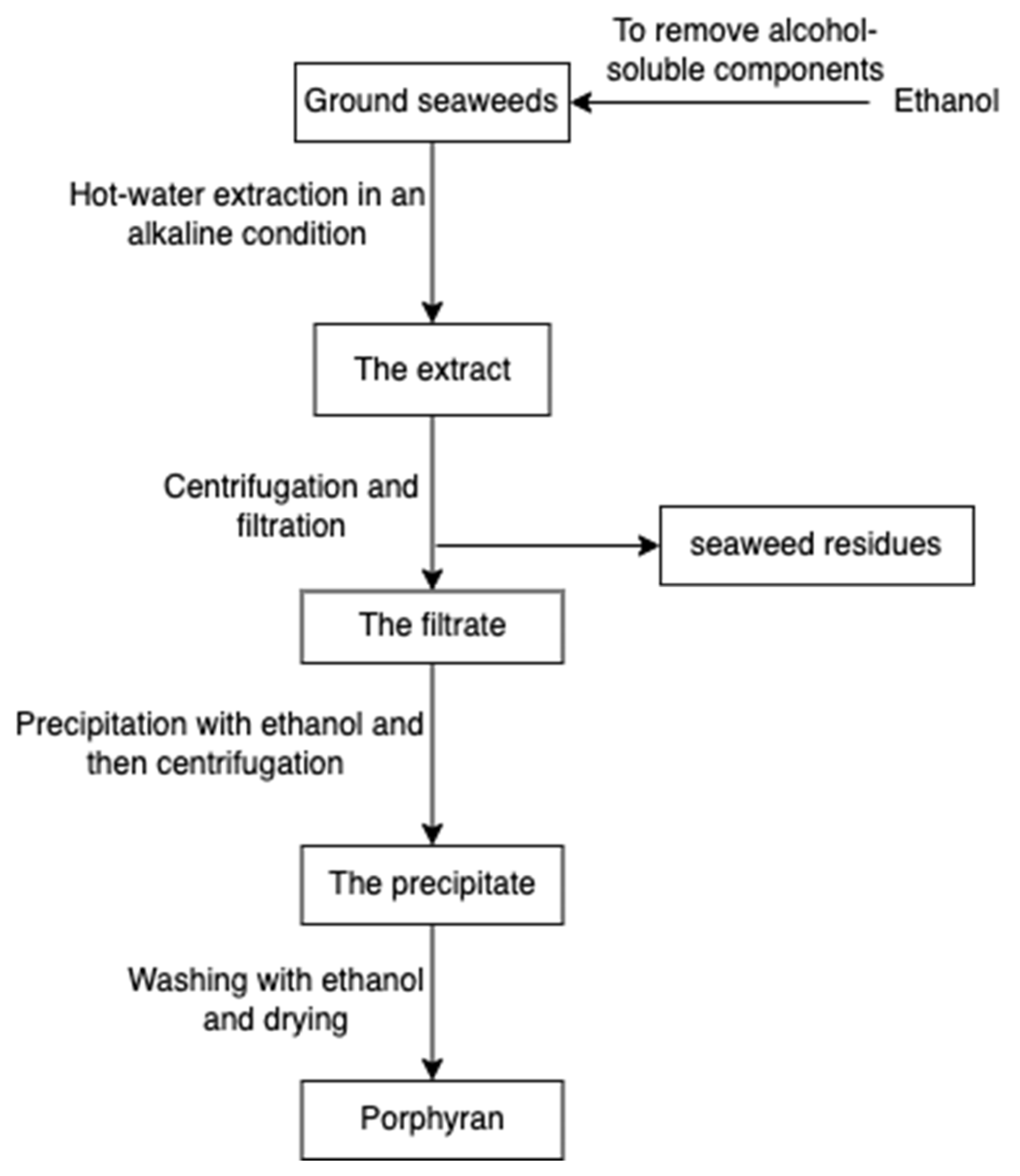

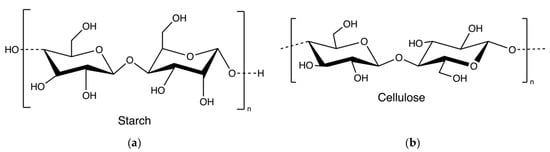

2.8. Starch and Cellulose

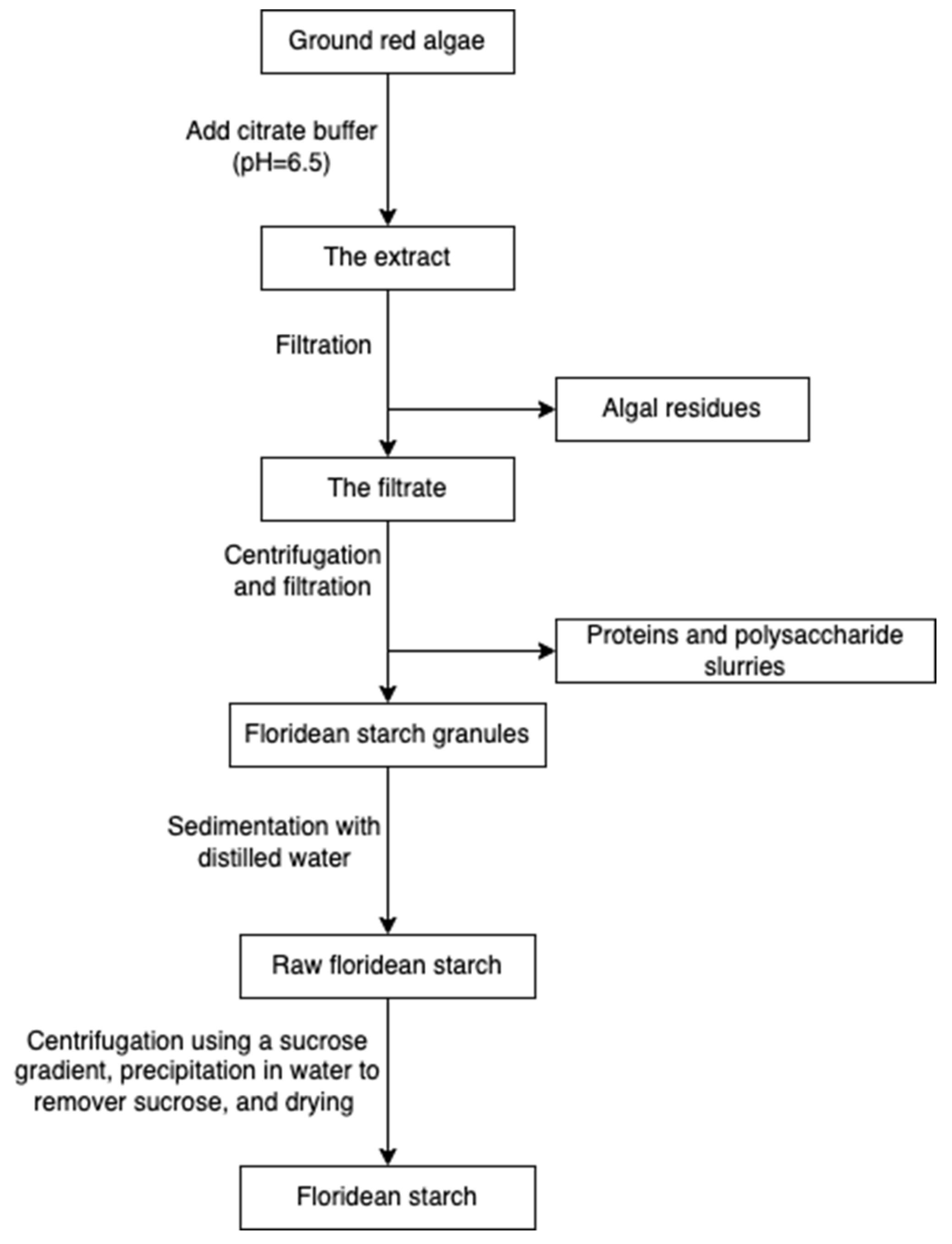

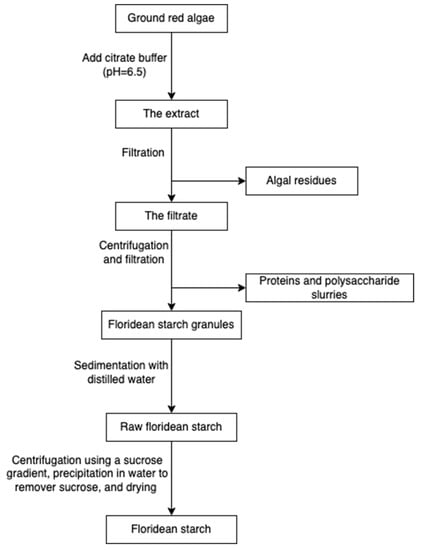

Starch and cellulose (Figure 16) are two common polysaccharides from plants, while they can also be found in algae. Floridean starch, isolated from red algae class Florideophyceae, is an α-1,4-glucosidic linked glucose homopolymer with α-1,6-branches functioning as carbon and energy reserve in the cells. Over 80% of the cell volume of red algae is filled with floridean starch. The extraction process involves citrate buffer treatment, filtration and separation, purification by sedimentation, centrifugation using a sucrose gradient, and precipitation in water (Figure 17) [30].

Figure 16.

The chemical structure of starch (a) and cellulose (b).

Figure 17.

The scheme of starch extraction.

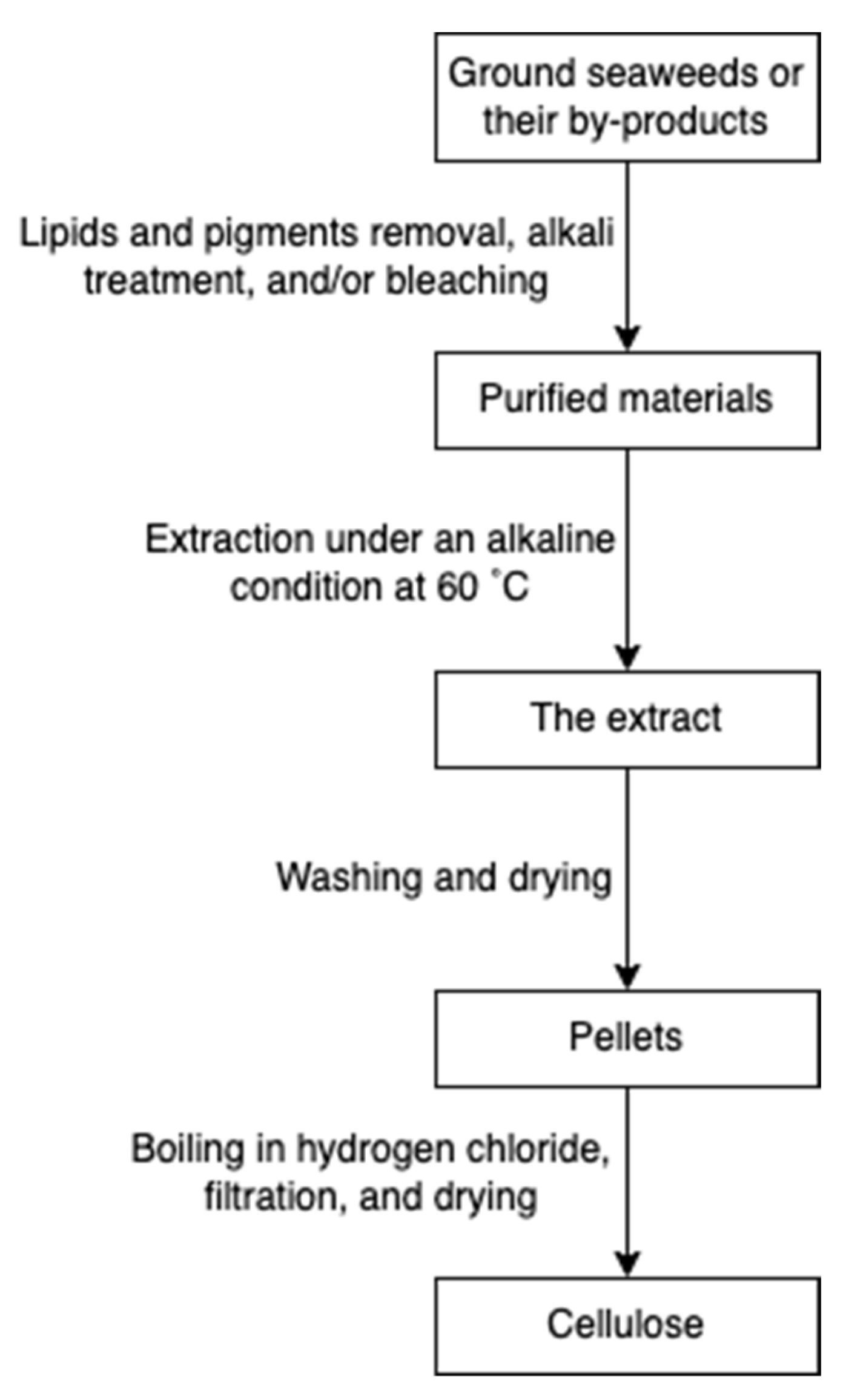

Cellulose is widely spread in green algae [38], brown algae [80], and red algae [31]. Particularly, it can be extracted from the by-products of the industrial extraction processes of algal polysaccharides [31,81]. To remove non-target compounds, the cellulose-rich wastes from algae are purified through lipids and pigments removal, alkali treatment, and/or bleaching steps (Figure 18). The purified materials are extracted with sodium hydroxide at 60 °C overnight [82]. Additionally, hydrochloric acid treatments can be added to increase the purity [81]. The purified cellulose can be further processed into hydrogel-forming derivates, such as cellulose nanofibers or nanocrystals [65].

Figure 18.

The scheme of cellulose extraction.

3. Characterization of Algal Polysaccharides

Unlike synthetic polymers, which are prepared by a bottom-up approach (from monomers to polymers), natural polymers, such as polysaccharides from algae, are obtained through a top-down method. The complexity of the biomatrices may result in the extract containing impurities, such as proteins, lipids, inorganics, and other organic compounds [65]. Thus, it is necessary to determine the chemical composition and structure of the extracted algal polysaccharides.

The properties of polysaccharides depend on their monomer composition. In order to analyze the monomer units eliminating the effects of the polymer structure, acid hydrolysis is used to decompose polysaccharides into monomeric sugars [83,84]. The monomeric sugars are analyzed and quantified by gas chromatography with mass spectrometry or a flame ionization detector (GC-MS/FID) [85,86,87], high-performance anion-exchange chromatography with a pulsed amperometric detector (HPAEC-PAD) [84], high-performance liquid chromatography with ultraviolet-visible spectroscopy (HPLC-UV-Vis) [88], high-pressure size exclusion chromatography (HPSEC) [36], or ion chromatography with a refractive index detector [89]. GC is frequently used, and this analytical method requires derivatization to allow simple sugars to volatilize [90]. Although these approaches can be used to determine the quantity of each sugar in polysaccharides, less common sugars or generally charged sugar units may not be detected using a standard method and will require more specifically tailored procedures. Different methods based on nuclear magnetic resonance (NMR) systems have been developed to quantify or to profile polysaccharides. After hydrolysis, monomeric sugars and functional groups of polysaccharides can be identified and quantified [91,92,93]. Either 1H or 13C involved NMR systems are widely used to analyze polysaccharides presented in different algae species [36,59,94,95,96,97]. Moreover, 22 saccharides in raw honey, in the form of a monomer, dimer, or trimer, can be distinguished without pre-treatment using NMR based on the chemical-shift-selective filtration with total correlation spectroscopy sequence [98]. Before analysis, researchers also employed desulfation and methylation methods to determine additional structural information [99,100].

To estimate the presence of possible impurities in the extracted polysaccharides, some rapid qualitative assays for testing the existence of flavonoids, alkaloids, tannins, terpenoids, steroids, saponins, glycosides, phenols, and phlorotannins according to Evans and Trease [101] and Sofowara [102], are usually considered in characterization [59]. Those methods are all regarded as colorimetric analysis, determining the concentration of the analyte by comparing the color changes of the solution. Similarly, the total carbohydrate content and the amount of 3,6-anhydrogalactose unites can also be quantified by colorimetric methods–the phenol-sulfuric acid method [103] and the resorcinol method [104,105]. Furthermore, to measure the sulphate content, the method based on turbidity measurements using barium chloride causing the precipitation of the insoluble barium sulphate is used [106,107]. The sulphate ions originate from polysaccharide hydrolysates. As such, conductometric titration can be used to quantify charged repeating units with different pKa (acid dissociation constant) values in polysaccharides [108,109].

At the macromolecular level, the length of the polymer chains is the most significant property since it determines a variety of characteristics of polysaccharides. Although the polymer length may be defined in relation to the degree of polymerization, that is, the average number of monomer units per polymer chain, it is most typically expressed in terms of the number-averaged and weight-averaged molecular weights [65]. Because of the polymer degradation occurring in the process of extraction and purification, the weight-averaged molecular weights of polysaccharides are different. That means polysaccharides with a lower degree of polymerization exhibit higher purity [65,110]. Pozharitskaya et al. discovered that algal polysaccharides with high molecular weight exhibited promising therapeutic properties in pharmacological applications [111]. The absolute molecular weight of polysaccharides is commonly determined by methods based on light scattering techniques. Moreover, combining light scattering methods with a size-based separation method, such as gel permeation chromatography or size exclusion chromatography, yields not only the averaged molecular weights but also the molecular weight distribution and polydispersity values [112].

4. Hydrogel Synthesis

Hydrogel design is a vital step in developing systems with new structures and properties for multiple applications in medical, agricultural, environmental, and cosmetic fields. The hydrogel structure is determined by hydrophilic groups and the polymeric networks, basically forming three-dimensional networks through crosslinking. The presence of crosslinks prevents the dissolution of hydrophilic polymers in aqueous environments [1]. Therefore, establishing crosslinking within structures is the key factor for hydrogel preparation. Hydrogels can be crosslinked by either physical or chemical procedures [113]. The physical interaction processes include association, aggregation, crystallization, complexation, and hydrogen bonding. Chemical hydrogels are covalently crosslinked formulations prepared by chemical reactions, the addition of crosslinkers, and polymerization.

4.1. Hydrogel Synthesis Mechanism

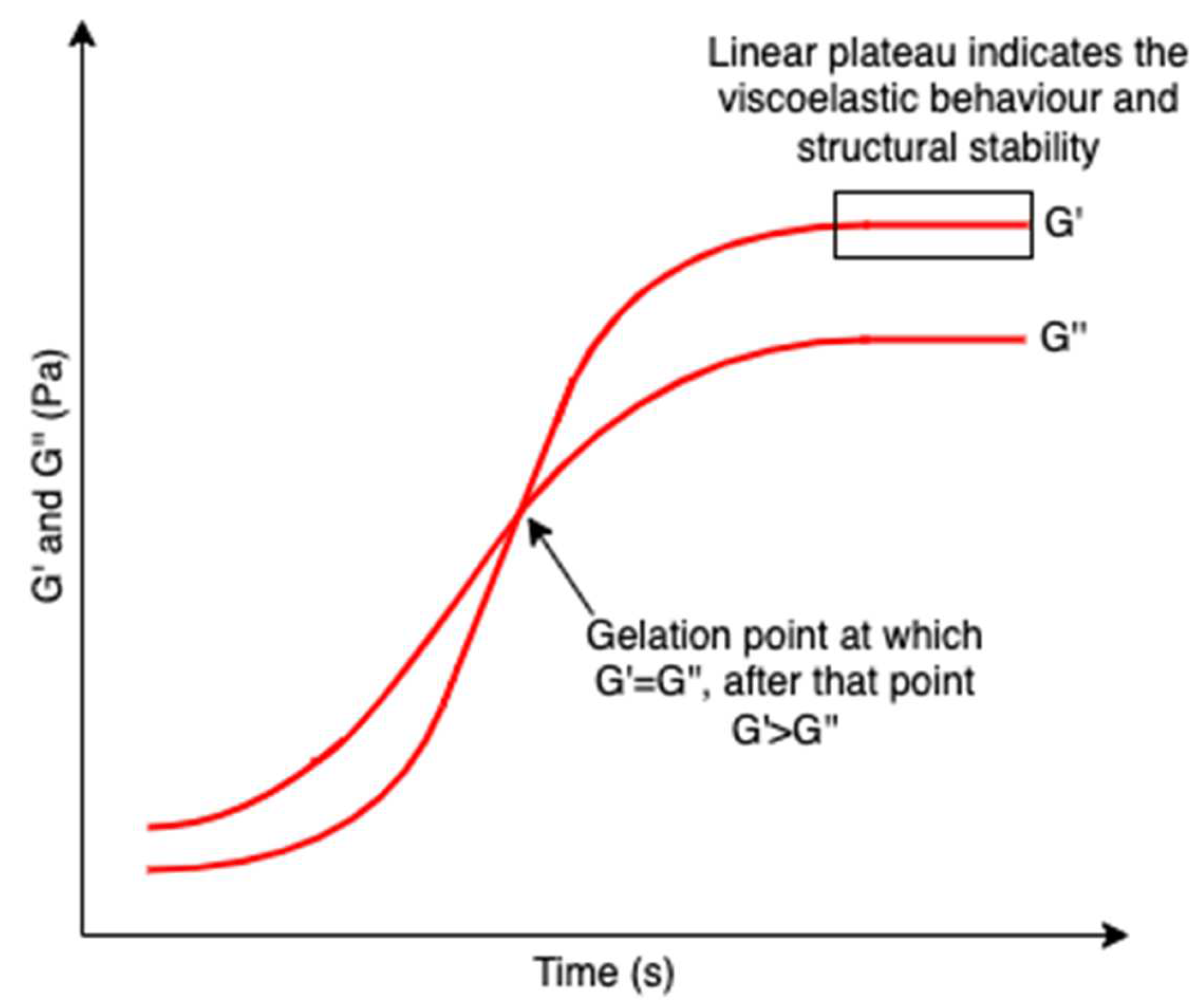

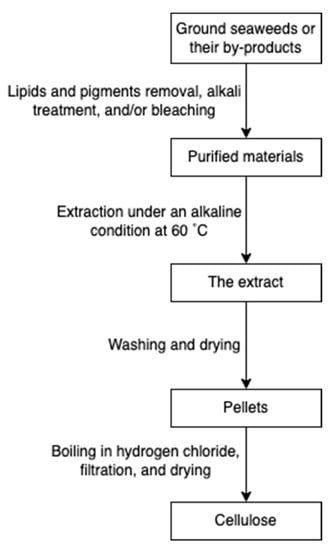

Hydrogels are three-dimensional networks composed of hydrophilic polymer chains that are crosslinked. The hydrophilic polymeric networks result in a hydrogel with a high water swelling and absorbing capacity while remaining insoluble in water. Their test-tube inversion test (invert the test tube with the hydrogel to observe its fluidity) always shows a lack of flow due to larger storage moduli (indication of hydrogel elasticity that measures the stored deformation energy) compared with loss moduli (indication of hydrogel viscosity that measures the dissipated energy) [114] and a linear plateau region of the storage modulus which indicates the viscoelastic behavior and structural stability of a hydrogel (Figure 19) [115]; as such, they are also regarded as rheological soft solids that behave similarly to solids and have viscoelastic properties [116]. The viscoelastic properties of hydrogels correlate strongly with their microstructures, giving important information to modulate their performance [117]. These unique properties attract increasing interest as biomedical materials since hydrogels can reproduce the hydration conditions of tissues in mammals and imitate some of the physical features of the extracellular matrix based on polysaccharides (e.g., hyaluronic acids) and protein (e.g., collagen) [118,119]. Polysaccharides are representative hydrogel-forming natural polymers, which mainly originate from seaweed/algae. In recent decades, polysaccharides isolated from algae have been widely used in hydrogel production.

Figure 19.

A schematic graph showing the formation of hydrogel network over time. G’ and G’’ represent the storage modulus and the loss modulus, respectively. The crossover point of G’ and G’’ indicated the gelation point, after which G’ > G’’. A linear plateau region of the storage modulus is also included revealing the viscoelastic behavior and structural stability of hydrogels.

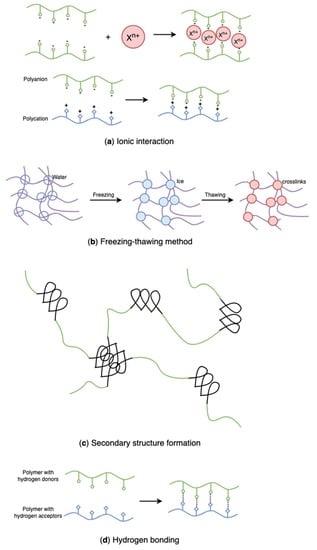

Algal polysaccharides-based hydrogels prepared through physical crosslinking form weak non-covalent bonding, such as van der Waals forces, electrostatic interactions, and hydrogen bonding, resulting in reversible gels based on the conformational changes. On the other hand, chemically crosslinked hydrogels develop covalent bonding between polymer molecules leading to irreversible networks based on the configurational changes [120,121]. As a result, the interactions between molecules of physically crosslinked hydrogels are easily broken with small energy, leading to the reversible sol-gel conversion [122]. The preparation of algal polysaccharides-based hydrogels, which revolves around physical and chemical crosslinking, is discussed in the following subsections.

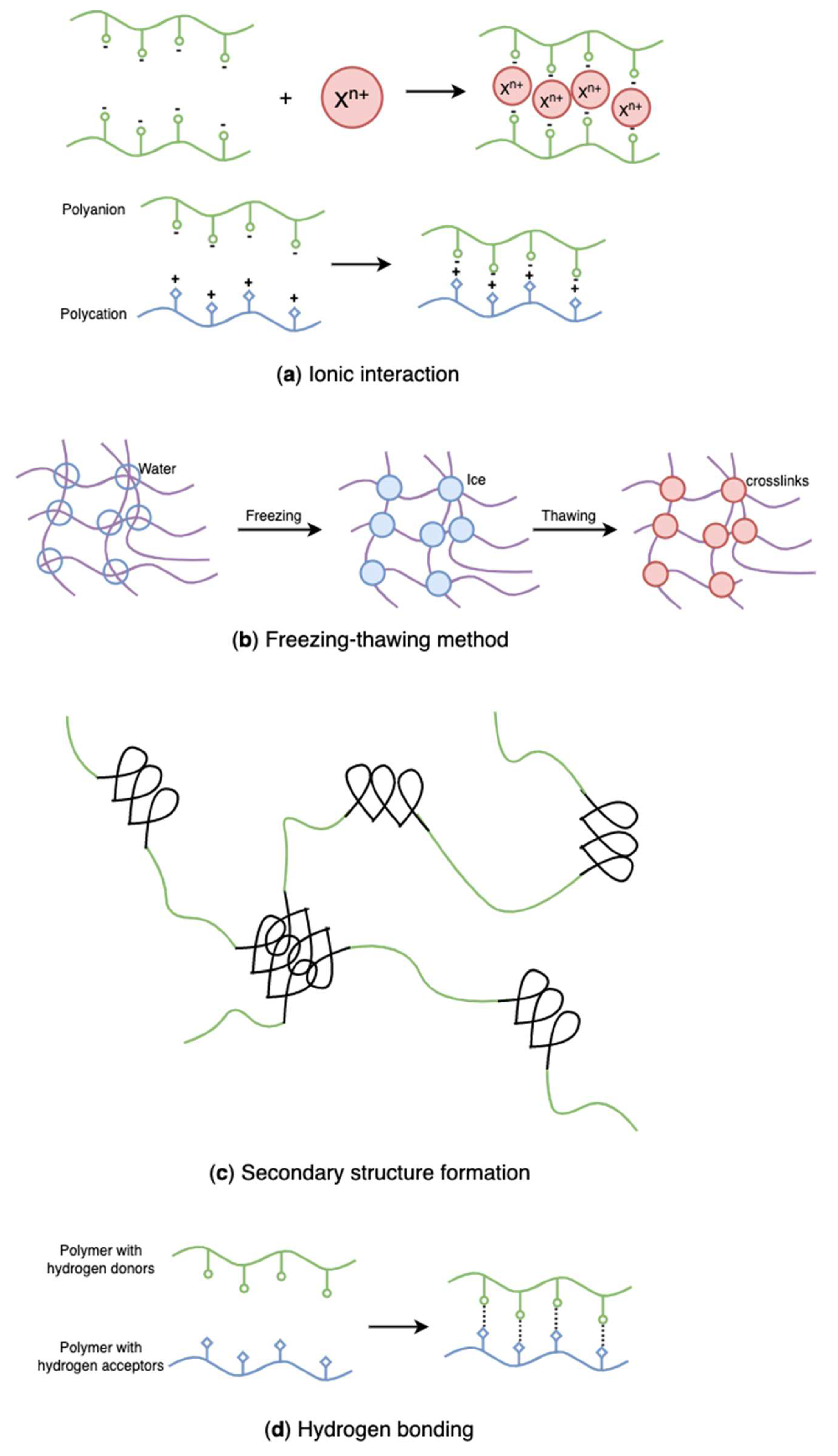

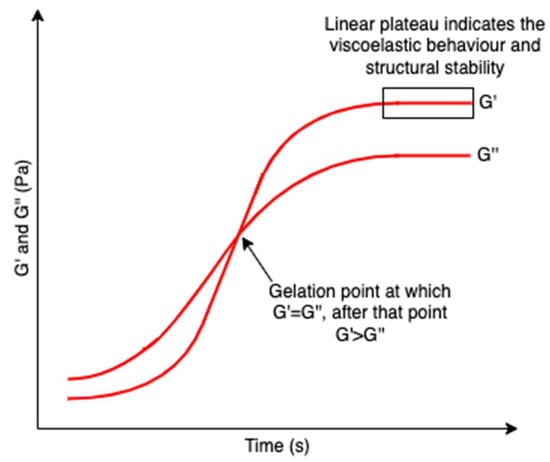

4.2. Physical Crosslinking

Physically crosslinked hydrogels form three-dimensional networks by physical interactions such as hydrogen bonding, chain entanglement, van der Waals forces, and electrostatic interactions. Recently, physical crosslinking methods (Figure 20) have attracted considerable attention due to the absence of crosslinking agents in the hydrogel preparation process. These chemical crosslinkers were usually toxic and might adversely affect entrapped compounds and their bioactivity [2]. Because hydrogels are broadly used for food packaging and biomedical purposes, the research focus on hydrogel formation is gradually shifting to physical crosslink. Table 1 summarizes physical crosslinking methods commonly used for algal polysaccharides-based hydrogels.

Figure 20.

Schematic representation of physically crosslinked, algal polysaccharides-based hydrogels: (a) ionic interaction, (b) freezing-thawing method, (c) secondary structure formation, (d) hydrogen bonding.

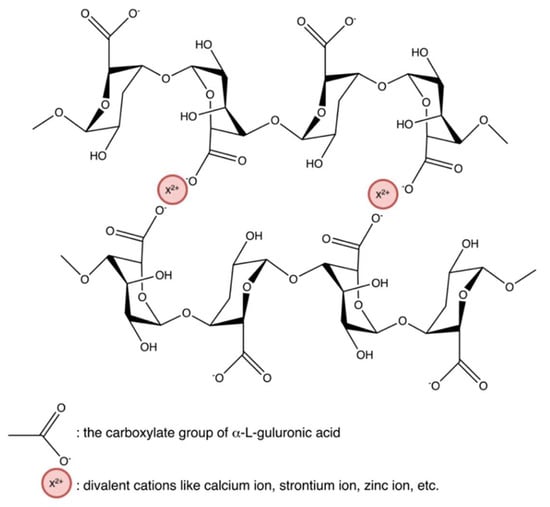

4.2.1. Ionic Interactions

Hydrogels crosslinked by ionic interaction (Figure 20a) can be achieved by adding multivalent ions with opposite charges to polyelectrolyte solutions or mixing polycations with polyanions. For example, alginates/sodium alginates are anionic biopolymers, and their common gelation process is associated with the exchange of sodium ions from alginate acids with divalent cations, such as calcium ions, strontium ions, zinc ions, and barium ions, interacting majorly with the carboxyl groups of α-L-guluronic acid to form an intermolecular crosslinking “egg-box” structure (Figure 21), in which each metal ion is coordinately bound to the carboxyl groups of guluronic acids, and the structure of guluronic acid offers the optimal distance between the carboxyl and hydroxyl groups, with a high degree of coordination with divalent cations (Table 1) [123,124,125,126]. The type of cation and corresponding concentration has been reported to impact the hydrogel properties [127]. Different cations result in required minimum concentrations, mechanical properties, and selectivity coefficient [124,127]. In comparison with magnesium ions, calcium ions exhibited stronger interactions with the alginate [124,125,128]; while compared with ions of copper, strontium, and calcium, the addition of zinc ions improved mechanical and physiological properties of the alginate-based hybrid hydrogels [129]. Furthermore, You et al., Xiao et al. and Hu et al. prepared chitosan-sodium alginate-based hydrogel via ionic gelation, in which anionic polysaccharide sodium alginate interacted with cationic polysaccharide chitosan (Table 1) [130,131,132]. The primary amino groups (−NH2) in the chitosan or water-soluble chitosan derivative chains serve as special joint points for both anions and small anionic molecules when they are protonated into ammonium groups (-NH3+) at a pH of 6.2 or less (pKa = 6.2) [133]. Similarly, Nuno Carvalho and his coworkers designed composite hydrogels with better mechanical properties based on the blending of marine origin biopolymers collagen, chitosan and fucoidan (Table 1) [54]. The ionic electrostatic interactions were promoted between the positively charged groups (protonated amines) of collagens and/or chitosan and the negatively charged groups (ester sulphates and carboxylates) of fucoidan. Therefore, as anionic polymers, alginate, fucoidan, and carrageenan, also usually crosslinks with various positively charged biopolymers (e.g., chitosan, starch, and cellulose) via electrostatic interaction instead of inorganic cations [53,54,130,131,132,134,135,136,137,138].

Figure 21.

Ionic interaction between alginate and divalent actions, forming the “egg-box” structure.

Running et al. synthesized hydrogels based on lambda-carrageenan in the presence of trivalent iron ions (Table 1) [139]. They found kappa- and iota-carrageenans showed gelation in the presence of mono- and di-valent ions, but lambda-carrageenan yielded only viscous solutions. That might be attributed to the amount of negatively charged sulphate group in every disaccharide repeating unit (Figure 4)–kappa-carrageenan has one negatively charged sulphate group showing selectivity to monovalent potassium ions, while iota-carrageenan has two sulphate groups preferring divalent calcium ions – based on that, researchers examined trivalent iron ions promoted interactions between lambada-carrageenan with three sulphate groups leading to gelation. Furthermore, because the storage moduli were much greater than the loss moduli, the iron(III)-lambda-carrageenan hydrogels were thermostable. Cao et al. identified specific binding between lambda-carrageenan and trivalent ions of iron and aluminum, but no interaction between lambda-carrageenan and trivalent chromium ions (Table 1) [26]. Mohamadnia et al. combined kappa-carrageenan and alginate to interact with divalent ions of calcium and monovalent potassium ions, forming ionically crosslinked carrageenan-alginate hydrogel beads (Table 1) [140]. Unlike the gelation mechanism of alginate-calcium cations developing an “egg-box” model, the sulphate esters and anhydro-oxygen atoms of kappa-carrageenan form an electrostatic attraction with potassium which functions as an intramolecular adhesive. Those homo-crosslinked polymer networks were held together by permanent entanglements. The resulting hydrogels exhibited a smoother surface morphology, and the carrageenan-potassium ions part appreciably enhanced the thermostability of the networks.

It has been reported that the presence of boric acid and divalent cations in ulvan causes the formation of thermoreversible hydrogels, which involves the formation of borate-polysaccharide complexes (Table 1) [141,142,143,144]; among which divalent cations formed ionic bridges between either the carboxylic group of uronic acid and/or sulphate groups with borate or used to stabilize the coordination of borate with the hydroxyl groups of ulvan [141,142]. Lahaye et al. also indicated stronger interactions between copper cations and ulvan, while no gelation occurred in the presence of magnesium ions [145].

4.2.2. Freezing-Thawing Method

While synthetic polymers have outstanding processability and mechanical properties, natural polymers are biocompatible, biodegradable, and non-toxic. Blends of natural and synthetic polymers have received much interest for biomedical applications due to their superior mechanical and thermal characteristics, as well as biocompatibility, compared with single-component materials [146,147]. Poly(vinyl alcohol) (PVA) is a non-ionic polyhydroxy polymer that is soluble in water. Due to its non-toxic, biocompatible, and gelation properties, PVA has been widely used in hydrogel formation for multiple purposes [148,149,150]. However, pure PVA hydrogels have restricted applicability owing to their poor swelling capacity and inert responsivity [151,152]. Introducing natural ionic biopolymers into PVA hydrogels and establishing in-between physical binding is an efficient method to improve the ionic behavior and the structure of PVA hydrogels. Recently, various studies have combined algal polysaccharides with PVA to develop new hydrogels with enhanced structure and properties [151,152,153,154,155,156]. As the mildest, most simple, and effective physical crosslinking method, freezing-thawing (Figure 20b) has gained considerable attention in recent years since it does not require the presence of toxic crosslinkers [151,157].

Such polymeric systems are designed under freezing conditions and stored in a frozen state. Subsequently, the initial solution or dispersions are thawed, establishing the precondition for gel structure formation and transition [158]. In the process, sufficient crystallization of initial systems is a necessity, so researchers usually repeat the freezing-thawing cycles. Cryogels or heterogeneous hydrogels are formed after melting down [159]. As the transformation of water to ice results in an increase in the polymer concentration, forced alignment within the chains of hydrogels builds a corresponding mechanism helping in forming side-by-side associations. After thawing out, these side-by-side associations still serve as the binding domains of the networking [27].

Jiang et al. prepared PVA/sodium alginate hydrogels with high toughness and electric conductivity by a freezing-thawing cycle (Table 1) [155]. The homogeneous solution of PVA and sodium alginate was frozen (−20 °C for 3 h) followed by being thawed (30 °C for 6 h). The process was repeated twice. Sequentially, in order to enhance strength and conductivity, the obtained hydrogel was immersed in a saturated sodium chloride solution. The operation contributed to the loss of free state water from hydrogels and the permeation of sodium and chloride ions into hydrogels. The treated PVA/sodium alginate hydrogel also resulted in the salting-out effect with increased chain entanglement. Furthermore, Hua et al. combined the ionic crosslinking and the freezing-thawing cycles (cooled at −20 °C for 48 h and then thawed at 25 °C for 4 h) to design dual-crosslinked PVA/sodium alginate hydrogels for controlled drug delivery (Table 1) [152]. The dual-crosslinked hydrogels included the pH-sensitive property of sodium alginate and the controlled drug release of PVA gels, showing improved swelling behaviors and encapsulation efficiency as well as a timed-release ability.

Shao et al. designed a self-healing hydrogel using PVA and agarose via the freezing-thawing method (frozen at −15 °C for 8 h and then thawed at 25 °C for 12 h) and hydrogen bonding (Table 1) [154]. Firstly, agarose was converted into linear molecules at a temperature above its melting point of 85 °C during the preparation of transparent, homogenous PVA/agarose solution. After cooling down to 25 °C, PVA-containing agarose single network hydrogels were crosslinked by the double helix formed by agarose linear molecules via the hydrogen bond. The freezing-thawing cycles caused crystallized PVA to form crystallites as physical crosslinks. Agarose and PVA networks were entangled through van der Waals force and hydrogen bonding. In comparison with the pure PVA hydrogel, the hybrid hydrogel exhibited higher thermal stability and enhanced compressive strength (eight times the strength of pure PVA hydrogel).

Mahdavinia et al. also synthesized magnetic hydrogels composed of kappa-carrageenan and PVA through the freezing-thawing method in the potassium ions-rich solution (Table 1) [156]. To crosslink the PVA component, the freezing-thawing process, in which the obtained solution containing PVA, kappa-carrageenan, and iron(II,III) oxide was frozen overnight and thawed at ambient temperature for 5 h, was used. After four freezing-thawing cycles, the hydrogels were immersed in the potassium chloride to crosslink the kappa-carrageenan component. To achieve the removal of cationic substances, researchers innovatively incorporated iron salts in the binary hydrogels to obtain a magnetic property. Although the introduction of magnetic nanoparticles into hydrogels caused a decrease in dye adsorption, increasing the ratio of kappa-carrageenan in the hydrogel composition could improve the adsorption ability of hydrogels.

4.2.3. Secondary Structure

The formation of a secondary structure (Figure 20c) refers to a three-dimensional network polymer adopted by the macromolecular chains. The formation process may involve a coil-to-helix transition. Once constructed, the helix can aggregate to establish points of contact between the polymer chains, resulting in creating a three-dimensional network. Electrostatic interpolymer chain repulsions induce the formation of helical aggregation, and then the structure is stabilized by weak attractive interactions. In these algal polysaccharide-based hydrogel systems, the helices may be broken owing to twists caused by the irregularity in the polymer chains, which consequently regulates the size of the crosslinking points [65].

Forget et al. reported hydrogels produced from algal polysaccharides, such as agarose and kappa-carrageenan possessing an α-helical backbone, could be customized by inducing a changeover in the secondary structure from an α-helix (a right hand-helix conformation) to a β-sheet (a generally twisted, pleated sheet) by carboxylation (Table 1) [28]. They blended α-helix-rich native agarose/kappa-carrageenan with the β-sheet-rich carboxylated derivative in the hot deionized water, achieving the conversion of an α-helix to a β-sheet; followed by an aggregation of polymer chains through β-sheet motifs and elongation of these aggregates into a high-aspect-ratio structure. The secondary structure formation enabled the gel modulus to be tuned over four orders of magnitude. Physicochemical properties of hydrogels could be tunable by switching their secondary structure from an α-helix to a β-sheet. The resulting hydrogels were examined to possess tailored mechanical properties as well as predictable roughness, fibre organization, and shear modulus [160]. Moreover, to further control the gel characteristics, the polysaccharide content can be increased to promote helix aggregation, which results in a higher gel strength [161,162].

When cations are present, both lambda- and kappa-carrageenan undergo a coil-to-helix transition, resulting in the formation of double helices. The development of a helix is followed by subsequent helix aggregation in kappa-carrageenan [163,164,165]. Still, this aggregation does not occur in lambda-carrageenan owing to the presence of two sulphate groups, which induces a greater electrostatic chain repulsion [166,167]. The gelation of kappa-carrageenan relies on monovalent cations [168]. The kind of cation used to initiate the gelation process influences the mechanical characteristics of hydrogels. For example, kappa-carrageenan forms a stronger gel when combined with potassium ions [168,169,170,171]. However, some anions, such as iodide anions, have been designed to attach to the helix, which affects the gelation mechanism, hindering helix aggregation and gelation [172,173,174]. Because the development of lambda- and kappa-carrageenan hydrogels is driven by their secondary structure, manipulating this structure, such as adding ions, may have a remarkable effect [65]. Additionally, single helices created by a single carrageenan chain [169,175] are different from double helices formed by the interweaving of two carrageenan chains [163,176] or the intramolecular cycling or hair pinning of a single carrageenan chain [177,178]. Voron’ko et al. prepared kappa-carrageenan/gelatin-based hydrogels with helical structures (Table 1) [179]. The process consisted of a mixture of anionic kappa-carrageenan and gelatin, the formation of self-assembling polyelectrolyte complexes, a coil to helix transition of gelatin, and subsequent aggregation of helices. The gelatin and kappa-carrageenan helices supported the stabilization of hydrogel networks. Kappa-carrageenan serving as host-polyelectrolyte, interacted with guest-polyelectrolyte gelatin, forming complex hydrogels in the presence of hydrophobic interaction, electrostatic interaction, hydrogen bond, and the secondary structure of triple collagen-like helices of gelatin and intramolecular double helices of kappa-carrageenan. By increasing the kappa-carrageenan/gelatin ratio, the gelation ratio would slow down.

4.2.4. Hydrogen Bonding

Hydrogels can also be formed through other secondary bonding–hydrogen bonding (Figure 20d)–because of the functional groups in polymers. Researchers have successfully prepared hydrogen-bonded hydrogels using polymers with carboxyl groups along their chains by lowering the pH of their aqueous solutions. In the research of Jing et al., novel sodium alginate/carboxymethyl chitosan hydrogel beads promoted by hydrogen bond were designed (Table 1) [25]. The hydrogel beads were prepared by dropping the blends of two polymers into the citric acid solution and showed excellent pH sensitivity and protein encapsulation capacity. Likewise, a hydrogen-bonded carboxymethyl cellulose-based hydrogel was prepared by dispersing carboxymethyl cellulose into hydrogen chloride and citric acid, in which the sodium in the carboxyl group was replaced with hydrogen in acidic solutions leading to the aggregation of carboxymethyl cellulose molecules (Table 1) [180]. However, the conversion of all the −COONa into −COOH in carboxymethyl cellulose results in excess crosslinks giving unstable and brittle hydrogels. That indicates that some carboxyl groups remaining in the form of -COONa help in stabilizing hydrogels. Decreasing acid concentration and increasing temperature also favour the stability of hydrogels. Additionally, Wang et al. prepared a fucoidan and kappa-carrageenan blend hydrogel through hydrogen bonding (Table 1) [181]. The addition of kappa-carrageenan promotes non-gelling fucoidan gelation, forming a strong entanglement network through hydrogen bonds, and the rheological properties, thermal stability, water retention, and frost resistance of fucoidan were improved by kappa-carrageenan.

Table 1.

Physical crosslinking methods for algal polysaccharides-based hydrogel preparation.

Table 1.

Physical crosslinking methods for algal polysaccharides-based hydrogel preparation.

| Crosslinking | Materials | Important reagents | Gelation | Properties | Ref. |

|---|---|---|---|---|---|

| Ionic interaction | Alginate/alginate sodium (brown algae such as Laminaria hyperborea and lessonia) | Divalent cations-containing solutions, such as calcium chloride, zinc chloride, etc. | Divalent cations interacted with their carboxyl groups to form intermolecular crosslinking “egg-box” structures | Biocompatible, biodegradable, divalent cations-affected mechanical properties | [124,125,126,128,129,130] |

| Alginate/Sodium alginate (brown algae) Chitosan derivatives | 5% acetic acid or other dilute organic/inorganic acids | Anionic sodium alginate interacted with cationic chitosan derivatives | pH-sensitive, biocompatible, biodegradable, high capacity to bind heavy metal ions, acidic gas, and basic gas | [130,131,132] | |

| Fucoidan (brown algae Fucus vesiculosus) Collagen Chitosan | - | Ionic electrostatic interactions between the positively charged groups of collagens and/or chitosan and the negatively charged groups of fucoidan | Degradable, biocompatible | [54] | |

| Lambda-carrageenan (red algae Sarcothalia lanceata) | Aluminium(III) chloride/iron(III) chloride/iron(III) chloride hexahydrate | Ionic interactions in the presence of specific trivalent ions | Thermostable, biocompatible, biodegradable | [26,139] | |

| Kappa-carrageenan (red algae) Sodium alginate (brown algae) | Calcium chloride and potassium chloride | Combined algal polysaccharides to interact with divalent calcium ions and monovalent potassium ions, forming alginate-calcium cation and kappa-carrageenan-potassium cation crosslinked networks | Thermostable, biocompatible, biodegradable | [140] | |

| Ulvan (green algae Ulva spp.) | Borate, calcium chloride | Boric acid and divalent cations such as calcium cations initiated ionic crosslinking. It also involved the chelation of calcium with hydroxyl groups of borates | Thermoreversible, biocompatible, biodegradable | [142] | |

| Freezing-thawing method | Sodium alginate (brown algae) PVA | Calcium chloride, and/or diclofenac sodium (changed from transparent to white and opaque solution) | Repeated freezing-thawing cycles on PVA-containing ionically crosslinked sodium alginate hydrogels for two times | Biocompatible, pH-sensitive, improved swelling behaviors and encapsulation efficiency | [152] |

| Freezing-thawing method | Agarose (red algae Rhodophyta) PVA | - | Thermal-induced aggregation (above 85 °C) of agarose followed by fabricating PVA hydrogels via the repeating freezing-thawing cycles. They entangled through van der Waals force and hydrogen bonding | Robust mechanical property, biocompatible, self-healing | [154] |

| Sodium alginate (brown algae) Poly(vinyl alcohol) (PVA) | Sodium chloride | Repeated freezing-thawing cycles on the homogeneous PVA/sodium alginate solution and then immersed the virgin hydrogel in the saturated sodium chloride solution | Biocompatible, high toughness and electric conductivity | [155] | |

| Kappa-carrageenan (red algae) PVA | Iron salts (iron(II) sulfate heptahydrate and iron(III) chloride hexahydrate), ammonia solution, potassium chloride | Mixed iron salts, PVA and kappa-carrageenan, followed by adding ammonia solution to adjust pH at 10 until magnetic nanoparticles with the dark color were formed. The polymer networks were crosslinked by the repeating freezing-thawing cycles and then ionic interaction with potassium cations | Magnetic | [156] | |

| Secondary structure | Native agarose (red algae Gelidium and Gracilaria) Kappa-carrageenan (red algae) | (2,2,6,6-Tetramethylpiperidin-1-yl)oxyl (TEMPO), sodium bromide, sodium hypochlorite, sodium hydroxide, ethanol, sodium chloride, and sodium borohydride | Blended α-helix-rich agarose/kappa-carrageenan with the β-sheet-rich carboxylated derivatives in the hot deionized water, achieving converting an α-helix to a β-sheet. Followed by aggregation of polymer chains through β-sheet motifs and elongation of these aggregates into high-aspect-ratio structure | Injectable, tunable mechanical and structural properties, biocompatible, biodegradable, formation in vivo | [28,161] |

| Kappa-carrageenan (red algae) Gelatin | - | Host (kappa-carrageenan)-guest (geletin) interaction generating electrostatic interaction, hydrophobic interaction, and hydrogen bonding, a coil to helix transition of gelatin, followed by aggregation of helices | Biocompatible, biodegradable | [179] | |

| Hydrogen bonding | Sodium alginate (brown algae) Carboxymethyl chitosan | Citric acid | Blended those two biopolymers in the citric acid solution, resulting in hydrogen bonding between the polymers and citric acid under an acidic environment | pH-sensitive, thermally stable, biocompatible, biodegradable | [25] |

| Sodium carboxymethyl cellulose (not specified) | Hydrochloric acid/citric acid | Mixed sodium carboxymethyl cellulose with acid, replacing sodium in carboxymethyl group with hydrogen. Carboxymethyl cellulose molecules aggregated because of reduction of the polymer solubility in water | Stable, biocompatible, durable | [180] | |

| Hydrogen bonding | Fucoidan (brown algae) Kappa-carrageenan (red algae) | - | Non-gelling polysaccharide fucoidan interacted with kappa-carrageenan under high temperature (approximately 95 °C), forming hydrogel bonds | Biocompatible, biodegradable, improved water retention and frost resistance, thermal stable, enhanced rheological properties | [181] |

| Freezing-thawing method | Agarose (red algae Rhodophyta) PVA | - | Thermal-induced aggregation (above 85 °C) of agarose followed by fabricating PVA hydrogels via the repeating freezing-thawing cycles. They entangled through van der Waals force and hydrogen bonding | Robust mechanical property, biocompatible, self-healing | [154] |

| Sodium alginate (brown algae) Poly(vinyl alcohol) (PVA) | Sodium chloride | Repeated freezing-thawing cycles on the homogeneous PVA/sodium alginate solution and then immersed the virgin hydrogel in the saturated sodium chloride solution | Biocompatible, high toughness and electric conductivity | [155] | |

| Kappa-carrageenan (red algae) PVA | Iron salts (iron(II) sulfate heptahydrate and iron(III) chloride hexahydrate), ammonia solution, potassium chloride | Mixed iron salts, PVA and kappa-carrageenan, followed by adding ammonia solution to adjust pH at 10 until magnetic nanoparticles with the dark color were formed. The polymer networks were crosslinked by the repeating freezing-thawing cycles and then ionic interaction with potassium cations | Magnetic | [156] | |

| Secondary structure | Native agarose (red algae Gelidium and Gracilaria) Kappa-carrageenan (red algae) | (2,2,6,6-Tetramethylpiperidin-1-yl)oxyl (TEMPO), sodium bromide, sodium hypochlorite, sodium hydroxide, ethanol, sodium chloride, and sodium borohydride | Blended α-helix-rich agarose/kappa-carrageenan with the β-sheet-rich carboxylated derivatives in the hot deionized water, achieving converting an α-helix to a β-sheet. Followed by aggregation of polymer chains through β-sheet motifs and elongation of these aggregates into high-aspect-ratio structure | Injectable, tunable mechanical and structural properties, biocompatible, biodegradable, formation in vivo | [28,161] |

| Kappa-carrageenan (red algae) Gelatin | - | Host (kappa-carrageenan)-guest (geletin) interaction generating electrostatic interaction, hydrophobic interaction, and hydrogen bonding, a coil to helix transition of gelatin, followed by aggregation of helices | Biocompatible, biodegradable | [179] | |

| Hydrogen bonding | Sodium alginate (brown algae) Carboxymethyl chitosan | Citric acid | Blended those two biopolymers in the citric acid solution, resulting in hydrogen bonding between the polymers and citric acid under an acidic environment | pH-sensitive, thermally stable, biocompatible, biodegradable | [25] |

| Sodium carboxymethyl cellulose (not specified) | Hydrochloric acid/citric acid | Mixed sodium carboxymethyl cellulose with acid, replacing sodium in carboxymethyl group with hydrogen. Carboxymethyl cellulose molecules aggregated because of reduction of the polymer solubility in water | Stable, biocompatible, durable | [180] | |

| Hydrogen bonding | Fucoidan (brown algae) Kappa-carrageenan (red algae) | - | Non-gelling polysaccharide fucoidan interacted with kappa-carrageenan under high temperature (approximately 95 °C), forming hydrogel bonds | Biocompatible, biodegradable, improved water retention and frost resistance, thermal stable, enhanced rheological properties | [181] |

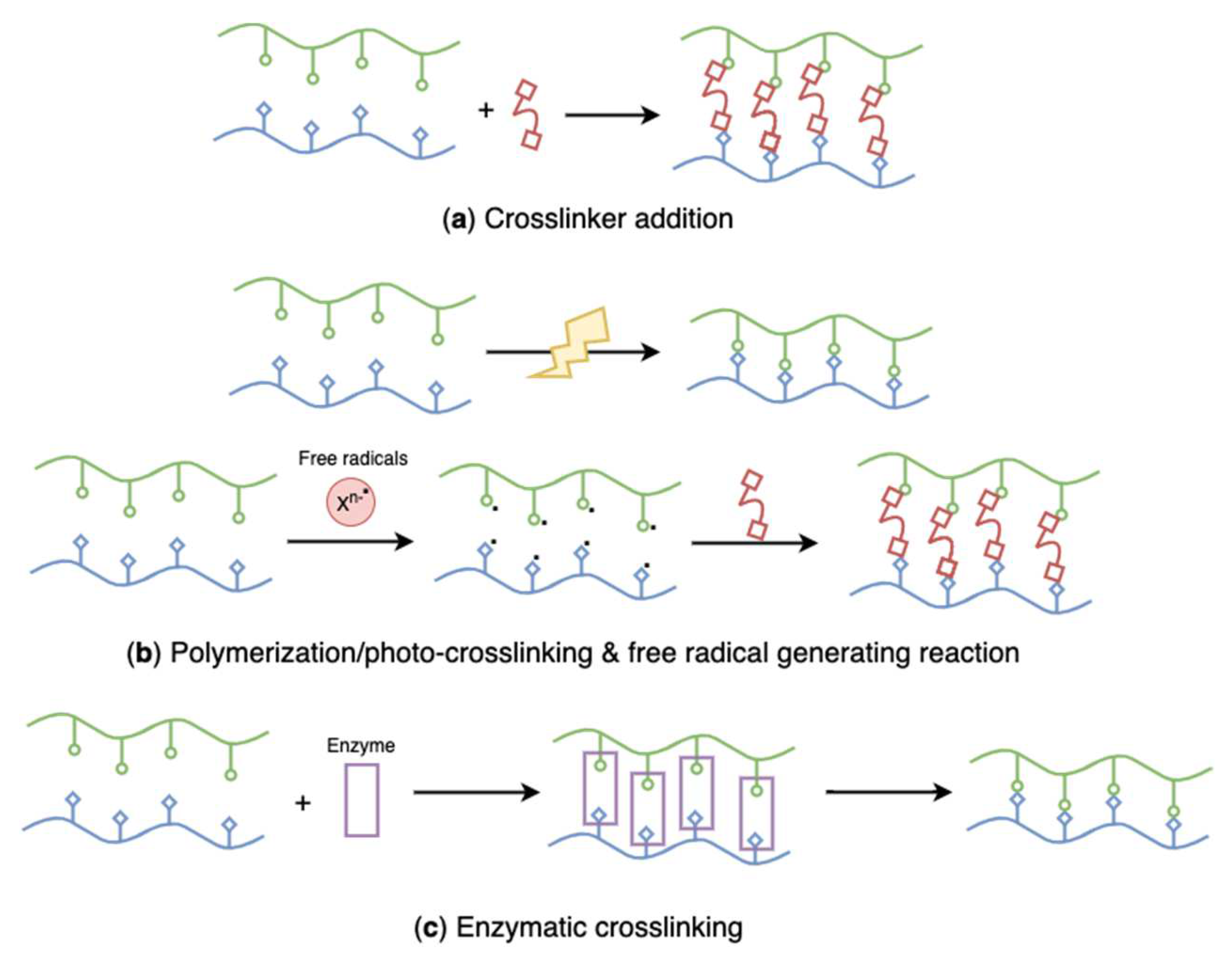

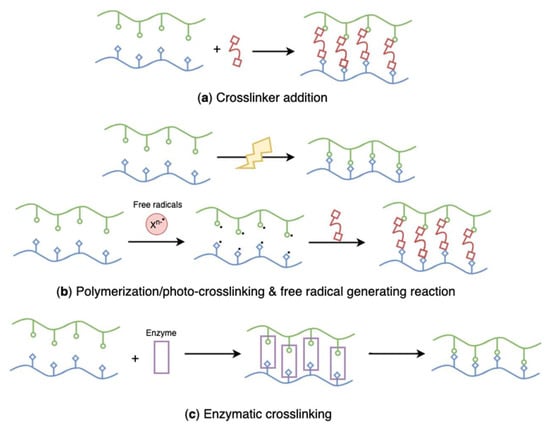

4.3. Chemical Crosslinking

Physically crosslinked hydrogels based on algal polysaccharides are attractive materials with broad applications due to their biocompatibility, biodegradability, non-toxicity, and the absence of poisonous crosslinkers. However, they are susceptible to external stimuli because of the reversible nature of interactions between polymer chains, and the gel to sol transformation degrades the designed structure. Thus, some chemically crosslinking methods (Figure 22) have been introduced to prepare polysaccharide-based hydrogels with controllable properties and irreversible networks. Table 2 presents some typical chemically crosslinked, algal polysaccharides-based hydrogels.

Figure 22.

Schematic representation of chemically crosslinked, algal polysaccharides-based hydrogels: (a) crosslinker addition, (b) polymerization/photo-crosslinking and free radical generating reaction, (c) enzymatic crosslinking.

4.3.1. Crosslinker Addition

Crosslinker addition (Figure 22a) is the most important strategy that has been extensively used to prepare chemically crosslinked hydrogels. Multifunctional polymers and photosensitive or enzyme-catalyzed agents are commonly employed as chemical crosslinkers [182]. Zhang et al. developed composite agarose/hyaluronic acid hydrogels with epichlorohydrin (a bifunctional alkylating agent [183]) as a crosslinking agent (Table 2) [184]. The study found that the hybrid hydrogels showed no cytotoxic effect, although epichlorohydrin is classified as a probable human carcinogen.

However, most crosslinkers possess toxicity and unknown biocompatibilities. To prevent the presence of crosslinkers and reaction by-products, multiple purifications are required before administration. On the other hand, crosslinkers may react with loaded active pharmaceutical ingredients, affecting the therapeutic effects [2]. As such, the main drawback of this method is the limited choice of safe and biocompatible crosslinking agents. Genipin is a representatively biocompatible crosslinker extracted from the gardenia (a flowering plant) [185]. It has been reported to be effective in crosslinking polymers with amino groups and demonstrates minor cytotoxicity compared with conventional chemical crosslinkers, such as glutaraldehyde [186]. Li et al. fabricated genipin crosslinked composite hydrogels comprised of kappa-carrageenan and chitosan (Table 2) [187]. Remarkably, pristine chitosan hydrogels prepared by the phase inversion technique were further fabricated with the genipin crosslinker, leading to hydrogels with improved mechanical properties under weak basic conditions. This novel hydrogel improved anticoagulant and antibacterial properties compared with the chitosan-based hydrogel. Similarly, Chen et al. also designed alginate-chitosan hydrogels composed of alginate cores and genipin crosslinked chitosan membrane, possessing effective resistance to mechanical force, calcium sequestration, enzyme degradation, and gastrointestinal impediments (Table 2) [188,189].

Additionally, polymers and hydrogels can be further reinforced by adding crosslinkers. Zhao et al. prepared cellulose (cotton linter pulp) hydrogels using sequential chemical and physical crosslinking, in which epichlorohydrin was introduced as the crosslinker, followed by hydron bonding and chain entanglement [190]. The incorporation of chemically crosslinked and physically crosslinked domains afforded cellulose-based hydrogels with relatively high stiffness, high toughness, and good recoverability compared to the single crosslinked hydrogel. Campos et al. chemically synthesized membrane-like hydrogels based on agarose and fibrin with genipin (Table 2) [19]. Researchers fabricated fibrin-agarose hydrogels using ionic interactions, followed by adding the crosslinking agent genipin to improve the structural and biomechanical properties.

Porphyrins have been proven their loading efficiency is limited [191,192], and they cannot form supramolecular gels by molecular self-assembly (intermolecular interactions that are established between molecules or structural motifs [193]). As a result, they have been migrated out of hydrogel materials. However, they can be synthesized as crosslinking agents [194]. Lovell et al. prepared porphyrin crosslinked hydrogels using a rapid stepwise condensation copolymerization reaction between poly(ethylene glycol) (PEG) and porphyrin (Table 2) [191]. The designed hydrogels were examined to have stable, alternating porphyrin and PEG subunits that provided significant near-infrared optical properties, allowing long-term, non-invasive fluorescence monitoring and image-guided surgical resection in vivo. So, the proposed hydrogels are ideal biomedical materials for fluorescence-guided monitoring and surgical resection.

4.3.2. Polymerization

Except for reactions with crosslinkers, polymerization (Figure 22b) through free radical crosslinking is also the most common method for chemical hydrogel preparation. Free radical polymerization, also known as photo-crosslinking, is a chemical crosslinking process involving free radical initiators, such as methacrylate, benzoyl peroxide, and ammonium peroxodisulphate [195]. To make polymers photopolymerizable, they are modified with specific unsaturated functional groups (e.g., acrylates) that undergo free-radical polymerization in the presence of a photoinitiator when exposed to ultraviolet (UV) light. Custódio et al. designed photo-crosslinked laminarin-based hydrogels to develop a new injectable biomedical system using UV irradiation (Table 2) [20]. Laminarin was not photo-crosslinkable, which requires chemical modification with acrylate groups before the hydrogel preparation. In the reaction process, 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone was used as a photoinitiator. The rapid gelation triggered by the low dose UV irradiation helped in the encapsulation of bioactive ingredients and cells, avoiding bioactive damage. Similarly, Feng et al. modified hydroxyl groups of laminarin with glycidyl methacrylate, followed by the photopolymerization of methacrylated laminarin via a radical reaction under UV irradiation [196]. Morelli et al. synthesized ulvan-based hybrid nanogels through radical copolymerization of N-vinylcaprolactam monomer onto suitably modified ulvan with acrylate groups (Table 2) [17]. The radical copolymerization process was induced by UV irradiation. In the preparation process, modified ulvan acted as not only the grafting from macromer during the polymerization of N-vinylcaprolactam but also a crosslinker during the synthesis of thermoresponsive Poly(N-vinylcaprolactam) networks. Apart from attaching photosensitive functional groups to polymers, researchers also combined algae-extracted polysaccharides with photo-crosslinkable polymers to synthesize composite hydrogels. El-Din et al. synthesized PVA/sodium alginate hydrogels by electron beam irradiation (Table 2) [22]. In this study, researchers found that the content of non-photo-crosslinkable sodium alginate could not exceed 40%; otherwise, no homogenous hydrogel could be produced.

Hydrogelation can also be induced by other high-energy radiation such as gamma rays [21,197] or electron beams [22,198]. High energy radiation has been proven to be a powerful and fast tool to sterilize and tailor the properties of algal polysaccharides-based hydrogels. It can also be used to treat prepared polysaccharides hydrogels to obtain customized mechanical, structural, and chemical properties for desired applications. For instance, Singh and her coworkers synthesized PVP-alginate hydrogels by gamma irradiation; meanwhile, they also included silver dressings into the prepared hydrogel using gamma rays, designing a tailored composite hydrogel with the antimicrobial property (Table 2) [21]. Notably, due to the different dissolution characteristics of alginate and PVP, the hydrogel content decreased as the amount of alginate increased. Krömmelbein et al. treated agarose hydrogels under 10 MeV electron beam [199]. The high energy electron irradiation tailored their properties as well as rheology and average molecular weight of agarose. Compared with UV- and gamma-rays, electron beam radiation is extremely effective owing to its large penetration depths and high dosage rates [197,199].

Moreover, polymerization can also be initiated by a free radical-generating system, which is regarded as a vinyl addition polymerization reaction (Figure 22b). Duman et al. prepared agarose/kappa-carrageenan composite hydrogel through a free radical crosslinking reaction in the presence of ammonium persulfate as a radical initiator, tri(ethylene glycol) divinyl ether (TEGDE) as a crosslinker, and N,N,N′,N′-tetramethylethylenediamine (TEMED) as a catalyst (Table 2) [11,200]. TEMED accelerates the formation rate of free radicals from persulfate, which catalyzes polymerization. The addition of ammonium persulfate generated negatively charged sulphate radicals, and then those radicals replaced hydrogens in the hydroxyl groups of the polysaccharides forming alkoxy radicals to crosslink with the crosslinker TEGDE.

4.3.3. Enzyme-Catalyzed Reaction

Crosslinking using enzymes (Figure 22c) is a novel approach used to form regular hydrogels or in situ hydrogels under mild conditions, such as physiological environments [2].

Enzymatically crosslinked ulvan-based hydrogels were prepared by blending ulvan with tyramine under the catalyzation of horseradish peroxidase enzyme, in which hydrogen peroxide was used as a reagent (Table 2) [23]. The tyramine modification caused ulvan to be susceptible to enzymatic recognition; as such, the polysaccharides could be crosslinked through oxidative coupling. Likewise, Hou et al. designed enzymatically crosslinked dopamine- or tyramine-alginate conjugates via the oxidative coupling of phenol or aniline moieties in the presence of horseradish peroxidase enzyme and hydrogen peroxide (Table 2) [24]. This method has emerged as an important method to synthesize in situ injectable hydrogels. Compared with photopolymerization, the enzyme-catalyzed reaction for in situ gelation shows its superiority – no photosensitizers and prolonged irradiation required – so that local temperature does not increase drastically, leading to damage to surrounding cells tissues [201]. However, it is necessary to reduce the concentration of hydrogen peroxide in future improvements to avoid its cytotoxicity [24].

Table 2.

Chemical crosslinking methods for algal polysaccharides-based hydrogel preparation.

Table 2.

Chemical crosslinking methods for algal polysaccharides-based hydrogel preparation.

| Crosslinking | Materials | Important reagents | Gelation | Properties | Ref. |

|---|---|---|---|---|---|

| Crosslinker addition | Agarose (red algae) Hyaluronic acid | Epichlorohydrin as a crosslinker, sodium hydroxide | Mixed alkali-treated agarose and hyaluronic acid together and reacted with chemical crosslinker epichlorohydrin | Non-cytotoxic, biodegradable, biocompatible, thermal stable | [184] |

| Kappa-carrageenan (red algae) Chitosan | Genipin as a crosslinker, sodium hydroxide, potassium chloride | Pristine physically-crosslinked chitosan hydrogels (phase inversion technique) reacted with crosslinking agent genipin, developing inner chitosan core and then immersed in carrageenan solution forming outer carrageenan shell in the presence of potassium ions | Biocompatible, anticoagulant, antibacterial | [187] | |

| Fibrin Agarose (red algae) | Calcium chloride, genipin as a crosslinker | Ionically crosslinked fibrin-agarose hydrogels were subject to chemical crosslinking with genipin | Biocompatible, biodegradable, biomimetic, enhanced structural and biomechanical properties | [19] | |

| Sodium alginate (brown algae) Chitosan | Calcium chloride, genipin as a crosslinker | Ionically crosslinked alginate hydrogels immersed into chitosan forming alginate-chitosan microcapsules. The microcapsules were further crosslinked by genipin | Biocompatible, stable, strong resistance to mechanical shear forces, calcium sequestration, gastrointestinal impediments, and enzymatic degradation | [188,189] | |

| Poly(ethylene glycol) (PEG) | Porphyrin (meso-tetrakis(4-carboxyphenyl) porphine) as a crosslinker | Synthesized porphyrin as a crosslinker to crosslink PEG through a condensation copolymerization reaction | Near-infrared optical properties, stable | [191] | |

| UV-initiated polymerization | Laminarin (brown algae Laminaria and Eisenia) | Glycidyl methacrylate, dimethyl sulfoxide, 4-(N,N-dimethylamino)pyridine as a catalyst in the methacrylation, 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone as a photoinitiator | Methacrylated laminarin was subjected to UV irradiation (320–500 nm) at 5–8 mW/cm2 for seconds | Injectable, biocompatible, mechanically stable, low viscosity | [20] |

| UV-initiated polymerization | Ulvan (green algae Ulva armoricana) N-vinylcaprolactam | Acryloyl chloride, sodium hydroxide, 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone as a photoinitiator | The synthesis involved the grafting copolymerization of N-vinylcaprolactam onto the side chains of acryloyl chloride-modified ulvan through UV irradiation (400 W, 365 nm, 8–10 mW/cm2, 70 °C) promoted radical process | Thermoresponsive, biocompatible, increased loading efficiency | [17] |

| Gamma rays-initiated polymerization | Alginate (brown algae) Poly(vinyl pyrrolidone) (PVP) | Silver nitrate | Combination of PVP and alginate was gamma irradiated at different doses of 25 and 40 kGy at a dose rate of 5.54 kGy/h. Nanosilver was incorporated in the PVP-alginate hydrogel using gamma radiation at 25 kGy, forming a composite hydrogel | Efficient fluid absorption capacity, biocompatible | [21] |

| Electron beam-initiated polymerization | Sodium alginate (brown algae) PVA | - | Exposed the completely miscible sodium alginate and PVA solutions under electron beam irradiation at a constant dose of 25 kGy of accelerated electrons | Highly hydrophilic, thermal stable, pH-responsive, temperature responsive, biocompatible | [22] |

| Free radical generating reaction (vinyl addition polymerization) | Agarose (red algae Rhodophyceae) Kappa-carrageenan (red algae) | Ammonium persulfate and N,N,N′,N′-tetramethyl ethylenediamine (catalyst) as a radical initiator-accelerator pair, tri(ethylene glycol) divinyl ether as a crosslinker | The addition of ammonium persulfate generated negatively charged sulphate radicals. The sulfate anion radical replaced hydrogen in the hydroxyl group of the polysaccharide substrate, forming alkoxy radicals. Crosslinking happened between alkoxy radicals and crosslinkers | Improved adsorption capacity, non-Fickian swelling, biocompatible | [11,201] |

| Enzyme-catalyzed reaction | Ulvan (green algae Ulva armoricana) | Tyramine hydrochloride, N-(3Dimethylaminopropyl)-N′-ethylcarbodiimide hydrochloride, N-hydroxysulfosuccinimide sodium salt, hydrogen peroxide, and horseradish peroxidase enzyme | Tyramine-modified ulvan was sensitive to horseradish peroxidase enzyme and then crosslinked polysaccharides through oxidative coupling | Injectable, biocompatible | [23] |

| Alginate (giant brown seaweed) | Dopamine hydrochloride or tyramine hydrochloride, 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide hydrochloride, N-hydroxysulfosuccinimide, hydrogen peroxide, and horseradish peroxidase enzyme | Crosslinked dopamine- or tyramine-modified alginate via the oxidative coupling of phenol or aniline moieties in the presence of horseradish peroxidase enzyme and hydrogen peroxide | Improved adhesion, in situ gelling, biocompatible | [24] |

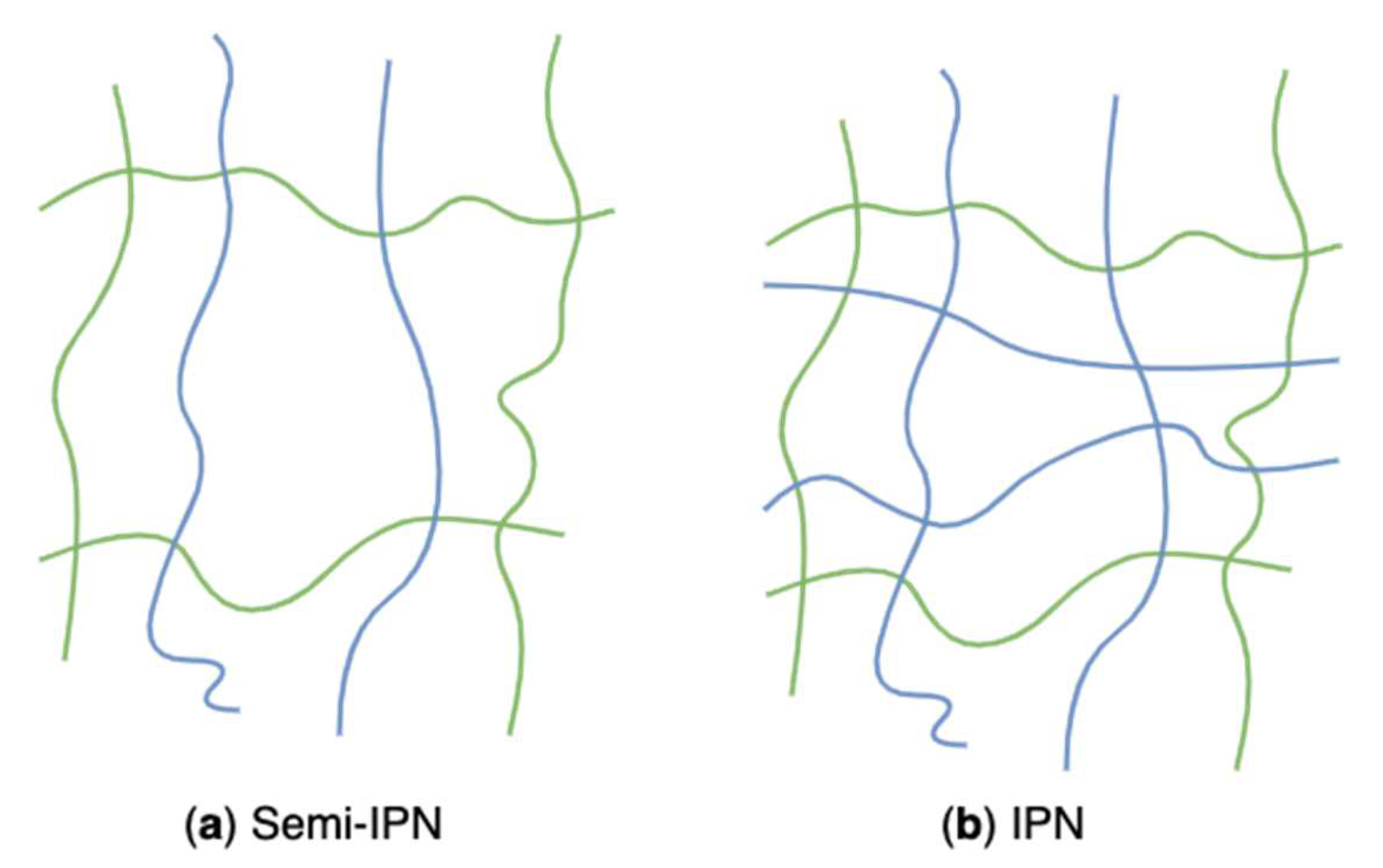

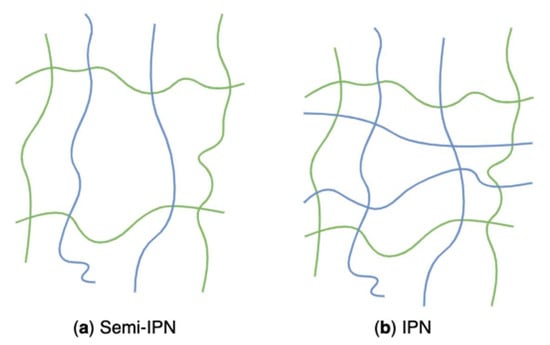

4.4. Semi-Interpenetrating and Interpenetrating Networks

Algal polysaccharides-based hydrogels can also be classified as two composite types: semi-interpenetrating networks (semi-IPN) (Figure 23a) and interpenetrating networks (IPN) (Figure 23b) according to polymeric composition and preparation methods. Those hybrid hydrogels have emerged as innovative materials for biomedical applications. Those structures combining the favourable properties of each polymeric component of the semi-IPNs or IPNs have attracted considerable interest. Their potentials lead to new systems with properties that are superior to those consisting of single components [202]. A linear polymer, such as alginate, agarose, and carrageenans, physically gets through another crosslinked network, but they do not covalently bond with each other. That is called a semi-IPN [203]. The grafted linear polymer modifies pore size and improves the slow release of loaded substances while simultaneously helping maintain the rapid kinetic response to external stimuli because of the absence of a restricting interpenetrating elastic network [120]. For example, semi-IPN hydrogels based on sodium alginate grafted polyacrylamide exhibited pH sensitivity, enhanced pH reversibility, and improved drug entrapment capacity, which was associated with the sodium alginate content [204]. Researchers conducted an in-situ free radical copolymerization between acrylamide and a bifunctional monomer in the aqueous solution of sodium alginate. During the process, semi-IPN hydrogels were formed through growing radicals of monomers and sodium alginate macroradicals. Algal polysaccharides-based hydrogels prepared from the freezing-thawing method (grafting algal polysaccharides to PVA hydrogel) are also regarded as semi-IPN networks.

Figure 23.

Schematic representation of algal polysaccharides-based semi-IPN (a) and IPN (b) networks.

The interpenetrating network can be obtained through inextricably combining two polymers, and at least one of them is synthesized or crosslinked when the other is present [205]. These polymers are partially interweaved on a molecular scale, but no covalent bond is formed within them. Inter penetrating networks are prepared by soaking a pre-polymerized hydrogel into a monomer solution and a polymerization initiator [120]. They possess dense hydrogel matrices resulting in more robust and controllable mechanical and physical properties and a higher drug loading capacity [206]. In drug delivery systems, the pore sizes and surface chemical compositions of the interpenetrating network are tunable so that the drug release kinetics, mechanical properties, and the interaction between hydrogels and the neighbouring tissues can be adjusted [207]. Kulkarni et al. synthesized a pH-responsive IPN hydrogel based on polyacrylamide grafted kappa-carrageenan and sodium alginate through free radical polymerization, followed by the addition of ionic cations and crosslinkers [208]. The prepared hydrogels showed pulsatile swelling and its drug release behavior in response to pH.

5. Performance of Seaweed Polysaccharide-Based Hydrogels

To design polysaccharide-based hydrogels with the desired performance and structure that can be well fitted to a certain application, the characterization of the hydrogel network is of great significance. In general, the characterization methods consist of structural analysis and functional analysis. Additionally, the assessment of cytotoxicity and biocompatibility is indispensable to demonstrate the safety and efficacy of hydrogels prepared for biomedical applications.

5.1. Morphology

Morphological and structural characterization is one of the most critical analytical methods that helps identify the hydrogel morphologies–the porous structure–the porosity affects the water absorption capacity and swelling kinetics of hydrogels [209]. Through a specific analytical technique–scanning electron microscopy (SEM), atomic force microscopy (AFM), or laser scanning confocal microscopy (LSCM)–researchers validate whether the tested hydrogels possess porous structure, as well as whether those pores allow water penetration and represent interaction sites for external stimuli and hydrophilic groups of hydrogels. Those techniques are conducive to capturing the surface morphology and topography of hydrogels and offer advice on their applications, such as their effectiveness as drug delivery systems. Moreover, by exploring the porous structures, the level of swelling can be observed [209,210].

SEM is the most popular technique for detecting the porous structure (formation, size, and shape) and crosslinks of hydrogels, as well as the effect of loading substances [211,212,213]. Before SEM analysis, hydrogels to be tested are treated with formalin and then freeze-dried under −52 °C for six hours, subsequently cutting from the cross-sections and sputtering with gold or gold/platinum under a vacuum [210,214]. Later, Shen et al. skipped the pre-treatment and dehydration instead of using a liquid nitrogen snap freezing [215]. However, some research claimed the liquid nitrogen snap freezing caused the shrinking of gel structures, eventually resulting in an inaccurate evaluation [216,217]. Although SEM is a powerful tool that is capable of acquiring hydrogel structure information, it still has limitations; for example, it only generates two-dimensional images, and its dehydration pre-treatment results in structural collapse. As a result, AFM and LSCM usually serve as alternatives providing supplemental information [113,209]. Rahman et al. reviewed the morphological characterization of hydrogels prepared directly from cellulose or its derivatives using different instruments [209]. The review article highlighted that researchers mainly used SEM to explore the porosity and nature of the structure of cellulose-based hydrogels, while simultaneously they applied AFM to evaluate topological characteristics of hydrogels to exhibit the uniformity of surface roughness of such hydrogels. AFM can also reveal the mechanical properties of the polymer structures [218]. Compared with SEM, no special pre-treatment is required prior to AFM analysis; however, AFM is a time-consuming measuring process with relatively small measured sample areas [65]. Furthermore, researchers use LSCM to analyze the oriented structure within multilayered hydrogels [209] and use magnetic resonance imaging and X-ray tomography to measure the pore size of hydrogels in the wet state [219,220]. Although a series of techniques are available for analysis purposes, contrast and resolution play significant roles in imaging, affecting analysis results [221].

5.2. Swelling and Diffusion, Sensitivity, Texture and Strength, Rheology, and Transparency

Hydrogel water content varies as its surrounding environment changes. The quantity of water per unit mass of the dry sample, which is defined as the swelling degree/swelling ratio (1), is, therefore, a crucial metric for the evaluation of swelling behavior [222,223,224,225,226]. The concept of hydrogel swelling is also important for controlled release systems applied in the biomedical, agricultural, and cosmetic sectors. Because of the presence of hydrophilic groups and the electrostatic repulsions of the amphiprotic groups in the polymeric chains, the solvent molecules are absorbed into the three-dimensional network in the swelling process, resulting in the extrusion of polymeric chains and a thermodynamic swelling force of the polymeric chains being balanced [12,227]. The change of water absorbed impacts the mechanical properties of hydrogels; as such, samples should always be tested in a swollen and equilibrated condition to provide a representative value of their performance during the actual application [228]. The swelling behavior is associated with the number of crosslinking junction points–swelling is reduced if there are more crosslinking connections–so a proper crosslinking control is necessary for the hydrogel fabrication [229].

where and represent the weight of swollen and dried hydrogels, respectively.

On the other hand, the diffusion of solvents into three-dimensional networks is expressed using the power law Equation (2) [230,231].

Where and represent the weight of hydrogels at a specific infiltration time t and at an equilibrium state, respectively; and the coefficient k is proportional to the spread of solvents into the networks.

Hydrogels sensitive to environmental stimuli exhibit promising prospects in functional applications. Changes in pH, temperature, and ion concentration are common in vivo or in different parts of human bodies; as such, hydrogels sensitive to those external triggers are ideal candidates for controlled drug delivery [232]. Additionally, hydrogels that can respond to molecules, light, pressure, moisture, and electrical signals also show promising potential in controlled delivery systems, biosensors, and bioseparation [233,234]. For the sensitive test, an equilibrium in the water content is introduced. For example, to test the temperature sensitivity, the prepared hydrogels are swollen to equilibrium in deionized water under a predetermined range of temperature. After 24 hours of incubation, the samples are removed, oven-dried, and weighed [224]. Similarly, the pH sensitivity can be evaluated by immersing the hydrogels in phosphate-buffered saline solution with different pH values. After equilibrium soaking, samples were wiped and then weighed [224,235]. The equilibrium water content of environmental-sensitive hydrogels is described based on the weight of swollen hydrogels at the equilibrium point and the weight of dried samples (3).

where and represent the weight of swollen hydrogels at the equilibrium state and the weight of dried hydrogels, respectively.

Unconfined compression testing is the simplest method for comparing the mechanical characteristics of hydrogels. It is performed using a typical universal tensile testing equipment fitted with compression plates, a texture analyzer, or a similar setup [65]. Feki et al. used a texture analyzer to assess the texture profile of hydrogel based on chitosan and red algal polysaccharides [224]. Texture parameters, including springiness, hardness, stiffness, adhesiveness, and rupture force, were quantified. The analysis enables the determination of the mechanical characteristics of hydrogel samples and the extraction of the compressive elastic modulus from the initial slope of the compression test curve. This modulus indicates the viscoelasticity of the sample; moreover, cyclic compressive tests may be used to determine the elasticity of hydrogels and their long-term stability under stress [65]. Stiffness measurements also contribute to detecting the sensing behavior of live tissues since living cells are capable of feeling and responding to the stiffness of a substrate material [236].