Efficient Purification of R-phycoerythrin from Marine Algae (Porphyra yezoensis) Based on a Deep Eutectic Solvents Aqueous Two-Phase System

Abstract

1. Introduction

2. Results and Discussion

2.1. Characterization of DESs

2.2. Establishment and Phase Behavior of DES-Based ATPS

2.3. Selection of DES-ATPS for the R-PE Extraction

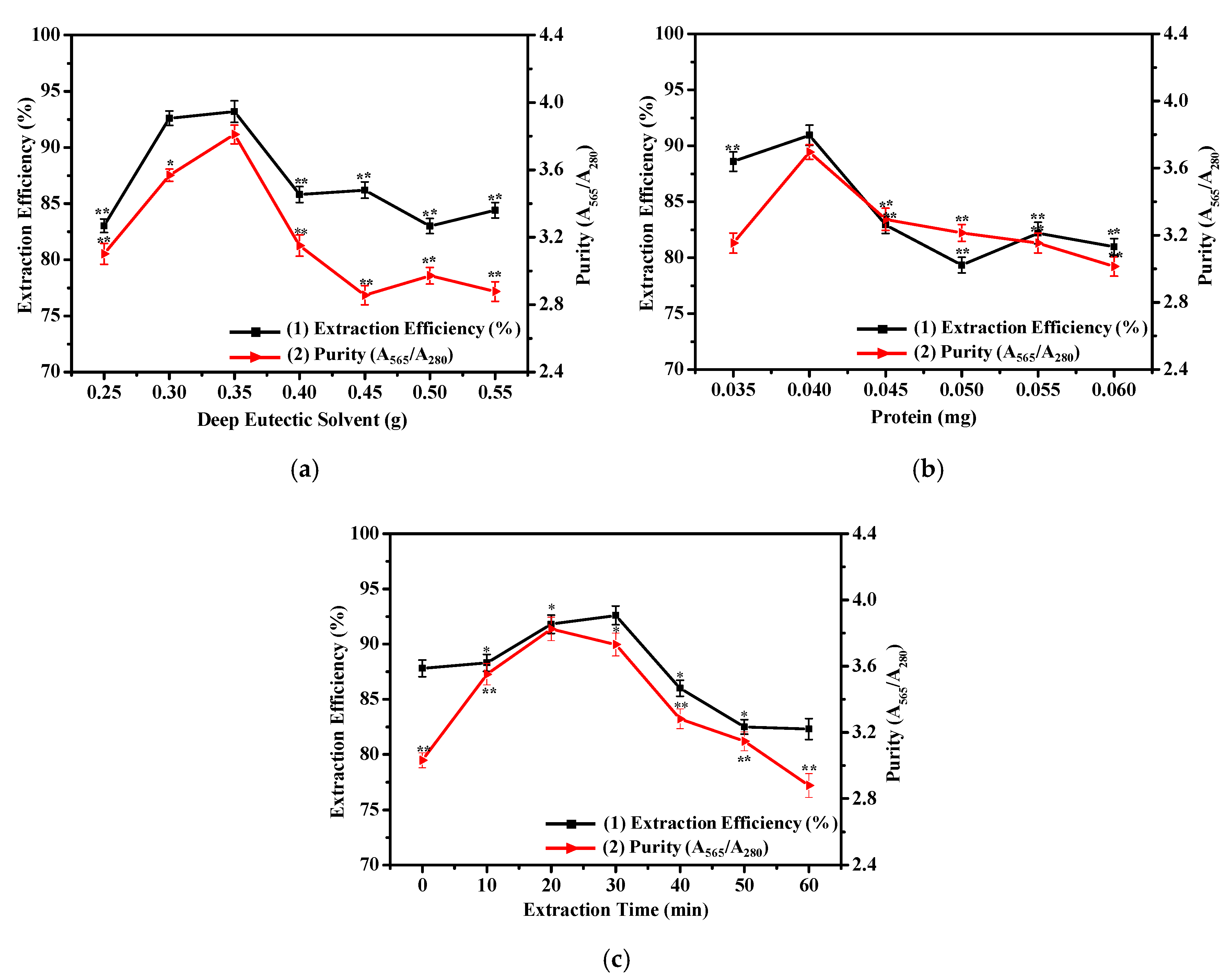

2.4. Single-Factor Experiments

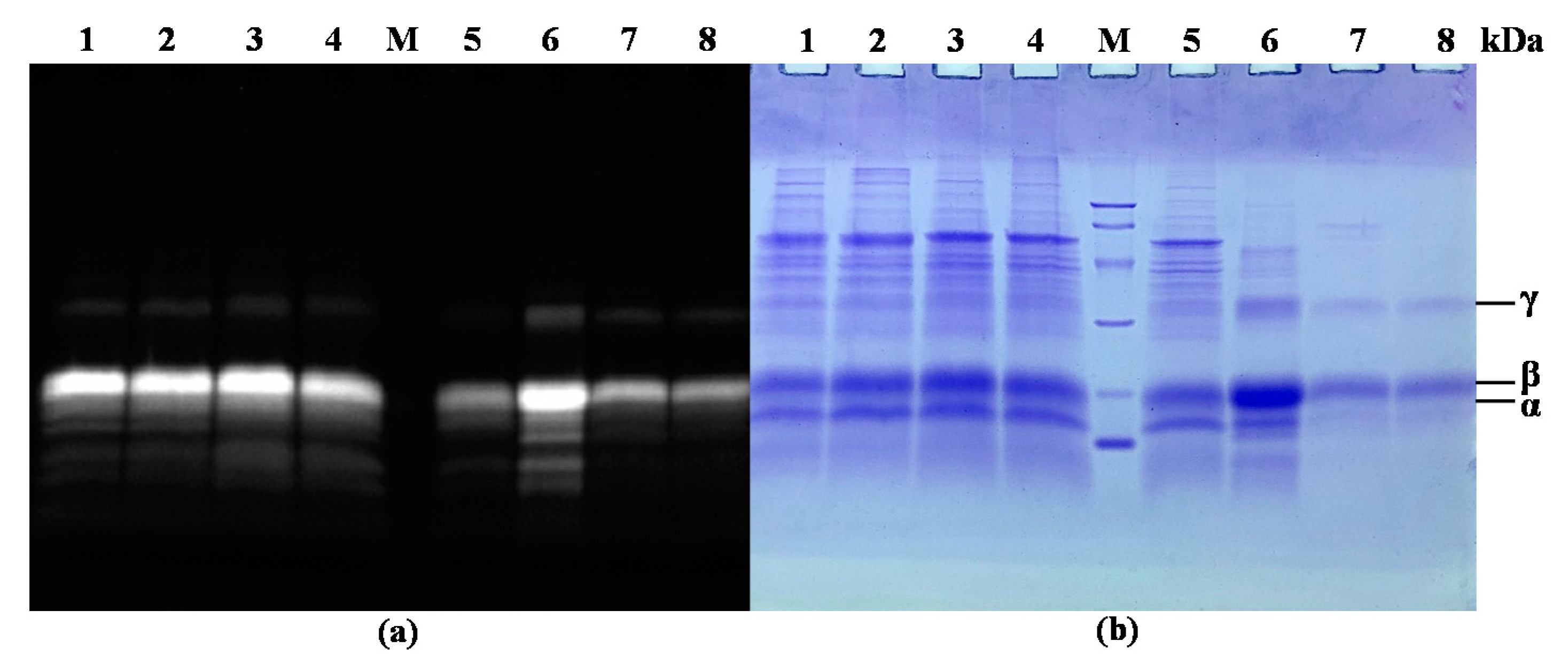

2.5. Electrophoresis Assay of Purified R-PE

2.6. R-PE Purity and Yield Analysis

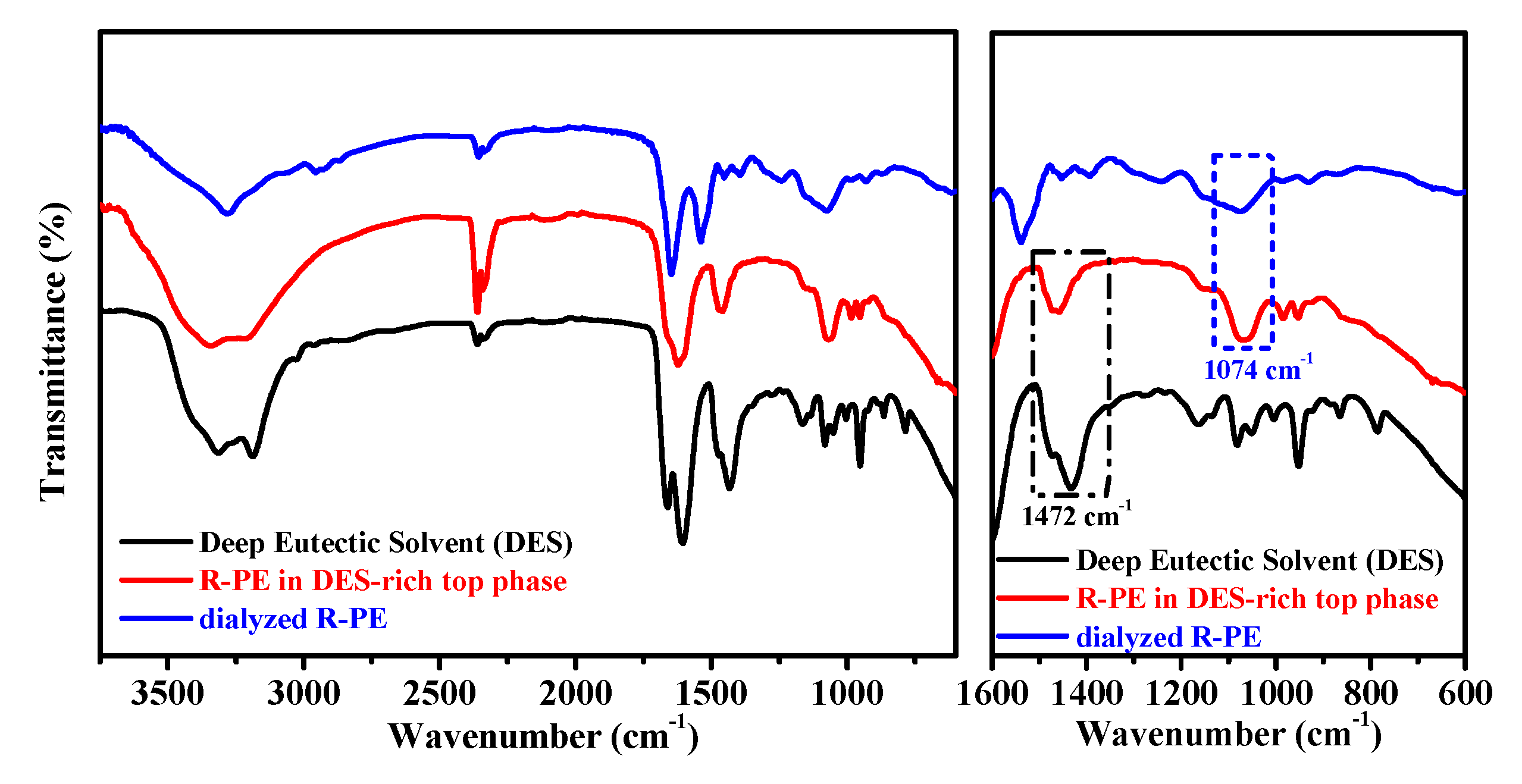

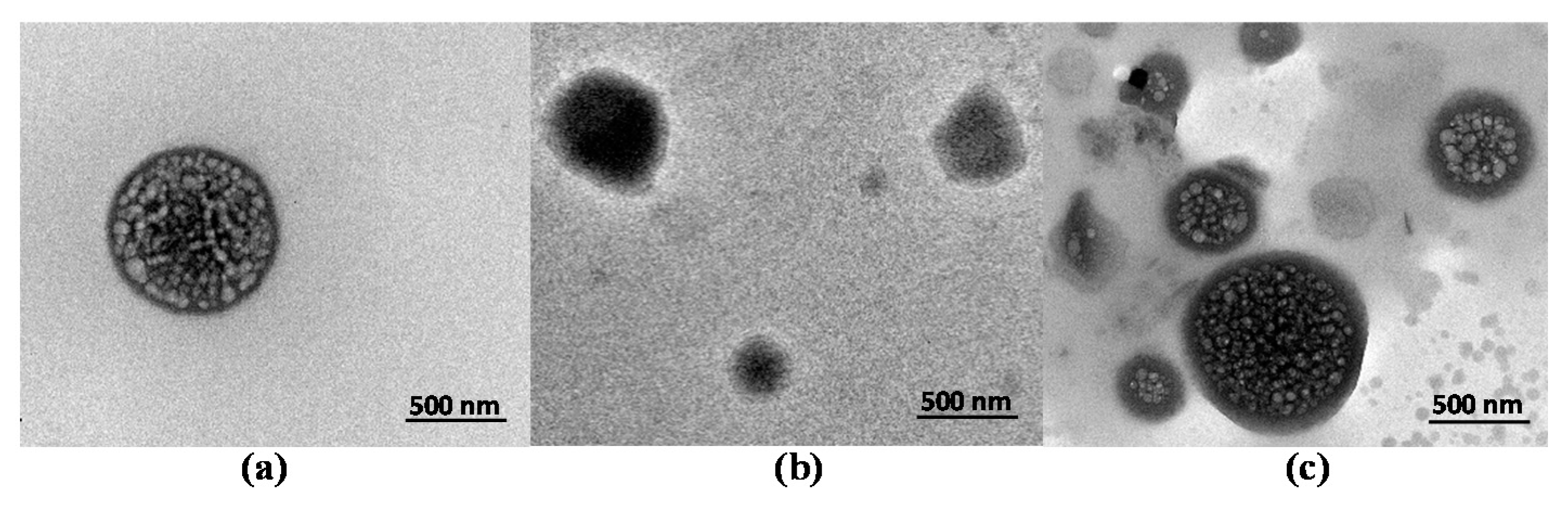

2.7. Characterization of R-PE Properties and Mechanism of Purification Method Based on DES-ATPS

2.7.1. Characterization of R-PE Optical Properties before and after Purification

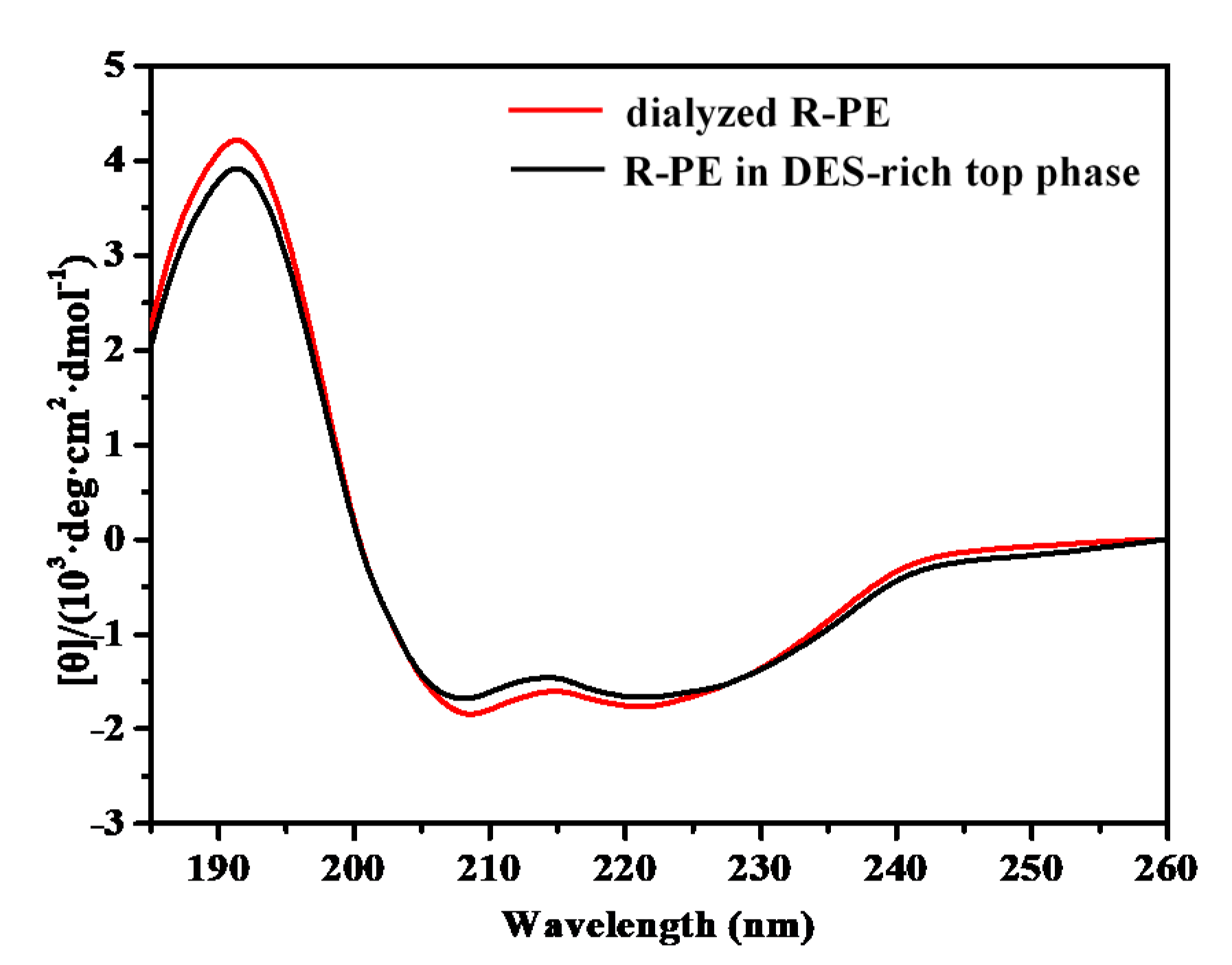

2.7.2. Characterization of R-PE by Circular Dichroism Spectra before and after Purification

2.7.3. Mechanism of the Purification Method Based on DES-ATPS

2.8. Comparison with Other Purification Methods

3. Materials and Methods

3.1. Materials

3.2. R-PE Pre-Treatment from P. yezoensis

3.3. Deep Eutectic Solvents Preparation

3.4. Establishment and Phase Behavior Study of the DES-Based ATPS

3.5. Selection of DES-ATPS for the R-PE Extraction

3.6. Single-Factor Experiments

3.7. Electrophoresis Assay of Purified R-PE

3.8. R-PE Purity and Yield Analysis

3.9. R-PE Properties Characterization and Measurement of the Extraction Mechanism

3.10. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Munier, M.; Morancais, M.; Dumay, J.; Jaouen, P.; Fleurence, J. One-step purification of R-phycoerythrin from the red edible seaweed Grateloupia Turuturu. J. Chromatogr. B-Anal. Technol. Biomed. Life Sci. 2015, 992, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Wang, S.; Gong, X.; Zhao, M.; Fu, X.; Wang, L. Isolation, purification and characteristics of R-phycoerythrin from a marine macroalga Heterosiphonia Japonica. Protein Expr. Purif. 2009, 64, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Isaka, S.; Cho, K.; Nakazono, S.; Abu, R.; Ueno, M.; Kim, D.; Oda, T. Antioxidant and anti-inflammatory activities of porphyran isolated from discolored nori (Porphyra yezoensis). Int. J. Biol. Macromol. 2015, 74, 68–75. [Google Scholar] [CrossRef]

- Fleurence, J.; Morancais, M.; Dumay, J.; Decottignies, P.; Turpin, V.; Munier, M.; Garcia-Bueno, N.; Jaouen, P. What are the prospects for using seaweed in human nutrition and for marine animals raised through aquaculture? Trends Food Sci. Technol. 2012, 27, 57–61. [Google Scholar] [CrossRef]

- Dumay, J.; Clement, N.; Morancais, M.; Fleurence, J. Optimization of hydrolysis conditions of Palmaria palmata to enhance R-phycoerythrin extraction. Bioresour. Technol. 2013, 131, 21–27. [Google Scholar] [CrossRef]

- Jiang, Z.; Hama, Y.; Yamaguchi, K.; Oda, T. Inhibitory effect of sulphated polysaccharide porphyran on nitric oxide production in lipopolysaccharide-stimulated RAW264.7 macrophages. J. Biochem. 2012, 151, 65–74. [Google Scholar] [CrossRef]

- Eduardo Sosa-Hernandez, J.; Isabel Rodas-Zuluaga, L.; Castillo-Zacarias, C.; Rostro-Alanis, M.; De la Cruz, R.; Carrillo-Nieves, D.; Salinas-Salazar, C.; Grunewald, C.F.; Llewellyn, C.A.; Olguin, E.J.; et al. Light intensity and nitrogen concentration impact on the biomass and phycoerythrin production by Porphyridium Purpureum. Mar. Drugs 2019, 17, 460. [Google Scholar] [CrossRef]

- Kersen, P.; Paalme, T.; Pajusalu, L.; Martin, G. Biotechnological applications of the red alga Furcellaria lumbricalis and its cultivation potential in the Baltic Sea. Bot. Mar. 2017, 60, 207–218. [Google Scholar] [CrossRef]

- Wu, Q.; Fu, X.-P.; Sun, L.-C.; Zhang, Q.; Liu, G.-M.; Cao, M.-J.; Cai, Q.-F. Effects of physicochemical factors and in vitro gastrointestinal digestion on antioxidant activity of R-phycoerythrin from red algae Bangia Fusco-Purpurea. Int. J. Food Sci. Technol. 2015, 50, 1445–1451. [Google Scholar] [CrossRef]

- Lee, D.; Nishizawa, M.; Shimizu, Y.; Saeki, H. Anti-inflammatory effects of dulse (Palmaria palmata) resulting from the simultaneous water-extraction of phycobiliproteins and chlorophyll a. Food Res. Int. 2017, 100, 514–521. [Google Scholar] [CrossRef]

- Tan, H.; Gao, S.; Zhuang, Y.; Dong, Y.; Guan, W.; Zhang, K.; Xu, J.; Cui, J. R-phycoerythrin induces SGC-7901 apoptosis by arresting cellcycle at S phase. Mar. Drugs 2016, 14, 166. [Google Scholar] [CrossRef]

- Cian, R.E.; Lopez-Posadas, R.; Drago, S.R.; Sanchez De Medina, F.; Martinez-Augustin, O. Immunomodulatory properties of the protein fraction from Phorphyra columbina. J. Agric. Food Chem. 2012, 60, 8146–8154. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Liu, Y.; Qi, X.; Liang, H.; Chen, H.; Jiang, P.; Wang, D. Dietary recombinant phycoerythrin modulates the gut microbiota of H22 tumor-bearing mice. Mar. Drugs 2019, 17, 665. [Google Scholar] [CrossRef] [PubMed]

- Niu, J.-F.; Wang, G.-C.; Tseng, C.-K. Method for large-scale isolation and purification of R-phycoerythrin from red alga Polysiphonia Urceolata Grev. Protein Expr. Purif. 2006, 49, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Wang, G.C.; Zeng, C.K.; Li, Z.G. The experimental research of R-phycoerythrin subunits on cancer treatment: A new photosensitizer in PDT. Cancer Biother. Radiopharm. 2002, 17, 35–42. [Google Scholar] [CrossRef]

- Kronick, M.N. The use of phycobiliproteins as fluorescent labels in immunoassay. J. Immunol. Methods 1986, 92, 1–13. [Google Scholar] [CrossRef]

- Oi, V.T.; Glazer, A.N.; Stryer, L. Fluorescent phycobiliprotein conjugates for analyses of cells and molecules. J. Cell Biol. 1982, 93, 981–986. [Google Scholar] [CrossRef]

- Sekar, S.; Chandramohan, M. Phycobiliproteins as a commodity: Trends in applied research, patents and commercialization. J. Appl. Phycol. 2008, 20, 113–136. [Google Scholar] [CrossRef]

- Manirafasha, E.; Ndikubwimana, T.; Zeng, X.; Lu, Y.; Jing, K. Phycobiliprotein: Potential microalgae derived pharmaceutical and biological reagent. Biochem. Eng. J. 2016, 109, 282–296. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, Y.; Hou, Y.; Wang, Y.; Yan, M.; Zhang, X.; Wang, H. Highly sensitive and selective fluorescence detection of Hg(II) ions based on R-phycoerythrin from Porphyra Yezoensis. RSC Adv. 2016, 6, 114685–114689. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Suresh, V.; Thangam, R.; Kurinjimalar, C.; Kavitha, G.; Murugan, P.; Kannan, S.; Rengasamy, R. Isolation and characterization of macromolecular protein R-Phycoerythrin from Portieria Hornemannii. Int. J. Biol. Macromol. 2013, 55, 150–160. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Ruiz, F.; Benavides, J.; Rito-Palomares, M. Scaling-up of a B-phycoerythrin production and purification bioprocess involving aqueous two-phase systems: Practical experiences. Process Biochem. 2013, 48, 738–745. [Google Scholar] [CrossRef]

- Chang, Y.-K.; Show, P.-L.; Lan, J.C.-W.; Tsai, J.-C.; Huang, C.-R. Isolation of C-phycocyanin from Spirulina platensis microalga using ionic liquid based aqueous two-phase system. Bioresour. Technol. 2018, 270, 320–327. [Google Scholar] [CrossRef] [PubMed]

- Gai, Q.; Qu, F.; Zhang, T.; Zhang, Y. Integration of carboxyl modified magnetic particles and aqueous two-phase extraction for selective separation of proteins. Talanta 2011, 85, 304–309. [Google Scholar] [CrossRef] [PubMed]

- Pang, J.; Sha, X.; Chao, Y.; Chen, G.; Han, C.; Zhu, W.; Li, H.; Zhang, Q. Green aqueous biphasic systems containing deep eutectic solvents and sodium salts for the extraction of protein. RSC Adv. 2017, 7, 49361–49367. [Google Scholar] [CrossRef]

- Abbott, A.P.; Boothby, D.; Capper, G.; Davies, D.L.; Rasheed, R.K. Deep eutectic solvents formed between choline chloride and carboxylic acids: Versatile alternatives to ionic liquids. J. Am. Chem. Soc. 2004, 126, 9142–9147. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, Y.; Xu, K.; Li, N.; Wen, Q.; Yang, Q.; Zhou, Y. Ternary and binary deep eutectic solvents as a novel extraction medium for protein partitioning. Anal. Methods 2016, 8, 8196–8207. [Google Scholar] [CrossRef]

- Pandey, A.; Rai, R.; Pal, M.; Pandey, S. How polar are choline chloride-based deep eutectic solvents? Phys. Chem. Chem. Phys. 2014, 16, 1559–1568. [Google Scholar] [CrossRef]

- Starykevich, M.; Salak, A.N.; Ivanou, D.K.; Lisenkov, A.D.; Zheludkevich, M.L.; Ferreira, M.G.S. Electrochemical deposition of zinc from deep eutectic solvent on barrier alumina layers. Electrochim. Acta 2015, 170, 284–291. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, C.; Crittle, T.D. Choline-based deep eutectic solvents for enzymatic preparation of biodiesel from soybean oil. J. Mol. Catal. B-Enzym. 2013, 85, 243–247. [Google Scholar] [CrossRef]

- Kaltsa, O.; Lakka, A.; Grigorakis, S.; Karageorgou, I.; Batra, G.; Bozinou, E.; Lalas, S.; Makris, D.P. A green extraction process for polyphenols from elderberry (Sambucus nigra) flowers using deep eutectic solvent and ultrasound-assisted pretreatment. Molecules 2020, 25, 921. [Google Scholar] [CrossRef] [PubMed]

- Bajkacz, S.; Adamek, J.; Sobska, A. Application of deep eutectic solvents and ionic liquids in the extraction of catechins from tea. Molecules 2020, 25, 3216. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Wang, Y.; Huang, Y.; Ding, X.; Chen, J.; Xu, K. Deep eutectic solvents as novel extraction media for protein partitioning. Analyst 2014, 139, 2565–2573. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Wang, Y.; Li, N.; Huang, X.; Ding, X.; Lin, X.; Huang, S.; Liu, X. Extraction of proteins with ionic liquid aqueous two-phase system based on guanidine ionic liquid. Talanta 2013, 116, 409–416. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Wang, Y.; Huang, Y.; Li, N.; Wen, Q. A green deep eutectic solvent-based aqueous two-phase system for protein extracting. Anal. Chim. Acta 2015, 864, 9–20. [Google Scholar] [CrossRef] [PubMed]

- Freire, M.G.; Pereira, J.F.B.; Francisco, M.; Rodriguez, H.; Rebelo, L.P.N.; Rogers, R.D.; Coutinho, J.A.P. Insight into the interactions that control the phase behaviour of new aqueous biphasic systems composed of polyethylene glycol polymers and ionic liquids. Chem. A Eur. J. 2012, 18, 1831–1839. [Google Scholar] [CrossRef] [PubMed]

- Duan, L.; Dou, L.-L.; Guo, L.; Li, P.; Liu, E.H. Comprehensive evaluation of deep eutectic solvents in extraction of bioactive natural products. ACS Sustain. Chem. Eng. 2016, 4, 2405–2411. [Google Scholar] [CrossRef]

- Li, N.; Wang, Y.; Xu, K.; Huang, Y.; Wen, Q.; Ding, X. Development of green betaine-based deep eutectic solvent aqueous two-phase system for the extraction of protein. Talanta 2016, 152, 23–32. [Google Scholar] [CrossRef]

- Niu, J.-F.; Chen, Z.-F.; Wang, G.-C.; Zhou, B.-C. Purification of phycoerythrin from Porphyra yezoensis Ueda (Bangiales, Rhodophyta) using expanded bed absorption. J. Appl. Phycol. 2010, 22, 25–31. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Zeng, Q.; Ding, X.; Huang, Y. Partition of proteins with extraction in aqueous two-phase system by hydroxyl ammonium-based ionic liquid. Anal. Methods 2014, 6, 4067–4076. [Google Scholar] [CrossRef]

- Souza, R.L.; Lima, R.A.; Coutinho, J.A.P.; Soares, C.M.F.; Lima, A.S. Novel aqueous two-phase systems based on tetrahydrofuran and potassium phosphate buffer for purification of lipase. Process Biochem. 2015, 50, 1459–1467. [Google Scholar] [CrossRef]

- Shang, L.; Wang, Y.; Jiang, J.; Dong, S. pH-dependent protein conformational changes in albumin: Gold nanoparticle bioconjugates: A spectroscopic study. Langmuir 2007, 23, 2714–2721. [Google Scholar] [CrossRef] [PubMed]

- Bekasova, O.D.; Shubin, V.V.; Safenkova, I.V.; Kovalyov, L.I.; Kurganov, B.I. Structural changes in R-phycoerythrin upon CdS quantum dot synthesis in tunnel cavities of protein molecules. Int. J. Biol. Macromol. 2013, 62, 623–628. [Google Scholar] [CrossRef] [PubMed]

- Mittal, R.; Sharma, R.; Raghavarao, K.S.M.S. Aqueous two-phase extraction of R-Phycoerythrin from marine macro-algae, Gelidium pusillum. Bioresour. Technol. 2019, 280, 277–286. [Google Scholar] [CrossRef]

- Liu, L.N.; Chen, X.L.; Zhang, X.Y.; Zhang, Y.Z.; Zhou, B.C. One-step chromatography method for efficient separation and purification of R-phycoerythrin from Polysiphonia Urceolata. J. Biotechnol. 2005, 116, 91–100. [Google Scholar] [CrossRef]

- Bai, C.; Wei, Q.; Ren, X. Selective extraction of collagen peptides with high purity from cod skins by deep eutectic solvents. ACS Sustain. Chem. Eng. 2017, 5, 7220–7227. [Google Scholar] [CrossRef]

- Chakraborty, A.; Sen, K. Impact of pH and temperature on phase diagrams of different aqueous biphasic systems. J. Chromatogr. A 2016, 1433, 41–55. [Google Scholar] [CrossRef]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

- Singh, N.K.; Parmar, A.; Madamwar, D. Optimization of medium components for increased production of C-phycocyanin from Phormidium ceylanicum and its purification by single step process. Bioresour. Technol. 2009, 100, 1663–1669. [Google Scholar] [CrossRef]

- Gao, H.F. The variation in the contents of phycobiliproteins from Porphyra haitanensis collected in different growing stages. Oceanol. Limnol. Sin. 1993, 24, 645–648. [Google Scholar]

| Purification Step | Total Protein Content (mg) | R-PE Content (mg) | Yield (%) | Purity (A565/A280) |

|---|---|---|---|---|

| First to fourth frozen-thawing extract (crude extract) | 174.62 | 88.29 | 94.43 | 0.713 |

| Two-step salting-out extraction (dialyzed R-PE) | 96.94 | 70.68 | 75.59 | 2.293 |

| R-PE after aqueous two-phase system (ATPS) | 69.23 | 65.45 | 69.99 | 3.825 |

| Method | Source | Yield (%) | Purity (A565/A280) | References |

|---|---|---|---|---|

| DEAE–Sepharose Fast Flow chromatography | Grateloupia turuturu | 27.00 | 2.890 | [1] |

| Gel filtration + DEAE–Sepharose Fast Flow chromatography | Heterosiphonia japonica | none | 4.890 | [2] |

| Ammonium sulfate precipitation +DEAE-Sepharose Fast Flow chromatography | Polysiphonia urceolata | 67.33 | 5.600 | [45] |

| Ammonium sulfate precipitation + Q-Sepharose column chromatography | Portieria hornemannii | 64.80 | 5.210 | [21] |

| Hydroxyapatite chromatography | Polysiphonia urceolata | 22.00 | 3.900 | [14] |

| Aqueous two-phase system (ATPS) (PEG 1450/K3PO4) | Gelidium pusillum | 72.00 | 1.100 | [44] |

| Deep eutectic solvent aqueous two-phase system (DES-ATPS) (choline chloride-urea/K2HPO4) | P. yezoensis | 69.99 | 3.825 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Wang, Q.; Hou, Y. Efficient Purification of R-phycoerythrin from Marine Algae (Porphyra yezoensis) Based on a Deep Eutectic Solvents Aqueous Two-Phase System. Mar. Drugs 2020, 18, 618. https://doi.org/10.3390/md18120618

Xu Y, Wang Q, Hou Y. Efficient Purification of R-phycoerythrin from Marine Algae (Porphyra yezoensis) Based on a Deep Eutectic Solvents Aqueous Two-Phase System. Marine Drugs. 2020; 18(12):618. https://doi.org/10.3390/md18120618

Chicago/Turabian StyleXu, Yifeng, Quanfu Wang, and Yanhua Hou. 2020. "Efficient Purification of R-phycoerythrin from Marine Algae (Porphyra yezoensis) Based on a Deep Eutectic Solvents Aqueous Two-Phase System" Marine Drugs 18, no. 12: 618. https://doi.org/10.3390/md18120618

APA StyleXu, Y., Wang, Q., & Hou, Y. (2020). Efficient Purification of R-phycoerythrin from Marine Algae (Porphyra yezoensis) Based on a Deep Eutectic Solvents Aqueous Two-Phase System. Marine Drugs, 18(12), 618. https://doi.org/10.3390/md18120618