Abstract

Finely dispersed copper nanoparticles were added as an additive to fully-formulated engine oils. The copper additive was in colloidal form, with an inner core of Cu2+ atoms covered by surfactants to form stable reverse micelles that are completely dispersible in the base oil. The tribological process to form protective films at the metal surface is comprised of three phases. Phase I can be considered a physical process involving the build-up of polar molecules by absorption to produce a friction modifier film, whereas phases II and III have to be treated as mechanochemical processes comprising a combination of redox reactions and a third body formation. The tribological performance was investigated using atomic force microscopy, a microtribometer, a pin-on-disk tribometer in combination with continuous and high-resolution wear measurements with radionuclide technique, and high pressure stressing in a thrust roller bearing test rig. In addition, the nanostructure of the additive was characterized by atomic force microscopy. Finally, the chemical composition of the metal surface was analyzed using photoelectron spectroscopy.

1. Introduction

Lubricant additives based on copper micro- and nanoparticles have been known for more than four decades. A significant amount of this work was carried out by Garkunov, Kragelskiy, and Rebynder. A summary of this research can be found in [1]. The technology was originally developed for use in high-wear applications. Historically, the effect of friction and wear reduction by copper films was discovered when analyzing the durability and endurance of compressors in refrigerators. According to Garkunov, it was found out that the copper tubing was attacked by an oil and dichlordifluormethane (freon) mixture. Due to friction, the attack became more aggressive with the formation of acids. As a result, copper was found to be suspended and dissolved in the oil as particles. When the copper particles were compressed between two friction bodies, it was found that layering occurs. The authors report copper layers with a thickness of up to 1 m. When the mechanical system was operated with no copper metal parts, it was found that the addition of copper particles also caused film formation, provided that the particles do not segregate. Under these circumstances, Garkunov et al. found that the copper film does not oxidize, and material can be transferred to the counter body. As a result, a copper–copper sliding interface is formed. The non-oxidizing effect is attributed to the catalytic action of copper transforming monomers of the lubricant into polymers, ensuring that copper remains in a non-oxidized state. The polymers that are formed cover the surface of the copper film, and, as a result, increase the viscosity of the fluid close to the surface and prevent oxidation. The effect of wear reduction by copper tribofilms has been demonstrated by many experiments, including both tribometers and real applications, such as pumps [1,2,3,4,5]. Yu et al. [4] explain the observed decrease in wear by the easier pass of the contact area (and, as a consequence, less abrasive wear), but also by the sedimentation and the filling of grooves with Cu nanoparticles of the oil, leading to a lower wear as determined by a balance [6]. A decrease in wear with increasing Cu-nanoparticle concentration was also found by Yang et al. [7], who explain the decrease in the wear scar diameter by the self-repairing function and the filling-up of wear grooves. Liu et al. [8] named this effect the “mending effect”, and attributed to it the decrease in friction, which is found by all the above cited authors and also described by Zhang et al. [9], who found the existence of a tribofilm, smoothening of the surface, and a decrease in friction, but not a significant reduction in wear. Yu et al. [4,6] find a lower hardness and modulus of the tribofilm compared to the bulk, and attribute the experimentally found lower friction to these tribofilm properties, as do Tarasov et al. [10], who argue that the friction reduction can be attributed to the tribofilm’s better damping of friction-induced stresses compared to the bulk. However, more recent research has shown that, when wear is measured with high-resolution methods such as the radionuclide technique (RNT), zero-wear can only be achieved under complete hydrodynamics, when both friction bodies are separated by a fluid film. In mixed lubrication condition, every machine part shows wear, although the wear rates may be small; for example, as low as 2 nm/h for connecting rod bearings in a combustion engine [11]. Consequently, recent research has focused on the reduction of friction in ultra-low wear applications in, for example, combustion engines [10,12].

A significant problem with the deployment of copper particles as lubricant additives in oil-based systems is the poor stability of suspensions and dispersions [13]. In additive systems where the particles are poorly dispersed, the suspension is not stable, and the particles accumulate, dropout, and form sediments. This makes the additive inactive, and it cannot provide any positive performance benefits. Current research has focused on improving colloid stability by modification of the surface of the copper nanoparticles with surfactant ligand molecules [5,14]. This helps to prevent the aggregation of the particles when suspended or dispersed in base oil.

Despite all this work, the mechanism of copper particles and film formation in systems operating in mixed or boundary lubrication regimes is not well understood. The mechanism by which copper additives reduce friction and protect against wear has remained unclear, because many laboratory tests do not properly simulate actual field operating conditions. The speeds, loads, and contact pressures in these tests often produce very high wear rates that are unrepresentative of real-world conditions. As a result, the additives cannot function properly or provide any real benefit. In practice, the wear rates in modern engines and gearboxes are ultra-low.

The current researchers have carried out studies using laboratory tests running under more realistic conditions, producing much lower wear rates typical of field conditions. The tests were performed with continuous wear measurement accompanied by state-of-the-art surface science, including XPS and atomic force microscopy (AFM). The formation of copper tribofilms was detected and analyzed, and a multi-phase wear and friction reduction mechanism was observed.

2. Materials and Methods

2.1. Lubricant

A patented process was used for the production of suspended and dispersed copper particles [15]. The commercially available additive Nanol®M[10.0-T] was supplied by Nanol (AB Nanol Technologies Oy, Helsinki, Finland) and added to a commercially available lubricant Chevron Taro 30 DP 40 (Chevron, San Ramon, CA, USA) and Teboil Ward (Lukoil, Moscow, Russia) in different concentrations, as explained below. In the production process, Copper was introduced as copper chloride and mixed with tin chloride. The salts were chosen because of their good solubility and low tendency to form sediments. There were no corrosion effects from the use of chlorides reported in field tests. Oleic acid was added to form copper oleate. After a complex chemical process, copper nanoparticles are produced with Cu0 as a central atom surrounded by Cu2+ in the outer shell. The mixture contains an excess of copper oleate, and the Cu2+ head group attaches to the copper shell and spreads out its nonpolar tail to the surrounding base oil with improved solubility and stability. As a result, a reverse micelle structure is obtained. Finally, succinimide was added as precursor to facilitate the copper plating process. Cyclic voltametry measurements were made on the redox potential and electrochemical reaction rates. The findings suggest that when the Cu2+ ions contact the oxide-free iron surface, a redox reaction is triggered, with the depostion of a pure copper film. The redox reaction leads to the oxidation of iron.

2.2. Microtribometry—Materials and Test Program

A reciprocating microtribometer (Basalt, Tetra GmbH, Ilmenau, Germany) was used to measure friction. The microtribometer applies a combination of precision drives for vertical and lateral motion, a force transducer with steel double leaf spring, and fiber-optical sensors to resolve friction forces in the mN range. In all tests, tribological conditions defined by sliding velocity, sliding distance, temperature, and relative humidity were kept constant. The normal force was varied between 0.1 and 180 mN to generate a contact pressure between 25 MPa and 975 MPa. The sliding velocity was 0.02 mm/s. Oil was supplied to a polished steel washer and formed a capillary neck with the counter sample, a sapphire ball with a radius of 5 mm. The friction tests were performed at 25 °C with 60% relative humidity. The first tests were carried out under dry sliding conditions. Then, the experiments were extended to tests with a reference lubricant (Chevron Taro 30 DP 40), and finally with this reference oil containing either 0.3 vol % or 3 vol % of the copper additive. The reference oil was a fully-formulated engine oil. In order to reduce cross-contamination, the sapphire ball was cleaned before each test. The coefficient of friction was averaged over the sliding distance during each cycle.

2.3. Macrotribometry—Materials and Test Program

2.3.1. Sliding Friction Tests with Radionuclide Technique

The tests with a commercially available pin-on-disk tribometer (TETRA GmbH, Germany) were carried out with a commercially available marine diesel engine oil (Teboil Ward, Lukoil, Moscow, Russia), with and without the copper additive at a temperature of 90 °C. The oil circuit was filled with 2.5 L. Using a central nozzle, oil was directly supplied to the disk and spread due to rotation. From the oil sump underneath the disk, a pump sucks the oil into the RNT sensor assembly and brings it back to the disk via the nozzle.

Gray cast iron (GG 25, lamellar graphite) was used as disk material. The 5 mm thick disk had a diameter of 80 mm and was manufactured by high-precision turning. The average roughness is 75 nm, and the standard deviation (RMS) is 100 nm, measured over an area of 100 μm × 100 μm with an atomic force microscope. Chromium-plated steel 100Cr6 was used as pin material. The pins have a diameter of 5 mm with a slightly tapered edge to prevent undesired cutting into the disk. In order to achieve a flat contact between pin and disk, the pin holder has a self-regulating adjustment. The tribometer covers a wide range of normal forces between 10 N and 1000 N and sliding velocities between 0.1 m/s and 10 m/s.

To achieve an overview of the tribological performance of the system, Stribeck curves were recorded using the reference oil at a sliding velocity of 2 m/s and contact pressures varying between 25 MPa and 45 MPa. Effective running-in conditons (i.e., the most significant drop of friction) were identified with a contact pressure of 25 MPa. To create a situation of slight over-stressing, all further tests were carried out with a contact pressure of 45 MPa. The concept of the running-in corridor—including the scenario of over- and under-stressing—has been discussed in [16]. After passing the running-in stage, a portion of the reference oil was replaced by the same oil, now containing 3% of the copper additive.

During the tests, wear of the pin was monitored continuously by radionuclide technique (RNT). In the entire pin area facing the disk, nuclide wear markers were generated. Across the pin, the simultaneous contact of many asperities contributes to wear. Thus, the amount of wear is an average of all the microscopic wear events. Although only the pin was irradiated for the RNT, conclusions about the wear behavior of the entire system can be made. In addition, the disk wear tracks were quantified after the test, using white light interferometry. With the radionuclide technique, micrograms of wear can be detected in the lubrication system that corresponds to a wear rate of only a few nanometers per hour. Details of the method were described by Scherge et al. [17]. To obtain wear tracers, pins were subjected to low-energy neutron radiation. Cr-51 was used as nuclide. The oil sump of the tribometer was connected to a gamma detector (Zyklotron AG, Germany), allowing continuous monitoring of wear in the oil. To account for decay effects, a reference measuring device was included in the oil circulation system.

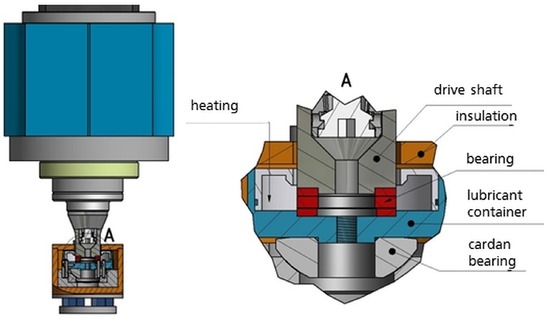

2.3.2. Rolling Friction Tests

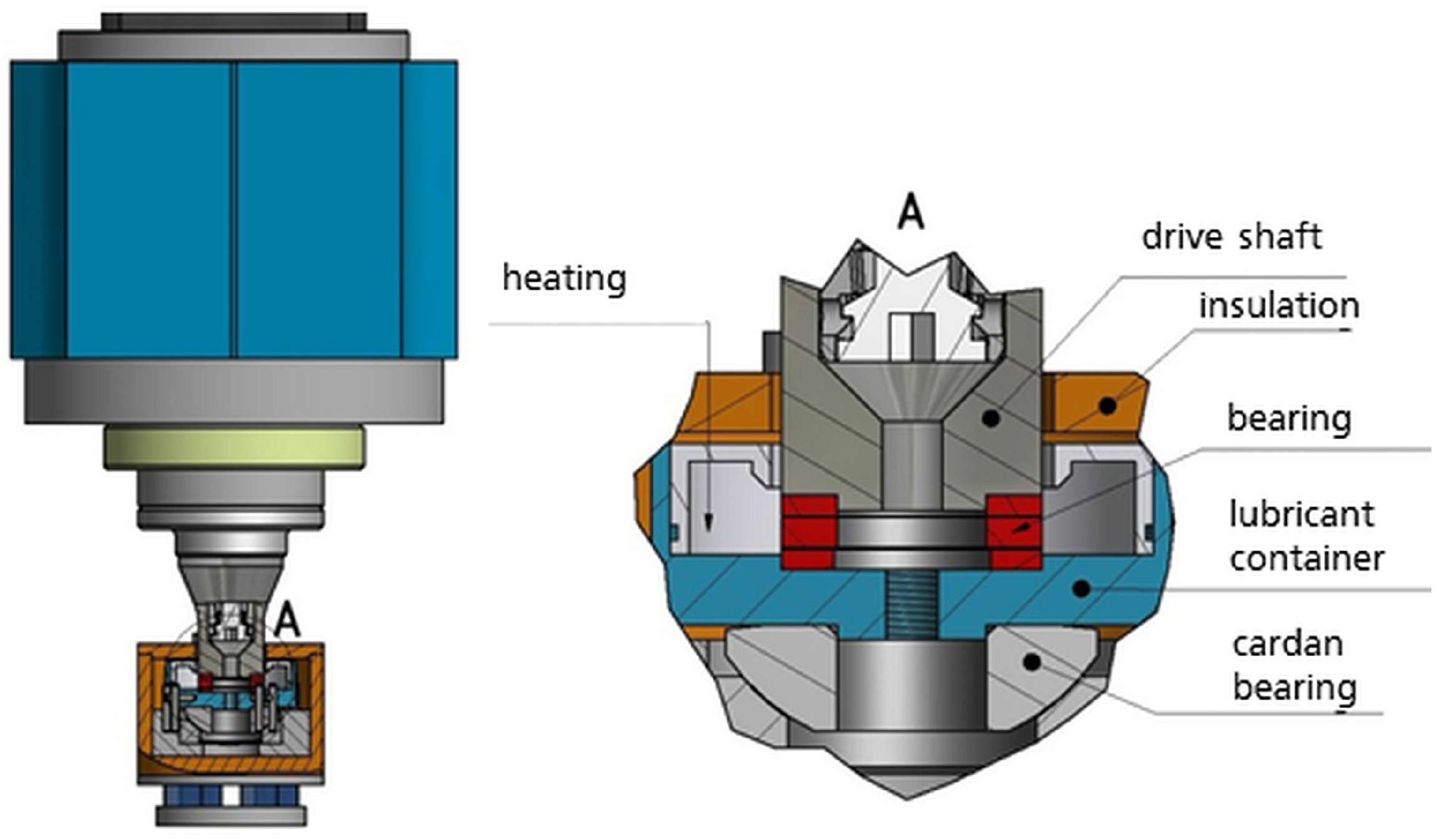

A custom-made thrust roller bearing test rig, made for 81104-TV thrust roller bearings (Schaeffler Technologies AG & Co. KG, Germany), was used to simulate rolling friction at higher contact pressures. The maximum load capacity is 10 kN at a rotational speed of 1500 rpm. During the bearing test, the frictional moment, the lubricant temperature, the load, the rotational speed, the displacement, and the duration were logged. Tests were performed with constant load and sliding velocity, and regular sets of Stribeck curves were obtained at a normal force of 8 kN, corresponding to a maximum Hertzian contact stress of 1930 MPa. The test rig was operated for a duration of 100 h at 700 rpm. The lubricant used was Chevron Taro 30 DP 40 with a temperature kept constant at 115 °C. The bearing consists of two 100Cr6 washers and roller bearing elements with a fatigue limit of 800 MPa and a yield stress of 1200 MPa. The predicted life time of the bearing was 443 h. A schematic of the machine is shown in Figure 1.

Figure 1.

Schematic of the thrust bearing test rig.

2.4. Microscopy and Physico-Chemical Analysis

Nanoscale topography imaging was used to characterize the surfaces with a commercially available ambient AFM (Veeco Dimension V Atomic Force Microscope, Bruker, Billerica, MA, USA). All measurements were made using a Si3N4 cantilever with pyramidal tip that has a manufacturer quoted radius of curvature of 20 nm. The samples were scanned in air with a typical scanning speed of 5 μm/s. All measurements were carried out using the same tip. By recording lateral forces, the frictional behavior of the surfaces was analyzed. For lateral force calibration, the method as described by Ogletree et al. and Varenberg et al. [18,19] was used.

Topography on a larger scale was investigated by white light interferometry (Sensofar, Barcelona, Spain). The lateral resolution of the device is 300 nm, whereas in vertical resolution, several nanometers can be resolved.

XPS depth profiles were recorded to quantify the intensity of tribological interaction using a PHI 5000 Versaprobe (Physical Electronics, Chanhassen, MN, USA) with 15 keV monochromatic Al-K-X-ray excitation and an energy resolution of 0.2 eV. Spectra were generated with 10 keV and 20 nA. Argon ions were used for material removal in order to obtain depth profiles. The sputter rate was determined by means of a silicon oxide reference, yielding comparable values with an error in the depth values of about 10%. The area exposed to argon ions was about 2 mm2. Photoelectrons were excited from an area of 300 μm × 300 μm.

The redox behavior of the additive was studied by cyclic voltammetry. The potential of the working electrode was measured versus a reference electrode maintained at constant potential, and the resulting applied potential produced an excitation signal. In the forward direction, the potential first scans negatively, starting from a greater potential and ending at a lower potential. The potential at peak is called the switching potential, and is the point where the voltage is sufficient to have caused an oxidation or reduction. In the reverse direction, the potential scans positively. It is important to note that some materials undergo oxidation first, in which case the potential would first scan positively. This cycle can be repeated, and the scan rate can be varied. The slope of the excitation signal gives the scan rate used. For the additive samples, the cyclic voltammograms were recorded with 10 μL and 20 μL of the sample mixed with 10 mL of 0.1 M TBABF4-ACN solution. The working electrode was a glassy carbon disk electrode, the reference electrode was an Ag/AgCl//3M KCl electrode and the counter electrode was a glassy carbon rod. Before measurement, the open-circuit potential was registered. Three cyclic voltammogram cycles were then recorded in the potential range +1 V to −0.5 V with a scan rate of 50 mV/s.

2.5. Summary of Test Conditions, Samples, and Oils

Table 1 summarizes the test conditions in terms of contact pressure, sliding velocity, and temperature. In addition, the table indicates the type of oil and its additivation.

Table 1.

Test conditions, sample materials, and oils. AFM: atomic force microscopy.

3. Results

3.1. Structure Analysis

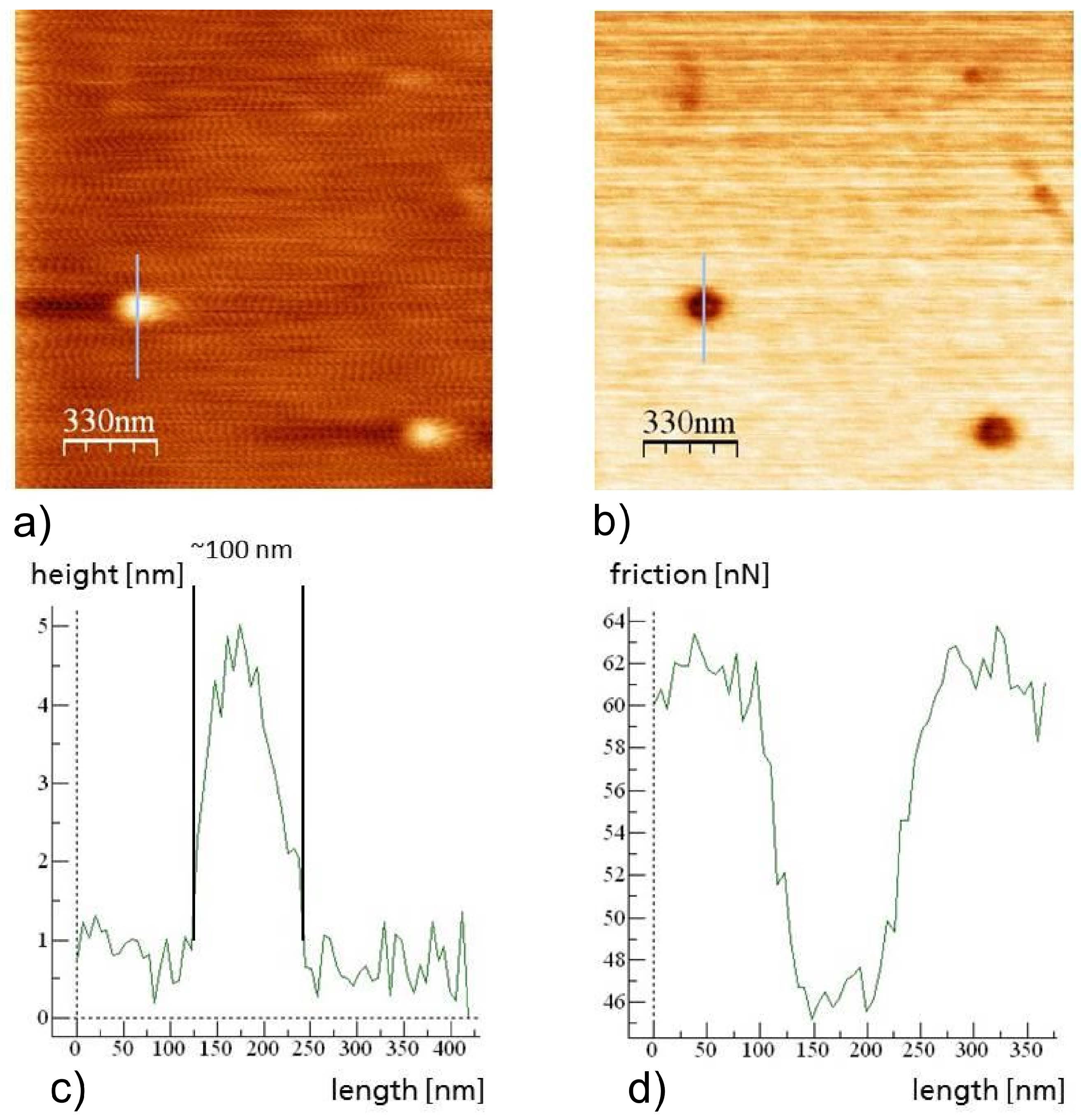

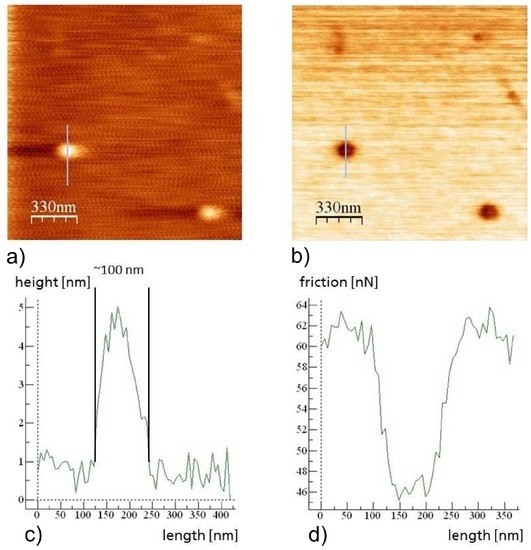

A thin film of oil containing 3% of the copper additive was prepared on an ultra-smooth silicon wafer. This was done by first taking two pieces of a silicon wafer prepared with a cleaning cycle of acetone (10 min) and ethanol (10 min) in an ultrasonic bath. To completely remove any trace of organic contamination, the sample was treated for 20 min with a UV light–ozone cleaner. Then, a small drop of oil was deposited on one of the Si pieces and spread using the other one. Finally, a drop of cyclohexane was deposited on the oiled sample, and the evaporation of the solvent (and dissolved oil) left an area free from oil in the center of the sample. The cyclohexane did not attack the micelles. Therefore, the oil evaporated together with the solvent, leaving the particles on the Si surface. With the AFM in contact mode, topography and friction signals were recorded. For each of four measured positions, islands with an height of 3–6 nm and a significant friction reduction were found (see an example in Figure 2). These spots have an average uncorrected diameter between 80 nm and 120 nm. The measured friction force varied from position to position, although the normal force was kept constant. It seems that the adhesion varied due to sample preparation, so that the measured friction reduction by AFM is only qualitatively described here.

Figure 2.

(a) AFM images of silicon surfaces carrying copper micella; (b) Friction force measurements. The location of the profile segment in (c) and (d) is indicated in the topography/friction map (a) and (b).

The height of the particles (≈5 nm) suggests that the diameter of the copper core is in the same range, and that the area with low friction indicates the size of the micelles.

3.2. Tribological Microscale Analysis

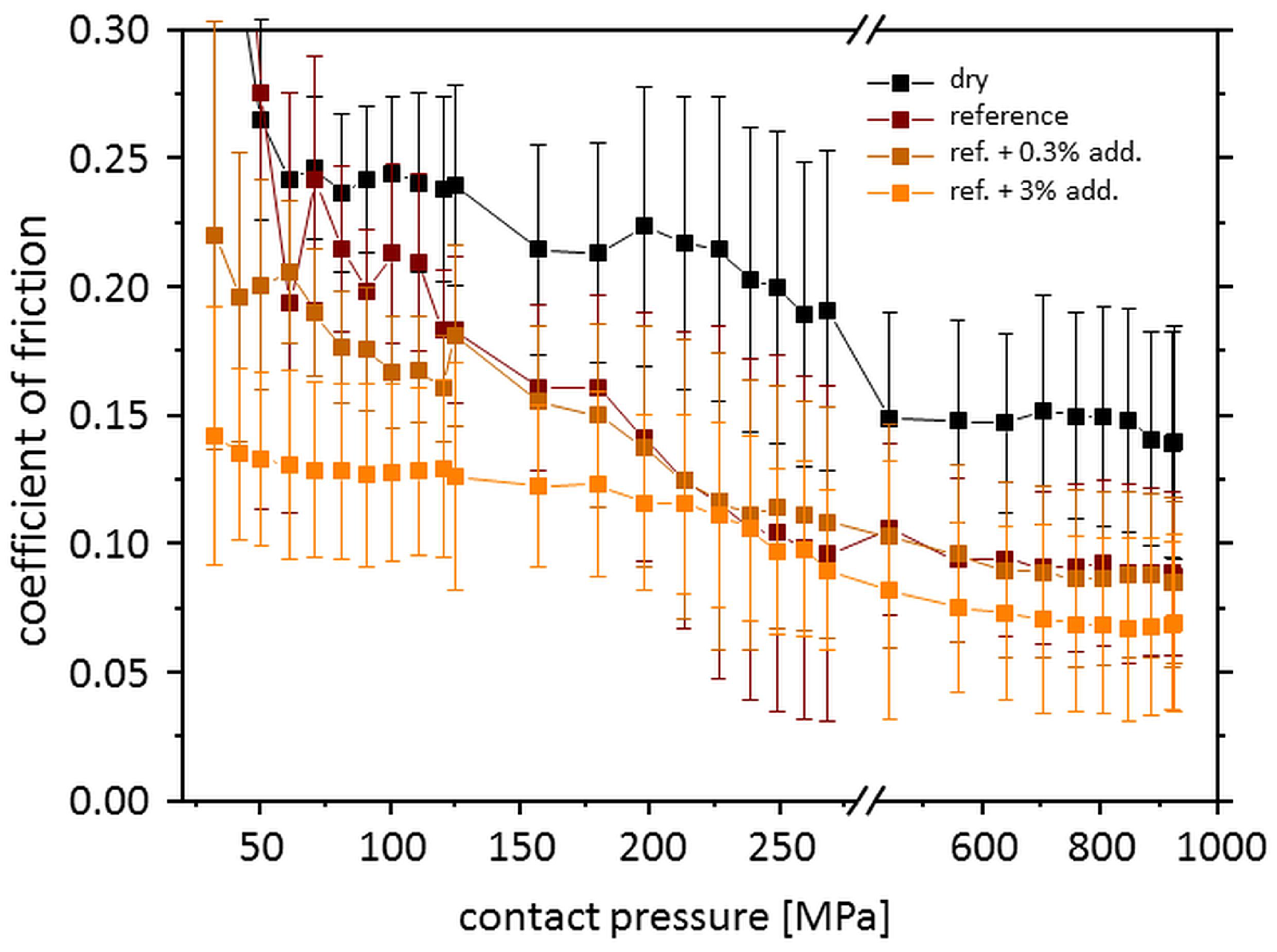

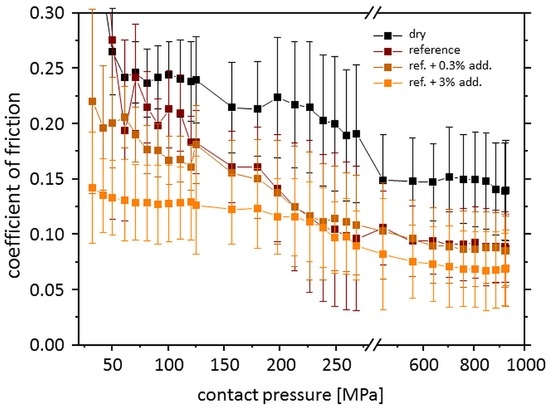

Microtribometer tests were conducted with a reference oil containing the copper additive. The results were compared with the reference oil and in the dry state. The objective was to determine the coefficient of friction in a mode with negligible wear. To achieve this, the number of cycles (i.e., trace and backtrace) was limited to 10. After the test, the wear state was probed by AFM. Topography images showed that no wear was detectable within the resolution of the device. Friction was determined as a function of contact pressure in a range that is characteristic for sliding applications like piston ring versus liner. In addition, the contact pressure was increased to higher values to simulate slip in rolling contacts. The results obtained show that the copper additive produces an instantaneous reduction in the coefficient of friction (see Figure 3). This is most pronounced at low contact pressures. It demonstrates that the additive behaves like a normal friction modifier. The polar head groups in the additive system adsorb on the metal surface to form a simple tribofilm that reduces friction.

Figure 3.

Friction measurements with the microtribometer. The color coding shows the different lubrication conditions.

3.3. Tribological Macroscale Analysis

3.3.1. Sliding Friction and Wear Tests

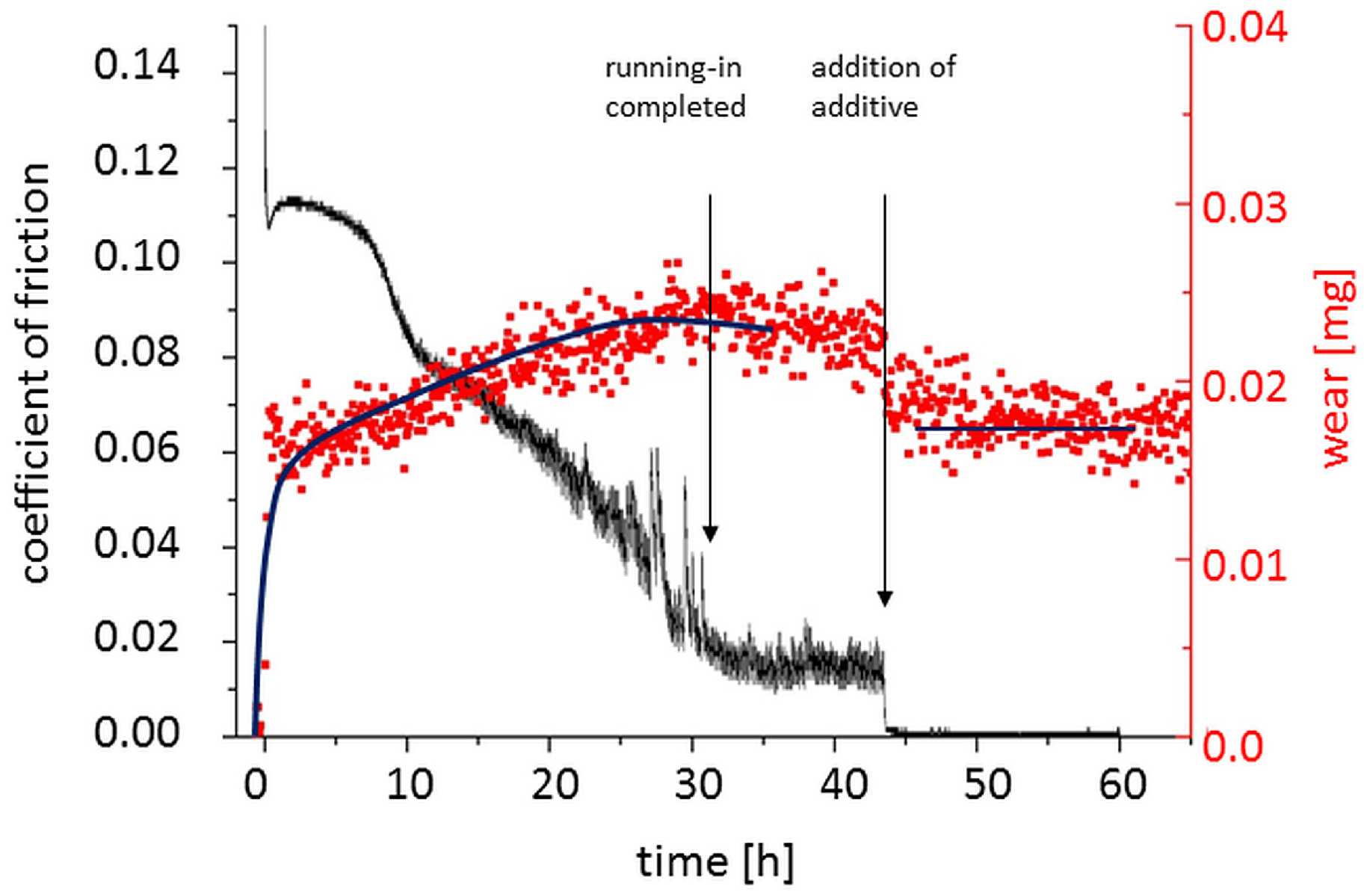

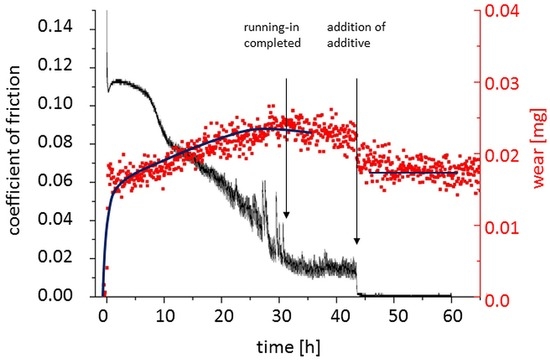

According to the friction and wear signals (see Figure 4), running-in was completed after 30 h. The initial drop in friction from 0.15 to 0.11 was caused by an instant decrease in roughness as a response to the first contact of pin and disk. A friction coefficient of around 0.1 is very similar to the values obtained by microtribometry. After the initial drop, friction slightly increased. In the course of the experiment, the third body developed. After some fluctuations, the friction signal stabilized to a constant value and remained at 0.015 until the oil change after 43 h. In the first minutes of the experiment, wear drastically increased, since the topographies of both friction partners were affected by the removal of material as wear debris. After the topographical running-in, the wear rate decreased. After 30 h, the decrease in wear was caused by an uncorrected slight radioactive decay of the nuclides inside the wear particles. At 43 h, 800 mL of the reference oil was replaced by 800 mL of reference oil containing 3% of the copper additive, so that an effective concentration of 1 vol-% was reached. Almost instantly, friction dropped to values below the resolution limit of the equipment, and remained extremely low until the end of the experiment. The replacement of 800 mL of oil was accompanied by a reduction in the amount of wear particles in the oil circuit. Therefore, the total wear signal decreased from 0.023 to 0.018 mg and remained constant. The tribometer was stopped after 60 h. The wear signal was recorded until 70 h. During the last 10 h, the oil was pumped through the circuit in order to detect segregated material. This experiment was carried out twice.

Figure 4.

Continuous friction and wear measurement. The wear signal of the pin in red was measured with radionuclide technique (RNT), as described in the text.

3.3.2. Rolling Friction and Wear Tests

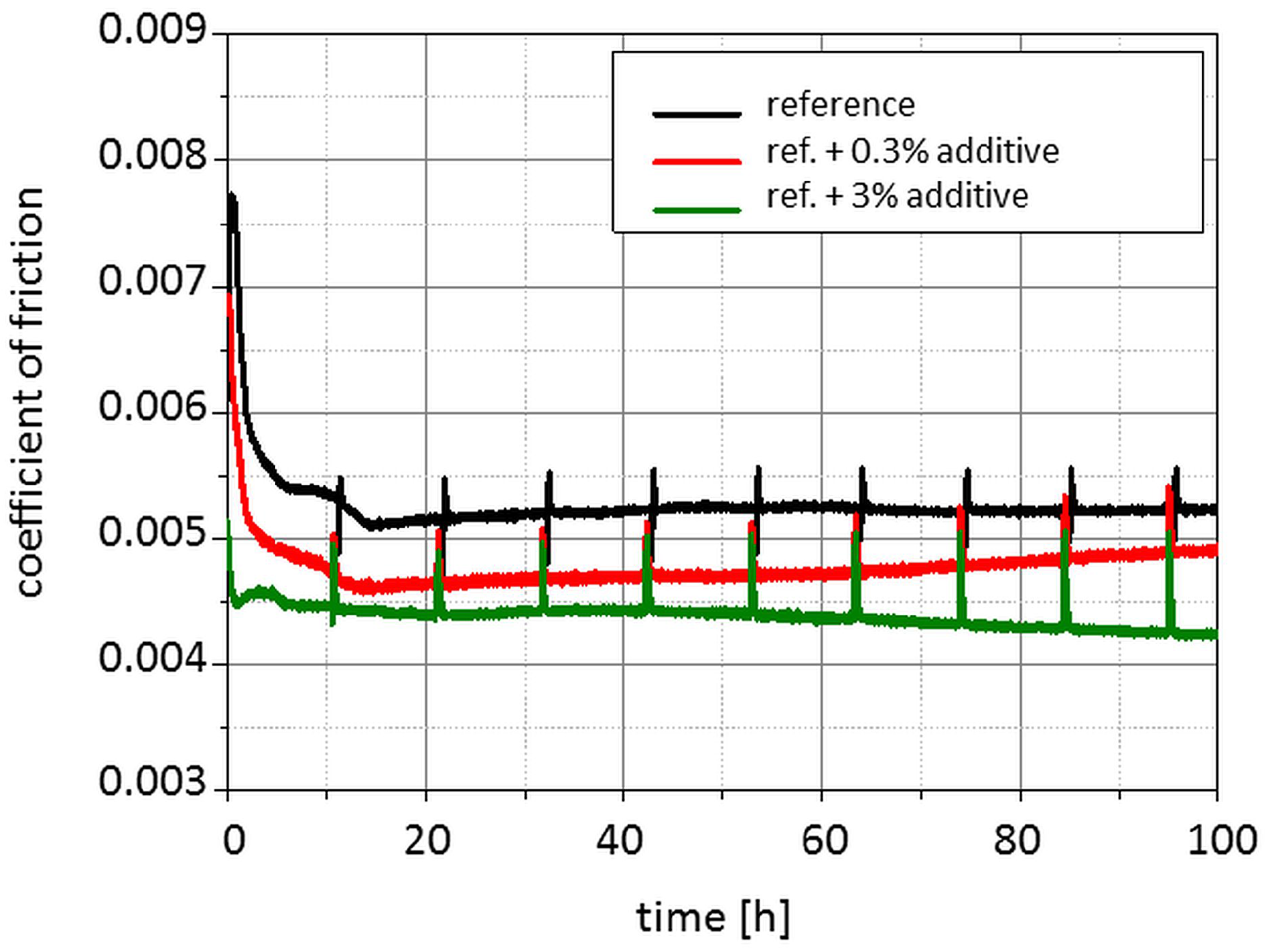

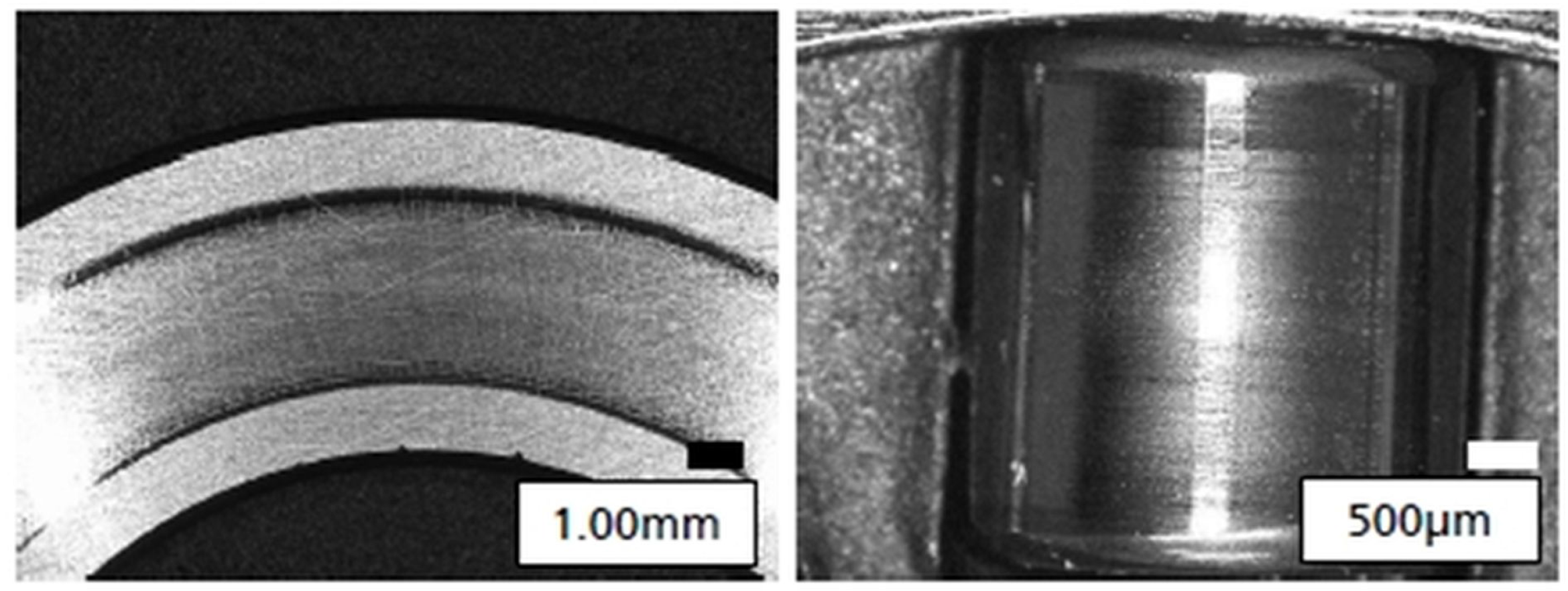

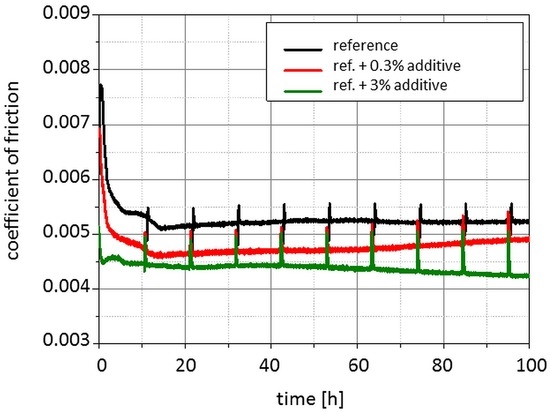

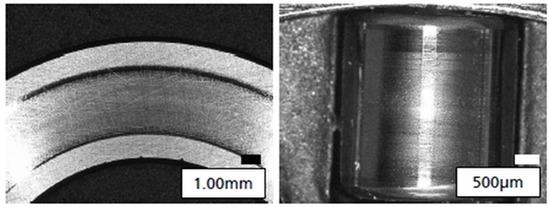

Thrust roller bearing rig tests were carried out using typical field conditions in terms of load and speed. The results confirm that there is a reduction to lower coefficients of friction with the copper additive (see Figure 5). After this initial reduction in friction, the coefficient of friction is stable on a long-term basis and shows no tendency to diminish. Wear was analyzed after the experiment, since the tester does not allow continuous measurements. No signs of severe wear or embrittlements were detected by either optical or scanning electron microscopy. Moreover, the grinding marks caused by finishing on the washer were still visible (see Figure 6).

Figure 5.

Summary of roller thrust bearing tests. The color coding indicates the different additive concentrations.

Figure 6.

Inspection of roller bearing parts after a test time of 100 h at 115 °C and a load of 8 kN. Surface topography features from the final machining are still clearly visible.

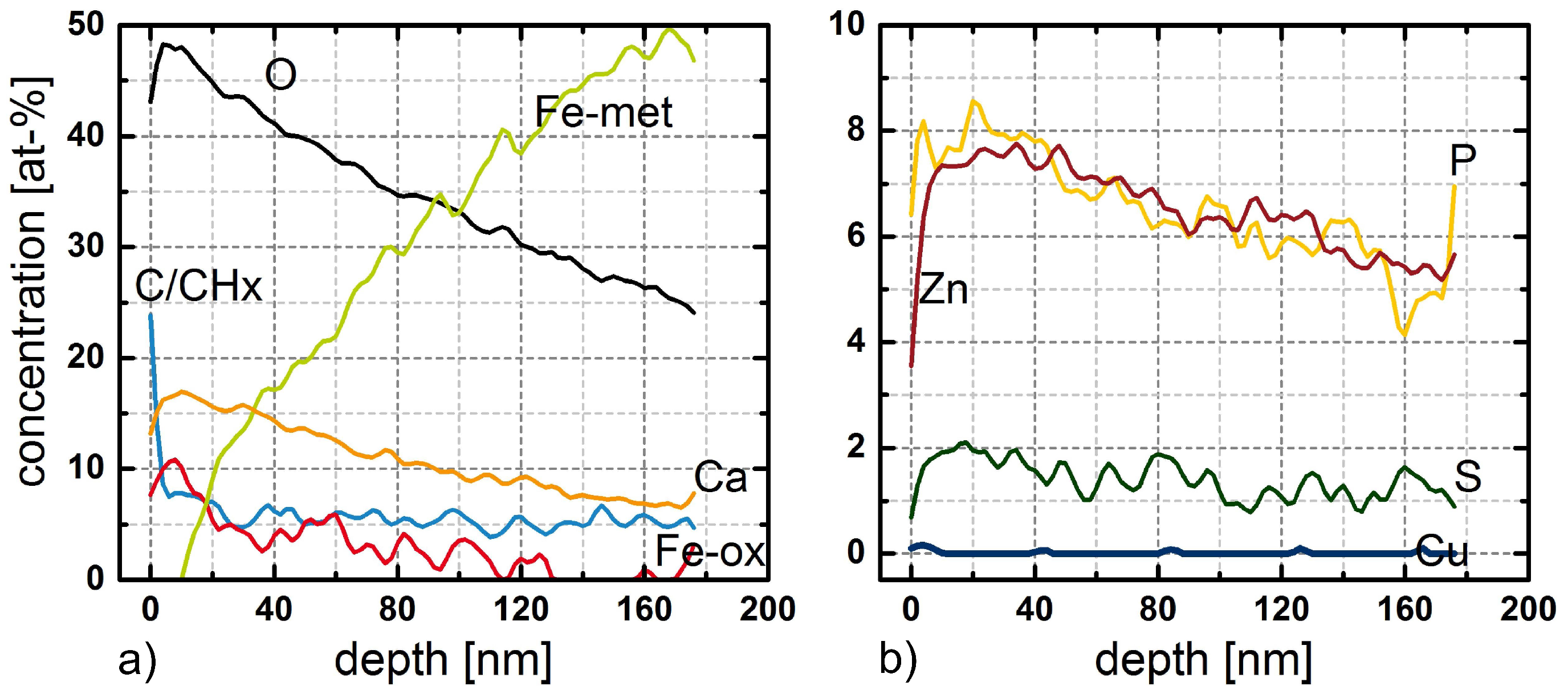

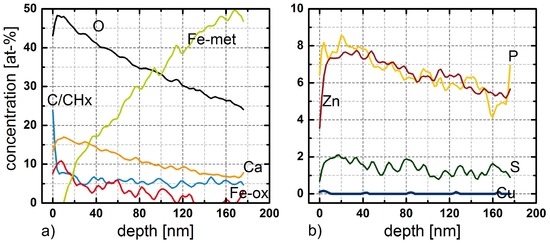

3.4. Physico-Chemical and Viscosity Analysis

Figure 7 shows a depth profile inside the wear track on the disk up to a depth of 180 nm. Close to the surface, iron was oxidized. The top surface was covered by a film of carbon and hydrocarbons. Calcium is the most prominent contributor from the lubricating oil additives, with a concentration of about 8% at 180 nm. It is estimated that the total depth of intermixing was about 500 nm. The diagram on the right-hand side covers the materials found at low concentrations. In addition, P, Zn, and S as constituents of ZDDP copper were detected up to a depth of about 10 nm. The copper concentration is very low, which can be caused by either a very thin layer or an irregular distribution across the surface.

Figure 7.

XPS depth profiles inside the wear track. Besides iron and oxide, oil constituents were found. (a) shows the elements with concentrations of more than 10 at %; The diagram (b) shows the elements present in concentrations below 10 at %.

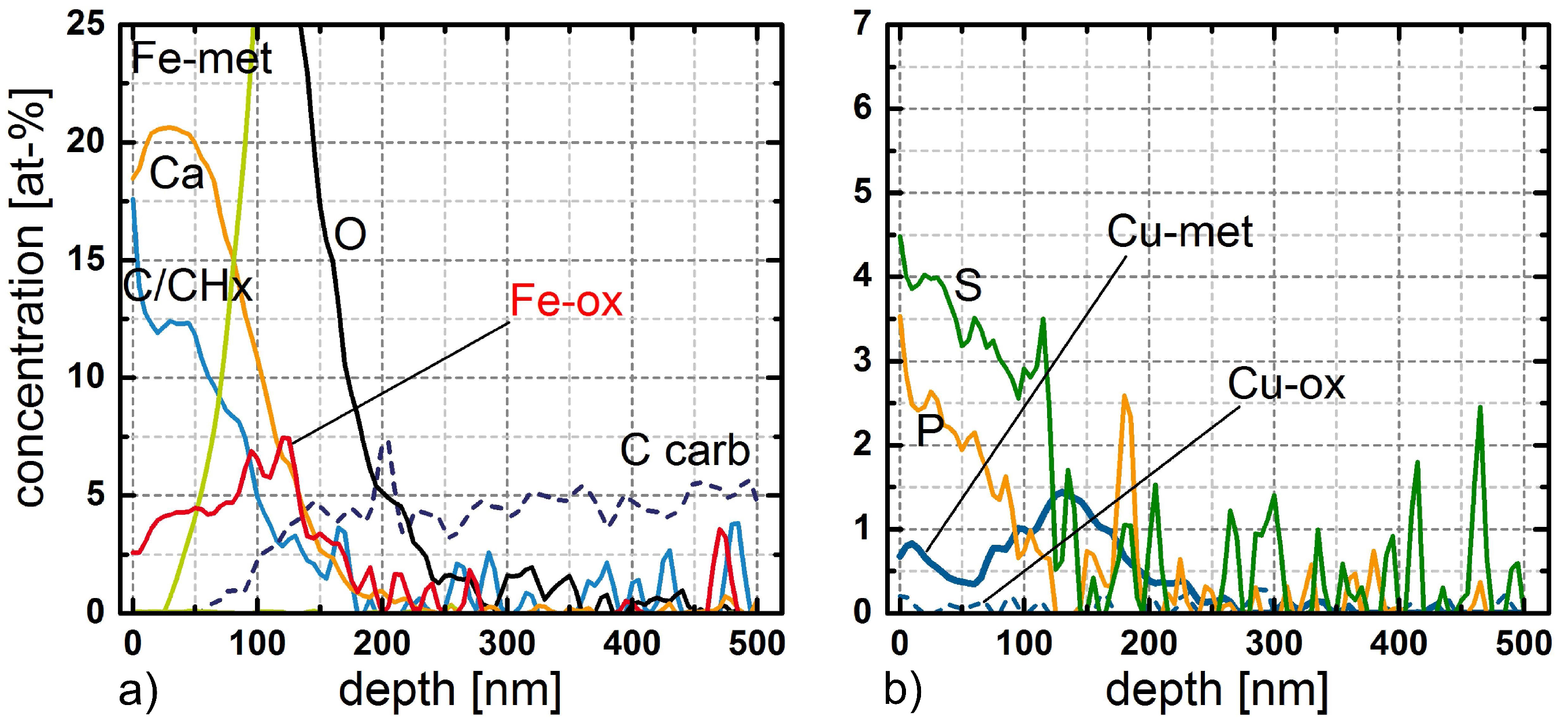

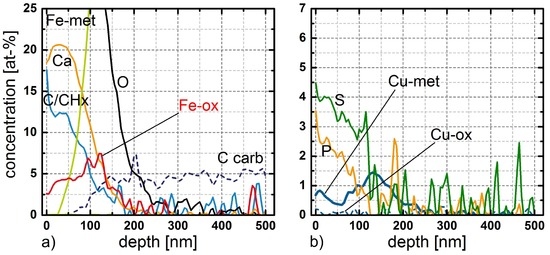

Additional XPS depth profiles were recorded with washer samples originating from the thrust bearing test rig. In these tests, the copper concentration of the additive was 3%. The surface of the washer shows a layer of calcium sulphonate and carbon, most probably from carbon–hydrogen groups. A layer of copper from the additive is intermixed with the iron lattice up to a depth of 300 nm (see Figure 8).

Figure 8.

XPS depth profiles on washer. Besides iron, carbon (bound in carbides) and oxides, oil constituents were found. (a) shows the elements with concentrations of more than 7 at %; The diagram (b) shows the elements present in concentrations below 7 at %.

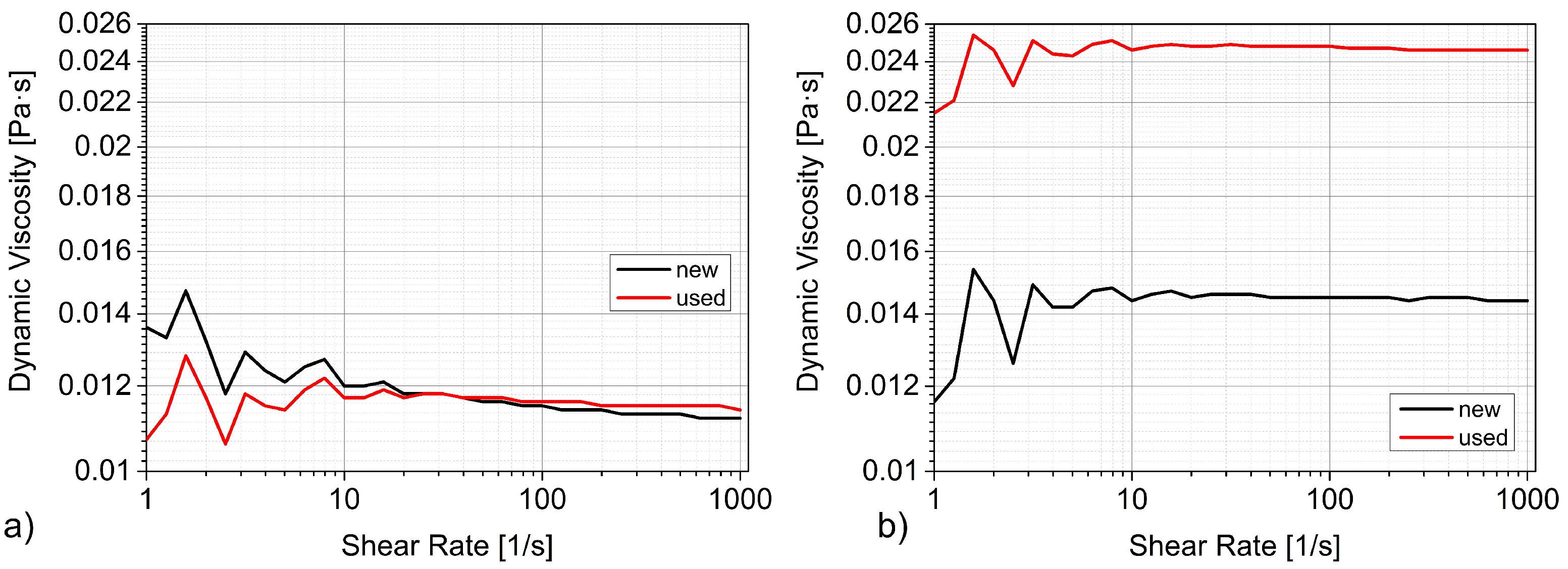

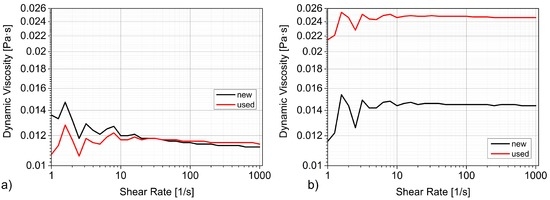

Oil viscosity was also measured before and after tribological stressing (see Figure 9). The viscosity measurements were done with an Anton Paar rheometer MCR 501 (Anton Paar GmbH, Ostfildern, Germany) of the MCR-series, applying the concept of sheared disks in a temperature range of 293.15 to 373.15 K at a rate of 5 K/min. The increase in shear rate was 50 s−1. Viscosity effects close to friction surfaces were found. Whereas the viscosity decreased with the reference oil, the oil containing the copper additive showed increased viscosity. Possible causes for this increase are debris particles, lubricant degradation, and reactions like thermal degradation or polymerization. The inspection of the roller bearing parts showed no signs of severe wear (see Figure 6). In addition, infrared analysis of the oil demonstrated that oil degradation effects were not a significant factor affecting the results.

Figure 9.

Change in viscosity before and after friction experiments on the bearing test rig. Results of oil with (a) and without (b) Cu-additive are shown.

The cyclic voltammograms showed that the redox wave for Cu2+/Cu is clearly seen. This confirms that copper remains in ionic form in these solutions. The addition of tin chlorides shifts the redox potential of Cu2+/Cu to slightly more positive values, but the effect is minimal.

4. Discussion

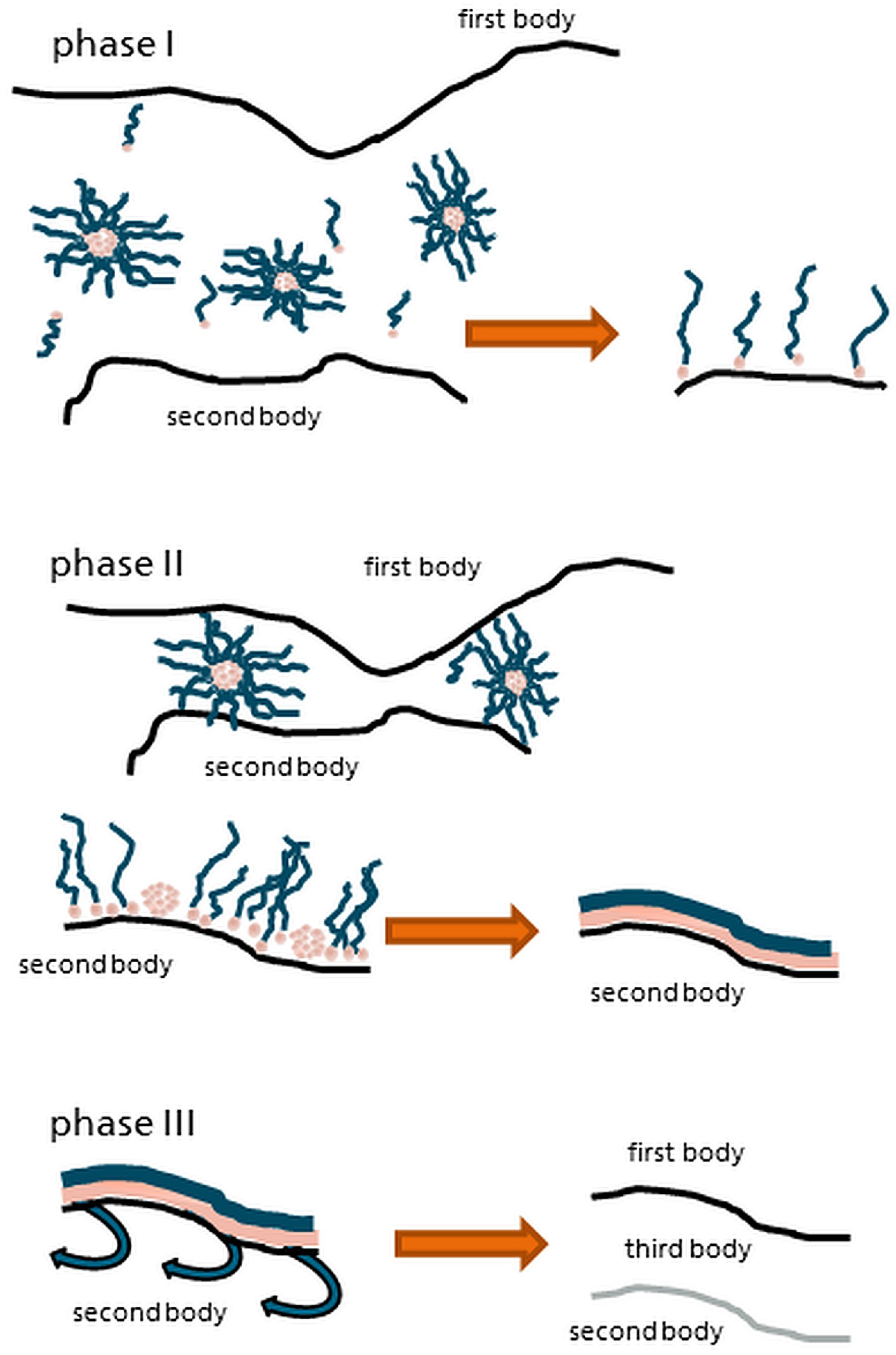

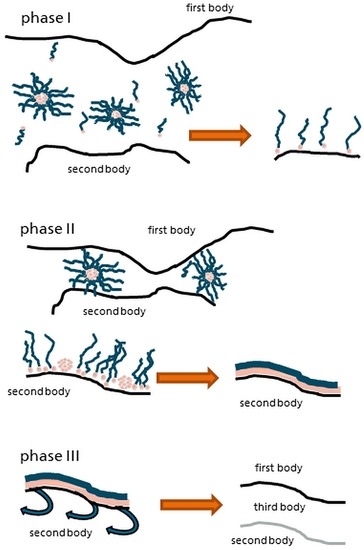

The mechanism of kinetic film formation found in these research studies consists of a three-phase process (see Figure 10). In the first stage, an organometallic salt—in our case copper oleate—that is an essential part of the additive system attaches and is adsorbed onto the friction surface to form a conventional boundary film. This enables an instant reduction in friction, as shown by the mictrotribometer friction tests.

Figure 10.

Three phase model. phase I: adsorption of excess oleate to the friction surface → instant friction reduction; phase II: shear-induced disruption of micelles → formation of additional copper oleate and copper nanoparticles → redox reaction: Cu2+ interacts with the iron of the surface and forms Cu0 → reinforced multi-layer tribo film; phase III: plastic flow of asperities → mechanical intermixing, tribo-chemical reactions, Cu, Zn, P, S, Ca become constituents of the third body → third body as self-regulating solid lubricant.

The second phase is initiated by the mechanical interaction of a single-asperity contact. Under the localized high temperatures and pressures, the micelles that form a critical part of the additive system become dislodged from the copper core. The freed copper particles then deposit on the nascent metal surfaces of the friction bodies. Copper particles adhere to the surface and accumulate to form a nanometer-thin metal tribofilm acting as a solid lubricant. This is an example of selective transfer to create a self-lubricating tribofilm. The tribofilm is in dynamic equilibrium, where layers of copper atoms are worn away but are then replaced by new particles in a self-healing process that sustains its performance. It enables a further increase and long-lasting reduction in friction.

In the third phase, the initial tribofilm, consisting of copper oleate and copper nanoparticles, becomes incorporated into the structure of the near-surface metal. The newly-formed material self-organizes by intense plastic flow, intermixing, and continued redox reactions to produce a robust film—the third body—that generates an additional protection against wear. The dynamics of the interaction maintains the third body with a co-existence of copper and other additive constituents. In addition, there will be tribochemical reactions between copper and the zinc, phosphorous, and sulphur constituents present in the lubricant.

During tribological interaction, the oil changes in viscosity. Usually, viscosity decreases due to degradation of the oil. In a few cases—for instance, when soot is active in the oil—viscosity may increase. As shown by the viscosity measurements before and after thrust bearing tests, viscosity increases when the copper additive is present. This fits the model of decomposition of micelles and, as a consequence, the formation of polymers at the surface, resulting in increased viscosity. The running-in tests demonstrated that the initial conditions with respect to normal force and sliding velocity have a significant influence on the performance of the three-phase mechanism. It was shown in the microtribometer experiments that initially friction decreases compared with dry conditions and the reference oil. However, friction coefficients in the order of 0.1 are not spectacular during phase I. At the beginning of the running-in, tribochemical reactions of phases II and III might be superimposed by the topographical adjustments accompanied by high wear rates. Thus, when a standard laboratory tribological test (like the four-ball test, which does not simulate the actual field operating environment) is applied, the additive cannot operate properly, and no tribofilm can be established. In contrast, when the additive was added to a tribological system which successfully completed the running-in stage, an instant drop of friction took place after the oil change. The instant drop in friction showed that no incubation time was necessary for the additive to become effective. This means that the additive initially acts like a conventional friction modifier based on a polar head group to adsorb onto the surface and a nonpolar tail strengthening the lubricant film. However, the instant drop of wear cannot be explained on this basis. A simple friction modifier would not be able to separate two friction bodies. This, however, must have been the case, because friction dropped to a very low level, which only happens when the tribological system shifts from mixed lubrication to hydrodynamics. After the addition of the copper additive, no further increase in wear was measured. Such a response is only possible when the friction bodies become separated by a layer of additional material, probably the polymeric copper–calcium film combined with the copper tribofilm. Given that the effect of low friction and zero-wear kept constant for another 20 h after the addition, the formed film must be stable to withstand the mechanical attacks of the asperities.

5. Conclusions

These laboratory tests and tribological investigations confirm that this innovative stable copper additive delivers long-lasting reduction in friction, protection against wear, and extended service-life. The mechanism and function of copper tribofilms involves a three-phase process. In the first phase, there is an instantaneous reduction in the coefficient of friction. The second phase results in the formation of a solid lubricant composed of copper monolayers. In the final step, there is plastic flow of the copper tribofilm combined with mechanical intermixing and tribochemical reactions, leading to the formation of the third body. In addition to the three phases, near-surface polymerization of monomers from the base oil leads to a protective top layer that helps to shift the systems towards hydrodynamic lubrication and prevents further attacks of oxygen. These complex processes provide self-sustained friction reduction and wear protection.

The following conclusions can be drawn about the works of Garkunov and colleagues:

- The protective and friction-reducing action of copper-based additives can be extended to the tribological regime at ultra-low wear rates.

- Garkunov demonstrated that the surface is covered by a copper film. However, in contrast to previous research, the copper film in the current work has a thickness in the nanometer range. Whereas under severe wear, thick films are necessary to protect the surfaces, in more realistic and representative ultra-low wear regimes, thin films provide sufficient protection. However, when the ultra-low wear regime protection is exposed to severe wear conditions unrepresentative of the actual field environment, the copper additive fails to protect the surfaces. This highlights the issue of how important it is to use appropriate laboratory screening test methods that truly simulate actual field test conditions.

- In addition to copper plating, third body formation plays an important role in friction and wear reduction.

- A polymeric film with a thickness of several nanometers protects the copper tribofilm and third body from oxidation.

Acknowledgments

The authors would like to thank A. Blockhaus and E. Nold and D. Marchetto for their help in tribometry, XPS and AFM. The authors thank Ab Nanol Technologies Oy for providing the additive and cyclic voltammetry measurements.

Author Contributions

Matthias Scherge conceived most of the experiments which were designed and performed, analyzed and discussed by Roman Böttcher, Dominik Kürten and Dominic Linsler at Fraunhofer IWM in Freiburg and Karlsruhe. The paper was written by Matthias Scherge and Dominic Linsler.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Garkunov, D.N. Scientific discoveries in tribo technologies. In No-Wear Effect under Friction: Hydrogen Wear of Metals; MAA Publishing House: Moscow, Russia, 2007. [Google Scholar]

- Zhou, J.; Wu, Z.; Zhang, Z.; Liu, W.; Xue, Q. Tribological behavior and lubricating mechanism of Cu nanoparticles in oil. Tribol. Lett. 2000, 8, 213–218. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.; Liu, W.; Fu, X. Performance and anti-wear mechanism of Cu nanoparticles as lubricating oil additives. Ind. Lubr. Tribol. 2009, 61, 311–318. [Google Scholar] [CrossRef]

- Yu, H.; Shi, P.; Xu, B.; Wang, X.; Liu, Q. Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant. Trans. Nonferr. Met. Soc. China 2008, 18, 636–641. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, J.; Zhang, Z.; Liu, W.; Xue, Q. Study on the structure and tribological Properties of surface-modified Cu Nanoparticles. Mater. Res. Bull. 1999, 34, 1361–1367. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Shi, P.; Xu, B.; Wang, X.; Liu, Q.; Wang, H. Characterization and nano-mechanical properties of tribofilms using Cu nanoparticles as additives. Surf. Coat. Technol. 2008, 203, 28–34. [Google Scholar] [CrossRef]

- Yang, G.; Chai, S.; Xiong, X.; Zhang, S.; Yu, L.; Zhang, P. Preparation and tribological properties of surface modified Cu nanoparticles. Trans. Nonferr. Met. Soc. China 2012, 22, 366–372. [Google Scholar] [CrossRef]

- Liu, G.; Li, X.; Qin, B.; Xing, D.; Guo, D.; Fan, D. Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol. Lett. 2004, 17, 961–966. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, S.; Song, S.; Yang, G.; Yu, L.; Wu, Z.; Li, X.; Zhang, P. Preparation and tribological properties of surface-capped copper nanoparticle as a water-based lubricant additive. Tribol. Lett. 2014, 54, 24–33. [Google Scholar] [CrossRef]

- Tarasov, S.; Kolubaev, A.; Belyaev, S.; Lerner, M.; Tepper, F. Study of friction reduction by nanocopper additives to motor oil. Wear 2002, 252, 63–69. [Google Scholar] [CrossRef]

- Scherge, M.; Martin, J.M.; Pöhlmann, K. Characterization of wear debris of systems operated under low wear-rate conditions. Wear 2006, 260, 458–461. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiza, R.; Prosycevas, I.; Kreivaitis, R. Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar] [CrossRef]

- Pilkington, G.A.; Briscoe, W.H. Nanofluids mediating surface forces. Adv. Colloid Interface Sci. 2012, 179–182, 68–84. [Google Scholar] [CrossRef] [PubMed]

- Bulgarevich, S.B.; Boiko, M.V.; Feizova, V.A.; Akimova, E.E. Effect of pressure on chemical reactions in the zone of direct friction contact of systems with selective transfer. J. Frict. Wear 2011, 32, 145–149. [Google Scholar] [CrossRef]

- Albrecht, E.; Mamykin, S.M. Composition Lubrifiante. European Patent EP2626405A1, 14 August 2013. [Google Scholar]

- Scherge, M.; Linsler, D.; Schlarb, T. The running-in corridor of lubricated metal-metal contacts. Wear 2015, 342–343, 60–64. [Google Scholar] [CrossRef]

- Scherge, M.; Pöhlmann, K.; Gerve, A. Wear measurement using radionuclide-technique (RNT). Wear 2003, 254, 801–817. [Google Scholar] [CrossRef]

- Ogletree, D.F.; Carpick, R.W.; Salmeron, M. Calibration of Frictional Forces in Atomic Force Microscopy; Departmental Papers (MEAM), Paper 96; University of Pennsylvania: Philadelphia, PA, USA, 1996. [Google Scholar]

- Varenberg, M.; Etsion, I.; Halperin, G. An improved wedge calibration method for lateral force in atomic force microscopy. Rev. Sci. Instrum. 2003, 74, 3362–3367. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).