The Effects of Adding a Gel-Alike Curcuma longa L. Suspension as Color Agent on Some Quality and Sensory Properties of Yogurt

Abstract

:1. Introduction

2. Materials

2.1. Yogurt Preparation

2.2. Characterization of the Yogurts

2.3. Ph and Titratable Acidity

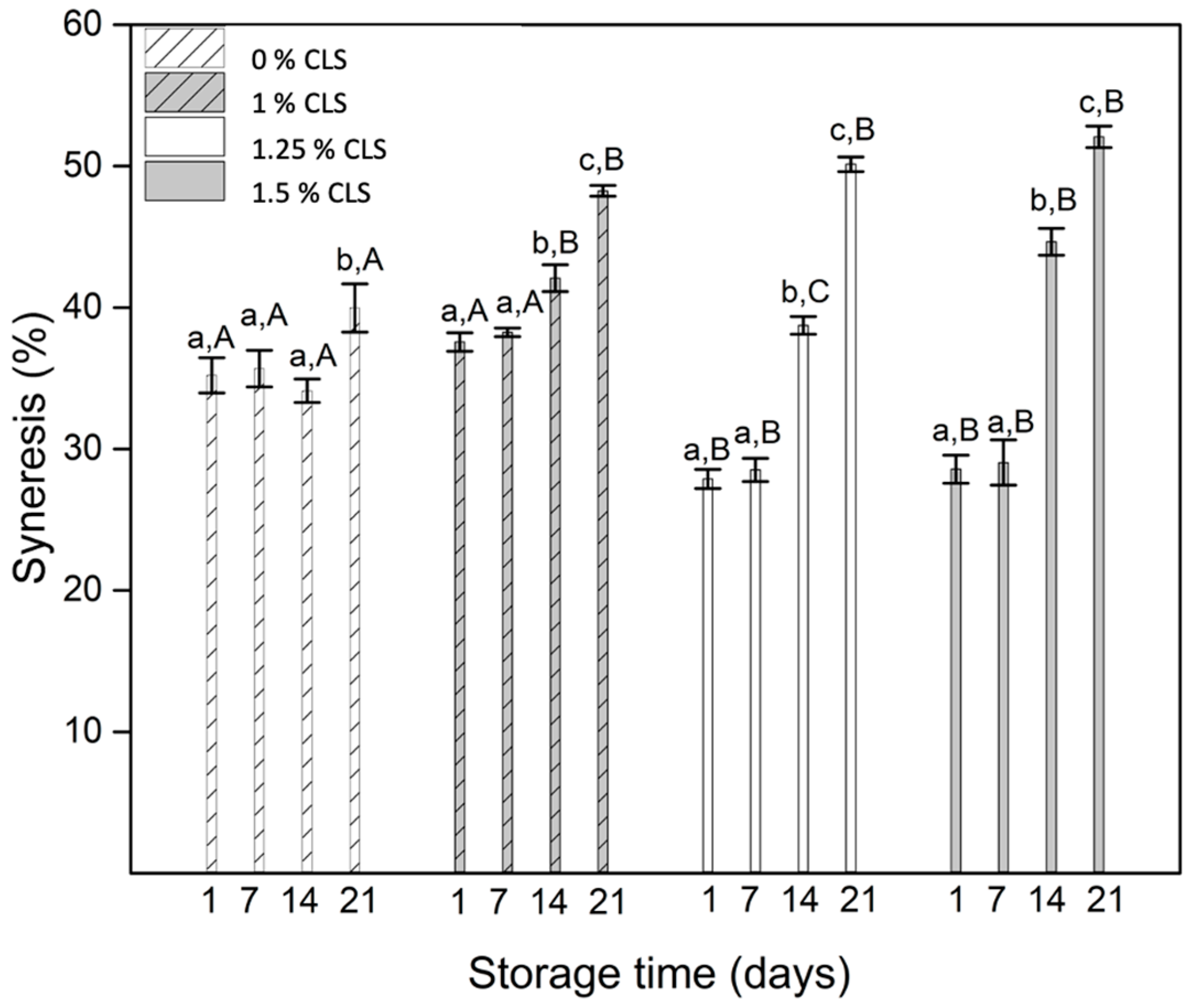

2.4. Syneresis

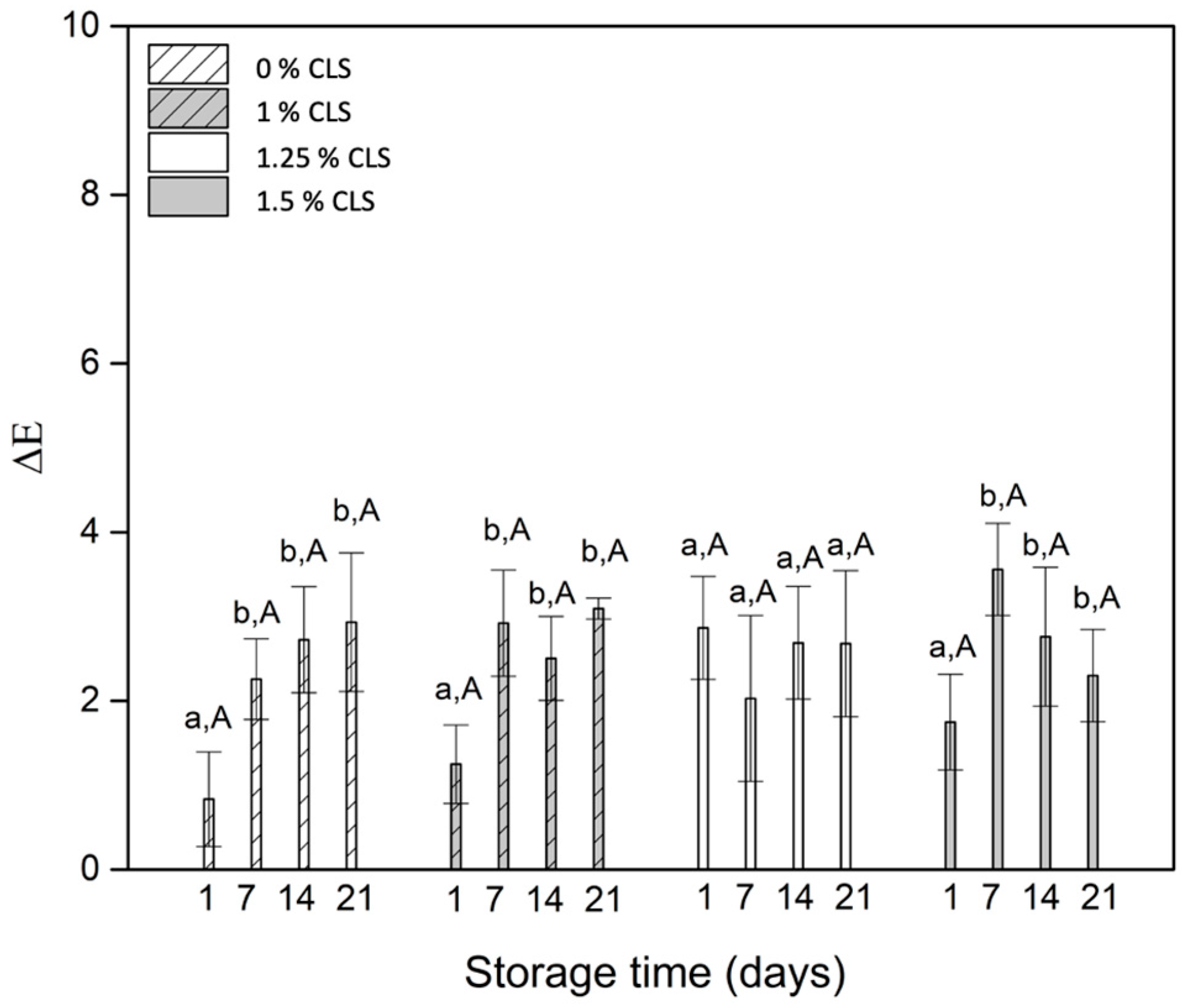

2.5. Color

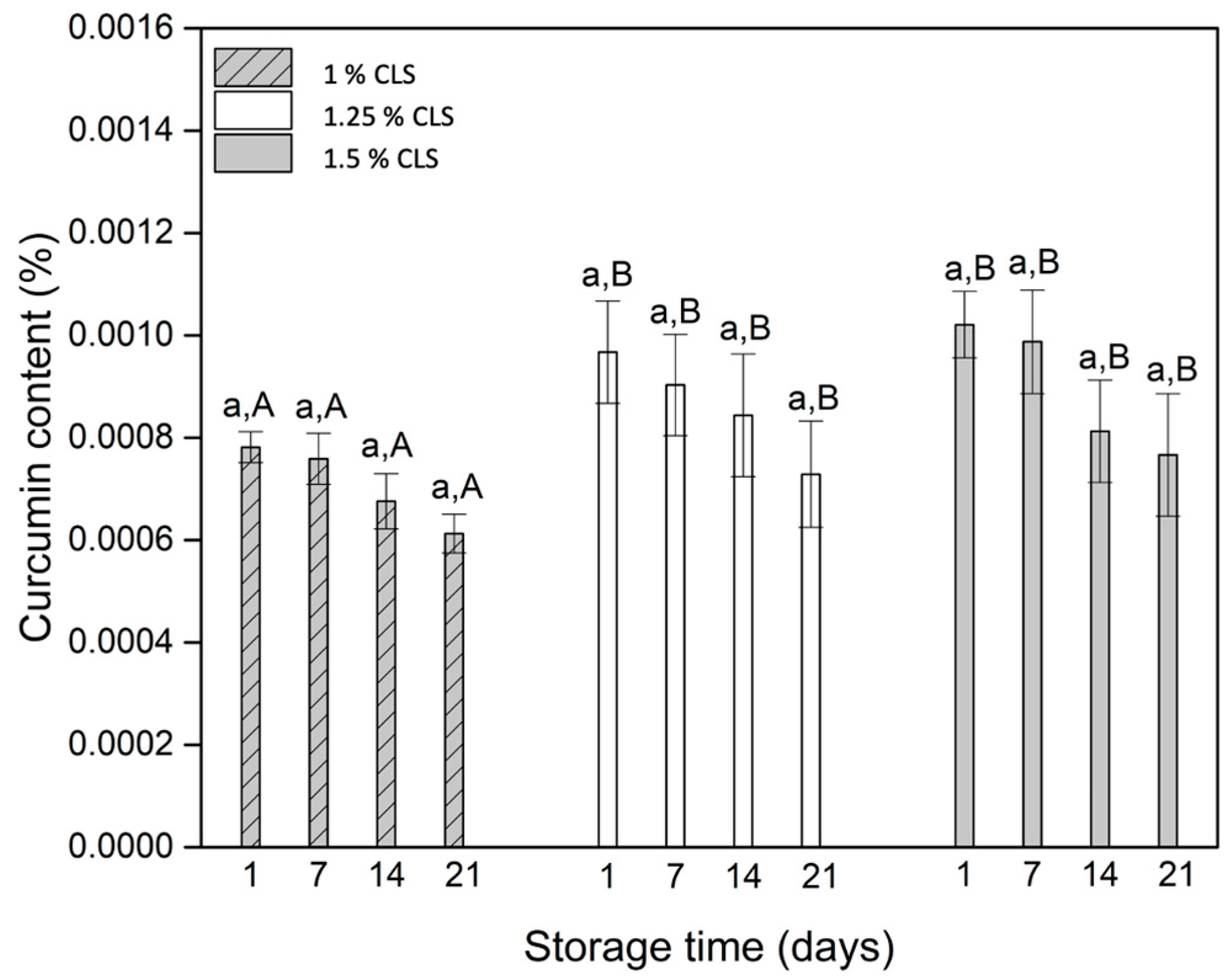

2.6. Curcumin Quantification

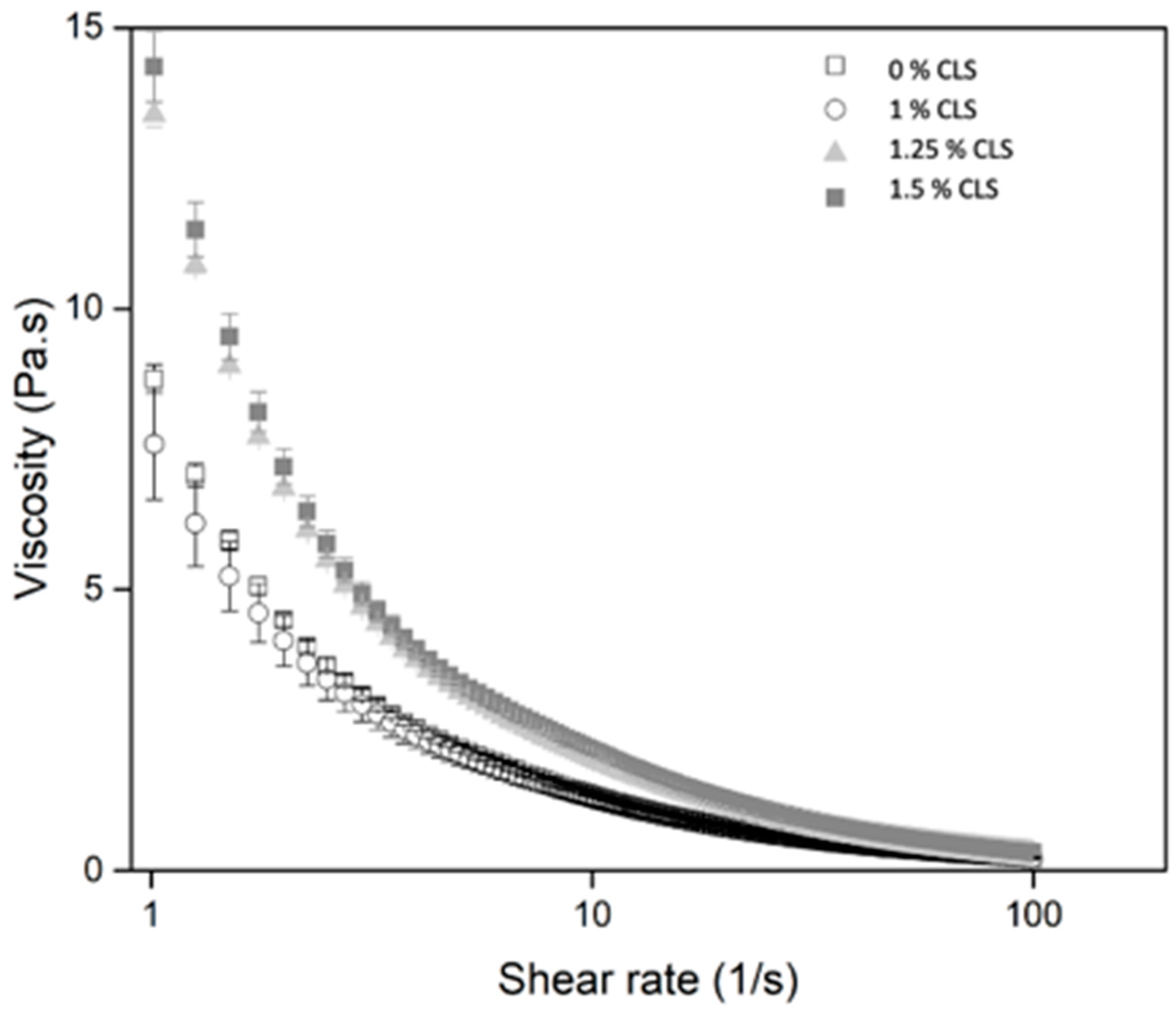

2.7. Rheology

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Ph and Titratable Acidity

3.2. Syneresis

3.3. Color

3.4. Curcumin Content

3.5. Rheology

3.6. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Li, S.; Yuan, W.; Deng, G.; Wang, P.; Yang, P.; Aggarwal, B.B. Chemical Composition and Product Quality Control of Turmeric (Curcuma longa L.). Pharm. Crops 2011, 2, 28–54. [Google Scholar] [CrossRef]

- Eigner, D.; Scholz, D. Ferula asa-foetida and Curcuma longa in traditional medical treatment and diet in Nepal. J. Ethnopharmacol. 1999, 67, 1–6. [Google Scholar] [CrossRef]

- Codex Alimentarius. General Standard for Food Additives (GSFA): Proposals for New and/or Revision of Food Additive Provisions. Roma. 2018. Available online: http://www.fao.org/fao-who-codexalimentarius/sh-proxy/pt/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FMeetings%252FCX-711-50%252FWD%252Ffa50_08x.pdf (accessed on 15 October 2019).

- Mahfouz, H. Protective action of vitamin C against mutagenic effects of synthetic food color tartrazine. Afr. J. Pharm. Pharmacol. 2013, 7, 2474–2483. [Google Scholar] [CrossRef]

- European Food Safety Authority. REGLAMENTO (CE) No 1333:2008; European Union: Maastricht, The Netherlands, 2008; pp. L354/16–L354/33.

- Kurien, B.T.; Singh, A.; Matsumoto, H.; Scofield, R.H. Improving the Solubility and Pharmacological Efficacy of Curcumin by Heat Treatment. ASSAY Drug Dev. Technol. 2007, 5, 567–576. [Google Scholar] [CrossRef]

- Guerra, A.M.S.; Hoyos, C.G.; Velásquez-Cock, J.A.; Penagos, L.V.; Rojo, P.G.; Acosta, L.V.; Pereira, M.A.; Zuluaga, R. Effect of ultra-fine friction grinding on the physical and chemical properties of curcuma (Curcuma longa L.) suspensions. J. Food Sci. 2020, 85, 132–142. [Google Scholar] [CrossRef]

- Serpa Guerra, A.M.; Gómez Hoyos, C.; Velásquez-Cock, J.A.; Gañán Rojo, P.; Eceiza, A.; Urbina, L.; Zuluaga, R. Cellulose nanofibers from banana rachis added to a Curcuma longa L. rhizome suspension: Color, stability and rheological properties. Food Struct. 2021, 27, 100180. [Google Scholar] [CrossRef]

- Wallace, T.; Giusti, M. Determination of Color, Pigment, and Phenolic Stability in Yogurt Systems Colored with Nonacylated Anthocyanins from Berberis boliviana L. as Compared to Other Natural/Synthetic Colorants. J. Food Sci. 2008, 73, C241–C248. [Google Scholar] [CrossRef]

- Canning, K. Colors for Dairy Products Are Going Natural. Dairy Foods. 2020. Available online: https://www.dairyfoods.com/articles/94550-colors-for-dairy-products-are-going-natural (accessed on 25 February 2021).

- Almeida, H.H.; Barros, L.; Barreira, J.C.; Calhelha, R.C.; Heleno, S.A.; Sayer, C.; Miranda, C.G.; Leimann, F.V.; Barreiro, M.F.; Ferreira, I.C. Bioactive evaluation and application of different formulations of the natural colorant curcumin (E100) in a hydrophilic matrix (yogurt). Food Chem. 2018, 261, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Pires, T.C.; Dias, M.I.; Barros, L.; Barreira, J.C.; Santos-Buelga, C.; Ferreira, I.C. Incorporation of natural colorants obtained from edible flowers in yogurts. LWT Food Sci. Technol. 2018, 97, 668–675. [Google Scholar] [CrossRef] [Green Version]

- Calvo, C.; Salvador, A.; Fiszman, S.M. Influence of colour intensity on the perception of colour and sweetness in various fruit-flavoured yoghurts. Eur. Food Res. Technol. 2001, 213, 99–103. [Google Scholar] [CrossRef]

- Gao, H.-X.; Yu, Z.-L.; He, Q.; Tang, S.-H.; Zeng, W.-C. A potentially functional yogurt co-fermentation with Gnaphalium affine. LWT Food Sci. Technol. 2018, 91, 423–430. [Google Scholar] [CrossRef]

- Abdelmoneim, A.H.; Sherif, A.M. Rheological Properties of Yoghurt Manufactured by using Different Types of Hydrocolloids. Austin J. Nutr. Food Sci. 2016, 4, 2. [Google Scholar]

- Mendoza, J.; Rodríguez de Sousa, A.; Millán, P. Caracterización físico química de la Uchuva (Physalis peruviana) en la región de Silvia Cauca. Biotecnol. Sect. Agropecu. Agroind. 2012, 10, 188–196. [Google Scholar]

- Cheng, J.; Weijun, K.; Yun, L.; Jiabo, W.; Haitao, W.; Qingmiao, L.; Xiaohe, X. Development and validation of UPLC method for quality control of Curcuma longa Linn.: Fast simultaneous quantitation of three curcuminoids. J. Pharm. Biomed. Anal. 2010, 53, 43–49. [Google Scholar] [CrossRef]

- Pang, Z.; Deeth, H.; Prakash, S.; Bansal, N. Development of rheological and sensory properties of combinations of milk proteins and gelling polysaccharides as potential gelatin replacements in the manufacture of stirred acid milk gels and yogurt. J. Food Eng. 2016, 169, 27–37. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Hamid, M.; Romeih, E.; Huang, Z.; Enomoto, T.; Huang, L.; Li, L. Bioactive properties of probiotic set-yogurt supplemented with Siraitia grosvenorii fruit extract. Food Chem. 2019, 303, 125400. [Google Scholar] [CrossRef]

- Perina, N.; Granato, D.; Hirota, C.; Cruz, A.; Bogsan, C.; Oliveira, M. Effect of vegetal-oil emulsion and passion fruit peel-powder on sensory acceptance of functional yogurt. Food Res. Int. 2015, 70, 134–141. [Google Scholar] [CrossRef]

- Zhang, T.; Jeong, C.H.; Cheng, W.N.; Bae, H.; Seo, H.G.; Petriello, M.C.; Han, S.G. Moringa extract enhances the fermentative, textural, and bioactive properties of yogurt. LWT 2019, 101, 276–284. [Google Scholar] [CrossRef]

- Gonzalez, N.J.; Adhikari, K.; Sancho-Madriz, M.F. Sensory characteristics of peach-flavored yogurt drinks containing prebiotics and synbiotics. LWT Food Sci. Technol. 2011, 44, 158–163. [Google Scholar] [CrossRef]

- Deepa, J.; Rajkumar, P.; Preetha, P. Development of yogurt with bioactive molecules. Asian J. Dairy Food Res. 2016, 35, 283–287. [Google Scholar] [CrossRef]

- Tomovska, J.; Gjorgievski, N.; Makarijoski, B. Examination of pH, Titratable Acidity and Antioxidant Activity in Fermented Milk. J. Mater. Sci. Eng. A 2016, 6, 11–12. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Kristo, E.; LaPointe, G. Adding apple pomace as a functional ingredient in stirred-type yogurt and yogurt drinks. Food Hydrocoll. 2019, 100, 105453. [Google Scholar] [CrossRef]

- Güler-Akın, M.B.; Ferliarslan, I.; Akın, M.S. Apricot Probiotic Drinking Yoghurt Supplied with Inulin and Oat Fiber. Adv. Microbiol. 2016, 6, 999–1009. [Google Scholar] [CrossRef] [Green Version]

- Dönmez, Ö.; Mogol, B.A.; Gökmen, V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. J. Dairy Sci. 2017, 100, 901–907. [Google Scholar] [CrossRef]

- Cárdenas, A.; Gutierrez, H.A.; Castillo, G.V.; Obregón, J.; Vásquez-Villalobos, V. Optimización mediante diseño de mezclas de sinéresis y textura sensorial de yogurt natural batido utilizando tres tipos de hidrocoloides. Agroind. Sci. 2013, 3, 35–40. [Google Scholar] [CrossRef]

- Cardines, P.H.; Baptista, A.T.; Gomes, R.G.; Bergamasco, R.; Vieira, A.M. Moringa oleifera seed extracts as promising natural thickening agents for food industry: Study of the thickening action in yogurt production. LWT Food Sci. Technol. 2018, 97, 39–44. [Google Scholar] [CrossRef]

- Jiménez, D.; Morales, S.; Ruiz, V. Efecto de la adición de fibra y la disminución de grasa en las propiedades fisicoquímicas del yogur. Rev. Mex. Ing. Química 2004, 3, 287–305. [Google Scholar]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Walstra, P.; Wouters, J.T.; Geurts, T.J. Food Science and Technology Segunda; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Leonel, M.; Sarmento, S.B.; Cereda, M.P. New starches for the food industry: Curcuma longa and Curcuma zedoaria. Carbohydr. Polym. 2003, 54, 385–388. [Google Scholar] [CrossRef]

- Da Silva, D.F.; Junior, N.N.T.; Gomes, R.G.; Pozza, M.S.D.S.; Britten, M.; Matumoto-Pintro, P.T. Physical, microbiological and rheological properties of probiotic yogurt supplemented with grape extract. J. Food Sci. Technol. 2017, 54, 1608–1615. [Google Scholar] [CrossRef] [Green Version]

- Hematyar, N.; Samarin, A.M.; Poorazarang, H.; Elhamirad, A.H. Effect of gums on yogurt characteristics. World Appl. Sci. J. 2012, 20, 661–665. [Google Scholar] [CrossRef]

- Teuver, M. Fermented Milk Products. In The Microbiological Safety and Quality of Food; Lund, B., Baird-Parker, A.C., Gould, G.W., Eds.; Aspen Publishers: New York, NY, USA, 2000; pp. 535–589. [Google Scholar]

- Capron, I.; Rojas, O.; Bordes, R. Behavior of nanocelluloses at interfaces. Curr. Opin. Colloid Interface Sci. 2017, 29, 83–95. [Google Scholar] [CrossRef]

- Lelis, A.L.R.C.; Gomes, A.; Tibolla, H.; Menegalli, F.C.; Cunha, R.L. Cellulose nanofibers from banana peels as a Pickering emulsifier: High-energy emulsification processes. Carbohydr. Polym. 2018, 194, 122–131. [Google Scholar] [CrossRef]

- Ni, Y.; Li, J.; Fan, L. Effects of ultrasonic conditions on the interfacial property and emulsifying property of cellulose nanoparticles from ginkgo seed shells. Ultrason. Sonochem. 2020, 70, 105335. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, W.; Jia, H.; Gao, G.; Wang, X.; Zhang, X.; Wang, Y. Using Cellulose Nanofibers and Its Palm Oil Pickering Emulsion as Fat Substitutes in Emulsified Sausage. J. Food Sci. 2018, 83, 1740–1747. [Google Scholar] [CrossRef]

- Djali, M.; Firbiani, M.; Marsetio, M. The Effect of CMC Addition on the Characteristics of Sweet Potato (Ipomoea Batatas L. Cv Cilembu) Velva. In Proceedings of the 2nd International Conference on Sustainable Agriculture and Food Security: A Comprehensive Approach, Jatinangor, Sumedang, West Java, Indonesia, 12–13 October 2015; Knowledge E Publishing: Dubai, United Arab Emirates, 2017; pp. 680–688. [Google Scholar] [CrossRef] [Green Version]

- Machado, T.A.D.G.; de Oliveira, M.E.G.; Campos, M.I.F.; de Assis, P.O.A.; de Souza, E.L.; Madruga, M.S.; Pacheco, M.T.B.; Pintado, M.M.E.; Queiroga, R.D.C.R.D.E. Impact of honey on quality characteristics of goat yogurt containing probiotic Lactobacillus acidophilus. LWT Food Sci. Technol. 2017, 80, 221–229. [Google Scholar] [CrossRef]

- Hashim, I.; Khalil, A.; Afifi, H. Quality characteristics and consumer acceptance of yogurt fortified with date fiber. J. Dairy Sci. 2009, 92, 5403–5407. [Google Scholar] [CrossRef]

- Lopez, C. Milk fat globules enveloped by their biological membrane: Unique colloidal assemblies with a specific composition and structure. Curr. Opin. Colloid Interface Sci. 2011, 16, 391–404. [Google Scholar] [CrossRef]

- Ghidouche, S.; Rey, B.; Michel, M.; Galaffu, N. A Rapid tool for the stability assessment of natural food colours. Food Chem. 2013, 139, 978–985. [Google Scholar] [CrossRef]

- Mezquita, P.C.; Barragán-huerta, B.E.; Ramírez, J.P.; Ortíz, C. Milks pigmentation with astaxanthin and determination of colour stability during short period cold storage. J. Food Sci. Technol. 2015, 52, 1634–1641. [Google Scholar] [CrossRef] [Green Version]

- Lim, H.S.; Park, S.H.; Ghafoor, K.; Hwang, S.Y.; Park, J. Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem. 2011, 124, 1577–1582. [Google Scholar] [CrossRef]

- Bagchi, A. Extraction of Curcumin. IOSR J. Environ. Sci. Toxicol. Food Technol. 2012, 1, 1–16. [Google Scholar] [CrossRef]

- Cristóvão, R.; Botelho, C.; Martins, R.; Boaventura, R. Determination of Yogurt quality by using rheological and textural parameters. Int. Proc. Chem. Biol. Environ. Eng. 2012, 32, 12–16. [Google Scholar] [CrossRef]

- Codină, G.G.; Franciuc, S.G.; Mironeasa, S. Rheological Characteristics and Microstructure of Milk Yogurt as Influenced by Quinoa Flour Addition. J. Food Qual. 2016, 39, 559–566. [Google Scholar] [CrossRef]

- Pang, Z.; Xu, R.; Luo, T.; Che, X.; Bansal, N.; Liu, X. Physiochemical properties of modified starch under yogurt manufacturing conditions and its relation to the properties of yogurt. J. Food Eng. 2019, 245, 11–17. [Google Scholar] [CrossRef]

- Vercet, A.; Sánchez, C.; Burgos, J.; Montañés, L.; Buesa, P.L. The effects of manothermosonication on tomato pectic enzymes and tomato paste rheological properties. J. Food Eng. 2002, 53, 273–278. [Google Scholar] [CrossRef]

- Yang, M.; Fu, J.; Li, L. Rheological Characteristics and Microstructure of Probiotic Soy Yogurt Prepared from Germinated Soybeans. Food Technol. Biotechnol. 2012, 50, 73–80. [Google Scholar]

- Rasic, J.; Kurman, J. Yogurt: Scientific Grounds, Technology, Manufacture and Preparations; Dairy Publishing: Copenhagen, Danmark, 1978. [Google Scholar]

- Rojas-Castro, W.N.; Chacón-Villalobos, A.; Pineda-Castro, M.L. Características del yogurt batido de fresa derivadas de diferentes proporciones de leche de vaca y cabra. Agronimia Mesoam. 2007, 18, 221–237. [Google Scholar] [CrossRef] [Green Version]

- de Campo, C.; Assis, R.Q.; da Silva, M.M.; Costa, T.M.H.; Paese, K.; Guterres, S.; Rios, A.D.O.; Flôres, S.H. Incorporation of zeaxanthin nanoparticles in yogurt: Influence on physicochemical properties, carotenoid stability and sensory analysis. Food Chem. 2019, 301, 125230. [Google Scholar] [CrossRef]

- Silva, L.; Nelson, D.; Drummond, M.; Dufossé, L.; Glória, M. Comparison of hydrodistillation methods for the deodorization of turmeric. Food Res. Int. 2005, 38, 1087–1096. [Google Scholar] [CrossRef]

- Lee, S.H. Physicochemical and Sensory Characteristics of Yanggaeng added with Turmeric Powder. Korean J. Food Nutr. 2013, 26, 447–452. [Google Scholar] [CrossRef]

| Sample | Storage Time (Days) | pH | Titratable Acidity (wt. % Actic Acid) |

|---|---|---|---|

| 0% CLS | 1 | 4.410 ± 0.017 a,A | 0.938 ± 0.044 a,A |

| 7 | 4.307 ± 0.067 a,A | 0.914 ± 0.012 a,A | |

| 14 | 4.383 ± 0.015 a,A | 0.919 ± 0.001 a,A | |

| 21 | 4.363 ± 0.047 a,A | 0.913 ± 0.005 a,A | |

| 1% CLS | 1 | 4.347 ± 0.127 a,A | 0.900 ± 0.003 a,A |

| 7 | 4.357 ± 0.025 a,A | 0.931 ± 0.031 a,A | |

| 14 | 4.340 ± 0.069 a,A | 0.932 ± 0.010 a,A | |

| 21 | 4.330 ± 0.020 a,A | 0.912 ± 0.019 a,A | |

| 1.25% CLS | 1 | 4.373 ± 0.015 a,A | 0.936 ± 0.011 a,A |

| 7 | 4.367 ± 0.040 a,A | 0.918 ± 0.004 a,A | |

| 14 | 4.360 ± 0.061 a,A | 0.919 ± 0.001 a,A | |

| 21 | 4.353 ± 0.045 a,A | 0.887 ± 0.074 a,A | |

| 1.5% CLS | 1 | 4.340 ± 0.036 a,A | 0.902 ± 0.022 a,A |

| 7 | 4.313 ± 0.015 a,A | 0.906 ± 0.038 a,A | |

| 14 | 4.327 ± 0.006 a,A | 0.923 ± 0.002 a,A | |

| 21 | 4.320 ± 0.026 a,A | 0.948 ± 0.020 a,A |

| Sample | Storage Time (Days) | L* | a* | b* |

|---|---|---|---|---|

| 0% CLS | 0 | 88.122 ± 1.600 a,A | −2.265 ± 0.306 a,A | 6.590 ± 0.989 a,A |

| 1 | 88.705 ± 0.434 a,A | −2.242 ± 0.250 a,A | 6.740 ± 0.490 a,A | |

| 7 | 90.285 ± 1.139 a,A | −2.425 ± 0.208 a,A | 6.295 ± 0.238 a,A | |

| 14 | 90.687 ± 0.456 a,A | −2.120 ± 0.810 a,A | 6.253 ± 0.212 a,A | |

| 21 | 90.885 ± 0.725 a,A | −2.105 ± 0.120 a,A | 6.178 ± 0.760 b,A | |

| 1% CLS | 0 | 85.565 ± 1.623 a,A | −3.203 ± 0.244 a,A | 37.905 ± 0.299 a,B |

| 1 | 85.618 ± 0.506 a,A | −3.700 ± 0.306 a,B | 38.648 ± 0.721 a,B | |

| 7 | 86.288 ± 2.029 a,A | −4.225 ± 0.316 a,B | 38.355 ± 1.726 a,B | |

| 14 | 87.530 ± 0.741 a,A,B | −4.433 ± 0.453 a,B | 37.873 ± 0.508 a,B | |

| 21 | 87.890 ± 0.439 a,B | −4.518 ± 0.590 a,B | 36.585 ± 0.392 a,B | |

| 1.25% CLS | 0 | 84.327 ± 0.649 a,A | −2.723 ± 0.491 a,A | 41.893 ± 0.279 a,C |

| 1 | 85.225 ± 2.438 a,A | −2.888 ± 0.374 a,A,B | 42.745 ± 1.283 a,C | |

| 7 | 85.897 ± 0.820 a,A | −3.067 ± 0.287 a,A | 43.015 ± 0.344 a,B,C | |

| 14 | 86.041 ± 1.858 a,B | −3.710 ± 0.215 a,A,B | 42.976 ± 0.184 a,C | |

| 21 | 86.109 ± 0.858 a,B | −3.875 ± 0.143 a,B | 43.396 ± 0.184 a,C | |

| 1.5% CLS | 0 | 85.313 ± 1.252 a,A | −2.298 ± 0.433 a,A | 44.885 ± 0.558 a,D |

| 1 | 85.675± 1.572 a,A | −2.310 ± 0.267 a,A | 45.075 ± 0.715 a,C | |

| 7 | 85.078 ± 1.599 a,A | −3.078 ± 0.162 b,A | 45.805 ± 3.039 a,C | |

| 14 | 86.945 ± 0.620 a,A,B | −3.160 ± 0.516 b,A,B | 46.019 ± 1.775 a,C | |

| 21 | 87.013 ± 0.335 a,B | −3.410 ± 0.051 b,B | 45.914 ± 0.368 a,D |

| CLS | K (Pa.sn) | n | R2 | ||

|---|---|---|---|---|---|

| 0% | 0.377 ± 0.024 A | 6.186 ± 0.263 A | 0.716 ± 0.006 A | 0.996 | 411.562 ± 53.856 A |

| 1% | 0.386 ± 0.011 B | 7.663 ± 0.270 B | 0.766 ± 0.003 B | 0.995 | 407.714 ± 21.919 A |

| 1.25% | 0.573 ± 0.009 C | 11.792 ± 0.079 C | 0.777 ± 0.003 C | 0.995 | 727.393 ± 21.267 B |

| 1.50% | 0.609 ± 0.025 D | 12.688 ± 0.491 D | 0.781 ± 0.001 D | 0.995 | 785.999 ± 30.875 C |

| CLS | Color | Odor | Texture | Flavor | Overall Acceptability |

|---|---|---|---|---|---|

| 1% | 7.075 ± 1.248 a | 6.650 ± 1.292 a | 6.800 ± 1.713 a | 6.150 ± 2.007 a | 6.425 ± 1.517 a |

| 1.25% | 6.850 ± 1.545 a | 6.375 ± 1.690 a | 6.575 ± 1.752 a | 6.275 ± 1.867 a | 6.350 ± 1.642 a |

| 1.50% | 7.225 ± 1.250 a | 4.925 ± 1.269 b | 6.925 ± 1.700 a | 5.050 ± 2.459 b | 5.850 ± 1.777 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerra, A.S.; Hoyos, C.G.; Velásquez-Cock, J.; Vélez, L.; Gañán, P.; Zuluaga, R. The Effects of Adding a Gel-Alike Curcuma longa L. Suspension as Color Agent on Some Quality and Sensory Properties of Yogurt. Molecules 2022, 27, 946. https://doi.org/10.3390/molecules27030946

Guerra AS, Hoyos CG, Velásquez-Cock J, Vélez L, Gañán P, Zuluaga R. The Effects of Adding a Gel-Alike Curcuma longa L. Suspension as Color Agent on Some Quality and Sensory Properties of Yogurt. Molecules. 2022; 27(3):946. https://doi.org/10.3390/molecules27030946

Chicago/Turabian StyleGuerra, Angélica Serpa, Catalina Gómez Hoyos, Jorge Velásquez-Cock, Lina Vélez, Piedad Gañán, and Robin Zuluaga. 2022. "The Effects of Adding a Gel-Alike Curcuma longa L. Suspension as Color Agent on Some Quality and Sensory Properties of Yogurt" Molecules 27, no. 3: 946. https://doi.org/10.3390/molecules27030946

APA StyleGuerra, A. S., Hoyos, C. G., Velásquez-Cock, J., Vélez, L., Gañán, P., & Zuluaga, R. (2022). The Effects of Adding a Gel-Alike Curcuma longa L. Suspension as Color Agent on Some Quality and Sensory Properties of Yogurt. Molecules, 27(3), 946. https://doi.org/10.3390/molecules27030946