Abstract

In recent years, Internet-of-Things technology (IoT) has been the subject of research in diverse fields of applications. IoT plays an essential role in transitioning enterprises towards a more interconnected paradigm of manufacturing, logistics, services, and business, known as Industry 4.0. This paper presents an operational concept for a system that implements IoT technology in pallets, which are used to move products along supply chains. These sensors will help us gain insight into the conditions experienced by products and unit loads. Having this capability will allow us to obtain the information necessary for better control of product distribution along the supply chain, and to design packaging that is more efficient and effective in protecting products during distribution. In this paper, we show how Model-Based Systems Engineering (MBSE) can be leveraged to create models that capture the required system behaviors, and we address the complexity of an IoT system within the domain of packaging and logistics applications.

1. Introduction

Established protocols for package testing are limited in their capacity to accurately simulate real-world supply chain conditions. This results in suboptimal packaging designs that decrease the efficiency of logistics operations [1]. The concept of packaging is defined as “a means of ensuring safe and efficient delivery of goods in a sound condition to the ultimate customer, supplemented by efficient re-use of the packaging, or recovery and/or disposal of the packaging material at minimum cost [2]”.

Distribution packaging has an impact in the efficiency of logistics activities related to product distribution and customer service [3]. Specifically, understanding the distribution environment in critical phases like transportation and warehousing, and using this information to drive packaging design has the following advantages [3]:

- Lighter packaging which translates in less fuel consumption.

- Stronger packaging which reduces product damages.

In 2007, The World Bank published a study that stated that “80% of US trade is carried on pallets” [4]. It was estimated that this amounted to 2.6 billion pallets circulating in the United States in 2017 [5]. Pallets are a key component of distribution operations. They transport goods and are the main interface connecting material handling equipment and packaged products [6]. This makes pallets suitable vehicles for gaining insight into the conditions experienced by products and packages during distribution. We believe this can be achieved by using sensors embedded in pallets to capture data of interest about the physical conditions in the supply chain. These sensors could capture information that would be more reliable than what is currently available to engineers through generalized standards, and this new data may be leveraged to increase customization and optimization of packaging designs.

IoT aims to integrate the physical world with computational systems by embedding objects, such as pallets, containers, or packages, with sensors and software that can exchange collected data with cloud platforms and other smart objects, enabling opportunities to develop new applications that will improve the efficiency and performance of logistics and supply chain operations [7]. The implementation of IoT technologies will require greater interaction among the physical and virtual elements in the supply chain, which increases overall complexity. This makes necessary the adoption of an approach to tackle this emerging complexity in order to ensure that new IoT systems in supply chains are effective in responding to genuine needs and deliver real-world value.

In this paper, we apply model-based system engineering (MBSE) to develop a framework for an operational concept of an IoT system for the palletized distribution supply chain. The focus of this paper is to provide a conceptual solution to the problem of packaging design through the application of MBSE, which will set a sound foundation upon which specific system solutions can be developed in the future. This paper has two main contributions: first, a concept of operations which describes how the proposed IoT system would be useful and drive efficiency improvements in the packaging design process; secondly, the definition of requirements using MBSE constructs such as the semantically expanded sequence diagrams and signal elements of the System Modeling Language (SysML) in the True Model-Based Requirements (TMBR) approach.

To the best of our knowledge, this is the first paper that addresses the search for solutions within packaging and logistics domains by applying MBSE. Our intent is to show MBSE as a methodological approach that can support the development of solutions within the packaging and logistics domains. To this purpose, we take the implementation of IoT in pallets as a case study, due to its current relevance as a topic of interest in literature and among industry experts in the field. Empirical validation of the modeling constructs for the proposed system, as well as the selection of specific technologies is outside the scope of this paper.

The following research questions are formulated:

- Do companies have needs in their distribution packaging supply chain that makes necessary the adoption of such a system?

- How can IoT technology be implemented to address the needs of companies’ distribution packaging supply chains?

- How can MBSE contribute to the development of systems within the packaging and logistics domains?

2. Related Work

System development in the fields of logistics, supply chain, and IoT have focused on specific technology solutions, rather than defining system requirements, and it has so far lacked an approach with which to tackle the complexity of such system developments. Examples of different technologies are found in several authors works [8,9,10,11].

A system for supply chain management and integration based on the concept of cloud of things is presented in J. Yan et al.’s “Intelligent supply chain integration and management based on cloud of things” [8]. The proposed system’s architecture was composed of three layers: perception, network access, and management. The authors conclude that the distributed nature of the system increases the complexity of supply chain management.

An intelligent tracking system for the cold chain is found in H. Luo, et al.’s “An Intelligent Tracking system based on internet of things for cold chain” [9] based on a wireless sensor network built on Zigbee as its protocol for sensor communication within the IoT network and 2G, 3G, and 4G to transfer the information to monitoring servers. The sensors for this research were placed in cold storage warehouses and refrigerated trucks. They collected temperature data and emitted alerts when critical parameters became abnormal, aiming to have better control over the products and notify on site personnel to take action [9].

A supply chain mapping and real-time shelf-life prediction application is found in R. Jaderman, et al.’s “Remote quality monitoring in the banana chain” [10]. The temperature during transportation for bananas was tracked from Costa Rica to Germany by placing wireless sensors in the center of selected boxes. This allowed for more precise shelf-life estimations for products and helped to identify the “hot-spots” along the chain where conditions were more apt to cause damages to the cargo.

Limitations, and improvement propositions for packaging design, are found in these two articles: V. Rouillard’s “Generating road vibration test schedules from pavement profiles for packaging optimization” [1], and V. Rouillard and M. Lamb’s “On the effects of sampling parameters when surveying distribution vibrations” [12]. In them, the focus is on improving the characterization of the vibration environment during distribution. These studies emphasize the technical configuration of parameters to improve characterization. Our paper takes this aspect into consideration by incorporating it into a broader framework for distribution environment characterization using MBSE. Other works point to more specific relationships between unit load components that affect packaging design, such as C. Quesenberry, et al.’s “The effect of pallet top deck stiffness on the compression strength of asymmetrically supported corrugated boxes” [13].

In relation to the application of systems engineering (SE) techniques, F. Vanek, et al. [14] studied the benefits that using SE techniques generate in new product development. The authors found a positive association between high performing projects and utilization of SE techniques, and they also found that projects with deficient performance were characterized by a lack of SE technique implementation.

A bioanalytical system model based on MBSE is presented in E. Evin and Y. Uludag’s “Bioanalytical Device Design with Model-Based Systems Engineering Tools” [15], where different diagram elements are used to create a system model that enables multidisciplinary teams to work together. The authors concluded that better examples of the use of MBSE are needed, especially in domains where its implementation remains unexplored.

Based on this review of related work, we conclude: IoT is a relevant field of exploration for supply chains and logistics; there is a lack of a systematic approach towards tackling the problem of packaging design; and it is worthy to explore the use of MBSE to create a framework that will define requirements for a system that aims to improve packaging design in supply chain operations.

3. Capability Needs in the Packaging and Logistics Domain

We conducted a semi-structured interview with engineers and executives from 11 companies to understand the needs and challenges that companies face in relation to their packaging design processes and distribution operations. These companies were selected based on their availability and willingness to participate. The insights derived from these engagements are not meant to be representative of the entire industry, but rather to provide unique perspectives from different types of companies.

The engineers and executives in these companies were contacted via phone call. The following questions were utilized to guide the interview:

- Q1. What type of products does your company manufacture?

- Q2. How are your products distributed to your customers?

- Q3. What are the main distribution hazards that are present downstream in your supply chain?

- Q4. What type of information about your supply chain’s distribution hazards is currently available to you for the packaging design process?

- Q5. What information about the distribution conditions downstream in your supply chain, or about the conditions of your cargo, would be valuable for your company to know on a continuous basis?

One of the most crucial insights obtained from these interviews was that the type of information needed is dependent on the type of product being distributed and the type of supply chain. For example, companies that manufacture packaging for the pharmaceutical and food industries put a higher importance on safety and cleanliness.

Seven out of eleven participants had an interest in location tracking to increase visibility, control routes and lead times, and identify bottle necks. In the case of reusable packaging, location tracking would help prevent assets from being lost.

Seven out of eleven companies utilize international standards to design their packaging. Two of the interviewees stated that the standards were not aligned with their particular supply chain conditions. One of the companies interviewed expressed concern about implementing technology in their packaging solutions until they understood better what would happen to the physical technology infrastructure once the packaging unit reached the end of its lifetime. This was an important consideration to them, when planning for IoT technology infrastructure to be installed in reusable packaging. All but one company expressed interest in obtaining information about temperature, vibration, shock, location, humidity.

4. Using MBSE for IoT System Design

Systems Engineering is an engineering discipline that aims to tackle the growing complexity of sociotechnical systems; therefore, it studies the application of strategies to conceptualize, build, and operate engineered systems [16,17]. This approach has traditionally been used in the development of aerospace and defense related systems, but its implementation in civil and commercial applications has gained ground in recent years due to its demonstrated effectiveness in producing better performance outcomes [14]. This paper hopes to broaden systems engineering application to support the development of an IoT system that aims to improve packaging design and logistics operations. Model-Based Systems Engineering (MBSE) can be understood as the application of models to support system solutions in response to stakeholder needs [18], which tackles the complexity created by system interactions, and facilitates people from different disciplines working together in an integrated model when designing a system [15]. Furthermore, it has been suggested that the technological and commercial success of IoT systems is dependent on the application of sound systems engineering tools, and that without MBSE, IoT system development, deployment, and operation would require more resources from the stakeholders involved [19].

The application of a model-based approach to systems design has several potential advantages [18]:

- Enhanced communication among members of the development team and stakeholders.

- Higher quality requirements.

- More effective comparison of different design alternatives.

- Lower error rate during integration and testing.

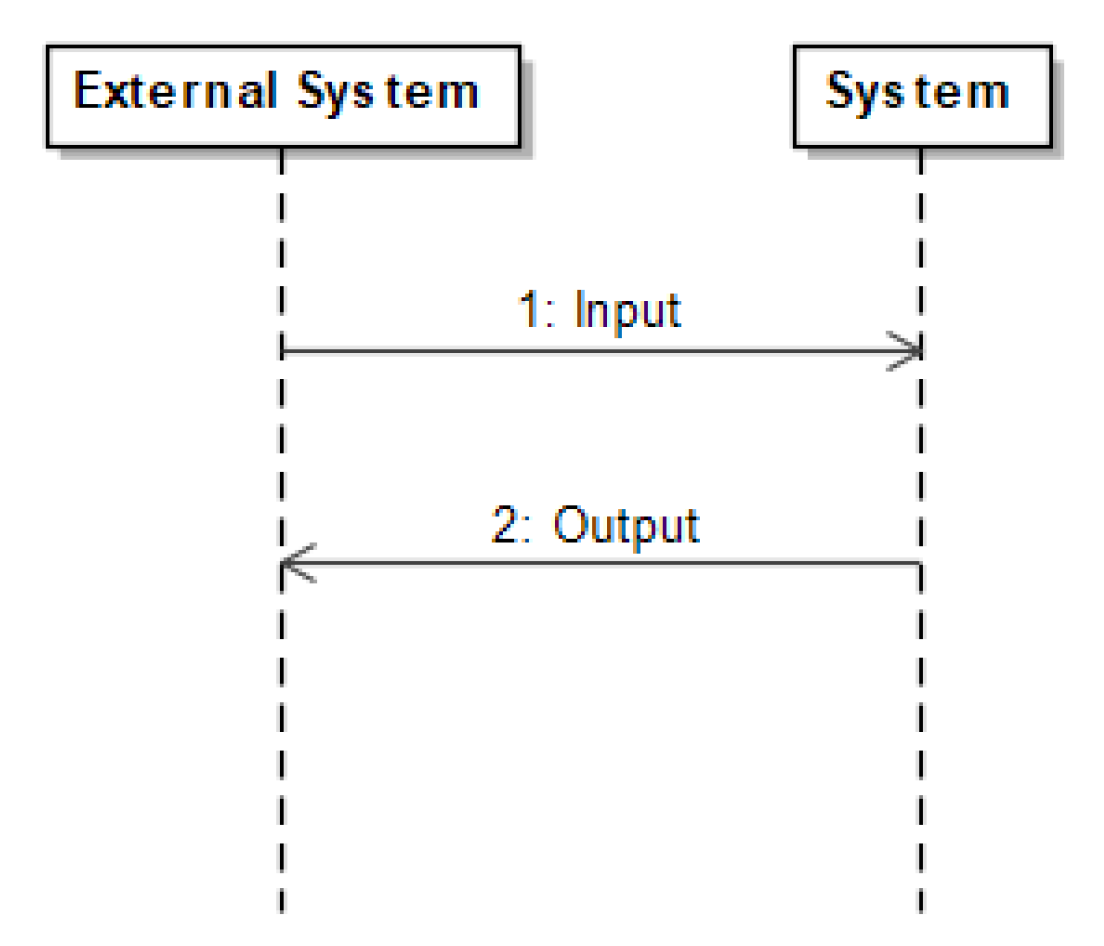

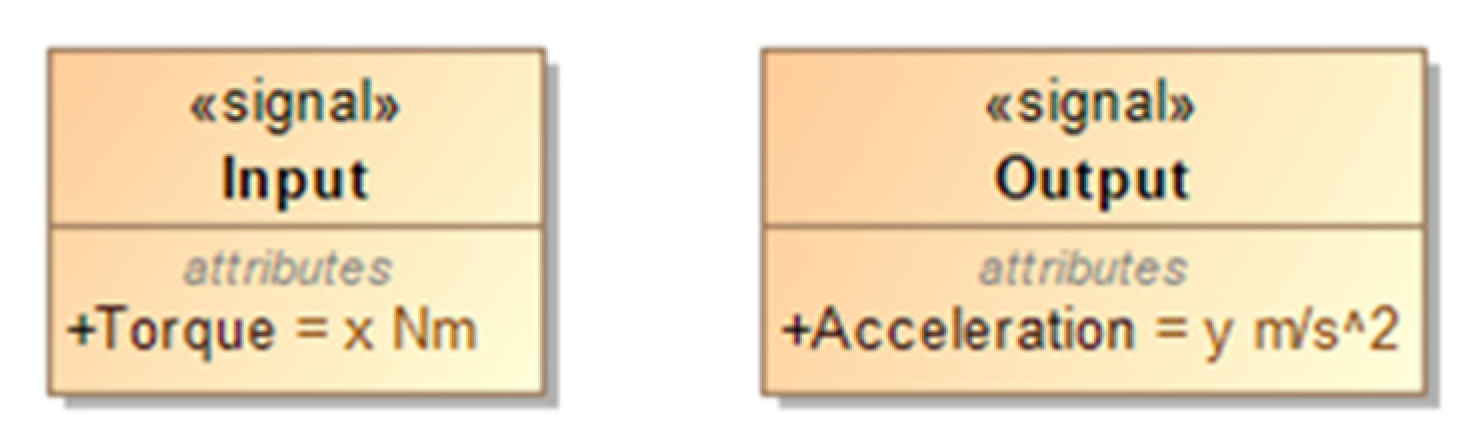

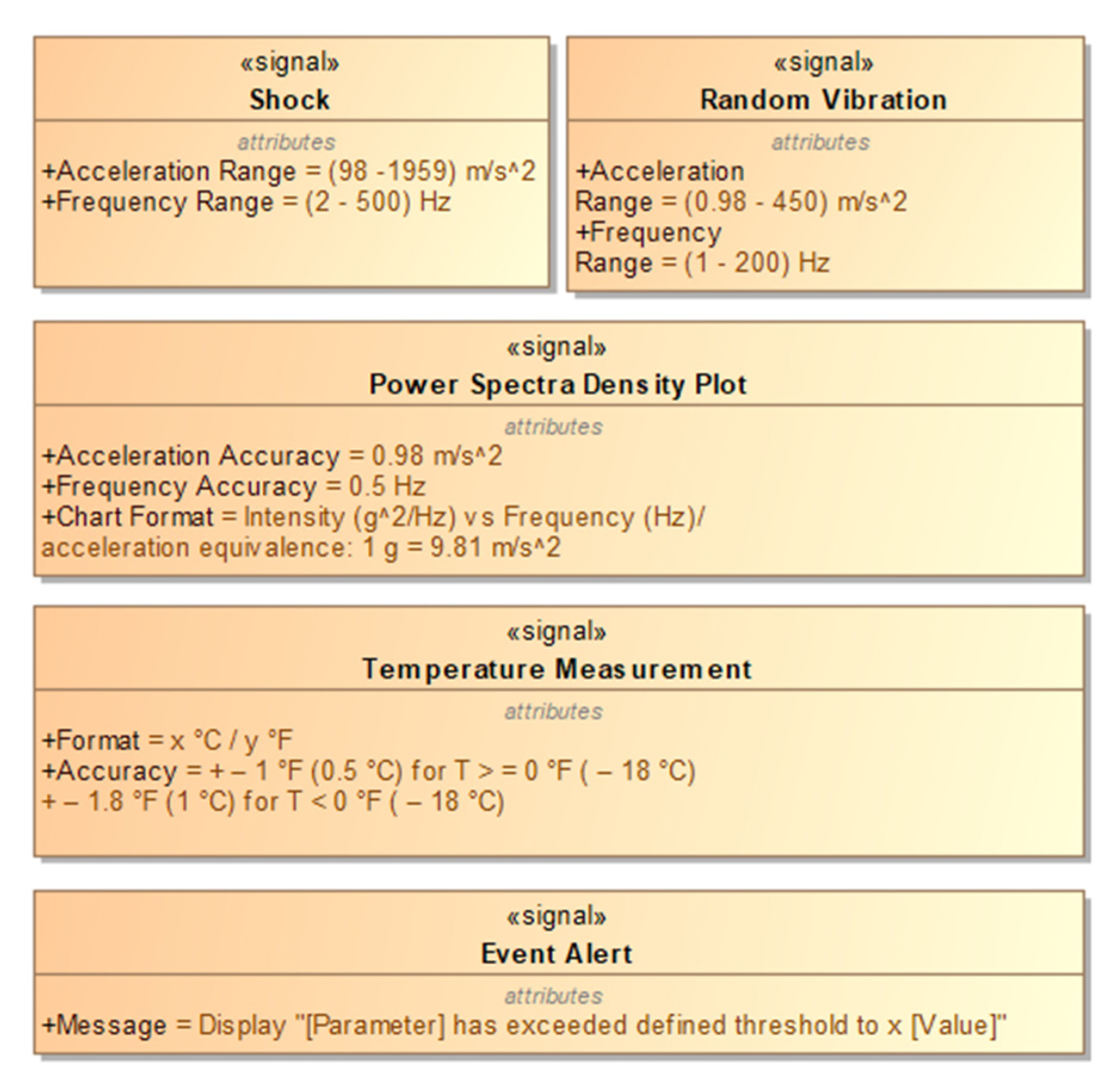

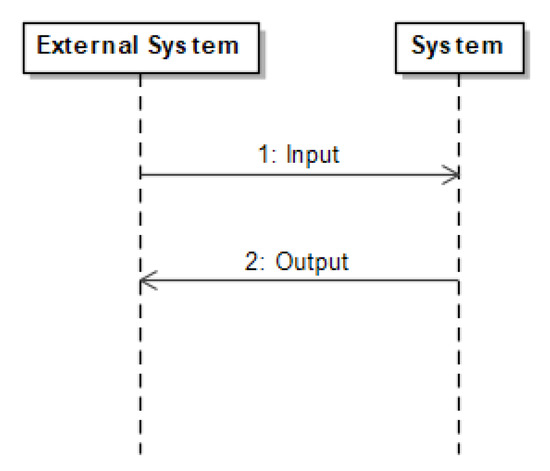

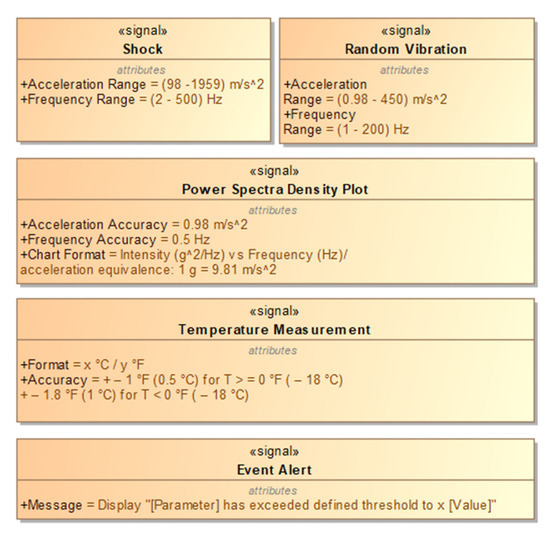

The system design concept presented in this paper was developed using systems engineering within an MBSE environment. The resulting models aim to replace document-based and textual representations of the different design artifacts. Furthermore, we make use of the True Model-Based Requirements (TMBR) approach [20], which uses an extended semantic interpretation for some of the traditional SysML constructs. This is necessary to not enforce design solutions in the requirements models [21]. Specifically, in this paper, we limit its application to modeling requirements as required transformations of input trajectories into output trajectories using Sequence Diagrams (ref. Figure 1), where the inputs and outputs, as well as their required characteristics, are modeled using Signal elements (Figure 2).

Figure 1.

Input/Output transformation sequence.

Figure 2.

Signal characterization.

5. Concept of Operations

Following [22], we describe the system’s concept of operations as a transition from the “As-Is” to the “To-Be” situations. In the “As-Is” situation, we describe how pallets are currently employed by companies, their interaction with the products they carry, and the process that is traditionally followed for packaging design. Here, we also indicate how certain pitfalls in traditional package design and pallet usage can lead to higher packaging costs. In the “To-Be” situation, we focus on showing how our proposed IoT system concept would change the way pallets are employed, and how this change could lead to efficiency improvements in the packaging design process that will produce more effective packages.

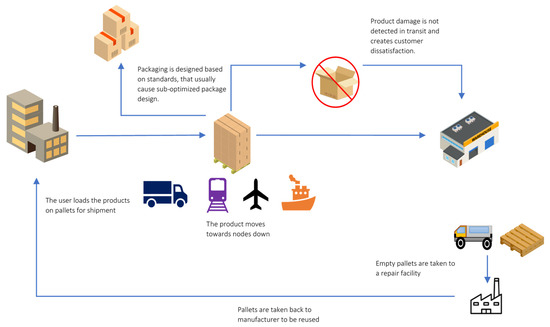

5.1. The Current State

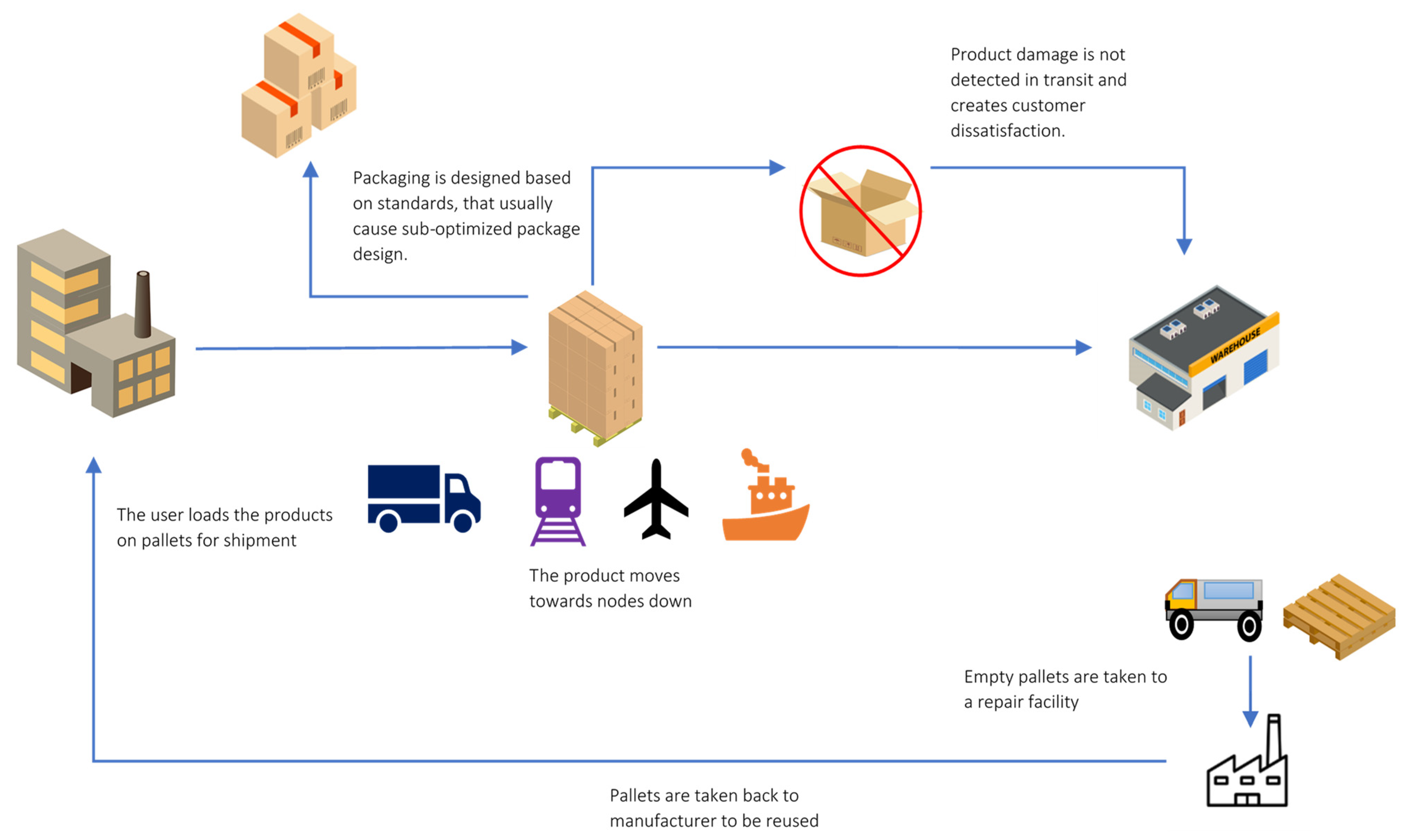

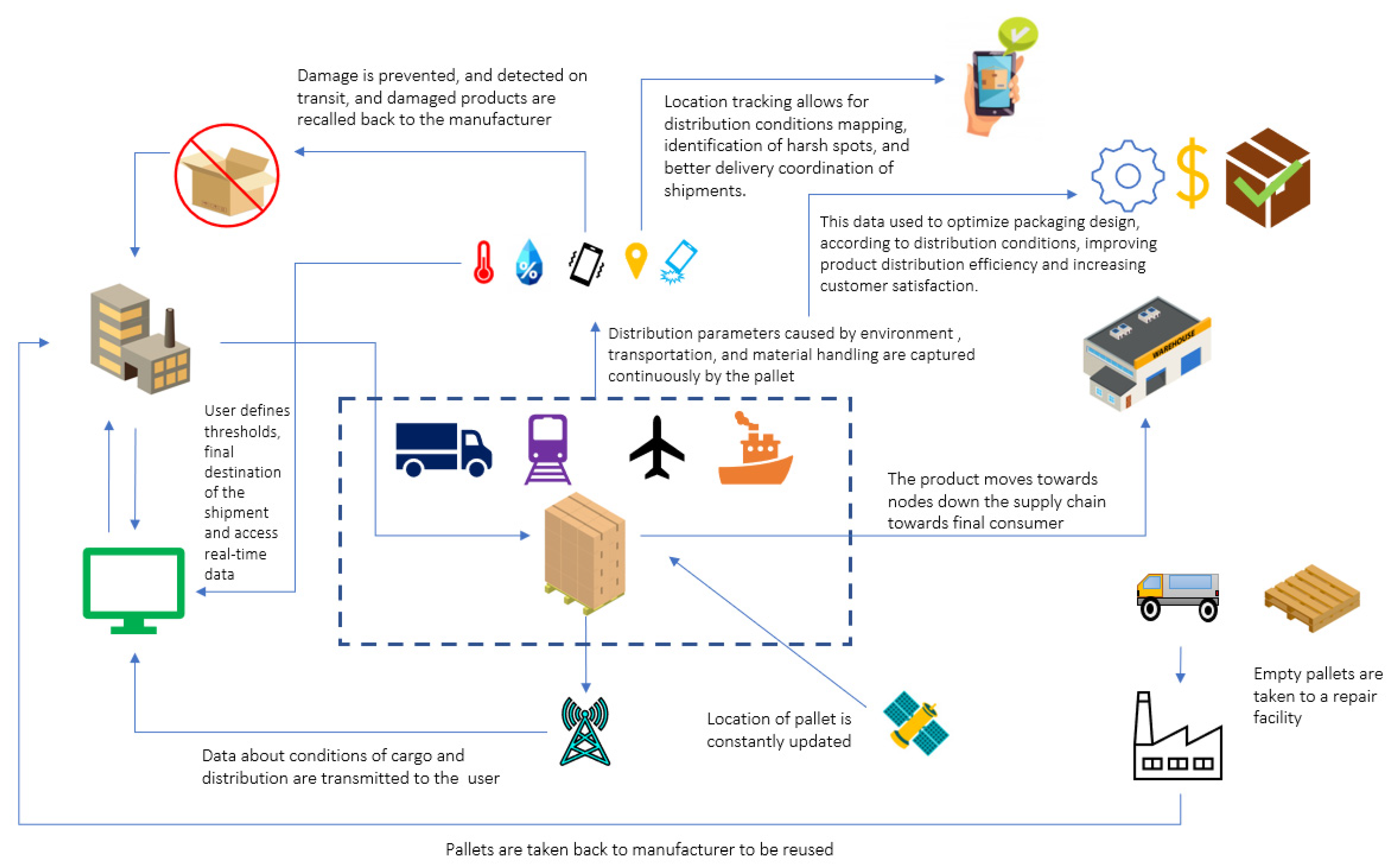

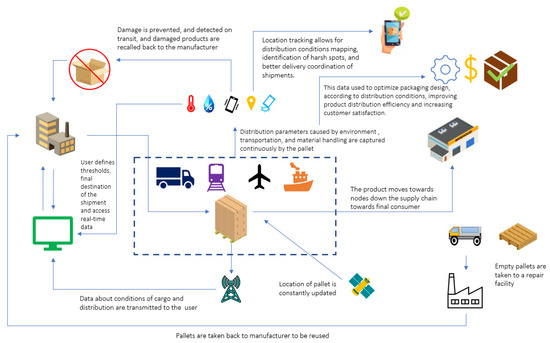

Pallets are used by manufacturers to transport products down the supply chain, either directly to a customer, to a distribution center, or to a warehouse in which the unitized load is stored, and later redirected to the final customer. Once the unit load arrives at its final destination, assuming there were no picking processes along the way, the product on the pallet is unloaded, and the pallet is put aside to be discarded, reused, or recycled. The primary purpose of the pallet is to protect the product and to enable its movement during distribution. An illustration of the traditional shipping of products is shown in Figure 3.

Figure 3.

As-Is Situation Concept of Operations.

The movement of finished products from the manufacturer to the final point of consumption implies the physical movement of a product through a series of nodes down the supply chain until it reaches the customer. This movement varies depending on many factors, such as the type of product and destination point.

All of the movements that occur in the process of transporting a product result in the product interacting with multiple external conditions known as distribution hazards, and may include shock, vibration, compression, and atmospheric conditions. Shock refers to the forces that products experience while they are being moved by material handling equipment, like pallet jacks, forklifts, and conveyors. Products also experience shock during transportation when they are subjected to the forces produced by jumps or sudden breaks in motion. Vibration is transmitted to products during movement by equipment like trucks, parcel delivery vehicles, airplanes, rail carts, and vessels. Compression refers to the forces products are subjected to as the result of being stored and transported with other products in the form of consolidated unit loads. Lastly, atmospheric conditions are those relating to the environment in which the product travels, like temperature, relative humidity, and atmospheric pressure.

The role of distribution packaging during distribution is to minimize the negative effects that these potential hazards pose to the products, and to help guarantee that the product reaches the customer in an acceptable condition in order to achieve consumer satisfaction.

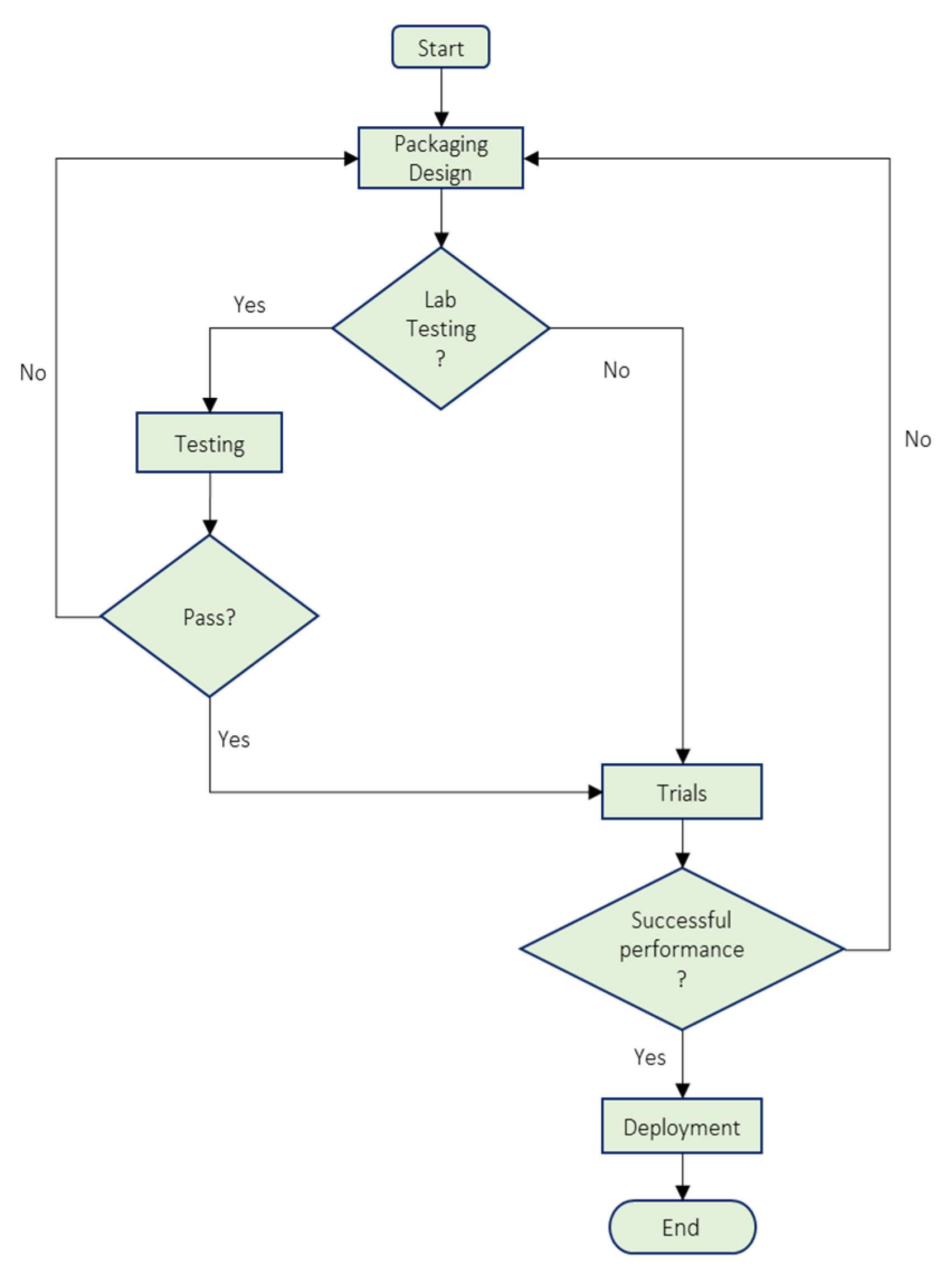

When designing a distribution packaging solution for a product, a company needs to have a sense of the physical conditions that the packages and products will experience during distribution. Once a design solution is chosen, the company needs to decide whether or not to proceed with laboratory testing. The purpose of testing is to establish with higher confidence if the package is fit to survive the distribution environment. However, testing implies increased costs for companies, and some may decide that the cost is not worth the higher confidence about a package’s adequacy for distribution. Testing is usually carried out following standardized sequences of distinct distribution hazard sub-tests, like shock and vibration, that are meant to resemble the exact conditions that the packages and products will face along the distribution supply chain. A prerequisite for successful testing is prior knowledge about the supply chain. The specific conditions of the supply chain will vary from case to case as different companies use different means of transportation, different material handling systems, and distribute across varied geographical areas.

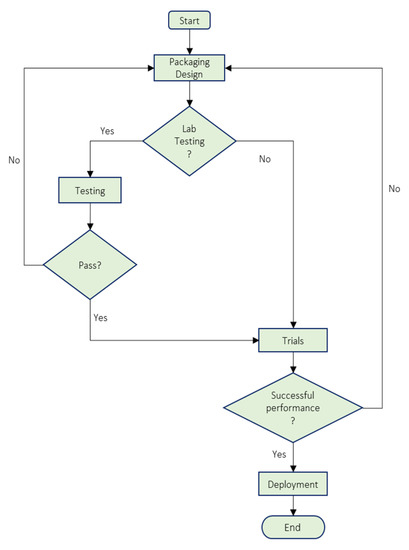

If the results of the laboratory testing indicate that the packaging will successfully protect the product, given their specific distribution conditions, then the packaging is put into use on a trial basis, using it to ship a sample load of products. Otherwise, the packaging is redesigned, and the testing process starts again. Once a trial run is successful, the packaging solution is deployed; otherwise, the package is redesigned, and the testing and trial process starts again. The flow diagram shown in Figure 4 describes the development process for new distribution packaging designs. In the diagram, rectangles represent processes, and diamonds represent decisions.

Figure 4.

Traditional Packaging Design Process.

Because of the high uncertainty associated with which distribution hazards are present during handling and transportation, as well as their intensity levels, companies usually choose one of two strategies. Either they choose to accept the losses resulting from the inadequate packaging solution, or they increase the level of protection by overpackaging their product, which increases packaging costs and decreases operational efficiency [23]. In this paper, we assume that by having greater certainty about the conditions present in the distribution supply chain, it is possible to design more efficient, effective, and appropriate packaging solutions for any given product.

Furthermore, in this traditional use of pallets and packaging, there is no visibility about the conditions of the products during transportation. This means that products that were damaged during the trip are more likely to reach the customer, which can cause several setbacks for the product owner. This is also indicated in Figure 3.

5.2. The Future State

In our proposed framework, the pallet collects environmental information. Specifically, the pallet collects information about temperature, relative humidity, vibration, shock, and location. At the end of the trip, the pallet stops collecting data, and is picked up to be re-allocated, repaired, recycled, or disposed.

In this future (desired) situation, the product location is captured as it moves towards the customer. Based on the user’s knowledge about the sensitivity of its products, when one of the parameters exceeds a predefined threshold, the user receives an alarm notification indicating the anomaly. This can trigger further control processes, like stopping the cargo in transit for inspection, assuring either that any damaged product does not reach the customer or to prevent damage from occurring.

Furthermore, the distribution environment characterization provided by the system can enable the optimization of packaging design. This is because the collected data is expected to allow the recreation of distribution conditions more accurately than what current standards provide. We believe this will have a positive impact on designing packaging solutions that adequately protect products, with the least use of material, hence reducing cost and increasing efficiency. The “To-Be” situation is presented in Figure 5.

Figure 5.

To-Be Situation Concept of Operations.

Realizing this future state will require the selection of technologies that are capable of sensing environmental data, communicating with the user, providing a user interface, and recording, organizing, and displaying information. The focus of this paper is to propose the conceptual system, rather than its physical implementation. In the next chapter, we present MBSE constructs that define system requirements, which will serve as baseline for specific technologies selection and evaluation.

6. Operational Design of Proposed Concept

6.1. System Use Cases

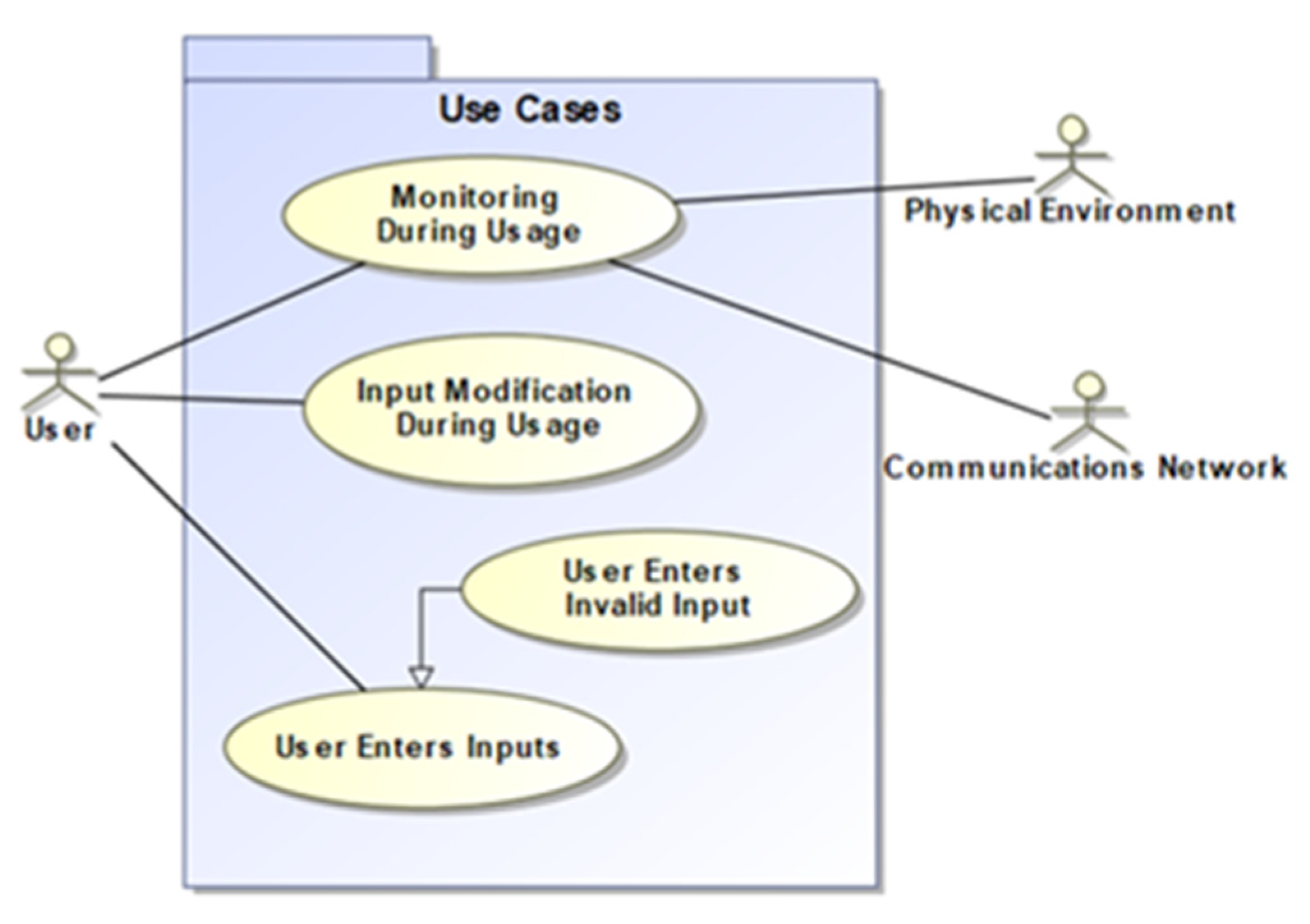

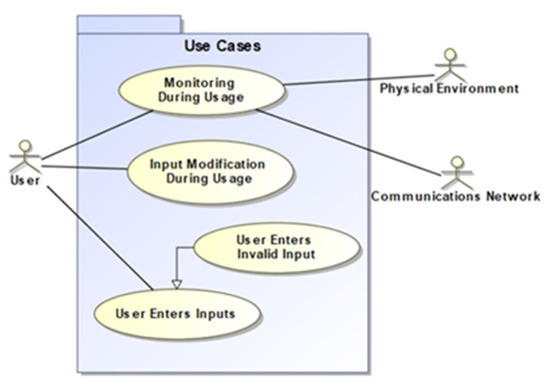

Two primary use cases, and two secondary use cases, are identified here. The first is “User Enters Inputs,” which describes a case where the user provides the system with information that determines its functionality, according to the specific user’s needs. The second use case is “User Enters Incorrect Input,” which captures what happens when the user enters information that cannot be accepted by the system. This is important because system functionality will be affected by these inputs, and unacceptable inputs or user mistakes must be identified and handled to ensure correct functionality. The third use case is “Monitoring During Usage,” and it captures the scenarios where the user monitors the distribution of products. A fourth use case is identified as “Input Modification During Usage.” This is an important consideration, given that the user might want to adjust the system once it is operational. For example, to correct erroneous configurations. Figure 6 shows the different use cases anticipated for this system and the actors that interact with it. Actors are either users of the system or external systems.

Figure 6.

System Use Cases.

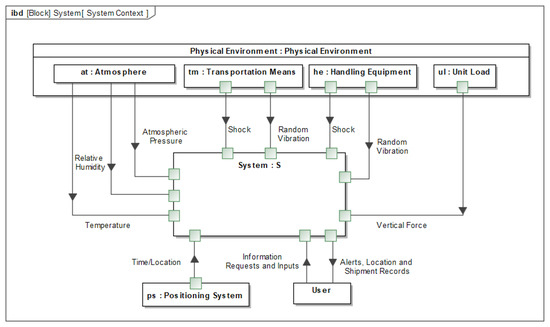

6.2. System Context

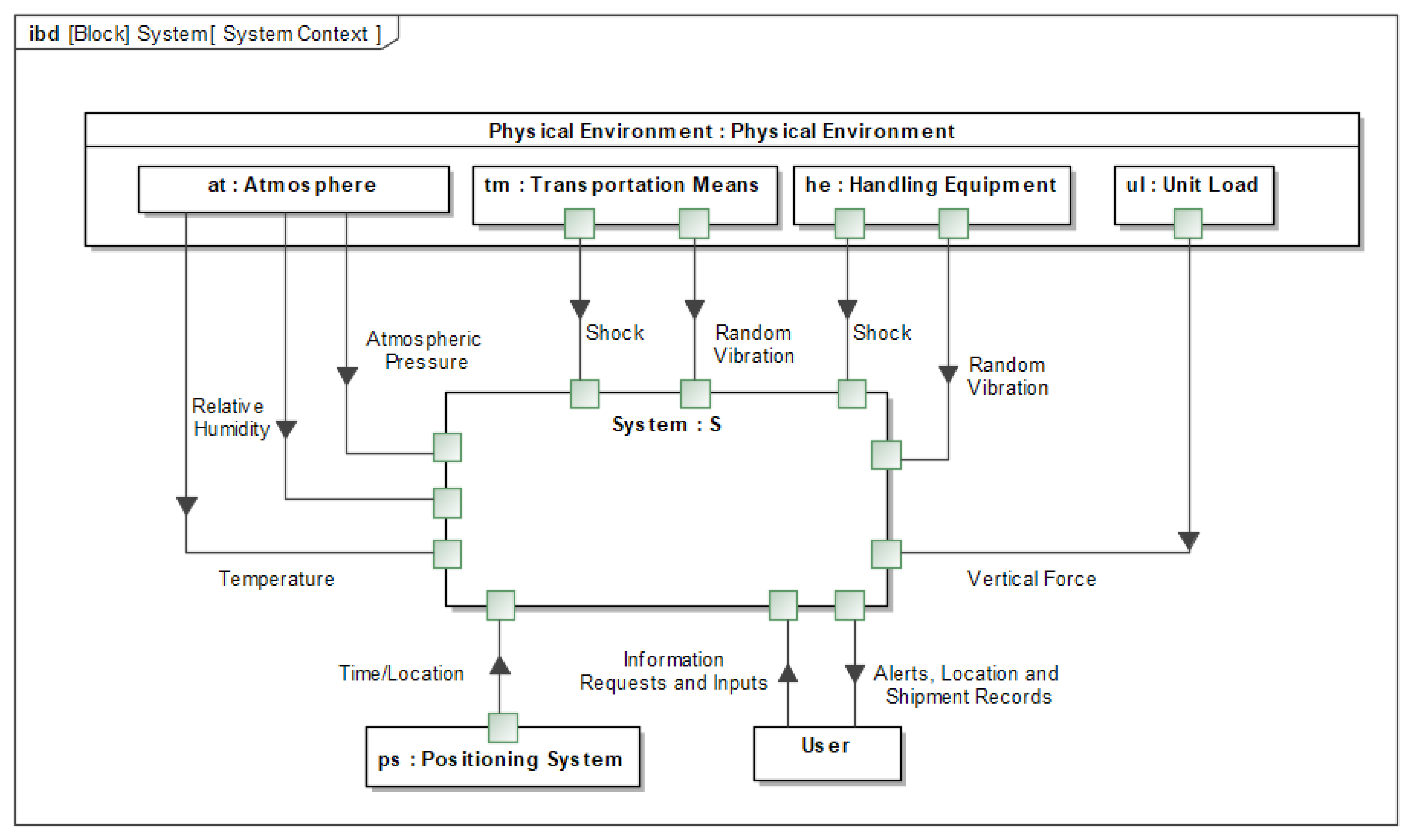

The system boundary, shown in Figure 7, is defined by establishing the interactions exhibited by the system. From the concept of operations, it is known that we will require the system to collect data about the environmental parameters experienced during transit between the different stages of the supply chain.

Figure 7.

System Context.

To achieve its purpose, the IoT system must interact with the physical environment to collect the inputs for the collection of distribution parameters. This physical environment has been broken down into four elements. First, the atmosphere, from which the IoT system senses temperature and relative humidity. Second, the transportation modes, which inputs shock impulses and random vibration to the IoT system. Third, the material handling systems, which also inputs shock and vibration forces to the IoT system. Fourth, the unit load that is placed on top of the pallet puts a vertical force on the system. We assume that the effects of this force are negligible; therefore, they have not been captured. The specific definition of the system’s external interfaces lies outside the scope of this paper.

6.3. System Interactions

The requirements defined for this conceptual system are created using Sequence Diagrams (with extended semantics), as discussed earlier. One Sequence Diagram is developed for each Use Case shown in Figure 6.

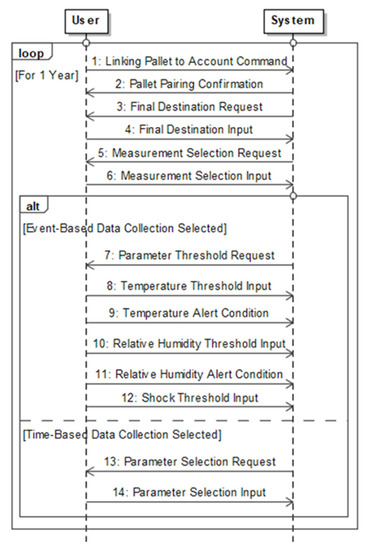

- User Enters Inputs

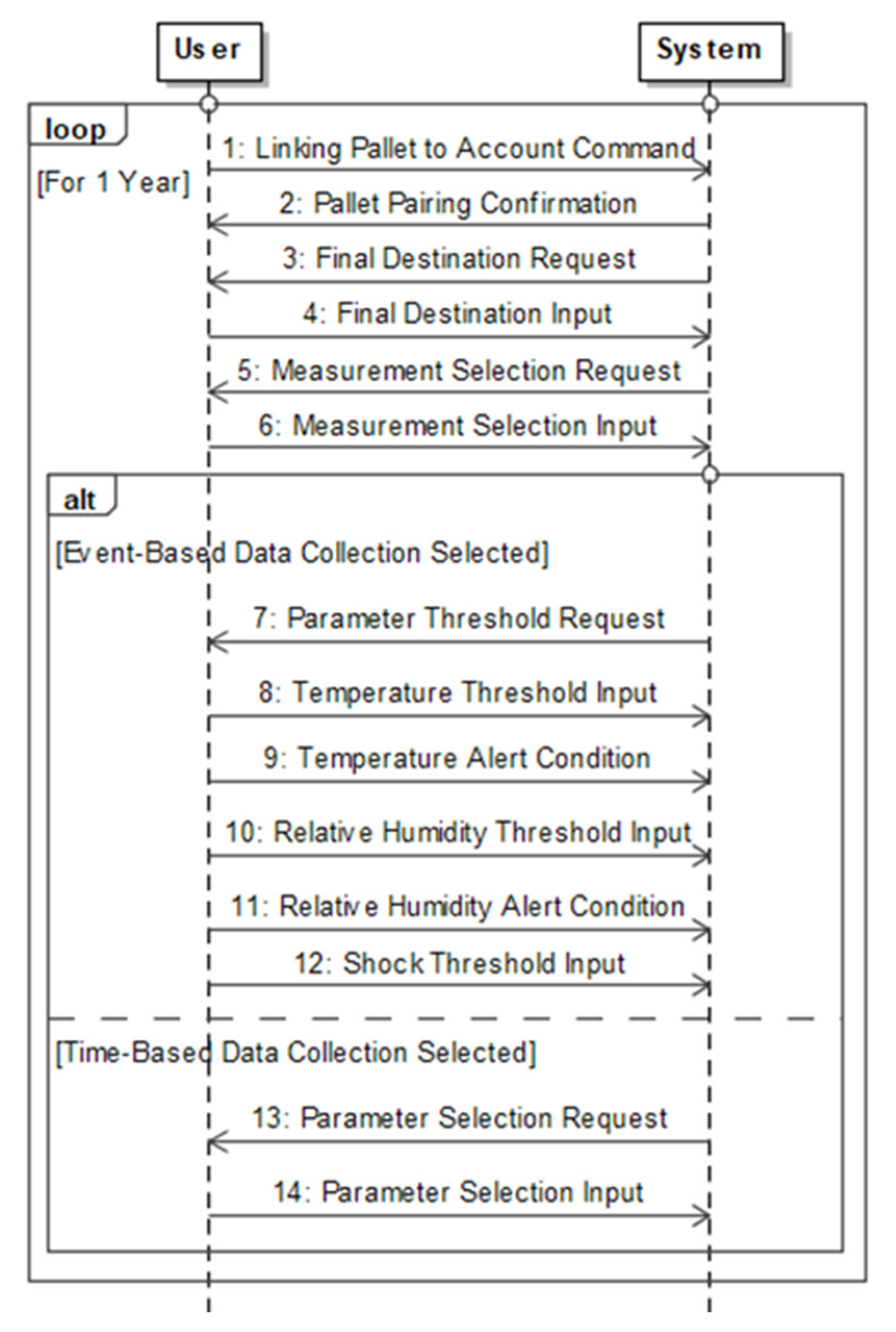

The elaboration of the use case “User Enters Inputs” is captured in Figure 8. The first required interaction goes from the user to the system and consists of a signal by which the user indicates to the system that a specific pallet must be linked to a shipment (Linking Pallet to Account Command). The system must then assign the chosen pallet to that user’s account and display back a message to the user confirming that the pallet has been paired (Pallet Pairing Confirmation).

Figure 8.

User Enters Inputs Sequence.

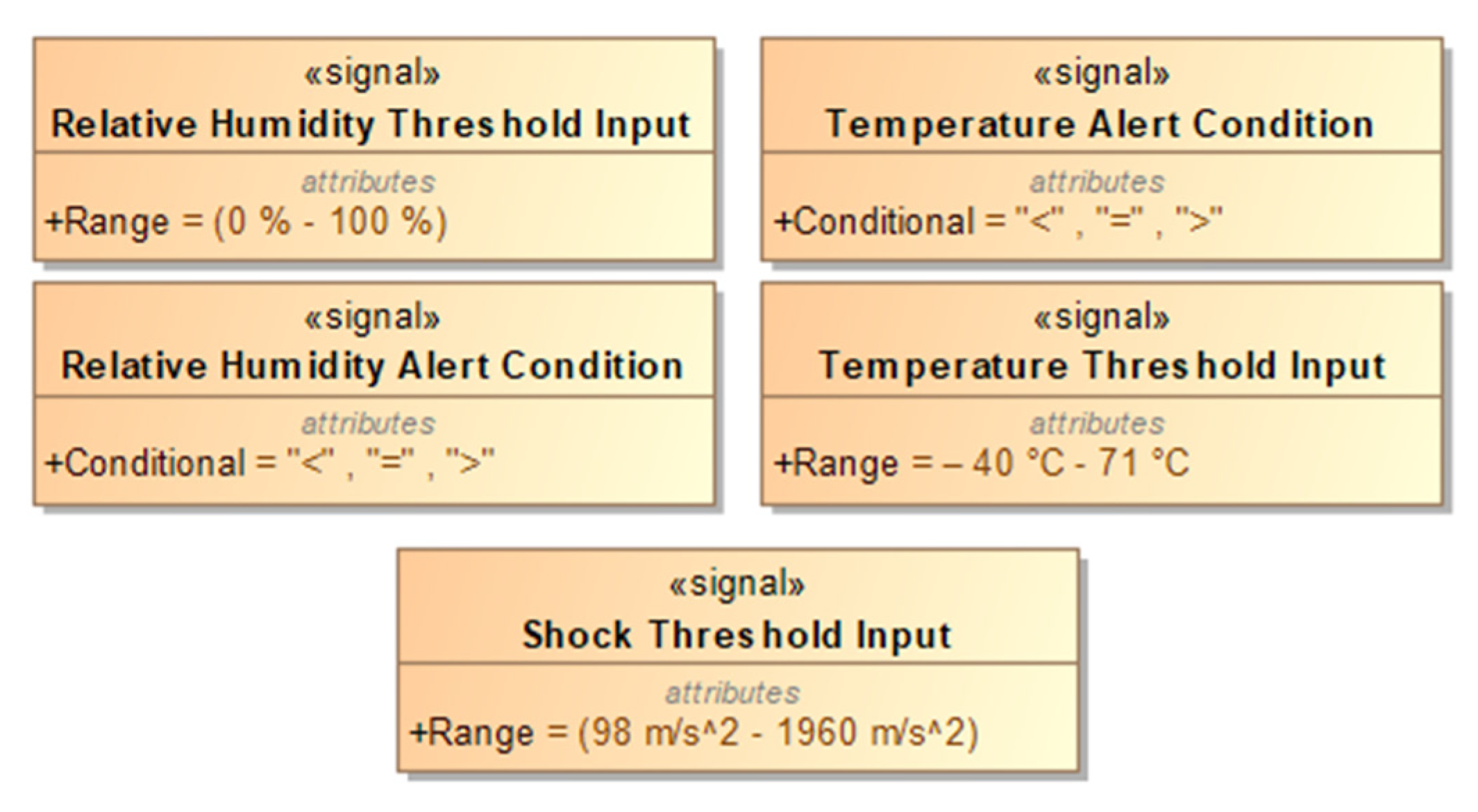

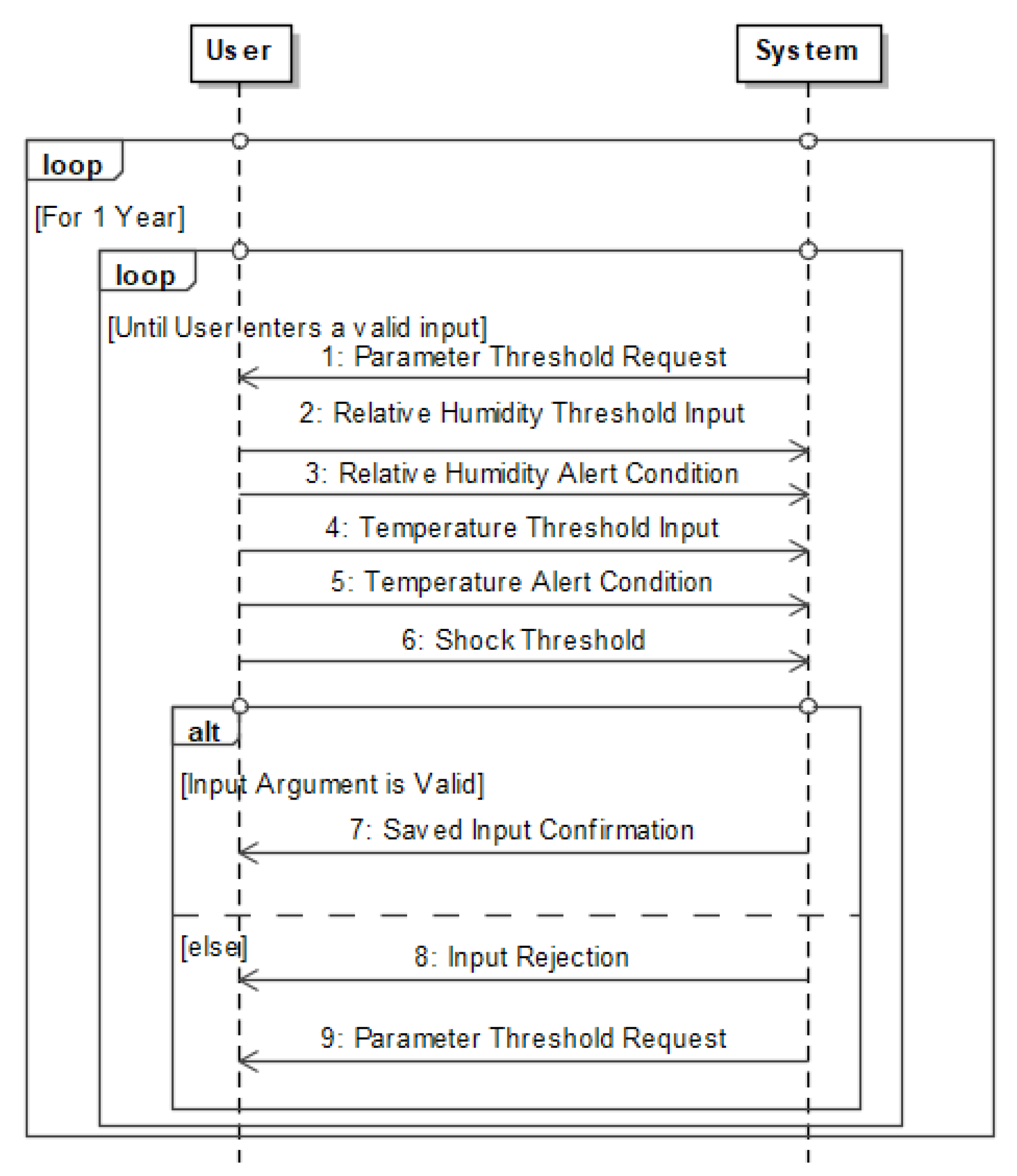

Once the pallet is linked to the user’s account, the system must receive certain input parameters from the user which are necessary for correct functioning. To begin with, the system must request the user to provide the final destination of the pallet (Final Destination Request and Final Destination Input, respectively). This input indicates when the system should stop collecting data. Second, the system must offer the user the option to select what type of measurements are to be collected (Measurement Selection Request), and later accept the user selection (Measurement Selection Input), which may indicate the selection of “Event-based data collection” or “Time-based data collection.” Different interactions are required depending on this selection (as captured by the alt construct). When “Event-based data collection” is chosen, the system must request from the user (Parameter Threshold Request), and accept from the user, the input of thresholds that specify the events to be tracked, which are characterized in terms of temperature (Temperature Threshold Input and Temperature Alert Condition), relative humidity (Relative Humidity Threshold Input and Relative Humidity Alert Condition), and shock (Shock Threshold Input). When “Time-based data collection” is chosen, the system must request from the user (Parameter Selection Request), and accept from the user, the parameters to be measured. The user can select from a combination of temperature, relative humidity, atmospheric pressure, vertical force, and random vibration (Parameter Selection Input). In contrast to “Event-based data collection,” there is no threshold or alert conditions because the purpose is to just periodically collect all data.

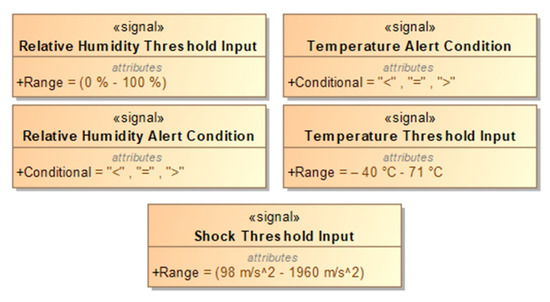

The lifetime of the system must be at least one year (captured by the loop construct). The required characteristics of some of the elements (signals) exchanged between the system are shown in Figure 9. For example, the system must measure temperature in the range between −40 °C to 71 °C, and hence this range must be defined for the Temperature Threshold Input. In a similar way, the system must identify when a temperature threshold has been surpassed, depending on whether the value measured is equal, lower, or higher than the threshold (Temperature Alert Condition). We have chosen for these examples the range of values for shock, temperature, and relative humidity that are recommended for field data collection by the International Safety and Transport Association (ISTA) [24].

Figure 9.

Required Signal Characterization for Inputs Entered by the User.

- User Enters Invalid Inputs

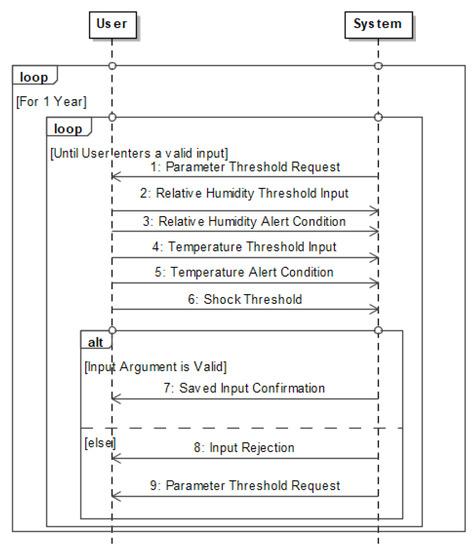

If the system receives threshold arguments that do not match the attributes required for each parameter, the system must reject the user’s attempt to enter them as input and must request the user’s input again (as captured by the alt construct). The use case “User Enters Invalid Inputs” is captured in Figure 10. This interaction will occur until the user’s input argument is valid (captured by the loop construct). The valid arguments are defined as signal attributes and are shown in Figure 9.

Figure 10.

User Enters Invalid Input Sequence.

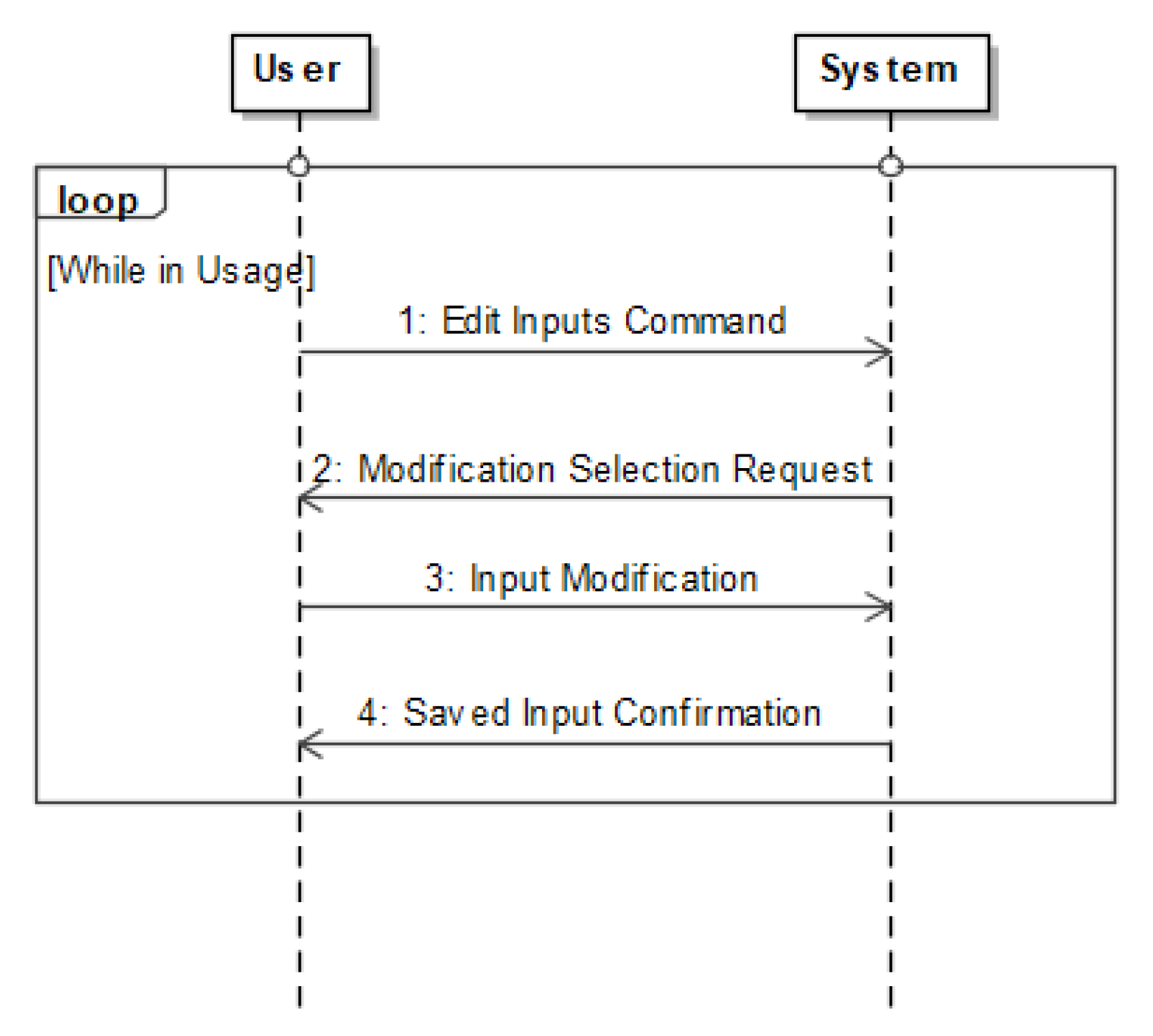

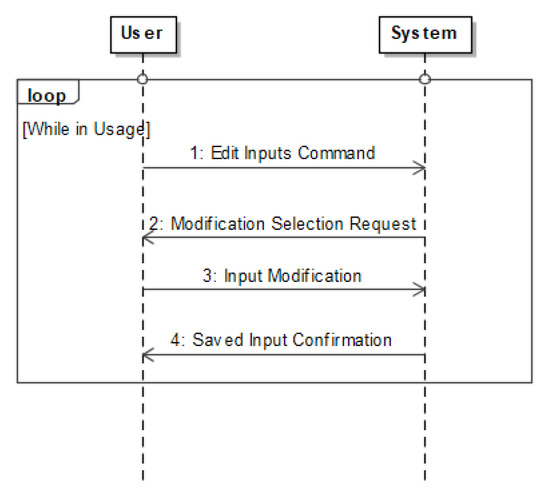

- Input Modification During Usage

It is possible that a user enters an input to the system that, although valid, might be incorrect in the context of the user’s application. A provision is made in the system concept, so that the user can correct for such mistakes. For example, if a user enters a final destination that does not correspond with where the pallet is actually travelling, the system will not be able to recognize that the pallet has arrived at the destination and will keep recording data that is not needed.

We capture the elaboration of the use case “Input Modification During Usage” in Figure 11. First, the system must accept an indication that a modification is intended to be made for an input (Edit Inputs Command). Then, the system must query which input must be changed (Modification Selection Request). After this, the system must accept the selection of the input to be modified (Input Selection) and make the modification on the input that was selected (Input Modification). Finally, the system must confirm that the change has been successfully saved in the system (Saved Input Confirmation).

Figure 11.

Modifying Inputs During Usage Sequence.

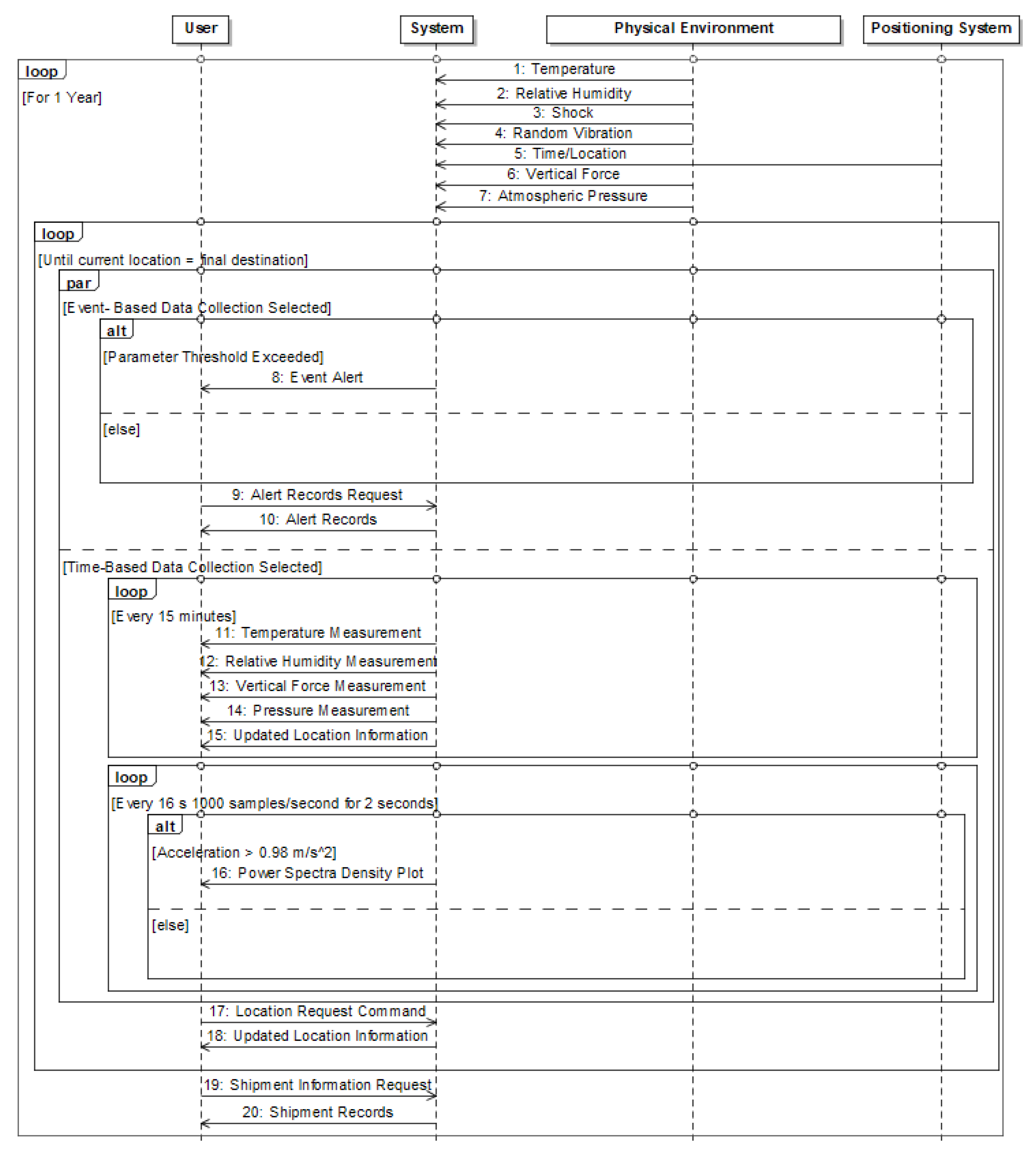

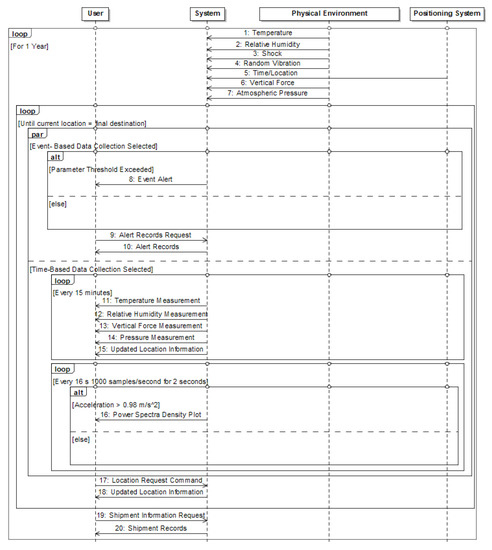

- Monitoring During Usage

The elaboration of the use case “Monitoring During Usage” is captured in Figure 12. During the course of one year, the system will receive Temperature, Relative Humidity, Shock, Atmospheric Pressure, Vertical Force, and Random Vibration inputs, as discussed previously (captured by the first loop construct). The system must then store these inputs until the pallet arrives at the final destination (captured by the second loop construct). The construct par is used to capture interactions that depend on the type of measurement chosen by the user. If the user previously selected “Event-Based Data Collection” as the way of measurement, and either temperature, relative humidity, or shock falls outside the specified condition (Figure 8), then the system must send an alert to the user (Event Alert); otherwise, no further action is required (as captured by the alt construct). During usage, the user may also inquire about previous event alerts (Alert Records Request), and the system must in turn provide all of the previous alerts that have been recorded (Alert Records). If the user previously selected “Time-Based Data Collection” as a way of measurement, every 15 min the system must collect the temperature (Temperature Measurement), relative humidity (Relative Humidity Measurement), Compression (Force Measurement), and atmospheric pressure (Pressure Measurement) in its immediate surroundings and determine its current location (Updated Location Information). This is captured by the third loop construct.

Figure 12.

Monitoring During Usage Sequence.

In addition, every 16 s, when the system receives random vibration with an acceleration greater than 0.98 m/s2, it must convert that signal into a power spectra density plot (as captured by the fourth loop construct). If the acceleration is lower than 0.98 m/s2, then no conversion or output is required (as captured by the second alt construct). These constraints are explained by the fact that trucks move intermittently on the road, stopping for traffic lights and other types of stops. When trucks are not moving, vibration data is not relevant, and it would be rather detrimental if these periods of non-motion were included, as it would cause the vibration profile represented by the power spectra density plot (PSD plot) to be underestimated. We selected a threshold of 0.98 m/s2 based on the International Safety and Transport Association (ISTA) standard for field data collection, which considers that a trigger level of 0.98 m/s2 allows to collect data any time a vehicle is in motion [24]. From here, we assume that any acceleration below that level would occur when the vehicle is not in motion. The PSD plot reflects the intensity of the entire trip from the point where the pallet is linked to the point where the pallet reaches the final destination. Previous studies have shown that to compute a representative PSD plot, it is necessary to collect 12.5% of the vibration during transit [1], which is achieved by collecting data every 16 s, at a rate of 1000 samples per second during an interval of 2 s (as captured by the fourth loop construct).

At any point during usage, the user can inquire about the location of a pallet (Location Request Command), and the system will provide its most recent location (Updated Location Information). Once the pallet has reached the final destination, the user can access the information collected by the system (Shipment Information Request). The system must in turn provide the user with the records of all the parameters tracked during the trip (Shipment Records).

Signal elements are used to specify the characteristics of the signals that arrive in the system from the physical environment, as well as the characteristics of the signals that the system sends to the user. Samples of input and output signal characteristics are shown in Figure 13.

Figure 13.

Signal Characterization for Inputs and Outputs During Usage.

7. Discussion

Packaging plays an important role in logistics operations and efficiency. Research in this field has centered on very specific aspects of packaging rather than on a systematic approach to improving its design. Our conversations with industry professionals indicated that there is an interest in understanding more accurately the environmental variables that affect packages and products. There is also interest in aspects like location, which do not relate directly to packaging design but to logistics operations. We believe that more accurate information about these types of environmental variables will lead to more efficient packaging designs that will produce positive outcomes in terms of material use reduction, weight reduction, and better product protection.

A review of related work points to increasing interest in research of IoT technology and its application in supply chains. However, research combining packaging and IoT remains absent. This paper brought these two fields together, adopting a systems-based approach in order to understand how IoT can solve problems in packaging and logistics domains. We have presented how IoT technology can be leveraged to obtain environmental data that can then be used to design more customized and efficient packages.

Throughout this paper, we have shown how MBSE artifacts can be used to conceptualize a new system and establish system requirements. The use of sequence diagrams, and signal elements to define requirements provides the advantage of avoiding unnecessary constraints on the solution space by making the system designer focus on the definitions of system boundaries and not on prescribing internal behavior [20]. We believe this is instrumental for novel fields like IoT, and its applications in packaging and logistics, because by defining a solution-independent set of requirements, there is no prescription of how such requirements are to be met, thereby bringing opportunities for creative and innovative design. From a packaging engineering perspective, the application of MBSE tools facilitate the conceptualization and visualization of the different elements that affect packaging performance. Efforts to improve packaging for a single variable, or to optimize a single element of distribution operations, have been found to increase costs and reduce operational efficiency [6]. We find that MBSE further aids in the implementation of a systematic approach to packaging design by enabling the creation of constructs that capture requirements at a system level.

We recognize that there are many practical challenges surrounding the application of IoT in supply chains: network access in multiple locations, data storage, cloud computing versus edge computing, power constrains, data sharing, and others. Our paper defined a framework of requirements so that specific technological solutions for each of these problems can be built.

8. Conclusions

An operational concept of a system that uses IoT technology to capture data about the conditions in a distribution environment has been proposed using a MBSE approach to achieve data-collection capabilities that satisfy the needs of industrial companies as related to packaging and product performance during distribution. MBSE is useful for this application because it addresses the complexities presented by the nature of IoT technology, so that the system developed is more likely to meet the requirements necessary to satisfy the user’s needs. Furthermore, the application of the systems engineering framework makes it possible to lay out a clear value proposition for the adoption of a new technology, like IoT, in the fields of packaging and logistics, so there is higher certainty that the new system will be responding to genuine user needs.

In this paper, we have shown how MBSE can be applied in the field of packaging and logistics to conceptually design a system that improves the package design process and increases visibility along the supply chain. We intended this study to serve as a framework on which to develop and validate specific system solutions. The MBSE constructs presented in this paper provide a baseline with which to evaluate the adequacy of specific solutions. For example, the construct shown in Figure 12 establishes that, when certain environment inputs exceed a threshold, the system shall send an alert to the user. We still do not know which specific technology, combination of technologies, or collaborations between different stakeholders in the supply chain, are necessary to satisfy this requirement. Therefore, future research will need to focus on realizing a system solution that will satisfy this requirement.

Author Contributions

Conceptualization, N.N. and L.H.; methodology, A.S.; validation, A.S. and L.H.; formal analysis, N.N.; resources, N.N.; writing—original draft preparation, N.N.; writing—review and editing, N.N., A.S. and L.H.; visualization, N.N.; supervision, L.H. and A.S.; project administration, L.H.; funding acquisition, L.H. All authors have read and agreed to the published version of the manuscript.

Funding

The research was financially supported by the Industrial Affiliate Program of the Center for Packaging and Unit Load Design at Virginia Tech.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rouillard, V. Generating road vibration test schedules from pavement profiles for packaging optimization. Packag. Technol. Sci. Int. J. 2008, 21, 501–514. [Google Scholar] [CrossRef]

- Bjärnemo, R.; Jönson, G.; Johnsson, M. Packaging Logistics in Product Development. In Proceedings of the International Conference on Computer Integrated Manufacturing (ICCIM), Singapore, 28–30 March 2000; Volume 1, pp. 135–146. [Google Scholar]

- Stock, J.R. Reverse Logistics, Green Logistics, and Packaging. In Logistics Engineering Handbook; Taylor, G.D., Ed.; CRC Press: Boca Raton, FL, USA, 2008; pp. 25–116. [Google Scholar]

- Raballand, G.; Aldaz-Carroll, E. How Do Differing Standards Increase Trade Costs? The Case of Pallets. World Econ. 2007, 30, 685–702. [Google Scholar] [CrossRef]

- Freedonia Group. Pallets: US Industry Study with Forecasts for 2019 to 2024. 2015. Available online: https://www.freedoniagroup.com (accessed on 4 April 2018).

- White, M.S.; Hamner, P. Pallets Move The World: The Case for Developing System-Based Designs for Unit Loads. For. Prod. J. 2005, 55, 8. [Google Scholar]

- Miorandi, D.; Sicari, S.; de Pellegrini, F.; Chlamtac, I. Internet of things: Vision, applications and research challenges. Ad Hoc Netw. 2012, 10, 1497–1516. [Google Scholar] [CrossRef]

- Yan, J.; Xin, S.; Liu, Q.; Xu, W.; Yang, L.; Fan, L.; Chen, B.; Wnag, Q. Intelligent supply chain integration and management based on cloud of things. Int. J. Distrib. Sens. Netw. 2014, 10, 624839. [Google Scholar] [CrossRef]

- Luo, H.; Zhu, M.; Ye, S.; Hou, H.; Chen, Y.; Bulysheva, L. An Intelligent Tracking system based on internet of things for coldchain. Internet Res. 2016, 26, 435–446. [Google Scholar] [CrossRef]

- Jedermann, R.; Praeger, U.; Geyer, M.; Lang, W. Remote quality monitoring in the banana chain. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130303. [Google Scholar] [CrossRef] [PubMed]

- Angulo, I.; Perallos, A.; Azpilicueta, L.; Falcone, F.; Hernandez-Jayo, U.; Moreno, A.; García Zuazola, I.J. Towards a traceability system based on RFID technology to check the content of pallets within electronic devices supply chain. Int. J. Antennas Propag. 2013, 2013, 263218. [Google Scholar] [CrossRef]

- Rouillard, V.; Lamb, M. On the effects of sampling parameters when surveying distribution vibrations. Packag. Technol. Sci. Int. J. 2008, 21, 467–477. [Google Scholar] [CrossRef]

- Quesenberry, C.; Horvath, L.; Bouldin, J.; White, M.S. The effect of pallet top deck stiffness on the compression strength of asymmetrically supported corrugated boxes. Packag. Technol. Sci. 2020, 33, 547–558. [Google Scholar] [CrossRef]

- Vanek, F.; Jackson, P.; Grzybowski, R.; Whiting, M. Effectiveness of Systems Engineering Techniques on New Product Development: Results from Interview Research at Corning Incorporated. Mod. Econ. 2017, 8, 141–160. [Google Scholar] [CrossRef]

- Evin, E.; Uludag, Y. Bioanalytical Device Design With Model-Based Systems Engineering Tools. IEEE Syst. J. 2020, 14, 3139–3149. [Google Scholar] [CrossRef]

- Salado, A. An elemental decomposition of systems engineering. In Proceedings of the 4th IEEE International Symposium on Systems Engineering, Rome, Italy, 1–3 October 2018. [Google Scholar]

- Ramos, A.L.; Ferreira, J.V.; Barceló, J. Model-Based Systems Engineering: An emerging approach for modern systems. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2011, 42, 101–111. [Google Scholar] [CrossRef]

- Friedenthal, S.; Moore, A.; Steiner, R. A Practical Guide to SysML: The Systems Modeling Language, 3rd ed.; Morgan Kaufmann: Waltham, MA, USA, 2015. [Google Scholar]

- Hause, M.; Hummell, J.; Grelier, F. MBSE driven IoT for smarter cities. In Proceedings of the 2018 13th System of Systems Engineering Conference (SoSE), Paris, France, 19–22 June 2018; pp. 365–371. [Google Scholar]

- Salado, A.; Wach, P. Constructing True Model-Based Requirements in SysML. Systems 2019, 7, 19. [Google Scholar] [CrossRef]

- Wach, P.; Salado, A. The Need for Semantic Extension of SysML to Model the Problem Space. In Proceedings of the Conference on Systems Engineering Research (CSER), Redondo Beach, CA, USA, 19–21 March 2020. [Google Scholar]

- Dam, S.H.; Verma, D. Concept of Operations & System Operational Architecture Introduction. In Applied Space Systems Engineering, 2nd ed.; Chesley, J., Larson, W., McQuade, M., Menrad, R.J., Eds.; CEI Publications: Trieste, Italy, 2014. [Google Scholar]

- Fragassa, C.; Macaluso, I.; Vaccari, M.; Lucisano, G. Measuring the mechanical and climatic conditions encountered by palletized products in handling and transport. FME Trans. 2017, 45, 382–393. [Google Scholar] [CrossRef]

- International Safety and Transit Association. ISTA’s Requirements for Measuring: Atmospheric, Shock/Impacts and Drops, Vehicle Vibration; International Safety and Transit Association: East Lansing, MI, USA, 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).