Workflow for High Throughput Screening of Gas Sensing Materials

Abstract

:Introduction

Experimental

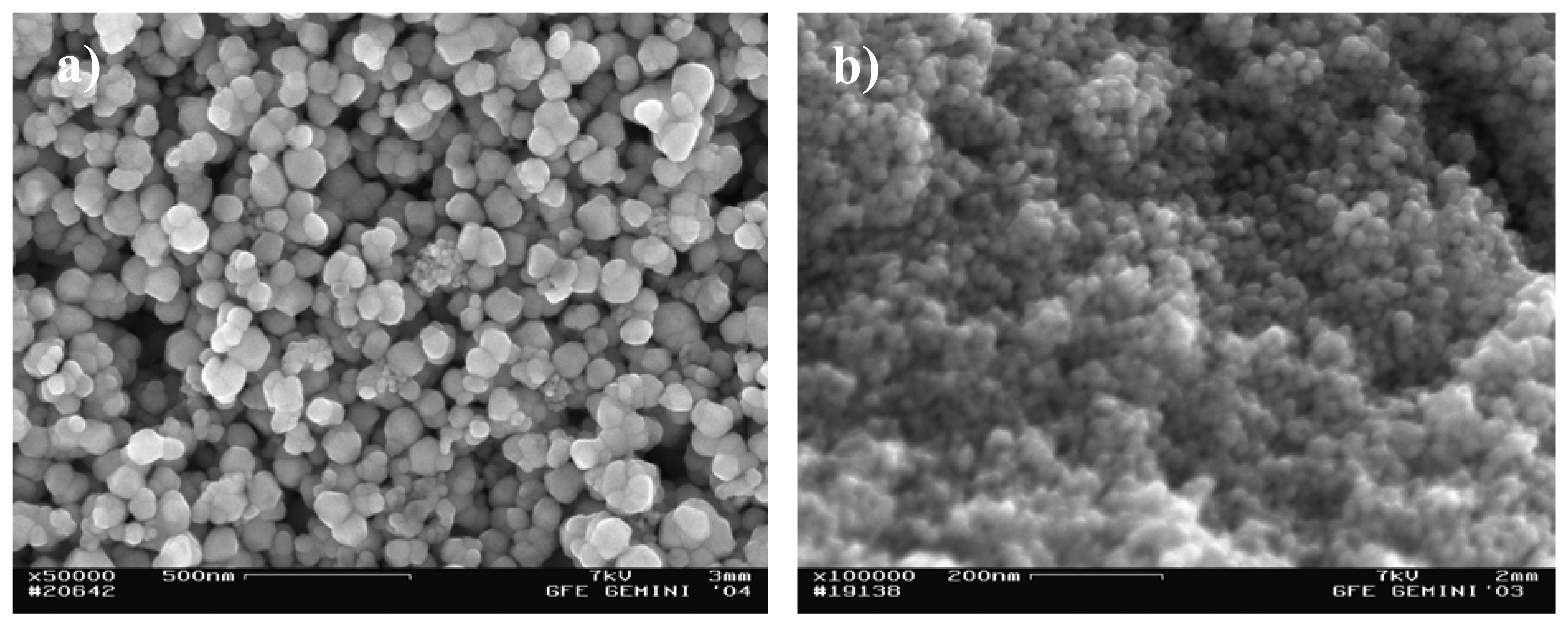

Material preparation

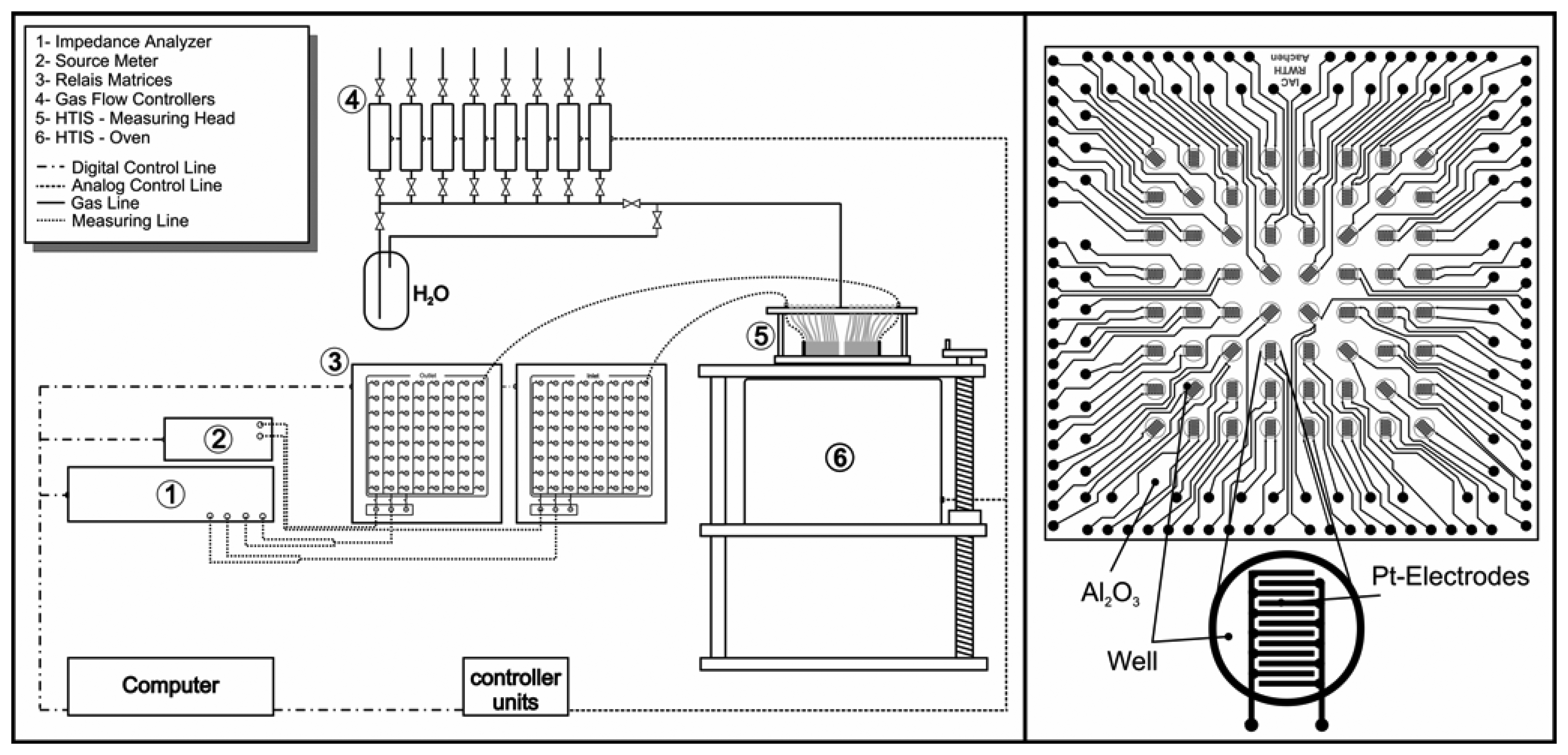

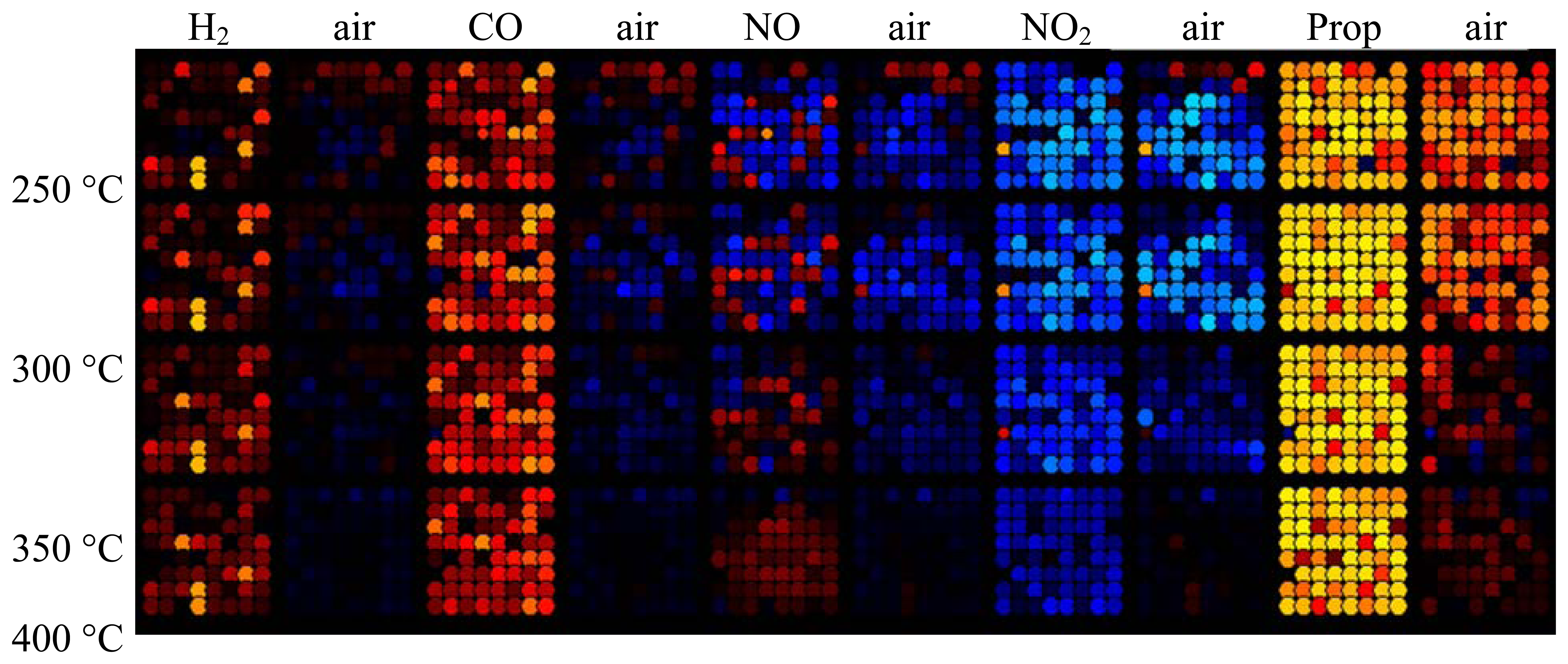

Screening

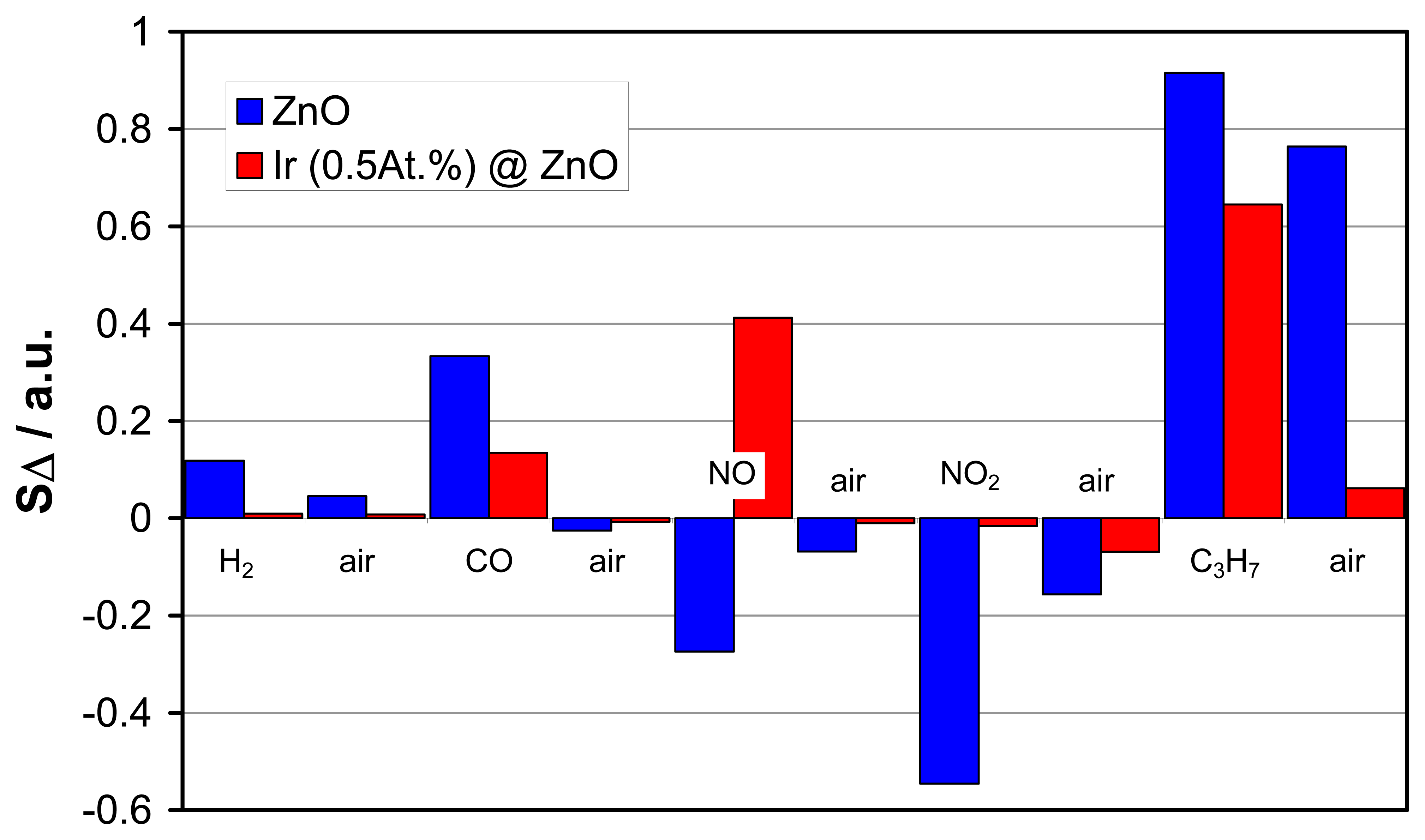

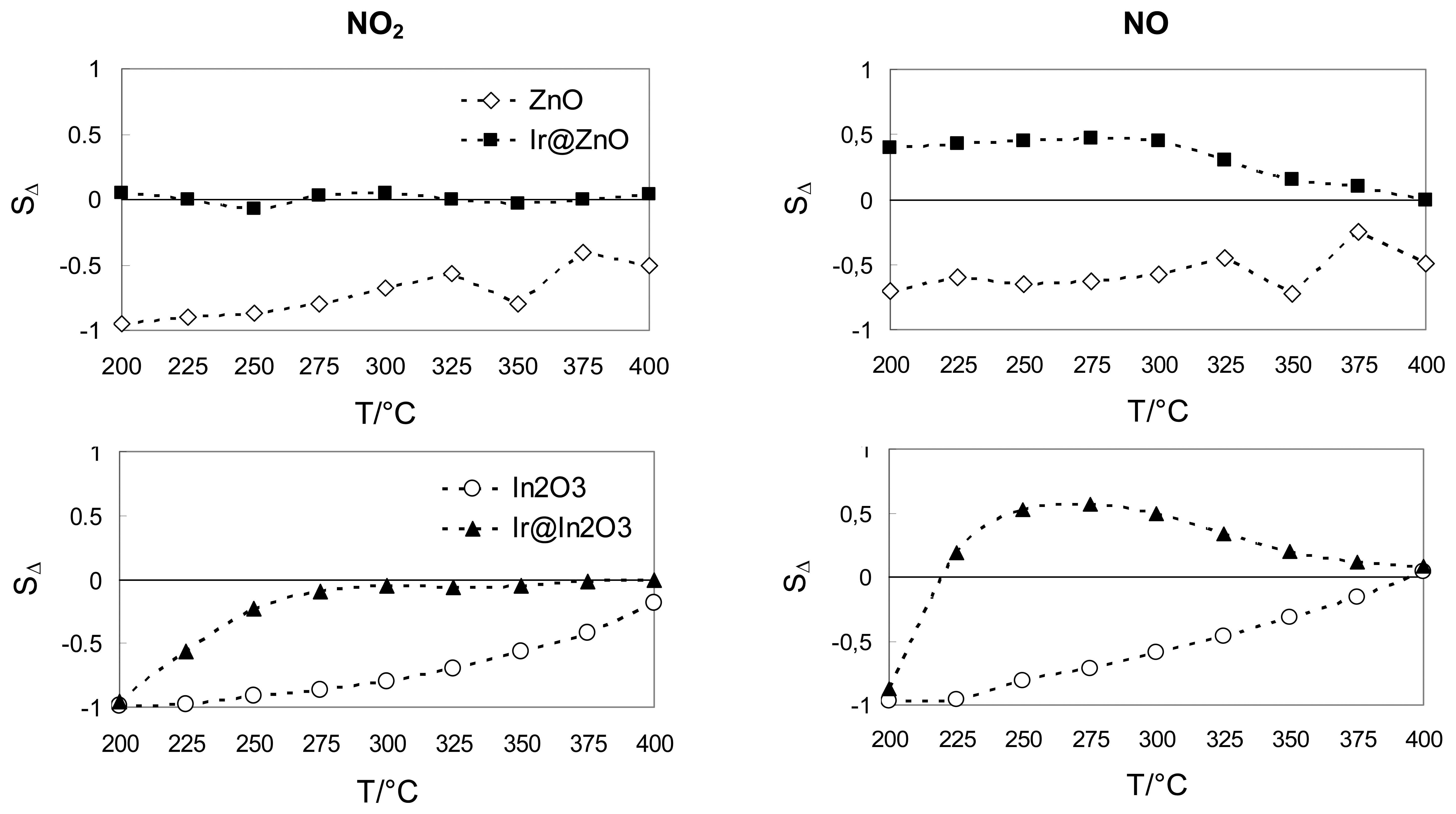

Results and discussions

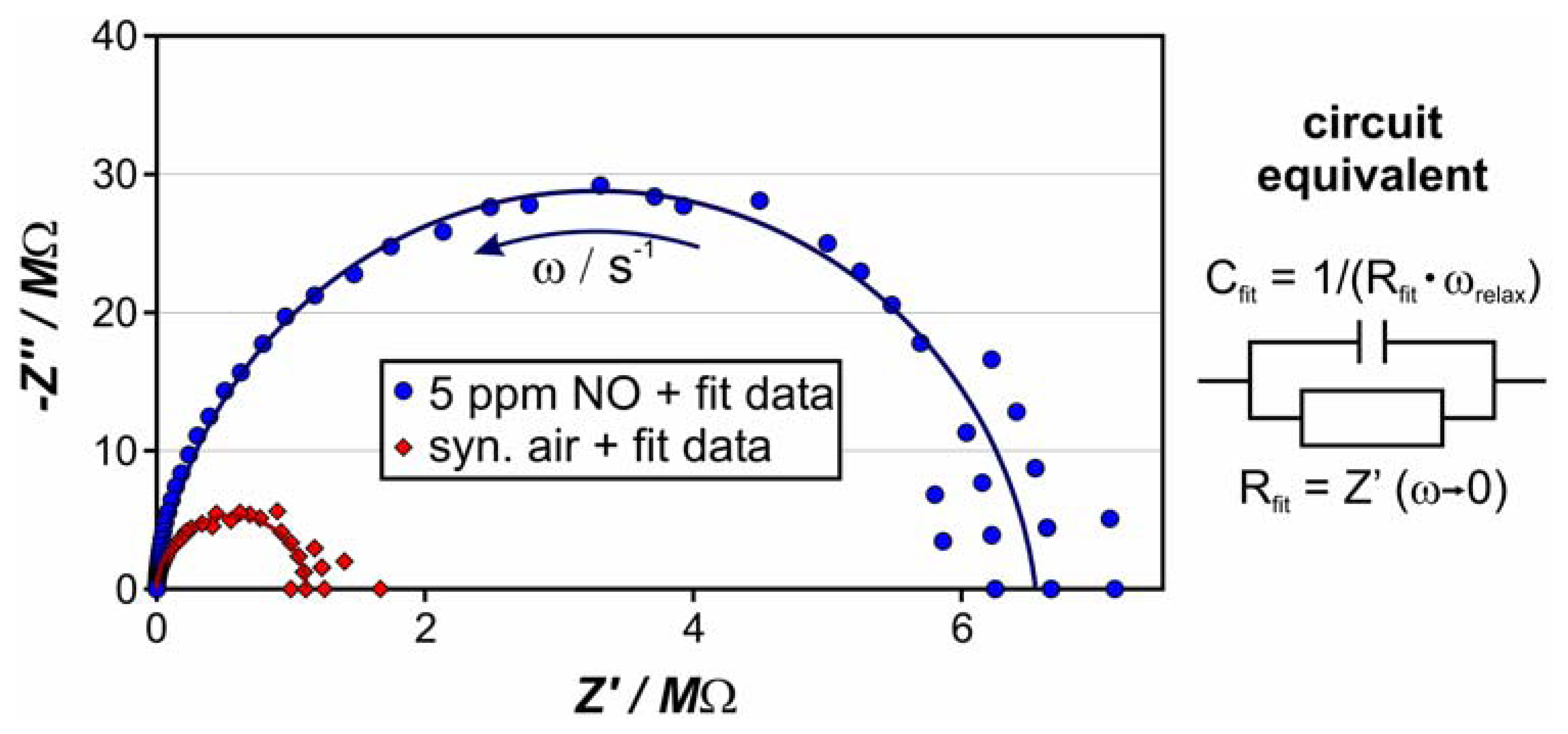

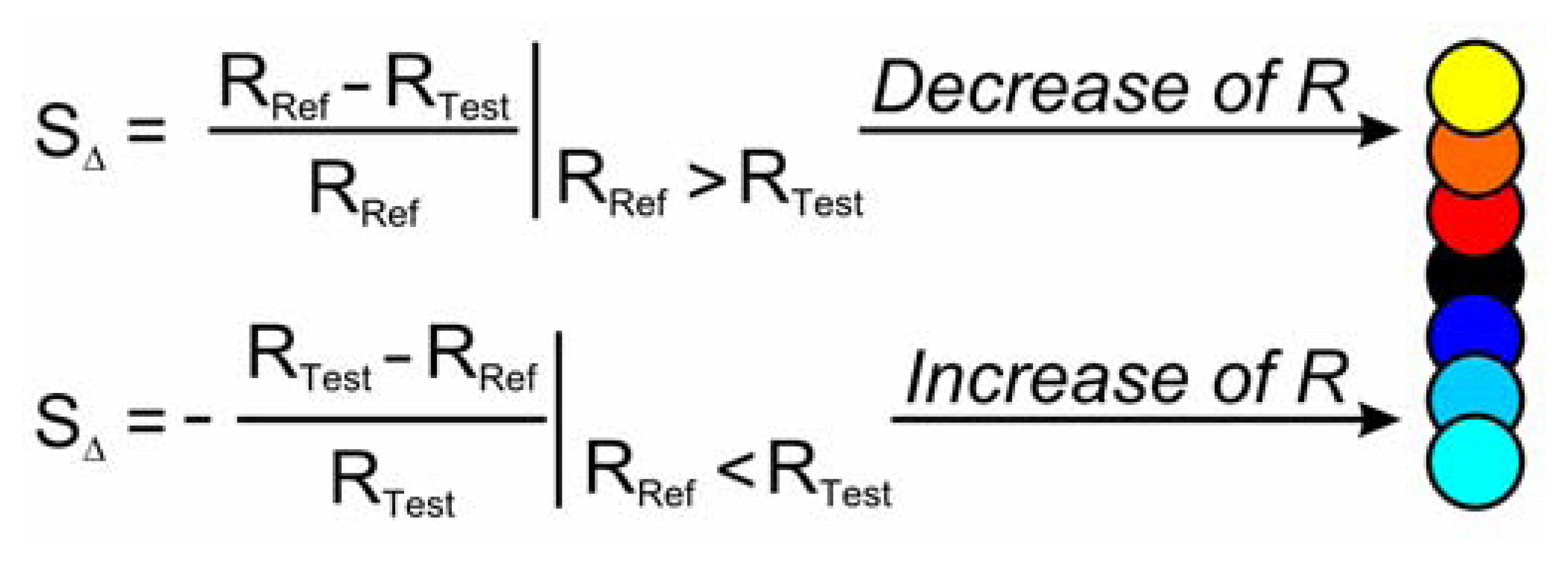

Selected example

Conclusions

Acknowledgments

References

- Seiyama, T.; Kato, A.; Fujiishi, K.; Nagatani, M. A new detector for gaseous components using semiconductive thin films. Anal. Chem. 1962, 34, 1502. [Google Scholar]

- Tagushi, N. Jpn. Patent 45-38200, 1962.

- Eranna, G.; Joshi, B.C.; Runthala, D.P.; Gupta, R.P. Oxide materials for developement of integrated gas sensors – A comprehensive review. Crit. Rev. Sol. State Mater. Sci. 2004, 29, 111. [Google Scholar]

- Maekawa, T.; Tamaki, J.; Miura, N.; Yamazoe, N. Sensing behaviour of CuO-loaded SnO2element for H2S detection. Chem. Lett. 1991, 575. [Google Scholar]

- Cabot, A.; Arbiol, J.; Morante, J.R.; Weimar, U.; Bârsan, N.; Göpel, W. Analysis of the noble metal catalytic additives introduced by impregnation of as obtained SnO2 sol-gel nanocrystals for gas sensors. Sens. Actuat. B 2000, 70, 87. [Google Scholar]

- Göpel, W.; Schierbaum, K.D. SnO2 Sensors: Current status and future prospects. Sens. Actuat. B 1995, 26, 1. [Google Scholar]

- Yamazoe, N.; Sakai, G.; Shimanoe, K. Oxide semiconductor gas sensors. Catal. Surv. Asia 2003, 7(1), 63. [Google Scholar]

- Franke, M.E.; Koplin, T.J.; Simon, U. Metal and metal oxide nanoparticles in chemiresistors: does the nanoscale matter? Small 2006, 2, 36. [Google Scholar]

- Jandeleit, B.; Schaefer, D.J.; Powers, T.S.; Turner, H.W.; Weinberg, W.H. Combinatorial materials science and catalysis. Angew. Chem. 1999, 111, 2648, In. Ed. 1999, 38, 2494. [Google Scholar]

- Hagemeyer, A.; Stasser, P.; Volpe, A.F., Jr. (Eds.) High-throughput screening in chemical catalysis; Wiley-VCH: Weinheim, 2004.

- Simon, U.; Sanders, D.; Jockel, J.; Heppel, C.; Brinz, T. Design strategies for multielectrode arrays applicable for high-throughput impedance spectroscopy on novel gas sensor materials. J. Comb. Chem. 2002, 4, 511. [Google Scholar]

- Franzen, A.; Sanders, D.; Jockel, J.; Scheidtmann, J.; Frenzer, G.; Maier, W.F.; Brinz, Th.; Simon, U. High-throughput method for the impedance spectroscopic characterization of resistive gas sensors. Angew. Chem. 2004, 116, 770, In. Ed. 2004, 43, 752. [Google Scholar]

- Simon, U.; Sanders, D.; Jockel, J.; Brinz, T. Setup for high-throughput impedance screening of gas-sensing materials. J. Comb. Chem. 2005, 7, 682. [Google Scholar]

- Figlarz, M.; Fiévet, F.; Lagier, J.P. Process for reducing metallic compounds using polyols, and metallic powders produced thereby. Europ. Pat. 0113281, 1982. [Google Scholar]

- Toneguzzo, Ph.; Viau, G.; Acher, O.; Guillet, F.; Bruneton, E.; Fievet-Vincent, F.; Fievet, F. CoNi and FeCoNi fine particles prepared by the polyol process: Physico-chemical characterization and dynamic magnetic properties. J. Mater. Sci. 2000, 35, 3767. [Google Scholar]

- Poul, L.; Ammar, S.; Jouini, N.; Fievet, F.; Villain, F. Synthesis of inorganic compounds (metal, oxide and hydroxide) in medium: A versatile route related to the sol-gel process. J. Sol-Gel Sci. Tech. 2003, 26, 261. [Google Scholar]

- Jézéquel, D.; Guenot, J.; Jouini, N.; Fiévet, F. Submicrometer zinc oxide particles: Elaboration in polyol medium and morphological characteristics. J. Mater. Res. 1995, 10, 77. [Google Scholar]

- Feldmann, C.; Jungk, H. Polyol-mediated preparation of nanoscale oxide particles. Angew. Chem. 2001, 113, 372, Int. Ed. 2001, 40, 359. [Google Scholar]

- Siemons, M.; Weirich, Th.; Mayer, J.; Simon, U. Preparation of nanosized perovskite-type oxides via polyol method. Z. Anorg. Allg. Chem. 2004, 630, 2083. [Google Scholar]

- Sabine, T.M.; Hogg, S. The wurtzite Z parameter for beryllium oxide and zinc oxide. Acta Crystallogr. B 1969, 25, 2254. [Google Scholar]

- Zachariasen, W. The crystal structure of the modification C of the sesquioxides of the rare earth metals, and of indium and thallium. Norsk Geologisk Tidsskrift 1927, 9, 310. [Google Scholar]

© 2006 by MDPI ( http://www.mdpi.org). Reproduction is permitted for non-commercial purposes.

Share and Cite

Koplin, T.J.; Siemons, M.; Océn-Valéntin, C.; Sanders, D.; Simon, U. Workflow for High Throughput Screening of Gas Sensing Materials. Sensors 2006, 6, 298-307. https://doi.org/10.3390/s6040298

Koplin TJ, Siemons M, Océn-Valéntin C, Sanders D, Simon U. Workflow for High Throughput Screening of Gas Sensing Materials. Sensors. 2006; 6(4):298-307. https://doi.org/10.3390/s6040298

Chicago/Turabian StyleKoplin, Tobias J., Maike Siemons, César Océn-Valéntin, Daniel Sanders, and Ulrich Simon. 2006. "Workflow for High Throughput Screening of Gas Sensing Materials" Sensors 6, no. 4: 298-307. https://doi.org/10.3390/s6040298

APA StyleKoplin, T. J., Siemons, M., Océn-Valéntin, C., Sanders, D., & Simon, U. (2006). Workflow for High Throughput Screening of Gas Sensing Materials. Sensors, 6(4), 298-307. https://doi.org/10.3390/s6040298